COMPANY PROFILE

Welcome to the partner that keeps your business moving – and your customers loyal

At Palcut, we don’t just sell anti-slip paper and sheet dispensers. We deliver serious results: rock-solid pallets, faster production, smarter packaging, and fewer complaints clogging up your day.

Palcut has led the way in Europe for over 20 years — with smarter palletizing solutions that help distributors win more business.

Now we’re bringing that same winning formula to partners across America.

With over 900 installations, 70+ distributors worldwide, and a U.S. warehouse ready to ship fast, we combine global muscle with local, hands-on support.

Quick support. Consistent quality. Fast deliveries. That’s not just a promise — it’s how we work.

At the core of everything we do is the Palcut Solution — the perfect match between our anti-slip paper and fully automatic sheet dispensers. Together, they supercharge efficiency, crush downtime, stop collapsed pallets cold, and free up valuable space in every warehouse.

Less waste. More uptime. Stronger deliveries.

When your customers win, you win. And we’re here to make sure you crush it — every single day.

Why choose Palcut?

Because working with Palcut isn’t just easy — it’s a serious advantage.

You’re offering your customers more than stability. You’re offering them speed, savings, safety — and peace of mind.

Every Palcut Solution is designed to make your customers’ operations faster, safer, and more efficient — while making you the hero who delivers real results.

• Boost your customers’ productivity

• Cut their downtime

• Help them ship smarter and safer

• Strengthen their loyalty to you

Your 5 big wins with Palcut

RELIABLE PRODUCTS. RESPONSIBLY MADE.

We use recycled, FSC®-certified (FSC®C147797) anti-slip paper — so you can offer stable palletizing with a responsible footprint. It’s one more reason your customers will trust what you sell.

CONSISTENT QUALITY. SPEEDY DELIVERY.

Every sheet. Every dispenser. Every order. Same top quality. Shipped from our U.S. warehouse within 2 business days.

SALES & MARKETING TOOLS THAT MAKE SELLING EASIER.

Access a full library of videos, case studies, tutorials, onboarding tools, and brochures etc. — ready when you are.

FAST SUPPORT. ALWAYS. Questions? Special project? Urgent need? We answer fast — no runaround. Got a tricky customer? We’ll even help explain the solution for you.

SOLUTIONS MADE TO FIT.

We tailor our machines and paper to match your customers’ exact needs — so you can offer the right setup, every time.

What you’ll be offering — and why it matters

As a Palcut distributor, you’re offering practical tools that improve how your customers work — faster, safer, more efficient palletizing.

You’ll be the one who helps production teams avoid frustration, reduce waste, and deliver pallets that arrive just as they should. Whether it’s solving stretch film overuse, unstable stacks, or long changeovers — you’ll bring real solutions to the floor.

Your product lineup at a glance:

ANTI-SLIP PAPER

Grippy, high-friction, and delivery-ready interlayer paper. Designed to hold loads in place through transport and storage — and available in reels or pre-cut interlayer sheets to fit different production needs.

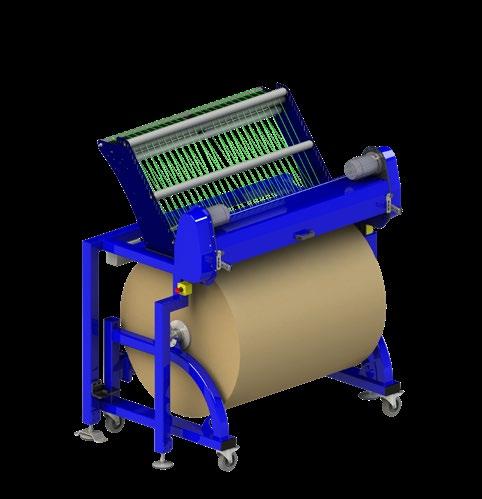

STANDARD SHEET DISPENSERS

Reliable, quick-to-install, and built for standard use — with optional small adjustments to match your customer’s setup. Our dispensers automate sheet placement to reduce downtime, improve accuracy, and make day-to-day operation smoother for your customers.

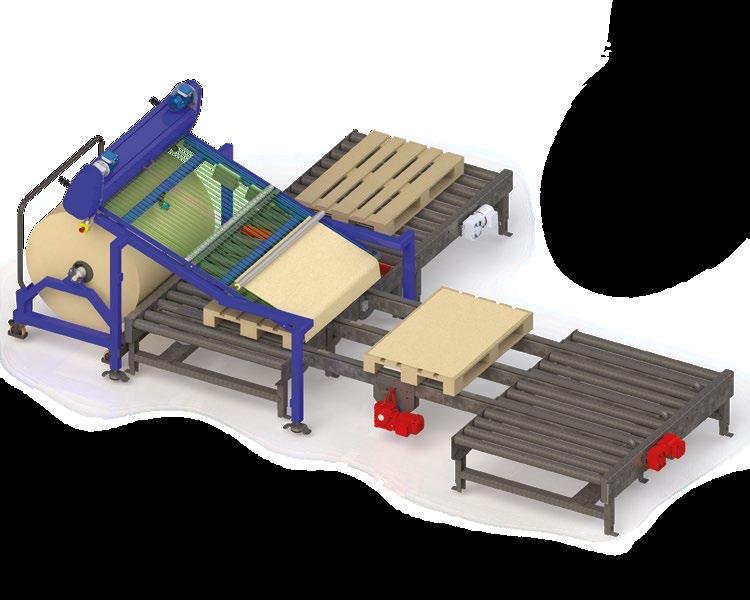

THE PALCUT SOLUTION (PAPER & TAILORED SHEET DISPENSERS)

This full system combines our anti-slip paper with a tailored automatic sheet dispenser. It’s custom-fitted to your customer’s production needs for seamless, efficient palletizing — from loading to shipping. It’s smart, compact, and proven in high-speed lines.

PRODUCT WORKS IN PRACTICE?

Turn the page — and we’ll walk you through it.

Anti-slip paper that locks layers in place

Stronger pallets. Fewer complaints. Less waste. Palcut’s anti-slip paper gives your customers the stability they need — whether they’re stacking boxes, bags, or bottles. It can be used throughout internal handling or external shipping processes, placed between layers during palletizing to stop loads from slipping or shifting. This not only protects the product — it also helps create a safer, more controlled workflow during internal handling or transport.

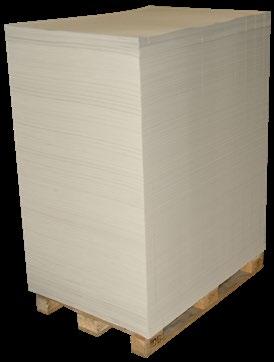

Available in pre-cut sheets or reels, it locks each layer in place and helps cut down on stretch film use. Plus, it saves serious storage space compared to traditional cardboard sheets.

3,800 sheets of anti-slip paper

650 sheets of corrugated cardboard

One pallet. 3,800 sheets. That’s the power of anti-slip paper.

Corrugated sheets can’t compete — not on space, performance, or pallet stability. Here’s how anti-slip paper outperforms cardboard:

• Cuts paper consumption by up to 40%

• Delivers up to 5,000 sheets per pallet/reel

• Reduces stretch film usage by up to 30%

• No harmful substances or coatings

• Fewer deliveries = lower transport emissions and handling costs

• Reduces the CO2 impact of your customers’ palletizing setup

Antim® — for heavy or demanding loads

Some products just need extra grip — like bags, boxes, or slippery packaging.

The Antim product group offers maximum hold and stability with a full-coverage friction coating, making it perfect for customers handling challenging or unstable loads.

ANTIM

Keeps products stable on the pallet

• Ideal for heavy, slippery or unwieldy products

• Meets transport safety standards

• Reduces the use of stretch film

• 100% recyclable paper

ANTIM X

Ensures secure transportation

• Ideal for boxes with large contact surfaces and lighter items

• Less coating, same function, lower price

• Stabilizes pallets during transport

• Reduces the use of stretch foil

• 100% recyclable paper

Liquim® — when moisture is a factor

Transporting beverages, chemicals, or goods with condensation?

Liquim combines anti-slip power with liquid resistance, keeping layers secure and dry — even in humid or wet conditions.

LIQUIM GOLD

Avoids leakages & minimizes losses

• Ideal for bulk bags, chemicals and pharmaceuticals

• Liquid-resistant barrier and anti-slip coating

• Ensures pallet stability despite condensation

• 100% recyclable paper

LIQUIM SILVER

Prevents condensation from affecting stability

• Ideal for transport in humid environments or where temperatures cause condensation

• Liquid-resistant barrier and one-sided anti-slip coating

• 100% recyclable paper

LIQUIM BRONZE

Protects products against moisture

• Ideal for flour, sugar, cement etc.

• Liquid-resistant core

• Keeps products dry despite condensation

• Ideal as base sheet

• No anti-slip coating

• 100% recyclable paper

Sheet dispensers that keep lines moving

One sheet. No waste. Smoother palletizing. Palcut’s fully automatic sheet dispensers are designed to keep your customers’ production running smoothly — one perfectly cut sheet at a time. They integrate seamlessly into most lines and reduce handling, downtime, and manual work.

Each sheet dispenser is made to match your customer’s setup, cutting sheets directly from a reel in the exact size needed — no pre-cutting, no hassle. That means faster changeovers, more uptime, and fewer production headaches.

NO FUSS. JUST FAST, RELIABLE DISPENSING.

• Cuts one sheet at a time — no pre-cut stacks, no jams

• Plug-and-play setup (only needs 240V power)

• Keeps robot pick-up height fixed — faster line startup

• Up to 5,000 sheets per roll = less storage, fewer changeovers

• Works stand-alone or with palletizing system

• 15 pre-programmed sheet sizes for fast changeovers

• Sheet output: quarter, half, or full pallet sizes

• Easy to run, safe to use, simple to install

• Want to see it in action?

• Scan the QR code to watch how our sheet dispensers deliver one perfect sheet at a time — no jams, no slowdowns, just smooth palletizing.

The Palcut Solution. One smart combo.

Two tools. One system. Built to fit and made to flow. The Palcut Solution brings it all together — anti-slip paper with grip that holds, and a tailored sheet dispenser built to fit the setup. It slides into the line, runs automatically, and keeps production moving. Less manual work. Fewer slowdowns. A smarter way to palletize.

(Just ask McBride — they haven’t had a single stoppage since).

• And here’s what that looks like:

The global laundry detergent manufacturer, McBride, faced repeated palletizing stoppages due to poor sheet handling — until they switched to the Palcut Solution.

BEFORE PALCUT SOLUTION

“We had an unimaginable number of stops… The robot often gripped several sheets at once.”

— Dennis Lago Hansen, McBride

• Frequent line stoppages

• Robot grabbed multiple sheets

• Misaligned or dropped sheets

• Manual fixes with broom handle

• Safety risks and frustration

• Lost time and production

AFTER PALCUT SOLUTION

“Since we set it up, we haven’t had a single machine stoppage.”

— Dennis Lago Hansen, McBride

• Zero machine stoppages

• One perfect sheet every time

• Precise, stable placement

• Fully automatic operation

• Safer for operators

• Faster, more efficient operations

WANT THE FULL STORY?

Scan here to read the complete McBride case and see how the solution paid off.

4 customers. 4 very different setups.

One thing in common: Operational Efficiency

No two production lines are alike — and neither are our solutions. Big or small. Tight spaces or tall lifts. We shape the solution around your customers’ needs — not the other way around.

These 4 examples show how different the right solution can look when it’s built for real workflow.

Compact sheet dispenser designed to save space in a tight production area — without compromising performance.

Extra-tall sheet dispenser integrated in a Bila system with 10 feet pick-up and 45° angled delivery. Built to solve height and access challenges — with a focus on user-friendliness.

Extra-tall sheet dispenser developed to deliver sheets at height with a large, angled table tailored to the customer’s setup.

Tailored base dispenser built to run without a robot. Paper is placed inline to match the palletizing workflow.

What better palletizing looks like — and why it works

With anti-slip paper that locks loads in place and sheet dispensers tailored to fit the line, the Palcut Solution gives your customers safer, smoother palletizing from start to finish.

Here’s a quick look at the biggest benefits of using anti-slip paper and automatic sheet dispensers together — the core of the Palcut Solution.

STABLE PALLETS

EVERY TIME

• Keeps loads steady during transit and handling

• Reduces product damage and pallet failures

• Delivers consistency that builds customer trust

REELS TAKE UP LESS SPACE

• Up to 5,000 sheets per reel = fewer roll changes

• Free up floor space compared to cardboard sheets

• Less storage, more efficiency

SAFETY

AT EVERY STAGE

• Prevents slips, strain, and lifting injuries

• Reduces load shifts during picking and transport

• Safer workflows for operators

• Eliminates manual sheet handling

MORE OUTPUT. LESS DISRUPTION

• Exact-sized sheets mean smoother runs

• Fixed pick-up height improves reliability

• Cuts errors and unexpected stops

• No manual handling or mid-run reel changes

FEWER PIT STOPS

• Long-lasting reels reduce refill frequency

• No need to stop lines to reload

• Up to 15 pre-set sheet sizes available

LESS WASTE. NO COMPROMISES.

• Uses less paper and stretch foil

• Cuts waste with precise sheet sizing

• Helps prevent overuse of packaging materials

GOT CUSTOMERS WHO NEED BETTER PALLET STABILITY?

Let’s team up — just scan to get started.