7 minute read

The Sun rises on solar

Dr Isao Takasu, Toshiba Corporation,

Japan, discusses the growing global solar market and the developments in photovoltaic technology that are helping the industry to flourish.

Across the world, countries and organisations are striving to reduce their carbon emissions and meet ambitious sustainability goals. The recent United Nations Climate Change Summit (COP26) in Glasgow, Scotland, placed a magnifying glass on the current situation, and it is vitally important in the coming months and years that sustainability efforts continue to intensify both at a geopolitical, enterprise, and societal level.

As carbon emissions are reduced, the emphasis must be placed on transitioning to renewable energy sources to replace them. Steady progress is being made here – according to the International Energy Agency (IEA), renewables made up 29% of global electricity generation in 2020.1 While hydropower is currently responsible for much of this, both wind and solar power are also growing in usage and are expected to contribute to two-thirds of total growth in renewables. The concern is that, with over 70% of energy still being generated by non-renewable sources, the rate at which the transition to sustainable power generation is achieved needs to exponentially increase.

The rise of solar

Solar itself offers significant potential, but is one such renewable energy source yet to be maximised. There are several ways in which solar energy can be generated, including concentrated solar energy (CSP) and thermal, but currently photovoltaic (PV) modules are the primary source. Global electricity generation by this method is rapidly growing – it is expected to have increased by almost 18% in 2021.

Yet even with this significant forward step, greater progress is required. As the IEA states, while “policy deadlines led to a PV deployment boom in 2020 […] more effort is needed to reach 2030 net zero levels.”2 Put simply, increasing usage of PV power generation will be essential to achieving carbon neutrality.

Maximising the potential of PV modules

Today’s most widely used PV modules are made with crystalline silicon – a heavy and rigid composition which limits where they can be installed. For example, as of today mega-solar power plants have generally been installed on vacant sites or in mountains, but there are fewer places where conventional silicon mega-solar power plants can be installed. Yet given the need for more rapid acceleration towards solar, there is a growing need for large scale electricity generation in urban areas. Local production for local consumption will be the key in the future.

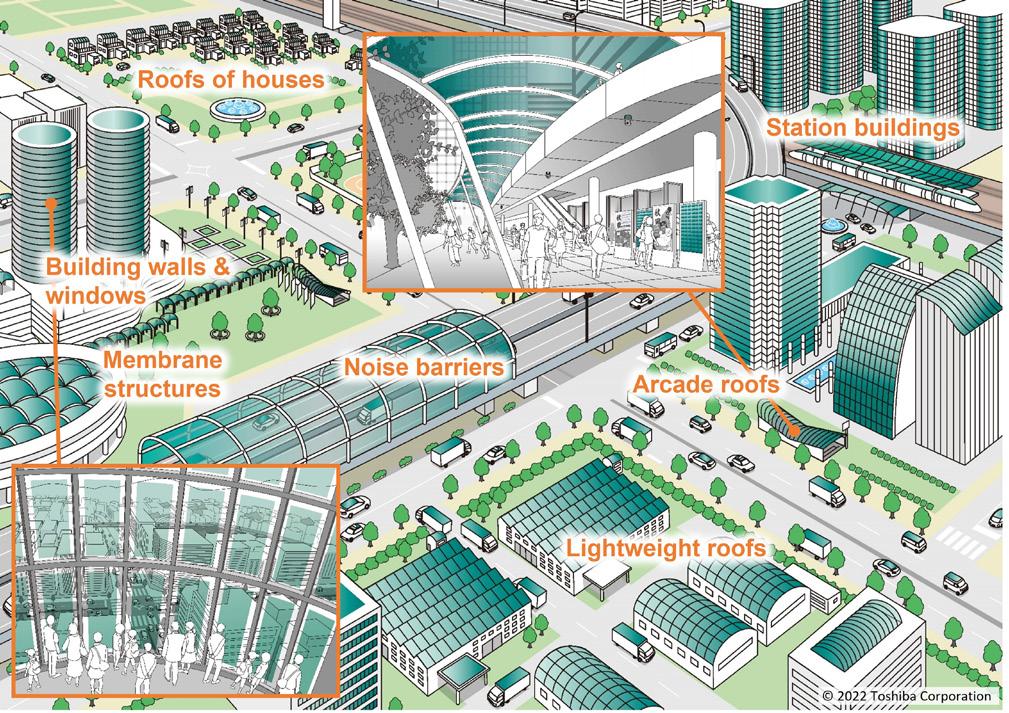

It is for this reason that the polymer film-based perovskite PV module offers an attractive next-generation alternative, boasting a number of benefits over the widely-used crystalline silicon PV modules. Thinner, lighter, and more flexible perovskite PV modules can be installed in locations where it is too difficult to use silicon PV modules, such as low load-bearing roofs and office windows. Within urban environments where space is at a premium, this offers a game-changing solution for solar power generation – significantly expanding the number of existing locations where PV modules can be installed. One need only imagine the financial or business district of any major city, filled with glass-fronted buildings, to realise the opportunity for such technology.

While polymer film-based perovskite PV modules have the potential to drive solar power generation to the levels needed to meet carbon net zero targets, the current issue with them when compared to

the silicon modules is their comparably inefficient power conversion efficiency (PCE) rates. That is to say, they cannot yet generate as much energy from a set amount of sunlight as their counterparts.

Innovation paving the way to change

‘Yet’ is the crucial word in the previous sentence – the potential for perovskite PV modules to deliver similar PCE rates to silicon versions is very much real, and Toshiba has made significant steps in achieving this through its new one-step meniscus coating method. The coating method for perovskite PV modules has been a stumbling block until now, as a previous two-step method led to a low-coating rate which often resulted in unreacted sections in the perovskite layer – and subsequently a lower PCE.

The breakthrough one-step coating method boosts PCE to 15.1% for a 703 cm2 sized module – the world’s highest for any large, polymer film-based perovskite PV module (based on a Toshiba survey of 100 cm2 or larger film-based perovskite solar modules with a plastic substrate, as of 10 September 2021). This is because Toshiba uses improved ink, as well as enhanced film drying processes and production equipment, to form a uniform perovskite layer over the entire area. A further benefit is the speed at which the coating is applied, with it now being 25 times faster than Toshiba’s previous two-step process. This results in the wider process being 50 times faster, given there is a need for just one layer of coating, and subsequently means the solution now achieves a rate that meets the requirements for mass production. In turn, this both simplifies and reduces the costs of production, making the technology a commercially viable option for the future.

While these latest advancements are significant, there are further challenges ahead within the research and development phase before such technologies are ready to be commercialised, with Toshiba aiming to bring its modules to market in 2025. Within the next three years, there is a need to achieve even greater levels of conversion efficiency, as well as higher durability levels. It is also important to bring down the manufacturing costs of the panels through the use of more cost-effective materials.

Figure 1. An overview of the types of locations that could benefit from the lighter and more flexible perovskite photovoltaic (PV) modules, enabling the more widespread generation of solar energy.

Applications from urban to rural environments

Coupled with the aforementioned benefits of perovskite, Toshiba’s innovation paves the way for potential wide scale implementation of next-generation solar panel technology. It is estimated that the new technology could generate enough power to cover two-thirds of the annual power consumption of homes in Tokyo, Japan, if installed on a roof area of 164.9 km2 – that being roughly equal to the roof surface area of all buildings in Tokyo, Toshiba estimates.3 However, application examples are not just limited to metropolitan areas, with the technology potentially being beneficial across industries such as manufacturing and agriculture too.

Take the latter of these as an example. As the transparency of perovskite solar cells can be controlled by how thin the layer of perovskite is made, they can be used to cover greenhouses, enabling farmers to let in the correct amount of light as is required for the crops, while also generating the energy needed to power the farming process. When considering that agriculture was directly responsible for 8.5% of all greenhouse gas (GHG) emissions in 2019, according to the Intergovernmental Panel on Climate Change (IPCC),4 it is clear that such technologies can have a major impact in helping some of the worst performing sectors work towards carbon net-neutrality and subsequently contribute towards a circular economy. The same applies to the buildings and building construction sectors, which, the IEA reports, combine to be “responsible for over one-third of global final energy consumption and nearly 40% of total direct and indirect CO2 emissions.”5

Beyond perovskite PV technology which can revolutionise the use of solar across almost all types of buildings, complementary technologies such as tandem-type solar cells are also consistently evolving to themselves also offer better PCE. Solutions such as Toshiba’s Cu2O-Si tandem cell boast an estimated PCE of 27.4% based on the company’s estimates and, developed using low-cost and naturally abundant materials, have the capacity to carry an EV 35 km without any need to be recharged. This kind of solar technology has the potential to transform mobility-based applications.

A global effort towards net zero

As society looks to navigate the numerous and varied environmental problems it now faces, including climate change and the depletion of energy resources, the role of solar energy alongside other renewables is vitally important in building a sustainable future. Toshiba shares this vision, aiming to reduce GHG emissions by 70% across its value chain by 2030 and closely aligning itself and its solutions to the United Nation’s sustainable development goals (SDGs). As a result, a commitment to developing technologies such as polymer film-based perovskite PV modules which help contribute to a circular economy is of paramount importance, and it will be interesting to see how the technology evolves as more countries and organisations look towards a solar future.