PREMIUM BEVERAGE PACKAGING

HOW ARE SUSTAINABILITY DEMANDS PUSHING INNOVATION?

Packaging Europe Ltd

HOW ARE SUSTAINABILITY DEMANDS PUSHING INNOVATION?

Autumn has started, and with it a very busy time in the packaging industry calendar. Here at Packaging Europe HQ, it’s been all hands on deck to put the finishing touches to the programme of our Sustainable Packaging Summit, which is taking place on November 14th and 15th at the iconic Beurs van Berlage in Amsterdam. We are proud to have pioneered a unique event format with the purpose of uniting influential figures and thought leaders from the packaging industry and beyond and are looking forward to building on last year’s success with an expanded focus. You can find out more about the format, agenda and key topics within the pages of this magazine.

Of course, we will also be unveiling the winners of this year’s Sustainability Awards at a special dinner at the event on November 14th. We have had a record-breaking number of submissions of outstanding quality this year, and we can’t wait to unveil the winners!

At the same time, the Active & Intelligent Packaging Industry Association will join Packaging Europe at the Beurs van Berlage for the AIPIA World Congress. To get a glimpse of the topics covered in the event, make sure to read Emma Liggins’ article, looking back at the most exciting developments in the smart packaging space this year, from optical-AI technology, bacteria sensors to paper-based NFC tag labels and much more.

In our headline story, Libby Munford takes a close-up look at premium beverage packaging and explores the question of whether the concepts of premium and sustainability have to compete with each other, or whether a sustainable design can actually make a pack premium. She also explores recent market launches, such as Absolut’s paper-based bottle and Kingsland Drinks’ bag in box wine.

Elsewhere, Victoria Hattersley updates us on recent developments in the area of smart manufacturing, including digital twinning and Industry 5.0 as well as virtual factories, the benefits of cloud and edge computing and AI. She also speaks to Elopak to find out how companies across the packaging value chain can build a strong sustainability strategy from the ground up in the latest edition of our Wider View series.

Adhesives play a key part in packaging and add valuable functionality, but what about recyclability? I talk to experts in the plastics recycling space, RecyClass and the Association of Plastics Recyclers, to get their perspectives. We hope you enjoy the latest issue of this magazine – and we can’t wait to welcome you in Amsterdam for the Sustainable Packaging Summit and AIPIA World Congress in November.

SkodaIn our headline story, Libby Munford takes a close-up look at premium beverage packaging and explores the question of whether the concepts of premium and sustainability have to compete with each other, or whether a sustainable pack can actually make a pack premium.

How are sustainability demands pushing innovation within the premium beverage packaging market? Libby Munford hears views from leading providers of packaging: Saxon Packaging (part of Smurfit Kappa) and Graphic Packaging International; and about the latest launches from top drinks brands: Absolut and Kingsland Drinks Group.

There are assumptions when it comes to the term ‘premium packaging’. Adriana Dale, marketing director, global beverage and machinery, Graphic Packaging International states:

“Most of us associate the word premium with the overall quality and aesthetic appeal of a product. For a long time, minimalist packaging has been seen as cheap or economical, the type of material used can reinforce this view.

“As market trends change and consumer awareness and education evolve, premium now also encompasses how a product conforms to sustainability trends and views; especially concerning the environment.”

As a producer and supplier of paperboard products, designing for the environment is at the core of GPI’s packaging developments. “Our virgin paperboard, selected specifically for the beverage industry for its long

fibres and high strength, provides an excellent substrate surface for a variety of print effects and enhancements to reinforce that premium feel and shelf appearance,” says Adriana Dale.

GPI’s most recent projects surrounding premium beverage packaging have been the evolution of Fully Enclosed Carton (FEC) solutions, complementary to the QuikFlex™ machinery range. Some of its developments include the utilization of rounded corners, no top flaps and innovative shelfready packaging.

GPI has met challenges when designing a premium pack for the market. Consumers want convenience, but it should not be at the cost of reducing the sustainability profile of the pack.

“We all make subconscious decisions on what we buy; whether that be driven by price, habit, accessibility or simply something that catches our eye. For a premium brand, customers want to know their purchase decision feels worth it – taking into account the feel and appearance of the product itself, and of both the primary and secondary packaging,” Adriana Dale enthuses.

“Sustainability is having a huge impact on products and pack design. Utilizing a renewable or recycled material and using as little of that material as possible to perform the required function are consistent requirements we receive from our customers from both an environmental and cost point of view.”

For some, the solution can be minimal packaging that highlights a premium primary pack material such as its KeelClip™ range, for others the solution utilizes innovative design and shelf differentiation across GPI’s FEC range.

“Our designs encompass environmental considerations regarding how the product is packed when it comes to machinery efficiencies, the tertiary packaging required for transport, the in-store display, sustainable sourcing, minimized environmental impact, circularity, and end-of-life,” Adriana Dale shares.

“Sustainability and design for the environment certainly have their place in premium packaging. And there is space in the market to redefine

what premium looks like. All companies should have this on their agenda; not only because this is the right thing to do, but also because today’s consumer demands it.”

“We look to use the minimum amount of material that will provide the required solution whilst making sure the customer’s brand is reflected,” Mike Impson, sales director of Saxon Packaging (part of Smurfit Kappa) comments.

“You could say minimum material, maximum impact.”

Saxon Packaging’s preference for premium litho-printed packaging would be to mount printed sheets to E flute which is a thinner material and provides “a nicer substrate to work with,” according to Mike Impson. “We mount our printed sheets to double-faced corrugated board rather than to single-faced corrugated which, when combined with a film laminate, virtually removes all the flute shadow that you can see on a lot of litho-printed packaging resulting in a more premium, high-end finish. We discuss everything from the weight of the product to how it’ll be shipped and displayed.”

Saxon Packaging recently completed a project for one of its partners featuring a litho-printed can pack with a clear glitter varnish. “This eye-catching effect gives a textured finish to replicate the surface on the actual cans

“Sustainability and design for the environment certainly have their place in premium packaging. And there is space in the market to redefine what premium looks like.”

themselves delivering a tactile and cohesive brand experience,” says Mike Impson. “We’ve also worked on some unique projects that showcase a special soft-touch finish that uses a spot UV varnish with foil blocking applied to give a luxurious feel.”

packaging. Our Better Planet Packaging initiative is all about making a positive impact on billions of supply chains and consumers by reducing the environmental impact of packaging and its impact on the planet. It’s a team effort and we’re excited about leading the way when it comes to education and facilitation,” says Mike Impson.

Creating innovative and impactful premium beverage packaging should not be at the cost of harming our planet or wasting natural resources. “By using renewable, recyclable, recycled and biodegradable materials to create our cutting-edge range of sustainable packaging solutions, we’re playing an important role in ensuring that at their end-of-life, our products are recycled,” states Mike Impson.

There is more education required around the recycling and recyclability of products in the packaging industry. “We need to be clear and concise for people to fully understand how we can all help with better planet

Paper-based bottles have made waves in the industry in recent years. We caught up with Elin Furelid, Director of Future Packaging at The Absolut Company, to discover why they have added a paper-based bottle to the portfolio:

“Our single-mould paper-based bottle will become a part of our packaging portfolio, complementing, not replacing, Absolut’s iconic glass bottle. While standard glass bottles are also recyclable, our paper-based bottles are eight times lighter and easier to carry. We believe consumers will use them for different occasions, be it at home, at a festival or anywhere inbetween.

“Glass and paper will continue to represent the future of alcohol packaging, our goal and the way we think of premium is to have packaging material that is best suited for each market, the customer and consumer behaviour.

“Paper is tactile, it’s beautiful, it’s authentic, it’s light and we have looked to embrace these qualities in our design. As a new type of packaging that is not familiar to consumers, it was important for us to use cues that signal the material the bottle is made of, whilst keeping the key design elements of Absolut Vodka intact to ensure it is aligned with the premium

“We look to use the minimum amount of material that will provide the required solution whilst making sure the customer’s brand is reflected. You could say minimum material, maximum impact.”

quality of the brand. The paper-based bottle retains its apothecary-inspired design and is instantly recognisable both in shape and logotype. We also felt it was important to talk about our journey towards a 100% bio-based bottle; with the campaign headline of ‘not just an idea on paper’ we wanted to inspire consumers and the drinks industry alike to join us on this journey to find packaging for a more sustainable future.”

Absolut’s long-term goal is to develop a fully bio-based bottle, which is recycled through the paper recycling system. The results of the latest three-month trial in Manchester will inform the next iteration of the bottle, which will then be tested in the market again to get additional feedback and insights from consumers.

Absolut hopes that through this partnership with Paboco, it can help to engage and advance the global recycling industry, create effective recycling streams worldwide, as well as drive consumer engagement in sustainability. “As we have said, this is not just an idea on paper,” Elin Furelid concludes. “We want to invoke real and long-lasting behavioural change both within the industry and with consumers.”

KEurope sat down with Jo Taylorson, head of marketing and product management at Kingsland Drinks, to find out why.

“We have invested in a state-of-the-art bag-in-box production line which supplies formats of 1.5L, 2.25L and 3L to some of the UK’s biggest retailers, as well as contract packed products for multiple national brands and Kingsland own brands, such as the cult-wine and critically acclaimed brand, Campaneo.

“Bag-in-box wine is more efficient to transport versus individual glass bottles, resulting in a lower carbon footprint when moving around the UK and can be a more sustainable alternative to glass. We have also moved from an unrecyclable inner to a bag that can be recycled with soft plastics in most supermarkets to ensure the packaging is as sustainable as possible.

“We are also currently working on a number of more premium wine projects where we are considering innovation in inks and varnishes for daring effects, and also really pushing the aesthetics of caps with dynamic designs, as this can often be an afterthought in terms of design.”

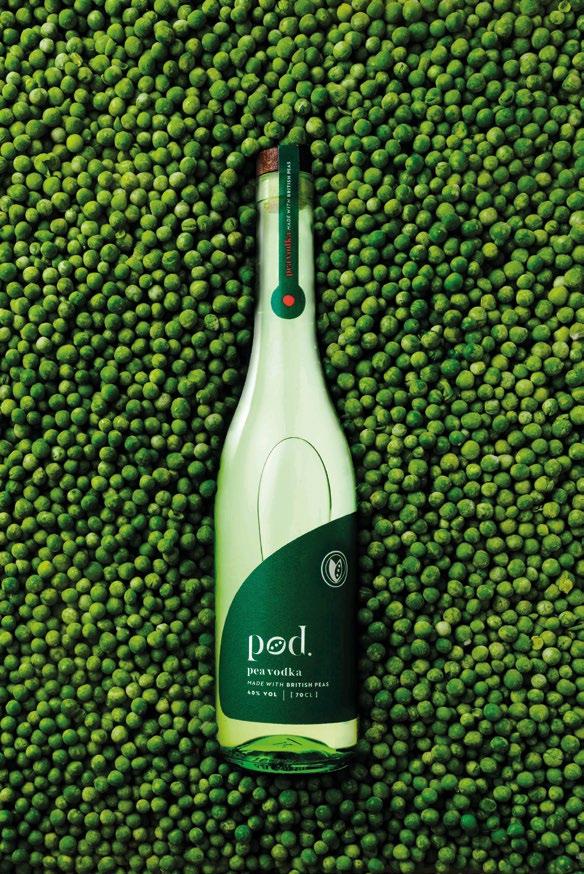

Another example of innovation is Kingsland Drinks’ pod Pea Vodka. “We have considered everything from the liquid (peas are one of the most sustainable crops you can grow), the bottle (we use transition glass which is the ‘imperfect’ glass normally unused when colours change on the furnace, to the label (recycled paper, avoiding any high wastage effects such as foils). We have also now removed the (recycled) plastic seal and are looking at a compostable T-cork,” shares Jo Taylorson.

On the 14th and 15th November 2023, AIPIA, the Active & Intelligent Packaging Industry Association, will join Packaging Europe at the Beurs van Berlage in Amsterdam for the AIPIA World Congress, held concurrently with the Sustainable Packaging Summit. As we count down the days until the event begins, Emma Liggins glances back at this year’s developments in the smart packaging space.

A report by MarketWatch previously predicted that anti-counterfeit packaging in the consumer goods market will reach a value of $166,810 million by 2029. Smart packaging has played its own part in keeping up with this growth and combating illicit activity.

For example, a strategic partnership between Unitag.io and PiQR.io sought to enhance security and copy detection for QR coding in the packaging industry. Compatible with flexo, offset, digital, and select inkjet printing technologies, its QR code solutions claim to bring enhanced copy protection to a product and assure consumers of its authenticity. Alongside its anti-counterfeit measures, it also unlocks detailed product information, promotions, instruction videos, loyalty programmes, real-time consumer engagement, and more.

In its own effort to prevent counterfeiting and grey market activity, Alitheon’s patented FeaturePrint system identifies an item’s authenticity

using optical-AI technology. After taking an initial photo of an object using an off-the-shelf industrial camera or mobile phone, it is connected to one of thousands of item-unique identifiers to create a digital footprint, meaning the product can be identified anywhere on its value chain by taking another photo. It is item agnostic, meaning it doesn’t need to ‘learn’ new objects to function. In theory, it would negate the need for barcodes, QR codes, holograms, and other such smart packaging technology.

Additionally, as the barcode turns 50 years old, GS1 seeks to expand its ‘next generation’ alternatives – such as QR technology powered by GS1 or GS1 DataMatrix codes – to help consumers make smarter purchasing decisions. Such codes can provide consumers with information like a product’s provenance, organic value, and any allergens it contains; but they can also offer sustainability metrics, like a product’s recyclability and environmental footprint.

With AIPIA expressing its interest in producing antimicrobial and antibacterial packaging from cellulose, it turns its attention to Melodea. The company uses proprietary technology to create cellulose nano-crystals, or CNCs, which can then be incorporated into other materials, such as its MelOx and VBcoat high-barrier coatings, to enhance their features – and, reportedly, their eco-friendliness.

Wood pulp sourced from industrially grown trees are amongst the possible sources for the CNCs, with such materials also serving as a carrier platform to introduce and disperse other active nanoparticles or modify optical properties, gas barrier, active catalysts, and more. Suitable for a range of packaging formats from moulded pulp to pouches, the solution seeks to provide short and long shelf-life storage for various packaging formats in the food, pharma, agriculture, and other industries.

Meanwhile, Toppan has developed a paper-based substrate for the aluminium antennae of its new NFC tag labels, replacing the conventional PET alternative. Designed to break when removed to prevent fraudulent use, it aims to meet increasing interest in lowering the environmental impact of packaging by offering a 30% reduction in thickness compared to Toppan’s existing PET substrates and saving space.

In a less technological development, the Guerrero-based branch of Agency BBDO created an open-source, plastic-free shampoo bar shaped like a bottle. Its design intends to help consumers adjust to what may be a new medium for them, while its ‘dissolvable font’ reinforces its sustainability messaging throughout the product’s life cycle.

Traditional liquid shampoos come in cheap, lightweight plastic bottles, but these contribute to environmental pollution – and the heavy water in the product itself drives up transport costs. Therefore, as its branding calls upon consumers to remain eco-conscious, its physical make-up is hoped to deliver as strongly on a practical front.

Researchers at McMaster University have integrated a sensor into a window at the bottom of a new food tray. Its purpose is to catch salmonella, E.coli, listeria, and other pathogen infections before a pack is even opened. Designed to resemble the shape of a shallow boat, the sloped sides of the pack direct any juices into the sensor. Users can apparently scan the underside of the packaging with a smartphone and gauge whether the product inside contains any pathogens. It is anticipated that the solution will lower an estimated global figure of 600 million cases of

How can companies across the packaging value chain build a strong sustainability strategy from the ground up?

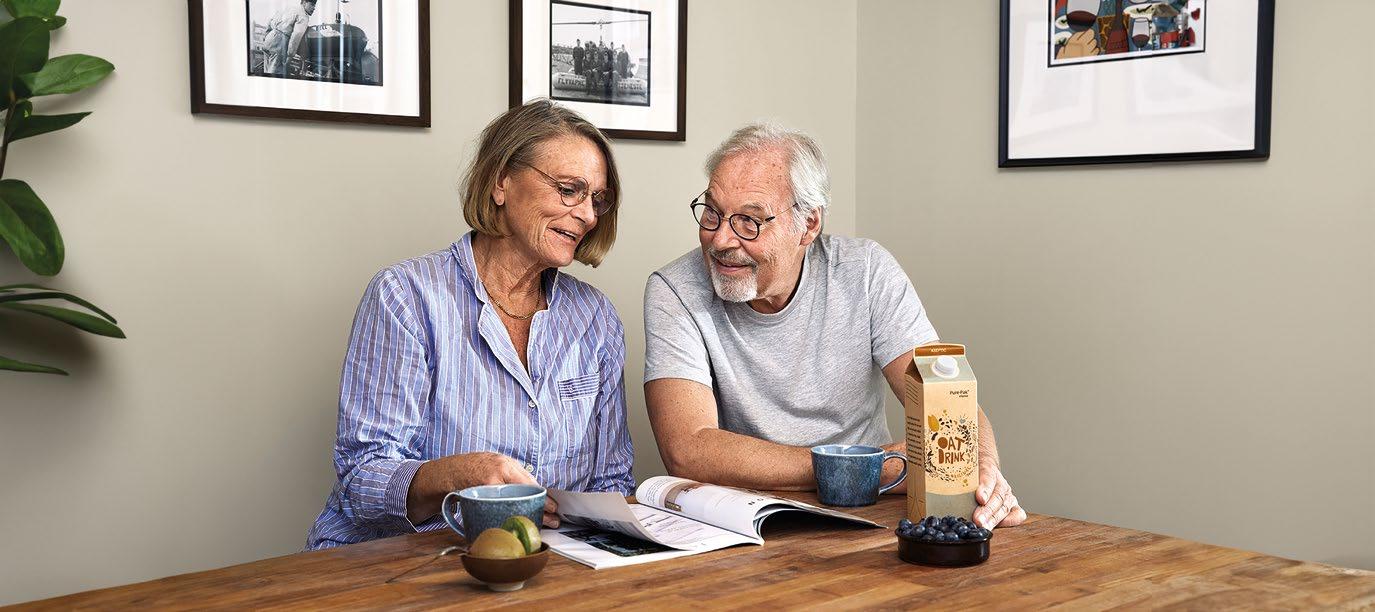

Elopak, the focus of our latest Wider View article, is a clear example of how this can be achieved through putting environmental efficiency at the heart of product design, customer support and day-to-day business operations. Victoria Hattersley spoke to Chief Marketing Officer Patrick Verhelst to find out what this looks like in practical terms.

Elopak is a Norway-based supplier of carton packaging and filling equipment with a global outreach. It was also one of the finalists in our 2022 Sustainability Awards with its Pure-Pak® eSense carton. The company has a strong environmental ethos with a focus on educating the industry about the benefits of fibre-based solutions as well as the importance of corporate responsibility. As we will see, the lessons of its broader sustainability strategy can be applied to companies across the value chain.

“Part of our strategy is getting companies and consumers to transition away from their habitual reliance on plastic bottles and realize that cartons are a far more sustainable solution,” says Patrick Verhelst. “At Elopak we call this the ‘plastic to carton conversion’.”

This ‘conversion’ is a cornerstone of Elopak’s approach and there are numerous real-world examples of its application. In 2022, the company’s US-based partner Boxed Water Is Better® joined forces with CorePower Yoga – the largest yoga studio brand in the US – to replace all single-use plastic water bottles at its more than 200 studios nationwide. Elsewhere, the Irish company Glanbia switched its Avonmore milk brand from PET bottles to Elopak Pure-Pak® cartons.

Elopak is even breaking into new product segments. For instance, in 2021 it partnered with Orkla and their brand Klar to provide refill packs of soap and laundry detergent packaged in cartons, followed by several other Orkla brands the year after. And this year it started packaging mouthwash for German oral care brand Paperdent.

“Innovations such as this are crucial in communicating to companies and consumers alike that containers made of paperboard are a sustainable packaging option.”

That last point is key: when you look at the evidence it’s easy to comprehend Elopak’s strong emphasis on moving from plastics to cartons. Fibre-based packaging has long been recognized for its environmental benefits and beverage cartons are designed to be fully recyclable.

perspective. According to ACE, 51% of all beverage cartons placed on the EU market in 2019 were recycled.

Furthermore, Life Cycle Analysis (LCA) studies have shown that cartons have a much lower overall environmental impact than plastic bottles. One such study from the University of Southampton showed that for fruit juices, cartons were less impactful than either plastic or glass bottles.

Still there is a lot that can be done to further reduce the environmental footprint of cartons and simplify the recycling process – a challenge that Elopak is addressing through its own product development. Its Elopak Technology Centre is focused on creating the optimal carton solutions for customers. One of the results is its latest innovation, Pure-Pak® eSense, the first aseptic gable top carton made using a polyolefin-blend barrier as opposed to aluminium.

“This equates to a much smaller carbon footprint than cartons containing aluminium – up to 50% smaller when compared with a standard aseptic carton,” says Patrick Verhelst. “This is because it is very energy intensive to extract and process aluminium. Polymer-based layers allow for a one-operation separation of the fibres which simplifies the recycling process.”

As it works to meet the challenges of sustainability through new product development, Elopak, like many other companies we talk to, is also well aware of the vital importance of cross-value chain R&D partnerships. To give an example, it has worked closely with its paperboard supplier Stora Enso to produce a more sustainable carton made without bleaching chemicals.

“The resulting Natural Brown Board has a significantly smaller carbon footprint and uses fewer wood fibres, since unbleached fibres are naturally stronger,” says Patrick. “The carton also has an appealing, rustic look that signals its sustainability to the consumer. This innovation is incredibly popular: in 2021 we surpassed one billion units, with 20% of the milk cartons we sold in Western Europe being made with Natural Brown Board.”

Part of our strategy is getting companies and consumers to transition away from their habitual reliance on plastic bottles and realize that cartons are a far more sustainable solution.

Patrick Verhelst, Chief Marketing Officer

Alongside the cartons themselves, Elopak offers a range of filling machines for aseptic, fresh and non-food applications to help its customers improve the overall efficiency and sustainability of their operations. The filling machines come with a variety of production capacities to fill a wide range of carton sizes and shapes. Each machine features a unique modular design for ‘exceptional flexibility’ in installation, operation and maintenance. In addition, machines are adapted and certified to meet different standards around the globe.

Furthermore, says Patrick, “State-of-the-art top and bottom sealing ensures reliable protection of the filled product. Reliability also comes from tested and validated combinations of closures, blanks and machine forming and one single point of contact. Different machine capacity options are available to meet customer needs with a low waste rate for lean and

sustainable operations. The machines also have a relatively small footprint, without stand-alone components for efficient use of floor space.”

One of the latest introductions to this range is the Pure-Fill™ aseptic filling machine platform, which is a ‘winning combination’ when combined with the Pure-Pak® eSense carton. According to Patrick, “The Pure-Fill™ platform offers major advantages in marketing more sustainable carton packaging solutions and its revolutionary design is introducing eco-friendly ways to lower energy and water consumption.

This year, Patrick tells us Elopak will be also introducing a new generation filling machine for ESL (Extended Shelf Life) products, an optimal solution for products with shelf life of 60 days.

“The filling machine delivers high precision for impeccable carton integrity and efficient switch between products, reducing food waste. With the improved hygienic filling and sealing chambers with automated clean-

ing, the machine is exceeding hygiene expectations, and secures that the food is kept safe and fresh until it reaches the consumer.”

The aim of this solution is to help customers look at sustainability from both a packaging and a technology point of view – thus enabling them to take a more holistic approach to production.

But Elopak also recognizes that in order for the above-mentioned ‘plastic to carton conversion’ to be successful it is not enough to simply offer the right fibre-based products or filling equipment – the two must be tied together to form a complete solution. As a result, it has also adapted its offering to include comprehensive after-market assistance and technical services to support its clients in their shift from plastic cartons. It provides a full-service portfolio which covers the entire customer journey with frequent touch points. These services include technical planning, machine connectivity, upgrades, retrofits and optimization services, as well as maintenance and customer staff trainings.

“Our full-scale service solutions ensure that our customers get production efficiency, food safety and predictability of costs,” says Patrick. “Our 200+ highly skilled, technical and maintenance engineers have the expertise and capability to design, install and maintain complete packaging solutions running to the highest operational excellence standards. Our decentralized structure as well as the expertise of our engineers provides our customers with the highest service quality and highest efficiency.”

Of course, when it comes to sustainability, it’s not all about the product and service portfolio – it’s also vital for each individual company to optimize their internal processes. Elopak itself has strong environmental principles

which are manifest across our operations. “The results of this can be clearly seen in its annual Sustainability Reports.

“For Elopak, sustainability isn’t something we do – it’s who we are,” said Thomas Körmendi, Elopak’s CEO. “We were one of the first companies to set net zero targets approved by the SBTi in 2022. It’s also why we were the first company to offer CarbonNeutral® packaging for beverages and liquid food in 2016.”

In addition, since 2016, Elopak has sourced 100% of its electricity from renewable resources – part of its plan to become a net-zero company by 2050. In 2022 it reduced its direct, scope 1 and 2 greenhouse gas emissions by 20% compared to the 2020 baseline, and also reduced its value chain emissions by 7% in the same time period. It also sources its wood fibres from sustainably managed forests, purchases its electricity from renewable sources and works with governments and local authorities to drive up beverage carton recycling rates.

“The first step to solving any problem is accurately identifying it,” says Patrick. “That’s why Elopak has been publishing independently verified environmental impact assessments since 2008. In 2021 we were awarded a platinum rating by EcoVadis, the world’s largest and most trusted provider of business sustainability ratings.”

In future, it hopes that more and more companies will follow suit.

“We encourage other companies to publish similar climate reporting and to work with independent organizations to assess their impact.”

This strong, industry-leading stance on sustainability is not a new development for Elopak – in fact, this year it celebrates 15 years of ‘structured sustainability work’ – and it is never a task that can be considered ‘complete’. In the years to come it will continue to build on these solid foundations and work to help FMCGs reduce their plastic use and move towards cartons.

In last year’s Industry 4.0 update, we discussed concepts such as digital twinning, the growth in mass personalization and Industry 5.0, among other things. In this year’s piece, we again take a look at developments in some of these areas as well as touching upon other topics such as virtual factories, the benefits of cloud and edge computing, and AI. Victoria Hattersley reports.

ASever, one thing to bear in mind when we’re talking about Industry 4.0 is that the topic has a very broad definition and scope. This can mean it is difficult – if not impossible – to really gauge how far the industry has progressed. What we will try to do here is give a flavour of the current possibilities in some of the key areas, throw some light on the challenges associated with them and what we might expect to see in the coming years.

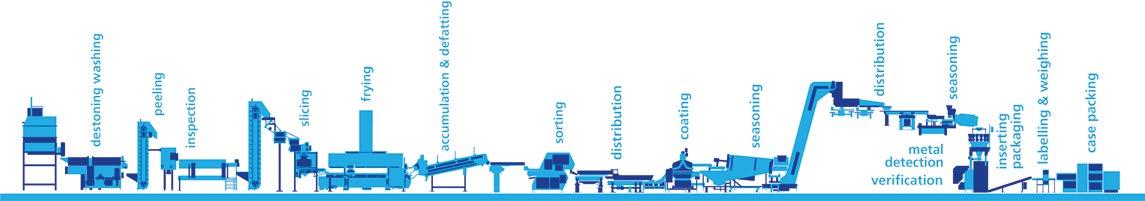

Digital twins – virtual replicas of processes, production lines and factories –are one aspect of Industry 4.0 that has the potential to transform the way in which companies operate, improving productivity, efficiency and sustainability. We spoke to Natasha Avelange, Global Extended Reality Manager of TNA Solutions, to learn about the concept of the ‘virtual factory’ in relation to digital twinning, and the benefits this can bring.

“The Virtual Factory from TNA is a pioneering, highly advanced solution that leverages the power of extended reality (XR) to create a fully functioning and interactive digital twin of any planned or current operations. It gives all stakeholders the ability to see the outcome of any changes or additions to manufacturing facilities, enabling the optimization of physical footprints and seamlessly integrating line equipment. This means that any potential hazards and challenges can be mitigated before anyone sets foot on site. Regardless of their location globally, all stakeholders can meet virtually, saving time and reducing carbon footprint by minimizing travel.

“In addition, the remote capabilities of the Virtual Factory facilitate immersive and interactive training, as well as access to virtual support.”

An increasing number of companies are adopting cloud computing as the cornerstone of their Industry 4.0 strategy. Storing data in the cloud can enable it to be processed more efficiently, enabling true connectivity and integration of production, supply chain, sales and distribution. But for many producers, it is preferable to maintain a little more control over their data – perhaps because the demands of production necessitate it, for example in situations where an immediate safety issue calls for real-time data analysis in order to reduce downtime. For these, edge computing is the logical approach as the data stays near source but they can still maintain the

“The Virtual Factory from TNA is a pioneering, highly advanced solution that leverages the power of extended reality (XR) to create a fully functioning and interactive digital twin of any planned or current operations.”

necessary level of security. Which approach a company goes for – pure cloud computing or a combination of cloud and edge – depends entirely, therefore, upon their specific operations, as Sachin Mathur, Regional Director, Europe, Middle East and Africa at Rockwell Automation, explains.

“Each approach has its unique benefits and use cases, and they can be com bined strategically to address different requirements. Whereas cloud computing involves using remote servers hosted on the internet to store, manage, and pro cess data, applications, and services, thereby providing several ways to enhance the value chain with scalability, flexibility, accessibility, reduced infrastructure costs and enhanced collaboration, edge computing involves processing data closer to the source, such as IoT devices, therefore offering advantages like low latency, bandwidth optimization, offline operations and data privacy.

“The combination of cloud and edge computing allows businesses to harness the strengths of both approaches. Critical real-time processing can occur at the edge, while complex analytics and long-term data storage are handled in the cloud.”

AI and machine learning can aid companies in utilizing the sometimes huge volume of information generated on factory floors, across other business units as well as from partners or suppliers. It can provide insights into the predictability and automation of various processes to improve efficiency, safety and sustainability across operations. Malte Schlüter, Global Director

can exceed 15 years. This is combined with a higher cost sensitivity that has ruled out the implementation of advanced technologies. But over the last few years, many things have been changing faster. Reduced lot sizes and even ‘lot size one’ are becoming more common in the e-commerce industry, with millions of packaging units a day having to be 100% customized.”

It would be fair to say that the COVID-19 pandemic has also helped speed up the pace of adoption. By forcing us to move many of our everyday activities online it has shown us that change can be achieved quickly when necessary.

“What the pandemic proved was that the industry is in a transitional phase, born out of necessity,” says Natasha Avelange. “Travel was severely restricted, and the digital alternatives that emerged have continued long after restrictions were lifted. Virtual meetings are now commonplace, and solutions such as the Virtual Factory elevate to a level that many will not have experienced before. Additionally, there are labour issues relating to both the skilled and unskilled workforce – it is increasingly difficult to find and retain people.”

Sachin Mathur agrees that the rate of uptake is accelerating: “We worked with a research company last year and we looked into several hundred manufacturers around the world. We discovered the amount of technology adoption and innovation a customer would normally do in about 15 to 20 years, they did that in two years in the manufacturing industry. That is the acceleration that COVID provided.”

For Malte Schlüter, it is vital not just to collect data but to ensure we are turning it into useful information and creating value-added insights through the use of analytics – and individual companies should also, he adds, avoid attempting to do too much at once.

“It important to digitalize factories in small steps. The path to success is to identify the most urgent need and/or pain point and solve this with digital technologies. After completing this first implementation, it is possible to repeat this strategy to optimize other activities and ultimately the entire factory.”

The buzz around the concept of Industry 5.0 is becoming steadily louder. In brief, Industry 5.0 can act as a complement to Industry 4.0 technolo-

gies but it places the wellbeing of the worker at centre-stage. In last year’s Industry 4.0 update we discussed how technologies such as robotics can not only improve efficiencies, but also relieve pressure on human workers. How are things progressing, and what will this look like in practical terms for the industry?

“Industry 4.0 opened the door to digitalizing individual assets or systems, creating islands of automation,” says Malte Schlüter. “The next step is to link them, digitalizing entire environments, connecting virtual and physical worlds. Compatibility and interoperability across the entire factory are the keywords to future success, as the factory of tomorrow will be hyper modular and flexible.

“Realistically, we will see Industry 2.0 to 5.0 processes and machines next to each other in factories.”

Sachin Mathur is also keen to stress why Industry 5.0 is such an important – and distinct – concept: “The tagline for 2.0 was electrification, 3.0 was automation, and 4.0 was digitization. This one is nothing about the technology itself; whether it is electricity or automation, it is about humanization, that is the difference. Simply put, it is about the application of that technology and how does that make a difference to my children, your children, or those who have not yet been born?”

There are many trends that will drive the next generation of digital technologies – whether that is an increased focus on supply chain visibility, the shift back from globalization to localization, or, of course, the continued need for sustainability across the supply chain.

“The next step for packaging is the same as every other industry or traditional manufacturing organization,” says Sachin Marthur. “They need to have a bit more user-centricity about truly defining what digitization would mean. Whether it is to do with cloud or edge computing, they need to be more explicit when adopting digital technologies on what their target outcomes are.”

The topic of Industry 4.0 is a dynamic and continually evolving one. Packaging Europe will continue to bring you the latest news and analysis of technologies and trends as they emerge.

“The ultimate implementation of AI will be to support closed-loop prescriptive maintenance process optimizations. The equipment will be able to recognize that a tool is wearing down.”

The Sustainable Packaging Summit has pioneered a unique event format with the purpose of uniting influential figures and thought leaders from both inside and outside the industry. Its primary objective is to address the challenges and obstacles that hinder our journey toward sustainability. Capitalizing on the strong community that has emerged from previous Summits, the 2023 edition is back with an expanded focus, several thematic tracks, a larger participant base, and even more ambitious goals.

Taking place on November 14th and 15th, in Amsterdam, the Sustainable Packaging Summit is built upon the insights and challenges uncovered during the groundbreaking conversations held in Lisbon last year. This summit will concentrate on tackling essential goals that require collective effort. It will offer a platform for leaders in the value chain to engage in candid discussions about strategic obstacles and discover ways to synchronize business practices, regulations, and societal efforts in order to establish a circular, net-zero packaging ecosystem.

The program for this year’s summit builds upon the transformative concept introduced last year. In addition to the initial emphasis on highlevel panel discussions involving crucial stakeholders addressing our strategic hurdles, the comprehensive Amsterdam itinerary incorporates a fresh Innovation Horizon segment. This new stream will delve into significant technological prospects, research and development strategies and showcase presentations from the most promising startups making waves in sustainable packaging. The Summit will also introduce more diverse formats, with central panel discussions interspersed with agenda-setting keynote addresses and interactive workshops designed to dissect pivotal issues.

Key topics on the agenda include:

• Critical review of sustainability goals and progress

• Net Zero strategies

• Regulation and its implications for our strategies: PPWR and the UN Treaty on Plastic (with live updates from Nairobi)

• Intercontinental dialogue on the circular economy, learning from each other and harmonization

• EPR & unlocking investment

• Innovation Horizon: keys to a successful R&D strategy

• Start-up pitches

• Sustainable substrates: renewables, future plastics and infinite materials

• Digital transformation: driving sustainability by bringing together the connected factory and the digital consumer

• Scaling up reuse and refill models

• Chemical recycling & mass balance

• Hear directly from the key value chain platforms and associations

We’re incredibly excited to open the doors at the Beurs van Berlage on the 14th of November for what we believe will be our most impactful summit to date.

How does Mondi, one of the world’s largest packaging producers which employs 22,000 people across 100 production sites in more than 30 countries, translate sustainability theory into practice?

We caught up Elisabeth Schwaiger, Head of Research and Development and IP Flexible Packaging at Mondi, to find out.

To start with, I think it’d be useful to get a general overview of Mondi’s sustainability strategies and objectives. Could you break down the ‘Mondi Action Plan 2030’ goals and what it means for Mondi Flexible Packaging?

MAP2030 formalizes our proactive commitment to sustainability, setting out clear targets to create circular driven solutions, to take action on climate change, and to empower our people. The targets are aligned with the Sustainable Development Goals (SDGs) set by the United Nations. For instance, through our target to make 100% of our packaging and paper portfolio reusable, recyclable or compostable by 2025, we aim to contribute to a responsible consumption and production (SDG 12).

For flexible packaging, this means for example investing in and leveraging our R&D centre and lab network and utilizing our expertise to constantly improve existing products and develop innovative and sustainable solutions.

And how do these goals manifest themselves in Mondi’s day-to-day activities? What is your R&D approach in working towards these goals?

One example of this is the work being carried out in our in-house recyclability testing laboratory in Frantschach where we test different materials and solutions first-hand and in real time, so that we can offer our customers the best and most sustainable packaging solutions while maintaining their core functionality: protecting the product. This saves time in the development process and supports a fast and high-quality launch on a large scale, giving us and our partners a competitive advantage.

It is difficult to choose one product from our broad portfolio, but our functional barrier papers are a good example: they are recyclable in existing paper recycling streams throughout Europe and can replace plastics in many industries. Thanks to our extensive research and development work, our expertise in both paper and plastics, and our continuous investment in new technologies, we were able to constantly evolve this portfolio. Different barrier properties mean that this range of paper-based packaging can be tailored to a range of applications, contributing to a circular economy.

Mondi has a holistic approach related to packaging materials. Why did the company select this approach, and can you give us an example of it working in practice?

Our approach to packaging is to keep the needs of the customer and the packed product in focus at all stages of the design process. We consider, for example, which types of barrier properties are needed, shelf-life requirements, logistical challenges, the use of renewable resources and/or recycled content, as well as optimal disposal to keep materials in circulation and minimize waste.

We want to close the circularity loop wherever possible: by developing fitfor-purpose paper-based, flexible plastic mono-material or hybrid solutions that are sustainable by design. This addresses the key challenges we face as a society today, such as preventing food waste, using resources wisely and efficiently, and eliminating plastic pollution.

One example is Advantage StretchWrap – a fully recyclable kraft paper designed to stretch and resist punctures, replacing plastic stretch wrap

for pallet wrapping and transport. According to a peer-reviewed life cycle assessment, it has 62% less CO2 emissions when compared to plastic made with virgin content to wrap one pallet.

And what are some of the key challenges in terms of implementing this approach? How does Mondi combat them?

The challenge is to provide packaging that considers a responsible and efficient use of resources and raw materials, a sustainable end of life and at the same time, fulfils the core function of packaging: protection. We also need to think in a holistic system approach and not solely on a material level as well as taking the full value chain of paper and packaging into account.

To achieve this, we at Mondi for example closely collaborate with various stakeholders along the value chain. We are constantly working on innovative ideas using a network of expert knowledge, embracing university institutes and OEM partnerships, often thinking out of the box to find new approaches.

Designing packaging that is recyclable and contains recycled content is key to reaching ambitious circularity goals. Adhesives play an important part and add valuable functionality to a pack, but how do they perform when it comes to recyclability? Elisabeth Skoda gets the expert perspective on adhesive circularity within plastics from RecyClass and the Association of Plastics Recyclers.

function to allow reverse printing.

Flexible packaging offers product protection at a low packaging weight, but there are some challenges around recycling, especially with multi-layer packaging, where adhesives are used to bond different layers together.

A laminating adhesive itself cannot be defined as recyclable. At best it can be defined as compatible with recycling, as Fabrizio Di Gregorio, PRE Technical Director at RecyClass points out.

“RecyClass evaluates laminating adhesives’ recyclability through RecyClass Recyclability Evalu ation Protocols. These protocols establish standard

Fabrizio Di Gregorio PRE Technical Director RecyClassmainly true for aromatic laminating adhesives. Secondly, a presence of gels and build-ups in the recyclate could arise, due to adhesive clusters. This problem is more frequently faced for high-performance laminating adhesives. For barrier films, the presence of laminating adhesive could be disruptive in compatibility with recycling.” RecyClass has approved laminated barrier films if they had a limited amount of laminating adhesives in combination with low-concentration metallization or EVOH.

“The main goal for the industry should be always to limit the concentration of laminating adhesive as much as possible to reduce polymer degradation and recycled plastic contamination,”

APR, the US-based Association of Plastics Recyclers defines adhesives as a feature, like a label, ink or a closure.

“As a feature, there are a number of testing protocols we use to ensure that adhesives are compatible with the current recycling system. There are different tests, for example for hotmelt or pressure-sensitive adhesives that hold a label to a PET bottle to see how efficiently a label can be removed. The challenge there is to ensure that converters and brands use recycling-friendly adhesives,” explains Scott Trenor, technical director at the Association of Plastic Recycling.

In the US, there is currently no established mechanism to collect flexible packaging kerbside, which means that flexible packag ing recycling is limited.

“Most of the flexible packaging we collect is via store takebacks, mostly for dry goods. With these, our test protocols ensure that when multi layer structures are melted down, the residual adhesive doesn’t lead to gel defects in another blown film.”

Scott Trenor Technical Director Association of Plastic Recycling

He is optimistic that flexible packaging recycling might become more widespread in the US.

“Currently there is a lack of legislative framework, but it’s changing in some states. So hopefully we’ll get broader collection schemes coming as some of the EPR schemes come into play in states like Colorado, Oregon

Labels are a popular feature to give shelf appeal, enable branding and inform consumers on the contents of a packaging, but labelling adhesives also come with their own challenges.

“It is important to make sure that the label will not hamper the sorting of the packaging in the right recycling stream. Besides, the best design for labels is to have them separable during the recycling process, meaning having a washable/releasable adhesive,” says Mr Di Gregorio.

Labels should ideally release during the wash, explains Mr Trenor.

“In an ideal world, for a PET water bottle or carbonated beverage, that bottle will go through either a wet and dry delabeler, then a wet delabeler and then flake washing and during one or all of those processes, the label will easily dissolve if it is properly designed. We prefer polyolefin labels for PET packaging. The label will float during the sink float process and not cause contamination. With PE milk bottles, or gallon jugs we have in the US, the adhesive there should be designed to do essentially the same way as for a PET bottle and be released during the wash process to ensure that natural high density can be used again in food contact applications.”

Both interviewees agree that innovation is essential to the future of recyclable and circular packaging.

Mr Di Gregorio adds that for both laminating adhesives and adhesives for labels, innovation is key to drive the industry to better designs and improve the quality of recycled plastic and its application in packaging to reduce dependency on virgin materials.

“Therefore, innovation can enable better separation of labels during recycling, or can also allow to get similar performances with less adhesives.”

Mr Trenor points out that adhesive manufacturers are willing and working hard to improve their products to boost recyclability.

“A few years ago, a new bottled water was launched in the US with full wrap-around labels. However, there were challenges around the label releasing from the bottle during recycling. APR members then developed a wash-off adhesive for these, and within a few months, the major beverage companies moved to the new adhesive. This is a good example of how rapidly some of these manufacturers can react to problems in the recycling industry and move the market to more recyclable solutions.”

He also sees innovation in recycling equipment as a boost.

“In terms of recycling equipment, the market is continuously evolving, enabling the removal of the adhesive and the labels, which leads to higher quality materials.”

Mr Di Gregorio highlights the fact that simplicity is key when it comes to creating a sustainable pack and adhesive.

“The best solution remains to simplify the design of plastic packaging when possible. That means eliminating a component if it is not functional or limiting adhesive concentration in the packaging to reduce contamination in recycled plastic. In that regard, when an adhesive can be avoided or replaced, it should be.”

He points out that nevertheless, adhesives perform an important function and will remain necessary in numerous applications. There are various ways in which the compatibility of adhesives with recycling could be improved.

“Plastic packaging recycling could be improved by reducing the number of adhesive formulations, using only adhesives tested and approved with standard testing procedures, and limiting their concentration in the final packaging as much as possible. While some industry players already have had their adhesives approved with RecyClass, a lot of improvement is still necessary from the full value chain.”

We recently got the opportunity to talk with Thomas Körmendi, the CEO of carton specialist Elopak, for the latest edition of our ‘In Conversation With…’ series. In a wide-ranging conversation, we discussed his views on the paper versus plastic debate, some of the biggest trends around this issue, and where the debate might ultimately end up.

The paper vs plastic debate has been ongoing for years now, with everyone having their own opinion. Indeed, each person seems to have a different perspective on the issue, and most can cite evidence and research that backs up their argument. Our first question is this: in 2023, where are we at with this issue? How is this issue trending?

At Elopak, we are confident that we are on the right side of history. Multiple Life Cycle Analysis (LCA) studies – the gold standard for environmental impact assessments – show that beverage cartons are more sustainable than plastic bottles. Indeed, a standard Elopak carton will have a 60% smaller carbon footprint than a PET bottle and a carton made with unbleached, brown board will have a 70% smaller carbon footprint.

Cartons are recyclable, and made almost entirely from wood: a naturally renewable resource that captures carbon dioxide during its lifecycle. Carton can also be folded up flat, making for easier and more efficient transportation.

One trend we are increasingly seeing is companies transitioning their products out of plastic bottles and into more sustainable options such as cartons. Currently we are receiving requests from both new and old customers to repackage their products into cartons.

This is not only occurring in the food and drink sector – where cartons have traditionally been popular – but also in markets such as hygiene and personal care products. Earlier this year, we partnered with oral hygiene company Luoro to launch the first mouthwash packaged in cartons. The Paperdent vegan, alcohol free mouthwash is now available at pharmacies and supermarkets across Germany and Austria.

From a functionality perspective, can you discuss your thoughts on the trade-offs between plastic and paper-based packaging? How do you think this aspect affects consumer perceptions and buying habits?

In terms of consumer convenience, plastic bottles and beverage cartons are almost identical. Both are suitable for fresh and aseptic products; both can be resealed with a screw-top cap; and both come in multiple sizes. One of the practical advantages with cartons over bottles though, is that they also come as an alternative without a screw cap. Our closure-free cartons is an even more sustainable choice as they have less plastic and a lower carbon footprint compared to similar Pure-Pak® cartons with a closure.

Beverage cartons also have the advantage that they can be folded easily to ensure every drop of product is squeezed out of the carton.

This aspect, coupled with the admittedly ergonomic design of a hand-held plastic bottle, probably influences consumers into thinking of cartons as more suitable for the home and bottles as more appropriate in on-the-go settings. This is changing however, as evidenced by the popularity of products like Boxed Water Is Better, which is sold in handy 250ml and 500ml Elopak cartons.

to be done in this area?

We’re making great progress in terms of improving the sustainability of our carton barriers. Elopak already offers cartons made with bio-based polymer coatings derived from renewable feedstock.

Added to this, in 2022 we launched the Pure-Pak® eSense: our first aseptic carton made without an aluminium barrier. Instead, the new polymer-based barrier reduces the aseptic carton’s carbon footprint by up to 50% and also simplifies the recycling process, allowing for a one operation separation of the paper fibres and polyolefin layers.

The plastic barrier is already a very small component of the carton and is vital in ensuring product integrity.

The scale of plastic pollution is devastating, with plastic waste volume currently set to triple by 2060. Furthermore, emissions from plastic are predicted to make up 19% of the global greenhouse gas volume that would be allowed under a 1.5ºC model for global warming.

If we are to succeed in drastically reducing plastic pollution, we need to turn off the tap for plastic production. Cartons are a part of this solution. www.elopak.com

In collaboration with our partners AIPIA, we bring you the latest from the world of intelligent packaging.

Maison Burtin, a champagne producer located in Epernay, France has chosen an identification execution solution from technology company Zetes to provide traceability of its bottles from packaging to delivery. The system combines the ZetesAtlas solution with Zetes MD smart printing and applicator labelling stations, linked to the ZetesMedea order preparation solution. This project forms part of a global digitalization strategy aiming to optimize the company’s packaging and picking solutions.

To improve quality control, reduce errors and enhance its brand image, Maison Burtin decided to digitalize its traceability by integrating automated processes using new label printing/ application and picking technologies.

The ZetesAtlas solution which is fully integrated into the company’s ERP [Enterprise Resource Planning] guarantees total automated

control of the marking of the packing boxes on its packaging lines, it says. This is controlled via a central operator interface. For each box processed, one or two brand and reference labels are printed and affixed to identify the champagne cases. In addition, to prevent any production downtime the printing head and the label applicator head have been duplicated on each line to facilitate spool replacement.

Once the boxes have been labelled, palletization is the next step. Again, the process is fully automated. It is then identified and validated by two pallet labels applied to two faces by the Zetes MD6000 smart printing and applicator stations and stored prior to dispatch to the warehouse.

Enabled by the imminent integration of the ZetesMedea solution, the company will also be able to modernize its order picking processes by adding an automatic picking system con-

nected to the mobile technology. The purpose of this solution will be to replace the old picking method, which is still a paper-based system.

The company claims this comprehensive global project integrating the entire chain from production to packaging and shipping of its bottles has led to a substantial increase in productivity, combined with the guarantee of perfect traceability.

Queensland fruit producer Piñata Farms is using Australian-designed Escavox technology to track the temperature and location of premium berries and mangoes along the supply chain, giving it valuable data for optimizing delivery, according to a report in PKN Packaging News, Australia. The company has

smart trackers in every berry consignment leaving its main packing operation at Wamuran.

A quick-chill cool room at Piñata’s packing shed uses the latest technology to take field heat out of the berries faster, before packaging in heat-sealed punnets. The Escavox devices, about the size of a mobile phone, are placed by Piñata Farms in a carton or container on loading and are retrieved by Escavox for reuse after the consignment’s arrival.

The tracking technology enables the fruit producer to have real-time data on each carton, giving its exact location and its current temperature. “This was information previously unavailable to us. We now have smart trackers in every berry consignment leaving our main packing operation and every mango load leaving three farms in the Northern Territory during mango season,” said Piñata Farms’ managing director Gavin Scurr.

“We have gained complete visibility over our consignments and can effectively share this information with customers at any time. We could have 30-40 consignments on the road right across Australia at any time and need to know that temperature has been maintained and that the consignment is on time to meet delivery timeslots. The system gives us transparency. If there’s product loss, the system provides an indisputable record of what has happened and who is liable,” he added.

Temperature information includes whether produce is too hot, too cold or exposed to too much light, humidity or movement, based on what the category requires to retain optimal quality and freshness. If the temperature was compromised for any reason (such as truck breakdown or equipment malfunction), drivers could take action to rectify the situation, Scurr explained.

According to a recent survey commissioned by Molson Coors’ brand Simply Spiked Lemonade, just over half (51%) of Canadians aged 19+ have lied to avoid conflict and/or protect someone’s feelings. A new-to-Canada alcoholic lemonade drink is trying to help them be more honest with a clever piece of packaging technology.

Simply Spiked aims to bring awareness to this ‘dishonest politeness’ and help Canadians be their true, unapologetic selves, says the company, with a lie detector housed within a can of the alcoholic juice brand. The ‘Keep It Real Can’ features Galvanic Skin Response to monitor sweat gland activity and Pulse Rate electrodes to measure the

heartbeat, much like a normal lie detector. The ‘Keep It Real Can’ spots the fakes and determines when someone is truly keeping it real, it claims.

To administer the test, the can is connected to a smartphone via WiFi and is conducted via a browser app. The test taker holds the can with fingers over the sensors, and when a lie is detected, a ring of light at the bottom glows red. When the Keep It Real can reads the truth, the light turns green, and blue indicates an inclusive response or error in reading.

To conduct the ‘tests’, the Keep It Real Can is paired with an iOS or Android device. “As the world’s first lie detector in a can, it was a priority

to make the experience feel seamless. From the moment someone picks up the can, they know to put their fingertips on the sensors. There is little need for instruction. When the person administering the questions asks and receives an answer, it needs to feel like magic for the person answering. That was the primary challenge. To make it easy to experience but feel complex in execution,” a company spokesperson says.

Wunderman Thompson Turkey has developed a new label and Instagram filter to prevent foodservice outlets from serving imitation ketchup in Heinz bottles by identifying the exact Pantone shade of the sauce.

The development comes in response to small Turkish street food restaurants refilling empty Heinz Ketchup bottles with imitation products to attract customers. To combat this, Wunderman Thompson Turkey has matched a stripe around the Heinz Tomato Ketchup label with the exact red of the sauce using the Pantone colour scale.

Using an Instagram filter, consumers can compare the colours of the stripe and the sauce and, if the shades do not match, instantly identify an inauthentic product.

“Our goal was to put an end to this so called ‘ketchup fraud’ and create an innovative solution to help customers identify whether they were using the real deal or an imposter,” says Onur Kutluer, creative director at Wunderman Thompson Turkey.

Apparently, the launch of the new label generated 100K organic shares, 800K likes, and over 2,000 tweets, and the campaign has been named as one of AdAge’s ‘Top 5 Campaigns You Need to Know About Right Now’.

New AIPIA member Alitheon, an optical AI technology company, has joined with Peer Ledger, the ‘responsible supply chain’ company, to integrate Alitheon’s patented FeaturePrint technology into Peer Ledger’s patented MIMOSI Connect platform.

The combined solution will provide seamless no-touch authenticity verification and traceability for many types of industrial and consumer products along the chain of custody, ensuring their integrity, they claim.

MIMOSI Connect, a ‘comprehensive’ Digital Product Passport platform using cloud, blockchain, AI, GPS and IoT technologies, gives companies a trusted, permanent record of validated transactions, documents and ESG metrics across the entire supply chain, the company says. This

supports responsible sourcing and due diligence. Integrating FeaturePrint into MIMOSI Connect creates an additional layer of proven trust for supply chains to mitigate environmental and human rights risks.

MIMOSI Connect is interoperable and supports any ESG standard, tracks product life cycle events and collects high-quality verified ESG data from extraction to transfer and transport, transformation, distribution, retail, recycling and end-of-life along all types of product supply chains, says its developer.

The FeaturePrint integration enables industries to authenticate and trace physical goods along their supply chains and throughout the life of the product, thereby ensuring physical and digital provenance. These events are made

visible almost immediately to authorized parties thereby further improving governance, according to the companies.

Most recently the partnered platforms have been used to prevent conflict financing. Illegal activity surrounding gold bullion is a problem that continues to grow, with misled and uninformed dealers requesting greater tracking, tracing, and authentication tools.

Coming soon! Hive is a brand-new set of tools created by Packaging Europe that aims to help packaging professionals know more about the industry they work in, offering briefings, reports, digital live events and a cutting-edge data tool.

We share another snapshot of the information that Hive has to offer. Deposit Return Schemes (DRS) have been set up to boost recycling

rates. Within the scheme, consumers are charged an additional deposit fee when they buy a drink in a single-use container. This deposit acts as an incentive to support recycling and can be redeemed when the consumer returns the empty container to a return point. A planned DRS scheme in Scotland has been delayed until at least 2025, but they are already up and running in a range of European countries.

14-15 NOVEMBER, AMSTERDAM

TICKETS AVAILABLE NOW FOR THE AIPIA WORLD

CONGRESS 2023 SCAN ME!

14-15 NOVEMBER, AMSTERDAM

TICKETS AVAILABLE NOW FOR THE SUSTAINABLE PACKAGING SUMMIT 2023 SCAN ME!