YOUR WAY TO A MORE EFFICIENT & RELIABLE PALLETISATION

A sheet dispenser from Palcut makes traditional sheet magazines a thing of the past.

The sheet dispenser produces one interlayer sheet at a time in a preprogrammed length, directly from the reel. There is always only one sheet ready for the robot, and the pick-up height is fixed. This increases the speed of your palletising and enables quick and precise placement on the pallet. Every time.

This means no more downtime due to:

• Time-consuming changeovers

• The robot picking up more sheets at a time

• Replenishing interlayer sheets

We offer both standard and customised sheet dispensers for smooth integration into any palletising line.

• Free up storage space, increase efficiency, and reduce downtime

• Improve your bottom line and save money from day one

• Minimise collapsed pallets and product damage during transportation

• Reduce material consumption and CO2 emission

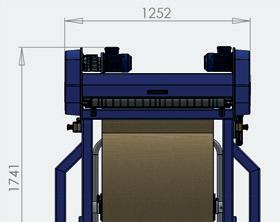

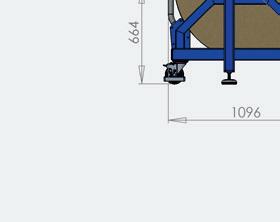

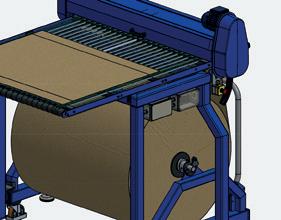

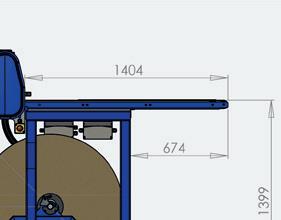

Palcut 800 is a fully automatic sheet dispenser that quickly and accurately cuts paper into interlayer sheets in a desired length, directly from the reel. The dispenser ensures that there is always a single sheet ready for the robot to pick up.

Reel width: Max 820mm

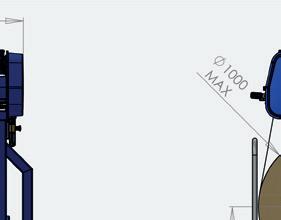

Max reel diameter: Up to Ø 1,000mm

Power supply: 240V

PLC & HMI Siemens

Controller panel size 500mm x 500mm x 200mm (H x W x D)

Paper material From 60 to 400 g/m2 paper

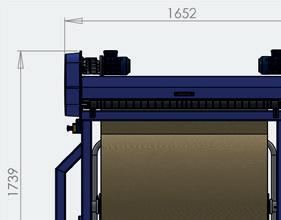

With Palcut 1200, you get the same sheet dispenser as with Palcut 800. The only difference is that Palcut 1200 is more flexible in relation to cutting different sheet formats, as the reel is wider. When palletising with interlayer sheets between the product layers, Palcut 800 or 1200 may be the right choice for you.

Reel width: Max 1220mm

Max reel diameter: Up to Ø 1,000mm

Power supply: 240V

PLC & HMI Siemens

Controller panel size 500mm x 500mm x 200mm (H x W x D)

Paper material From 60 to 400 g/m2 paper

The Palcut base dispenser automatically applies base sheets to your pallets as they pass the line on their way to palletising – without stopping. It helps you increase capacity in the palletising process, as the base sheet is already on the pallet.

The base dispenser is compatible with all kinds of pallets and requires little space.

When you have to palletise with interlayer sheets as a base, the base dispenser may be the right choice for you.

Experience the countless benefits of our standard sheet dispenser for 3 months, without paying for anything, except your paper consumption.

Are you not happy with the results after the trial period, you can simply return the sheet dispenser and go back to your previous method. Contact us and learn more.

Adding an extra trolley to the sheet dispenser allows you to change reels of paper quickly and easily on the dispenser to save time.

The empty roll sensor helps you monitor the amount of paper left on the reel. It can be configurated through either external output signals or visual lighting.

The paper divider allows you to get multiple sheet formats from the same reel. Thus, it cuts the paper on the middle to make ½ and ¼ pallet sheets.

Add fencing to the Palcut dispenser to increase safety and prevent access to the robot cell, when the trolley is not in position. The sheet dispenser can be installed within the fence line. This allows you to change the paper outside the safety zone and helps you reduce downtime.

We have more than 20 years of experience developing customised sheet solutions for industrial companies all over the world.

With a customised Palcut solution, you increase your efficiency, reduce waste, and improve pallet stability without making significant changes in your existing setup – we modify our machine, so you don’t have to make changes to yours.

Anything is possible. Whether the sheet dispenser needs to deliver paper at a height of 5 metres or in a tight space, we will find the right solution for you.

WITH OUR SHEET DISPENSERS, YOU ALWAYS GET:

• Reliable & effortless handling

• User-friendly day-to-day operation

• Easy integration with existing system

• First-class machine safety

• Up to 15 pre-programmed sheet sizes

We continuously update and maintain our dispensers, ensuring user-friendly operation and first-class machine safety. The Palcut sheet dispensers are CE- and UKCA-marked. These marks certify that the dispensers comply with the relevant requirements of the Machinery Directive and standards for machine safety and health in the area.

Want smooth, reliable, and user-friendly palletisation for your production line – without obstacles such as difficult handling, material waste, lack of storage, and unplanned machine stoppages causing too much downtime?

With our fully automated sheet dispenser, you eliminate tiresome day-to-day obstacles and reduce your resources and costs in multiple ways.

FREE UP STORAGE SPACE AND REDUCE PRODUCT DAMAGE DURING TRANSPORTATION

• Reduce storage space by up to 90% - up to 5,000 sheets per reel

• Minimize collapsed pallets and damaged products – the pallet can be tilted up to 50°

• Optimize your goods-in-process due to fewer deliveries

SAVE MONEY FROM DAY 1 WITH PLUG AND PLAY INSTALLATION

• Easy to install – only requires a 240V power supply

• Seamless integration with new or existing systems

• Get up to 15 pre-programmed sheet sizes

• Easy day-to-day operation

MINIMISE MATERIAL CONSUMPTION AND IMPACT ON THE ENVIRONMENT

• Reduce paper consumption by up to 40%

• 100% recycled and FSC®-certified paper

• Reduce stretch foil consumption by up to 30%

• Minimise your CO2 emission by means of fewer deliveries

SIMPLIFY YOUR WORK PROCESSES, INCREASE PRODUCTIVITY, AND REDUCE DOWNTIME

• Replenish reels of paper continuously outside safety zones – without stopping production

• Reduce the number of replenishments by up to 90%

• Change sheet sizes in a flash

• Ensure a fast workflow with the fixed pick-up height

• Eliminate lost sheets – there is always one sheet ready for pick-up

Our automatic sheet dispensers allow you to use reels of recycled anti-slip paper rather than pre-cut pallet sheets as in your traditional sheet magazine system. This means that you get up to 5,000 interlayer sheets from our reels in contrast to 650 corrugated cardboard sheets on a standard pallet.

The combination of a sheet dispenser and reels of recycled anti-slip paper thus helps you reduce your storage space by up to 90%. Additionally, you minimise your paper and stretch foil consumption as well as the CO2 emissions associated with your palletising.

“We have increased productivity by at least 15% by using Palcut’s automatic sheet dispenser solution.”

“With the new Palcut sheet dispenser, there is no changeover time when changing pallet size, so we save 20 minutes each time.”

– Jan Stig, Vital Petfood Group A/S

The robot in your traditional sheet magazine tends to drop sheets on the conveyer. Every time the robot drops a sheet, it takes 4 minutes to recover. Let’s say that this happens 3 times a day, every working day in a year. This results in approximately 44 hours of downtime annually for your existing sheet magazine solution. With an automatic sheet dispenser from Palcut, you eliminate sheet drops – thus, you save those 44 hours of downtime.

See how we helped some of our customers enhance their production, boost efficiency, minimise waste, and enhance pallet stability – all with custom designed sheet dispensers.

McBride experienced challenges with unplanned machine stoppages every time their robot failed to grip the interlayer sheets properly, and when they had to change pallet sizes and replenish their sheet magazine manually. This caused errors and production downtime - sometimes several times a day.

At first glance, there was no room for a Palcut sheet dispenser. However, it was decided to include the adjacent room and make a hole in the wall to bring the new custom designed sheet dispenser’s pickup table through. This solution meant that virtually no changes were made to McBride’s existing facility.

The new solution has been of great significance to McBride; with 3,900 metres per reel, the company has significantly reduced their manual replenishments. The machine cuts and delivers the sheets optimally every time, which has led to an increase in the company’s production with subsequent financial gains.

“This has resulted in us not having had a single machine stoppage on the palletising line since setting up the sheet dispenser.”–

Dennis Lago Hansen, McBride

Aqua d’Or frequently needed to replenish their corrugated cardboard manually, which caused a lot of production stops in their palletising lines. Additionally, their storage space was limited due to their need for multiple pallets of different sized cardboard.

Customised sheet dispensers were installed on their palletising lines with reels of recycled anti-slip paper to replace their pre-cut cardboard. This enabled Aqua d’Or to cut interlayer sheets directly from the reels in the desired sizes for their bottles.

After having installed the automatic sheet dispensers, Aqua d’Or has increased their productivity by up to 8% due to a significant drop in production downtime. The switch to recycled anti-slip paper has also led to safer transportation and has freed up a lot of storage space, meaning more room for readypackaged pallets.

“The Palcut solution has seen productivity improve by 50,000-100,000 bottles a day, which is an improvement of 8%. Palcut is simply a brilliant idea.”

– Bruno Jensen, Aqua d’Or