8 minute read

Total Focus On Testing

Frederic Reverdy, Eddyfi Technologies,

France, outlines how advanced non-destructive testing can help improve mining equipment operations.

Underground and open pit mining sites rely on heavy equipment for everyday operations involving excavation, transportation, crushing, sorting, and analysis. With the potential threats found in this industrial environment, it is especially imperative to ensure the safe use of tools and machinery to prevent injury to mine personnel. The right non-destructive testing method can improve safety by detecting flaws and anomalies before a potentially catastrophic failure. Being able to detect a flaw when it is still tiny can save companies thousands, even millions, of dollars’ worth of repair work. It is certainly easier to repair a pinhole or crack in something like a process pipeline than to manage a full-scale rupture. Unfortunately, it can sometimes be difficult to get accurate details of minor flaws in order to address them effectively. The use of the total focusing method with phased array ultrasonic testing is widely accepted for similar applications across other industries, and the advanced inspection techniques are directly applicable to these more challenging mining equipment inspections.

Conventional ultrasonic testing

Conventional ultrasonic testing makes use of soundwaves to locate inconsistencies in parts. A probe, or transducer, passes over the material

and a high-frequency sound wave is sent out. In some instances, that wave will return to the same probe for a reading based on the echo it creates. This is called a pulse-echo ultrasound. Another technique is transmission mode which sends the sound wave to a separate receiver. Anomalies between those two points will diminish the sound wave.

Ultrasonic testing is a popular inspection method with the ability to test a wide range of materials. Technicians only need single surface access to inspect the item. It presents no health risks to users, unlike other methods like radiography. Abnormalities are discoverable regardless of orientation. Tests are relatively fast, and surface areas require minimal preparation.

While ultrasonic testing offers many benefits, much of the accuracy of readings depends on the skill of the operator. Poor operation will result in inaccurate results. Moreover, there are a few limitations inherent in these types of inspections. Sound waves may not reach every part of the inspected object, limiting result accuracy. Conventional ultrasonic testing is not ideal for inspecting over long distances. An uneven surface can result in poor alignment that gives inaccurate readings and false positives of flaws. Large grain materials, like austenitic steel, are challenging to inspect as the sound waves are attenuated and diffracted by the grains. For normal incidence inspections, such as corrosion mapping, a dead zone close to the surface makes flaws undetectable.

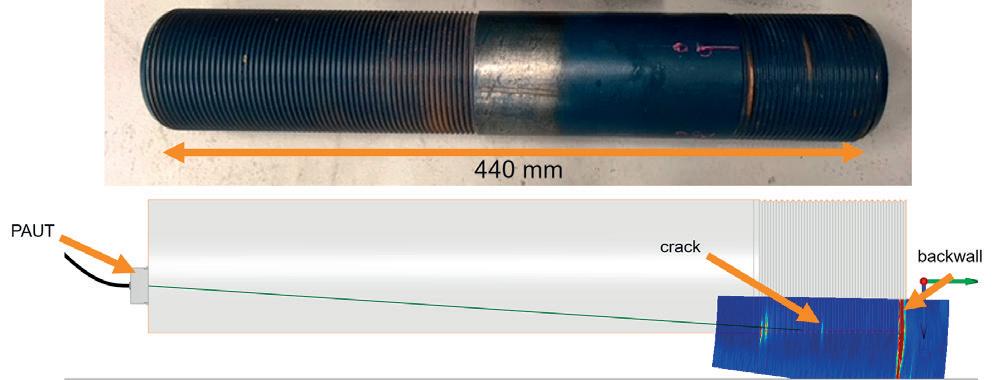

Figure 1. Cracking detected in long bolt.

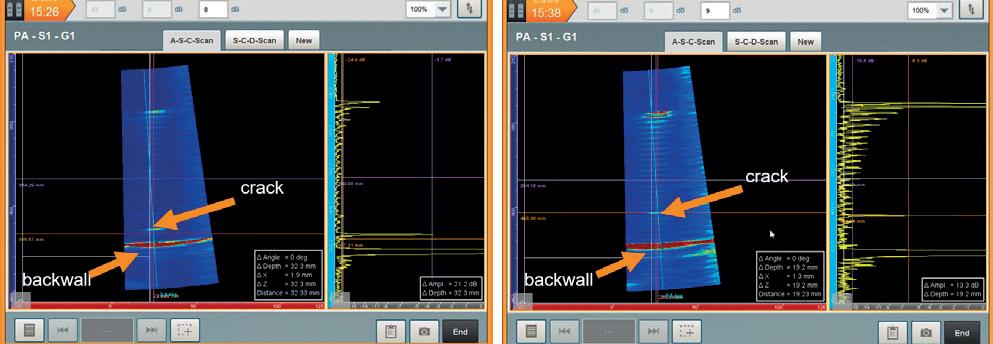

Figure 2. Total focusing method for better bolt inspection.

Phased array ultrasonic testing

These issues can result in unnecessary repairs or downtime for equipment, so it is critical to find ways to work around them. One option is to leverage phased array ultrasonic testing over conventional single probes. While conventional ultrasonic testing consists of a single active element that generates and receives sound waves, phased array probes typically consist of an assembly of small individual elements that can each be pulsed separately. The principle of phased array is to fire the elements in such a way that the wave fronts interfere constructively, or destructively, in predictable ways that effectively steer and shape the sound beam. Phased array ultrasonic testing is capable of detecting more flaws than conventional methods, including discontinuities in awkward angles that are challenging to locate. It also speeds up the inspection process and allows for the evaluation of larger parts common across mining assets.

Total focusing method

The increased accuracy of phased array ultrasonic testing does come with a stipulation: the operator needs to carefully choose the aperture and focusing of the beams to obtain the desired sensitivity. A more advanced algorithm is available to focus the acoustic energy everywhere within a region of interest thus optimising sensitivity. The total focusing method algorithm leverages phased array ultrasonic testing data for better, more accurate readings. As a result, it provides a clear picture of the part under inspection. With this method, it is easier to find and accurately detail tiny defects that may have avoided prior detection. It also minimises inspection dead zones as single elements are fired rather than larger apertures.

With the right equipment, it is possible to locate tiny flaws even in a material that is traditionally hard to read. Yet not all ultrasonic equipment is capable of supporting the total focusing method. Typically, the user will need full matrix capture (FMC), a method where the probe records the acoustic information for each element of the probe. The generation can be an elementary FMC for which all the elements are fired one by one, or any other kind of excitation. The full matrix capture provides the information needed for the total focusing method to create detailed inspections. The total focusing method helps to make phased array ultrasonic testing much more sophisticated while minimising the risk of human error.

Commercial phased array ultrasonic testing

The first commercially available portable instrument to offer total focusing method, Eddyfi Technologies’ Gekko, is a field proven flaw detector that offers phased array ultrasonic testing and total focusing method in a compact and portable package for in-service inspection of mining equipment and assets. The embedded software flattens the

learning curve for any level inspector who also benefits from high-resolution and speed when performing weld inspection and corrosion mapping.

When considering the various heavy machinery involved with mining operations, there is a range of critical components that require routine integrity assessments. For example, TKY joints are the result of joining two pieces of metal together, either perpendicular or at an angle, and they can be found across mining assets everywhere. Embedded software on the instrument features an application that allows operators to define this type of geometry and positioning of ultrasonic echoes in the geometry for better interpretation of the visual results.

Complex components make up essential mining equipment, and from an ultrasonic standpoint, the difficulty for inspection comes with trying to define a proper scan plan and interpret the various ultrasonic echoes. The right phased array ultrasonic systems will have the ability to import 2D CAD files to assist operators with properly defining their scan plan. This allows focusing on the right locations for maximum sensitivity to flaws. A CAD file also allows the superimposition of ultrasonic testing data on the test piece to take the guesswork out of interpretation and defect sizing.

This example looks at the inspection of long bolts. One can see a 1 mm crack located in the threads.

This cracking is one of the most hazardous types of metal fatigue that may otherwise be missed and quietly deteriorate the mining component over time. With the total focusing method, one can detect thread wear before it is too late.

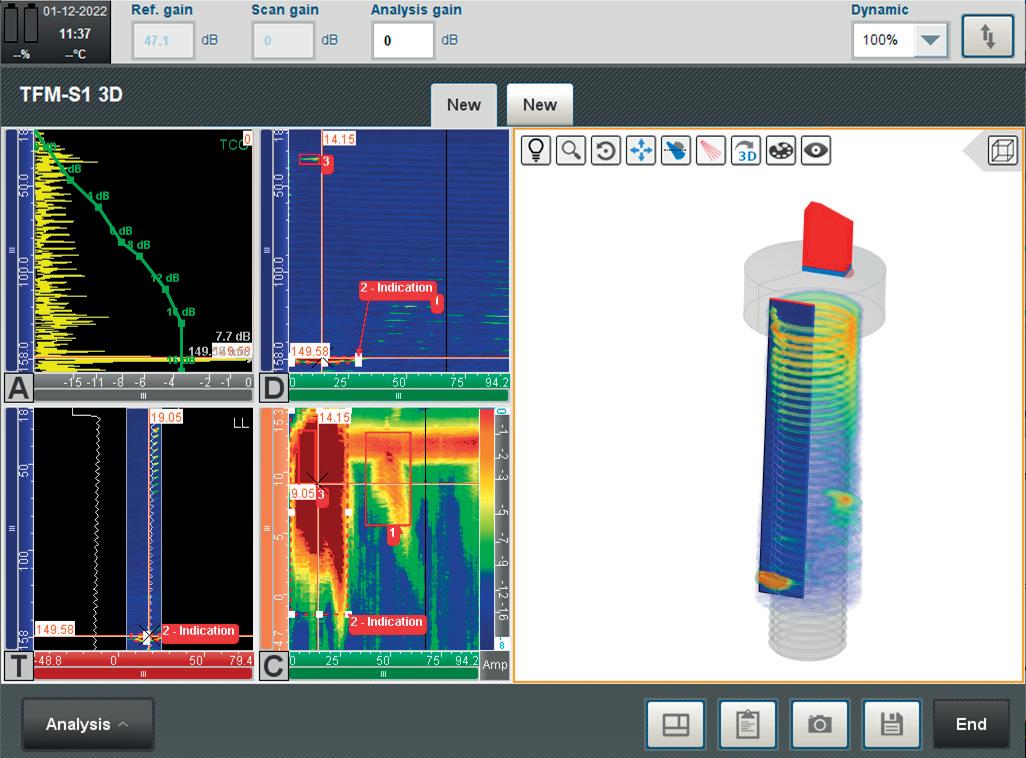

With conventional techniques, the ball studs connecting steering linkages found in industrial mining trucks present challenges around accessibility for inspection from the threaded side. However, phased array ultrasonic testing offers the solution by sweeping the beam along the tapered surface to look for cracks. By using a phased array ultrasonic testing probe positioned on one side and a set of delay laws focused along the opposite wall to maximise sensitivity, inspectors can discriminate indication from geometry echoes thanks to a superimposed overlay with the sectorial scan.

A phased array ultrasonic testing probe is also a great solution for bore and lug inspection, as it allows better coverage even with limited access, using multiple scanning angles for better detection and characterisation of cracking. Cracks are an inevitable result from the inner bore under high stress. It is preferred to perform inspection of these components with the pin or shaft in place, which allows for continued operation of the mining equipment. These components are usually thick with cracks, propagating in random directions. With a large aperture, the spatial resolution, and therefore sensitivity, for detection of smaller detects is improved. This allows preventative action to be taken with the more accurate sizing information.

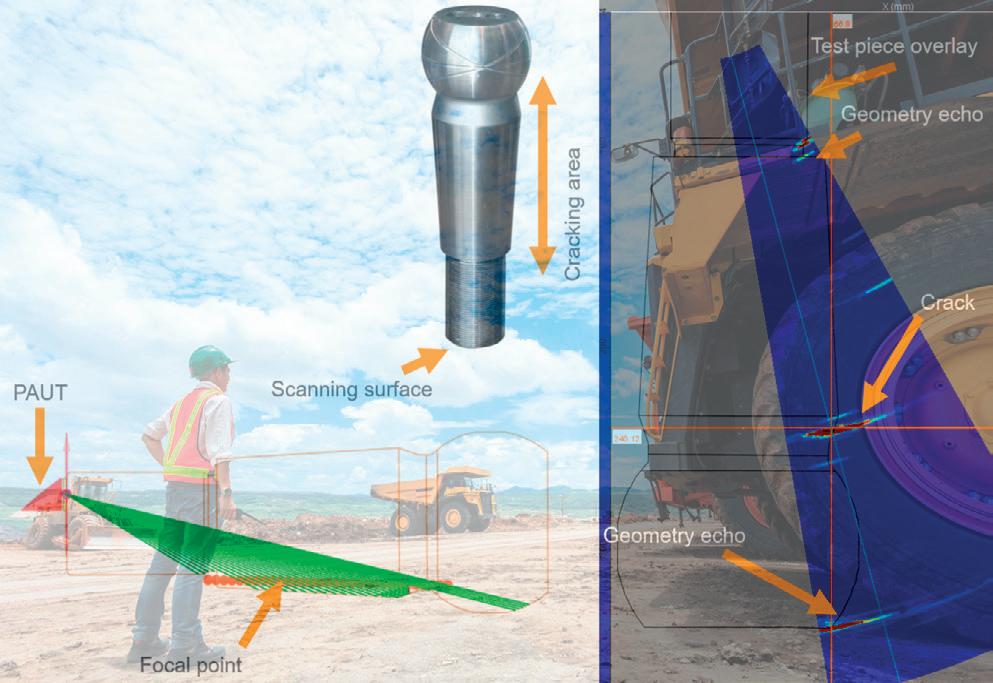

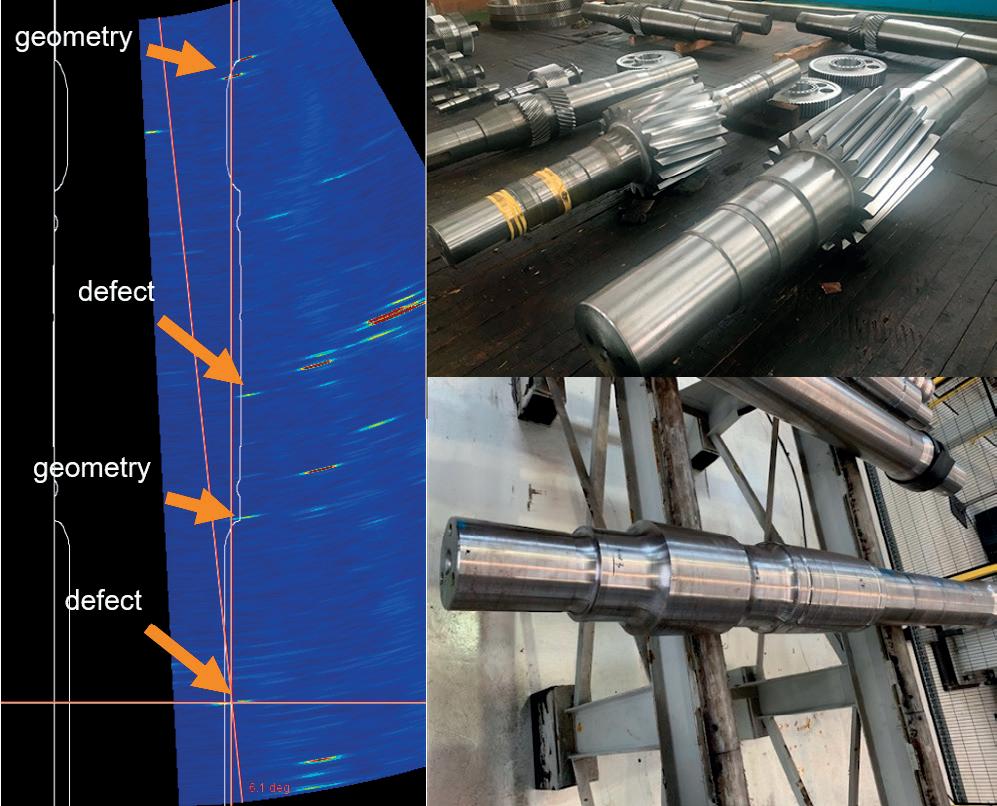

Just like it is better to keep the pin or shaft in place for bore and lug inspection, shafts and axle inspections benefit from this same action. To avoid dismantling and limiting production, inspection is then required from the shaft end; this means long ultrasonic paths when considering these big, heavy, thick components. Large aperture probes can focus energy further, improving spatial resolution and the ability to find small flaws early. Defects as far as 1200 mm away can be detected. Again, CAD overlays of axles superimposed on the inspection data facilitates better interpretation and probability of detection.

A final example of the benefits of phased array ultrasonic testing for mining equipment inspection is the application of gear teeth assessment. Phased array ultrasonic testing can complement eddy current array inspections by searching for and measuring any internal and sub-surface defects found. The same logic applies where large probes can detect and size indications at an early stage, and CAD files can correctly position the indications in the gear teeth.

Figure 3. Phased array ultrasonic testing enables clear flaw detection in ball studs.

Figure 4. Shaft and axle inspection.

Conclusion

While it is difficult to imagine a failure of massive mining machinery from any of these smaller components, it is all too well known that halted operations (or worse) are what is at risk without proper condition monitoring. Advances in non-destructive testing equipment remove the element of surprise with increased productivity and reduced risk, thanks to the proactive inspection data results offered.