9 minute read

Battling methane emissions head-on

Adam Murray, Vice President, Performance Products, WeldFit, USA, discusses how to safely and efficiently eliminate nearly all emissions associated with voluntary flaring and venting.

The world has fired another volley in the fight against climate change, and this time the target is methane. While carbon dioxide emissions continue to be enemy number one, methane was squarely in the crosshairs at the November 2021 Glasgow climate summit. Methane has more than 80 times the warming power of CO2 over the first two decades after it reaches the atmosphere, according to environmental defense fund research, so it’s not surprising that the need to reduce methane emissions would eventually emerge from CO2’s shadows. In Glasgow, more than 100 countries signed the global methane pledge, a US-led initiative aimed at cutting methane emissions by 30% within nine years, in large part by tightening regulations related to methane leaks from oil and gas operations.

While these requirements may be new, the industry’s interest in capping involuntary methane emissions isn’t. Methane intensity in US energy production dropped 17% between 1990 - 2019, while oil and natural gas production rose 66% and 96%, respectively.

Still, there’s plenty of room for improvement. Driven by their own ESG commitments as well as public and investor sentiment, midstream operators are among those working the hardest to meet methane reduction targets.

And though it may seem counterintuitive, many even welcome the new rules, says Eric Heinle, WeldFit President of pigging and performance products.

“Midstream operators with a large footprint realise that every reduction they make can have a meaningful impact both on

Figure 1. Emissions recovery/distribution pipeline replacement, 8 in. natural gas pipeline, 5.5 miles, 250 PSIG, Abilene, Texas, 2021.

the environment and the safety of people living near pipeline operations,” he said. “Companies see the new rules as a catalyst for service providers to bring methane-capturing technology to market as quickly as possible.”

The industry won’t have to wait long. In fact, in the US, at least, there’s really no wait at all. Gas recapture solutions that safely and efficiently eliminate nearly 100% of methane emissions associated with voluntary flaring or venting are already in use on American natural gas pipelines.

Venting in public Service providers have supported the industry’s efforts to reduce greenhouse gas (GHG) emissions for decades. New and better ways to detect leaks, capture and sequester carbon, and seize fugitive vapours are being introduced all the time.

Many of these technologies are aimed at mitigating the large-scale releases that attract the most attention. But it’s impossible to ignore the fact that methane emissions are a part of everyday life for energy companies. Thousands of tons of CO2 equivalent (CO2e) methane are released during routine operations. Before a technician opens a pig launcher at a natural gas processing facility, or a contractor removes and replaces a section of pipeline isolated by a hot tapping crew, the product must first be removed from the pressurised system. It’s not uncommon for the gas to be flared or vented, directly releasing methane and other greenhouse gases (GHG) into the atmosphere.

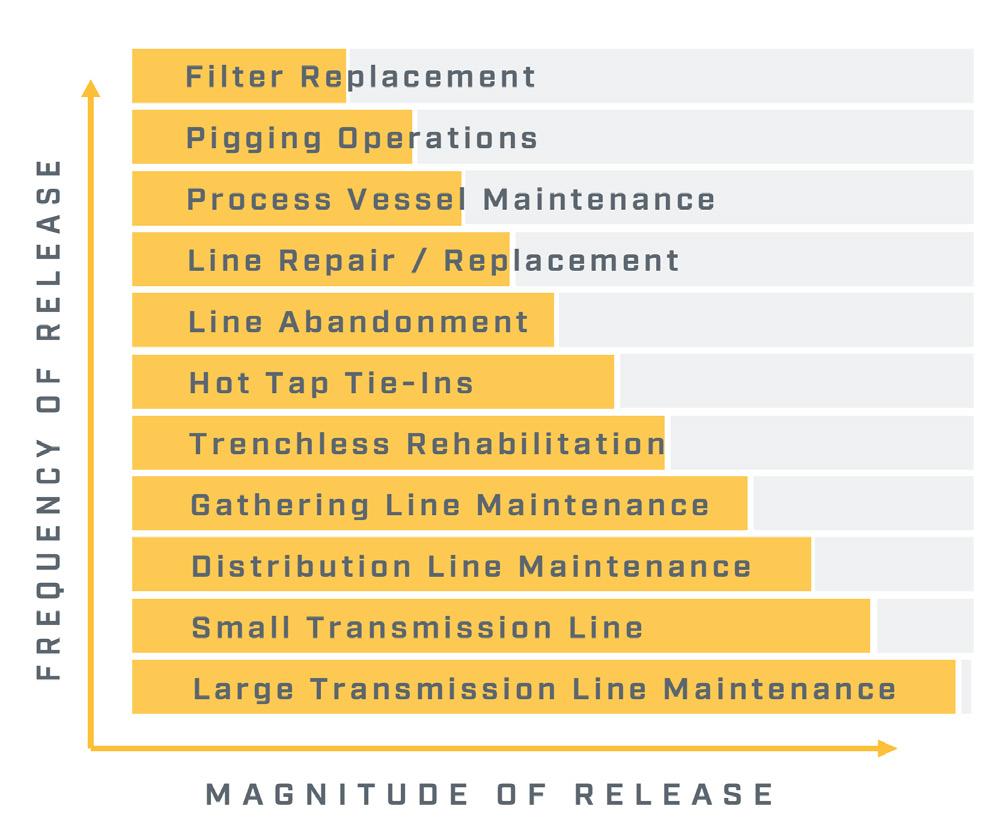

The total time needed for venting depends on a number of variables, but it’s rarely a quick, open-and-shut activity. Even an operation as simple as replacing a filter could require 10 min. of venting first. And while that might result in the release of just a small amount of methane, given how often filters are replaced it all adds up. On the other hand, isolating a large transmission pipeline for maintenance might occur infrequently, but the venting process can take days, with the associated methane emissions easily running into the hundreds or thousands of tons.

Venting isn’t just risky to the environment, of course; it’s also a personnel safety hazard. Opening a valve by hand or with a tool puts the technician in close proximity to the pressurised pipeline contents, which is inherently dangerous.

And it’s no secret that the sound of a high-pressure valve opening is disruptive to anyone living or working nearby and has even been known to attract unwanted attention. In fact, one producer said every time his company vented a section of isolated pipeline near a highway in New Mexico, it would attract protestors.

Fast and efficient One way to reduce the emissions from venting and flaring is to eliminate venting and flaring altogether. But since we’re not there yet, gas recapture systems provide a safe and efficient alternative that can achieve methane reductions of nearly 100%.

Generally speaking, these systems remove natural gas associated with blowdowns during common pipeline operations then return it to the pipeline for use. The concept may sound simple, but the reality is often far from it.

Many systems can’t recover gas at a constant rate from start to finish, meaning either speed or recovery rates are sacrificed.

To overcome these challenges, Houston-based WeldFit engineered and recently introduced a gas recovery system employing patent-pending technology to ensure a constant transfer rate. This makes gas recapture fast and efficient and brings ESG goals well into reach. In fact, environmental audits verify that WeldFit’s ReCAP™ Emissions Recovery System reduces methane emissions by up to 99.99% compared to venting or flaring.

The three-step ReCAP process recovers methane during pipeline depressurisation operations, recompresses it, then discharges into an adjacent pressurised system. The ReCAP technician makes just two connections, turns the system on, and the automated system does all the work. There’s little to no operator involvement.

What truly sets ReCAP apart from other systems, though, is its patent-pending XR technology. XR allows pipeline owners to safely recover gas and control the transfer of methane into the live pipeline at a constant rate, no matter the pressure differential, from 1440 - 0 psig. Competitive products struggle with either low pressures or high pressures, which slows down their performance and adds to the burden of downtime.

“The feedback we’re getting from our customers is ReCAP is faster than anything they’ve seen,” Heinle said.

Figure 2. Emissions recovery/transmission pipeline maintenance, 30 in. natural gas pipeline, 7.6 miles, 585 PSIG, Ogden, Iowa, 2021.

Figure 3. Emissions recovery/gathering pipeline tie-in, 8 in. natural gas pipeline, 2.5 miles, 135 PSIG, Carlsbad, New Mexico, 2021.

Figure 4. Complete depressurisation of pipeline to zero PSIG, emissions recovery/gathering pipeline tie-in, 8 in. natural gas pipeline, 2.5 miles, 135 PSIG, Carlsbad, New Mexico, 2021.

Figure 5. Reletative frequency-to-magnitude of voluntary venting or flaring events associated with common pipeline operations.

For example, in strictly regulated New Mexico – where new rules passed in March 2021 prohibit routine venting and flaring at new and existing wells — it took the ReCAP system only about 90 min. to depressurise a 2 mile section of 8 in. midstream pipeline to 0 psig prior to the onsite contractor commencing a tie-in. This level of efficiency is critical when there are construction personnel ready to go and high-day-rate equipment waiting in the wings.

“Our customers are willing to recover emissions responsibly, but they don’t want it to take longer than it should because that just adds unnecessary cost to the project,” Heinle said. “In our experience, the ReCAP solution is significantly faster than anything else out there. We’re able to allow our customers to achieve their reduction targets in the most efficient way possible.”

If trimming downtime were the only concern, ReCAP’s speed would be impressive enough. But the true test of its performance is how effective it is at keeping methane emissions from entering the atmosphere. In nearly every case, ReCAP’s emissions reduction levels exceed 99.97% when compared to venting; and on some of WeldFit’s larger projects, methane totaling 3700 metric t of carbon dioxide equivalent (CO2e) stayed in the pipeline instead of being released into the air.

Damage control While those projects were scheduled in advance, everyone knows that in the oil and gas industry, unplanned incidents are inevitable. The question isn’t whether an event will occur, but when – and how fast crews can be onsite to respond.

When a Dallas, Texas based utility company experienced a leak on one of their pipeline systems, before they could launch an emergency repair, they first had to quickly transfer gas from an isolated section of 20 in. pipeline.

The location of the leak made depressurisation more complicated. The section traversed a heavily populated residential and commercial area near Interstate 635, which makes a partial loop around the metroplex and carries 230 000 cars per day.

“We were tying into a valve station that was literally next to a neighbourhood,” Heinle explained. “The operator could have opened the valve to vent it but everyone in the neighbourhood would have heard it and smelled it and wondered what they were breathing – or more importantly, what their kids and pets were breathing.”

Instead, less than 24 hours after the utility had contacted them, the ReCAP team had arrived from Houston, prepared the site and completed the transfer project so repair crews could begin their work. Using ReCAP kept nearly 195 000 ft3 of natural gas in the pipeline, or 88 metric t of CO2e, and protected the environment in the process.

A significant victory Housed in a skid-mounted, weatherproof, sound-attenuated enclosure, ReCAP technology is unobtrusive and quiet, meaning there’s little risk of it drawing the kinds of crowds venting and flaring does. Even when it was used in a busy Dallas neighbourhood, there were no curious onlookers.

But it’s a different story for customers’ engineers and project managers, who are interested in watching the process from connection to completion. They’re really intrigued by what ReCAP can do and “how we get it done in a timely manner,” said Branden Allen, ReCAP Field Services Manager.

Obviously, moving natural gas in a pipeline isn’t new to them, Allen said. However, they don’t necessarily know what to expect from a gas recapture process, or how much incremental savings occur from ReCAP’s ability to depressurise the pipeline to zero.

“For example, they’re very surprised and pleased that ReCAP is able to get the pipeline decompressed efficiently, as well as to get the pressures down to zero so there’s nothing left in the pipeline,” he added. “We’ve had jobs where the project manager expected us to recover 80% and had their equipment lined up to come out and blow down the rest of the pipeline, but it didn’t take long for us to get that last 20% out of the system.”

Of course, as standards change, they may find that an 80% target is no longer acceptable.

“We’re helping customers who are trying to eliminate voluntary emissions get as close to zero as possible,” Heinle said.

The battle against emissions may not be over - but by taking direct aim at methane, ReCAP represents a significant victory in the overall war against climate change.