11 minute read

Heading offshore

Matthieu Guesné,

Lhyfe, France, looks at the development of offshore green hydrogen, and the role it will play in the decarbonisation of the mobility and industrial sectors.

Participants at COP26 in Glasgow, Scotland, pledged to put the planet on a 2.4˚C global warming trajectory, even though the 2015 Paris Agreement aimed to limit warming to 2˚C or even 1.5˚C above pre-industrial levels. For their part, CO2 concentrations have increased by 47% since 1850. This is the highest level in 2 million years.

There is a need to be more ambitious and to act immediately. Hydrogen is one of the many solutions that can help to achieve these climate goals. But under which conditions?

Hydrogen is a source of energy which offers all the advantages of petroleum and gas without their disadvantages: it is highly concentrated, it can be transported and stored, and it provides energy without emitting greenhouse gases (GHGs). Containing three times more energy per kg than petrol/gas, hydrogen is now a genuine alternative to fossil fuels for certain uses.

The use of hydrogen is particularly relevant:

F For mobility, to fuel buses, refuse collection vehicles, trucks, trains, boats, SUV cars, among others, which then give off no pollutants, just a few drops of pure water.

F In many industries as a raw material or a carrier gas (in the electronics, chemicals, glass metals industries, among others).

Currently, 95% of all hydrogen is manufactured using hydrocarbons (petroleum, natural gas, or coal). This process produces large quantities of CO2 (for every kg of hydrogen produced, up to 10 kg of CO2 is emitted). Manufacturing hydrogen with fossil energy sources simply shifts the problem elsewhere. Indeed, in 2018, global consumption of this form of hydrogen stood at 74 million t (mainly in industry).

Another hydrogen is now possible

The green alternative chosen by Lhyfe uses the water electrolysis technique and connects its electrolysis plants directly to sources of natural, renewable resources of all kinds: wind, photovoltaic (PV) solar, hydropower, solid biomass, biogas, geothermal, etc. which means there is no CO2 in either production or use. This renewable hydrogen can reduce GHG emissions from industry and transportation by up to 30%.

By 2050, renewable energies such as wind and solar will have to fill the massive world energy needs and contribute to the GHG emissions reduction of heavy industrial sectors either through electrification or hydrogen.

Figure 1. Lhyfe’s first production site, in Bouin, Vendée, France, the world’s first plant to produce renewable hydrogen from wind power on an industrial scale. Image courtesy of OHE, William Jezequel.

Figure 2. First delivery of Lhyfe’s renewable hydrogen to La Roche-sur-Yon’s multi-energy station, France. Image courtesy of OHE, William Jezequel.

The EU wants to build 40 GW of green hydrogen electrolysers by 2030 and estimates that 80 - 120 GW of solar and wind will be needed to power them. That is a new headache for Europe’s grid operators. Decarbonisation is expected to double the demand for electricity as transport and heat are also electrified.

Taking hydrogen production off the power grid could be a win-win solution to these problems. That is the idea behind plans for what is termed ‘islanded’ hydrogen, which would pair electrolysers with offshore wind farms and send hydrogen molecules, rather than electrons, back to shore. Industrial applications will be a big source of demand for hydrogen, even more so in the early days of this transition.

So, this process not only allows Lhyfe to offer totally clean hydrogen, but also allows the company to compete with fossil fuels. It can produce clean energy less and less expensively – compared with fossil energy that will become increasingly costly.

Deploying renewable hydrogen production sites

Lhyfe’s first renewable hydrogen production plant, located in Bouin in Vendée, France, has been operational since 2021, after a year of work, installation, and testing. This plant, which is the complete opposite of a conventional gas plant, produces up to 1 tpd of clean hydrogen and supplies the mobility and industrial uses of the Pays de la Loire region in France.

To produce the hydrogen, the company connects directly to three wind turbines (2.5 MW each). The electricity from the wind turbines allows the company to power its production process, composed of equipment selected on criteria specifically linked to Lhyfe’s technology and adapted for it. This process includes an electrolyser that uses seawater (pumped at a rate of only a few m3/d, in the immediate vicinity of the production site) to separate the water molecule to extract hydrogen. The hydrogen is then purified, compressed, and finally distributed to customers.

The impact is immediately positive. The hydrogen instantly decarbonises: F Transport, especially heavy transport, which is particularly polluting and difficult to decarbonise using battery technology.

F Industries using hydrogen called ‘grey hydrogen’ in their industrial process, i.e. a hydrogen produced from fossil energies which can, in its upstream manufacture, generate up to 20 kg of CO2/kg of hydrogen produced (whereas the green hydrogen produced by Lhyfe emits 8 kg of oxygen per kg of hydrogen produced).

This first-of-its kind production unit precedes the deployment of several tens of such units across the territory.

Specificities of the plants

The plants are designed to perfectly handle the native intermittency constraint of renewable energies through a control system developed by the company’s experts to ensure reliable delivery to customers despite fluctuant energy input.

The production process is also ideally optimised thanks to an accurate process modelling that guarantees the hydrogen availability at the most competitive cost.

Each deployed plant generates an immediate positive impact on the environment together with add-value for the hosting territory. The short distribution channel deployed (producing hydrogen from locally available energy and supplying local needs) allows Lhyfe to address and generate impact on local employment and resilient development of territories.

Going offshore

Lhyfe’s first industrial site has not been selected randomly. This first plant hosts, on top of the hydrogen production part, an R&D platform dedicated to the offshore solutions deployment. Geographic localisation (near shore) allows considering harsh marine environment testing of the devices subject to saline and a corrosive atmosphere expected in offshore production processes. The deployment plan entails a first demonstration as soon as 2022 and a first commercial production plant by 2025.

Why target offshore production?

Offshore production significantly increases the impact. It allows massive production quantities from a more powerful, more available, and less fluctuating energy, leading to more competitive production costs.

Today, the most competitive electricity production cost is obtained using PV panels in sunny regions of the world. However, this type of renewable energy implies a very low load factor. Thus, despite solar being a low-cost energy, the load factor prevents sustainable business plans from tackling 100% green hydrogen production in Europe.

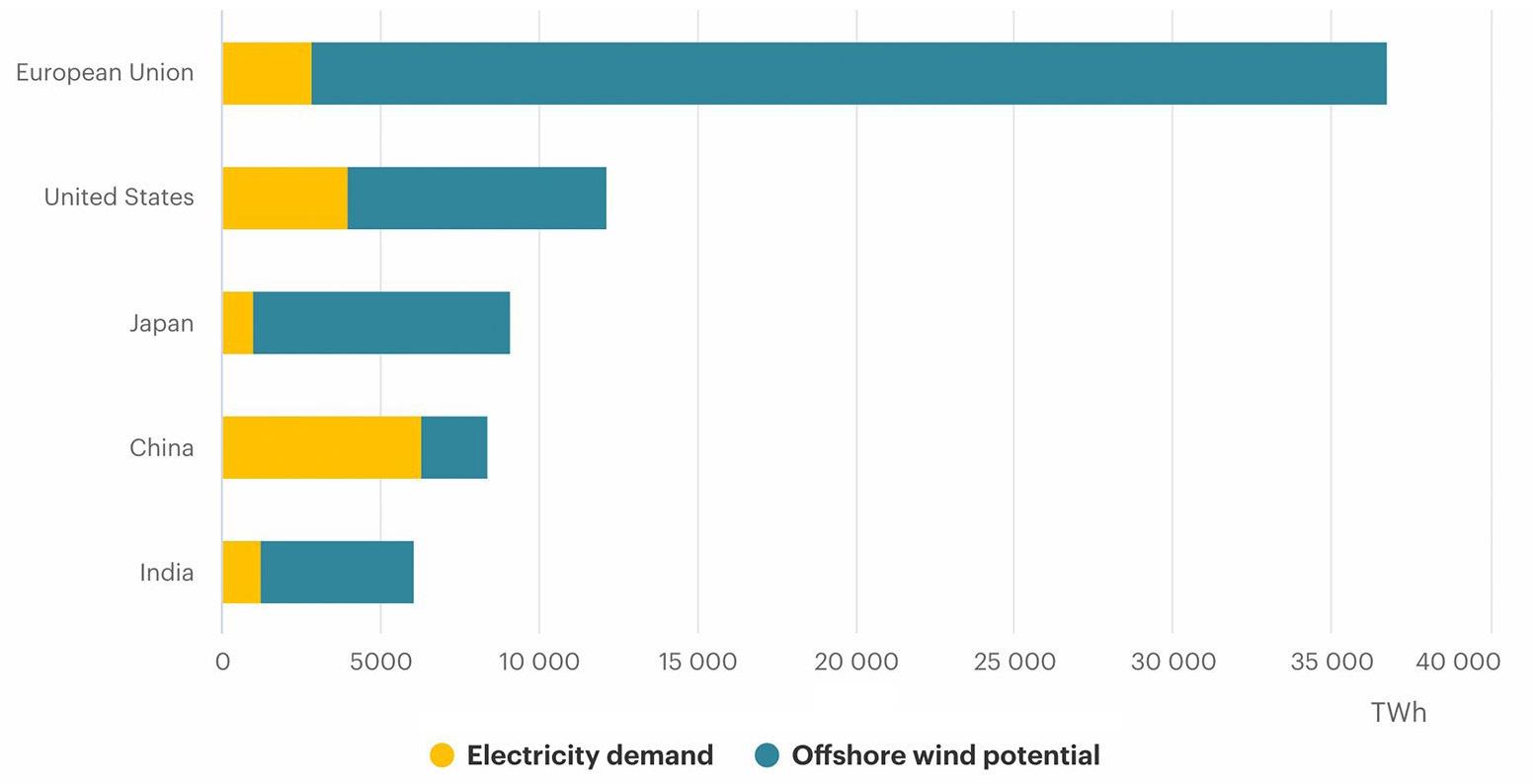

On the contrary, offshore wind energy cost has heavily dropped in the last years to reach €40 - €45/MWh on average. On top of this, the load factor of offshore wind is significantly higher than PV or onshore wind, achieving 60% targets.

Lhyfe’s currently developed concepts are thus sized to produce more than 9000 tpy of hydrogen. Only one of these platforms avoids more than 200 000 tpy of CO2. Considering the average lifetime of the plants (35 years), each platform could reduce CO2 emissions by 7 million t of CO2. With only 140 offshore platforms around the world (the North Sea already has over 1000 existing platforms), 1 billion t of CO2 will be avoided.

Offshore wind deployment potential exceeds the electricity demand by more than 18 folds. Coupling this renewable energy with hydrogen production makes it feasible to envision offshore wind farms further from coasts enabling valuation of currently hard to reach areas considering the electricity networks constraints.

On top of the ability for renewable wind energy to supply electricity demand by 2050, according to IAE, the renewable energy will significantly participate in the decarbonisation of activities releasing huge amounts of GHGs such as transportation, chemicals, or heavy industries. These sectors are specifically harder to decarbonise by electrification alone.

Far shore wind farms are also way more socially acceptable. Moreover, gas transportation allows the transfer of 15 times more energy than electricity through cables for a three times decreased CAPEX. Significant synergies can be found between these two sectors to take advantage of the energy potential, still limiting usage conflicts.

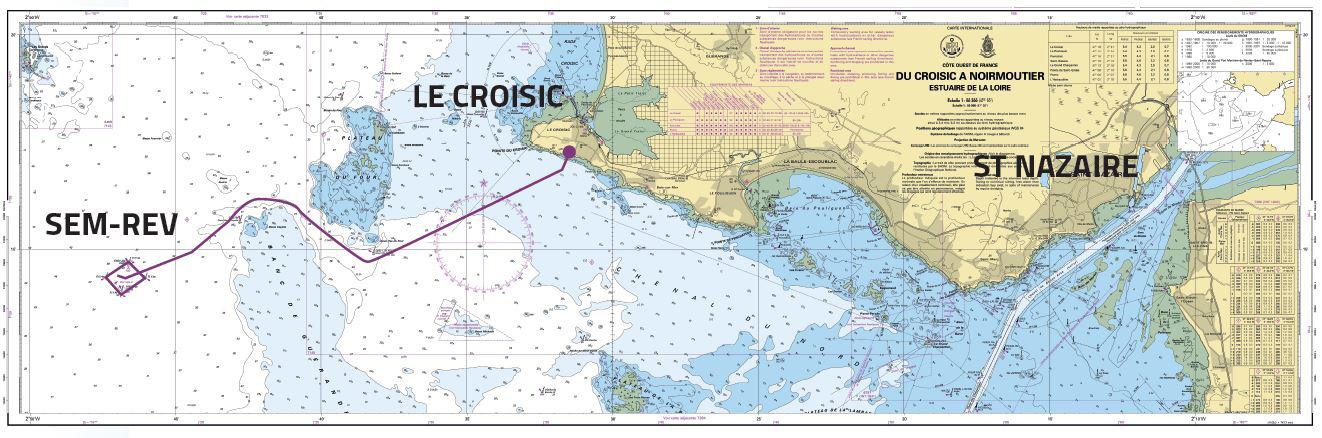

Figure 3. Location of the SEM-REV sea trial site. Image courtesy of SEM-REV/Centrale Nantes.

Figure 4. The SEM-REV site offshore Le Croisic in Brittany, France. Image courtesy of SEM-REV.

Reuse of oil and gas platforms

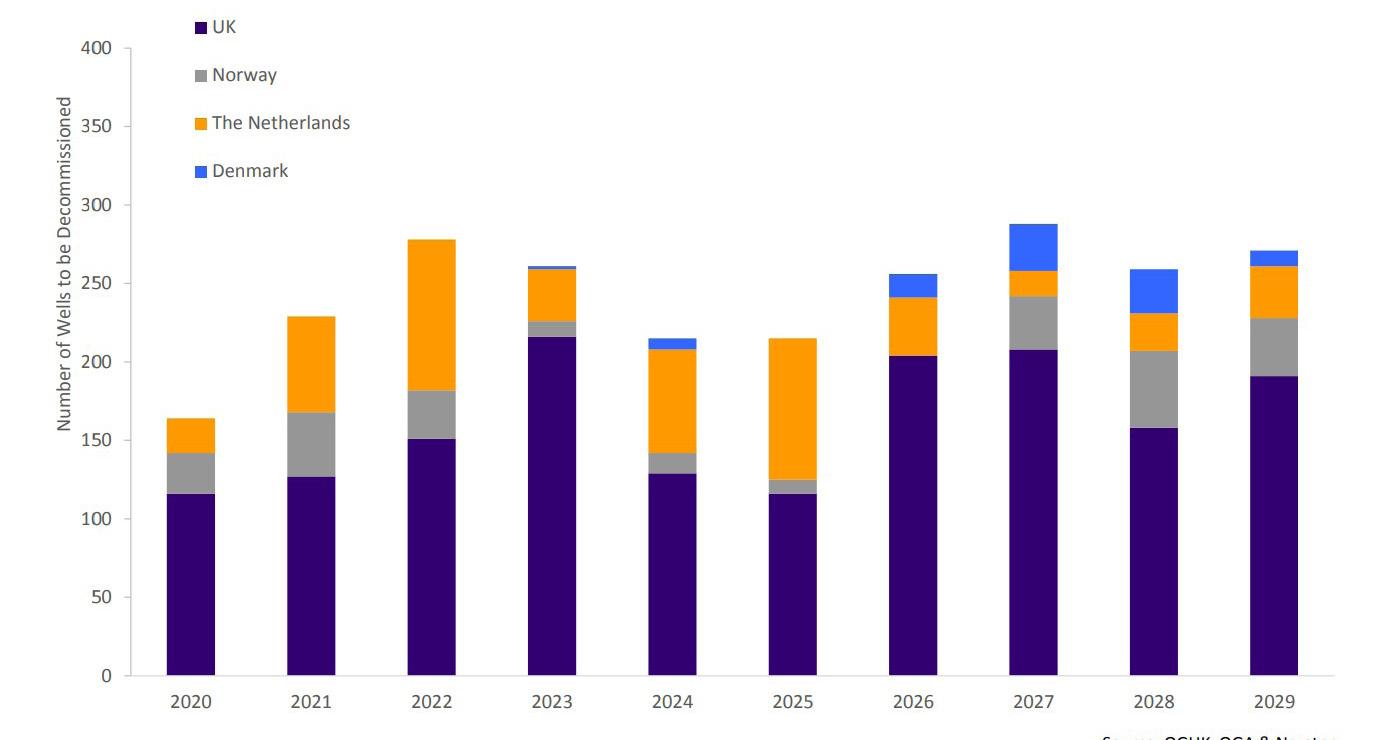

The current decline in offshore oil and gas production is a clear opportunity to deploy modular hydrogen production units at sea linked to offshore renewable electricity.

According to the net zero roadmap of IAE, oil consumption could fall by 70% between 2020 (approximately 90 million bpd) and 2050 (24 million bpd) when the gas consumption could drop by 55% and coal by 90%. From 2021, there could be no more demand for new oil and gas fields except those already started.

On the other hand, as an example, there currently are hundreds of existing platforms in the North Sea that will have to be decommissioned in the coming decade. Reusing existing offshore assets to produce hydrogen then seems possible and even represents a clear opportunity for stakeholders to extend asset lifetime by investing in the sustainable sector of green hydrogen production.

Such a process can require heavy investments from asset owners. During the next 10 years, there could be €65 billion invested for decommissioning processes of offshore assets.

According to DNV, 52% of oil and gas actors foresee hydrogen as a great part of the energy mix by 2030 and 21% admit to already having entered the hydrogen market.

The costs of transporting hydrogen from ocean platforms via pipeline may appear at first glance to be much greater than the costs of laying undersea transmission to carry electricity to shore. But that does not take into account the cost of offshore substations to collect wind farm power, or the severely congested state of the onshore power grid. A massive co-ordinated effort will be needed to whip those grids into shape to absorb the rapidly growing amount of offshore wind power being planned.

In light of these challenges, piping hydrogen back to demand centres may make sense, particularly for a North Sea region that already hosts an extensive undersea pipeline infrastructure and deep industry experience in building it. So far, the initial wave of islanded hydrogen projects is starting.

Finally, offshore wind appears to be an adequate energy source for hydrogen production thanks to the low cost of electricity (<40 MWh) coupled to a wide load factor (>50%). Thus, renewable offshore hydrogen establishes itself as a unique opportunity towards a 100% renewable energy world.

Validating the technology

To support the development of offshore hydrogen facilities, Lhyfe has decided to put an electrolyser on a floating barge. This is the first time in the world such production facilities will be put at sea to study and unlock the challenges linked to offshore floating hydrogen production. The SEM-REV site offshore Le Croisic in Brittany, France, has been chosen for this purpose. It is a unique site where renewable marine technologies can be tested, offering the possibility to study, measure, and collect data for offshore pilot tests.

The SEM-REV site is equipped with all offshore measurement tools. It is composed of a secured and reserved area of 1 km2 delimited by four buoys 20 km from Le Croisic and equipped with oceanographic and weather sensors (wind, wave, and water streams).

This site is an optimum place for testing offshore floating hydrogen as: F It hosts a 2 MW floating wind turbine which can and will be directly connected to the electrolyser. The site is also connected to the onshore grid allowing for electrical supply at any time.

F Permitting is already in place for technology experimentation.

F The site is located in the vicinity of Lhyfe’s head offices in

France as well as close to Bouin’s hydrogen onshore plant equipped with a 1 MW electrolyser.

The barge is planned to be installed onsite in September 2022, directly connected to an already existing floating wind turbine. The electrolyser’s capacity is 1 MW and the test will be carried out during one year.

The experimentation will help to crack the following key technological challenges: F Marinisation of the electrolysis unit, such as understanding the impacts of the accelerations generated by the swell on the production of the electrolyser, and the protection of the equipment against a highly corrosive environment.

FRemote operations, including operation management and monitoring systems respecting the required safety rules and regulations using a SCADA system interfaced with all Lhyfe sites. Also, the centralised operations from a remote operation room located in Bouin. Furthermore, the experiment will help with the development of a numerical twin allowing for an optimised hydrogen production to manage the production intermittency of the Floatgen wind turbine electrical production.

FOptimisation of utilities, as the harsh environment of the

SEM REV site does not allow access to the site on many occasions during the year, especially in autumn/winter seasons. Hence, the technology deployed on the barge will be carefully chosen and tested for operation without presence of personnel over several months.

In parallel, Lhyfe has initiated the development of several offshore concepts to prepare for the emerging and yet promising opening of the market to come. Through this conception phase, the company evaluates the suitability and effectiveness of different infrastructure types able to accommodate with its hydrogen production process (a modular topside dedicated to hydrogen production, a wind turbine floater, and a jack-up rig retrofit).

Figure 5. Offshore wind technical potential and electricity demand in 2018. Source: Offshore Wind Outlook 2019, IEA.

Figure 6. Well decommissioning activity in the North Sea, 2020 - 2029. Source: OGUK/OGA/Nextstep.