14 minute read

Coming out on top

Todd Razor, on behalf of Vacuworx, USA, discusses pipe handling systems that meet global engineering and safety standards.

nergy pipelines are becoming more diverse, and so are the machines relied on by humans to help lift and handle large diameter pipe lengths fabricated for the construction of new pipelines and natural gas transmission and distribution networks.

Certain hard costs, including those related to the materials and labour required to see major pipeline builds through to their successful completion, are widely anticipated and largely unavoidable. Managing certain complexities, however, on the logistical end of transporting, staging, stringing, and installing sizable quantities of large OD pipe can have an impact on overall project economics and outcomes.

The build out of major pipeline systems, such as the Baltic Pipe project in Europe, demand multipronged periods of collaboration – reflecting the great level of care and attention to detail required to keep thousands of 12 m (approximately 40 ft) double random joints safe, secure, and damage-free during the transportation, storage, staging and installation processes.

Operators considering a turn away from hooks, slings, and cables – or the use of mechanical aids that may result in metal-onmetal contact and could harm the integrity of coated steel pipe – are commonly on the lookout for safer, faster, and more contemporary solutions. When properly attuned and supported, vacuum lifting units have stood out as formidable manual labour-saving attachments in terms of versatility and stamina in the global oil and gas pipe handling fields.

Figure 1. An RC Series unit coupled with a large capacity CAT hydraulic excavator.

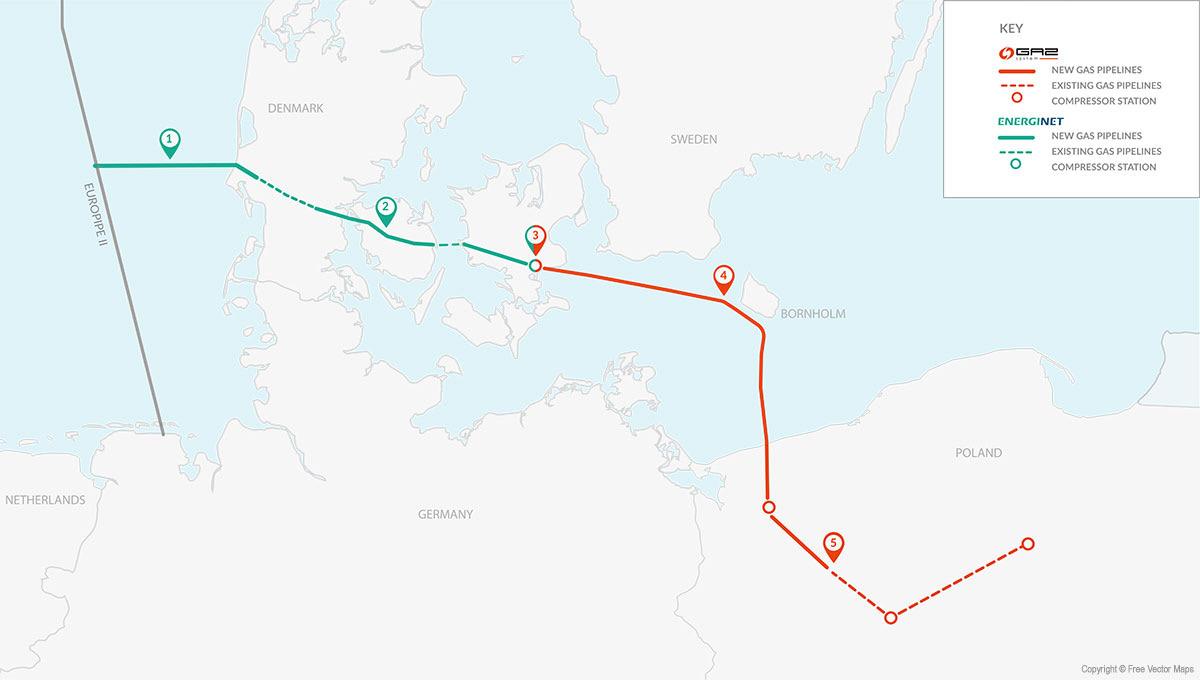

Off the shelf Bi-directional, the purpose-built Baltic Pipe project, allows for the flow of Norwegian shelf natural gas to Denmark and Poland. Developed by Denmark’s Energinet and Poland’s GAZ-SYSTEM, it represents a new step toward greater energy security for Poland; seeking greater energy independence and the capability to satisfy growing consumption and diverse energy demands.

The Baltic Pipe project is multi-segmented and includes the approximately 110 km (68 m), 800 mm (approximately 31 in.) OD North Sea offshore pipeline – connecting Norway’s gas system with Danish interests and landing on the west coast of Denmark near Blåbjerg – as well as the key 900 mm (approximately 35 in.) OD offshore Baltic Sea pipeline, estimated at 275 km (170 m) in length, providing bi-directional natural gas shipping capabilities between Denmark and Poland. Installed on the Baltic seabed, it crosses the marine areas of three countries: Denmark, Poland, and Sweden.

The overall project is additionally considered a major piece of gas infrastructure for the Baltic States, and creates a new supply corridor for the Central and Eastern European energy arena. The two-way gas flow is a boom for shippers, according to Energinet, as it allows for gas to flow bi-directionally and unswervingly from Poland to the Danish and Swedish markets, enhancing the potential for market flexibility.

Critical pieces Pipelines are a critical piece of oil and gas industry collateral. They are viewed as highly important to energy security and energy independence, as well as global decarbonisation activities and long-game sustainability initiatives, such as the sequestration of carbon, movement of low-carbon hydrogen, and transportation of cleaner-than-coal-burning natural gas.

Staying on top of material-handling complexities during major pipeline infrastructure projects is an extreme challenge. It is noteworthy to consider some of these complexities and delve into how handlers of large OD pipe may be working to overcome lifting and manoeuvring challenges in the field. What are some alternatives for a safer process that also mitigates potential for damage to pipe joints during complex handling and installation processes?

Pipeline installers deal with an array of activities ranging from stringing and trenching to welding, the application of field coatings, bending, lowering, and backfilling. All these and more must be considered while demonstrating the same level of care for both worker safety, and protecting the coated-steel pipe lengths from damage. Joints may need to be re-handled on multiple different sites and occasions throughout the course of their journey from steel mill to the ROW.

High standards have been set by regulatory authorities in Europe, the US, and other parts of the globe for the construction of energy pipelines, with strict attention paid to the integrity of individual pipe joints prior to lowering them in the ground. The tendency of fabricated pipe shippers is to try and minimise contact with the pipe, and the need to re-handle, as much as possible. The more limited repeated contact with the pipe becomes, the greater the potential is to reduce risk and mitigate exposure – automatically keeping more workers away from hazardous situations in which they may not need to be, and reducing the risk of damaging the pipe.

Figure 2. The Baltic Pipe project has included the construction of approxiamtely 900 km (559 miles) of a gas pipeline. (Courtesy of balticpipe.eu)

Robustness and versatility are companion traits shared by companies such as MAX STREICHER GmbH & Co., a wideranging organisation active in pipeline construction on the European continent and intercontinentally, and their Baltic Pipe employers. Staying productive and bolstering the safety factor while mitigating potential for damage is of key interest to all stakeholders eager for reports of smooth and efficient operations.

Improvements in Denmark and under the Little Belt have been completed, part of an expanded Danish transmission system. Planned expansions for Baltic Pipe infrastructure there included construction of a new pipeline from the beach near Blåbjerg to Nybro, a receiving terminal at Nybro, a new pipeline from Egtved to the Little Belt, a new pipeline across the Little Belt, a new pipeline over Fyn from the Little Belt to Nyborg, and a new pipeline from Kongsmark to the Baltic Sea offshore landfall at the southeastern part of Zealand.

In Denmark, involvement with building out the onshore pipeline, ranging in outer diameter up to 1016 mm (approximately 40 in.), was awarded to AARSLEFF-STREICHER-BUNTE JV I/S, a collaboration among MAX STREICHER GmbH & Co; Aarsleff, a Danish contracting company; and the pipeline construction division of JOHANN BUNTE Bauunternehmung.

A new compressor station in Zealand was also constructed near the Baltic Sea offshore pipeline in Denmark to increase pressure, ensuring natural gas can be transported to Poland. This compressor station also helps ensure reverse-flow capabilities – the transport of gas from Poland into the Danish system.

Polish gas system upgrades as part of the Baltic Pipe campaign included the new construction of the GoleniówLwówek natural gas pipeline, built in two stages, at 191 km (approximately 119 m) in length and 1016 mm (approximately 40 in.) in diameter, and a 41 km (approximately 25 m) pipeline connecting the Baltic Pipe project with Poland’s national transmission system. The newly developed Gustorzyn gas compressor station serves as an interconnection between the gas transport systems of the Republic of Poland and the Republic of Lithuania (GIPL). Two existing Polish gas compressor stations in Odolanów and Goleniów were modernised and extended.

GAZ-SYSTEM, which selected contractors for the construction of all onshore components of the Baltic Pipe in Poland, stated that the increased total gas compression of that country’s transmission system improves operational security and network flexibility. The landfall of the offshore pipeline can be found in the Rewal commune on the Baltic coast. Contracts for the Goleniów and Gustorzyn compressor stations were awarded to MAX STREICHER S. p. A. Handling innovations Vacuum lifting technology has been used for many years by pipe handlers worldwide including all over Europe, Australia, North America. Comprising a vacuum pump and right-sized

THE MOST SOPHISTICATED IN THE WORLD

FEATURING CAMOUFLAGE TECHNOLOGY

Building on Dairyland’s proven history of industry-leading product lines, the PCRX® represents the next technological leap forward in decoupling technology. Using a sophisticated design, the PCRX’s new camoufl age technology renders it virtually invisible to interrupted survey testing making it easier than ever to protect and maintain your CP system. Scan to watch a short video. For more product information, visit Dairyland.com/PCRX

Figure 3. A CAT 352 and Vacuworx lifter near Kolding, Jutland in Denmark.

Figure 4. The system at work handling Baltic Pipe lengths at a storage yard.

Figure 5. Lifting capacity on the RC Series ranges upward of 25 t (50 000 lb). vacuum pad and assembly, among other components, Vacuworx pipe handling systems are controlled via wireless remote operation and commonly tasked to work in conjunction with large-capacity excavators in the field. They can perform tasks ranging from loading to offloading trucks, barges, and railcars to stacking pipe in laydown yards, and more, such as helping fit up pipe to be welded or stringing joints alongside the ROW.

RC Series lifters developed by Vacuworx have lifting capacities ranging from 10 t (20 000 lb) to 25 t (50 000 lb) and more, demonstrating the ability to handle pipe approximately 102 mm (4 in.) in diameter and up with no maximum size limit. A hydraulic rotator provides for 360° movement of the lifting apparatus, enabling fast and precise placement of pipe. This generally makes things easier for operators to perform lifting and handling tasks from an improved position, enhancing views of the lift zone while keeping a safe distance – less proximity to the material being lifted.

MAX STREICHER GmbH & Co. and its counterparts value the use of high-quality construction materials, and the joint and constant optimisation of best practices to create efficient workflows, including the provision of all information and resources needed in a timely manner. The company’s role as part of the Baltic Pipe project build out was taking responsibility for welding, lowering, and connecting, as well as bending pipe to align with the ROW’s topography – to follow the Denmark onshore pipeline’s unique route and ground contours.

Mechanical damage defect types identified by the US Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA) include metal loss, metal deformation, cracking, and denting. Studies of mechanical damage also resulted in the development of guidance for inclusion in the American Society of Mechanical Engineers (ASME) codes covering the significance of avoiding damage or dents for gas transmission pipelines.

Dents, commonly caused by contact with construction equipment, are costly given inspections may be required to determine if they fall within acceptable tolerance limits. The pipe may have to be put up for repair, too, if a certain type of damage is deemed to have a possible detrimental impact on safety or the operational performance of a pipeline.

Though they may be potentially insignificant from a structural point-of-view, according to guidance offered in an International Pipeline Conference (IPC) proceedings paper on the effects of dents and gouges in pipelines, dents can present difficulties, and must be examined closely. A dent should never be underestimated, due to its potential to cause local stress and strain concentration, and a local reduction in the pipe diameter, reducing the static and cyclic strength of a pipe.

Dent depth is highly significant in terms of how such damage may affect the burst strength and fatigue strength. Plain dents do not significantly reduce the burst strength of the pipe, the IPC paper stated, but the fatigue life of

pipe containing a plain dent is less than the fatigue life of plain circular pipe. The burst and fatigue strength of a dented weld, or of a dent containing a defect such as a gouge, can be significantly lower than that of an equivalent plain dent. A smooth dent containing a gouge (or other part-wall metal loss defect) is a very severe form of mechanical damage.

Dents can also be associated with damage to pipe coatings – possibly leading to the initiation of corrosion or environmental cracking.

Handling manoeuvres related to specialised tasks such as pipe bending may require even more unique attention. The activity is generally accomplished using a pipe bending machine, with features that govern the amount of the bend in the pipe section in such a way that it avoids causing damage to the pipe or delicate bonded coatings.

Offset costs Costs related to materials, labour, ROW, and ancillary expenditures make up the total price tag of a pipeline construction project, with labour costs generally dominating the lion’s share of total expenditures. Material costs reportedly overshadow the total costs in the construction of compressor stations.

Overall costs can be exacerbated if the appropriate care to protect the integrity of products is unable to be maintained sufficiently and consistently throughout the entire course of a pipe handling job – and into operational status of a newly developed pipeline.

Technological advancements in pipeline materials and monitoring systems are making pipelines safer, helping reduce the probability of environmental impacts before, during and after an installation. The focus is on maintaining pipeline integrity, environmental consciousness, and the avoidance of severe consequences that could follow an incident or accident.

In the field, during boots-on-the-ground deployments, the absence of the right equipment or methods of pipe handling can be detrimental, from a safety standpoint and a pipeline integrity standpoint.

Mitigating the potential for events that could expose workers to possible hazards, require excessive labour units, or damage pipe during the transit and installation processes, can equate to less downtime, lower costs, and higher-value tasking of skilled employees.

From a material-handling perspective, pipe movers and logistics companies are gravitating toward technologies and machines that they can envision helping overcome handling challenges and fostering more attractive business outcomes.

For the Baltic Pipe job, STREICHER GmbH & Co. acquired an RC Series lifter and 1016 mm (approximately 40 in.) pad assembly directly from equipment dealer and Vacuworx distributor Maats Pipeline, based in the Netherlands. The lifter, coupled with a high-capacity CAT 352 hydraulic excavator, was deployed on their portion of the Baltic Pipe project in Denmark for several weeks.

“The lifting device from Vacuworx was used on the bending machine,” said Jens Mogwitz, Mechanical Engineering, MAX STREICHER GmbH & Co. “The pipes used here were 32 in., 36 in. and 40 in. (approximately 812 mm, 914 mm and 1016 mm). They were 12 m (approximately 40 ft) in length, with thicknesses between 19 mm and 30 mm (approximately 0.75 in. and 1.18 in.), and weights of up to 12 t (24 000 lb). We used the RC lifting device to unstack the pipes and took them to the pipelayer. This is just one way to use this lifting device.”

“Maats plays a major role in our department maintenance and mechanical engineering,” Mogwitz continued. “It’s a good address for spare parts, rental machines, and pipeline equipment.”

Vacuum lifters are respected on the European front for their durability and time-saving capabilities. The diversity of such machines is demonstrated in part by their ability to couple with different host carriers like excavators, skid steers and loaders – with custom vacuum pad assemblies available for adaptation of the machines during an array of different pipe lifting and manoeuvring scenarios.

RC Series lifters are powered by powerful and selfcontained diesel engines while ‘H’ model units operate via the hydraulics of carrier equipment. The manufacturer’s propriety vacuum pad seal material is engineered to cause zero damage to pipe coatings. All Vacuworx units are designed, engineered, and tested to meet or exceed many global engineering and safety standards, including the European CE Machinery Directive, CE Low Voltage Directive and CE Electromagnetic Interference Directive, and EN13155 standards that apply to vacuum lifters, among others.

“We operate worldwide and have already implemented many projects in our neighbouring countries as well as in Africa and Australia,” Mogwitz said. “As well as the order here in Denmark, the Baltic Pipe, which we did in cooperation with the company Aarsleff and the company Bunte. In Tunisia (Navara Pipeline), as another example, we used (an RC Series lifter) to unload the pipes from the truck and (string) lay them out. The device is really safe, and easy to use, and also saves two workers.”

Big commission The European Commission (EC) released approximately €215 million to help finance the Baltic Pipe project allowing, for the first time, for natural gas flows to Denmark and Poland from Norway. It also facilitates Poland’s ability to supply the Danish market and neighbouring Baltic states.

The capital expenditure for the Danish part of the Baltic Pipe project had been estimated at €1.1 billion, according to Energinet. Danish gas consumers, the company states, can expect the project to yield €270 million in savings on tariffs.

Poland’s energy policy aims to use natural gas as a transition fuel in pursuing its long-term goal of a zero-emission energy system, the International Energy Agency has stated. Consumption of natural gas in that country is set to increase to 30 billion m3 by 2030, as the share of coal is reduced in electricity generation and building heating.

The overall Baltic Pipe project’s original operation date had been set for October 2022, with full operational status and delivery of full capacity of 10 billion m3 expected in early 2023. The tie-in to the Norwegian natural gas supply source was made via existing North Sea infrastructure – Europipe II – currently connecting Norway and Germany.