8 minute read

Think outside the box

Herbert Williams, Keuka Energy, USA,

discusses how offshore wind can be stored as energy via liquid air and hydrogen, and looks at the opportunity this technology presents to help decarbonise the shipping industry.

Wind, solar, geothermal, and water are all known energy sources. They are renewable, environmentally clean, free, and each of them can produce electricity that can be used and stored. Keuka Energy focuses on far-offshore wind because it is stronger than wind on land, with no ‘not in my backyard’ issues, no bird or bat kills, has global potential, and there is limited space for wind projects on land. But most importantly, wind energy can be stored to be used as needed at a cost that is below that of natural gas or coal to produce electricity. Producing and storing enough energy at the cost utilities need to start phasing in clean energy can only happen when clean energy can produce electricity at a lower cost than natural gas or coal. Until another option arises that costs less than fossil fuel, coal and natural gas companies will have to keep the lights turned on, and customers will always choose the cheapest electricity available.

Can a new global player in offshore wind produce and store liquid air and/or hydrogen at a lower cost than natural gas? Keuka Energy’s RimDriveTM wind machine plans to do just that. The technology, which takes power from the tip of propeller blades instead of their central shafts, can play a big role in reducing the cost of stored energy and provides hope for cutting the planet’s dependency on fossil fuels.

Storing wind power

Stepping out of the ‘wind can only make electricity’ box, wind is also capable of storing its energy as liquid air and/or hydrogen on a global scale. When liquid air or hydrogen is produced and used as stored energy, it is dispatchable (can be switched on or off). Being dispatchable, it can be used as baseload or

spinning reserve to deal with wind and solar intermittency. This in turn makes wind and solar more valuable if they are selling to the same utility that is using liquid air or hydrogen storage. Wind and solar farms would be highly valuable if they could sell electricity as firm capacity (baseload) instead of as available (when the wind is blowing, or the Sun is shining). This stored energy can be used by ships offshore to clean up their fuel or by coastal utilities to produce electricity when they have a need for it.

For example, a utility could have a tanker load 12.5 GW of renewable stored liquid air energy at their beck and call to deal with wind and solar intermittency at a cost less than natural gas. This could bring relief to the International Maritime Organization (IMO) by producing hydrogen near shipping lanes to enhance bunker-c fuel for two ships at a time. Since the RimDrive hybrid machines liquify air and/or hydrogen, the plan is to locate some of the wind farms near shipping lanes to allow ships to birth in the calm water of the V-shaped platform and offload their bunker-c and replace it with bunker-c enhanced with hydrogen. The V shape of the flotation platform produces the calm water needed for berthing LNG-class tankers for loading liquid air or modified tankers for hydrogen. The floating platform can accommodate two tankers at a time, making it a ship service station.

The project will be the first to produce renewable utility scale stored energy while offsetting 4200 tpd of CO2 being released into the atmosphere. The Hybrid RimDrive will also be the first offshore project to produce liquid air and hydrogen instead of electricity.

Design and application

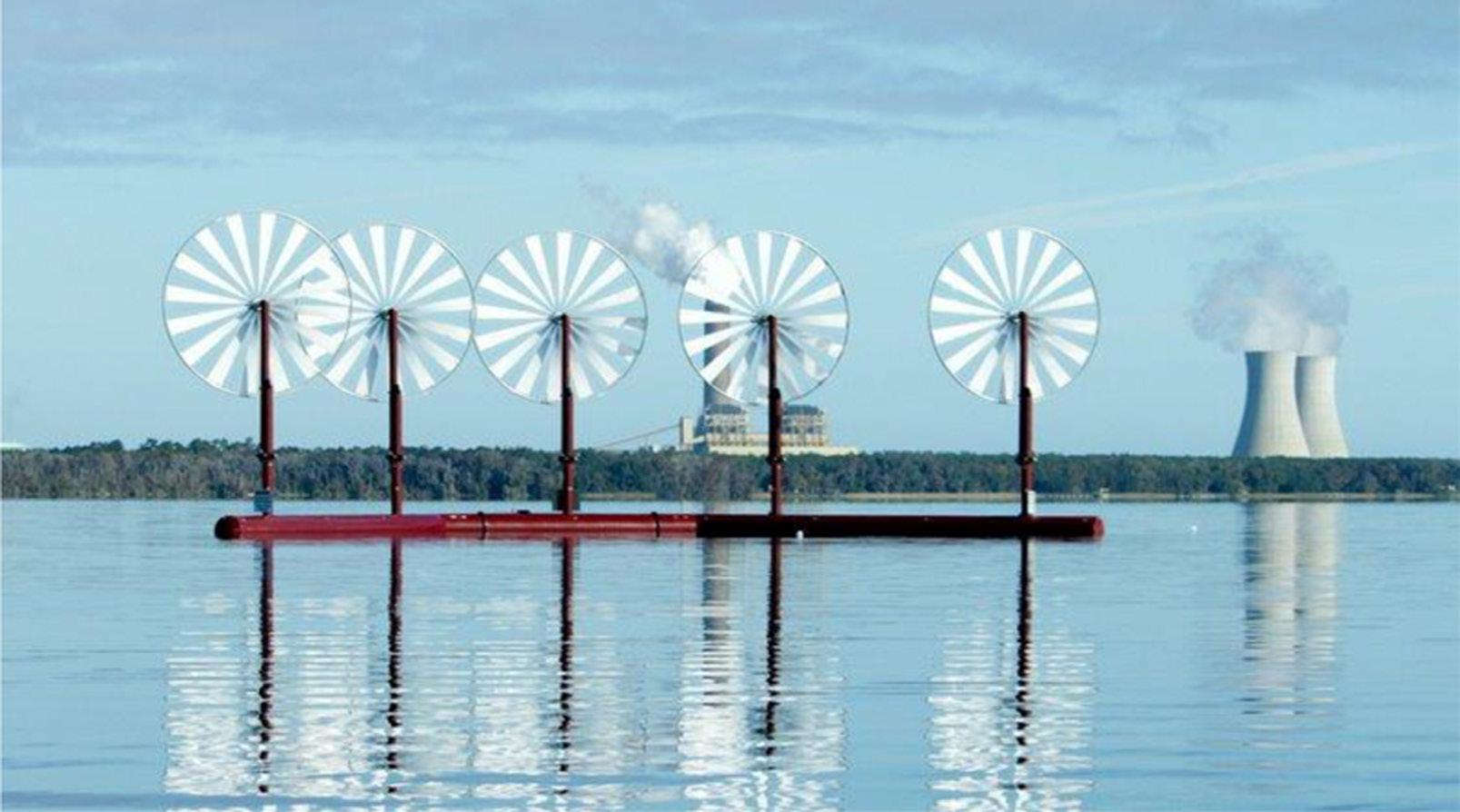

Figure 1. A 375KW (588 horsepower) prototype of RimDriveTM . The American Bureau of Shipping (ABS) and Bureau Veritas (BV) has reviewed the concept design process of both the Keuka Energy’s V-shaped liquid air/hydrogen storage wind platform which will be anchored well offshore, and its 300-t Tara Allen service vessel. The project has implications beyond advancing Keuka Energy’s core technology. The company is excited to be working on what may well be the first project with the potential to start reversing climate change on a global scale while being the answer to wind and solar intermittency. Even though the project sacrifices approximately 50% of its shaft horsepower to produce liquid air and approximately 65% for hydrogen, the low capital cost of the RimDrive system combined with mechanical liquefaction (without electricity) puts it at a lower levelised cost of energy (LCoE) than natural gas. The 235 000 horsepower (175 MW) wind farm and a near shore re-gas facility will mechanically produce 624 MW/d of liquid air using one support platform that doubles as cryogenic storage for a cost of less than US$1 milion/MW and has an LCoE of US$0.04/kWh. The LCoE of natural gas is approximately US$0.048/kWh. Since wind is free, the capital cost and O&M are the only significant cost in the wind farm’s future. Either liquid air or hydrogen can be used by utilities to make natural gas 30% more efficient at producing electricity. Liquid air can be used to increase mass flow to a utility’s gas turbines, allowing them not to need to use approximately 30% of the gas coming to the plant for compressing air but use 100% of the gas to turn the generator sections to produce electricity. The challenge faced by all gas turbines is that as ambient temperature or elevation rises, the density of the air naturally decreases, reducing the mass flow into the gas turbine. This reduced mass flow results

in reducing the fuel flow proportionately to hold turbine inlet temperatures constant. This results in lower output. Liquid air restores the mass flow that is naturally missing by injecting cold air into the compressor intake and adding turbine waste heat to the liquid air re-gas system to warm the incoming air, producing more energy for the generator section. The gas turbine control system reacts naturally and adds a proportionate amount of fuel to account for the increased air mass flow, resulting in constant combustion and turbine inlet temperatures. The increased mass flow through the turbine section increases the mechanical torque to the generator for producing electricity while allowing the compressor to act as spinning reserve when needed.

Fortunately, cryogenic liquid production, its distribution infrastructure, and equipment supply chain are already mature. LNG is the largest user of cryogenic systems and the only end-to-end system proven on a large scale. There are over 650 LNG tankers, most with a storage capacity exceeding 125 000 m3 plying the world’s oceans at any given hour. In addition, liquid air having no fuel combustion or high-pressure risks would make shipping and handling cost 5 - 15% less than that of shipping and handling LNG. Since a typical LNG tanker holds approximately 125 000 m3 of liquid and 10 m3 of liquid air produces approximately 1 MWh of electricity, imagine the comfort level a utility would have if it had 12 500 MWh of renewable stored energy at its beck and call. That would be 17.3 MW/h for one month (732 h) that it could use as needed. All renewable and all wind. Each 35 000 horsepower wind farm should produce approximately 46 120 m3 per month of liquid air. Typically, the single largest cost of producing liquid air is the electricity used to power the electric motors doing the work. When wind machines mechanically drive the liquefaction equipment, most of the costs of producing liquid air are eliminated. The only time electricity plays any role in the process is when the outer rim supplies the mechanical horsepower to drive the DC generators needed to produce hydrogen.

Minimising costs

The RimDrive wind machines take power from the outer rim and not the central shaft, thus requiring no gearbox. The US Department of Energy (US DOE) finds that the gearbox is 25% of the 30-year cost of conventional wind machines. Taking energy from the rim’s lowest point also keeps a considerable amount of the weight down low.

Figure 2. RimDrive prototype in St. Johns River, Palatka, Florida, US. This lends to less stress being placed on the tower and a much lower O&M cost. Additional cost is avoided by not needing large cranes to install or service the machines since the blades of the rim-driven machines lower on their own power when needed. Much higher speeds are achieved at the outer rim, and the machines can have numerous shafts being driven simultaneously so that a combination of work can be achieved at the same time, such as compressors, turboexpanders, etc. The blades are made of marine grade aluminium, are totally recyclable, have over 100-year service life expectancy, and cost less than 10% of today’s composite blades. National Renewable Energy Lab (NREL) tests show the RimDrive to be more powerful per square m of blade swept area than existing three bladed machines. The outer rim gives a flywheel effect that eliminates most wind gusting and turbulence problems and improves their scalability to multi-megawatt size. The semi-open centre produces less downstream turbulence and lends to placing more units per given area. Production costs are minimised with numerous turbines stationed on each V-shaped platform. The turbines have no need for costly yaw mechanisms since the entire support structure weathervanes into the wind as it is anchored to the sea floor using a single anchor line. It is dry-docked at sea eliminating the need to be brought back to land for maintenance and the support structure will stock all parts needed to maintain the wind machines.

Conclusion

Liquid air or hydrogen can only be a global player when it uses ocean transport or it is produced on location, and producing either on location will seldom be done. The tremendously large volumes needed to start changing the world’s course on climate change will be moved by ocean transport out of necessity. The wind machine design of the future will be the one that held the course long enough to allow the burning of fossil fuels to be replaced by a carbon free system that produces electricity.