POLITECNICO DI MILANO

School of Architecture Urban Planning Construction Engineering

Laurea Magistrale(equivalent to Master of Science) Architecture-Building Architecture

Academic Year 2021 / 2022

RESEARCH CENTER IN MILANO INNOVATION DISTRICT

A gate to the future

Authors:

Ardit Dobroshi 964039 Tomas Kedhi 965761 Yüksel Özle Oğuz 963463

Supervisor: Prof. Francesca Battisti

Co-Supervisors: Prof.Grigor Angjeliu Prof.Massimilano Nastri Prof.Giovanni Dotelli Prof.Francesco Romano

2

3

table of contents

INTRODUCTION 1.1 MIND : Milano Innovation District 1.2 Arexpo 1.3 Main Anchors 1.4 Accesibility 1.5 West Gate 2. URBAN STRATEGY 2.1 Urban Cut 2.2 Urban Morphology 2.3 MIND Site Analysis 2.4 East Gate Analysis 2.5 Master Plan 2.5.1 References 3. BUILDING DESIGN 3.1 Design Process 3.1.1 Morphology 3.1.2 Circulation 3.1.3 Functional Distribution 3.2 Case Study : Typological Series 3.3 Ground Floor as a “Common Ground” 3.4 Exhibition and Working Spaces 3.5 Laboratory Design 3.5.1 Case Study: Philosophy of Lab Design 8 12 10 14 16 18 20 22 24 25 29 32 33 38 40 41 42 45 46 50 52 60 68 70

0. ABSTRACT 1.

3.5.2 Types of Laboratories

3.5.2.1- Type 1: Experimental Laboratory

STRUCTURAL

Structural

SERVICES

5.1 Concept 5.2 Winter heat load analysis 5.3

load

5.4

76 80 82 85 92 99 100 107 113 110 115 116 118 120 122 124 132 134 136 140 144 148 151 147 154

3.5.2.2- Type 2.1: Research Laboratory 3.5.2.3- Type 2.2: Research Laboratory 3.6 Building Envelope 3.6.1 Cantilever Facade 3.7 Roof Design 3.8 Manifesto 4.

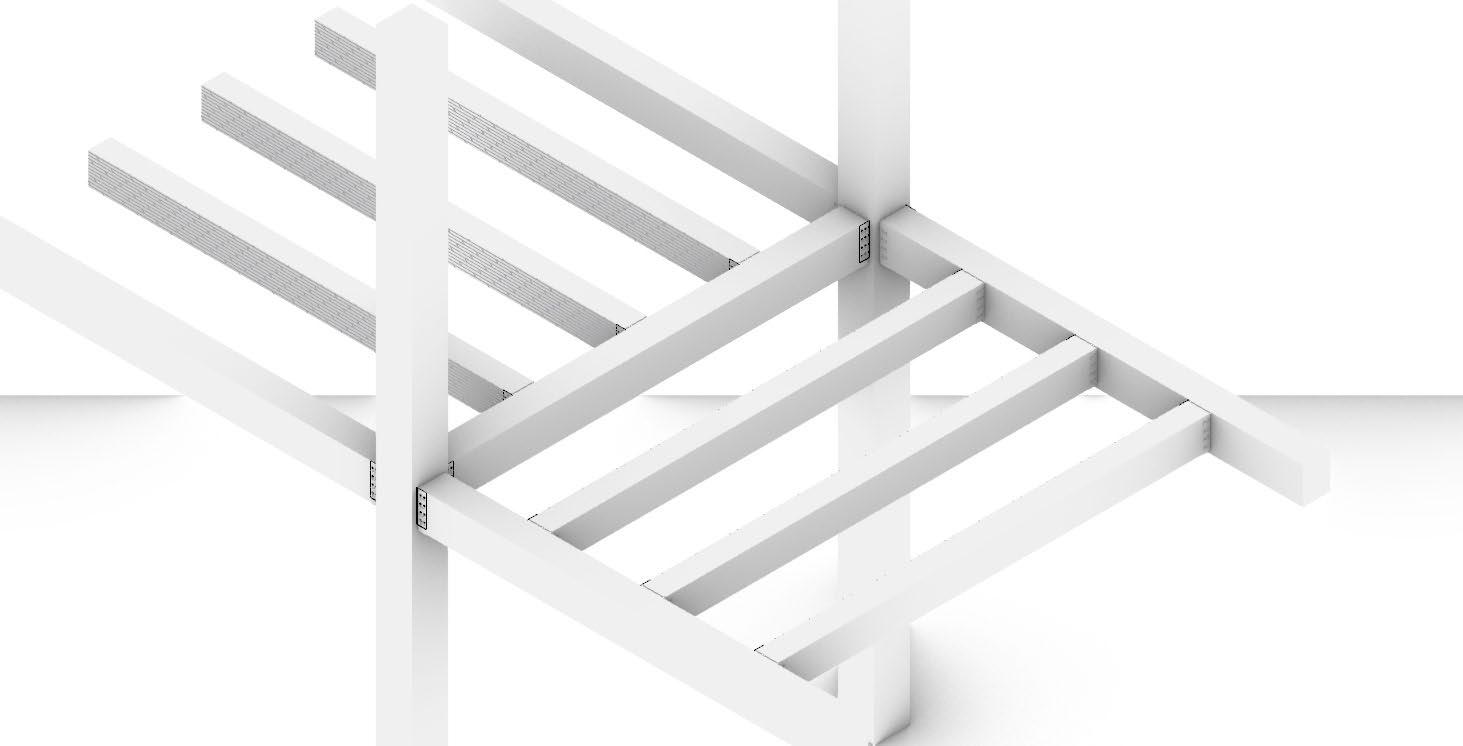

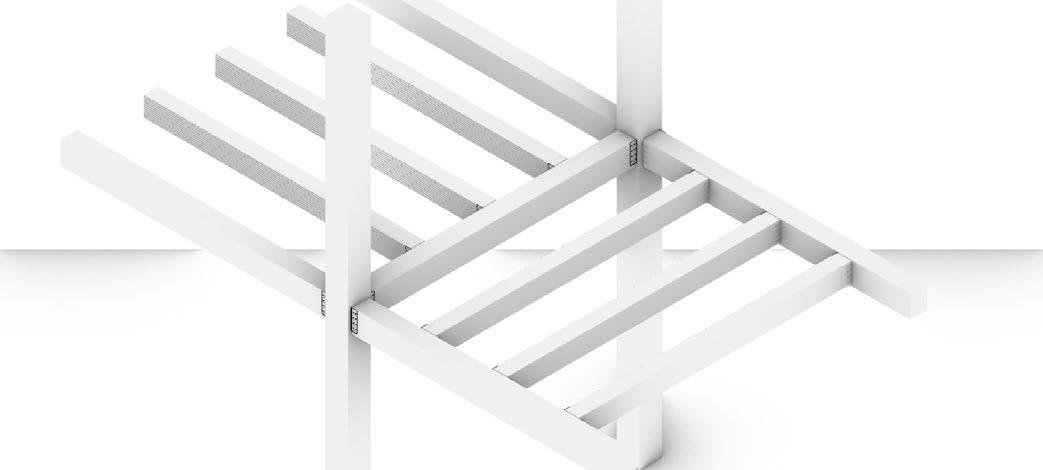

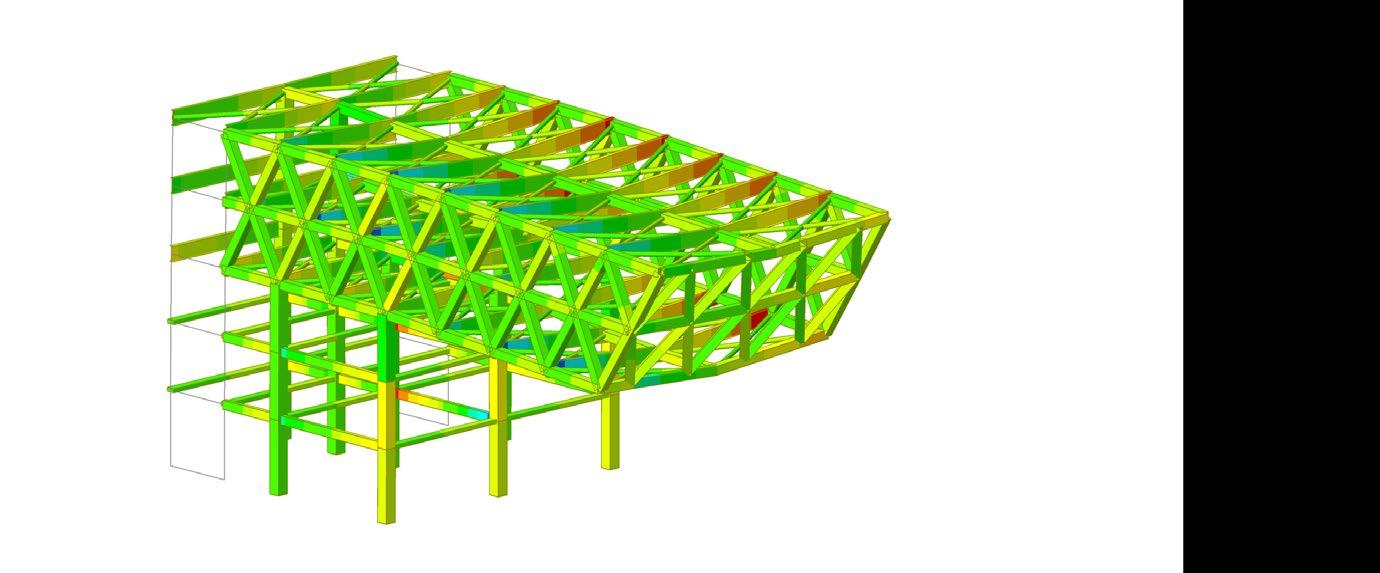

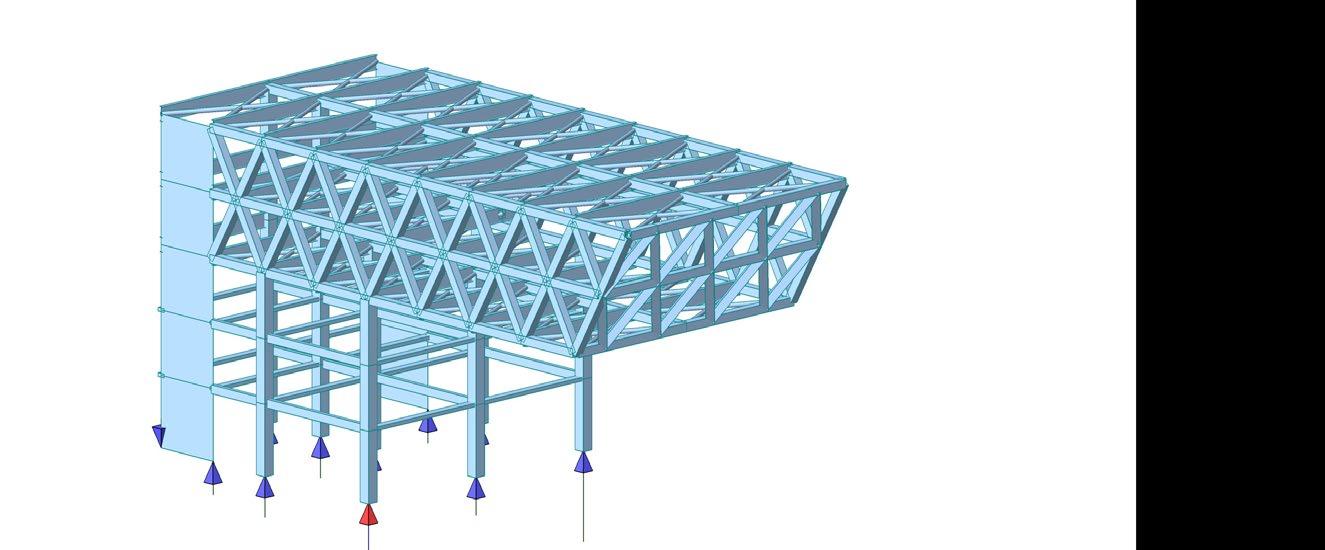

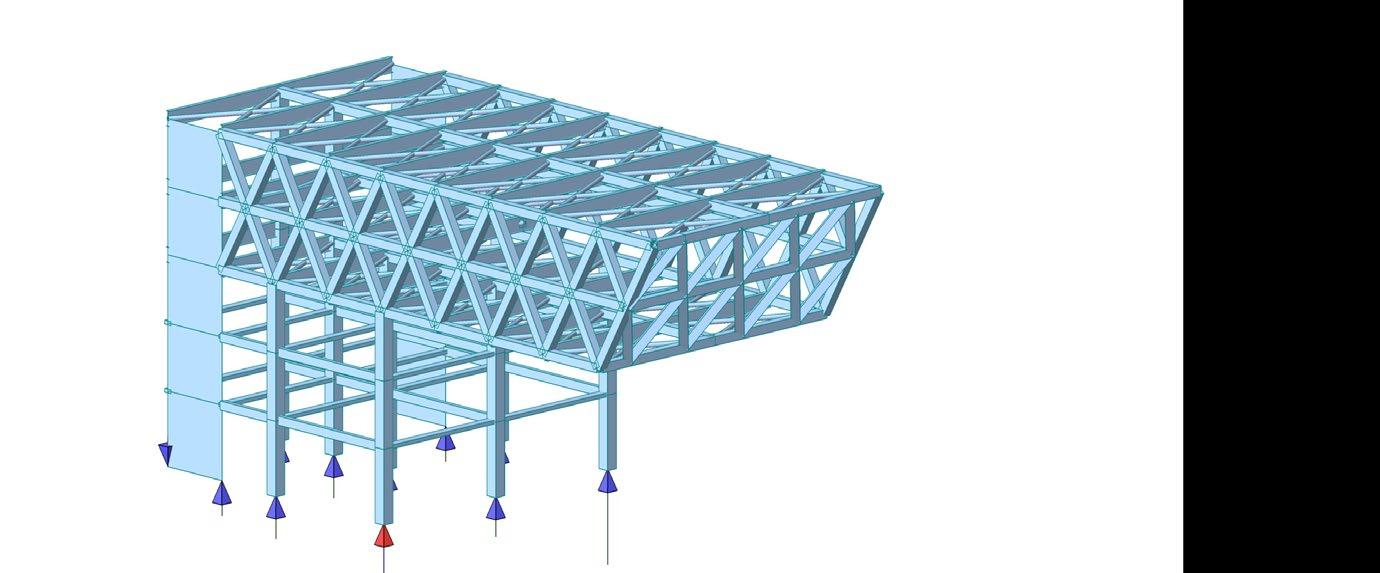

DESIGN 4.1

Concept 4.2 Cross Laminated Structural Design 4.2.1 Secondary Beam Design 4.2.2 Primary Beam Design 4.2.3 Typical Floor Load Calculation 4.2.4 Column Design 4.2.5 Structural drawings 4.3 Cantilever Design 4.3.1 Secondary Beam Design 4.3.2 Truss Design 4.3.5 Structural drawings 5.

DESIGN

Summer heat

analysis

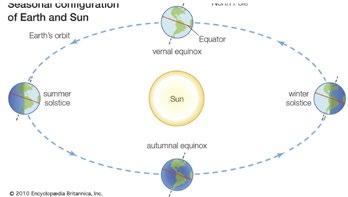

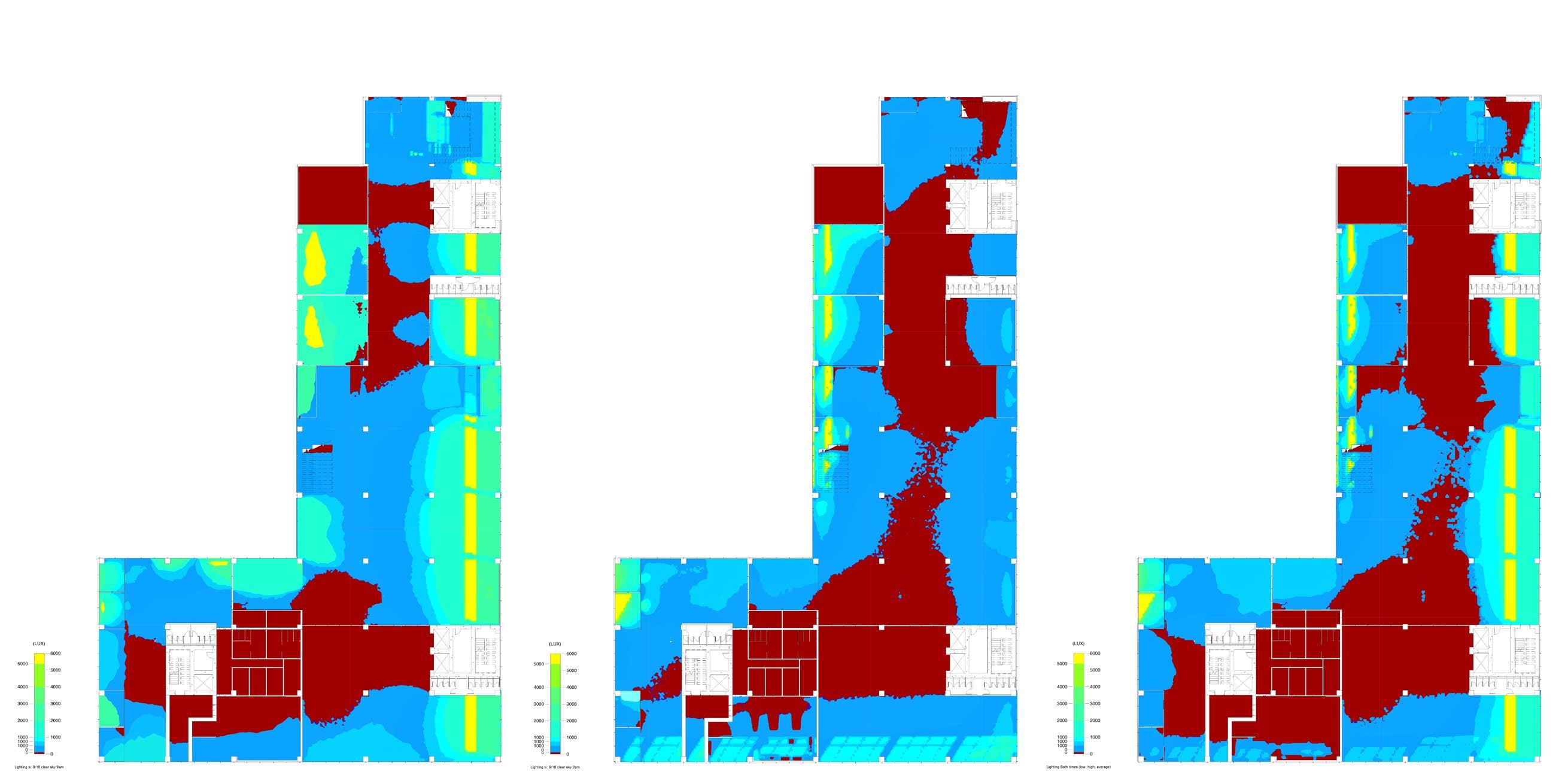

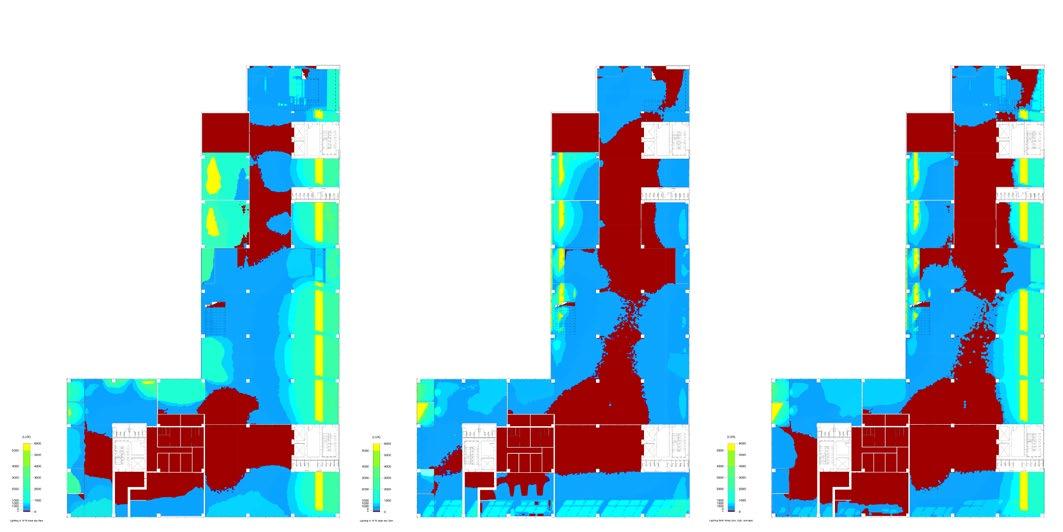

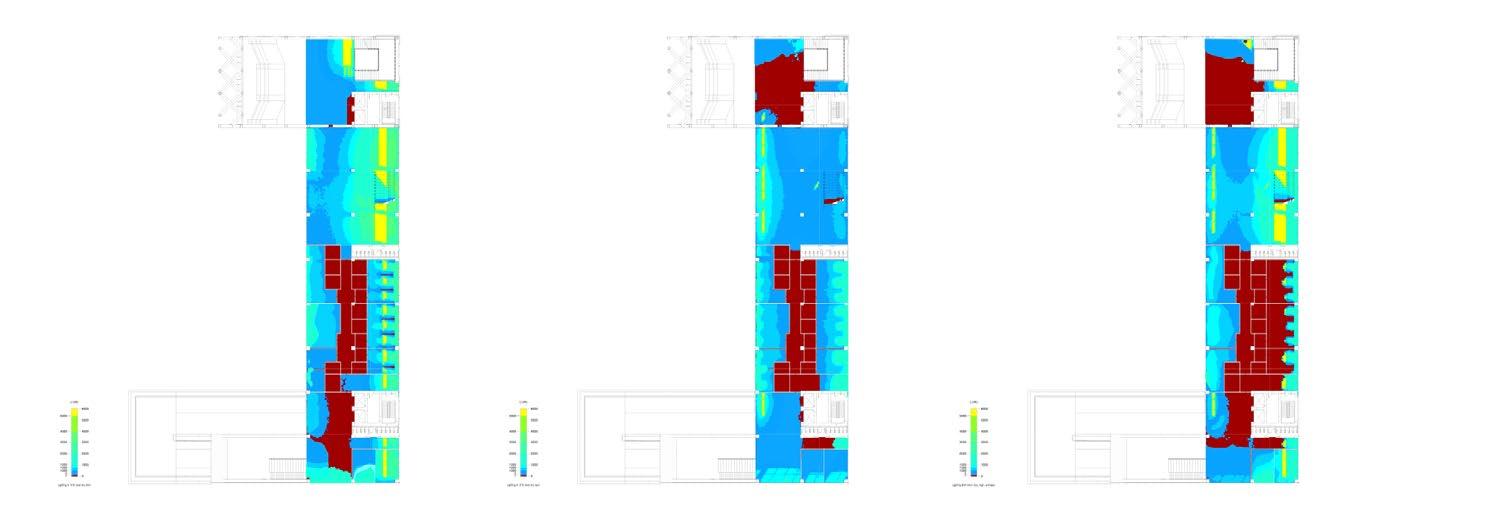

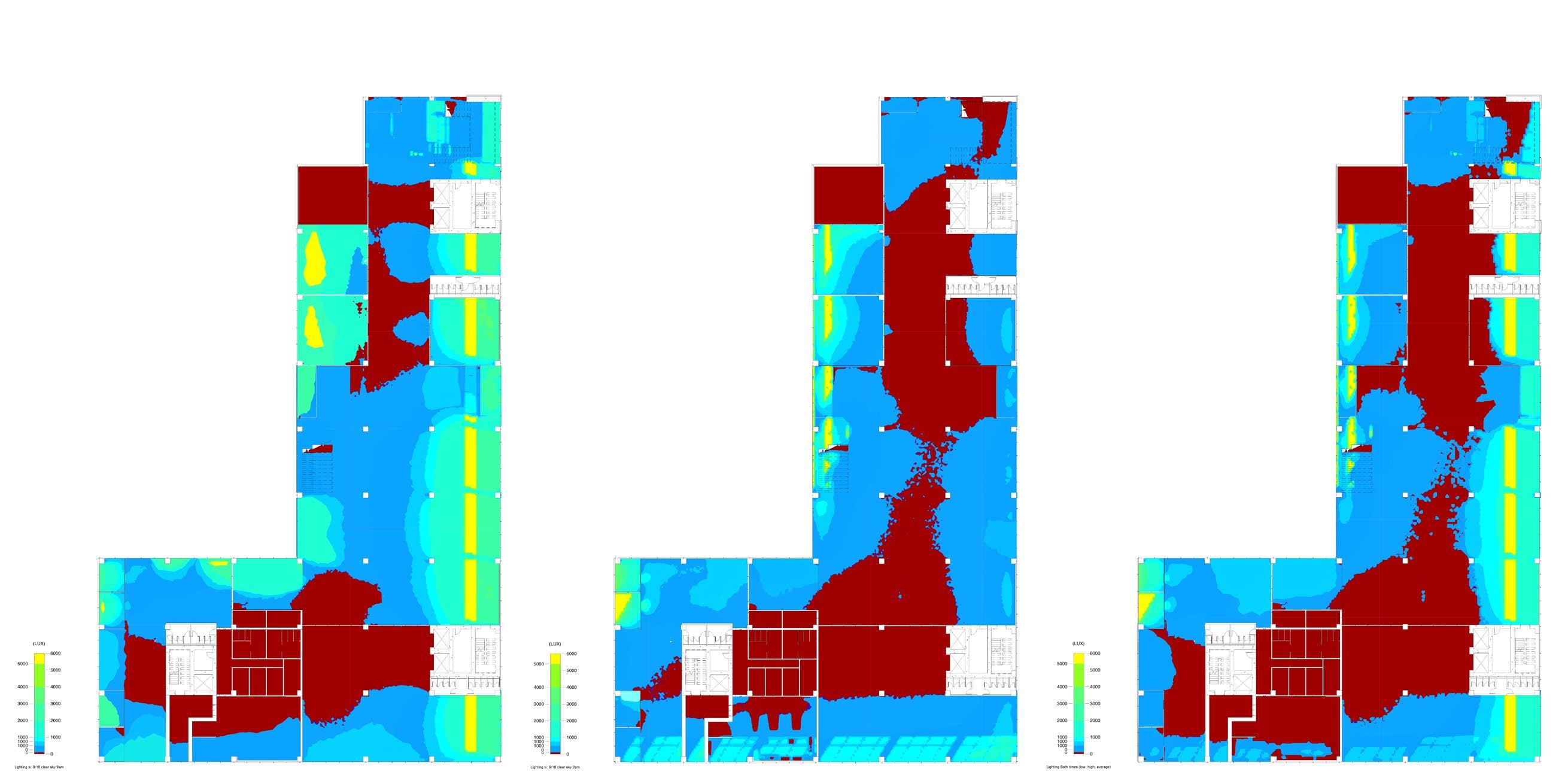

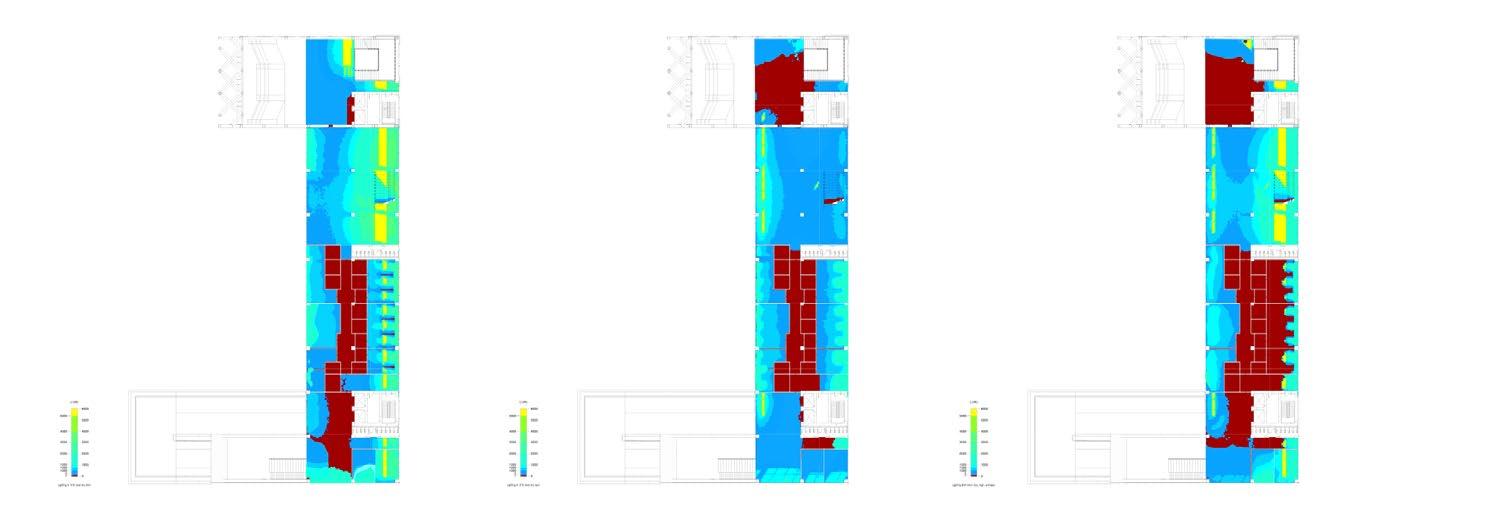

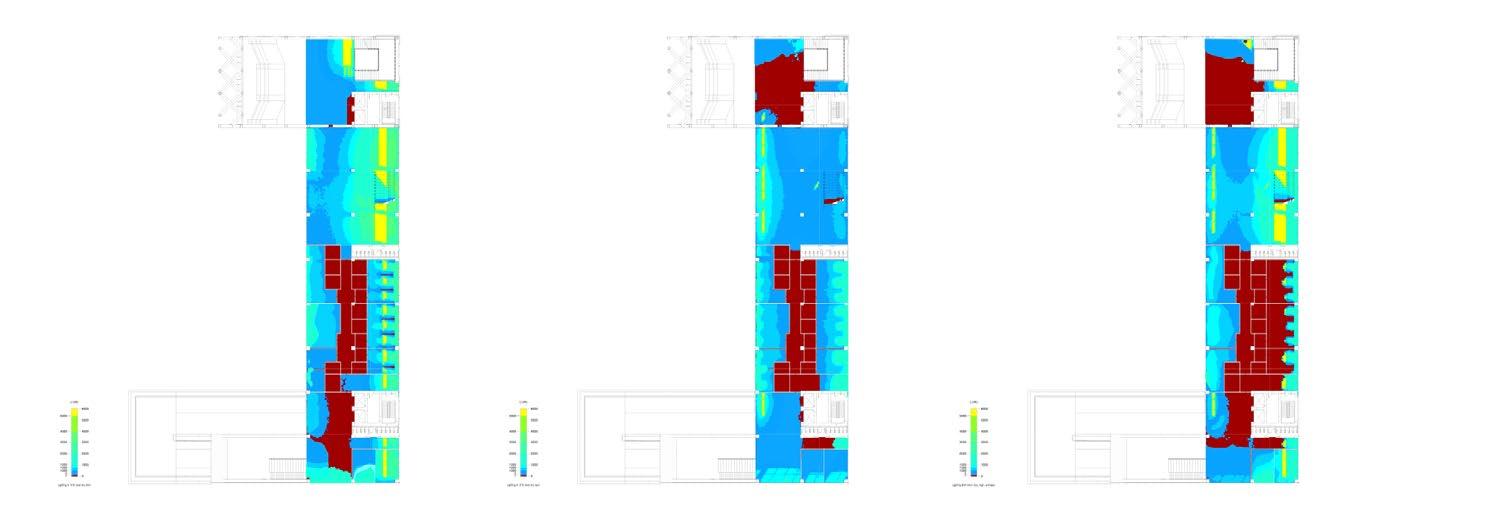

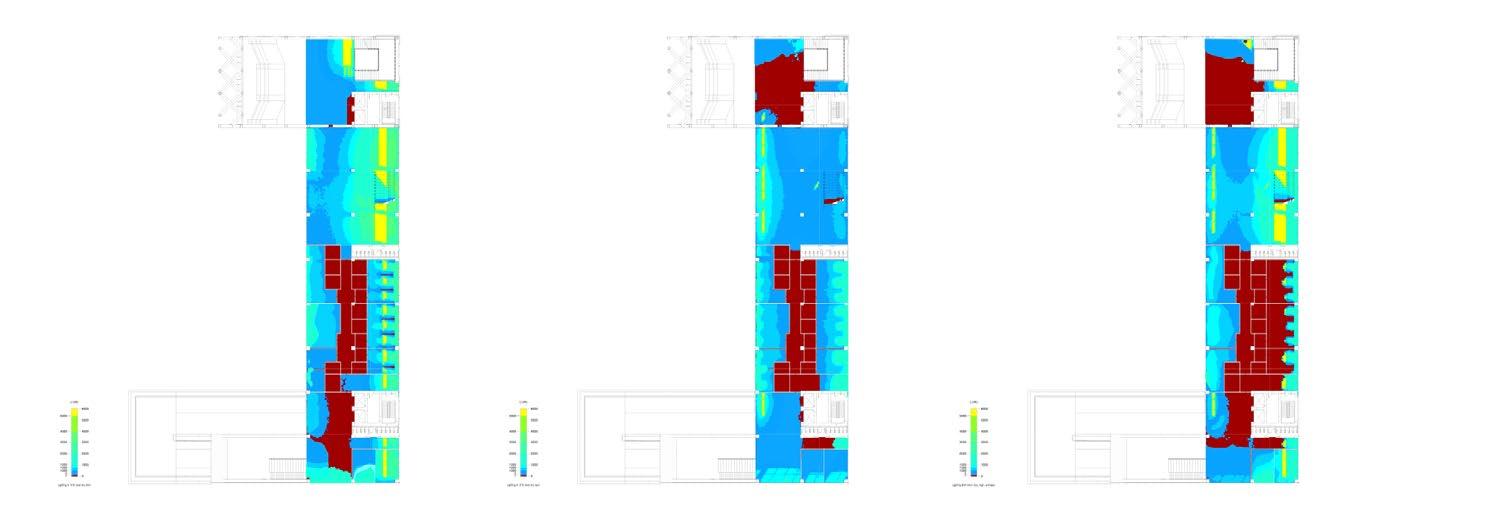

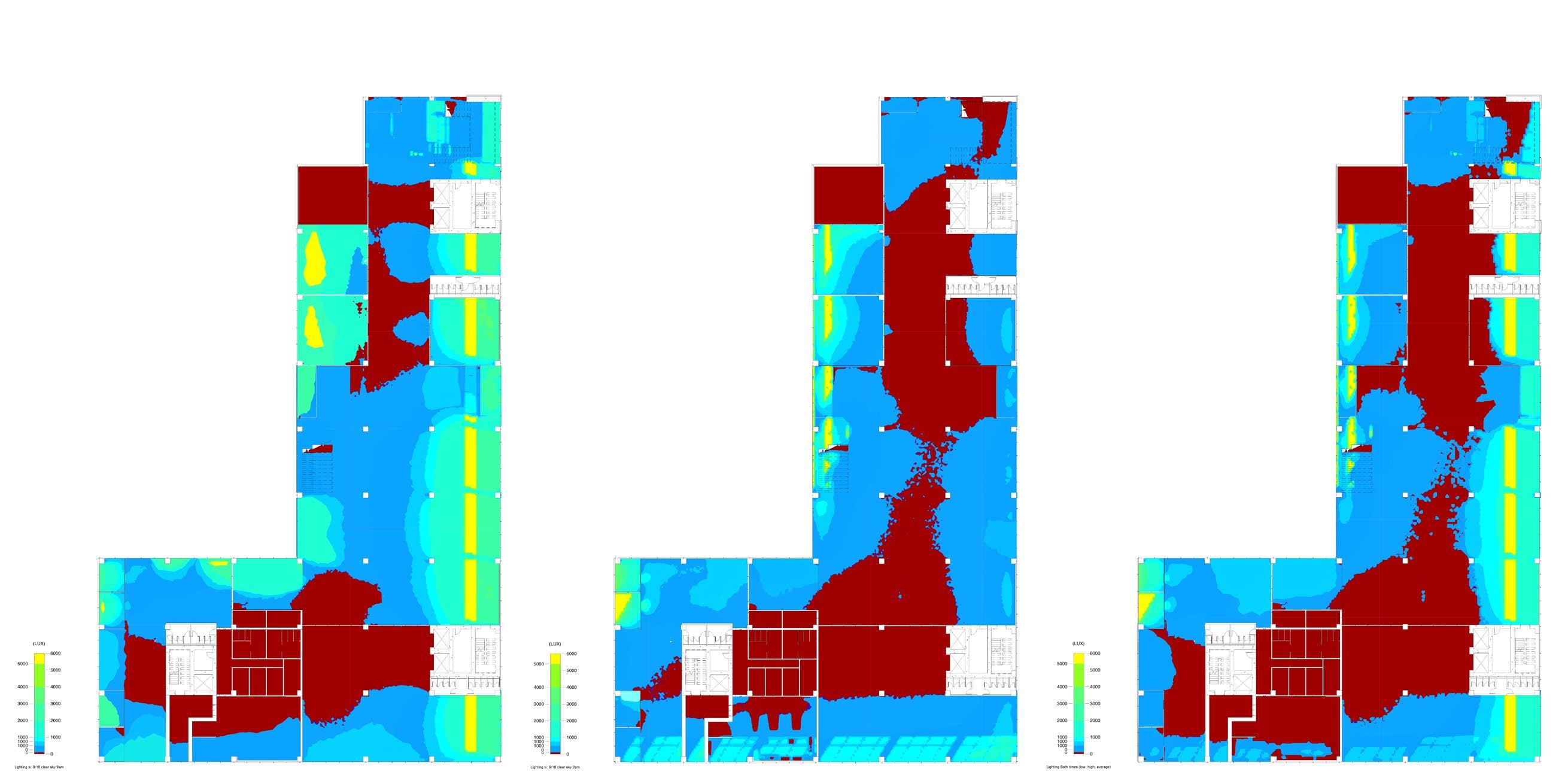

Producers

5.5 HVAC system 5.6 Gravity drainage system 5.7 Service drawings 6. SUSTAINABLE DESIGN 6.1 Sustainability 6.2 Climate Analysis 6.3 Solar Analysis 6.4 Lighting Analysis 6.4 Materials 7. CONCLUSION 8. BIBLIOGRAPHY 9. CITATIONS 10. SITOGRAPHY 11. LIST OF FIGURES 172 165 157 178 180 181 185 186 189 196 198 204 208 210

ABSTRACT

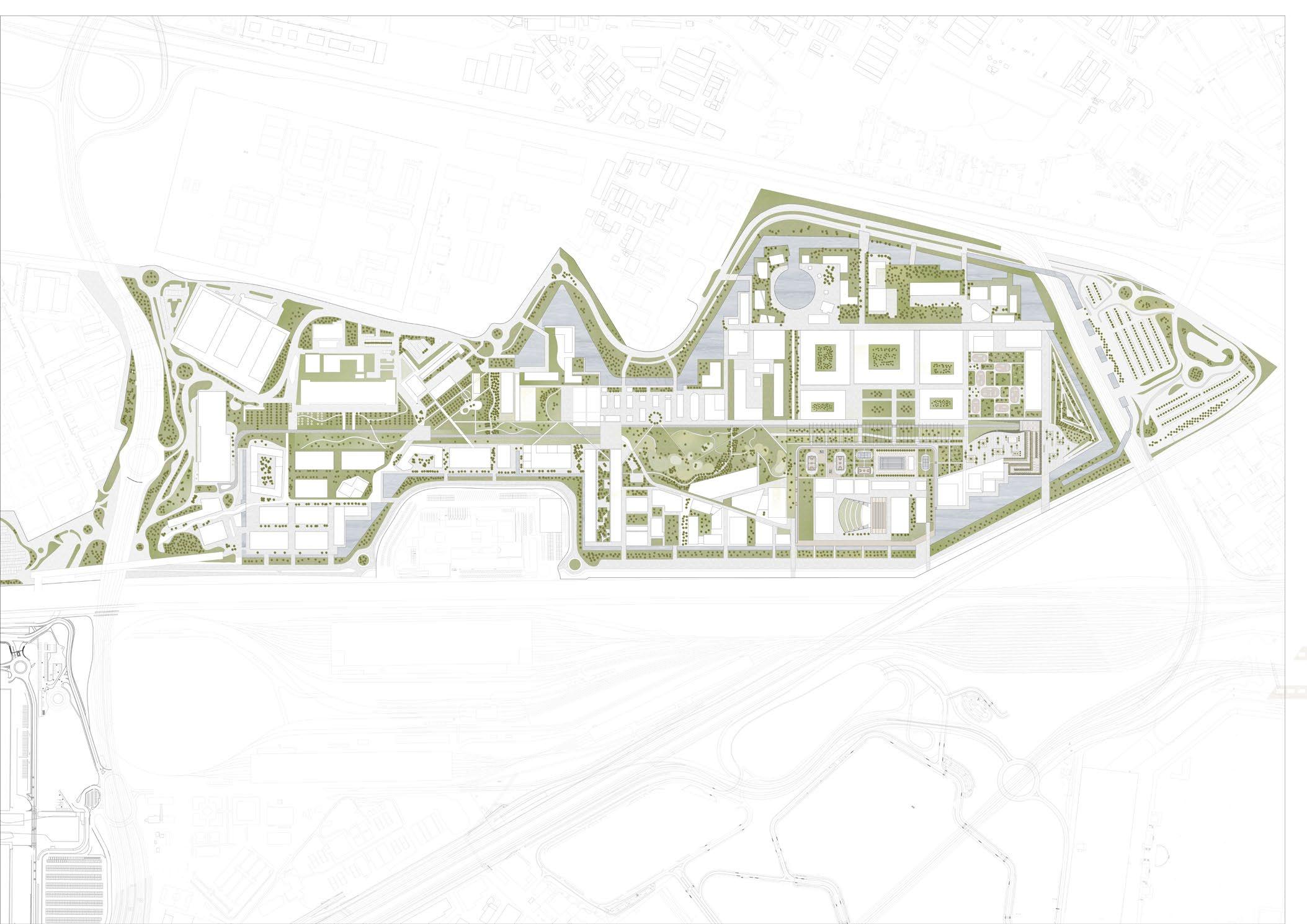

The Milano Innovation District dates to the time the city of Milan got elected to host Expo 2015. The end of the Expo was followed by a series of designs to transform the site into a center of knowledge and enterprise; to establish an ecosystem for social and economic development.

The backbone of the district is the decumano; a long artery that functions as an urban connector. It starts at the western gate and ends at the eastern one, where our intervention is centered. After a thorough understanding of the site, we aimed our design towards establishing a proper ending of the masterplan. Our starting point was the transformation of the area surrounding the new university campus into a park dedicated to sports and technology. Subsequent to this, we enclosed the east gate through the creation of a new building mass. The strategic location close to the new university and to the existing human technopole gave perfect ground for the development of a center dedicated to the research of natural science.

MIND is founded on several principles that serve as pillars for the architecture of the site. We have implemented such principles also in the design of the research center. First and foremost, the ‘common ground’ was one of the key elements on which we based our design. The ground floor is conceptualized as a translucent and flexible space, fully accessible by the public.

In contrast, the laboratories in the above levels feature a more enclosed design. A consistent repeated layout is distributed through the upper floors, consisting of incubated rooms, wet experimentation rooms, dry areas, individual working spaces, as well as open co-working areas.

Another design principle that is persistent throughout the MIND district is the accessible green roof. The creation of terraces can offer a remarkable experience of the site. In this design, the roof was an integral element that defined the morphology of the building. Since the starting point of our intervention was the park, we aimed to use the roof of the research center as a continuation of the masterplan. Along with the cross-laminated structure, the green roof is also aimed at lowering the carbon footprint of the building and thus increasing its sustainability.

In conclusion, our intervention aims at creating a unique space that brings together different disciplines of life. A work environment where new innovative ideas are generated and shared. The integration of such architecture into a new landscape gives birth to a new and more refined urban fabric.

Key words: flexibility, sustainability, green sloped roof, urban conclusion, common ground,

8

ESTRATTO

Il Milano Innovation District risale all’epoca in cui la città di Milano fu eletta ad ospitare l’Expo 2015.

La fine dell’Expo internazionale ha visto un susseguirsi di proposte progettuali col fine di trasformare il sito in un centro di conoscenza e impresa, creando così un ecosistema per lo sviluppo sociale ed economico

Il quartiere ha come spina dorsale il Decumano, una lunga arteria che funge da connettore urbano, il quale trova l’inizio nella porta occidentale andando a terminare in quella orientale: qui si concentra il nostro intervento. Dopo un’approfondita analisi del sito, abbiamo deciso di intervenire con la trasformazione dell’area, che circonda il nuovo Campus universitario, in un parco dedicato allo sport e alla tecnologia. Successivamente, abbiamo delimitato la porta est attraverso l’introduzione di un nuovo volume edilizio che funge da centro di sviluppo, dedicato alle scienze naturali, frutto della considerata posizione strategica vicino alla nuova Università e al Tecnopolo umano.

Il MIND si fonda su diversi principi che abbiamo incorporato nella progettazione del nostro progetto. Il progetto ha come concetto base il “common ground”, ovvero la realizzazione del piano terreno come uno spazio traslucido e flessibile, completamente accessibile al pubblico.

Al contrario, i laboratori situati nei livelli superiori, presentano un design più chiuso formato da locali incubatori, locali di sperimentazione umida, aree asciutte, spazi di lavoro individuale e anche aree open space dedicate al co-working.

Il tetto verde accessibile è un altro principio che, attraverso la creazione di terrazze, può offrire una notevole esperienza del sito. In questo progetto il tetto serve come un elemento integrante che definisce la morfologia dell’edificio. Poiché il punto di partenza del nostro intervento era la progettazione dell’area sportiva e quella di tecnologia , abbiamo utilizzato la copertura del centro ricerche proprio come una continuazione del parco. Insieme alla struttura in legno, il tetto verde mira anche a ridurre il carbon-footprint e quindi ad aumentare la sostenibilità dell’edificio.

In conclusione, il nostro intervento mira a creare uno spazio unico che riunisca diverse discipline della vita. Un ambiente di lavoro in cui vengono generate e condivise nuove idee innovative. L’integrazione di tale architettura in un nuovo paesaggio dà vita a un nuovo e più raffinato tessuto urbano.

Parole chiave: Flessibilita, sostenibilita, tetto verde inclinato, conclusione urbana, piano terra comune.

9

10

introduction

1

MIND: Milano innovation district

MIND Milano Innovation District is the unique Italian hub of scientific excellence and district of the city. It is a sizable, modern multinational neighborhood. Anyone who innovates conducts research is welcome to this hub of sustainable growth, as are institutions, businesses, and people’s lives. It is located northwest of Milan’s suburban area with a surface of around one million square meters. The new project adopted the robust intercontinental aspiration and further cooperation with public and private partners: Arexpo and Lendlease. They aspire to create a new evolution to the whole master plan. The matter of the most significant importance is to take care of the quality of the spaces by preserving them.

MIND is located in a well-planned position in Milan that is easily accessible by urban transportation. The project’s objective is to answer not only to the economy’s growth but also to face and give solutions to challenges such as a sustainable environment, hospitality, and socio-economic incorporation. The area is divided into three main parts: West Gate, MIND Village, and East Gate. While always on the changeover, Arexpo has managed to keep the site alive by hosting numerous social activities.The MIND is now a new ongoing situation that will host areas of science, innovation, knowledge, sport, habitation, and business. In brief, it is a city of the future where life and innovation coexist and is a place of new conception.

12

Fig 1: MIND site with surrounding - Carlo Ratti Associati (CRA)

MIND:Milano Innovation District

A City For the Environment

Sustainability depends on discovering ways to protect the environment, but it also depends on cutting expenses and developing a vibrant community. Cities can leave a net zero footprint for a better sustainable world through planned infrastructure, public green areas, smart garbage collection, and more. Milano Innovation District is a Zero-Carbon district with its renewing construction techniques, optimizing resources, and making room for nature and vitality. Mind`s responsibility is to develop a district powered entirely by certified renewable sources, starting with on-site solar energy.

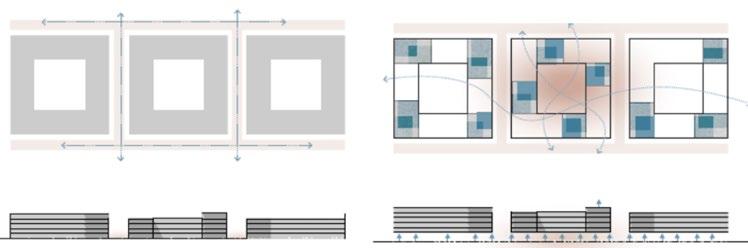

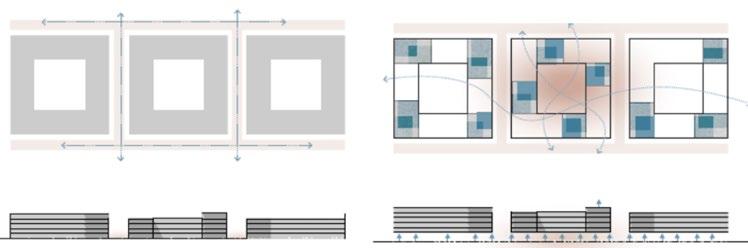

Common Ground

The idea of common ground is to create a single, expansive ecosystem open to interpersonal interchange. It aims to provide the best living conditions for the present, and future generations, forming the foundation of the entire district. It is one of the inspirational design concepts considered during the Research Center for Natural Sciences study. Traditionally the ground attack on the buildings observes the urban space between private courtyards and public streets. (Figure 4) Buildings are raised and separated at the common ground to grant permeability and assemble a constant public space. (Figure 5)

A Car Free District

Milano Innovation District`s surrounding scenery is breathtaking, and green can be seen on the facades and in the spaces between the buildings. Along the Decumano, the linear green park, tree-lined path, bicycles, and electric cars travel, and small animal colonies and pods find refuge in the waterways. A broad perspective of sustainability assumes the global goals for addressing climate catastrophe. On the other hand, the local viewpoint focuses on the happiness that a specific location can produce. MIND aims to develop to meet both needs.

13

Fig 2: Waterfront - MIND

Fig 3: External spaces - MIND

Fig 4: Traditional Ground Level, MIND

Fig 5: Common Ground, MIND

Fig 6: Bicycle roads, MIND

Fig 7: West gate, MIND

MIND:Milano Innovation District

The site is under the ownership of a private company named Arexpo. In 2011, Arexpo s.p.a. was established to acquire the land for the 2015 Milan Universal Exhibition. The place hosted the 2015 Universal Exposition (Expo 2015) in the past, having 141 countries addressed and visited by twenty-one million people Currently, Arexpo is in charge of developing and implementing the strategic

MIND : A Public Private Partnership

A strategic project for Lombardy Region and Italy

“Strong strategic vision and solid, efficient management skills.”

vision for constructing a cutting-edge, international Science, Technology, and Innovation Park.Arexpo’s shareholders are primarily public institutions. Italian Government (39.28%), Lombardy Region Government (21.05%), Milan (21.05%), Fiera Milano Foundation (16.80%), Milan Metropolis (1.21%) and the Municipality of Rho (0.61%).

in delivering large-scale urban regeneration projects”

They aspire to convert the area into a science, technology, and innovation district. Their Expo model is collaborating with public and private anchors for future developments.

Lendlease is a leading infrastructure group with operations in Australia, Asia, Europe, and America.They desire to create places that enrich people’s lives worldwide.

14

arexpo

Fig 8: Map of Expo 2015 Site,Arexpo

MIND continues the World Expo 2015 Legacy

Arexpo

“Trustworthiness

2011-2015

Arexpo is the owner of the land that is destined to host the universal exposition (Expo 2015) in 2021, The exposition gathers more than a hundred countries together and attracts tens of millions of visitors.

2015

The task changes with the end of the exposition. Encouraged by the ideas of innovation and research, Arexpo is assigned to reinvigorate the entire masterplan.

2017

The aspiration of the project is improved with ‘’multilateral talks between different sides. A 99-year-old concession was proposed and later awarded to Lendlease by Arexpo.

2018-2019

The masterplan of MIND is accelerated and strengthened inspired by cooperation between partners. It will attract the idea of having the science faculties of UNIMI – University of Milan.

2016-2017

The site had been open to events and collaborations until the start of construction to keep it active and not empty. Simultaneously the first agreement is reached with Human Technopole – life sciences and IRCSS health hub.

2022Still today the site is under development by Arexpo and Lendlease. Milano innovation district aims to become the focal point not only Milan but also in Italy.

15

Development of the Area : 2011- Present

Fig 9: Map of Expo 2015 Site, MIND

Fig 10: Unimi,Carlo Ratti Associati

Fig 11: The Italian Pavilion, Expo 2015, Inexhibit

Fig 12: The three of life, Arexpo

Arexpo

Galeazzi Hospital

Completion: 2022

Under construction, hospital with over 500 beds

West Gate

Completion: 2023-26

Commercial Workspace, Build-to-Rent, Industrial, Hotel and Retail

Human Technopole

Operational - Completion: 2024 Life Sciences Research Centre

Mixed use zone 3 Completion: 2031

Commercial Workspace, Build-to-Rent, Industrial, Hotel and Retail

Unimi - University of Milan Completion: 2025 University of Milan’s Science Campus

Mind Merlata Stop

Completion: 2024/2025

Location of Second Metro Stop

16

main anchors Main

Fig 13: Functional Map with anchor buildings - MIND

Anchors

Public Anchors Services

17

Public Anchors

Fig 14: Galeazzi Hospital, MIND Fig 15: Innovation Hub, MIND

Fig 17: Human Technopole, MIND

Fig 19: WG Common Ground, MIND

Fig 16: WG Common Ground, MIND

Fig 22: WG Common Ground, MIND

Fig 20: Horizon Retail Building, MIND Fig 21: Residential Building, MIND

Main

Fig 18: Zenith Multipurpose Building, MIND

Anchors

Galeazzi Hospital,University of Milan, Human Technopole

Offices,Co-working and incubators, Residential Retail,Hospitality,Cultural

Rho is a city and a municipality in the metropolitan city of Milano in Lombardy, Italy. Proved by archaeological artifacts found, the city of Rho is one of the oldest areas to be inhabited in the region of Lombardy. Rho is known for being a busy city with numerous industries. The city has a population of fifty thousand inhabitants. It is known for hosting the universal exposition in 2015 (Expo 2015), and the Milan Fair (Fieramilano), which is the largest of its type in Europe.

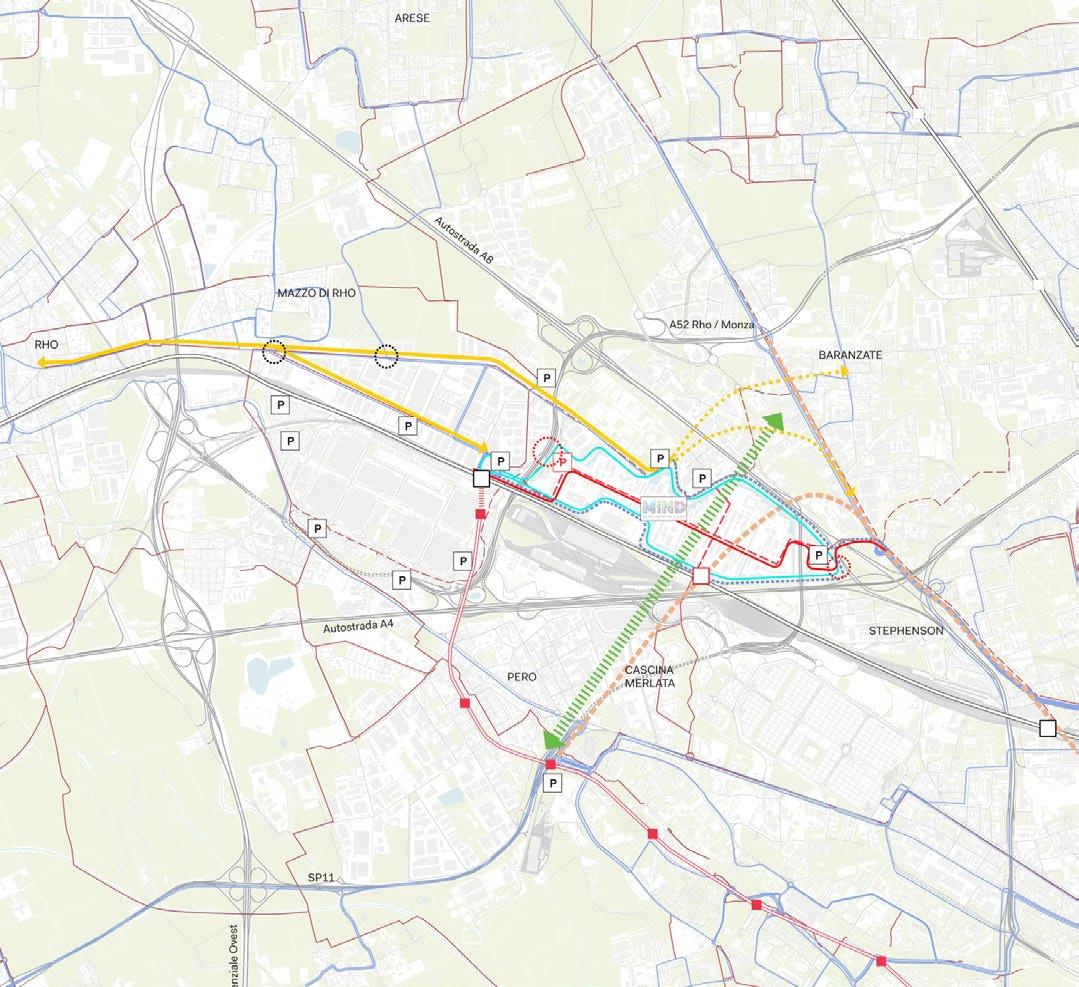

The metropolitan city of Milano has plentiful and diverse urban transportation.The Azienda Trasporti Milanesi (ATM), Milano’s public transportation agency serves the option to navigate through tramways, busses, metros, and trains. A new station will be extended to reach the Milano innovation district, through the first metro line (M1). In addition to that, it is possible to reach the site through the subway M1 and train to Milano’s Fair which is close to the site.

Airport Connections: 20 min to Milano Malpensa,30 min to Milano Linate,45 min to Bergamo Orio al Serio Urban Connections :30 min to the city center of Milan,10 min to Garibaldi Transport Interchange, 1 hour from Turin, Brescia and Parma stations

Railway Connections: Direct connection to main European corridors,3 hours connection to Rome,1 hour connection to Bologna 55 min connection to Turin,2 hours connection to Venice,4 hours connection to Zurich

18

A4 - C.Merlata A4 Zara-Expo ex SS11-A8 Merlata Metro Stop

Accesibility Urban Level Accesibility : Fig 23: 3D view, MIND

accesibility

Fig 24: Transport Insfracture,MIND, Systematica

Baranzate- Molino Dorino cross connection

Line M1 - Line M6

19

Accesibility

20

west gate West Gate

Fig 25: West Gate visualization, MIND

The area of West Gate will be the place of multifunctional activities. It is divided into four main functions: Hospitality, living, working and having social activities. The Innovation Hub at the West Gate will bring together the work and the joy where each floor is different from the subsequent.

It will contain diverse spaces such as private offices and coworking spaces, depending on the mood innovators will be able to think alone or brainstorm with a group. Moreover, Zenith, the multipurpose building will allow experts and specialists to operate freely with its flexibility.

The West Gate’s objective is to be exhilarating for the workers, and innovators.The Molo building dedicated to multipurpose use will also have laboratories for researchers and that will further strengthen the objective of sustainability with its refreshing architecture.

The West Gate will have a connection point called the common ground that will bring together the public and private areas, residents, and workers. The numerous activities provided, will bring together the youth and elderly into the common ground and beyond.

21

West Gate

Fig 26: Map of West Gate site with surrounding, MIND

22

urban strategy

2

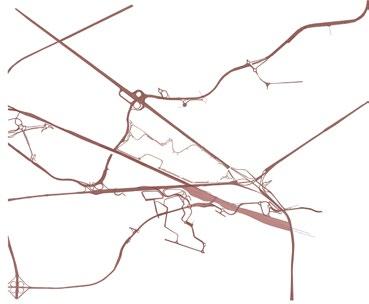

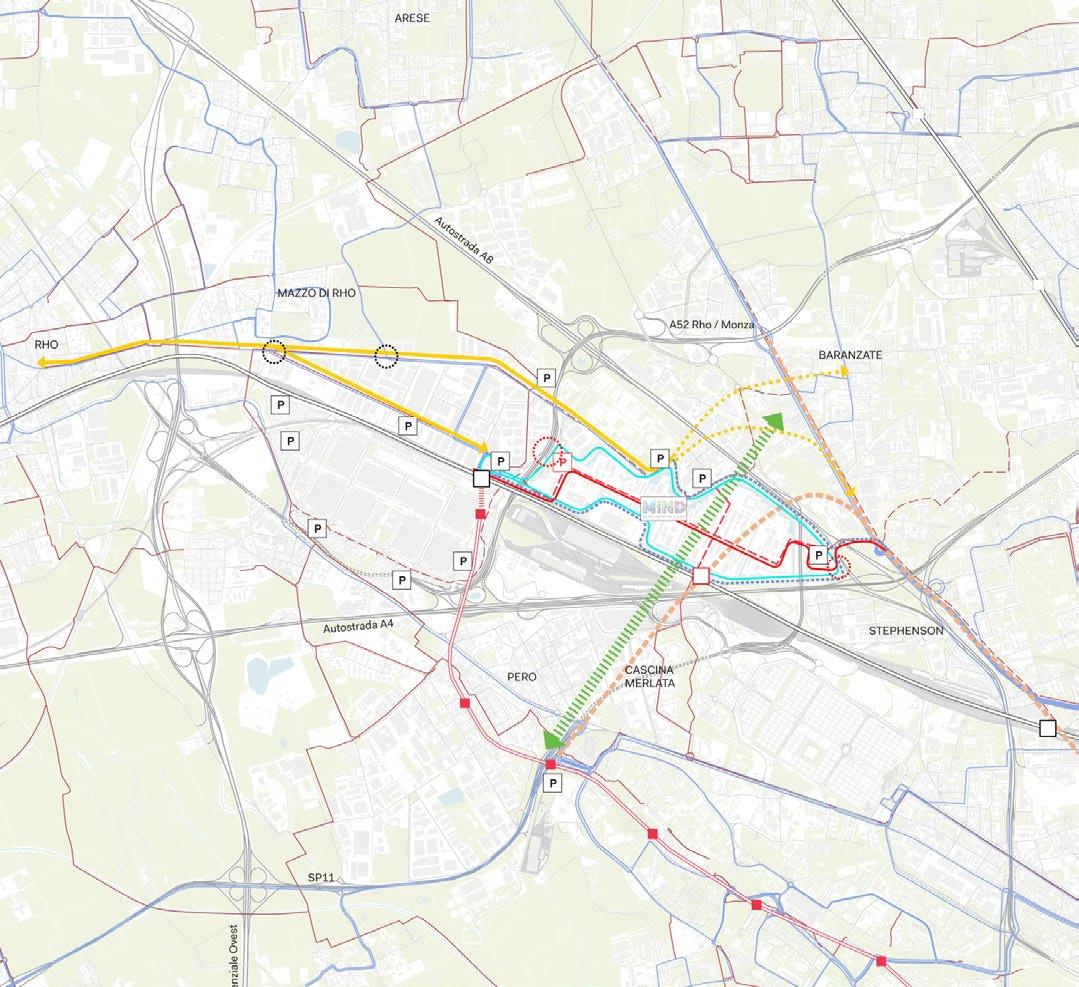

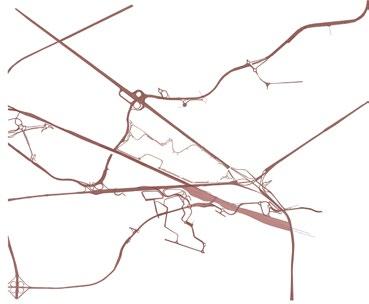

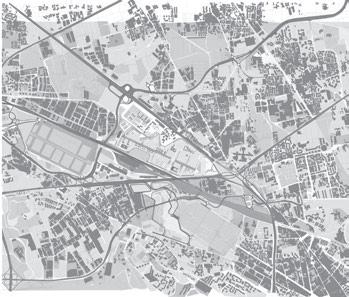

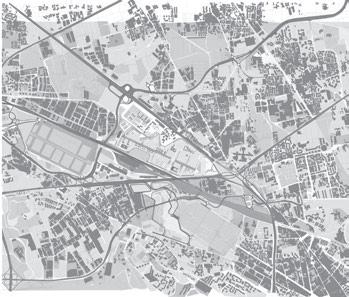

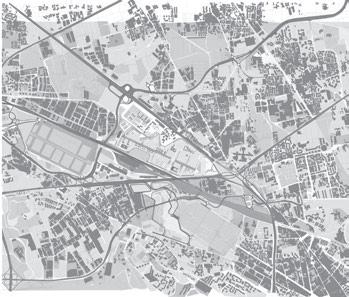

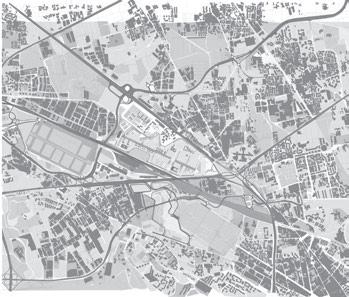

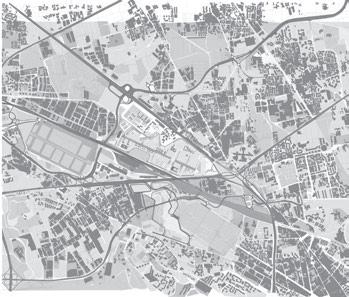

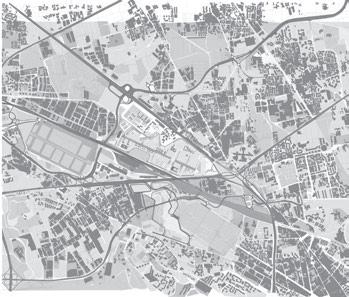

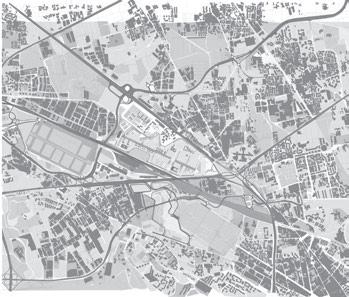

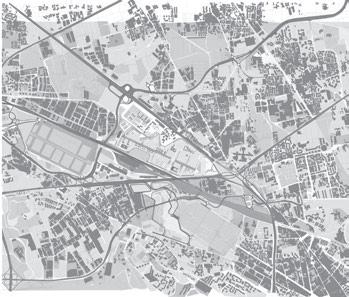

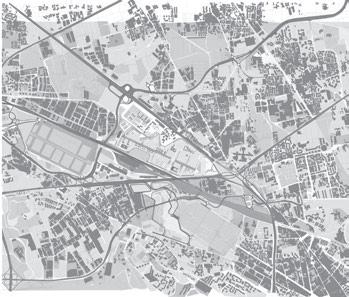

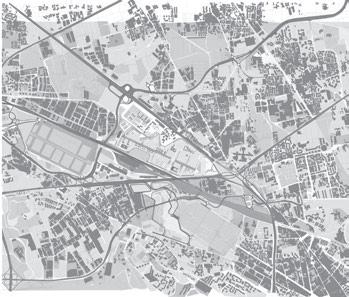

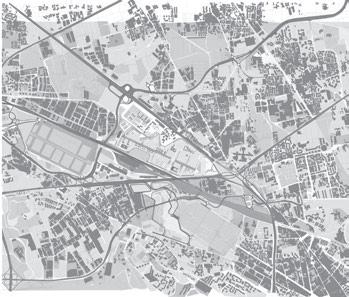

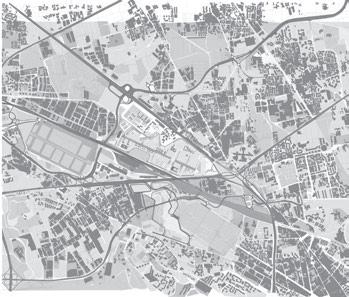

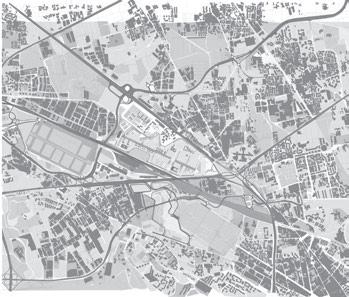

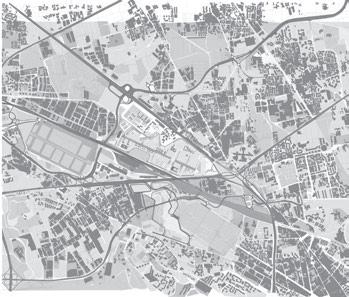

The urban cut aims to investigate the “morphological potential” of the project site, starting from the interpretative analysis of the relationship it has with the rest of the city and, especially, with the urban sector where it fits. The map highlights the main urban connections of MIND site with its surrounding.

Fig 27: Urban cut, Authors

Urban Cut

Buildings Transportation Parks Greenery Focal points City blocks Railways Agricultural areas Construction areas Water

urban cut

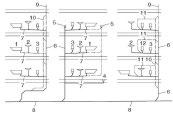

The morphological study was executed to understand the pattern of MIND and its surrounding, with the aim of measuring the morphological differences within the overall urban setting and their reciprocal dialectics. The understanding of the relationships between the intervention site and overall contexts has then assumed an essential role in founding the modifications introduced within MIND’s approved master plan and setting the rules of our urban design strategy. The first part of the study is concentrated on the connection between roads, green areas,

blocks, and the main axes within “MIND’s urban cut”. The area is located at a strategic infrastructural node in the northern part of Milano Metropolitan City. A green “texture” characterizes the environment all around, and the main grids are based on territorial connections of the site. Also, there is a main diagonal grid-axis that frames the borders of the future Milano Innovation District site, as highlighted in the roads’ map clearly. Urban blocks have not only various size, orientations, and types, but also reveal different types of yards, terraced houses,

urban morphology

and large-scale industrial buildings providing a heterogeneous “inventory”. The second part of the investigation, focused on the morphological analysis of MIND’s official masterplan, starting from grids, building blocks, and site-perimeter analysis to an inventory of the blocks, interpreted as redefined wider compounds including fabrics responding to the main morphological rules. Extracting portions from the master plan and observing each piece allows for exploring all the site qualifications well.

25

Fig 28: Grids, MIND, Authors

Fig 31: Roads, MIND, Authors Fig 32: Buildings,MIND, Authors Fig 33: Perimeter,MIND, Authors

Fig 30: Greenery, MIND, Authors Fig 29: Blocks, MIND, Authors

Urban Morphology

“Understanding urban morphology is a prerequisite to an awareness of urban aesthetics and a layer of meaning to townscapes” Michael Barke

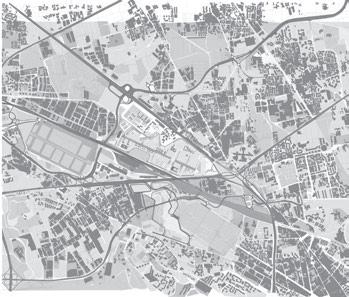

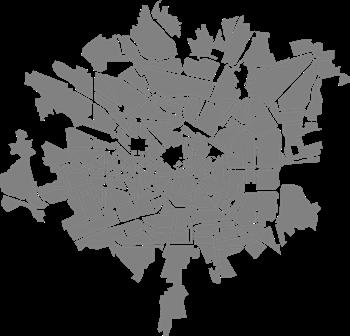

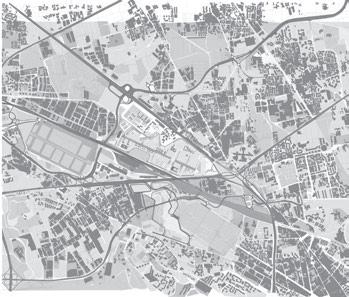

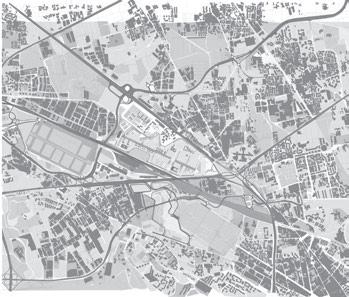

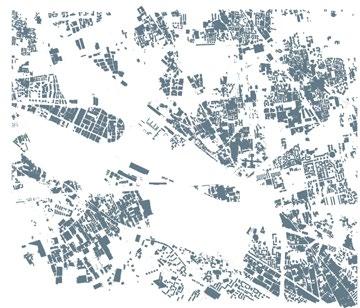

The urban context maps allow the reading - based on selected “thresholds” of 1956, 1972, and 2021 - of the urban growth characterizing the urban sector wherein MIND is rising and how the site’s relationships with the context have historically defined and evolved. The sequence of maps is mainly aimed at showing

the morphological structure of MIND’s site and surroundings, and its modifications since the mid of last century. According to MIND location in the north-western sector of metropolitan territory of Milan, the main concentrating zones are the municipalities of Rho, Pero, Garegnano, Cagnola, and Baranzate. In 1956, the population was denser in Garegnano, Cagnola, and the eastern part of these zones. In between 1956-1972 the western part of the urban sector started developing, also effect of industrialization, and economic development of the city.

26

The transformation of the urban context starting from 1956

Urban Morphology

Fig 34: Morphology map (1956) ,MIND, Authors

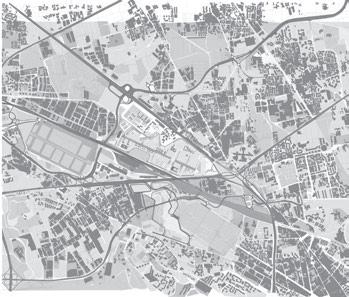

As we approached 1972, we observed that the density has increased, especially in the southern and northern parts.Another essential aspect is increasing density towards the eastern part. Between 1972 and 2000, the territory framed in the map was affected by several vital evolvements. Among them, the Bovisa district developed during this timeline, being involved in an urban transformation process wherein the opening of Politecnico di Milano-Bovisa Campus in 1989 was the main driver. Moreover, during the last phase of the period taken into consideration, a further profound urban and territorial change involved the

qualification of the Rho-Pero exhibition platform, the areas of the former Alfa Romeo of Arese, those of Bovisa as well, the areas around the new infrastructural nodes, the “cluster” of Mazzo di Rho and via De Gasperi, up to those of City Life, of the old fairgrounds, to those of Porta Nuova. In fact, during this period, the linear conurbation of Sempione was strengthened with the completion of the Turin-Milan high-speed railway line, the Passante Ferroviario and the infrastructural upgrades planned for the 2015 Expo, providing a new level of accessibility and connections.

27

Urban

Fig 35: Morphology map (1972) ,MIND, Authors

Morphology

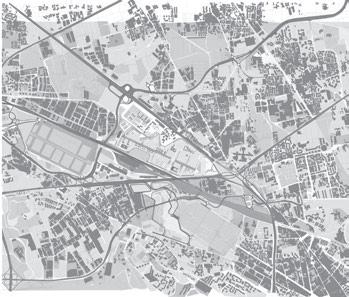

In particular, the “foundation” of the Expo 2015 site generated further transformations of the borders of the future MIND, which enlarged and became denser. The World Exhibition left as a heritage a new ecologically-sound urban area with great infrastructure, fully better integrated with the site and its surrounding.

In addition to Expo development, between 2016 and 2017, regeneration ideas for the entire area gained currency. One of the topics was to open the site for improvements and make it a center of innovation and research. Afterward, from 2017 to the present, the studies on MIND Master Plan began, and the idea of an innovation district vitalized all the surroundings of the site.

28 Urban Morphology

Fig 36: Morphology map (2021) ,MIND, Authors

MIND site analysis

29 MIND Site Analysis

Fig 37: MIND,MIND Village

Fig 40: Human Technopole, Authors Fig 41: Bridge, Authors

Fig 38: Decumano,Authors Fig 39: Bridge-Water, Authors

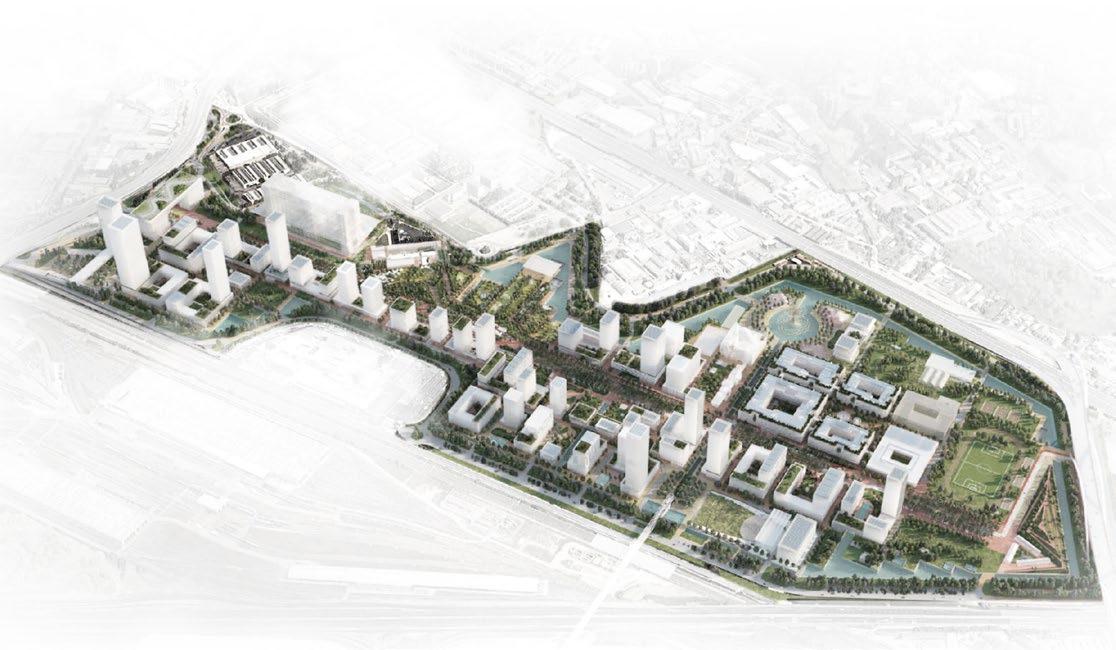

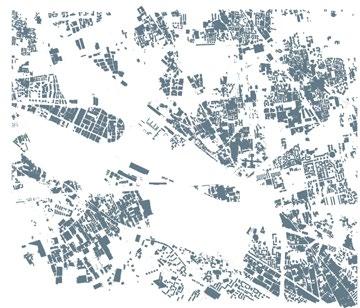

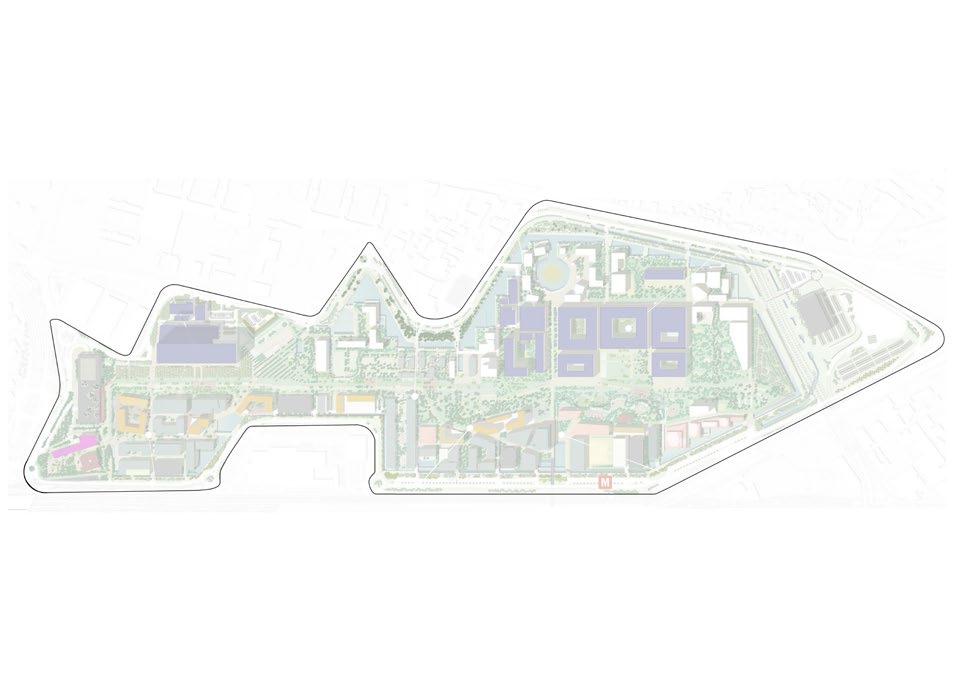

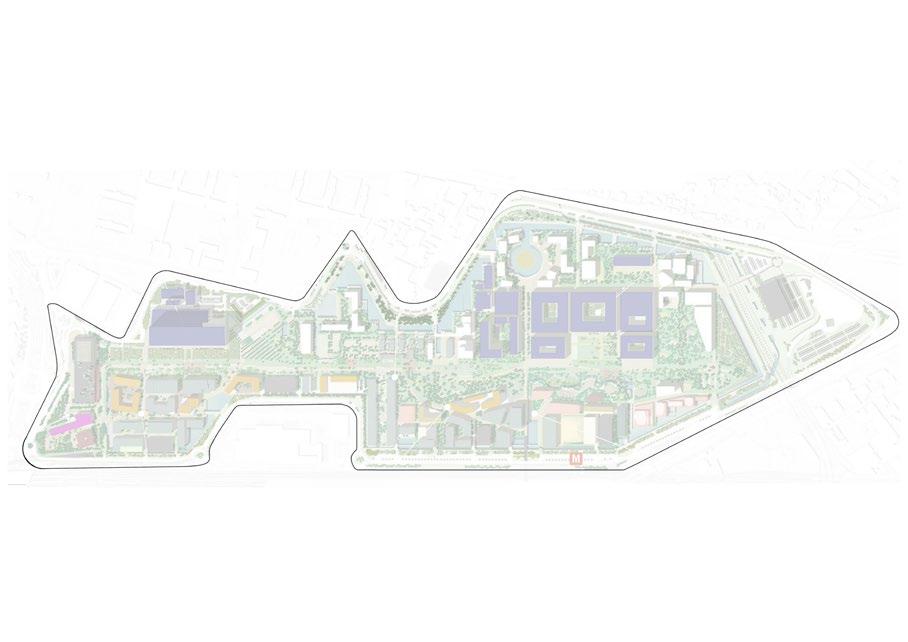

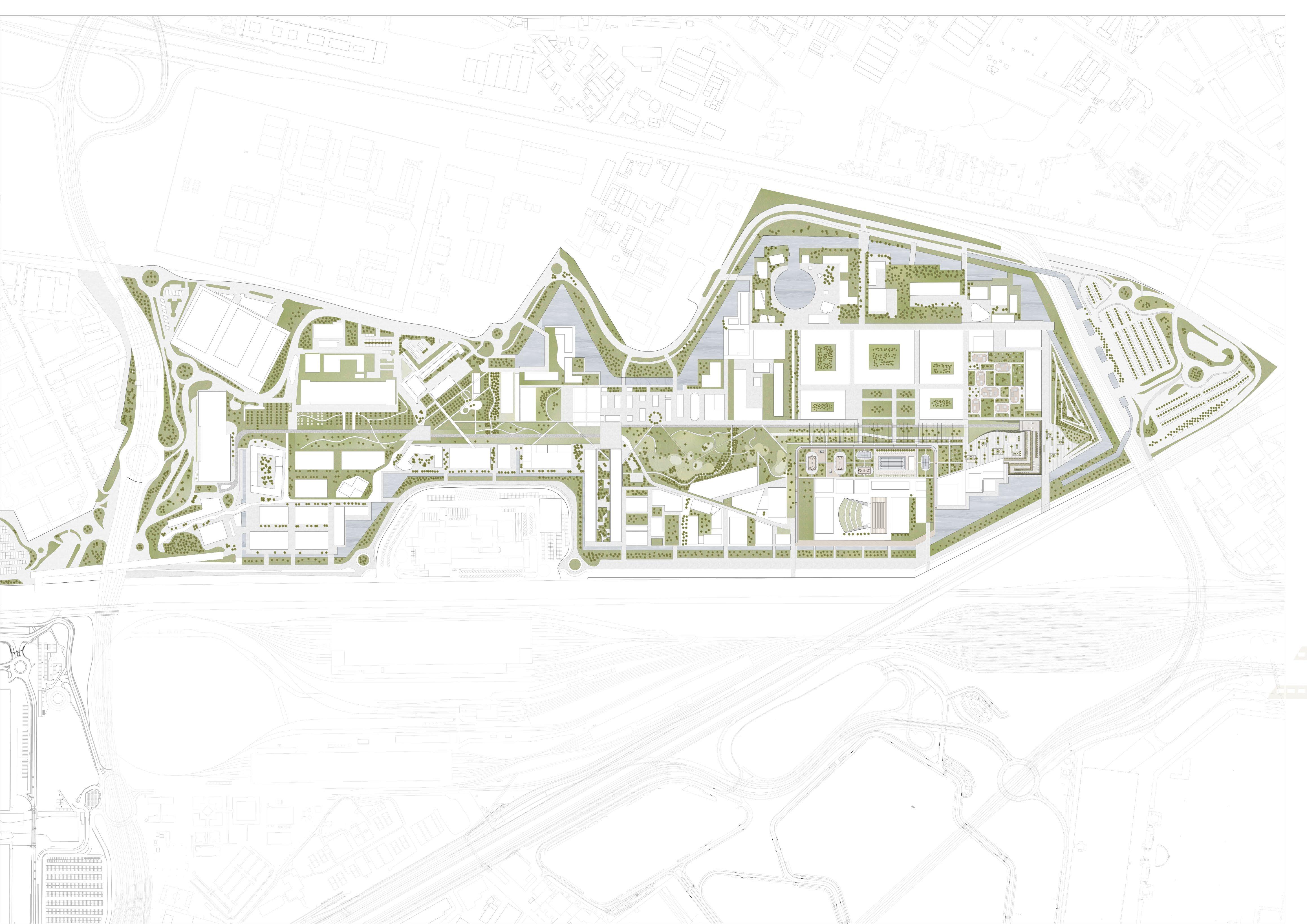

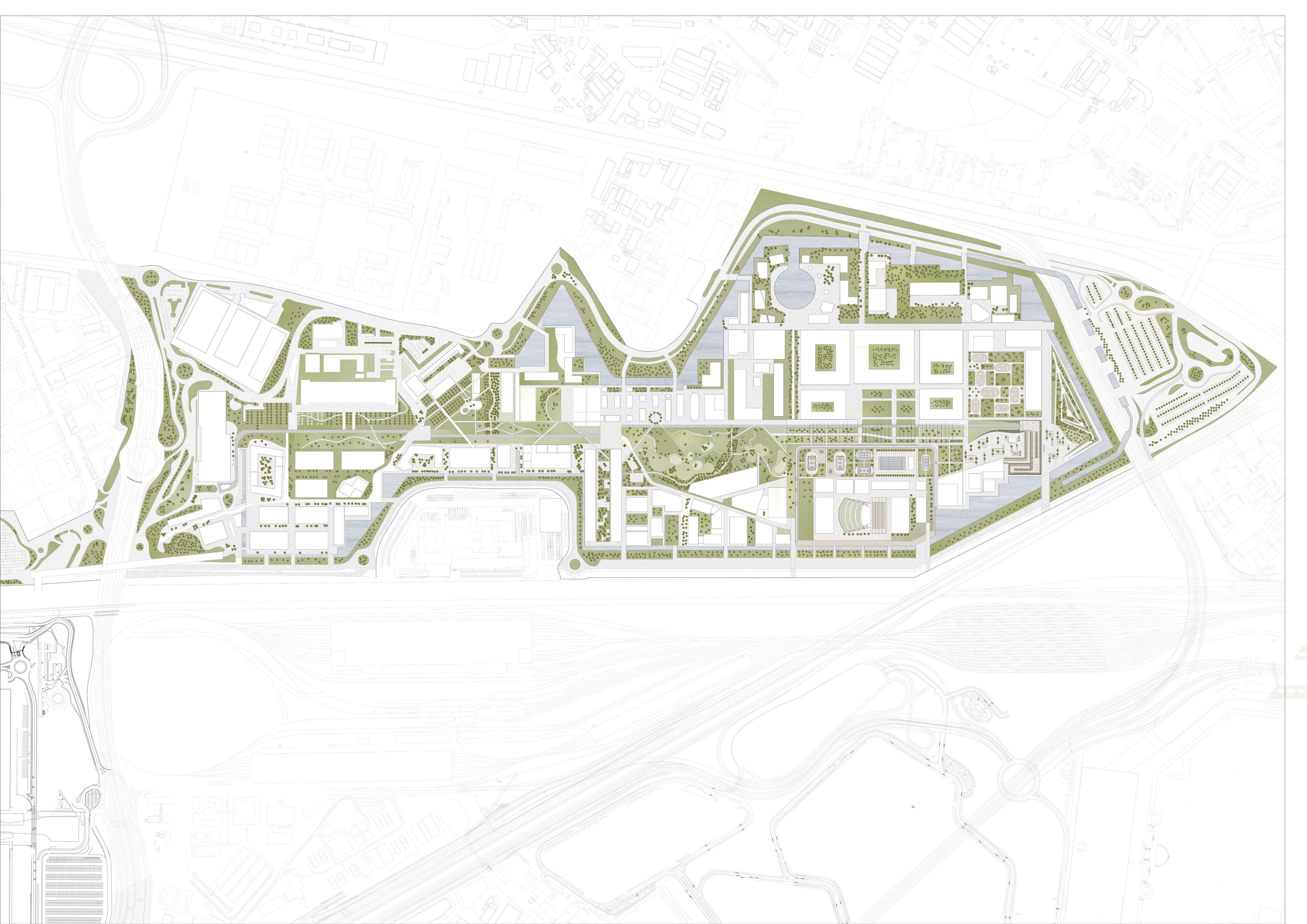

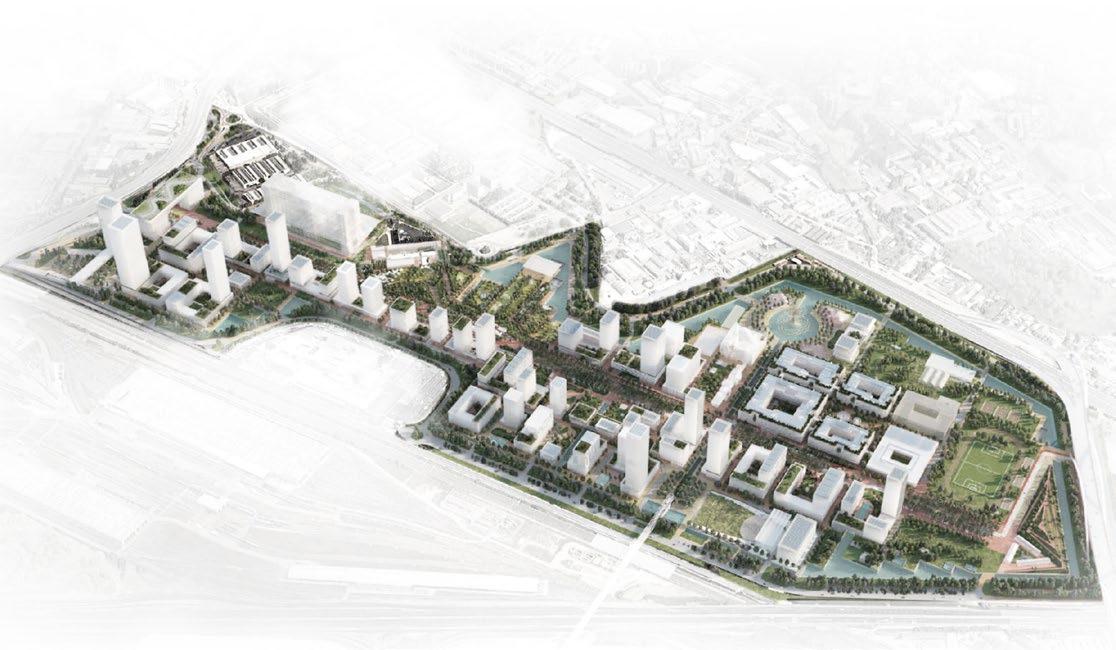

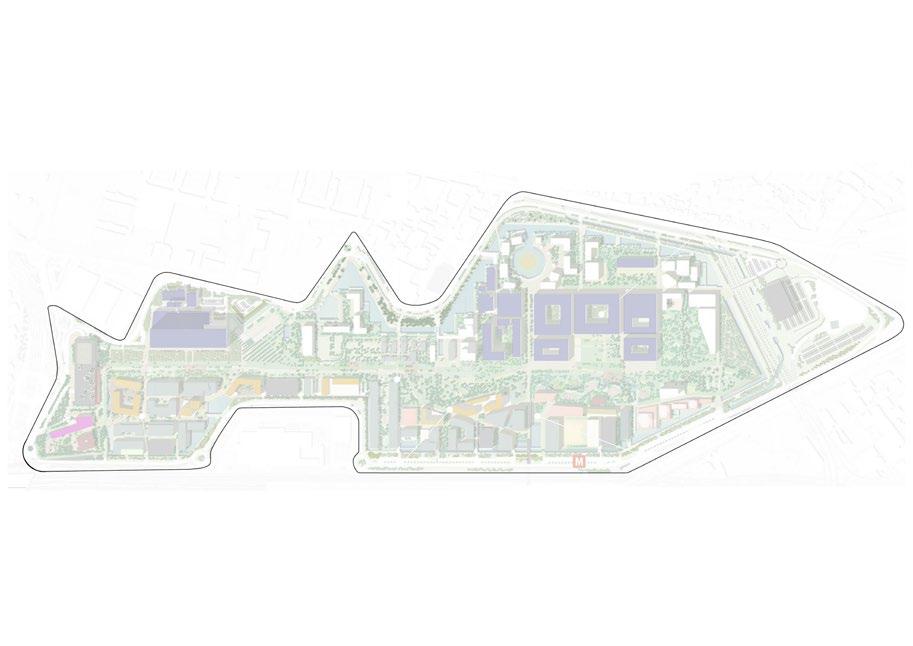

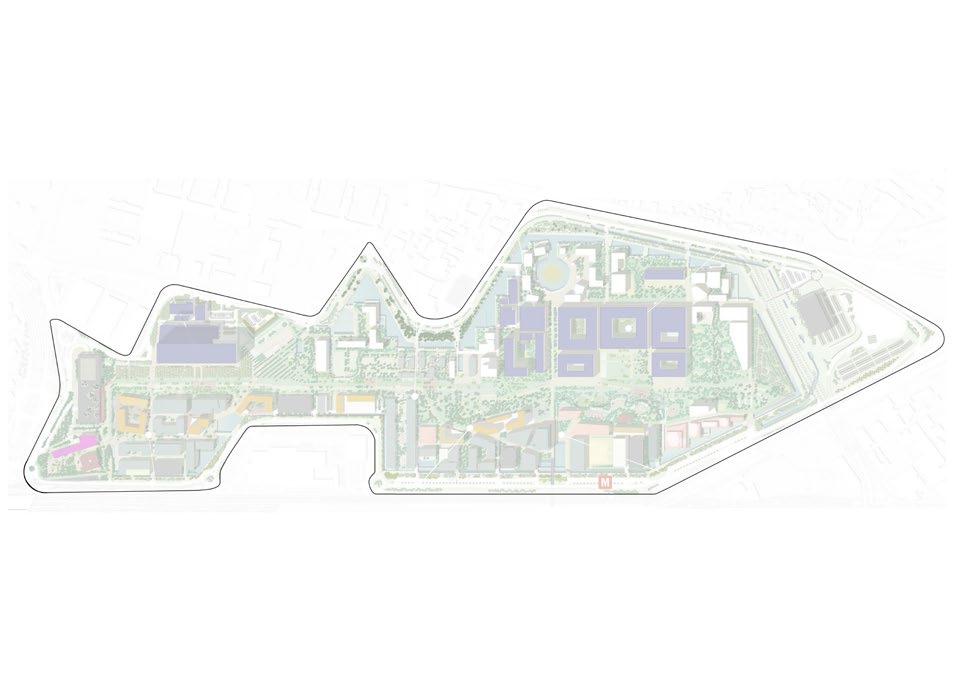

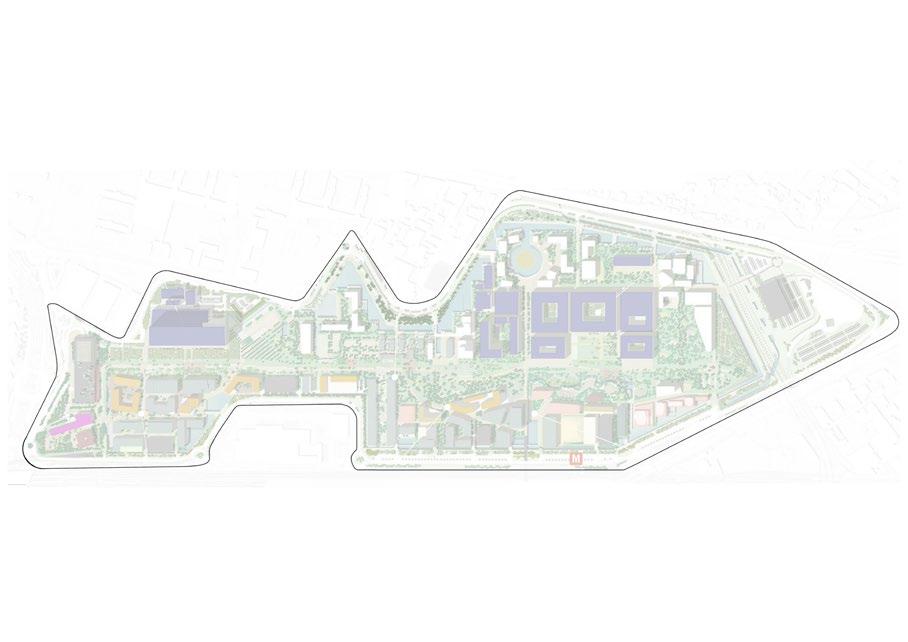

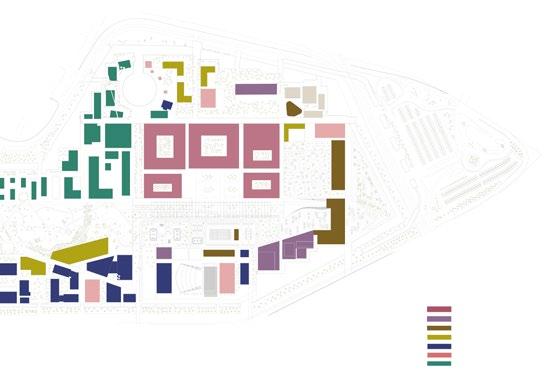

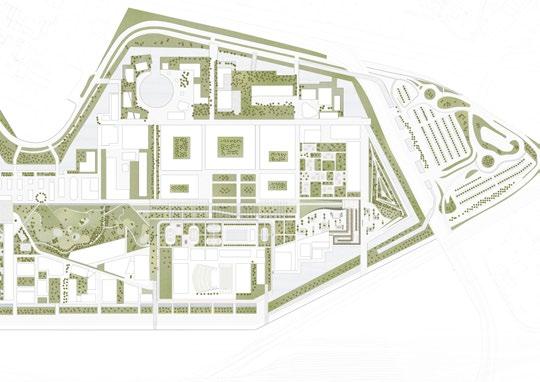

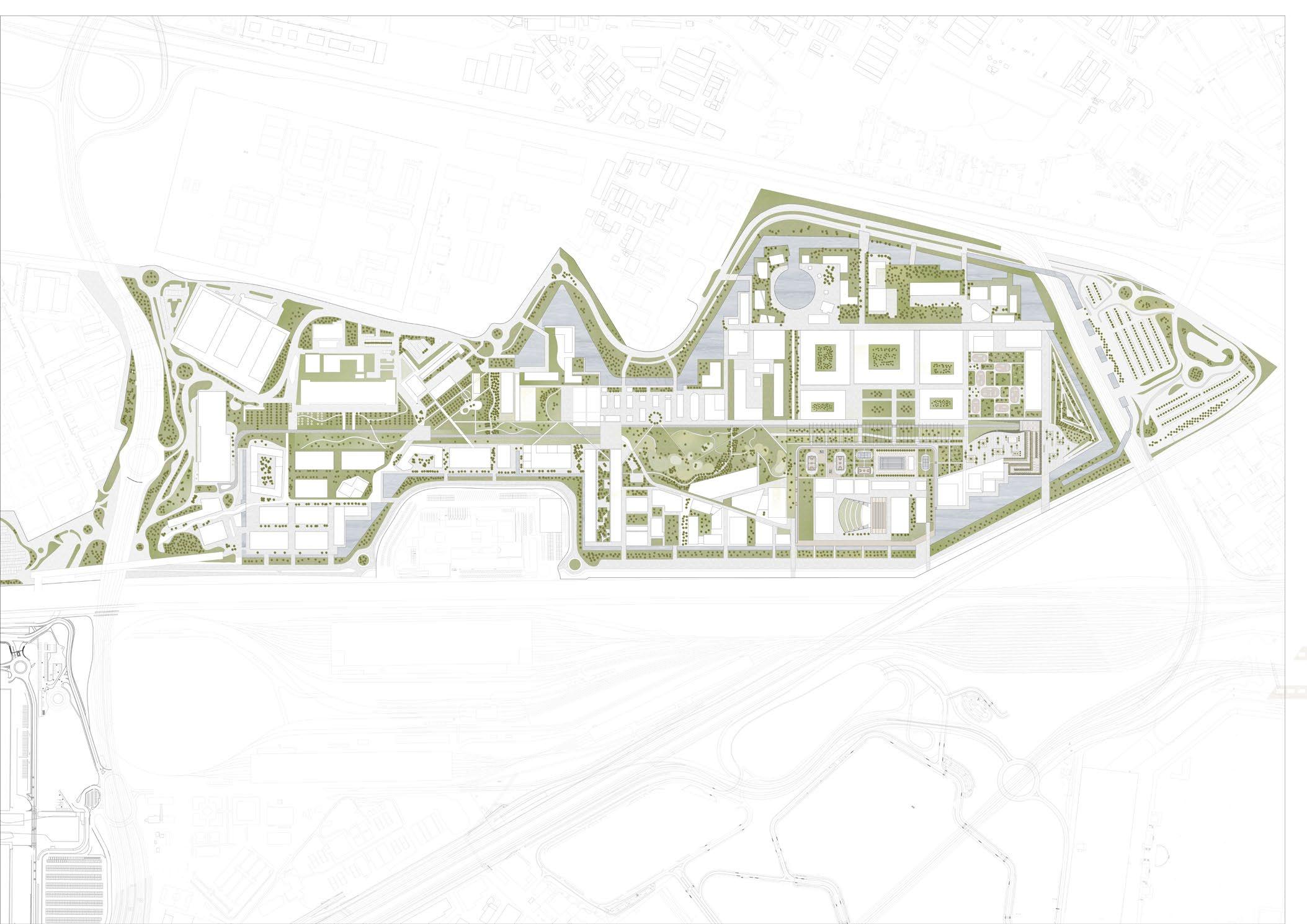

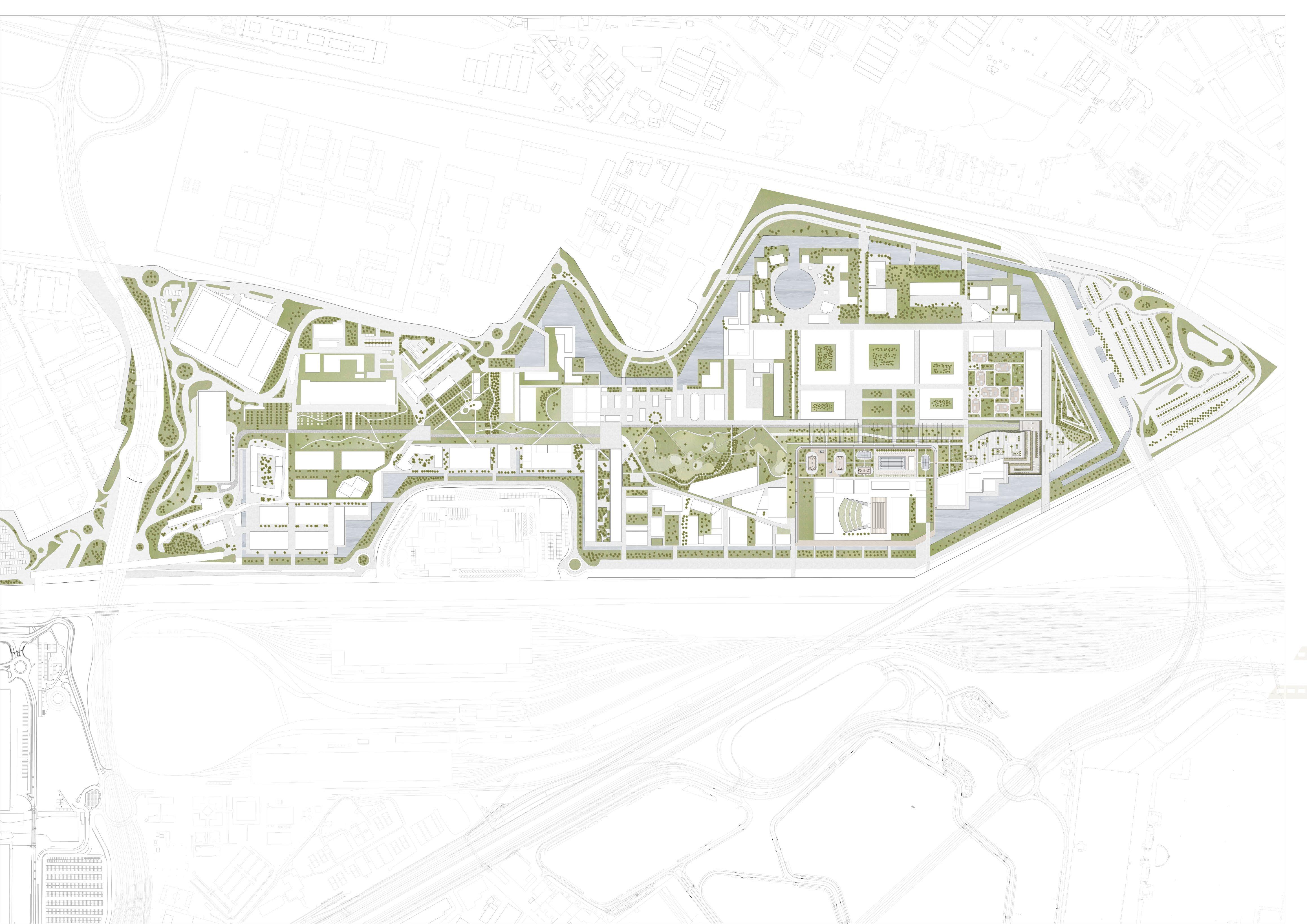

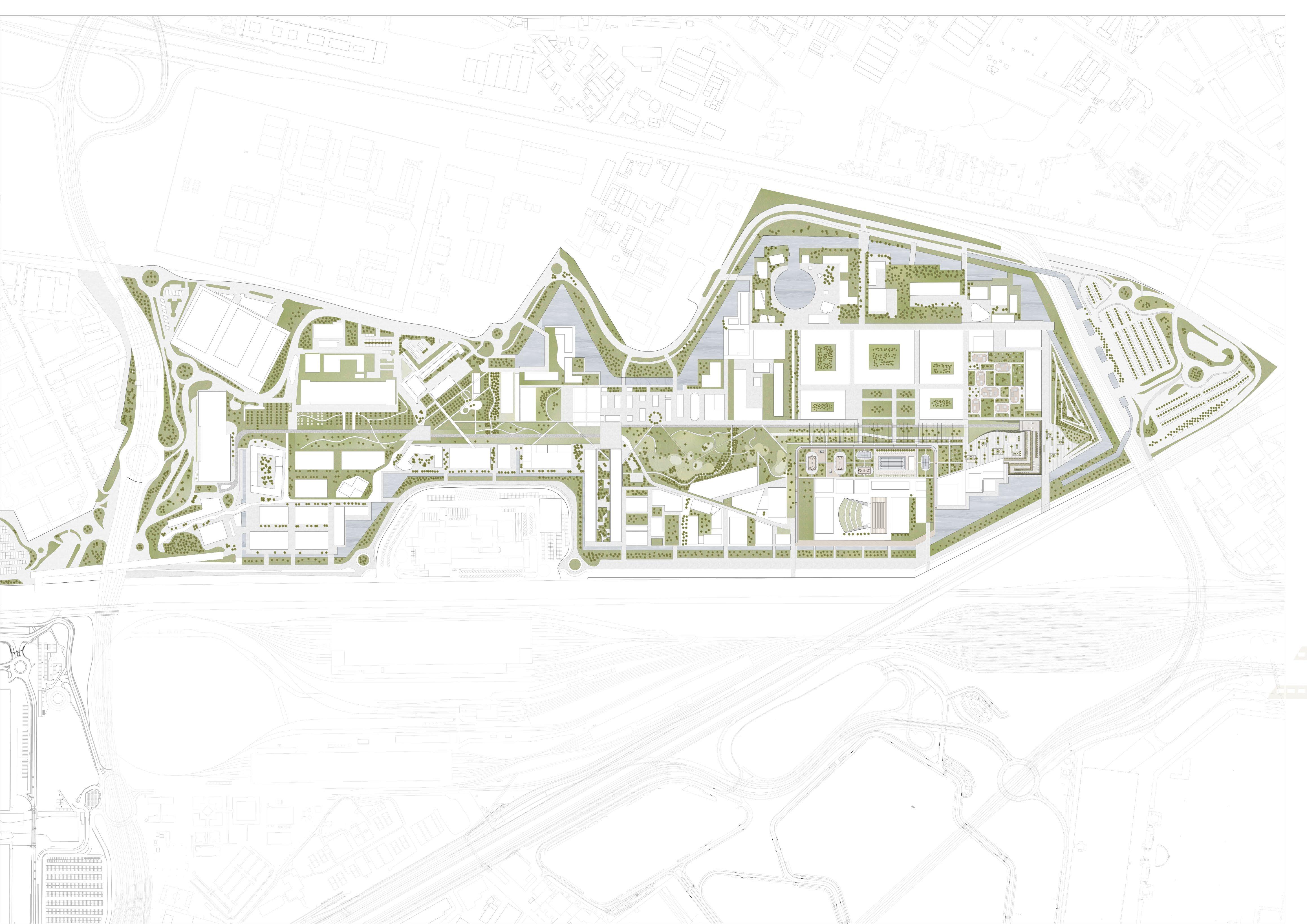

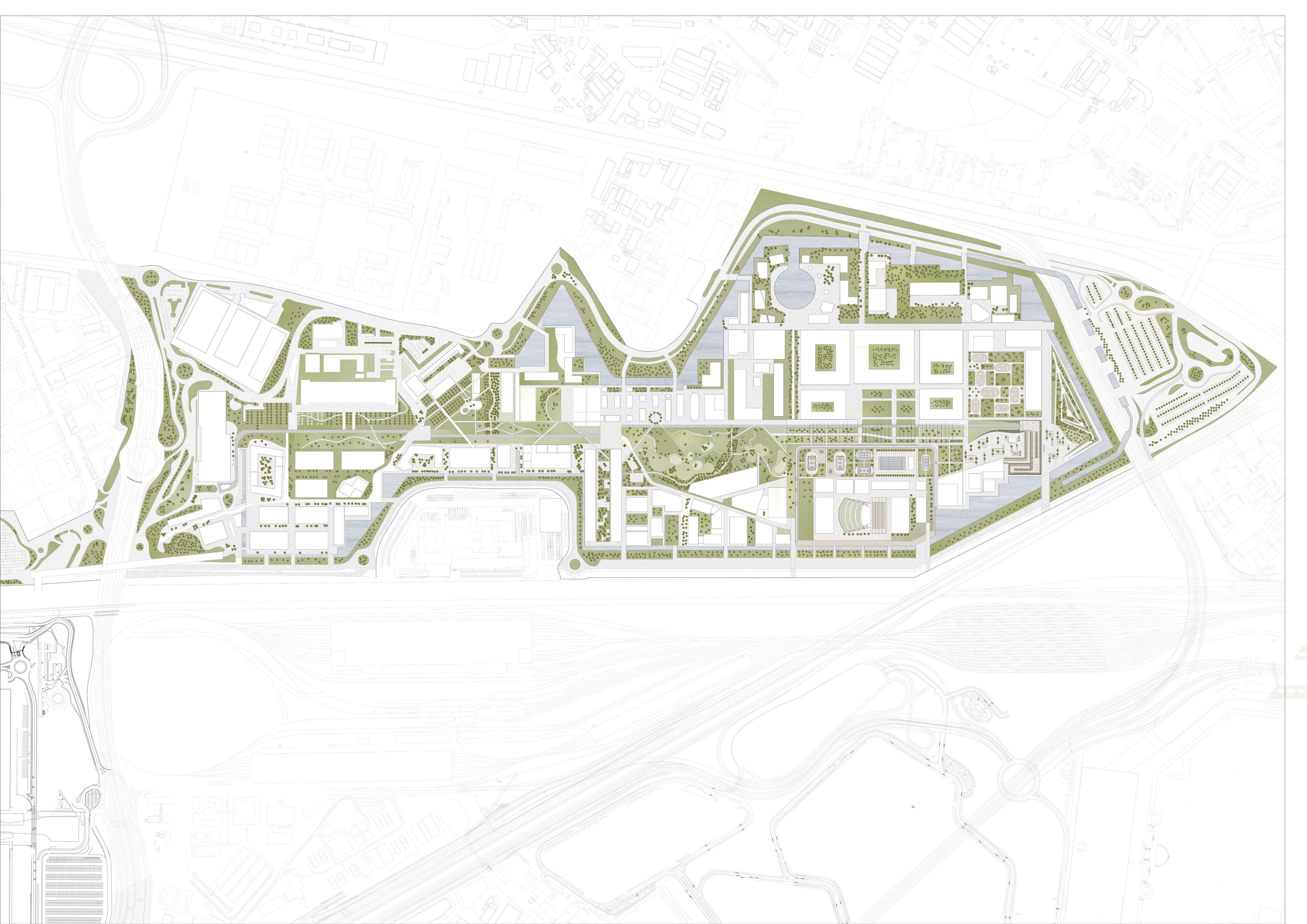

This part of the analysis is focused on the masterplan annexed to the Integrated Intervention Program that was signed in February 2020. Develop by Arexpo and Lendlease together with Carlo Ratti Associati, Land, Systematica, J+S, Bemaa, Rossi Bianchi, and GAD, the masterplan proposes a different urban arrangement even though having the same Guidelines of the first plan as a framework. All the three districts envisaged - West Gate, Green Heart, and Knowledge Hub - are considered entirely to better understand the morphological structure of the district, focussing on urban grid-entries, greenery, blocks and buildings. A grid system, linked to external ring road through several entries served by bridges, is the framework to the design of the urban blocks

of the overall district: the grid system - redefined in its “expanded” meshes by Arexpo and Lendlease - greenery, networks, and open spaces are a significant legacy of the Expo 2015 in Milan As we observed in the previous drawings, the site preserves a green legacy, which MIND calls the Blue-Green Belt. Greenery surrounds the area and spreads inside, following the same route as water, giving character to the context and proposes a chance to experience nature. The green system is then implemented with a large multifunctional theme park that develops as an ecological and social infrastructure along the Decumano, the Park for Healthy Eating and the Sports and Entertainment Park

30 MIND Site Analysis

Fig 42: Grids, MIND, Authors

Fig 43: Greenery, MIND, Authors

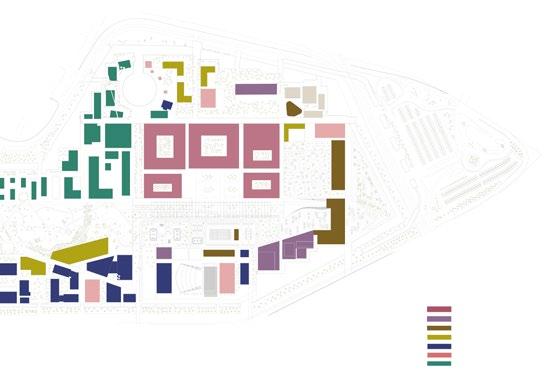

Blocks and buildings analysis is essential to read the “texture” of the site and understand its scale. The urban grid defined by the PII’s masterplan in 2019 acts as a reference system, a “framing tool”, to recompose the main axes and pedestrian paths in an overall framework, completed with the new interventions. Specially to the south of Decumano, within the private development sector, the large meshes of this urban grid don’t define in reality the “urban blocks”, but wider urban lots to be further articulated. The urban texture is so marked by a high diversity in morphology, determined by adding an axis with different orientations and a further minor pedestrian path to generate a “fine” urban grain, which leads through the blocks to coincide with single buildings (i.e., West Gate).

The flexibility of the land use mix and the fragmentation of the building permit into several sub-units to favour the adaptation of the project to future needs entails, in reality, the risk of weakening the control of the unique urban character of the district, as the “ scenarios” prefigured for MIND already suggest. To the north of Decumano, the presence of the major public functions working as urban drivers - the Human Technopole research center, the new Galeazzi hospital, and the new campus of the State Universityinstead allows the recognizability of the urban grid. For this reason, the “blocks” evidential in the scheme indicate wider compounds, including textures responding to different morphological rules.

31 MIND Site Analysis

Fig 44: Blocks, MIND, Authors

Fig 45: Buildings, MIND, Authors

east gate analysis

Main axis Secondary axis Entrances

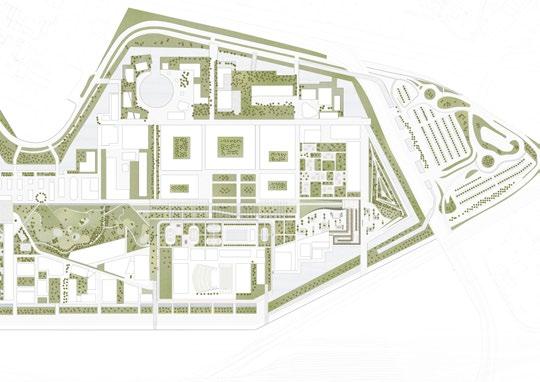

The main backbone of the site is Decumano, the Linear Park, and it continues all along the district, from the West Gate entrance to the Mediterranean Hill. The Cardo - a water Boulevard in the heart of the new Innovation district between the Human Technopole and the State University - collects the flows instead from the main access from the Cascina Merlata district and the routes crossing the perimeter Green-Blue Belt.

Fig 47: Greenery, East Gate, Authors

As mentioned in the previous chapters, MIND maintained existing greenery at the site. The Research Center for Natural Sciences master plan aims to respect the existing green texture and improve its quality, including new sports facilities or working areas within the different zone of the park. So, the ratio of the greenery guaranteed by the redefined master plan of the Knowledge Hub District is equivalent to the one provided by the official PII.

Fig 48: Built-Unbuilt, East Gate, Authors

During the design of the new master plan, different urban strategies and rules have been instead applied in revising the foreseen urban blocks to respond to the urban, programmatic, and functional requirements of the new intervention. The “BuiltUnbuilt Space” diagram shows the association between built areas and overall context.

Fig 49: Functions, East Gate, Authors

The area mainly consists of education (UNIMI) and cultural, public,retail and residential buildings. The Research Center for Natural Sciences location is close to the cultural and educational zone, which was one of the essential criteria that affected the building`s function.

32

Fig 46: Accesibility, East Gate, Authors

East Gate Analysis

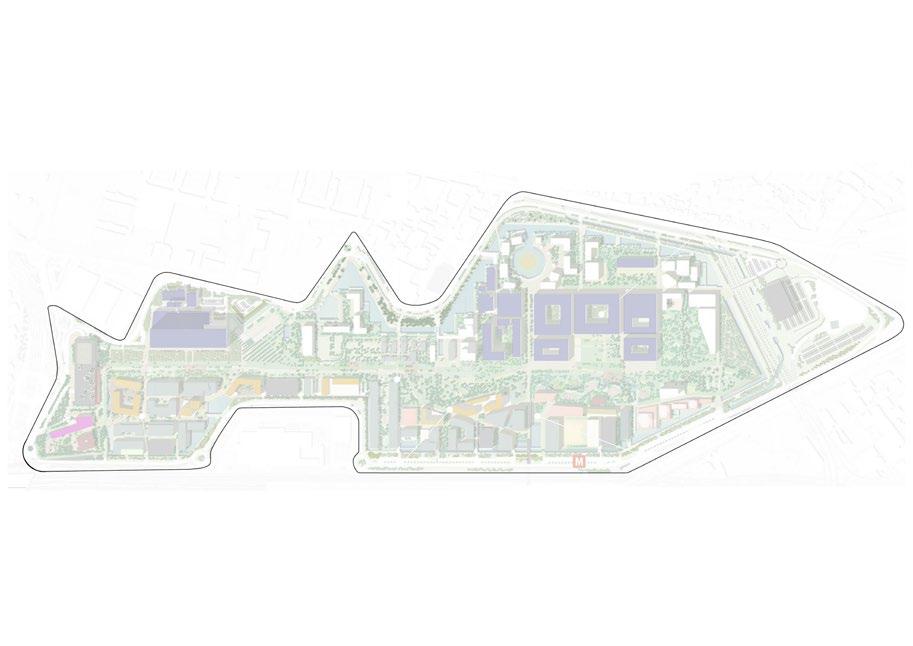

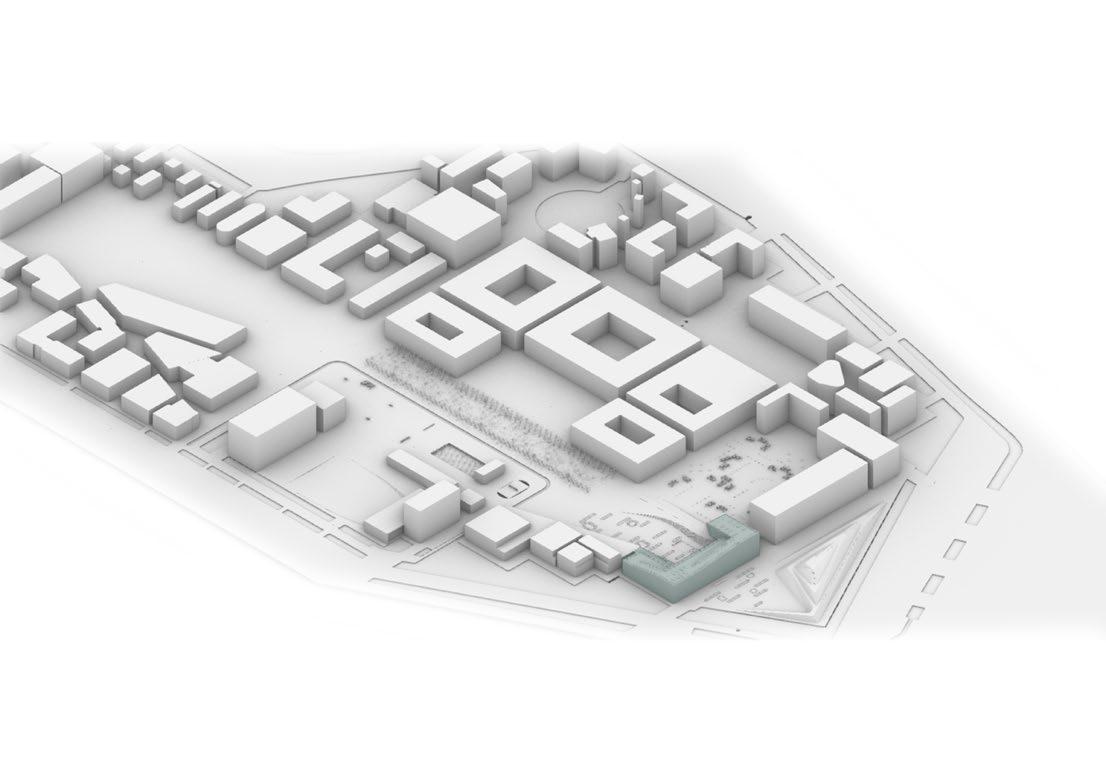

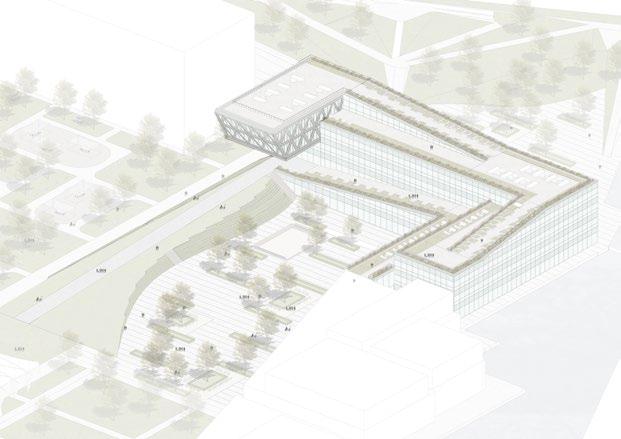

Master Plan

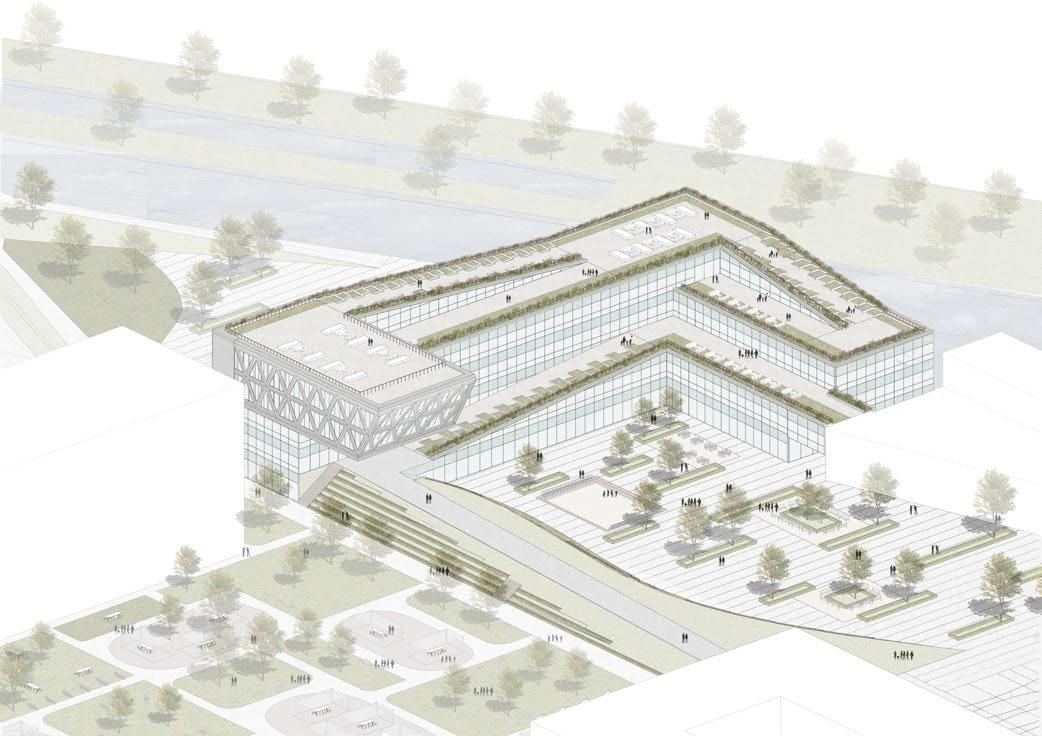

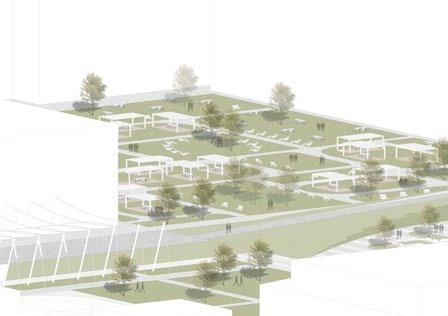

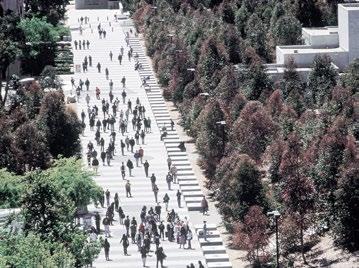

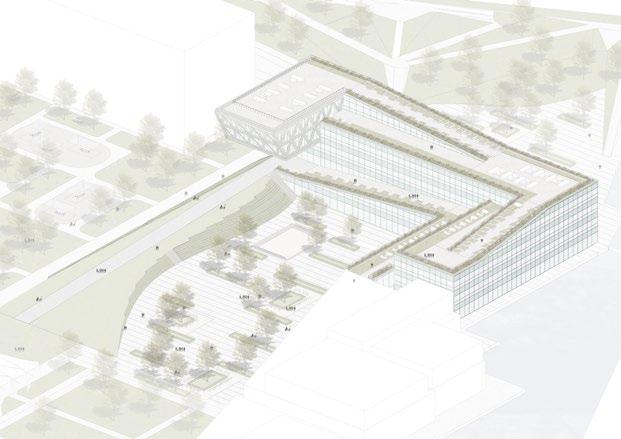

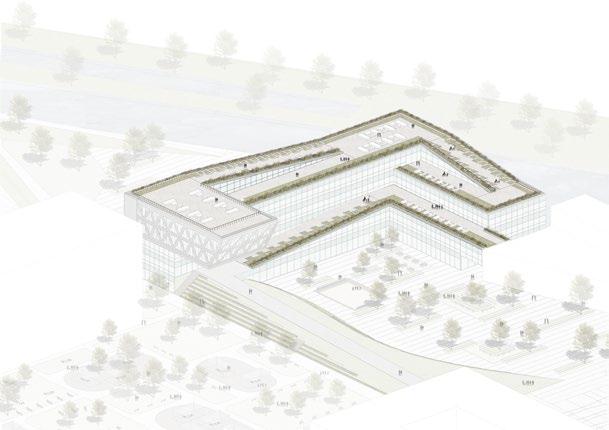

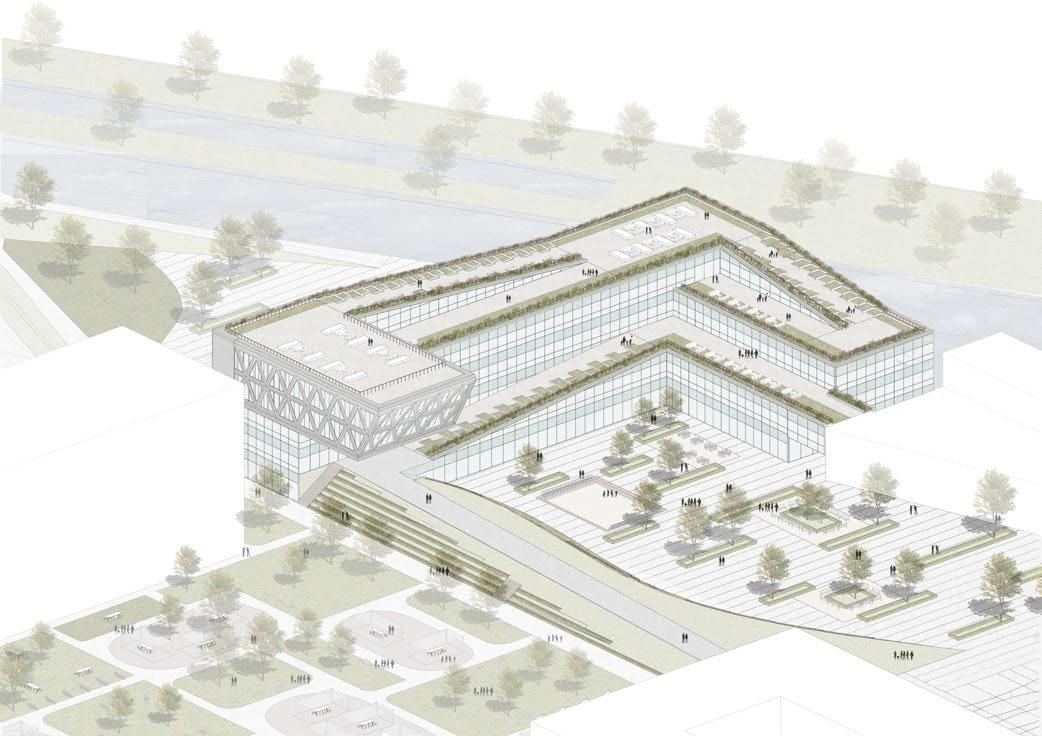

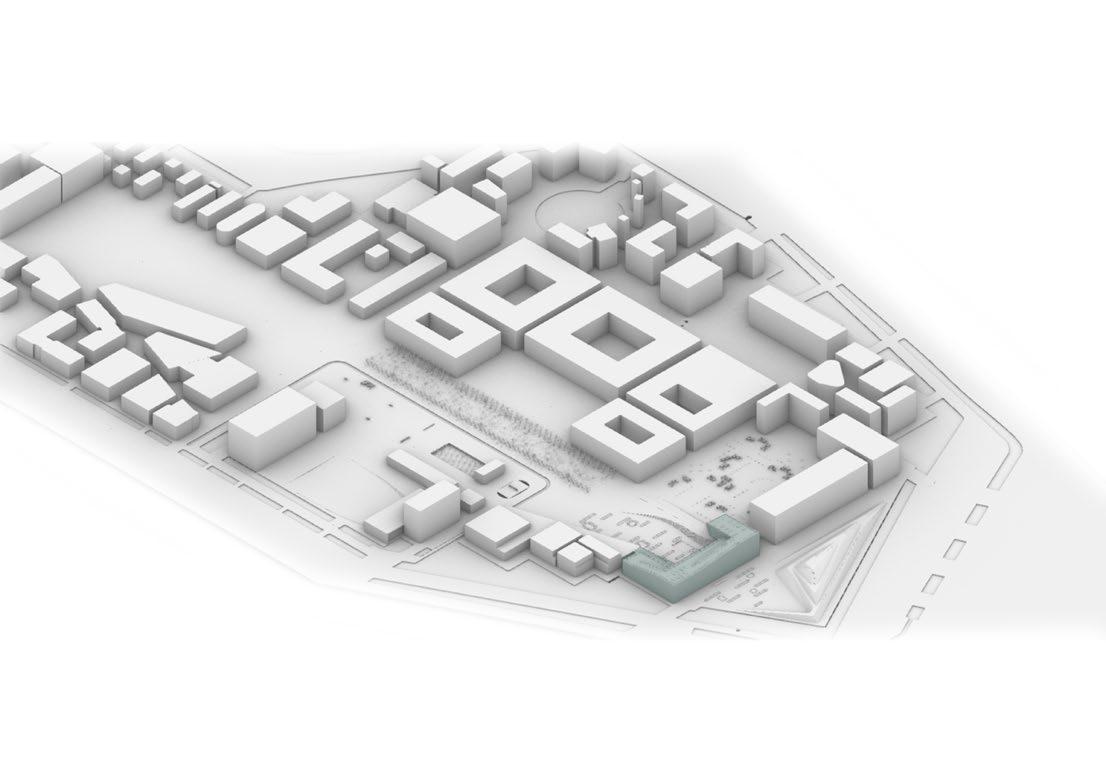

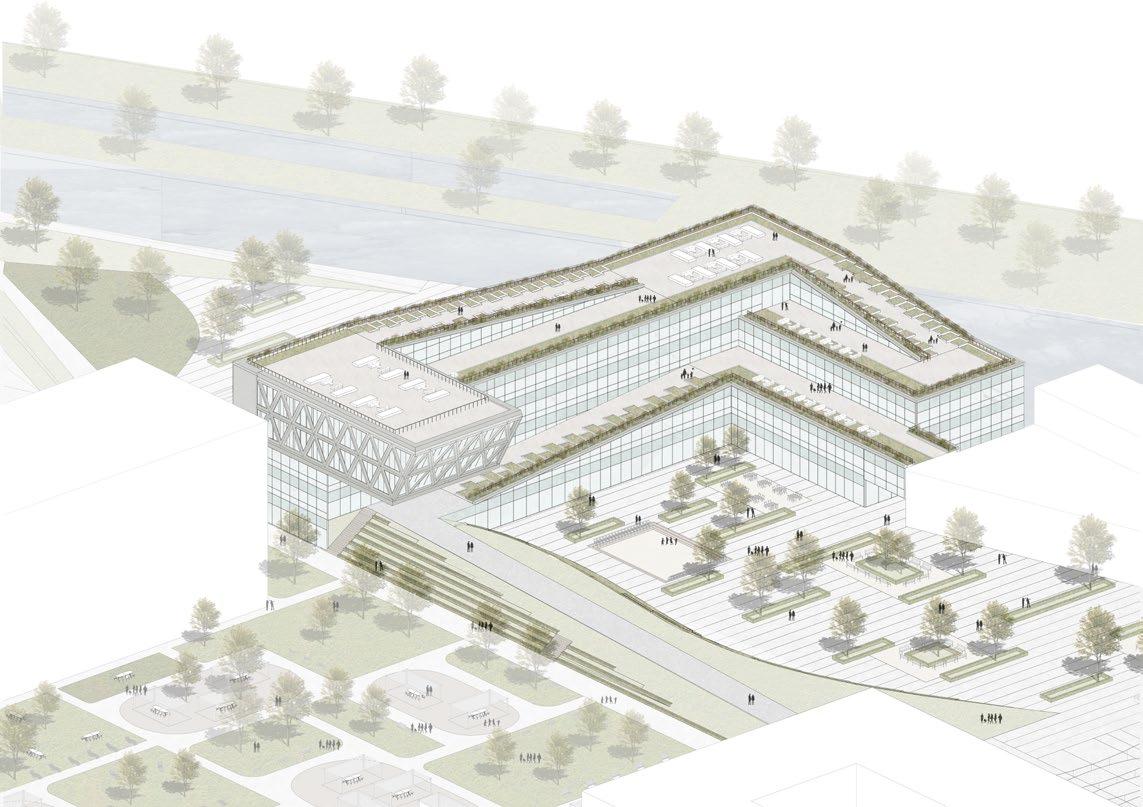

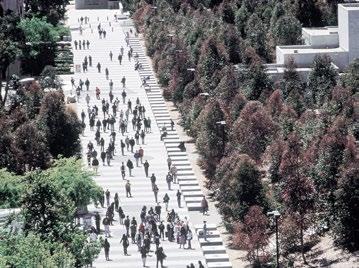

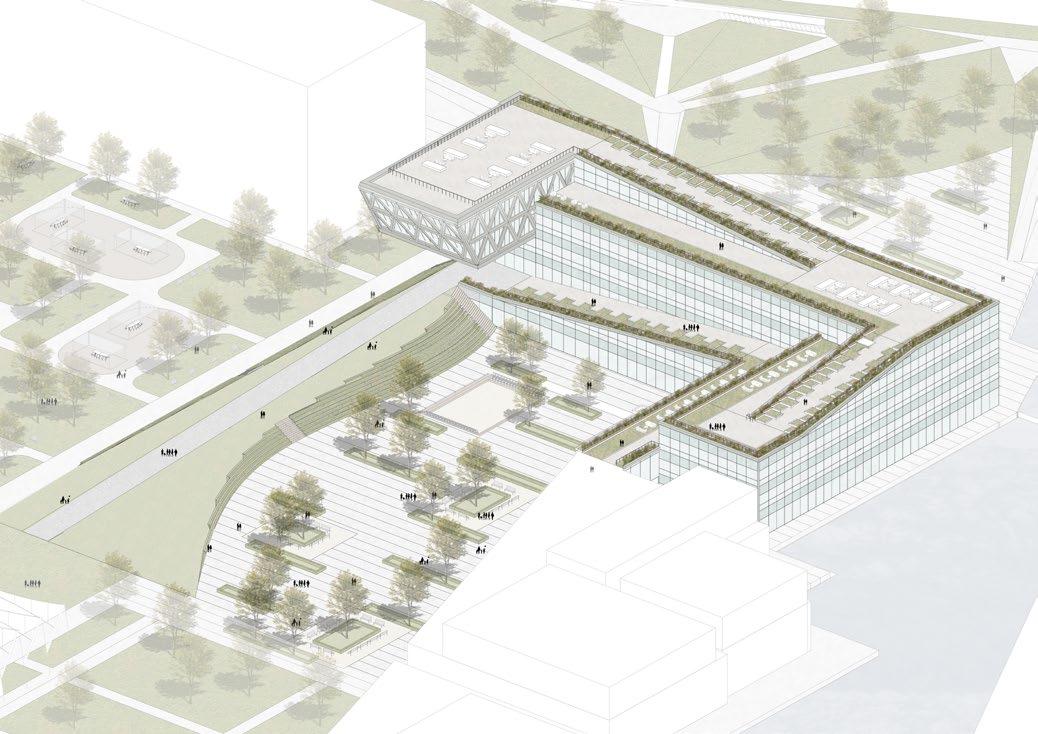

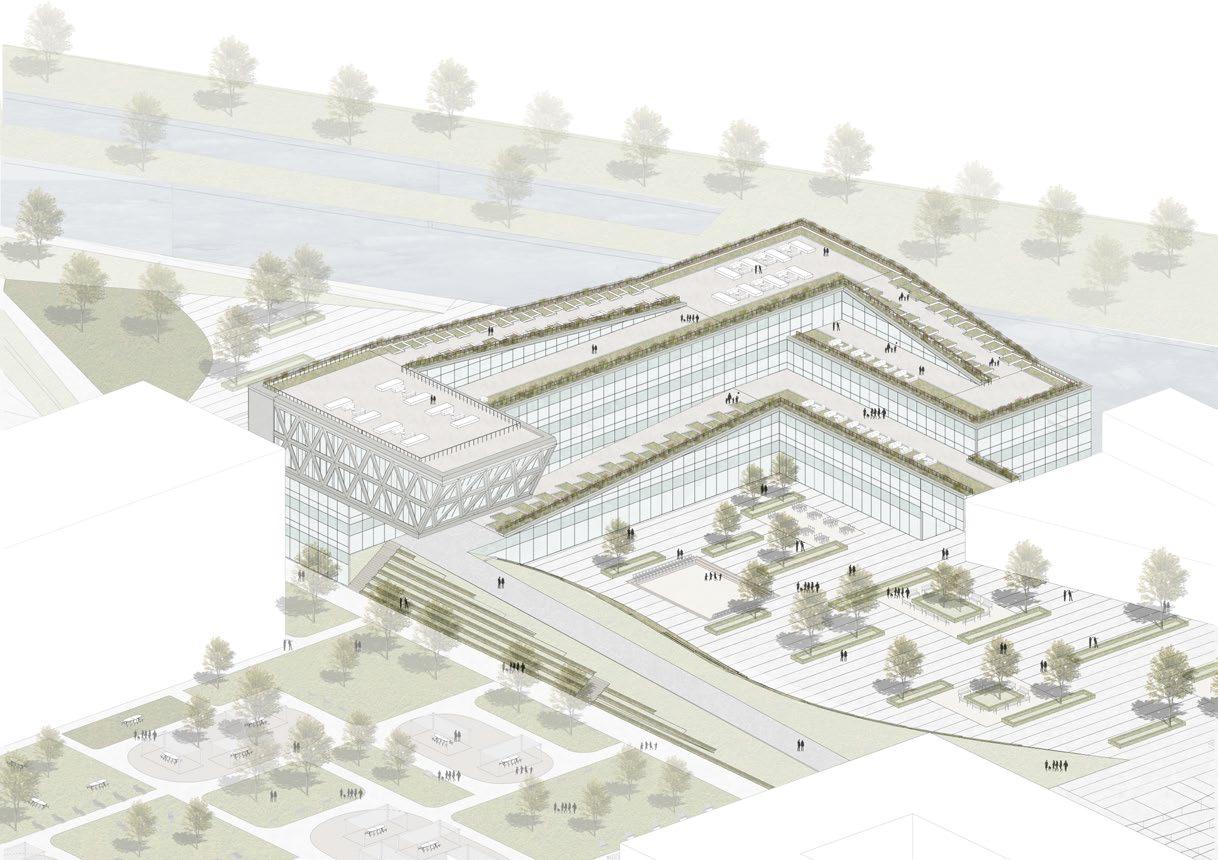

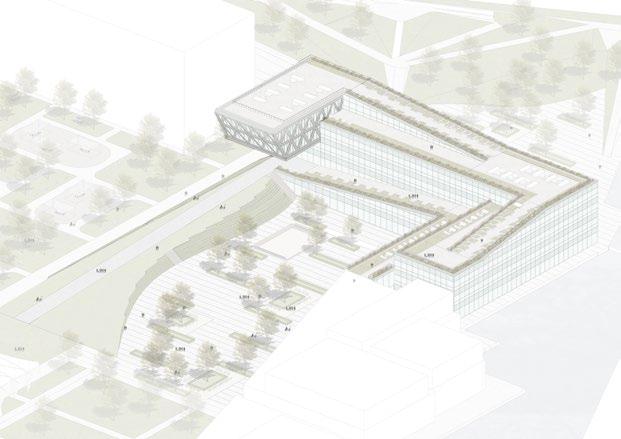

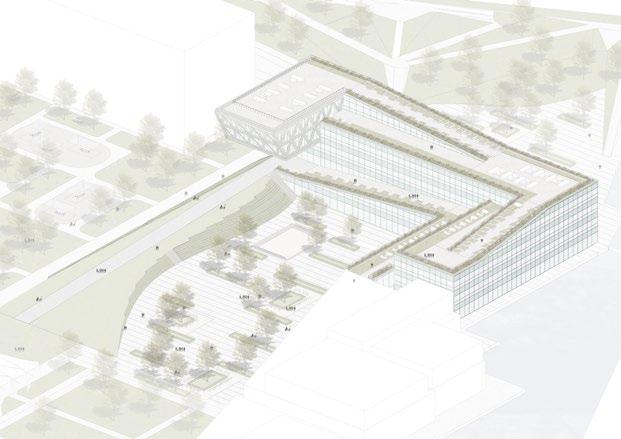

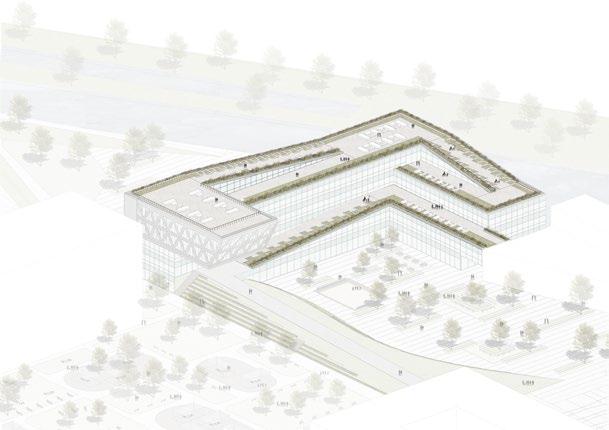

Fig 51: Perspective, Master Plan

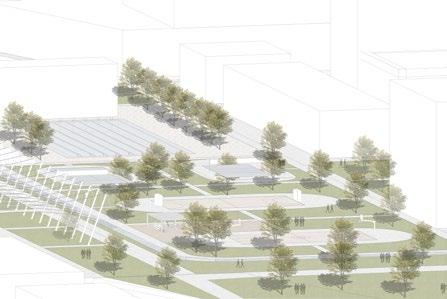

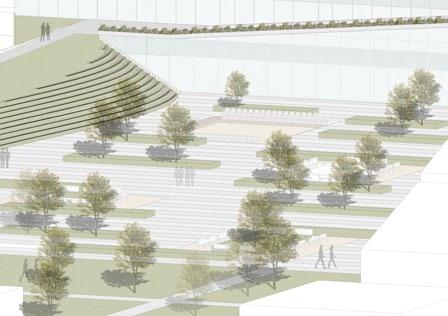

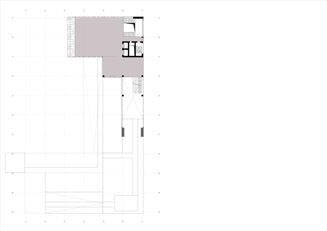

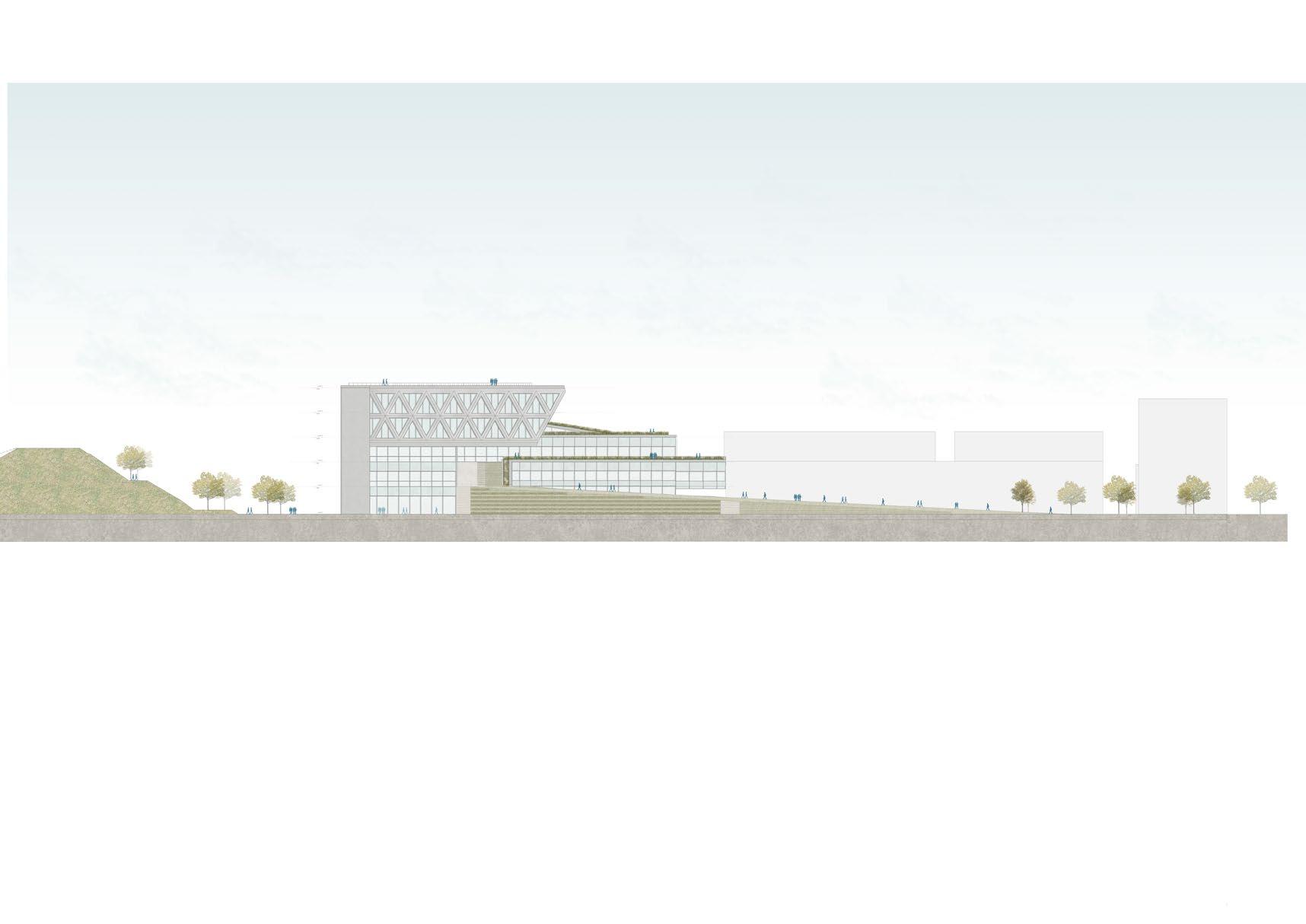

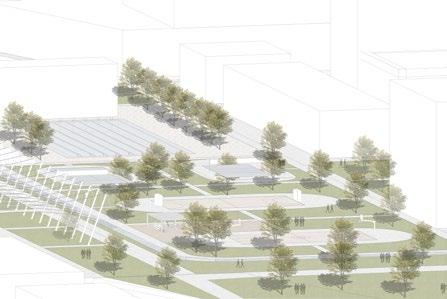

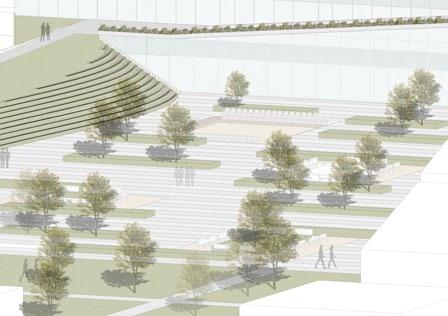

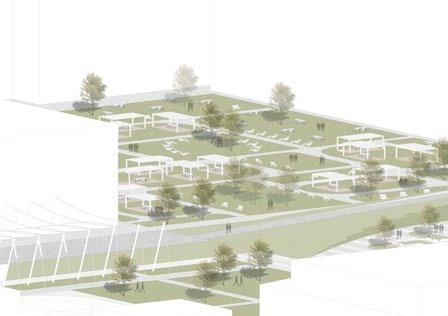

The Research Center for Natural Science is located at the East Gate of the MIND, within the Knowledge Hub. The urban strategy guiding the modification of the official master plan and the new landscape design for the Sports and Entertainment Park is to reinforce the ending part of the Decumano and its surroundings. The open spaces network and the park are articulated in different zones - including sports areas, digital parks, and event spaces, in accordance with general prerequisites of this District – to modulate the scale of the site and offer a rich, varied, and humanized environment, wherein each part can play a specific urban and social role. The articulation of parts of the Park is defined starting from the “grid” of paths that lead from the perimeter bridges, crossing the Blue-Green Belt, to the Linear Park which develops along Decumano. Trees are used as filtering in-between spaces. Especially trees chosen for the sports area are more elevated than in the quad facing the Research Center, especially to provide the needed privacy and protection to the sports field and open-air pool.Except for the event area, the project primarily consists of greenery, which is related to the “preserving nature philosophy” that shapes the main MIND’s green infrastructure.One of the vital design points aspects of the Research Center for Natural Sciences is the green pathway that, starting from the Linear Park, as a

“green strip,” keeps getting elevated as a slope and introduced into the building. While going through the journey along this lightly inclined route, the large artery slowly meta-morphs itself into the roof of the building. This gives the pedestrians a sense of movement and, thus, also a better experience of the surrounding context. This lightly inclined route surrounds the event space partially and turns into an open amphitheater, where the events are held. It invites people towards the Research Center and defines the neighboring open spaces, offering another “panoramic” ground floor at the higher levels and contributing to the vitalization of the place. Being a “natural border” for the different open spaces, the green ramp reflects and strengthens its edge by changing the material finish of the area. The chosen materials for the changes depend mainly on the zones, which are stone (darker, lighter), wood, and greenery, consistent materials with each other and suitable for the general concept. Overall, the master plan of the Research Center for Natural Science’s scope of intervention is marked by sustainable attitude and collaborative design principles, aimed at developing, in accordance with the landscape strategy foreseen for MIND, the multifunctional theme park as an ecological and social infrastructure, taking into consideration not only present but also future community and its necessities.

34

Master Plan

Zone 1 : Sports Area

Zone 2 : Digital Park Zone 3 : Event Space

Zone 1 : Sports Area

Fig 52: Zones, Master Plan, Authors Fig 53: View from sports area, Authors Fig 54: View from digital part, Authors

Master Plan

Fig 55: View from event space, Authors

36

Master Plan

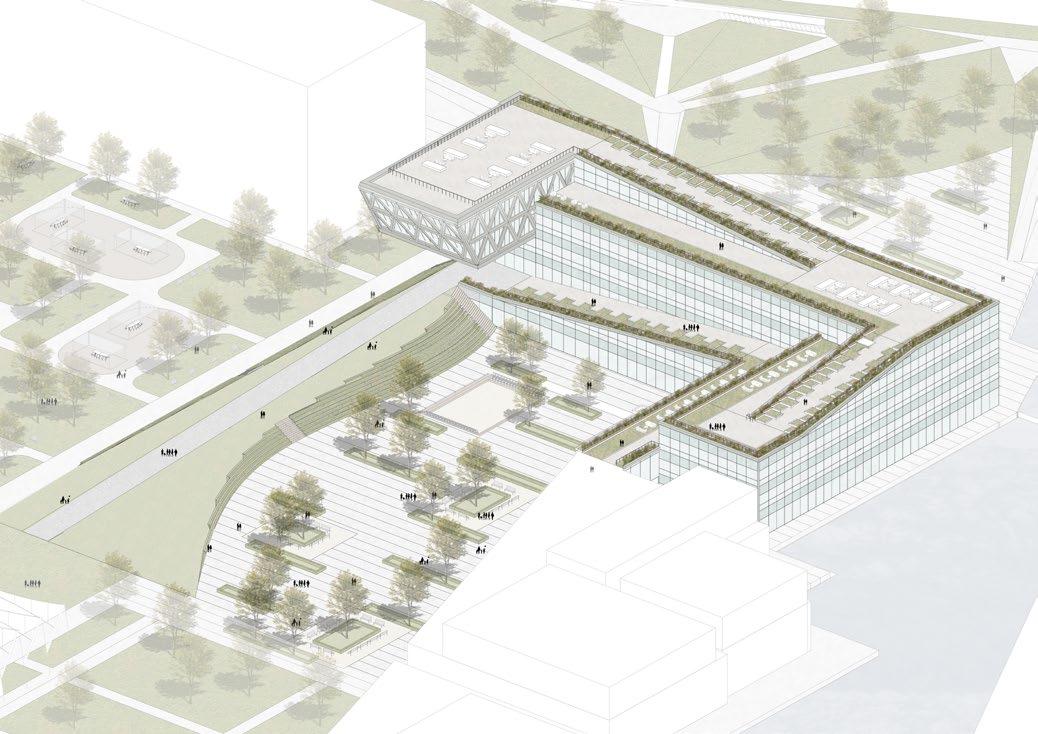

Fig 56: Axonometry,Research Center for Natural Sciences, Authors

Digital park is located near the hill and northern part of the Research Center for Natural Sciences. Buildings surround the area, aiming to give consistency to the space. In the first phase, the horizontal grids are specified by considering UNIMI, and the vertical grids are placed. The area consists of study places, walking paths, and relaxing areas. The relaxing part is located in the center of the park, a design concept inspired by BAM Biblioteca Degli Alberi Milan. These places are multifunctional, people can exhibit their digital artwork.The working spaces are made from wooden pavement to provide a warm atmosphere, and the other parts combine with concrete and greenery. Trees are encountered all around the area to provide privacy.

The area is located at the intersection of UNIMI and the Research Lab for Natural Sciences.It consists of a basketball court, tennis courts, an open swimming pool, a running track, and indoor facilities. The primary design concept was dividing the horizontal space into grids, and these grids connect to the main backbone,decumano. These grids are called walking paths and turn into the bridge when the water exists. The water covers the zone with a running track; it is one main partition element. Sport is one of the significant activities that connect people. They could socialize and change their atmosphere at work. However, to provide this, it was essential to give this place privacy, so when people come there, they should feel free. As a solution, trees and high vegetation are used as a filtering element, especially from the university. Mainly five elements are used during the design of the finishes. The area predominantly consists of greenery. The swimming pool has ceramic tiles for outdoor gym areas and a running track made from rubber. Tennis courts are assembled from asphalt, the walking paths are made of stone, and bridges consist of wooden pavement.

The event space is the place where the project proposes itself and welcomes people. It is located in front and back of the building and connects this zone until the end of the hill. The ramp is a natural border of this space and partially covers the space. The event space is placed where the open Amphi is, one of the central parts of the project. Considering the ground floor open dining areas close to the restaurant, which has separate entry.

The area was designed with vertical geometry combined with squares and rectangles. These geometric portions are like small meeting zones with trees and greenery. Mainly stone material is used, and it is combined with greenery in some parts. The aim of having trees at that part is to have natural shading while people are disbursing time there.

Fig 57: Digital

Master Plan,

Fig 58:

Fig 59: Event area, Master Plan, Authors

Park,

Authors

Sport Facilities, Master Plan, Authors

Master Plan

Event space

`A community-connecting new park is advancing universal accessibility and ecological restoration. `The linear park is one of the largest urban open spaces and acts as a walkable green corridor connecting otherwise separate green space and integrating with surrounding.

Decumano, Linear Park

Its combination of poetic form, cultural expression and ecological restoration creates a multi-dimensional experience that many generations will enjoy. A solid commitment to improving the ecological system and a people-oriented spirit is manifested in design details.

One of them is universal accessibility on all pathways. These native plantings support the local bio-community and efficient reuse of existing materials and on-site facilities. Its vertical grid pavement design with greenery was passionate for the design of the event space ( zone 3 ) at the Research Center for Natural Sciences.

The project of Library Walk, encountered at the University of California, San Diego Campus, is a pedestrian walking path that runs through the heart of the studentservices buildings and concludes at Geisel Library.

The promenade provides much-needed structure and a key pedestrian link to a loosely planned and sprawling campus. The walk to be multi-functional, a location for campus gatherings and fairs throughout the year.

During the design process of Decumano and its side green parks, the design ideology is based on Library Walk`s concept. The linear Path continues with trees and vegetation to give a sense the walking in the park.

38 references

Jiading Central Park, Sasaki, 2013, Shanghai, China

Library Walk University of California, PWP Landscape Architecture, 1995, San Diego, CA

Fig 61: Waterfront, Sasaki

Fig 62: Open space, Sasaki

Fig 60: Park, Sasaki

Fig 63: Library Walk, PWP

Fig 64: Library Walk, PWP

Fig 65: Library Walk, PWP

References

Walkpaths - Water - Sports area

The Riverlight project located at the London,UK and built in 2016.It is landscape development of the residential project designed by Rogers Stirk Harbour Partners One of the inspirational concepts for our design was a river walk.

Digital Park- Relaxing areas

It is slightly raised to allow views over the river wall to the Thames — which opens up a stretch of previously underused waterfront. It was a connection between Research Center for Natural Science`s walking paths near the water.

`Gillespies’ designs have captured the particular character of these bodies of still water in a series of contemporary water gardens that sit within the residential gardens`

The park is located around Porta Garibaldi Station. The park works as an urban connector and botanical garden. Paths are drawn from different areas around the site, assembling a grid of relations that overlap and intersect.

Routes, jointly with the irregular fields that are created in between, underlying traffic tunnels, create sound walls.Vegetations have been chosen specifically to be consistent with the site by considering its conditions.

The concept of the open spaces, creating a tree library inspired during the design not only the digital park but also the complete master plan. Especially the relaxing zones have wooden sunbaths surrounded by trees parallel the BAM`s tree library.

39

Riverlight, Rogers Stirk Harbour + Partners,2018, London,UK

BAM Biblioteca Degli Alberi Milan, Inside | Outside Petra Blaisse, 2013-2018, Milan, Italy

Fig 66: Waterfront, Rogers Stirk Harbour Partners

Fig 67: Yard, Rogers Stirk Harbour Partners

Fig 68: Waterfront, Rogers Stirk Harbour Partners

Fig 69: Relaxing area,InsideOutside

Fig 70: Park,InsideOutside

Fig 71: Nature Park,InsideOutside

References

40

building design

3

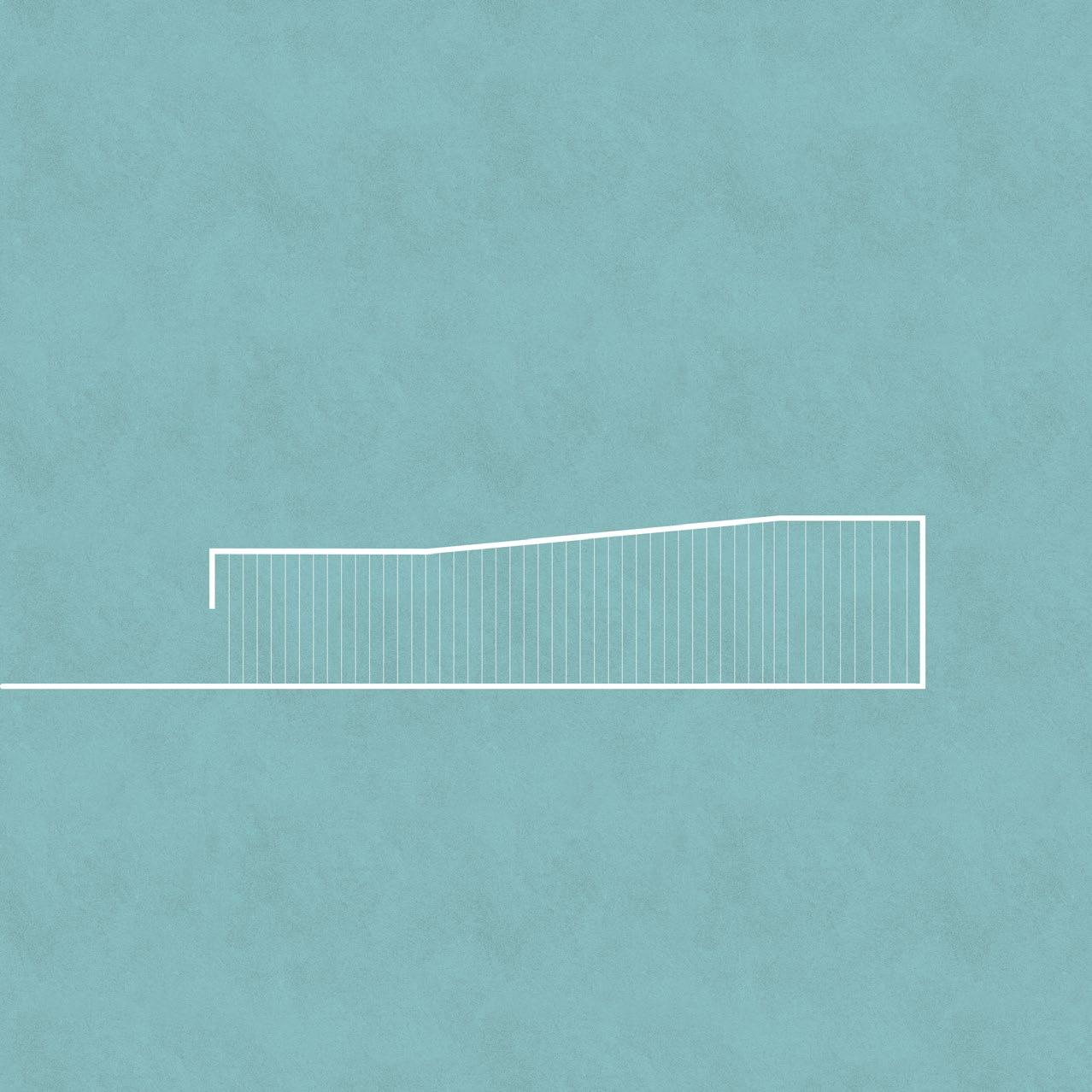

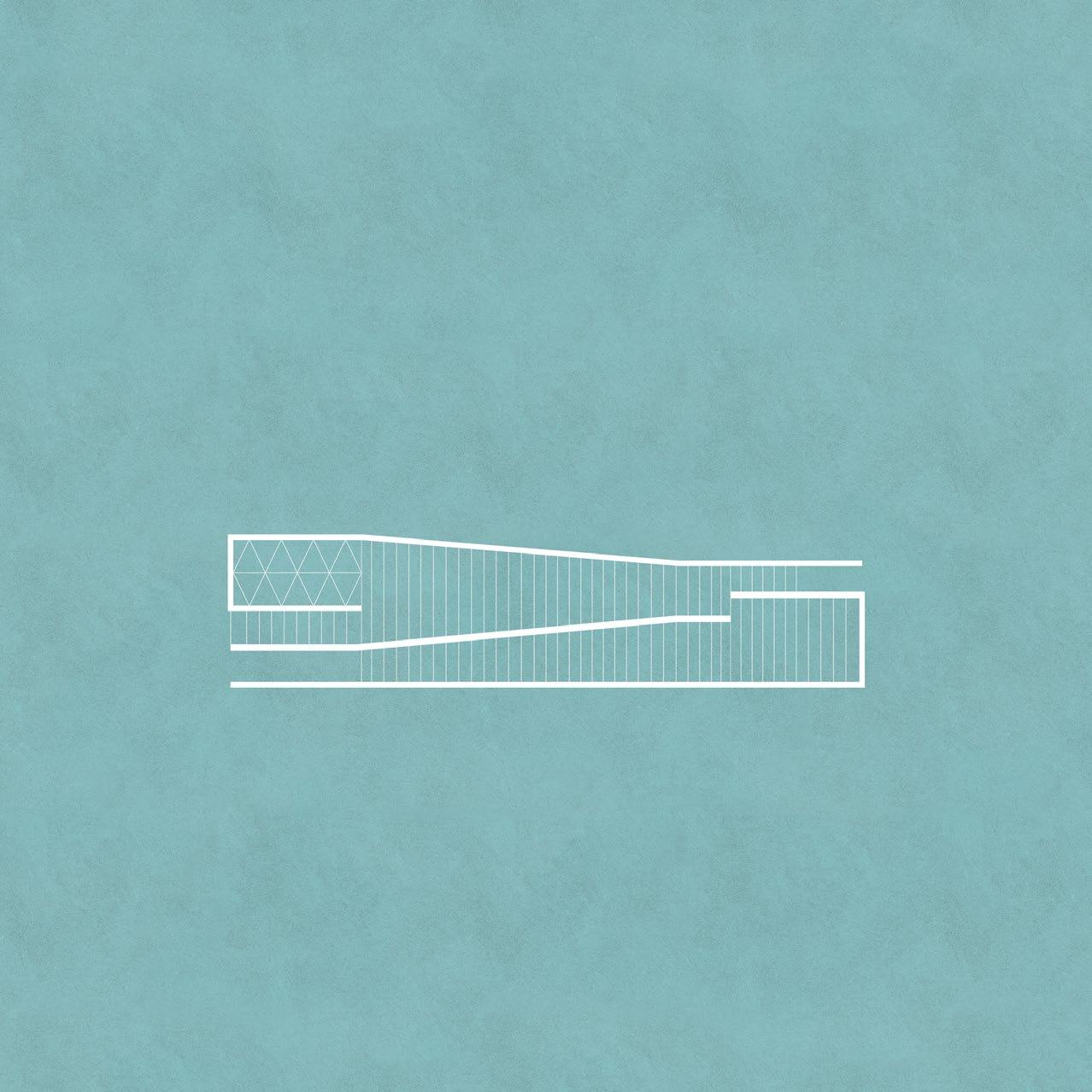

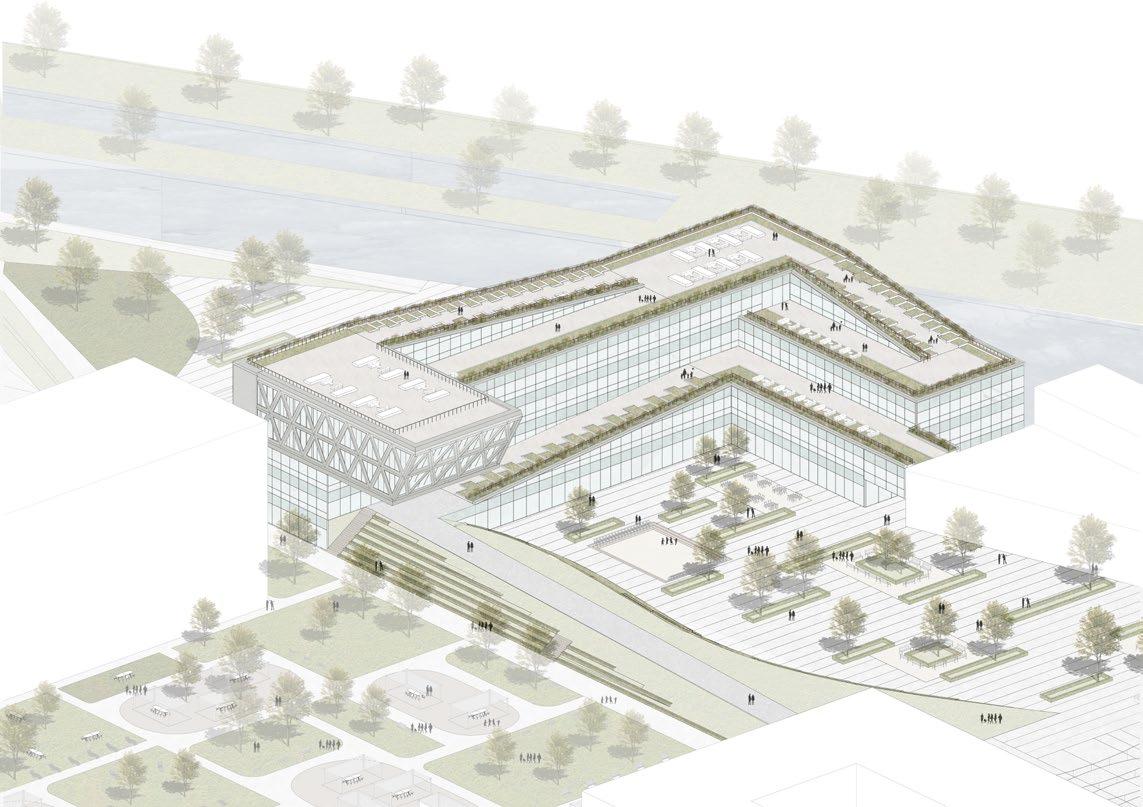

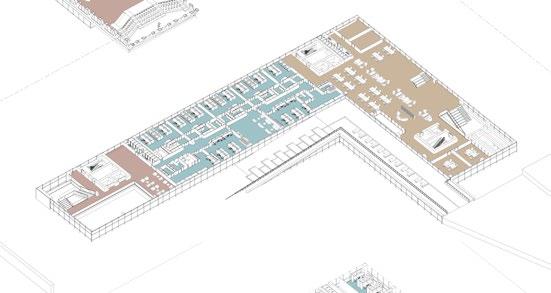

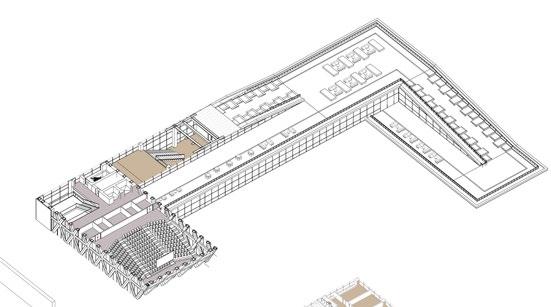

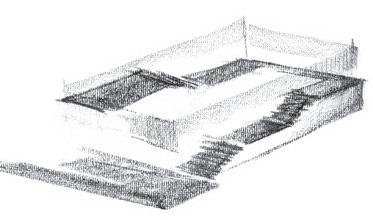

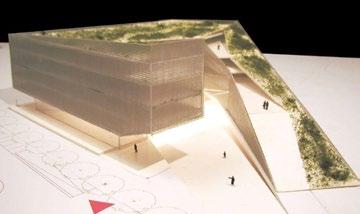

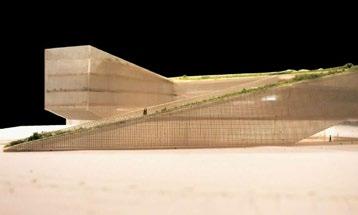

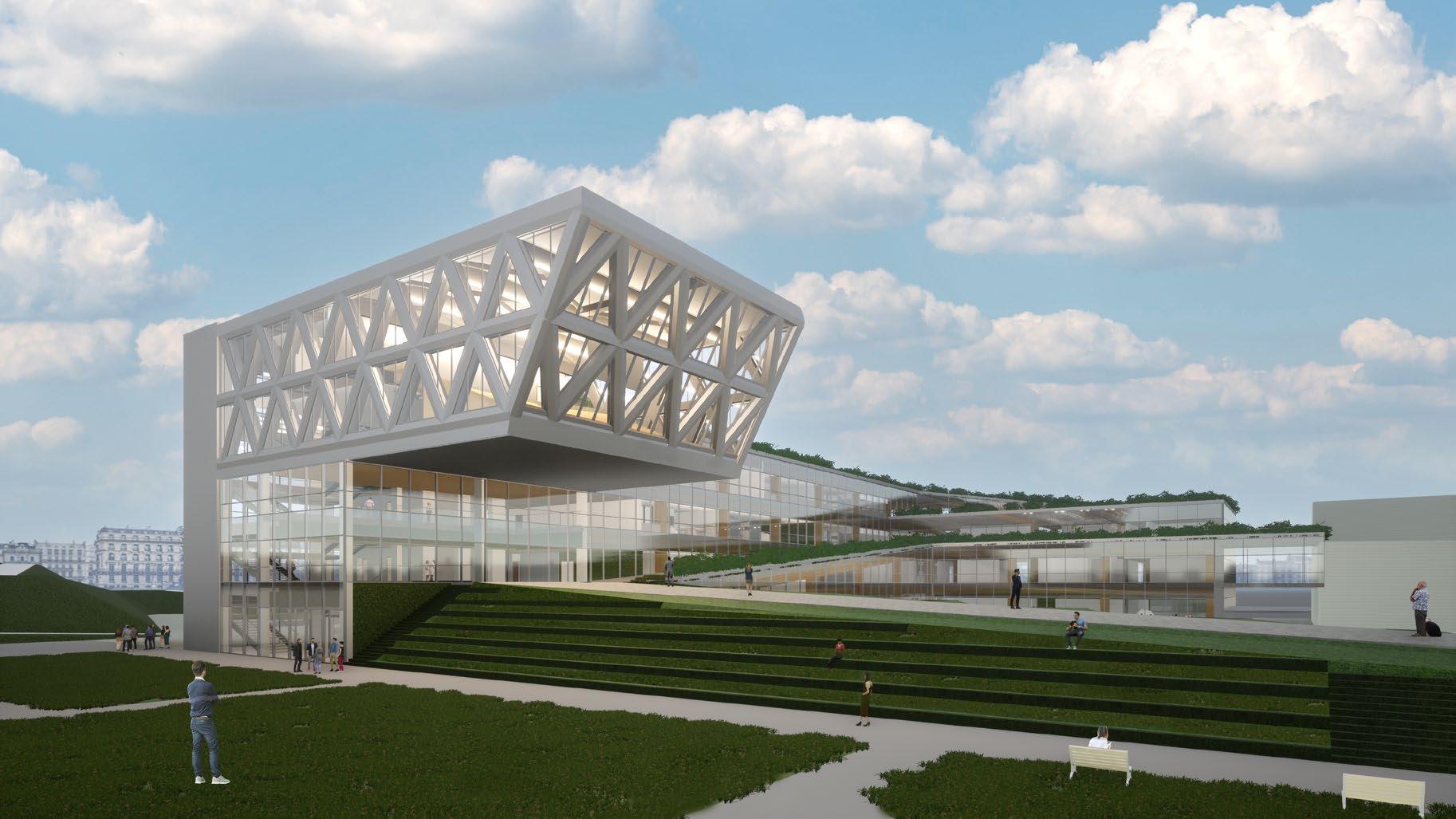

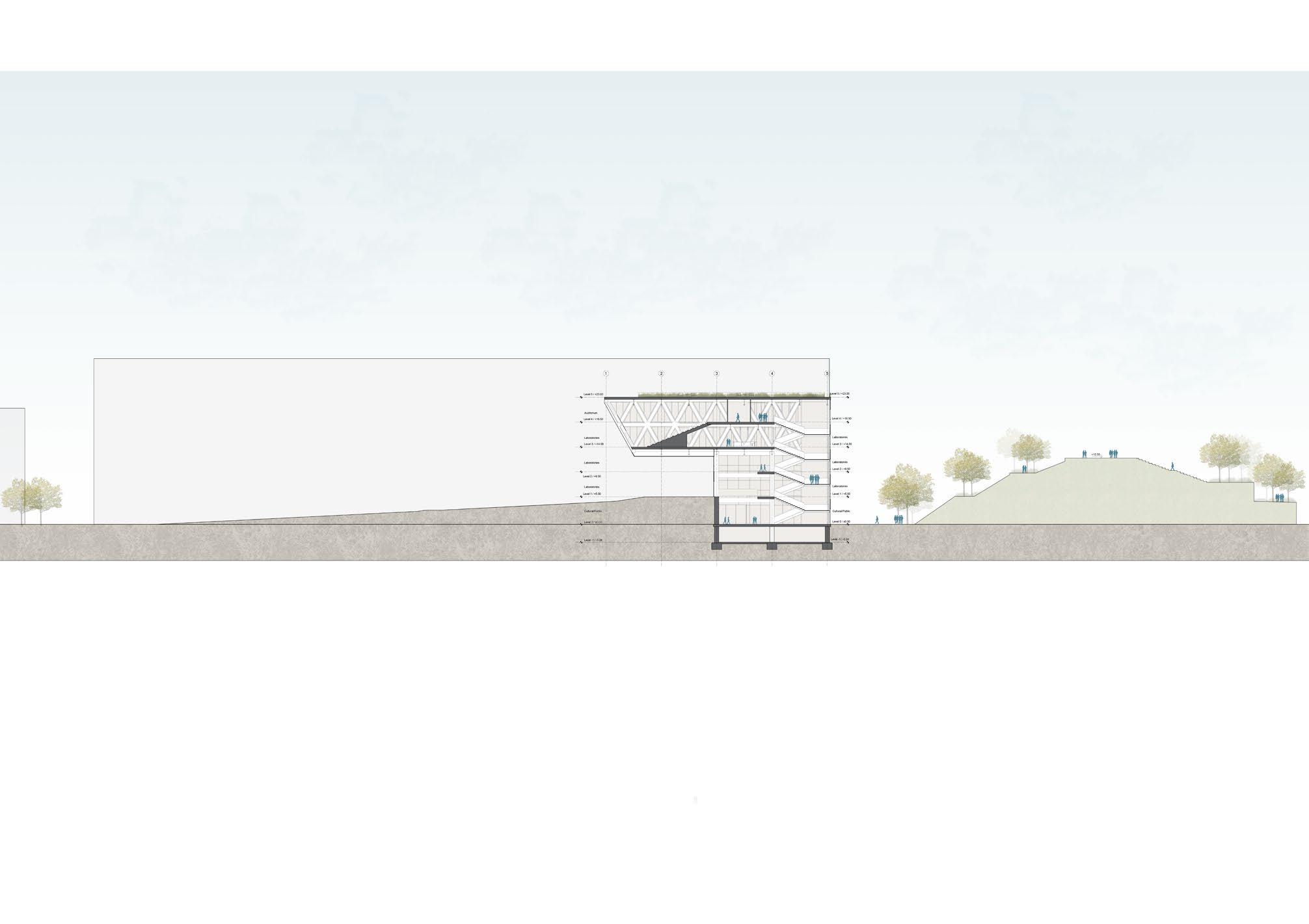

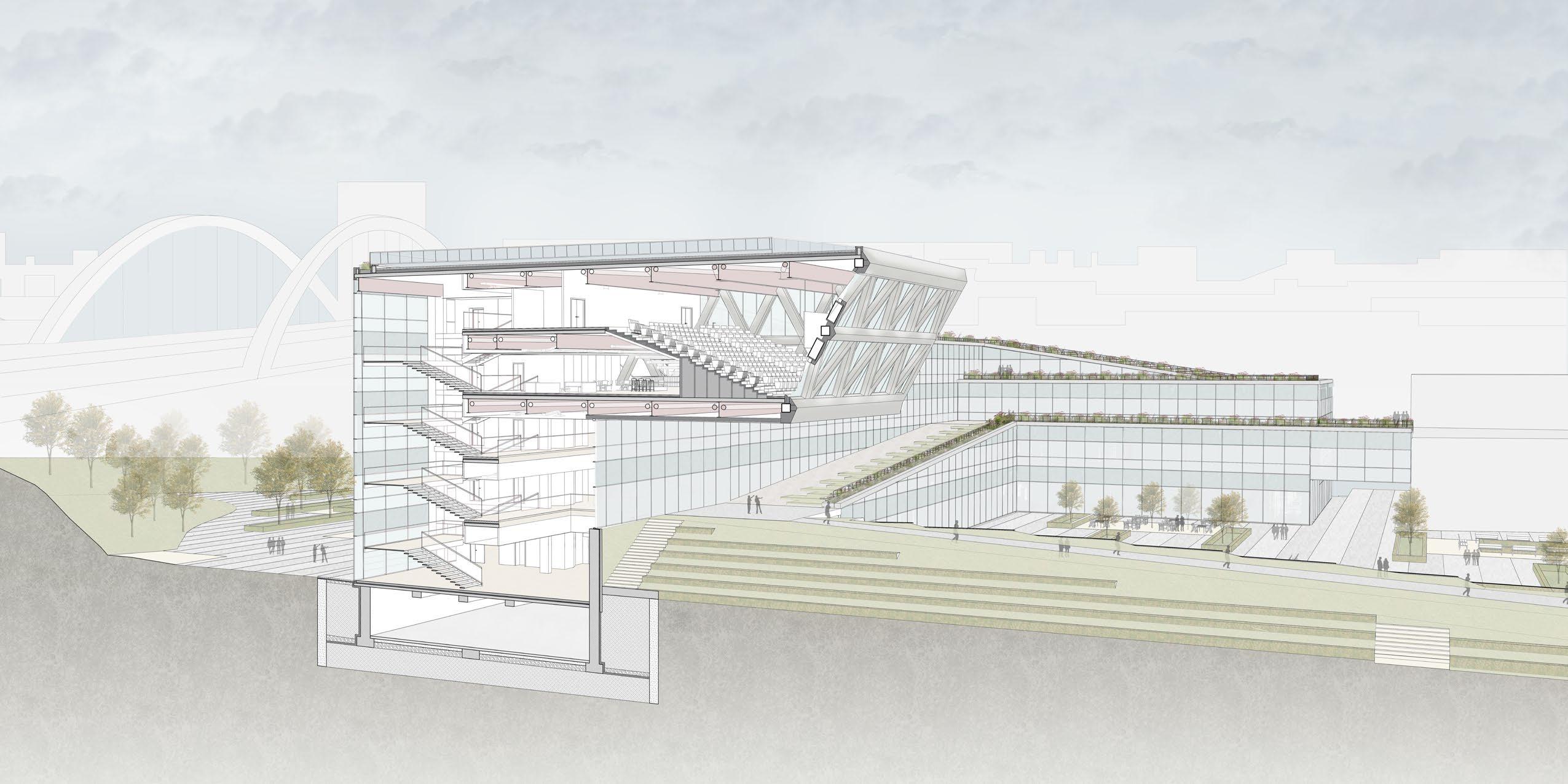

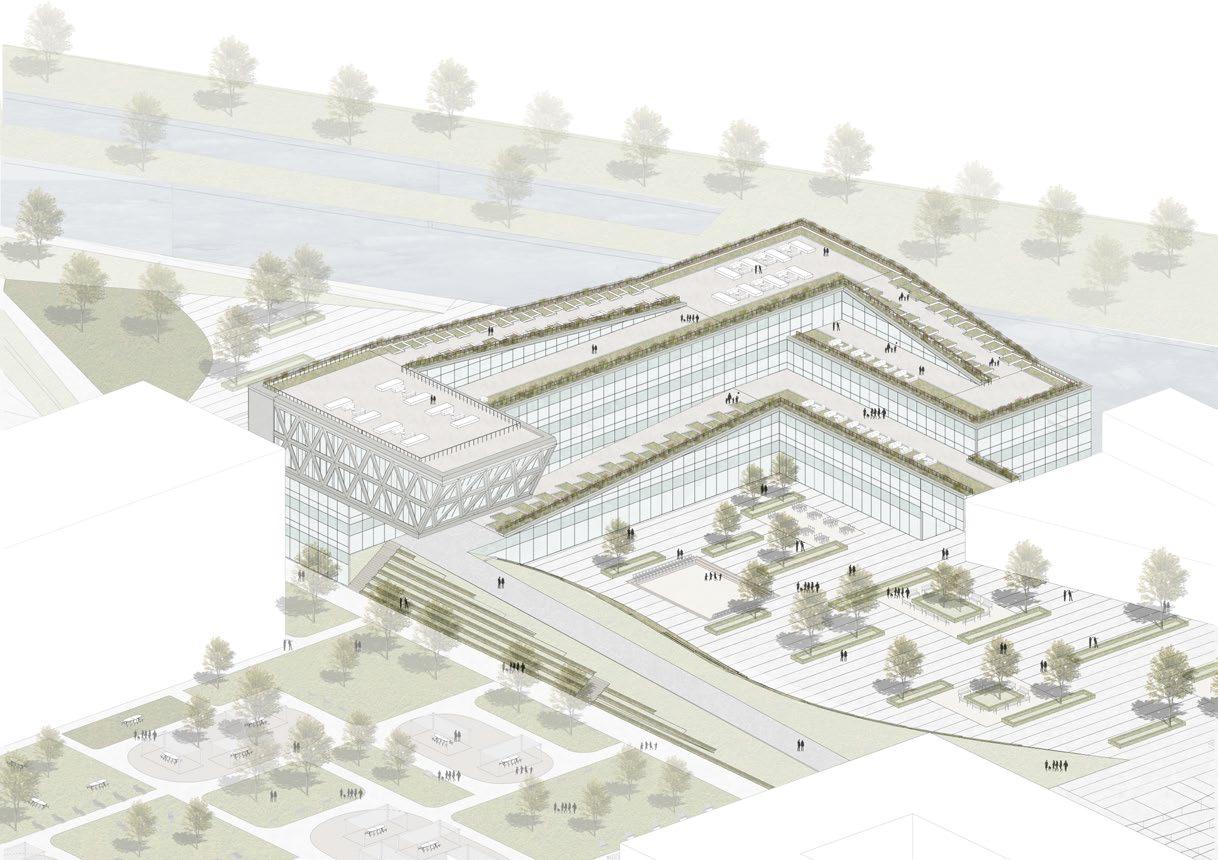

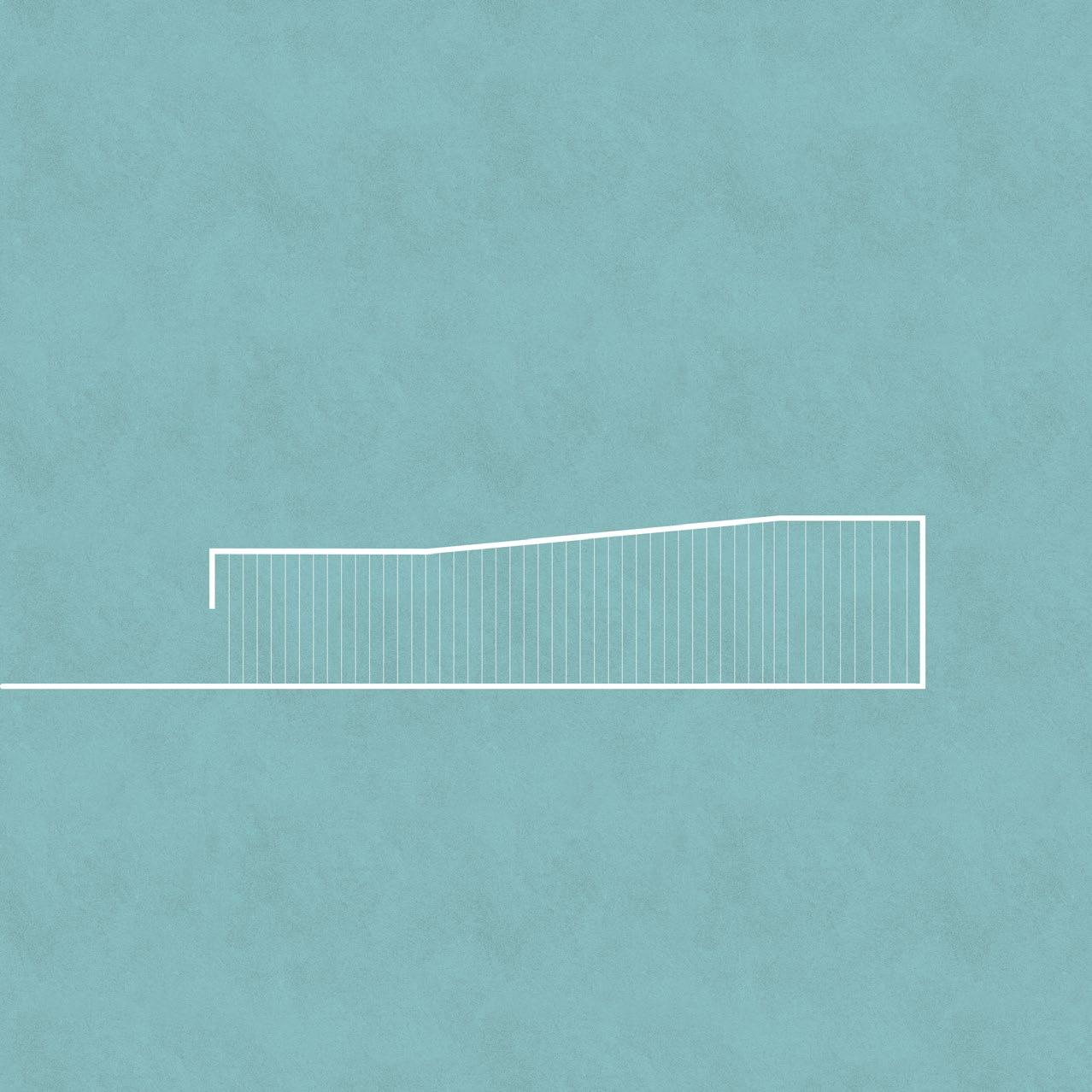

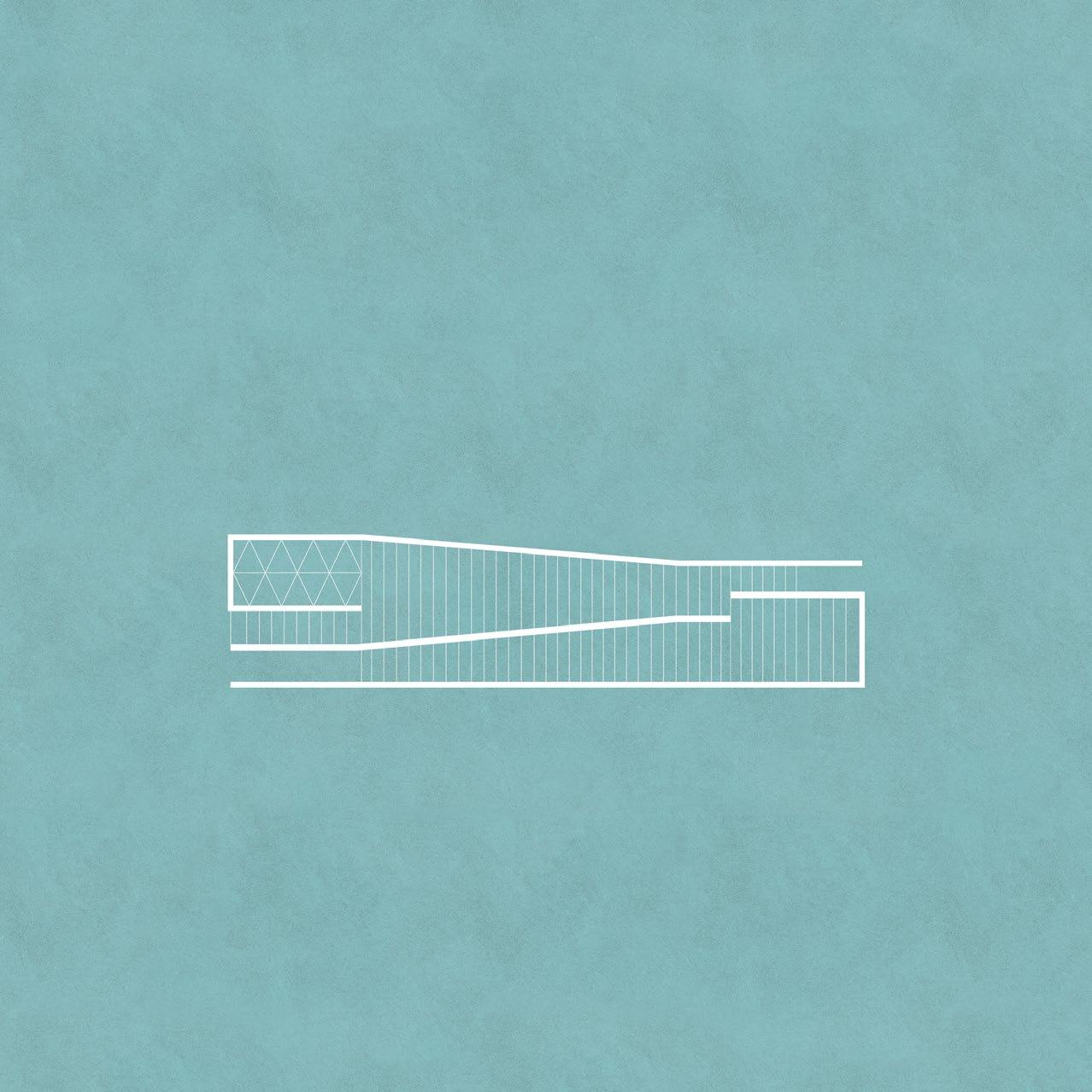

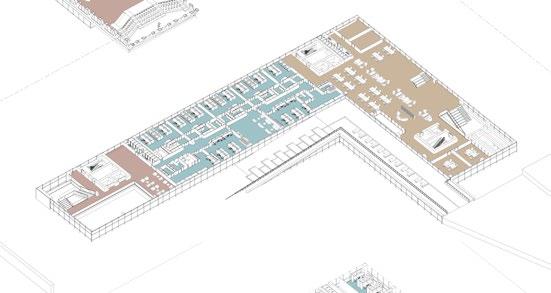

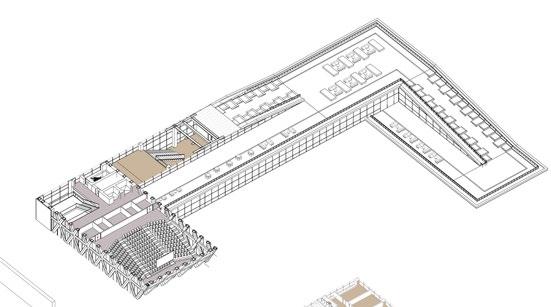

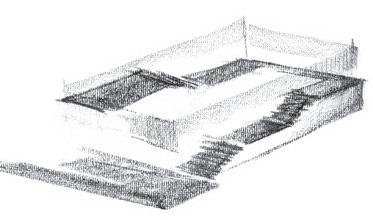

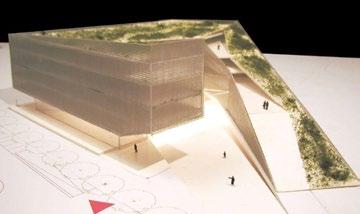

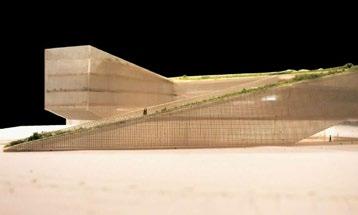

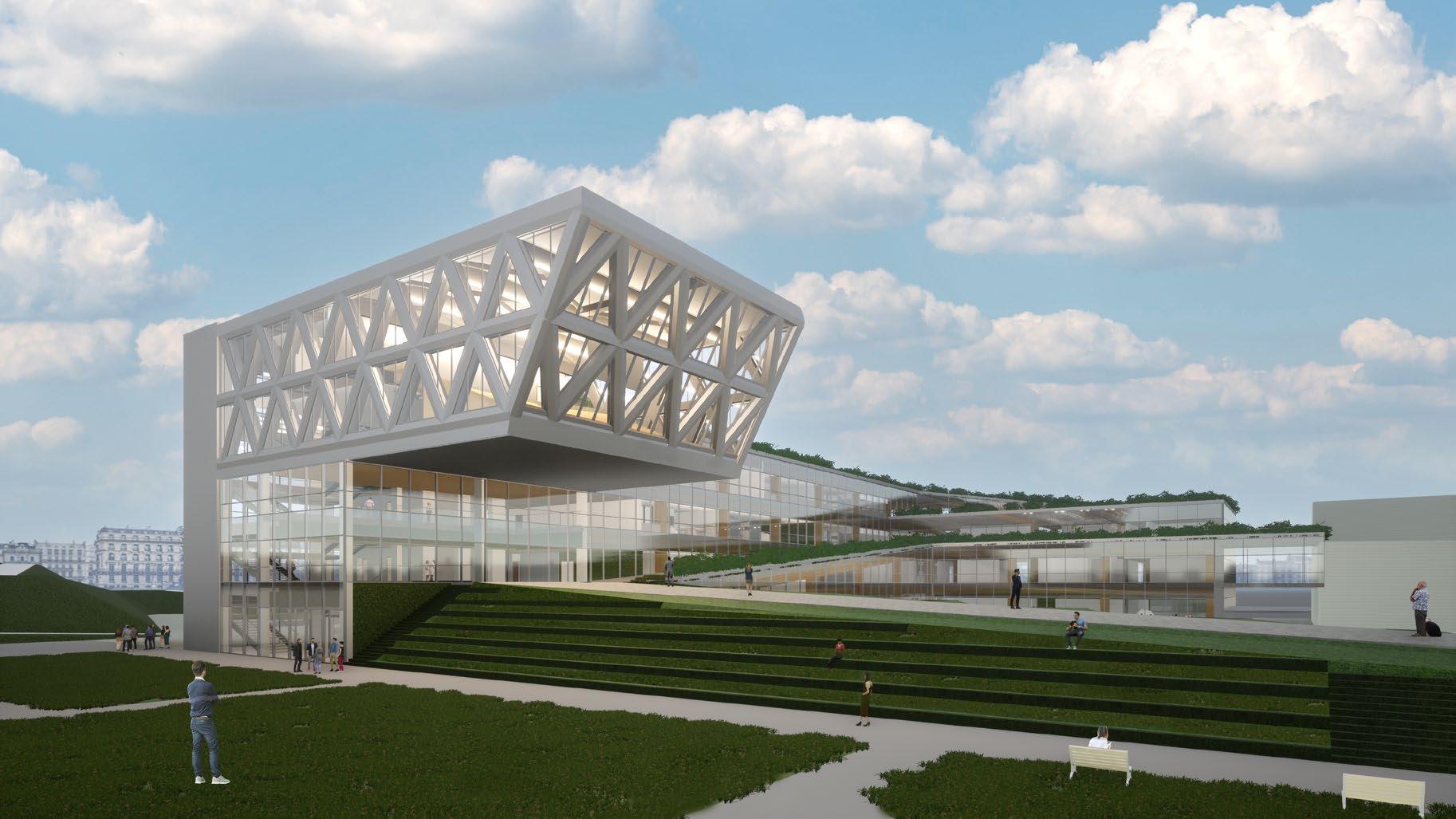

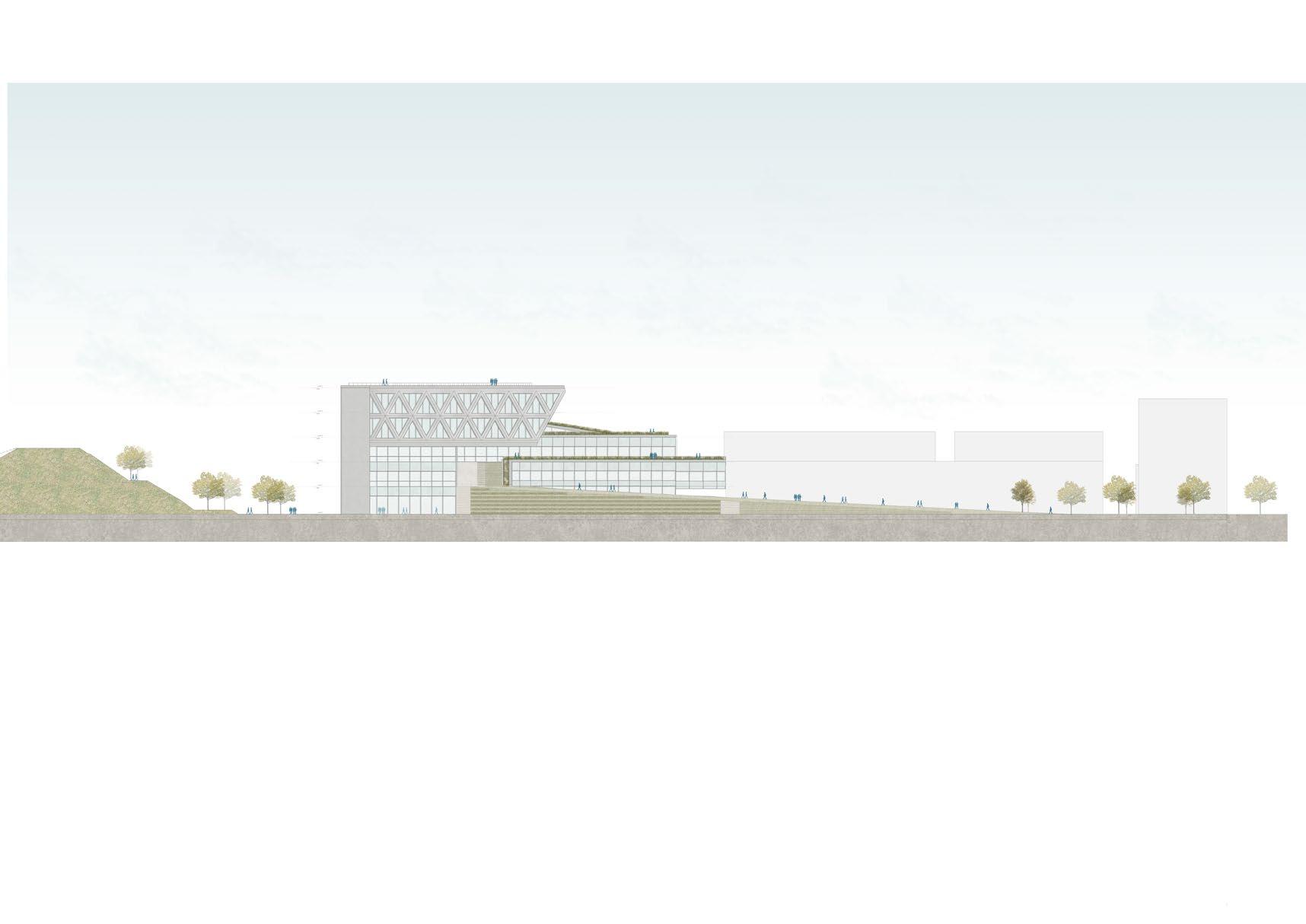

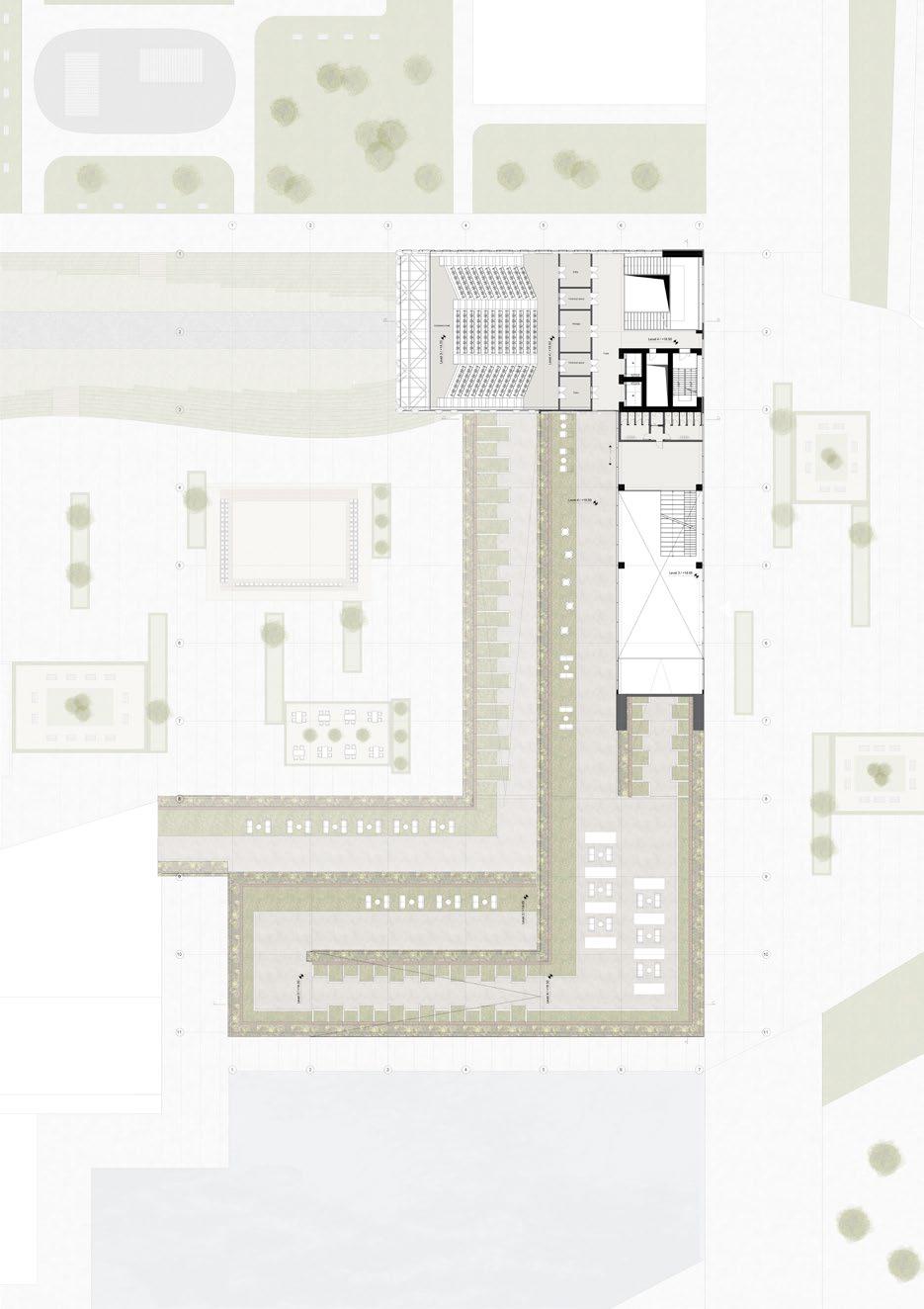

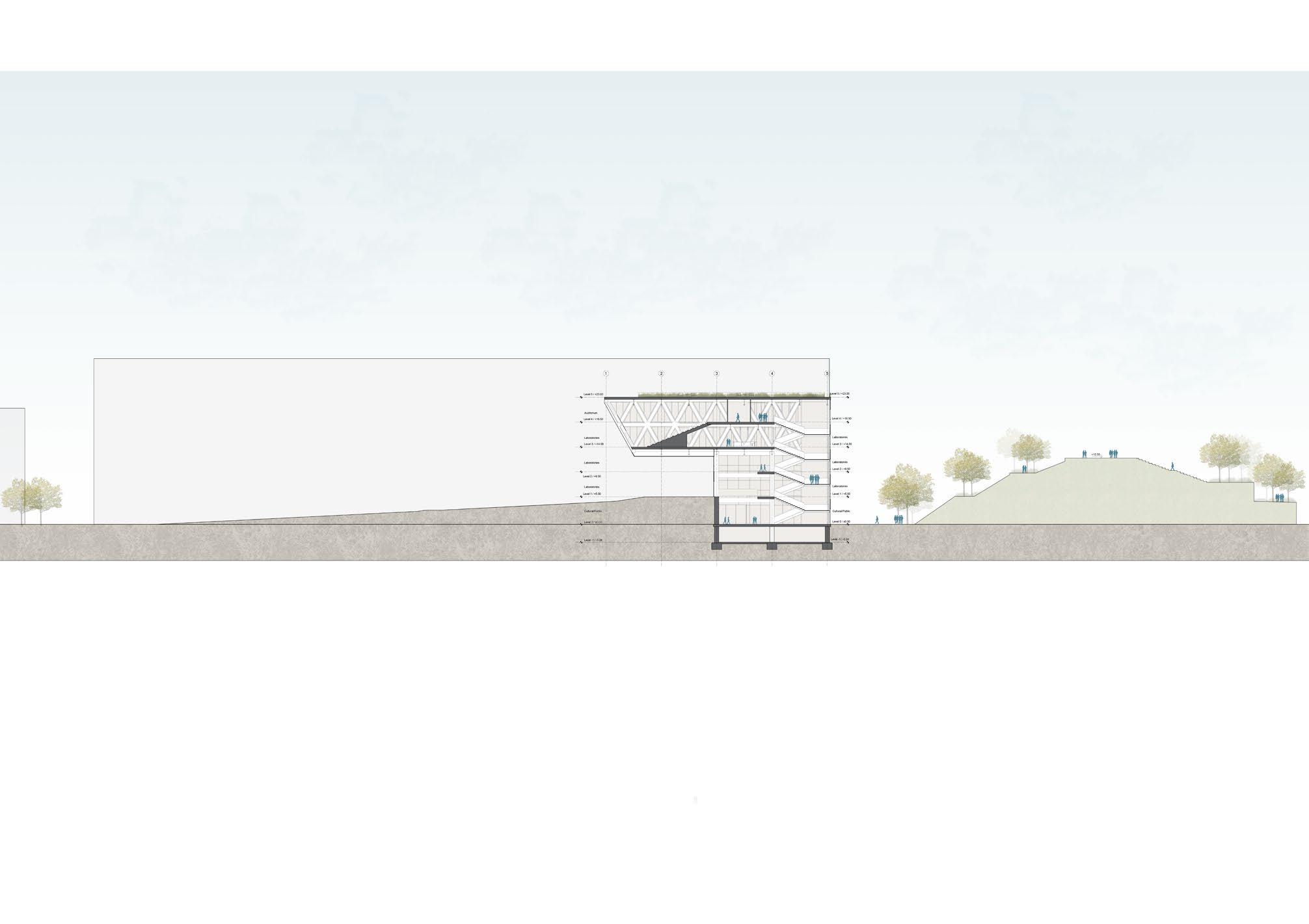

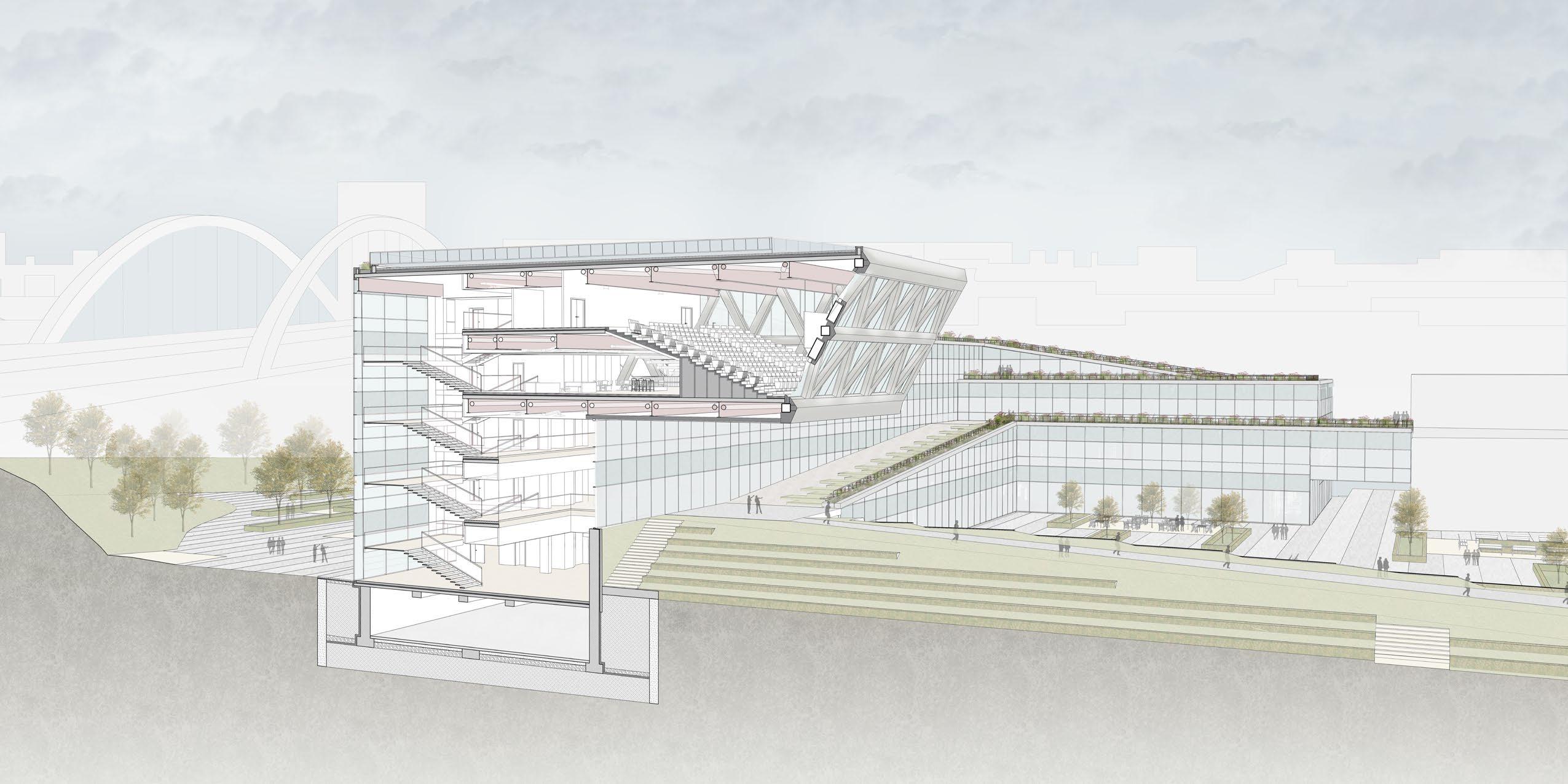

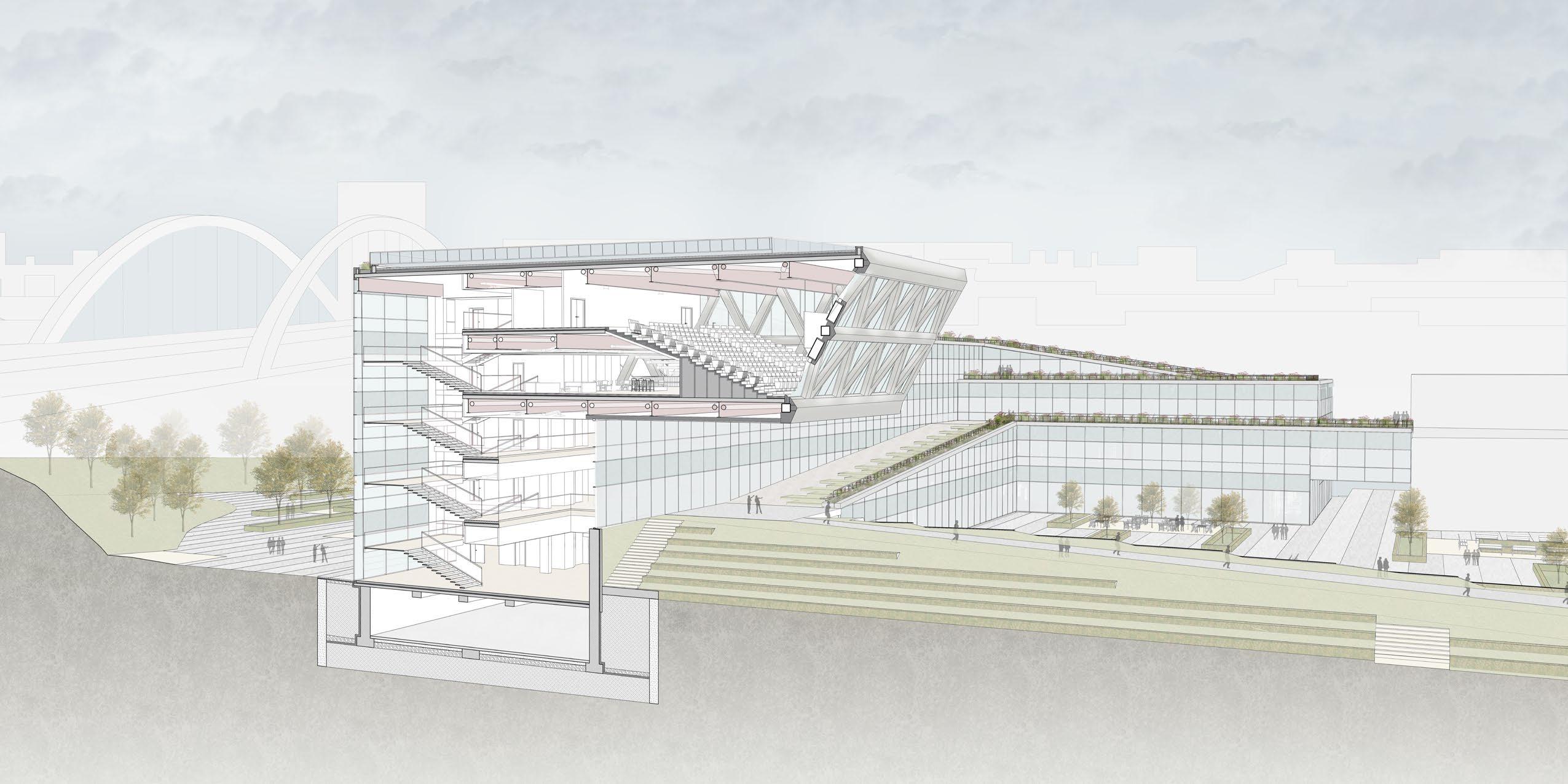

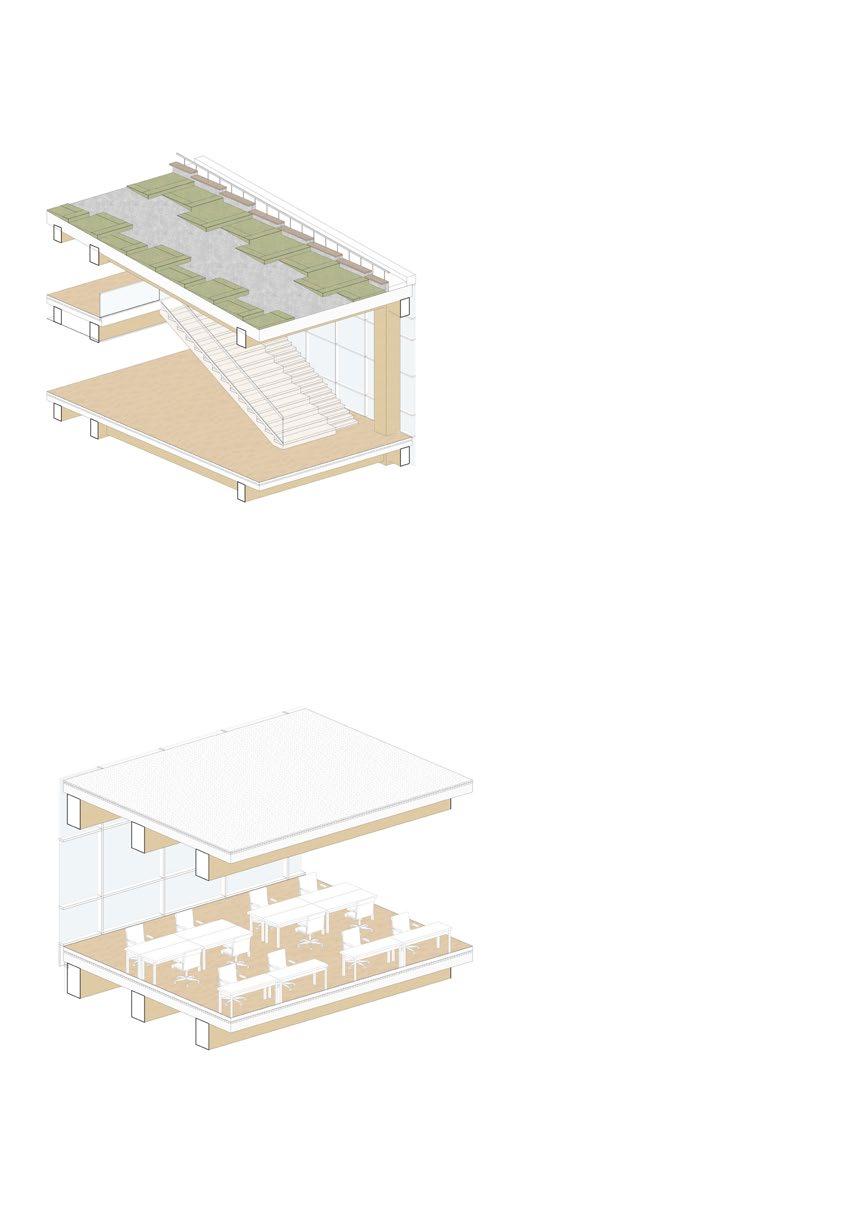

The morphology of the research center has been derived from the transformation of the surrounding context. It has been conceptualized as a series of inclined roofs that sought to morph the landscape into an inclined promenade.

Fig 72: Morphology diagram, Authors

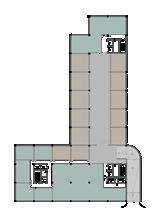

The boundaries of the volume are determined through the alignments with the predefined edges of the site. As a consequence, the new generated mass consists of a main body stretched along the new borderline fronting the sports park in the west, as well as two

5. 8. morphology

6. 9.

42 Morphology

wings positioned in the north and south. The alignment with the decumano on one side and the bridging with the contextual buildings along the waterfront, in the south, further emphasizes the concept of creating an enclosed space, as well as a visual end to the park. 1. 2. 3. 4. 7.

In addition to the aforesaid configuration and the concept of the inclined promenade, we sought to divide the building block into two main components; an inner volume which shapes the enclosed piazza, as well as an outer one which preserves the relationship with the external gateway and the hill.

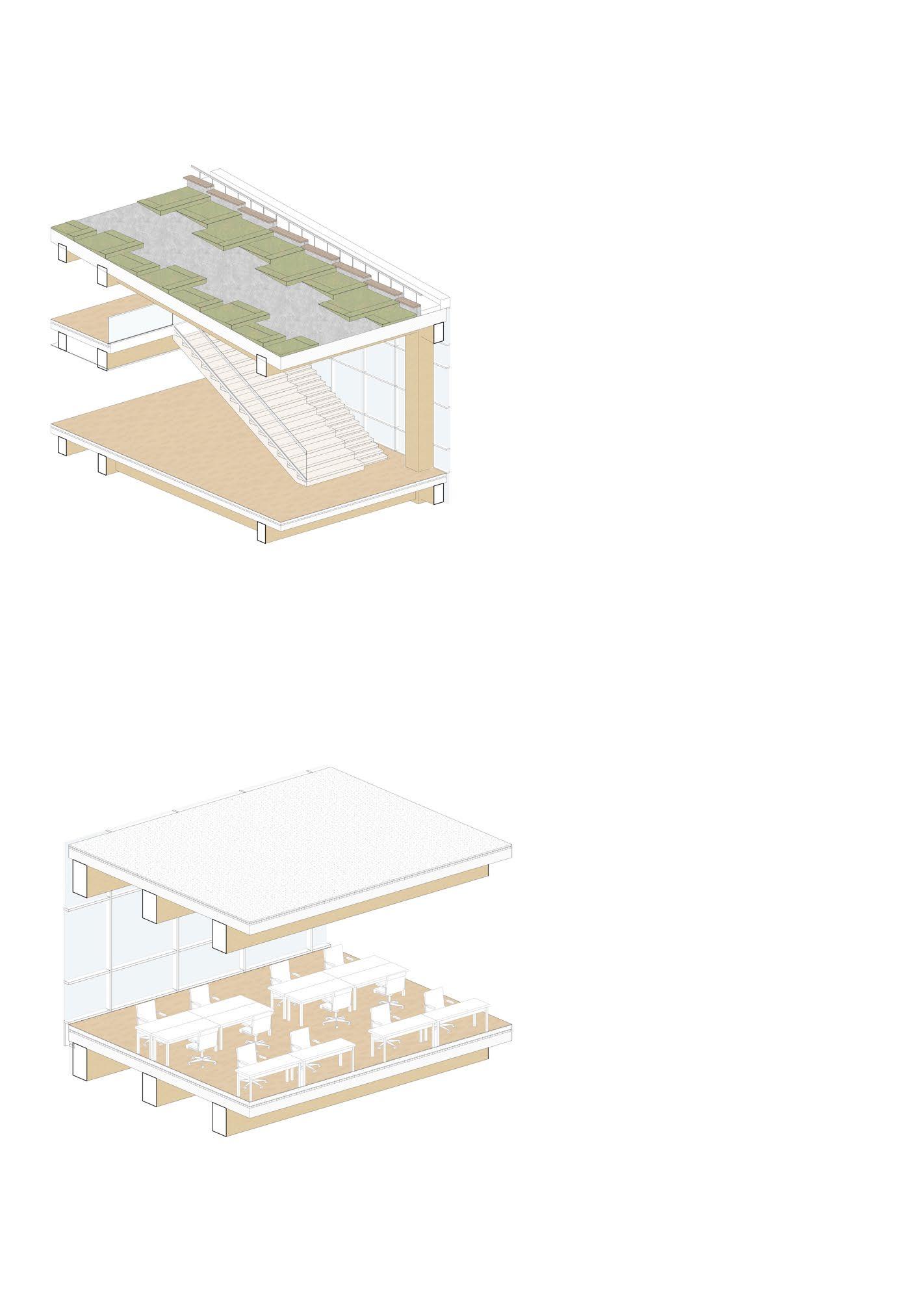

Simultaneously, these components ought to express a sense of movement as well as to integrate the concept of the inclined promenade. Such an action is provided through the division of the volumes in a system of terraces positioned at different heights. Additionally, these emanating terraces are further interconnected through the use of inclined pathways.

The interconnection of levels through ramps and the introduction of terraces is aimed at giving the building more dynamism. The inclined promenade has a large effect on the overall result of the facade.

The system of paths generated can be seen as a crowning of the building mass, the conclusion of which is reached through a final overhanging volume. Although this cantilever is a peculiar addition to the overall composition of the building, it can be viewed as a contrasting element that stretches out and pivots the attention back at the site.

As a consequence, the aforementioned configuration of the building volume proved to have a large effect in the quality of the interior. The utilization of terraces as junction points was further developed throught the division of the upper wide ramps into 2 equal spans. The expansion of the terraces established connections between the external environment and the interior coworking spaces, as well as new access points to the building.

43 Morphology

Fig 73: Axonometry

44

Morphology

Fig 74: Exterior Render

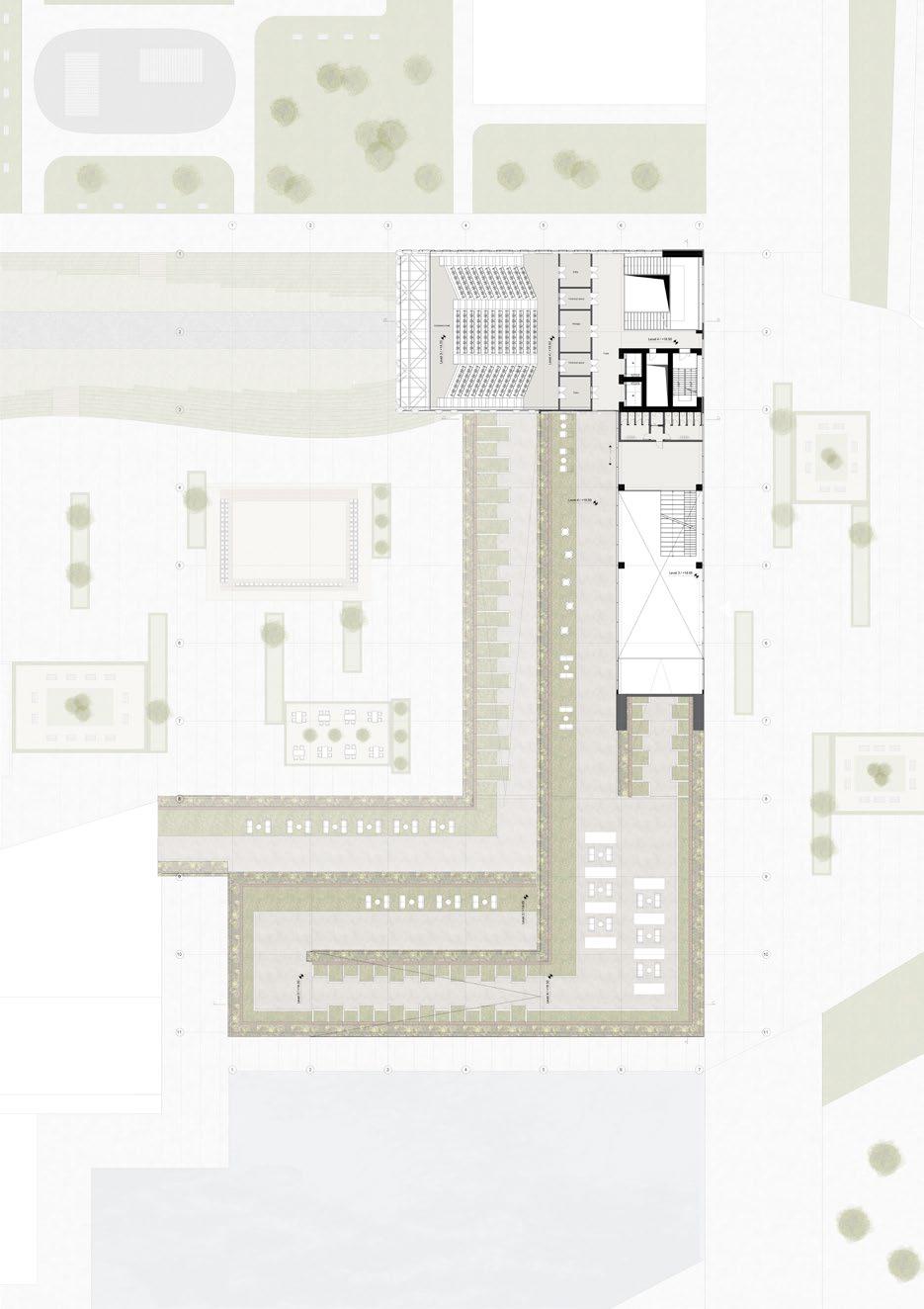

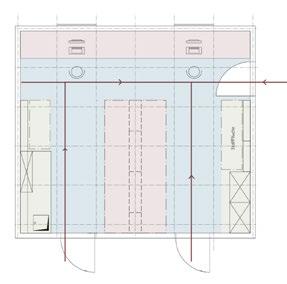

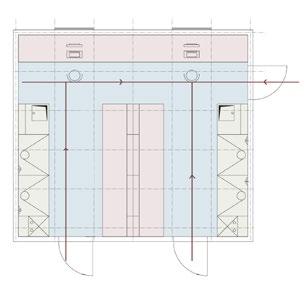

The continuation of the park and its translation into the green sloped roof had an indespensable importance for the project. As a consequence, the circulation created through this process generates a better relationship between the existing project and the new research center. The system of terraces previously described allows for different access points to the building.

Simultaneously, it offers a brand new external envirnoment that elicits new sensational viewpoints of the project site. However, not all parts of the roof are designed to be completely accessible. In the diagram adjacently represented, a distinction is marked between 3 separate areas. The first one highlighted in red is the public portion of the building. It creates accessibility through the ground and the first floor of the building.

Notwithstanding, it also builds a connecting point with the terrace of the public building on the eastern side of the research center.

The second set of ramps that lead to the top of the cantilever generate a number of terraces with a semi-public functionality. Lastly, the portion represented in blue gives restricted access only to the scientist or the university professors working in the laboratories.

45

Fig 75: Accessibility, Authors Fig 76: Accessibility, Authors

circulation Circulation

Fourth Floor

Conference Outdoor Gathering

Second Floor

GROUND FLOOR

Collective Working

Eating Studying

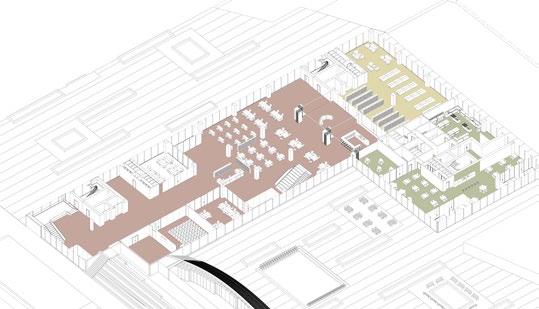

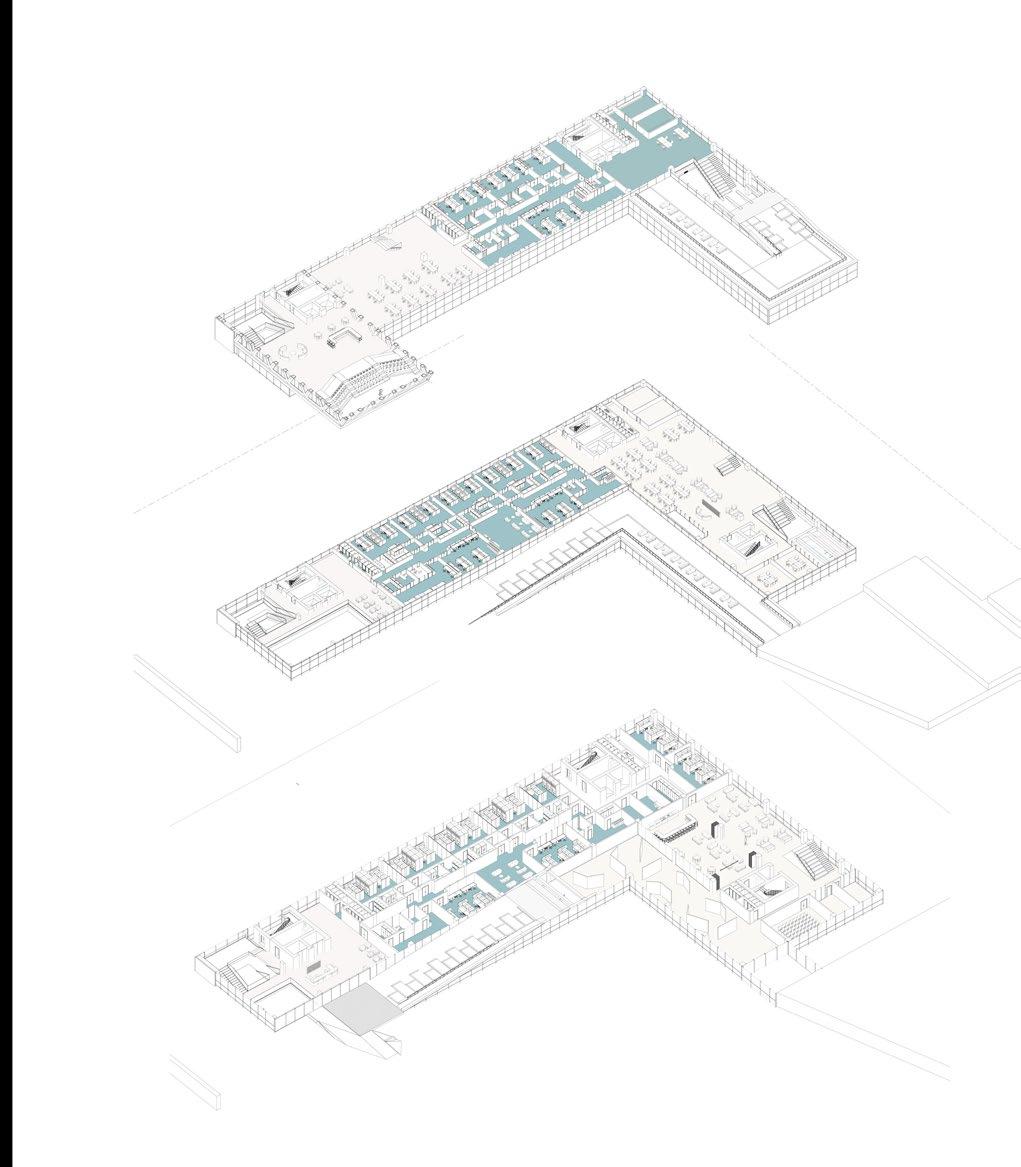

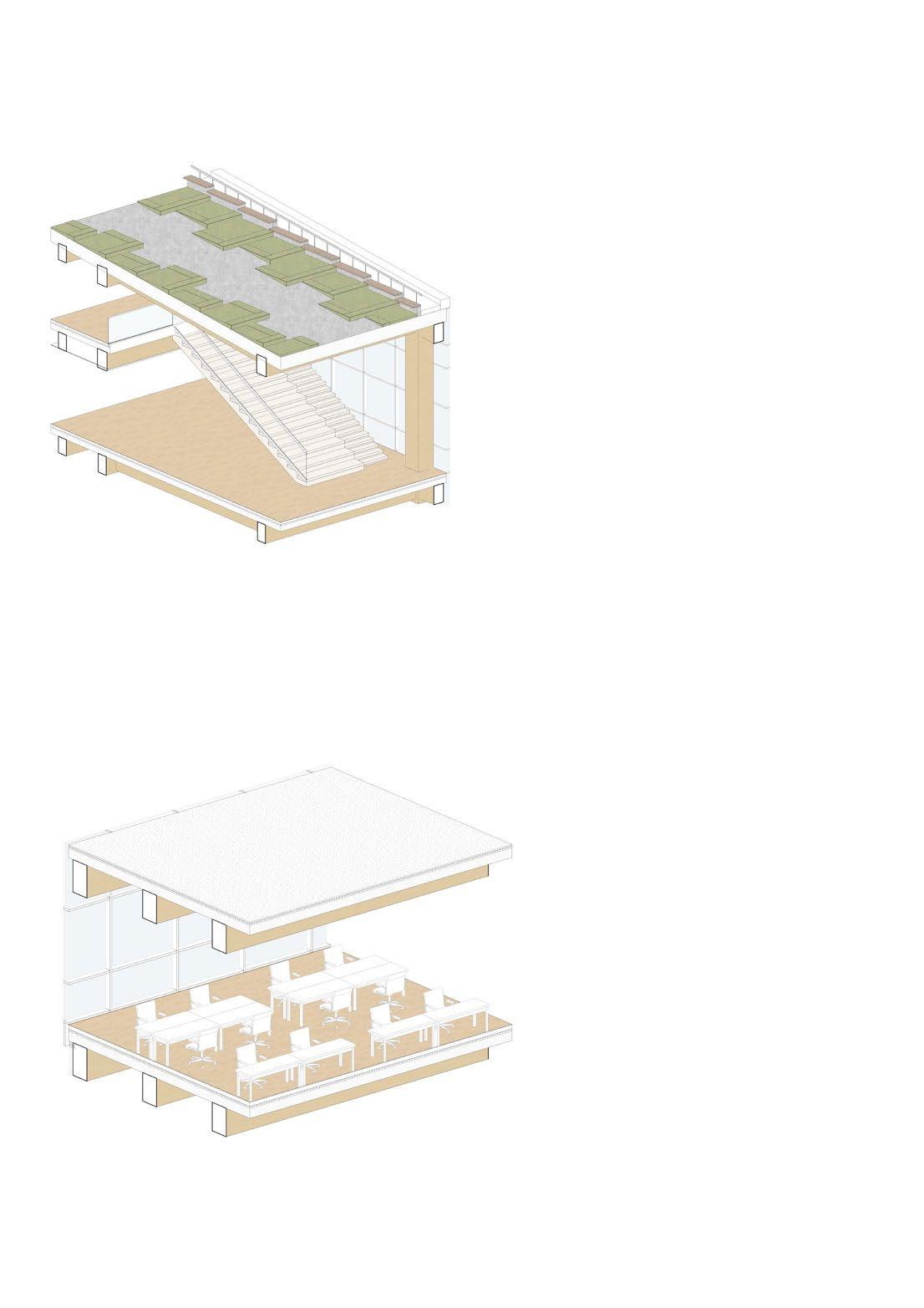

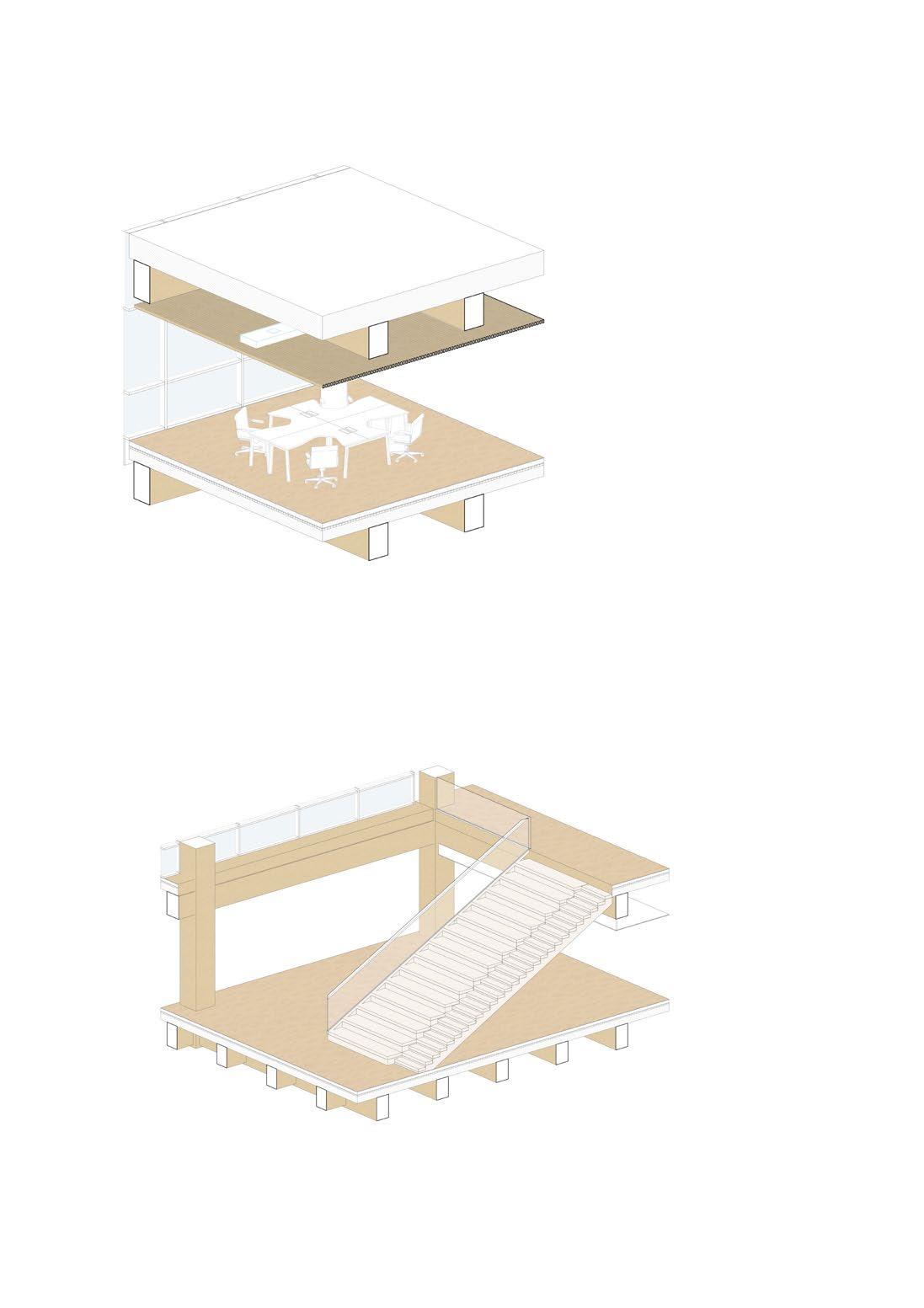

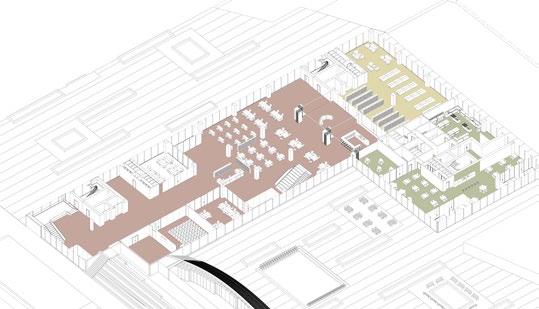

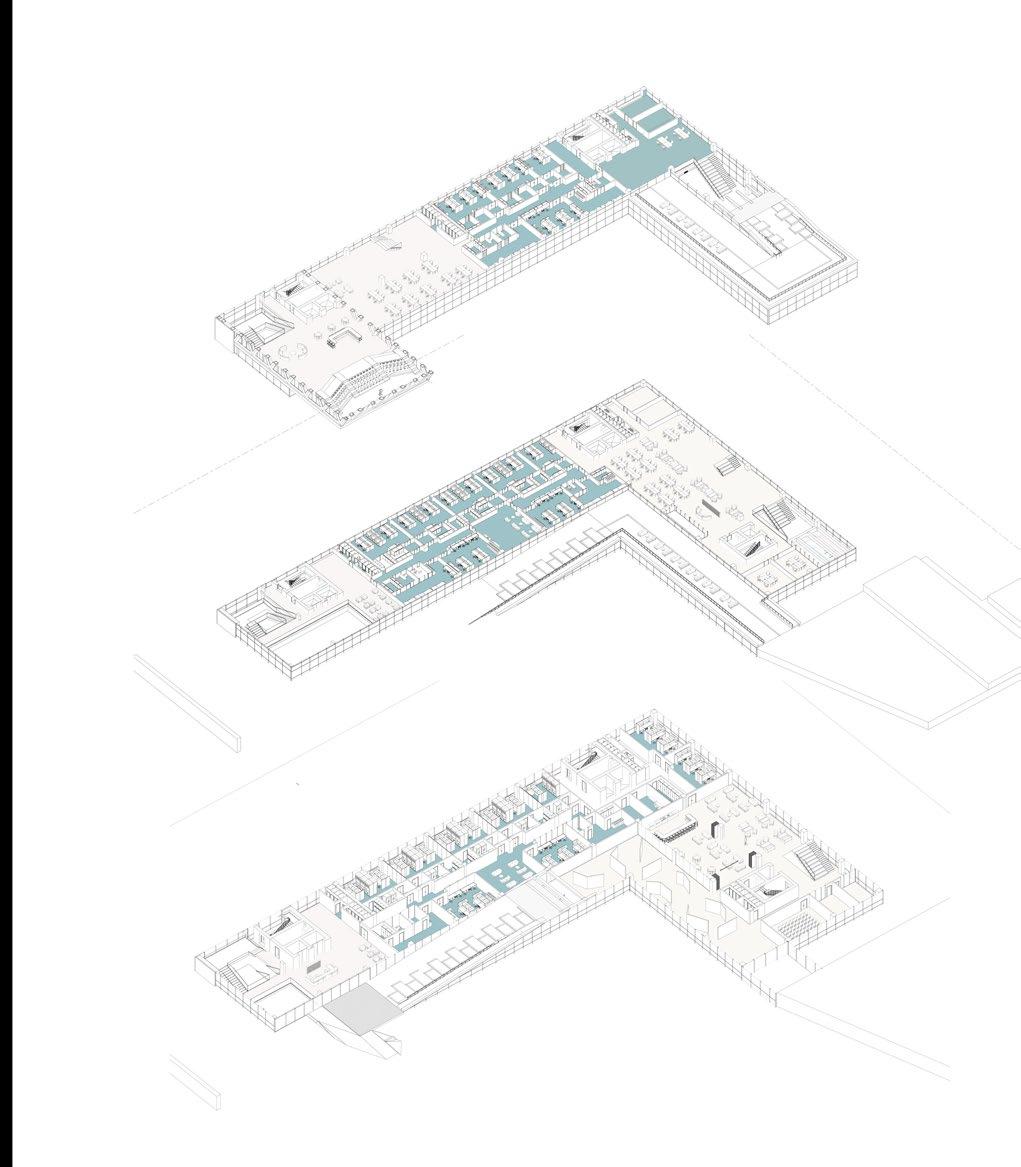

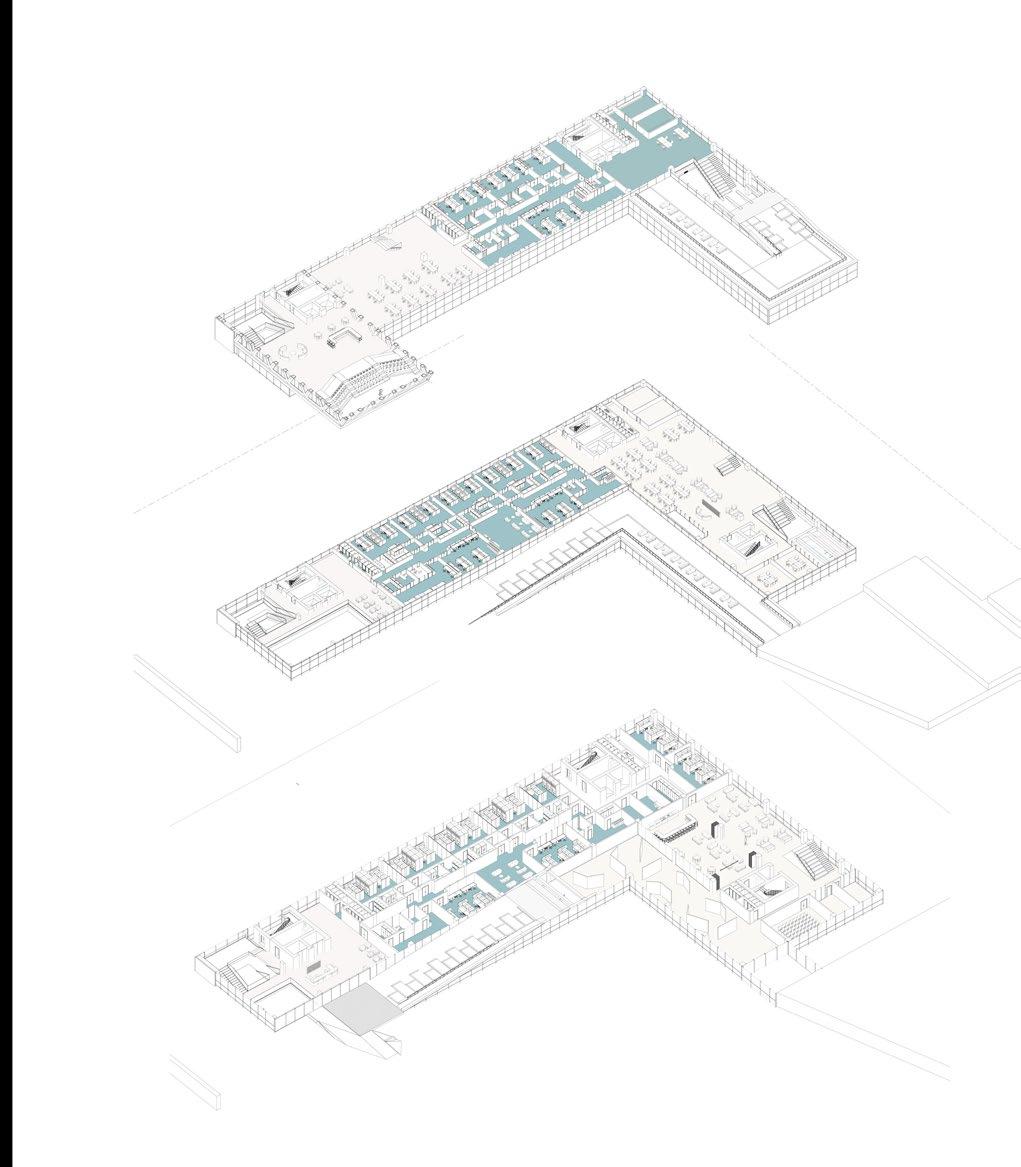

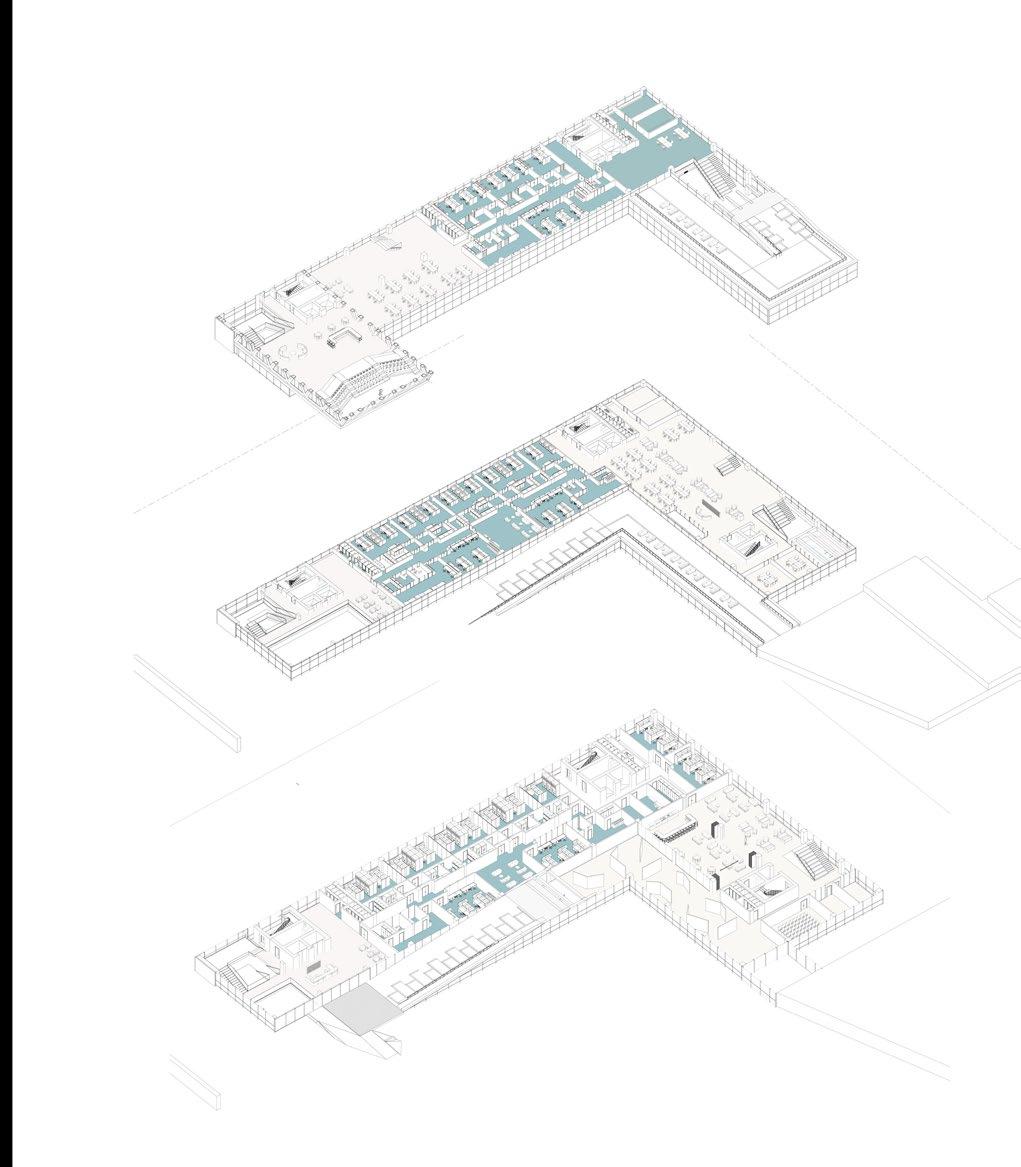

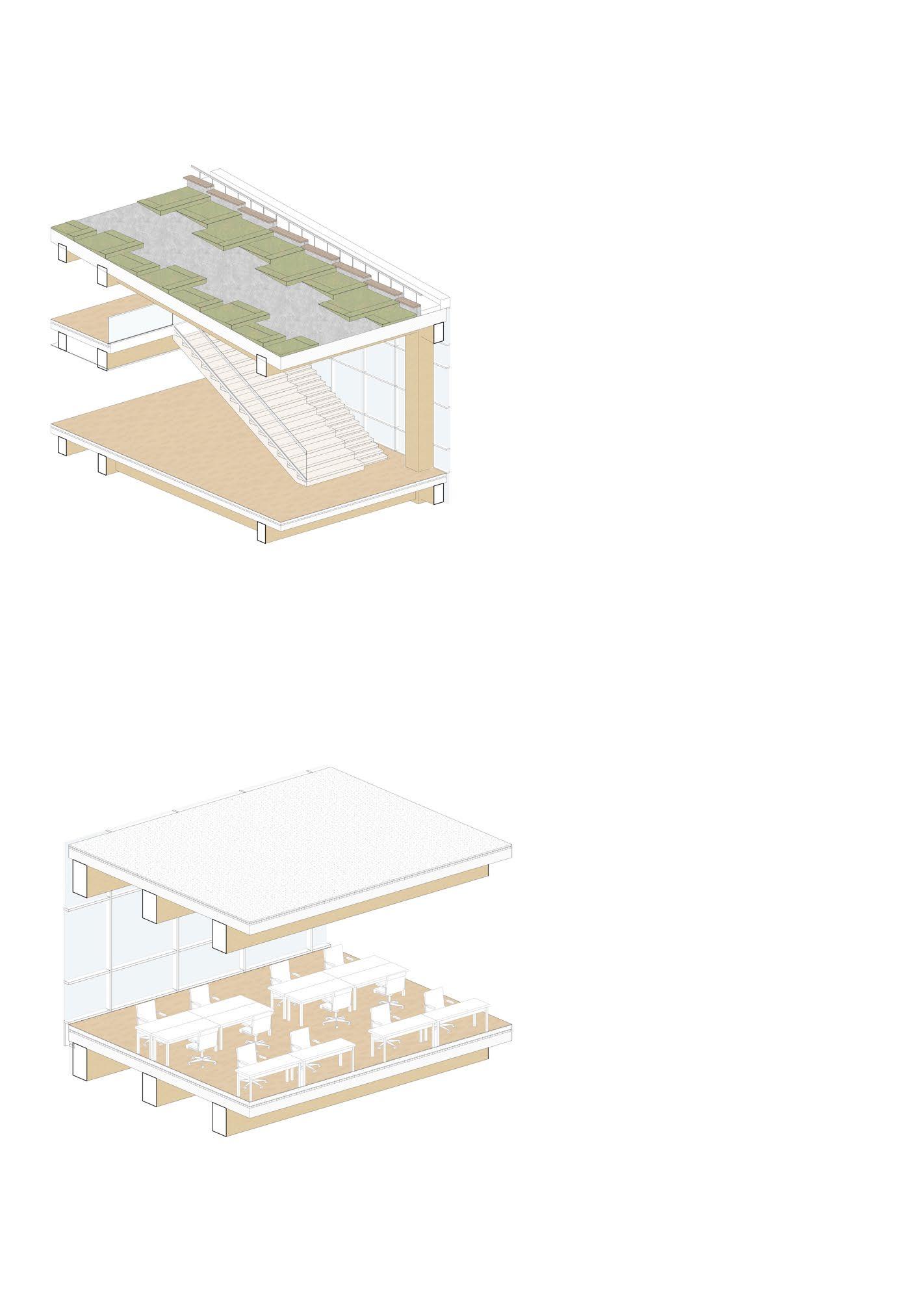

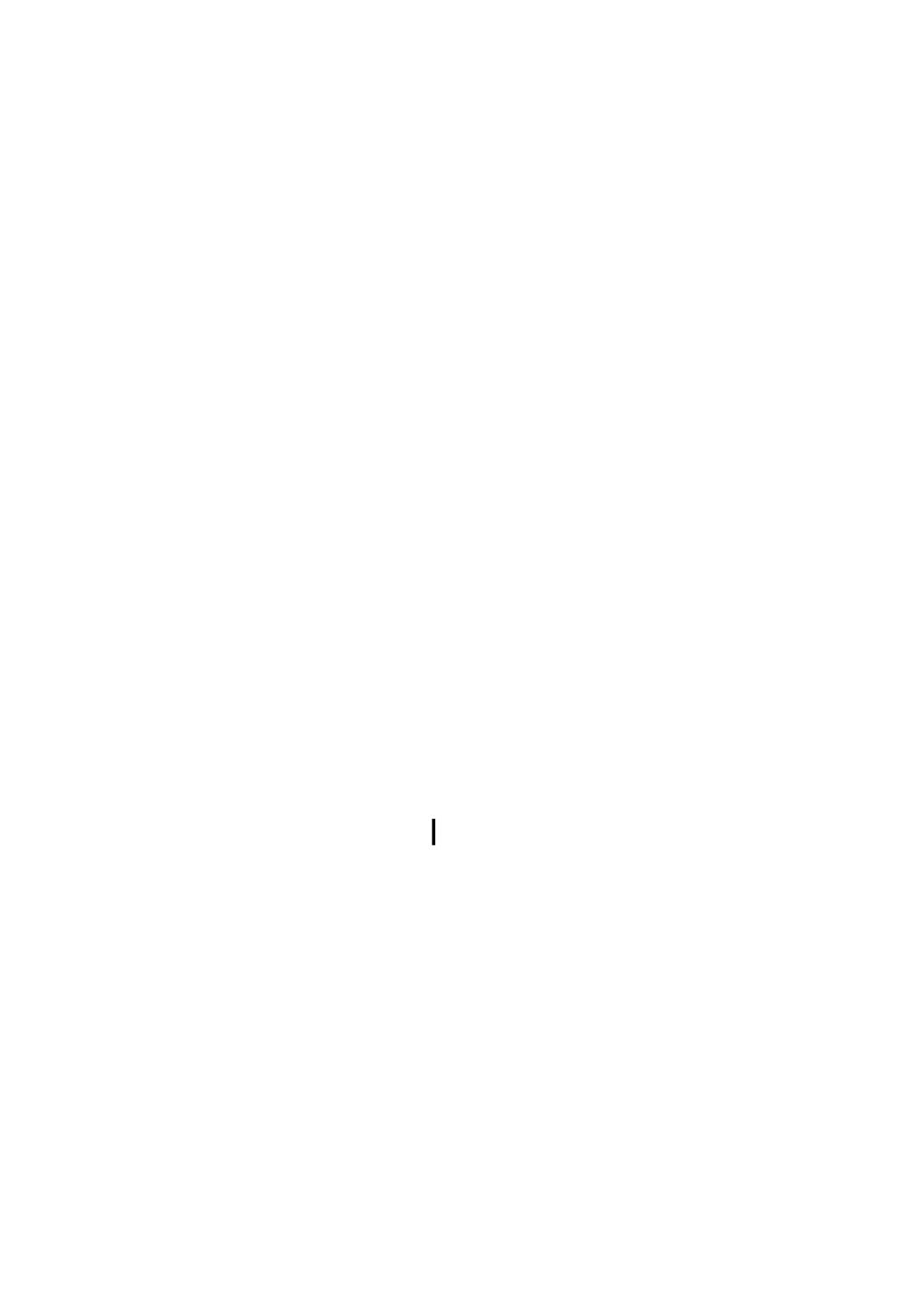

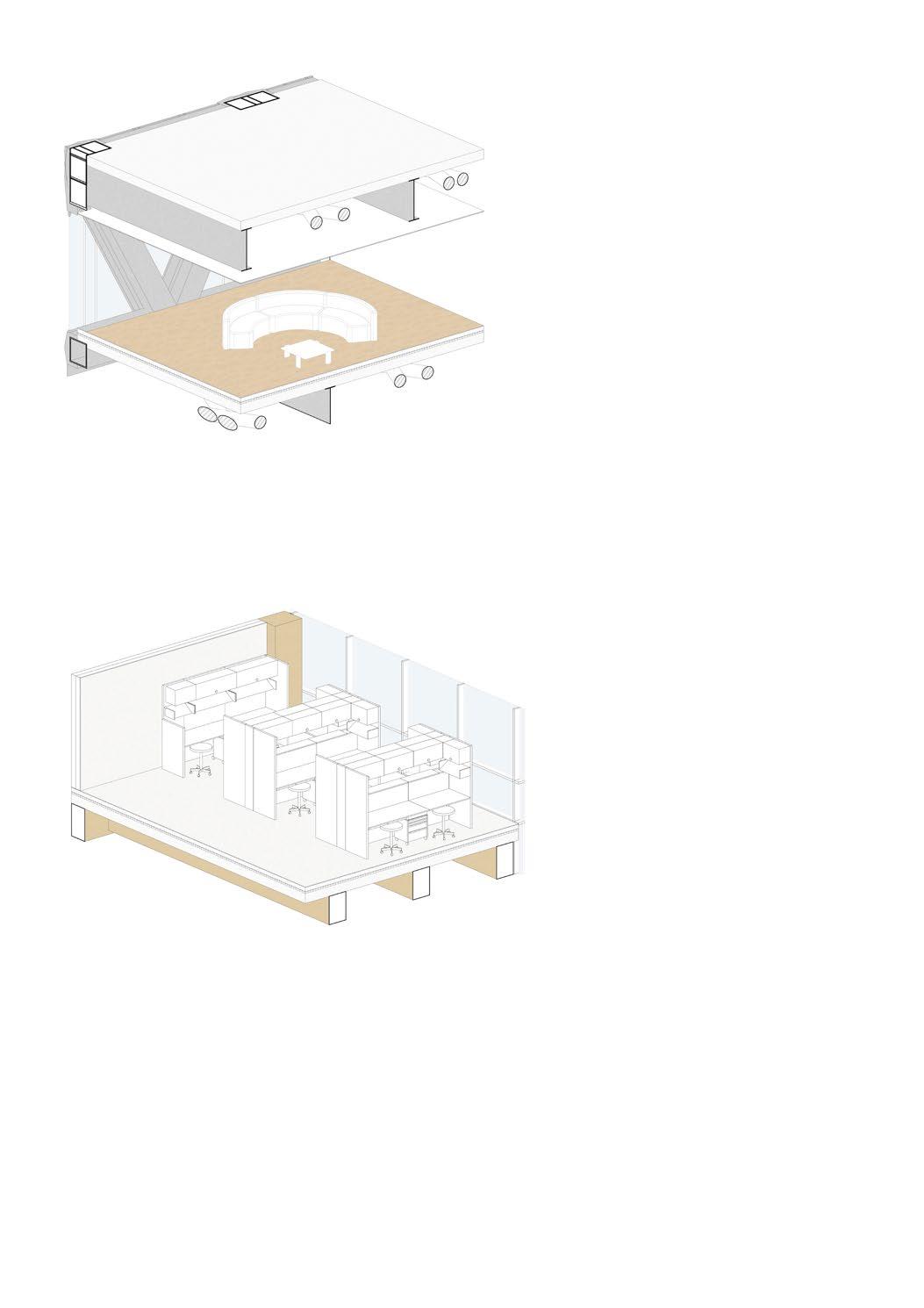

functional distribution

Technical Facilities

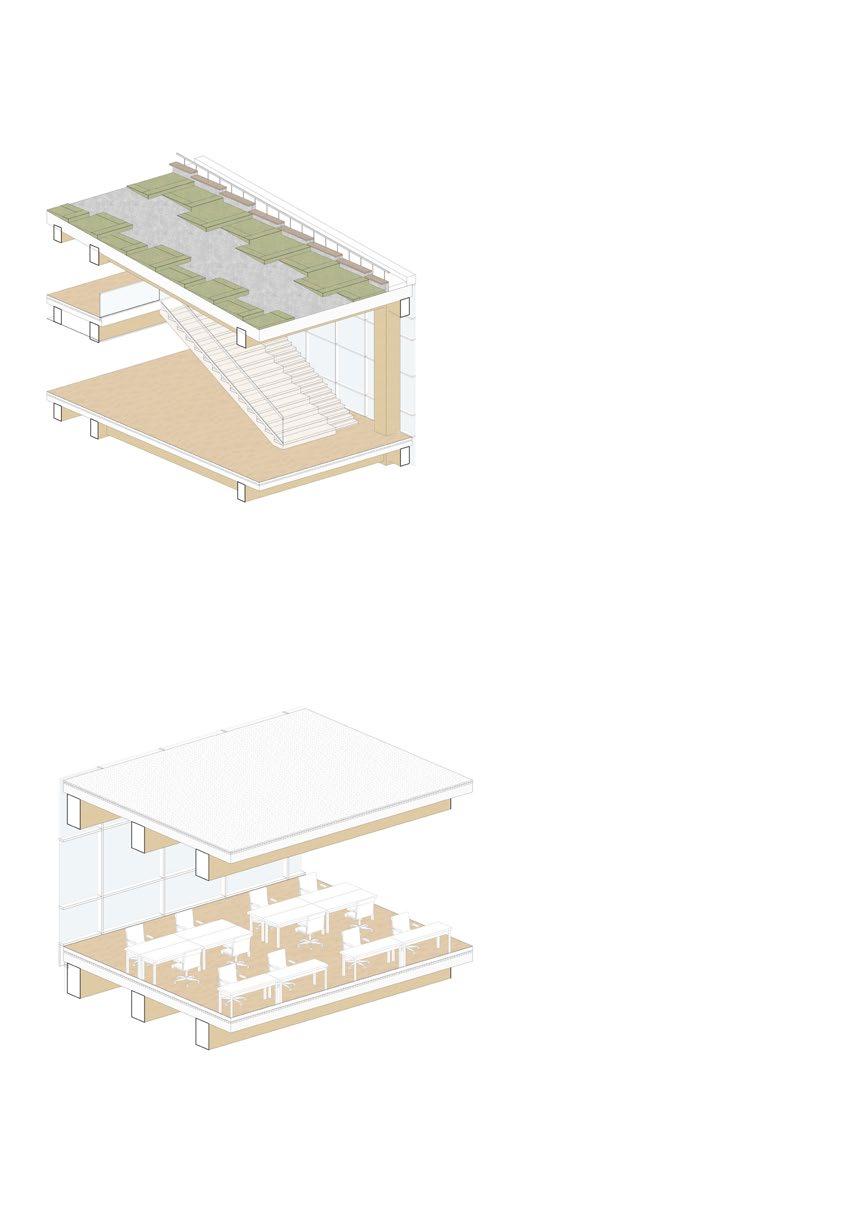

Storage

Fig 77: Exploded Axonometry, Authors

46

Functional Distribution

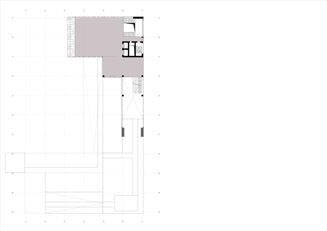

Underground Floor First Floor

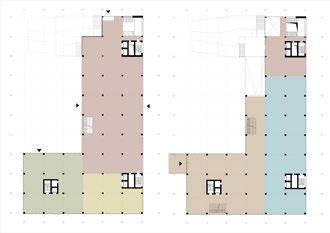

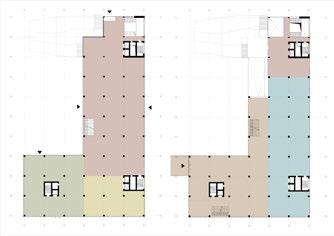

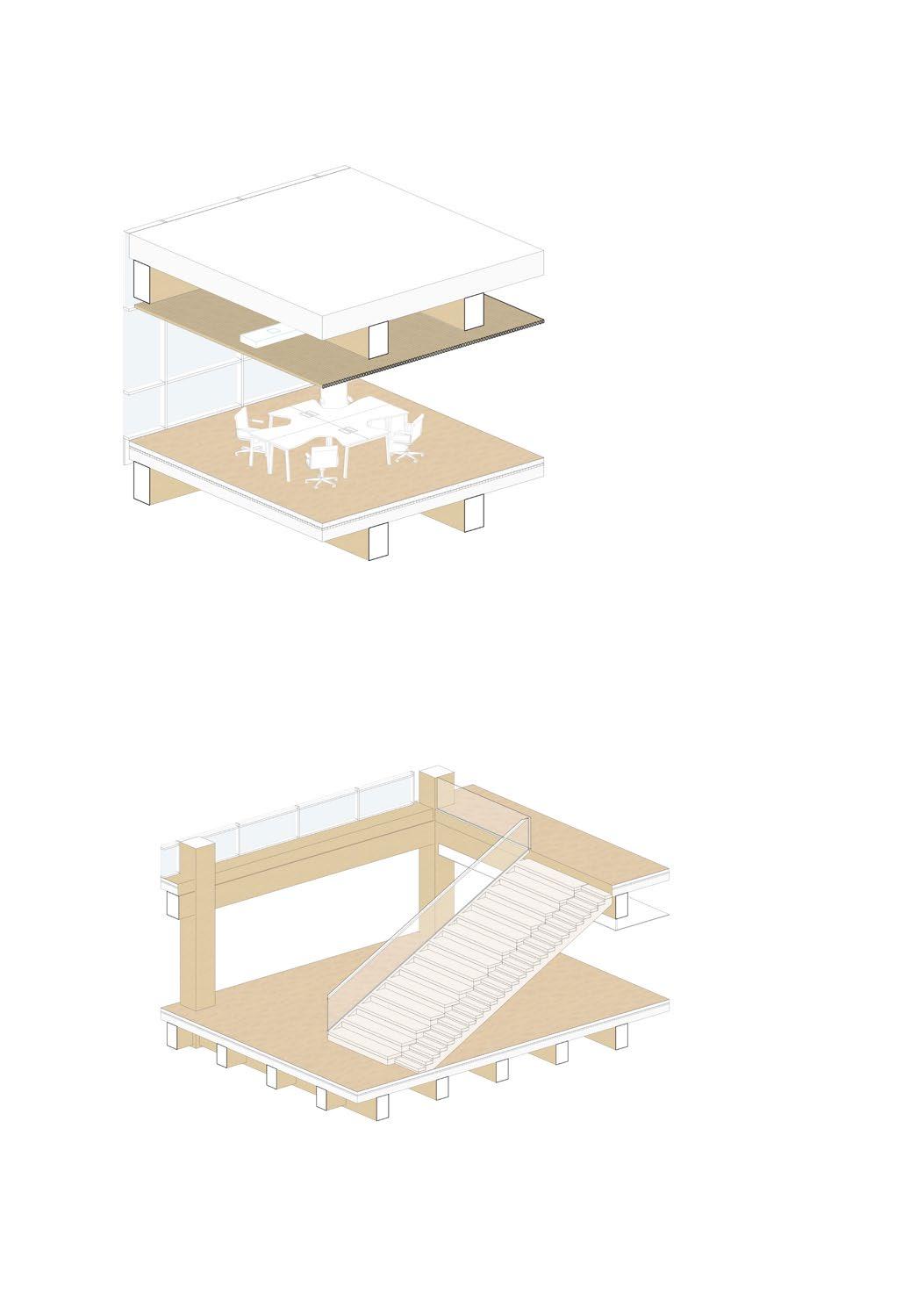

The underground floor is created mostly as a technical space for all the mechanical equipment that have to be provided for the building to work properly. Alongside this, it serves also as an accessible parking space for large vehicles needed to transport the machinery

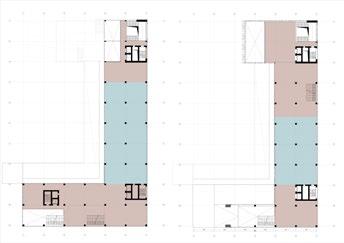

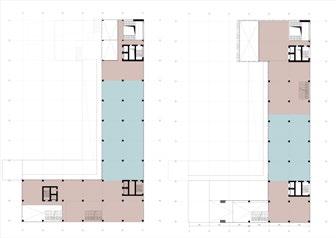

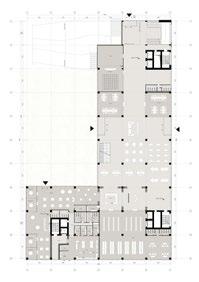

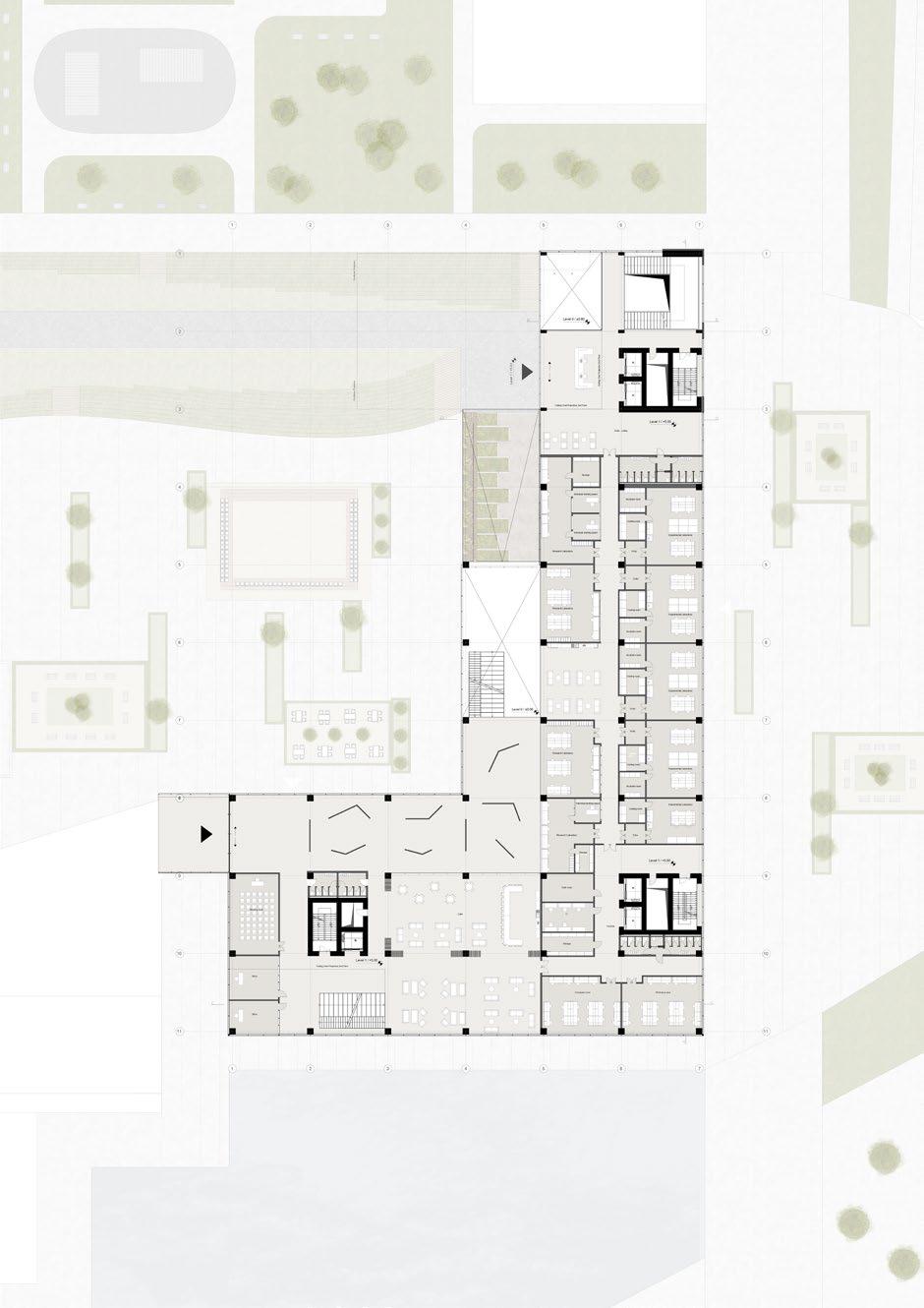

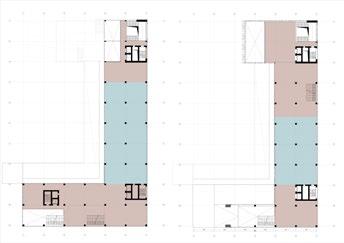

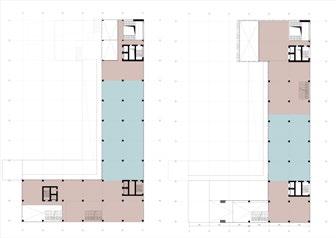

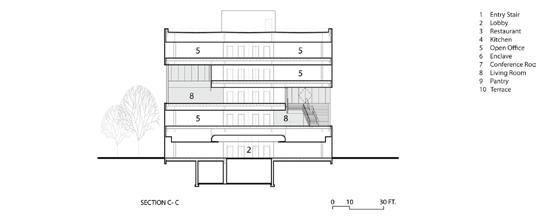

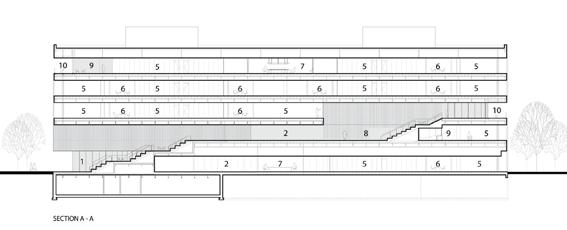

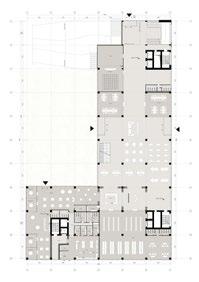

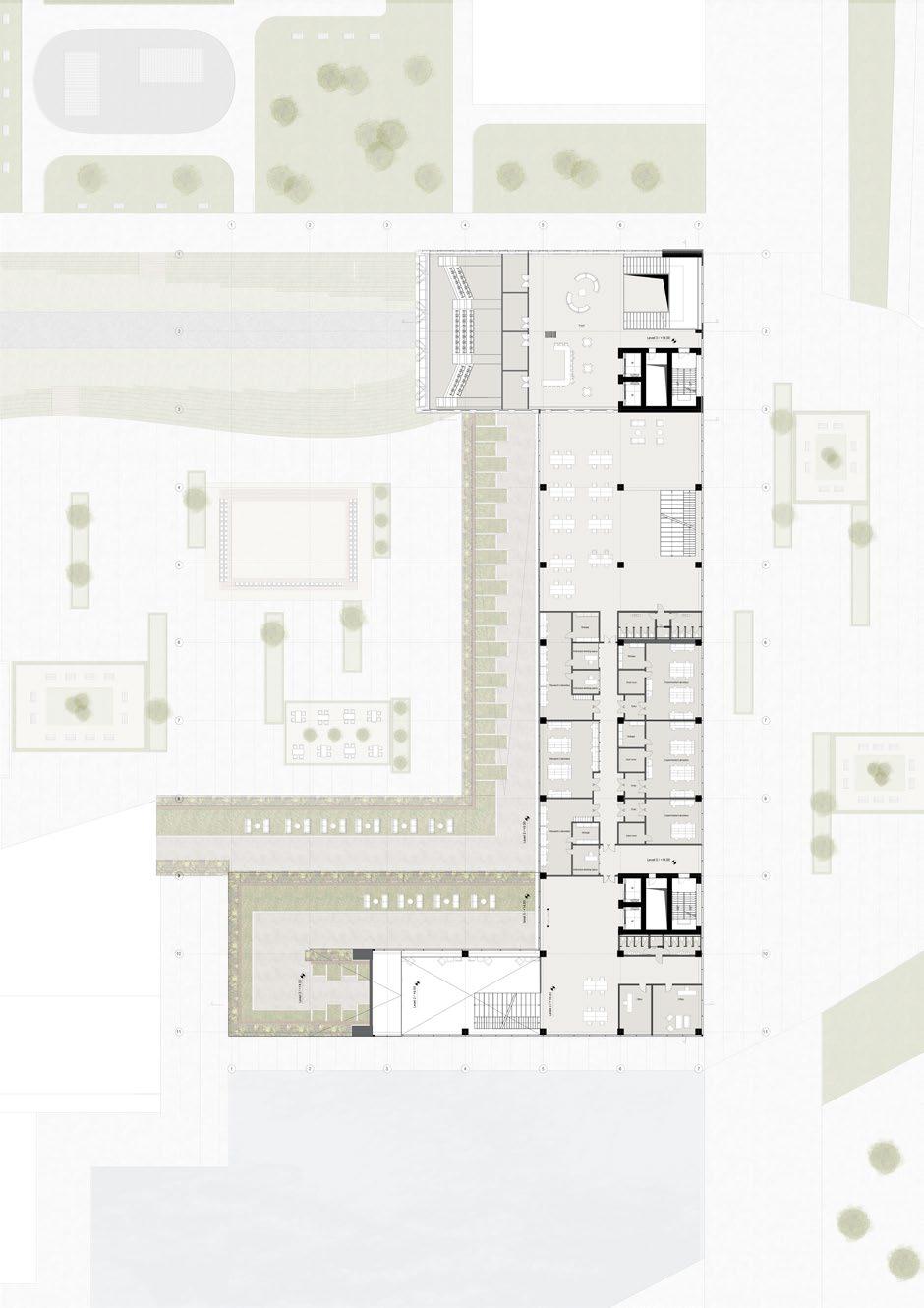

The first floor is dedicated to laboratories and exhibition rooms. The laboratories are arranged along the main body of the building. The units are connected together through a main enclosed corridor, which starts from the northern edge. The u-shaped staircase situated along the northern facade allows for vertical communication throughout all the floors of the building.

On the other side, the southern wing is occupied by a large exhibition space, which contains its own separate circulation.

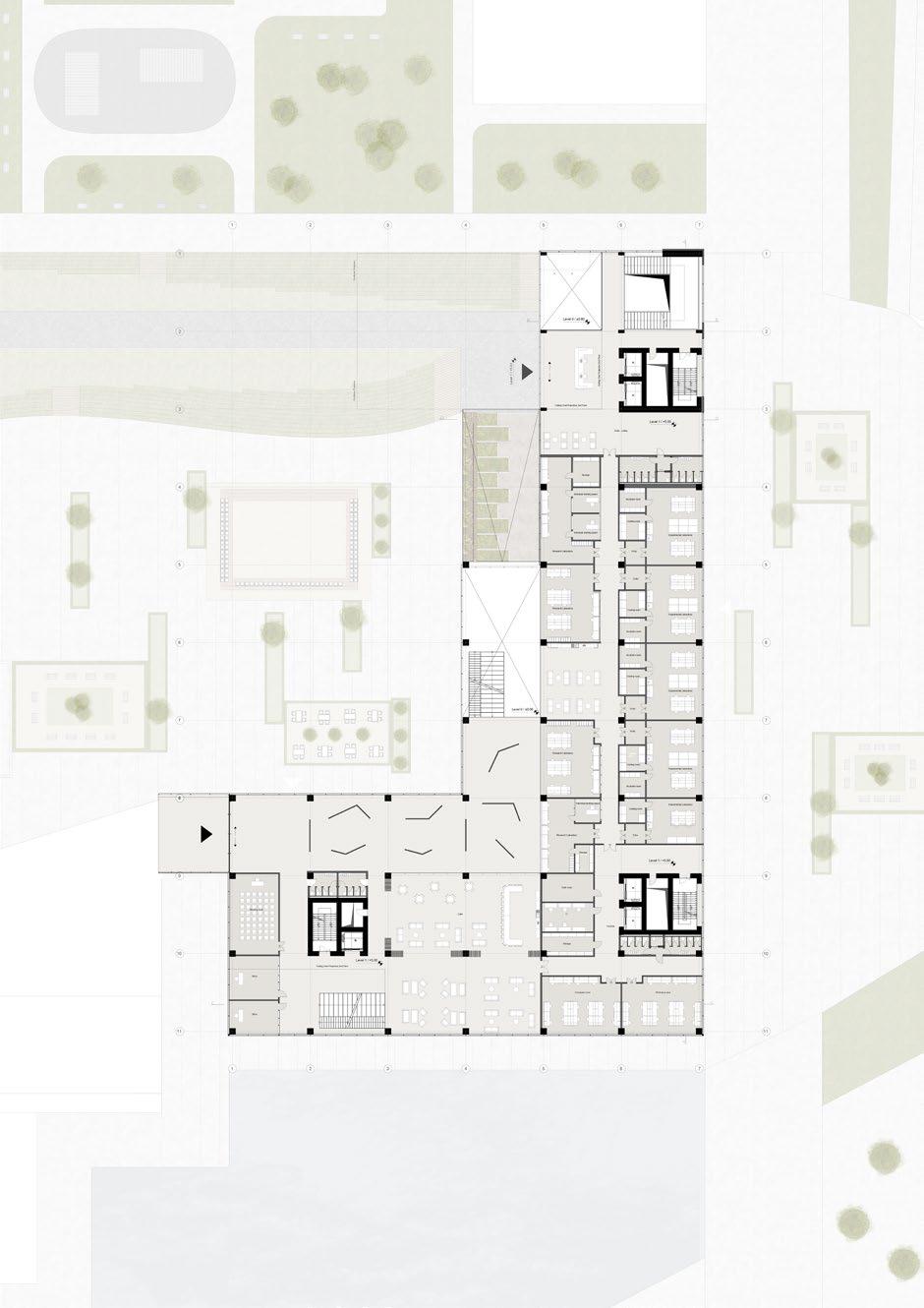

Third Floor

In the third level the building area reduces even further. Connections with new terraces which lead to the sloped roof are created. A smaller encapsulated space remains at the center dedicated to research facilities just like in the other floors, while on the northern and southern sides, open private areas for working are provided.

Fig 78: U.F. function layout

Authors

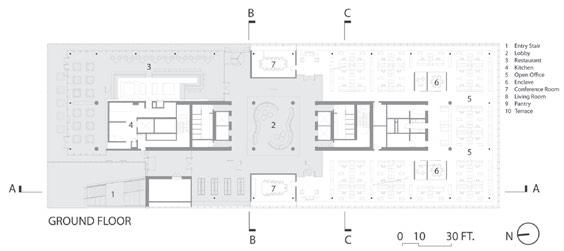

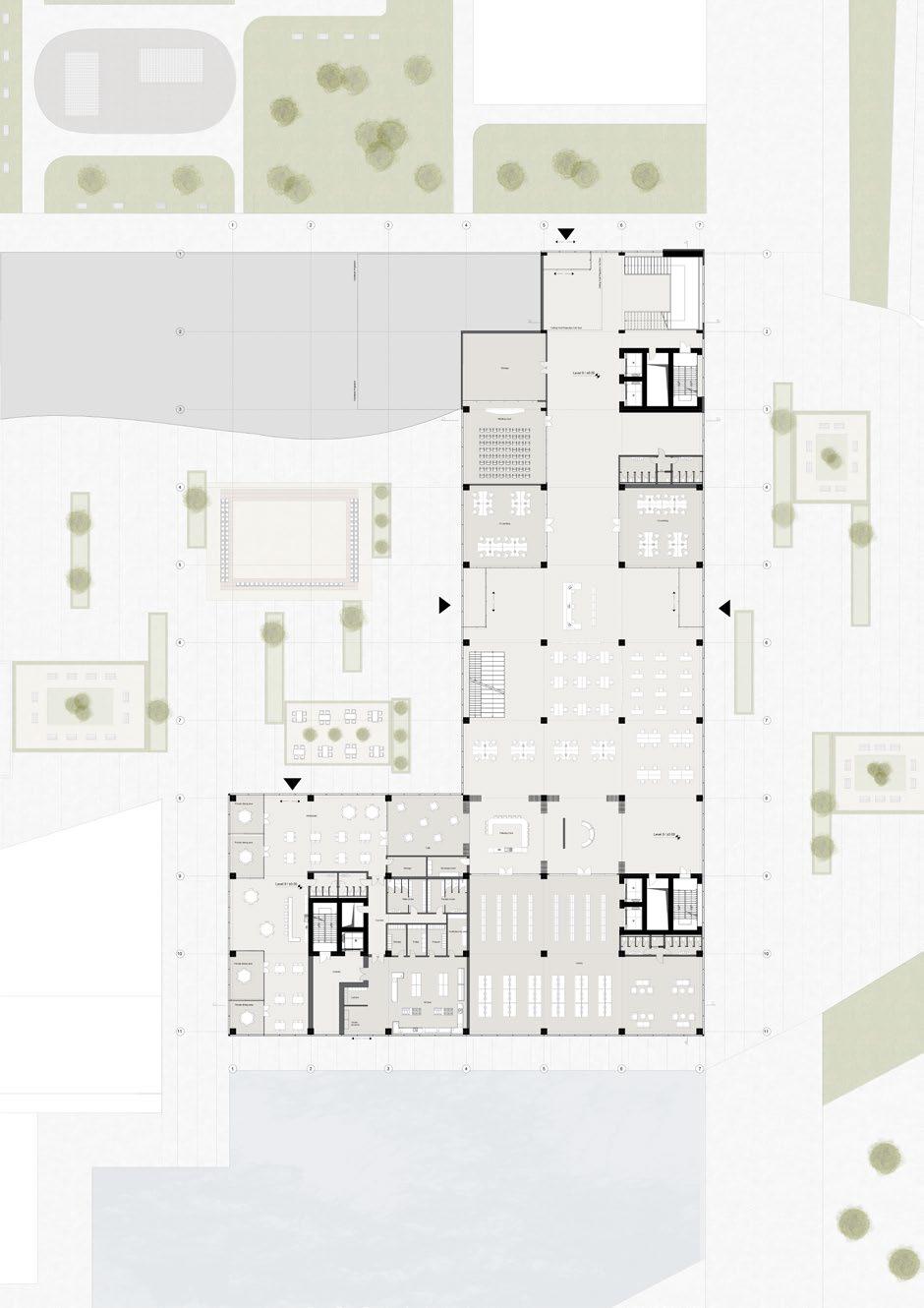

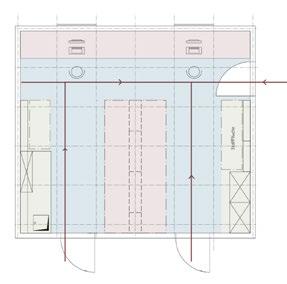

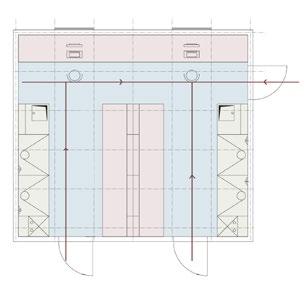

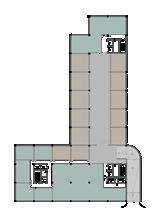

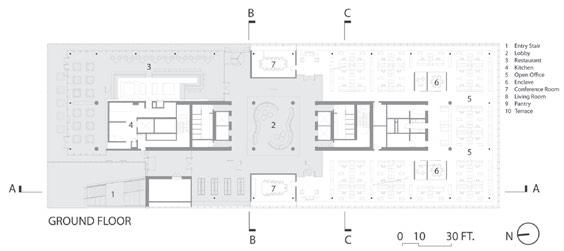

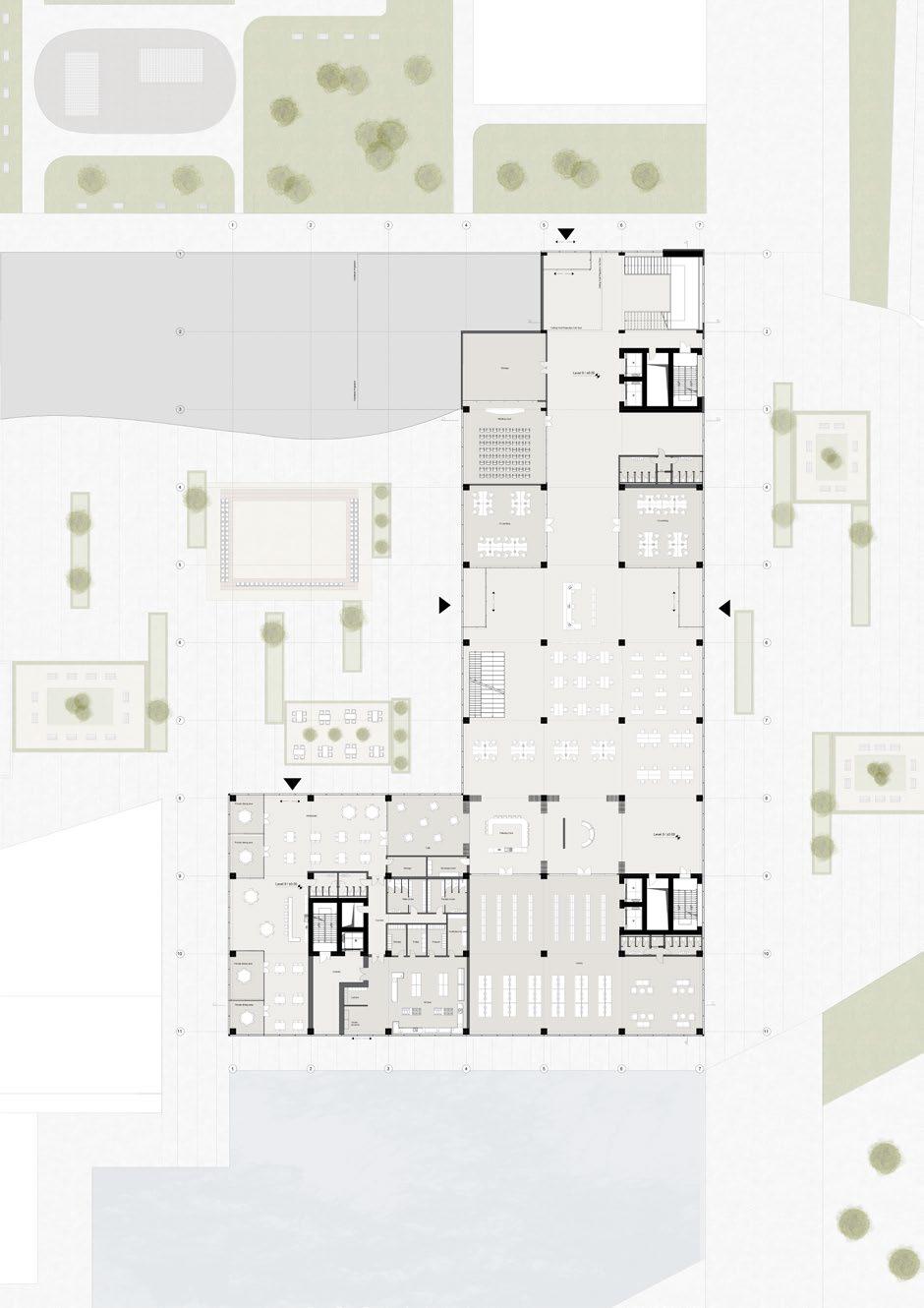

Ground Floor

The Ground Floor of the research center is characterized by functions that are vastly open to the public. In addition to this, the transparent skin of the building, together with the large open area the ground level provides, gives a welcoming feeling to visitors, university professors, or any other person seeking a working space. The functions of this large space are divided as follows:

- Closed and open co-working spaces, and meeting areas.

- A library and a reading area.

- Restaurants and cafes devoted to the public, workers, and researchers.

The co-working spaces are characterized by flexible lightweight walls, which are able to divide the area in several ways. This flexibility makes the plan more dynamic and adaptable to the people’s needs.

It is substantial to point out that this level is characterized by flexible walls in the laboratories as well as the exhibition area similar to the previous floor.

Lastly a final vertical connection is provided from the working space to the above terrace, which further leads to the final terrace of the building.

Fig 79: G.F. function layout, Authors

Fig 80: First Floor function layout, Authors

Second Floor

The logic used for the layout of the building plan becomes more apparent since a repeating pattern comes to our attention.

In this floor a similar arrangement of laboratories covers the main body of the edifice. However in the southern wing we notice a reduction of area due to the inclined green roof. From this external terrace, an additional entrance is provided to the building. The area accessed through this entrance is dedicated to co-working spaces.

Fig 82: function layout Authors

Fourth Floor

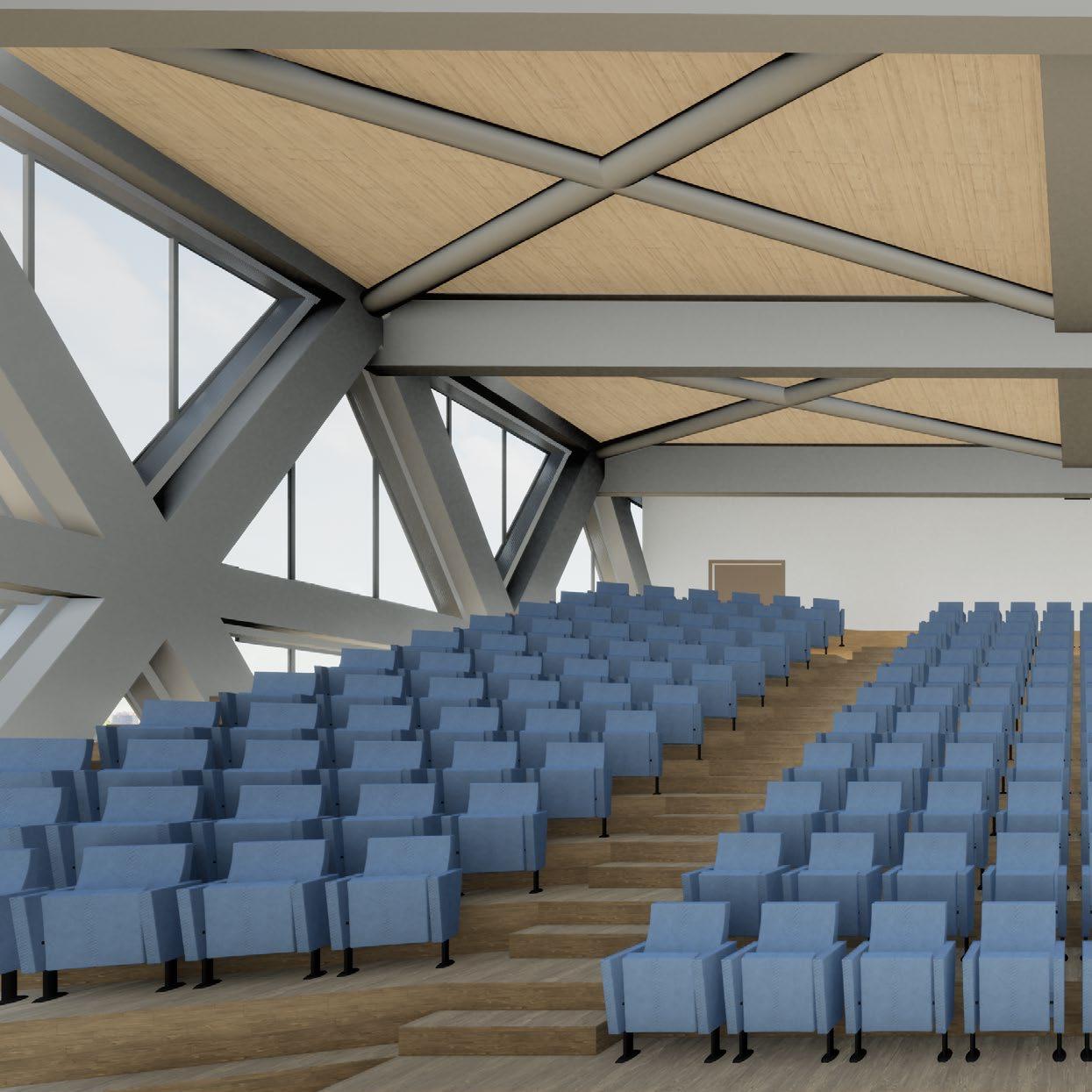

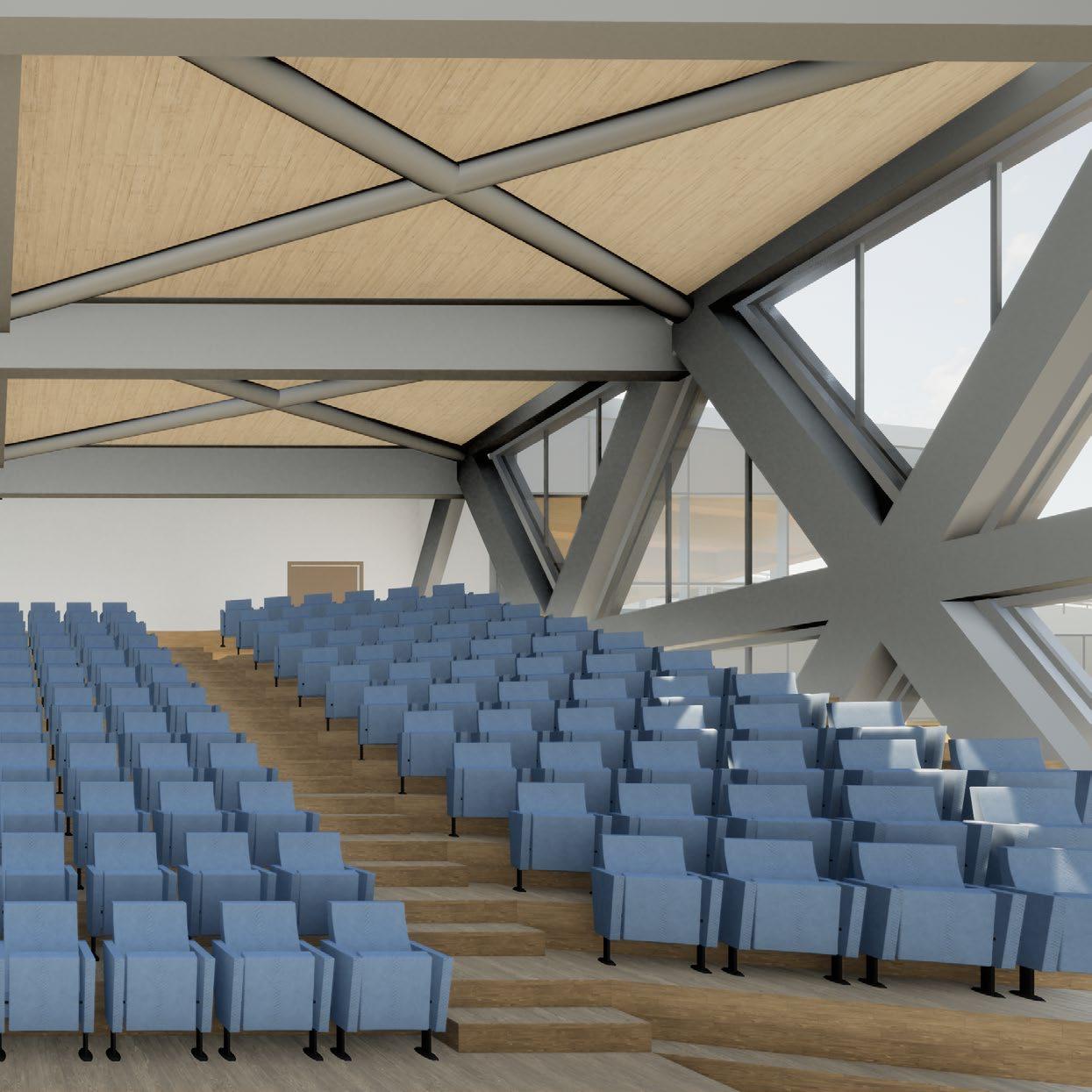

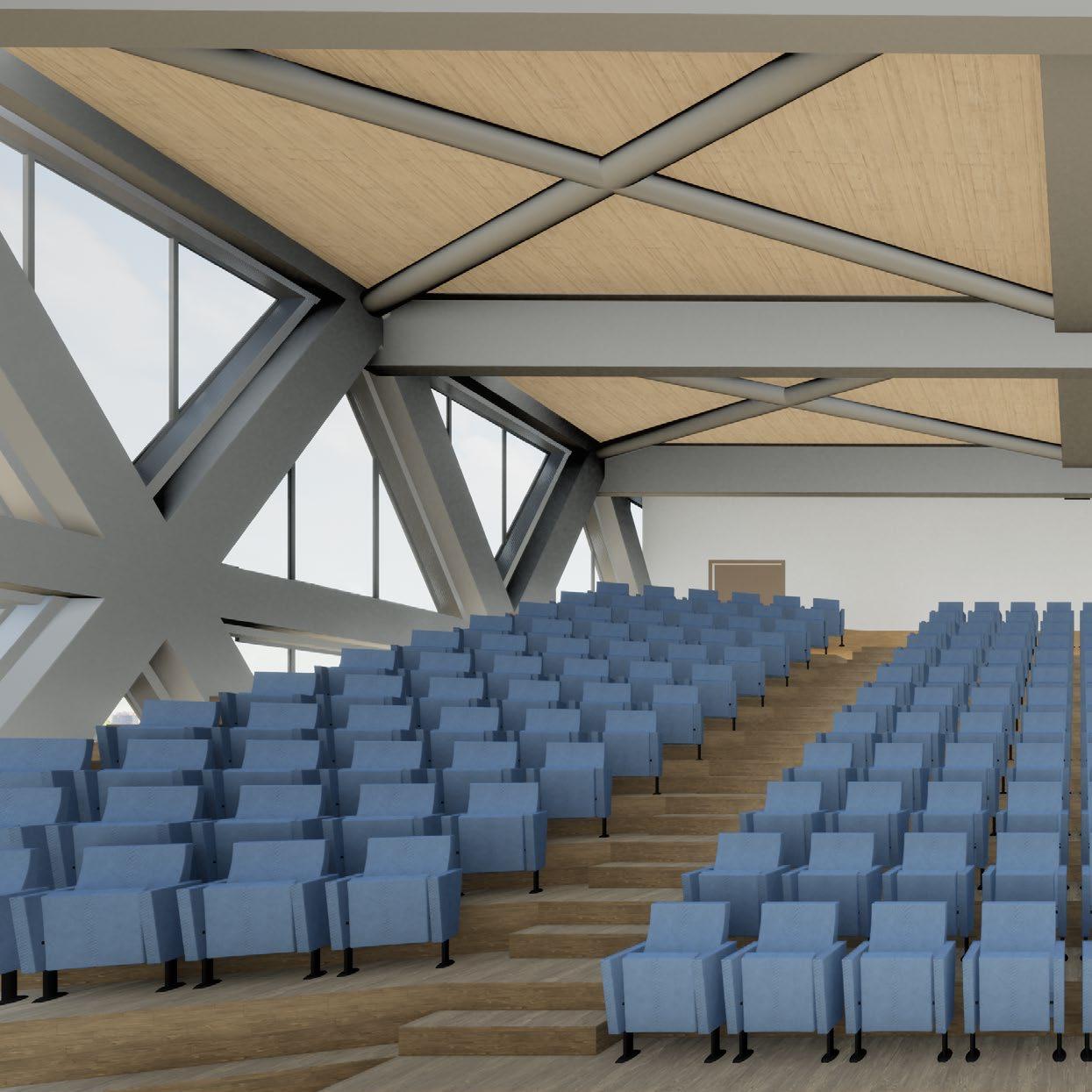

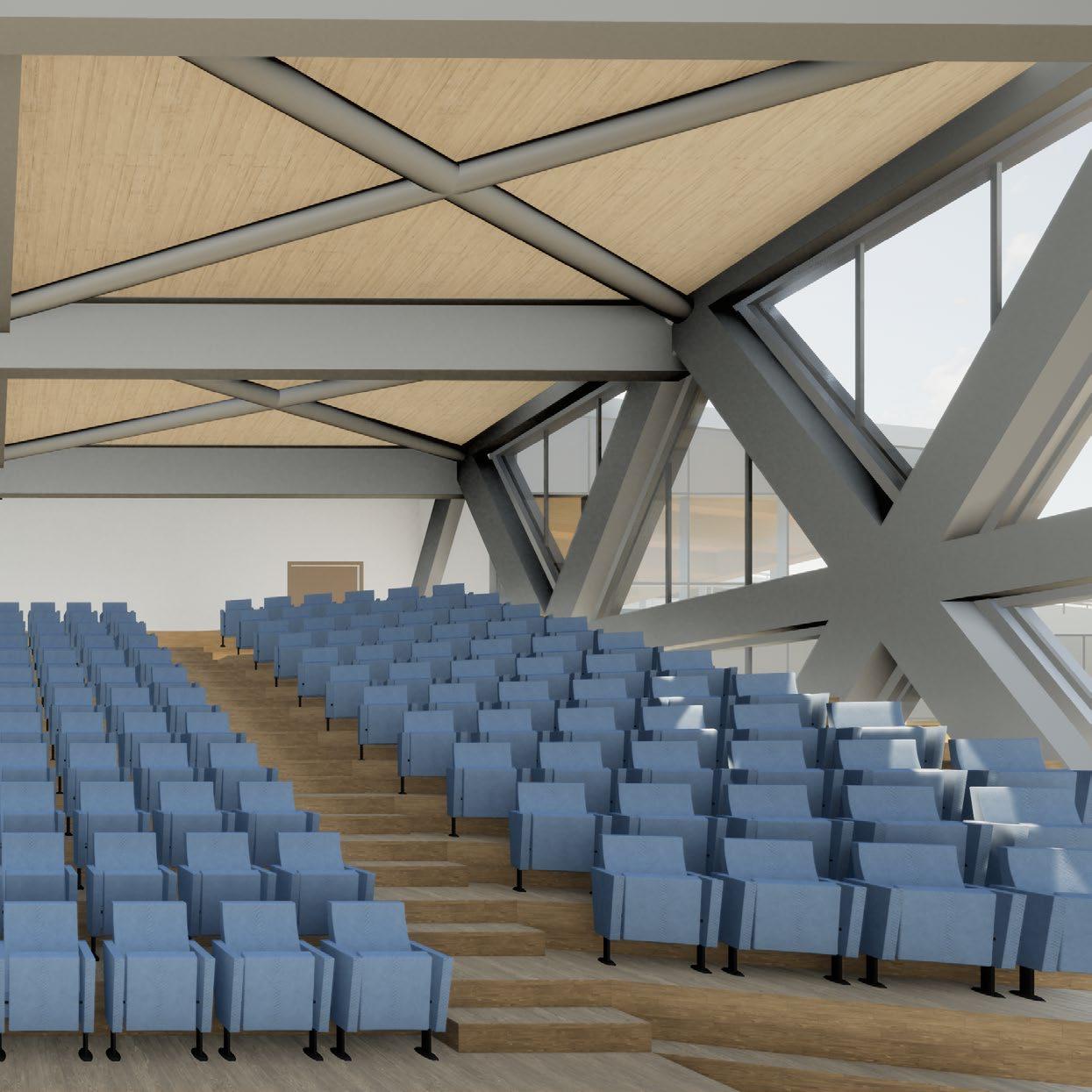

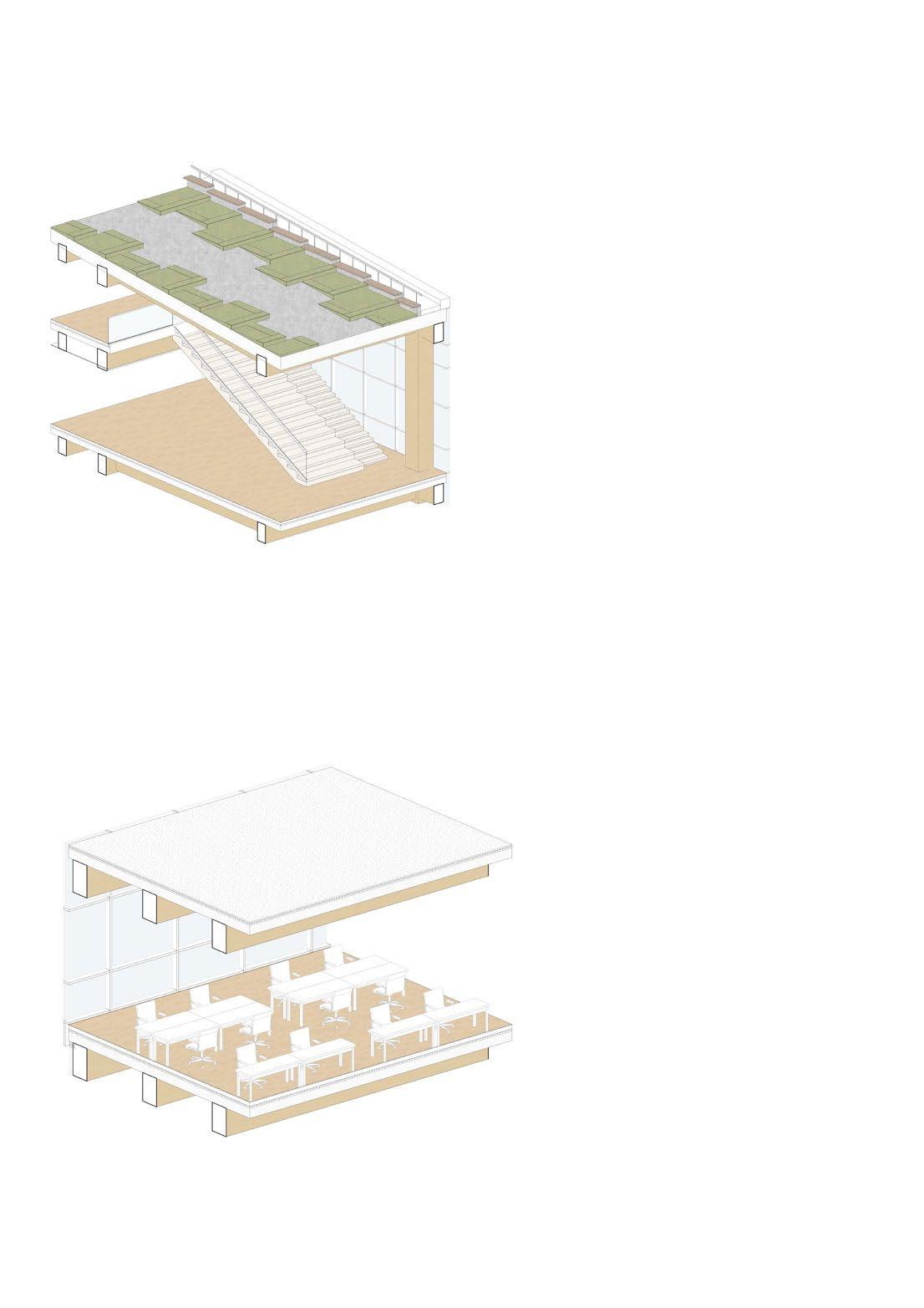

The particular features of the last floor stand in its materiality and morphology. On top of that, there is a distinction also in terms of functionality in regard to the other parts of the building. The large auditorium creates a detached space from the rest of the building which serves as a common event space. It stands at the peak height of the project and thus it gives a fascinating panorama of the whole MIND area to the visitor.

S.F. function layout

Th. F. function layout

47

Functional Distribution

Fig 84: Perspective of the recreational area Authors

48

Functional Distribution

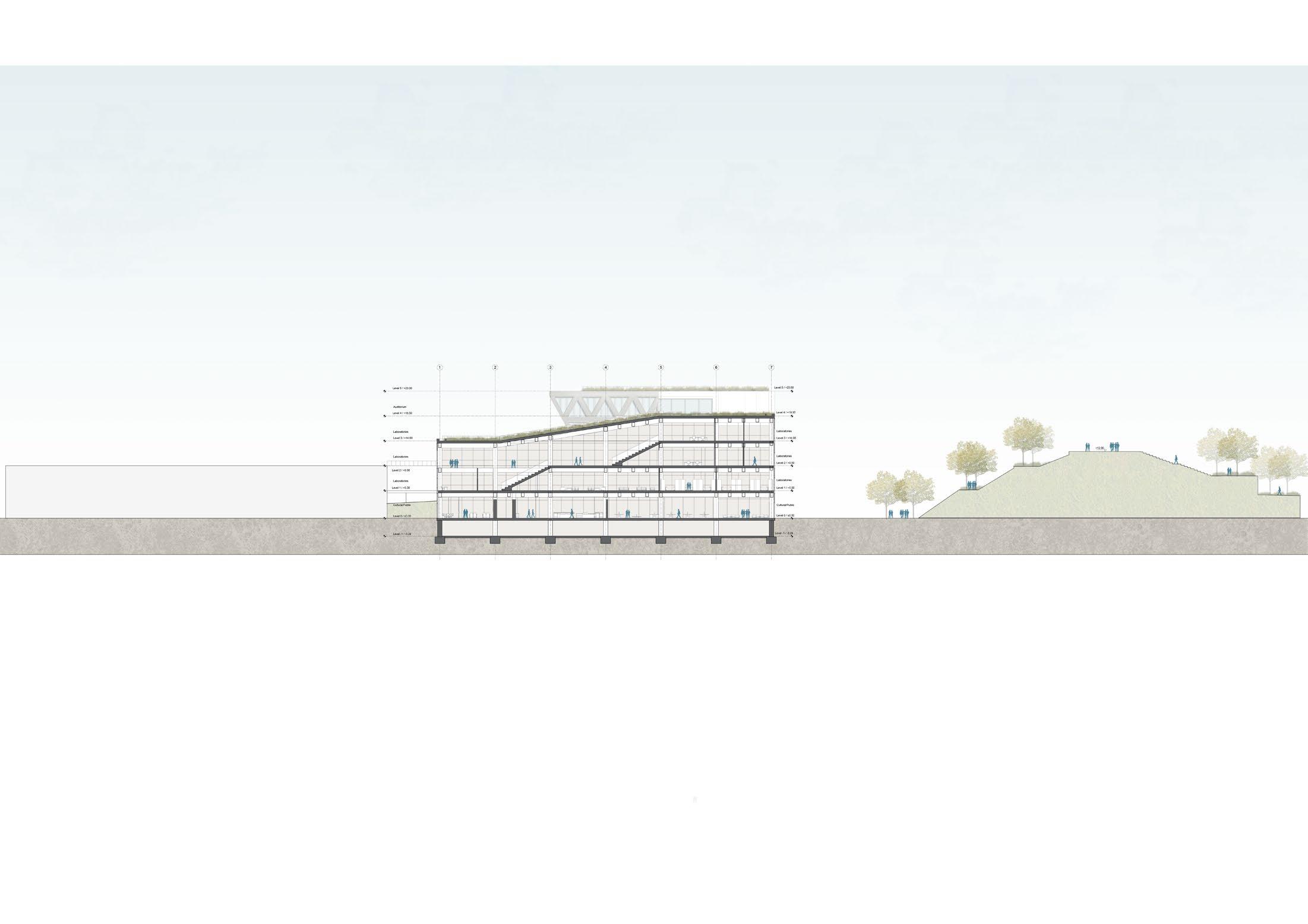

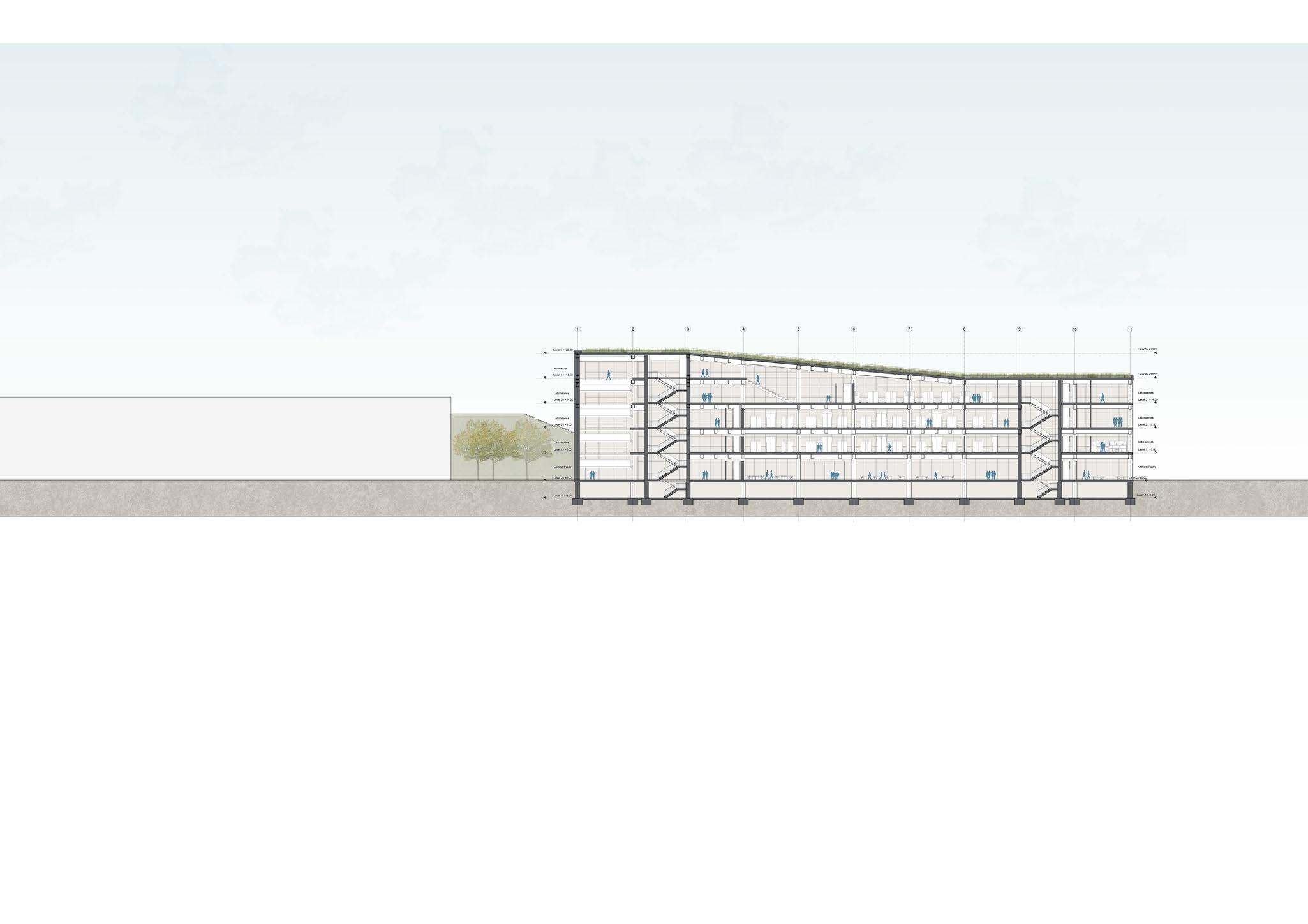

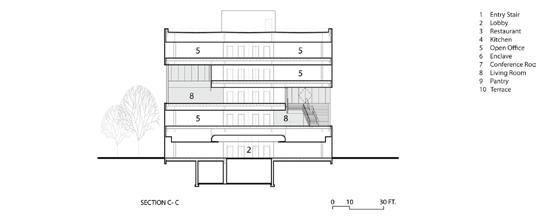

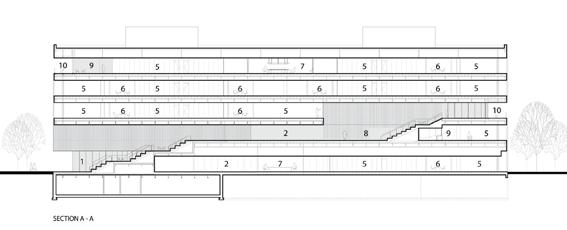

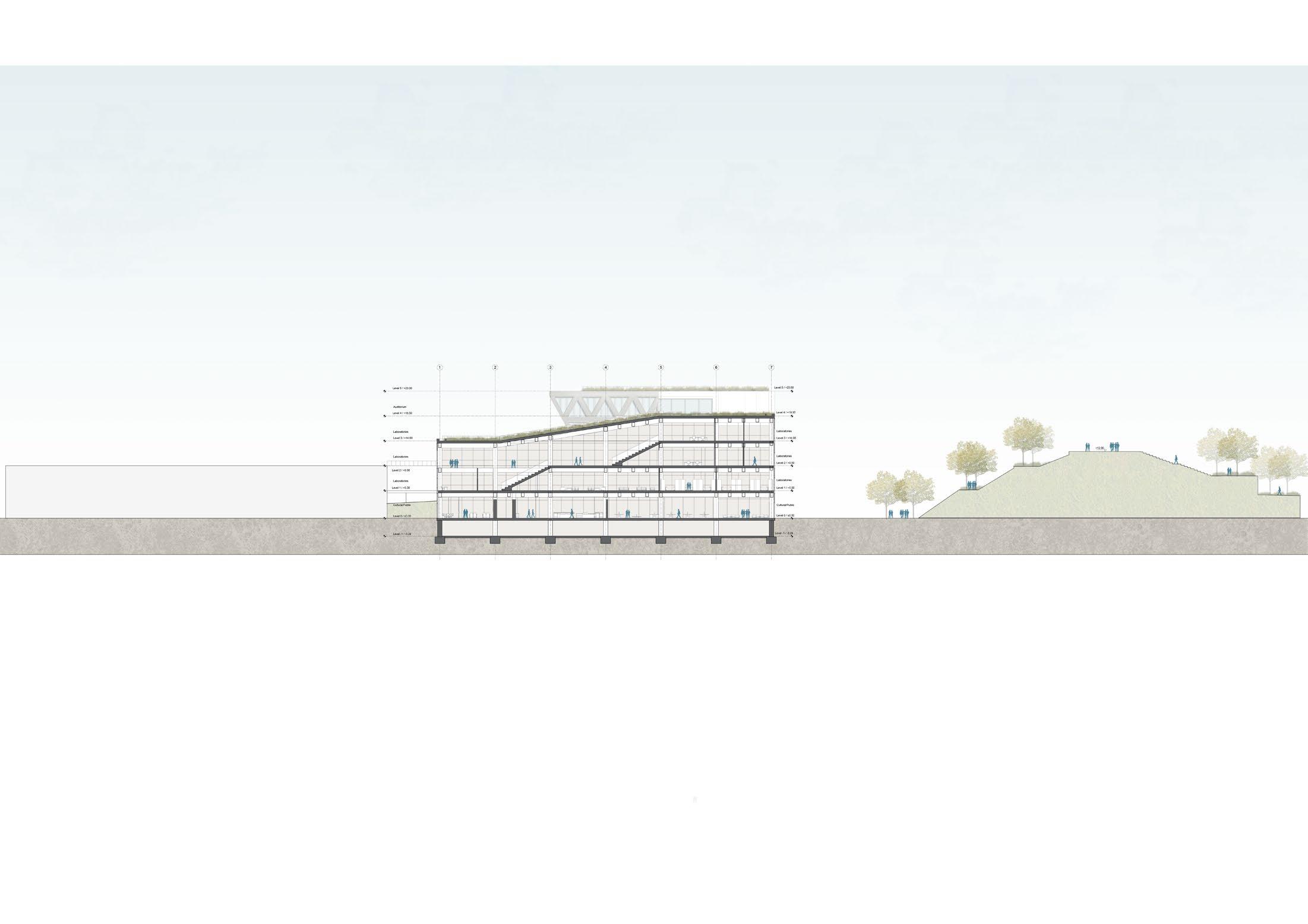

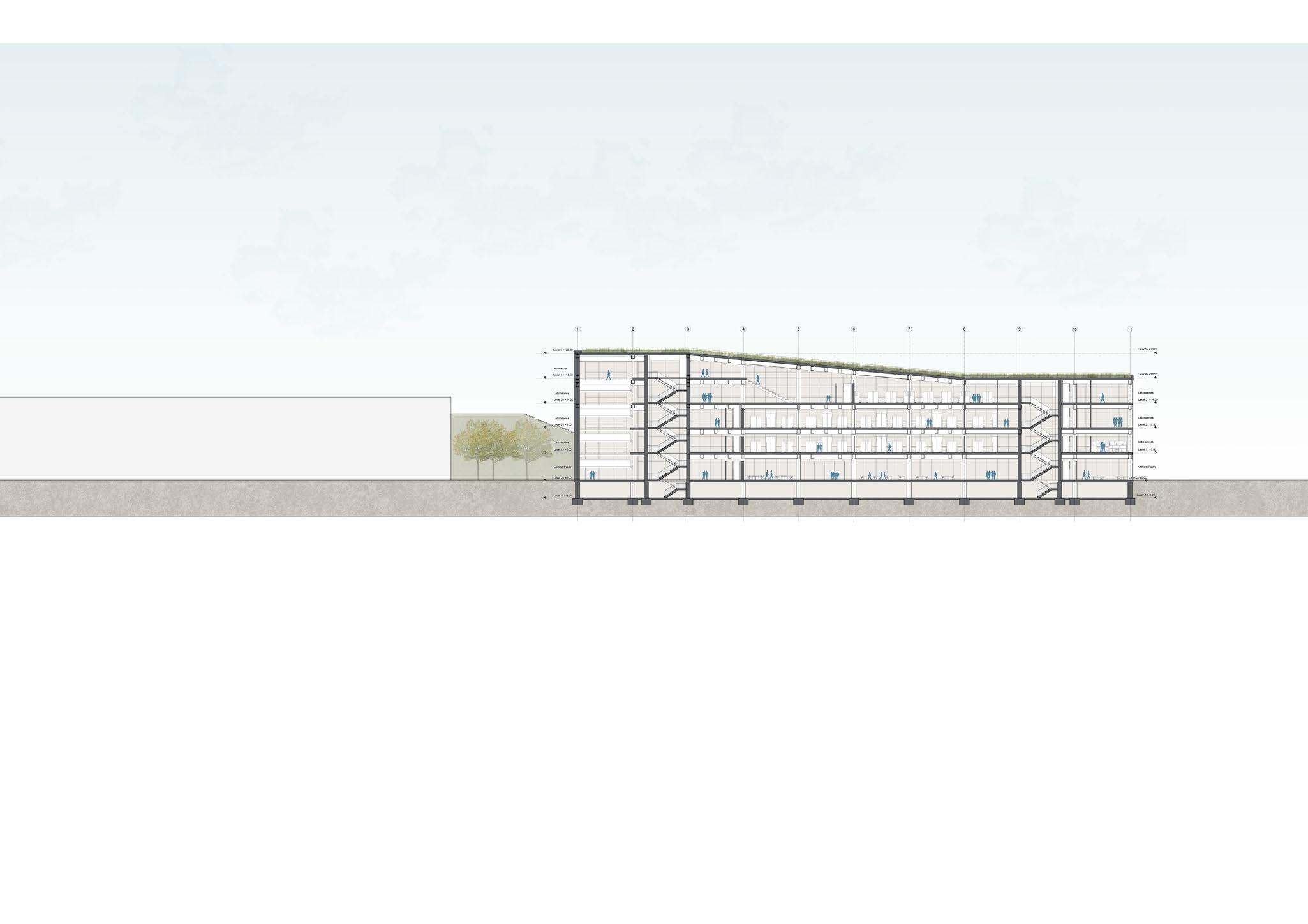

Fig 85: Section A-A, Authors

Fig 86: Section C-C, Authors

Functional Distribution

case study: typological series

Type, Variation, Transgression

The case study is based on observing theoretical and cultural foundations for designing new buildings. To learn from the past and explore modern ways. Typology studies are comparative studies to understand the difference between types and history.

One of the main aim was to highlight the significance of the new design buildings by making a comparison between other reference buildings. The process began by specifying our typology and then observing others.

The ‘typological series’ study is divided into three parts.In the first part, one of the main concepts, the typology of open spaces, will discuss. Then in the second part, superimposition and layers, the last part typology of the plan will be investigated.

Organisation of Ground floor - open spaces ,Sections, Circulation

Novartis Campus, Weiss Manfredi, 2013, East Hannover, USA

With its column-free spans and clear glass, which divides spaces for groups to collaborate, Novartis Campus introduces an innovative world.

Working areas have a light organization to allow flexibility, similar to the Research Lab Center. The concept of “ Common Ground” is one of the intersection points of the projects.

The primary connection between Novartis Campus and Research Lab for Natural Sciences is the design philosophy of the architectural stairs which connect the floor.

Fig 87: Ground Floor Plan, Novartis Campus

Fig 88: Section, Novartis Campus

Fig 90: Section, Novartis Campus

Fig 89: Section, Research Lab for Natural Sciences, Authors

Case Study:Typological Series

Fig 91: Building sketch, Novartis Campus

50

In the second part of the case study, the term ‘superimposition’ was one of the guides. Research Lab Center has diverse floor plans and buildings created by superimposing those different layers. The project Regione Lombardia shown in Figure 100, is an excellent reference to see the evolution of the floor plans, which is similar to our project’s design process.

The following approach is to study circulation, ramps, and circuits to focus on the buildings with identical design perspectives.The main design element of the Research Lab for Natural Sciences is green slope ramps which have created both external and internal concepts. This green slope is not only for transition

Figure 95 emphasizes the ramps that connect different levels at the Project of Regione Lombardia and Piacenza municipality building. The sense of taking and directing people to the building with a ramp at the entrance is parallel to the project

51

`Layers`

Superimposition -

Fig 92: Diagramatic plan schemes, Research Lab Center, Authors Fig 93: Lombardia Region Headquarters - Mario Cucinella , Foster + Partners

Fig 96: Municipality of Piacenza , MCA

Fig 95: 3D, Research Lab for Natural Sciences, Authors

Fig 98: Municipality of Piacenza , MCA

Fig 97: Municipality of Piacenza , MCA

Case Study:Typological Series

Fig 99 - Ground Floor Plan,

the common ground

52

The Common Ground

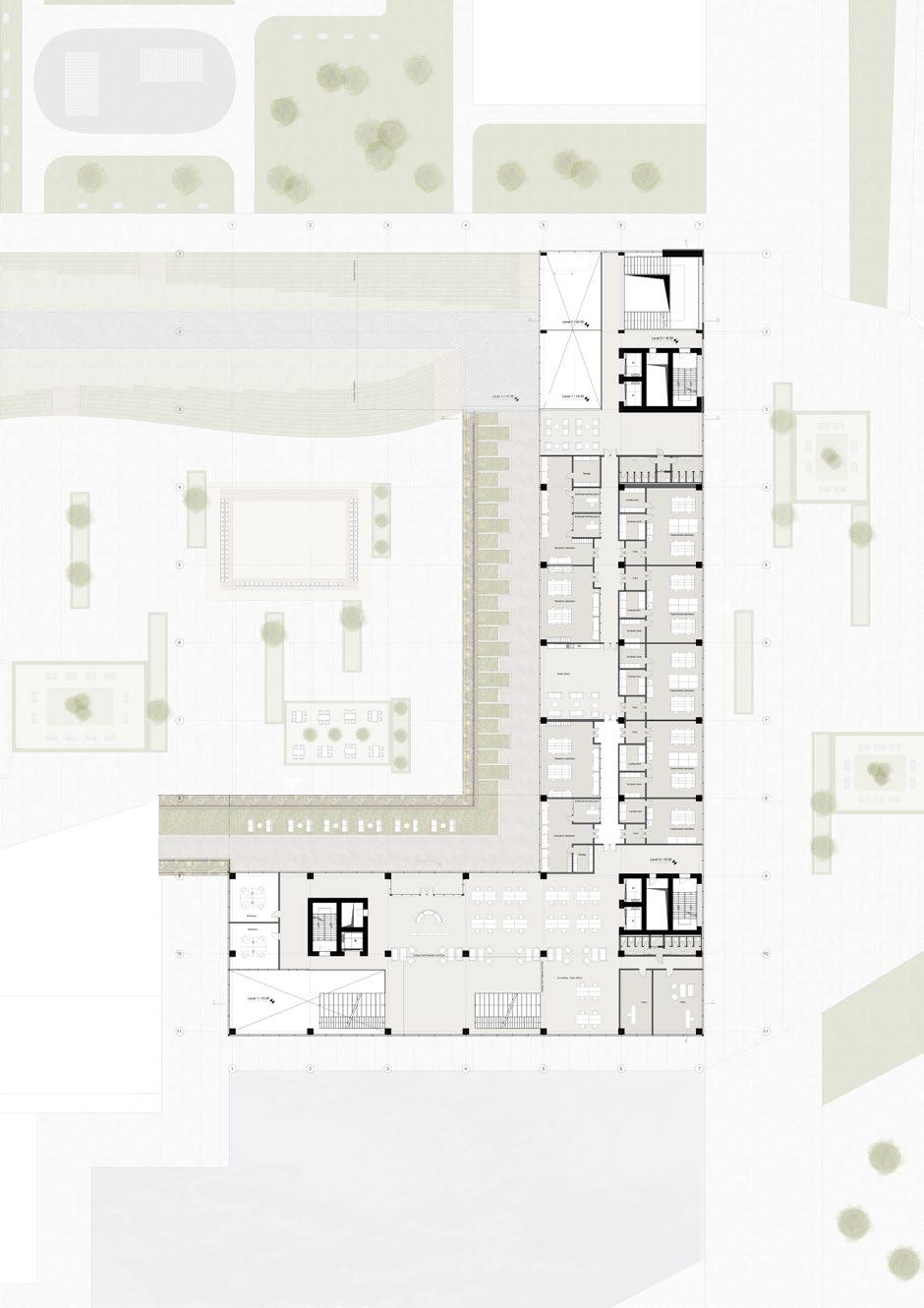

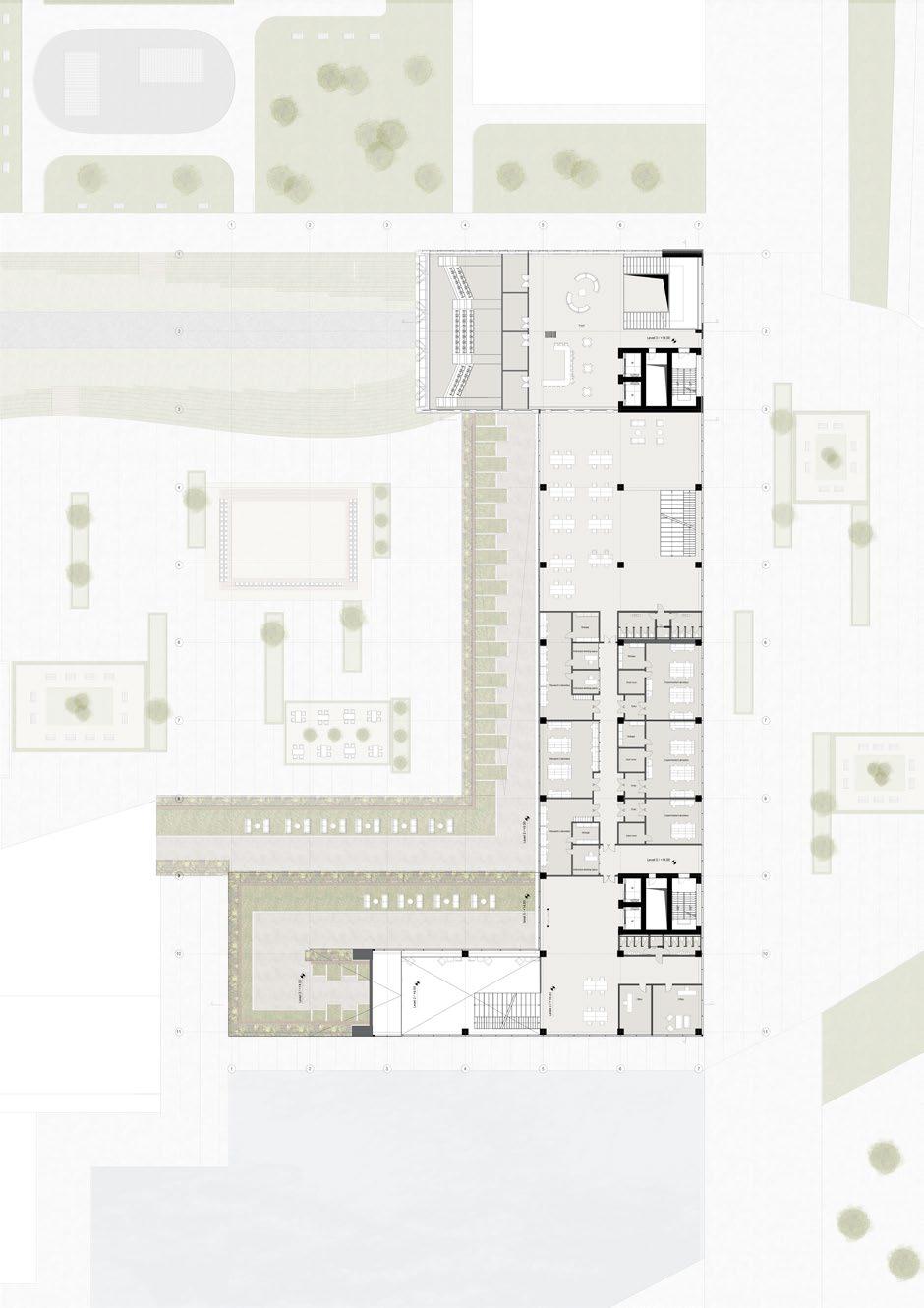

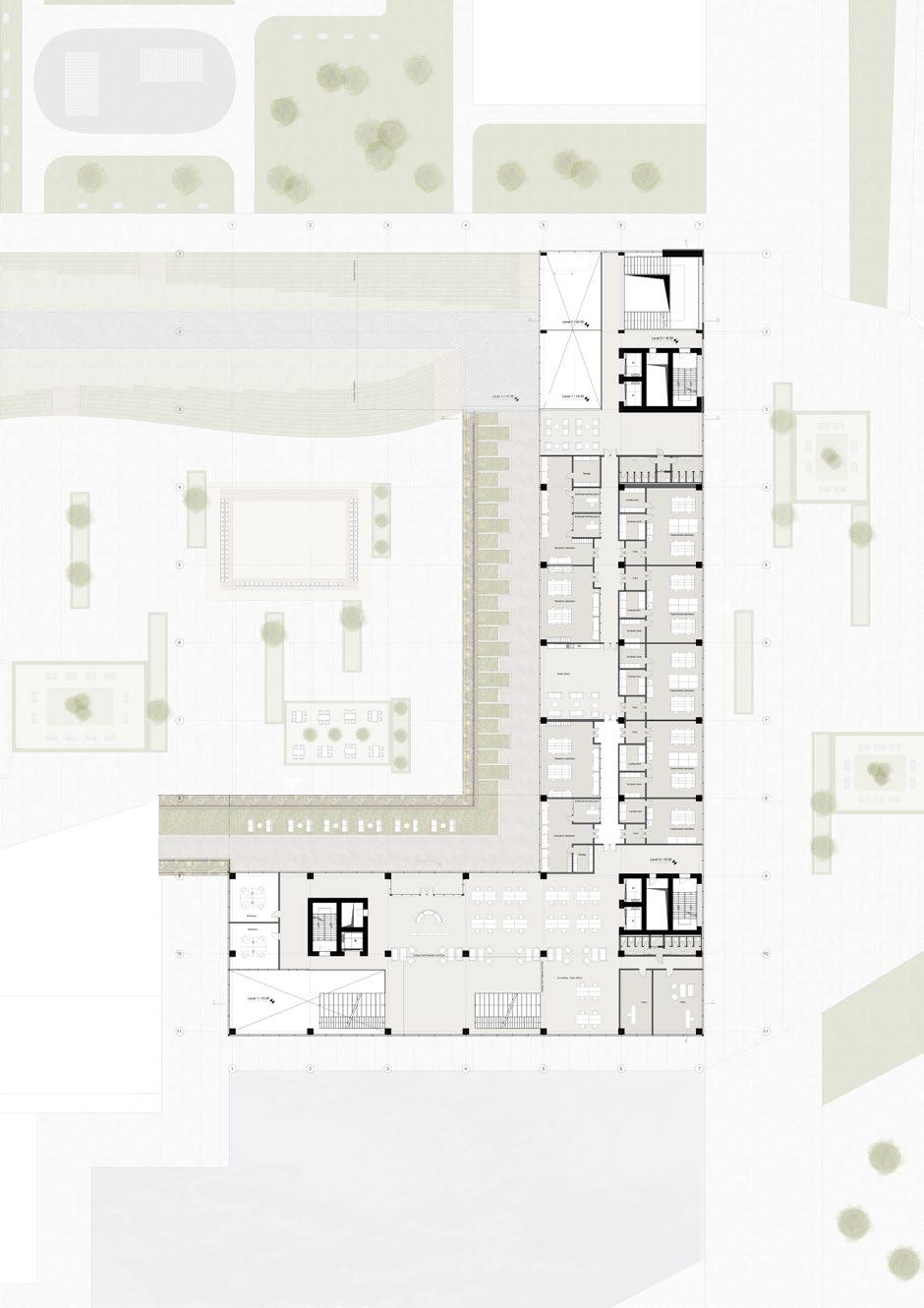

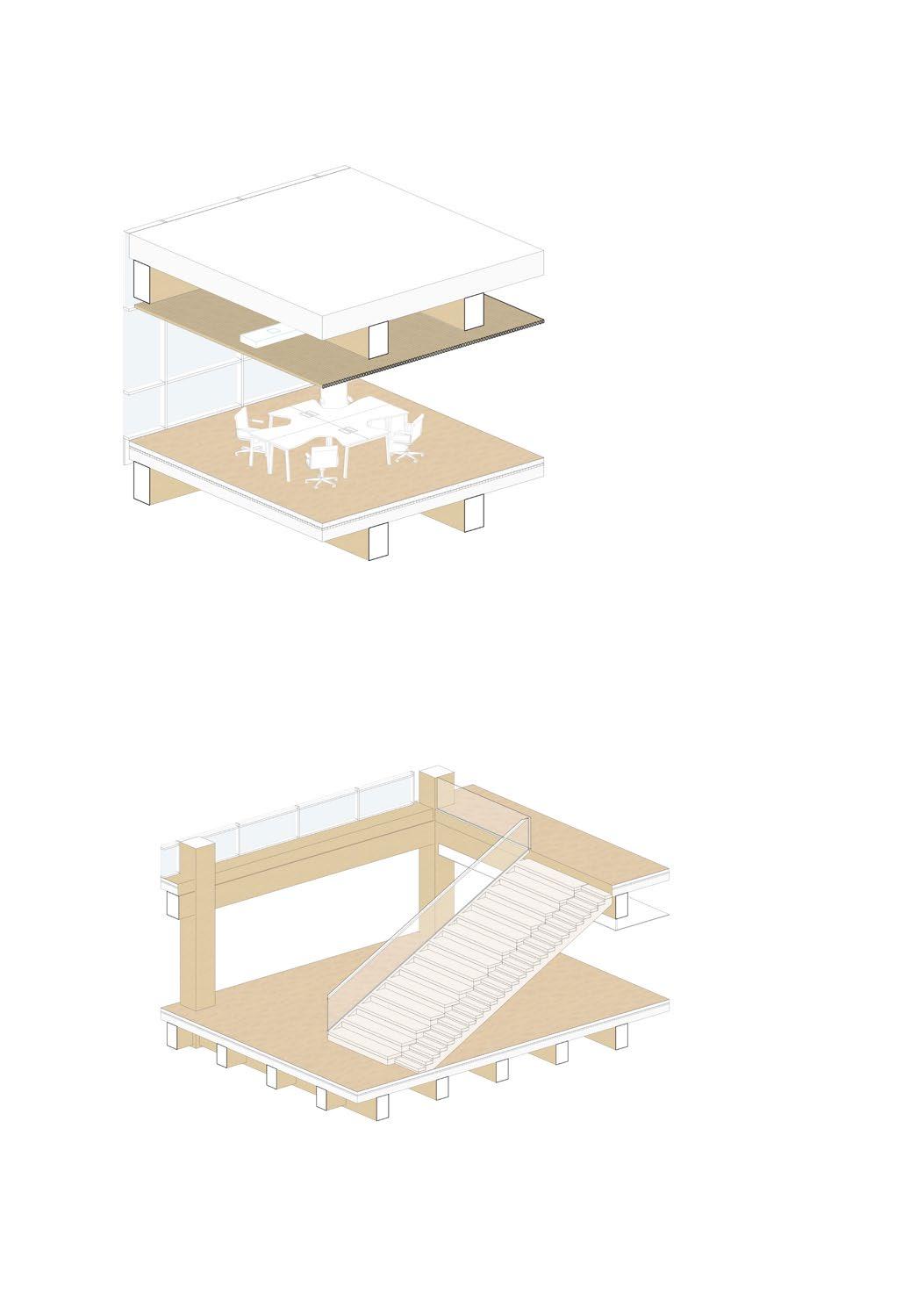

The structural layout played a key factor in the design of the common ground. The large spans inbetween columns provided a more transparent interior. The regularity of the structural grid allowed for a consistent configuration of the facade as well as for a better distribution of the functions throughout the building floors. In more concrete terms, the ground floor is separated into 3 areas ; the foaye occupying the northern wing, the co-working space allocated along the main body of the building and the southern wing, where the library and the rstaurant are distributed.

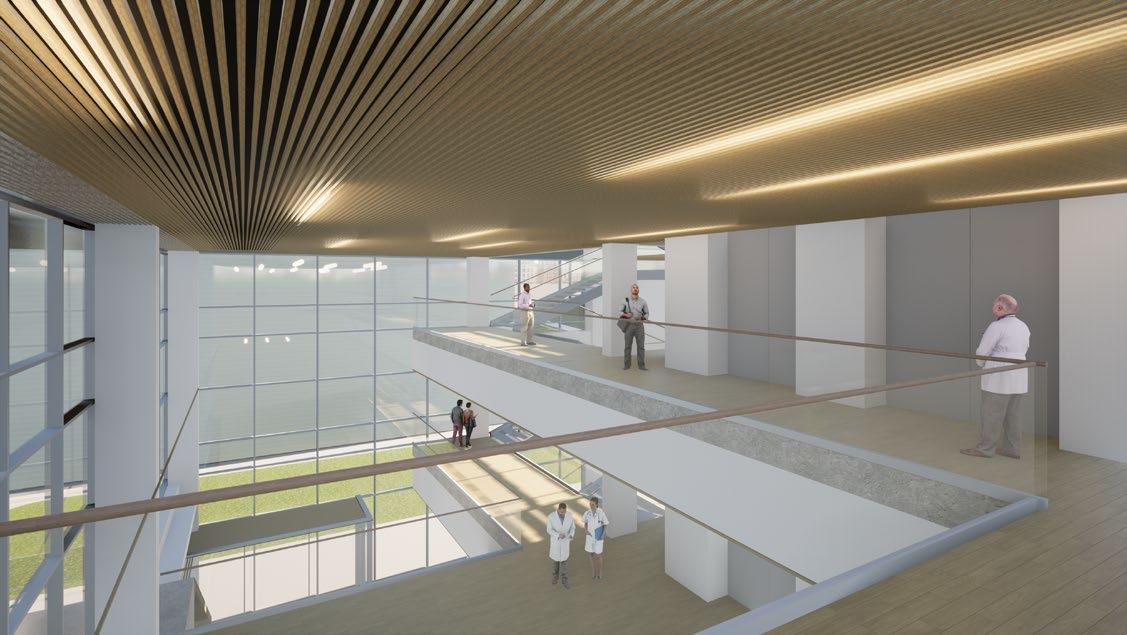

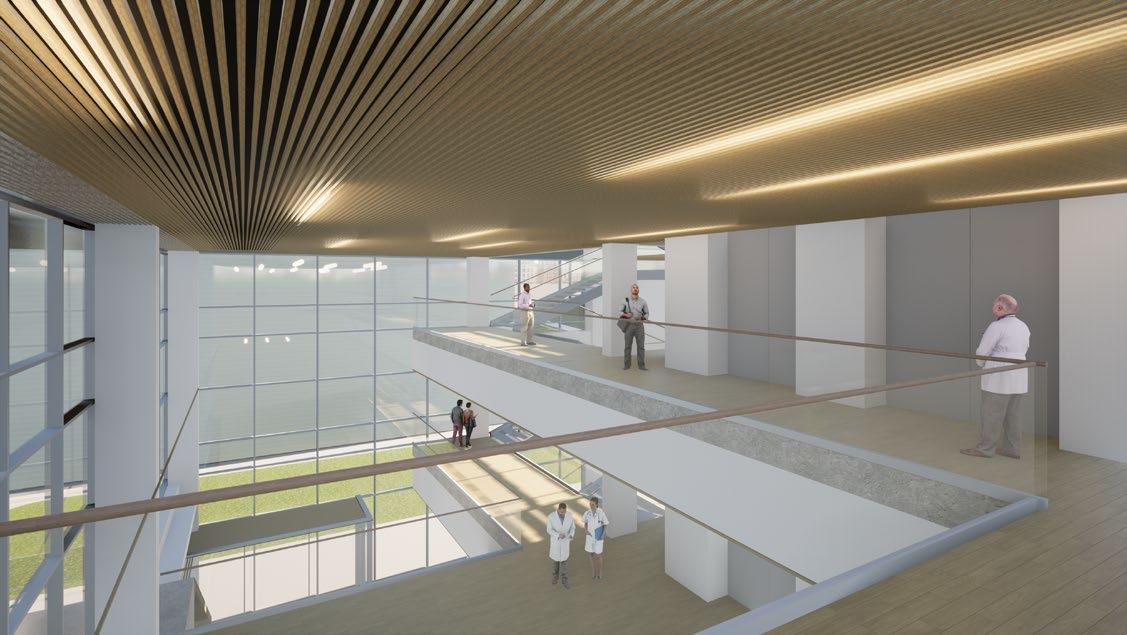

The foaye represented below is the interconnecting point between all the levels. The circulation that it provides gives access to all the laboratory areas in the upper floors, as well as the auditorium that occupies the overhanging volume. The height of the lobby reaches up to the ceiling of the 3rd floor, thus creating a unified space. In the first floor the access is granted through the ramp. Having said that, the second floor generates a bridge connecting the staicase to the laboratory area, from where the viewer overlooks the access points in the ground and the first floor.

53

The Common Ground

Fig 100 - Entrance render, Authors

Fig 101 - Co-working axonometry, Authors

54

The Common Ground

Co-Working space

The structure is distributed throughout a total span of 30 meters. Containing two access points, the co-working area can be regarded as an interconnecting point inbetween the eastern entryway and the rest of the masterplan.

The flexibility that characterizes the layout of this space, as well as the large spans generated inbetween the wooden structural components, transmit a feeling of unification through a collective workplace.

The area is accessed by anyone. Thus, it is conceptualized as a public point where ideas are communicated and exchanged. It is a hub of knowledge and circulation of information.

Adjacent to the workplace, we have introduced a filtering area enclosed with movable partitions, which is utilized as a break space, or a tansitioning room ahead of the south wing.

On the other hand, below the western entrance, the staircase is used as a connecting architectural element between the ground and the exhibition area in the above level. In addition to the circulation, the set of stairs function also as a reading and leisure space.

55

Center

Ground Floor Plan 1:

Fig 102 - Common Space: Co-Working Spaces, Authors

for Natural Sciences

200

Beverage room Filtering Zone Level 0 / ±0.00 The Common Ground

56

The Common Ground

Fig 103 - Recreation area axonometry, Authors

Library and restaurant

The southern wing shows a more rigid configuration compared to the previous workspace. However, it is mainly separated into two adjacent areas; the restaurant on the western side and the public library on the eastern one. The junction point inbetween the spaces is the filtering room described earlier. Both the library and the restaurant are conceptualized as public independant spaces that can also be directly accessed from the external piazza.

Even though, at first glance the layout of the south wing appears to be more rigid, it follows a similar logic as the other areas of the building. The wooden structure allows for a very straightforward distribution of space. The large spans provided from the columns, give flexibility to both the interior of the restaurant and the library. Notwithstanding, the structural cores adjacently located provide the perfect solution for the distribution of technical spaces, toilets, changng rooms, kitchen and other storage rooms.

In contrast to the co-working area, the structural frames are not visible in the foaye, the corridors , the library and the restaurant space. The slabs are covered through a system of linear wooden beams that constitute the false ceiling. The purpose of such decision is to cover the heating system above the ceiling structure and as a result to maintain a more neat interior.

57

M N D Research Center for Natural Sciences ENTRANCES LOBBY- CIRCULATION - : - Circulation : 200 sqm 1295 sqm - Restaurant (Including Kitchen&Staff) : 685 sqm - Cafe: 200 sqm - Co- working spaces : 820 sqm - Meeting Room 150 sqm - Library : 600 sqm ARCHITECTURE BUILDING ARCHITECTURE A. A. 2021/2022 03 CITY CAMPUS ARCHITECTURE Ground Floor Plan 1: 200 Floor height Total Area 3700 sqm Ground Floor: Section D-D’ 1:200 South Elevation 1:200

Fig 104 - Restaurant and Library, Authors

Goods received Lockers Kitchen Storage Fridge Freezer Ventilated dry store Male locker Female locker Storage Beverage room Corridor Corridor Restaurant Cafe Private dining area Private dining area Private dining area Private dining area 21 20 17 11 14 17.85 28 24 Level 0 ±0.00 Library Filtering Zone 21 20 17 11 13 28 28 25 24 Level 0 ±0.00 The Common Ground

58

The Common Ground

Fig 105 - Interior render of co-working , Authors

59

The Common Ground

Fig 106 - Interior render of library , Authors

60

Fig 107 - Render of the exhibition and lounge area, Authors

exhibition area Exhibition Area

61 Exhibition Area

Fig 109 - Axonometry of the exhibition and lounge area , Authors

62

Exhibition Area

The exhibition space is integrated as a place for communication thorugh the presentation of works as a manifestation of ideas, as well as an exchange of knowledge and experience. it is a place where the expertise and innovation achieved in research and science can be transmitted to anyone. Through such place any person can get a glimpse of how natural science is evolving and how it can affect the everyday life.

Allocated in the south wing, the main access point for this space is through the aforementioned staircase in the common ground floor. It is later followed by an open recreational area used as a large open breakroom.

The connection through different levels through the wooden staircase aimes at generating a continuity between the different levels. Just like the common ground also the recreational area is designed to express the same movement and dynamism. This fabrication of atriums comes also as a result of the integration of the sloped roof.

Fig 110 - First Floor zoom-in, Authors

63

Computer room Cafe Meeting room Workshop area 22 19 18 11 13 17.30 13 17.30 12 28 25 Ceiling Void Projection 2nd Floor Level 1 / +5.00 Cooling room Dry Room Cooling room Research Laboratory Lab Type 1 Lab Type 1 Research Laboratory Entry Corridor Dark room IT Storage Individual working space Storage 23 20 17 15 13 13 17.30 24 Level 1 / +5.00 Office Office

Exhibition Area

restricted co-working

64

Resricted Co-Working

Fig 111 - Co-working space render, Authors

65 Resricted Co-Working

Fig 113 - Perspective section of the south wing, Authors

66

Resricted Co-Working

67

Research is more lifestyle than work. It is a lifestyle that tends to form a large part of a researcher’s life.1

Laboratories are the place where researchers realize themselves. The atmosphere of the space leads the way in studying. Because of that it is essential to understand their history and meaning.

Additionally, the laboratory reflects modernity. It provides a connection between humans and technology and science; It has created history primarily as an enclosed space. Also, it is technically and organisationally highly refined, as they have to serve specialized work processes efficiently.

laboratory design

The research environment, which used to be more introverted in the past, today is more collaborative. This means space should be open to interaction and coworking for experiments. So architects should design space not only for research and technical equipment but also for social interaction between scientists.

68

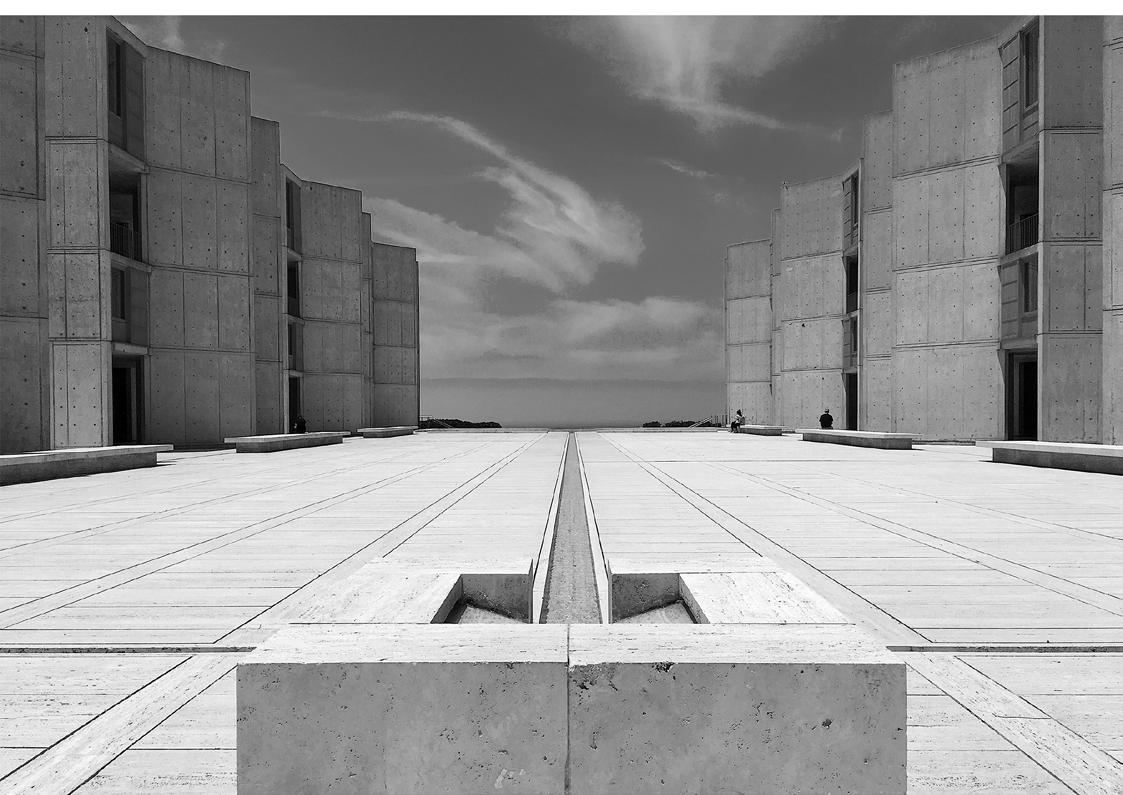

“ The nature of the space reflects what it wants to be” Louis Kahn

Fig 114: Salk Institude, Louis Kahn

Laboratory Design

History of the term “laboratory” :

The Latin term laboratorium (from the Latin term labor, meaning exertion, effort or work) was already in use in the medieval period. However, it was only in the late 16th century that the term assumed the meaning which it retains in modern languages today. Schmidgen H.(2011). History of the Beginnings of the Laboratory in the Early Modern World.

In the 14th century, the term laboratorium meant simply a task or work.Today, Oxford English Dictionary defines “laboratory” as a “building set apart for conducting practical investigations in natural science”.

Laboratory buildings are technically and organisationally highly refined, as they have to serve specialized work processes efficiently. Because of that reason, it is essential to understand their history and meaning.

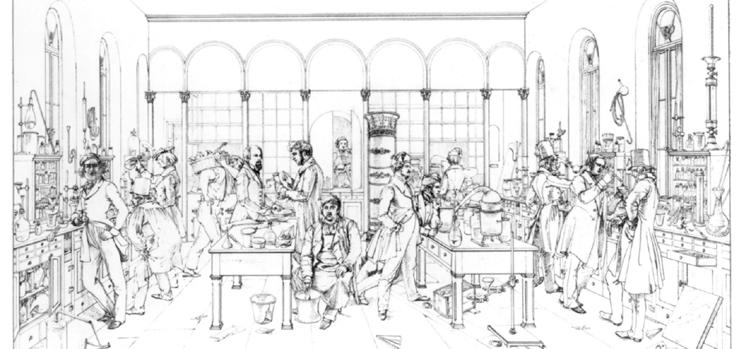

Figure 115 represents Encyclopédie is the first depiction of a laboratory organized according to scientific principles.

According to 1765`s Laboratory illustration there are some researchers in the room with a modern looking. According to sources, these researchers are scientists, physicists, and laboratory assistants. They are debating the experiments around the rectangular table. Also, there are some technical pieces of equipment around the table.

The Revolution of Laboratories:

During the 19th century, laboratories developed by the influence of university reforms and founding new universities. The university systems began to change. Universities became place of scientific and technical research.

Liebig’s famous laboratory in Giessen (Figure 116) has a collective working atmosphere and does not even seem to have had a special room for storing chemical substances

69

Fig 115: Chemical laboratory, 1765 / S.Henning

Fig 116: Liebig`s teaching laboratory

Early Modern Period : The Laboratories

Laboratory Design

case study: philosophy of lab design

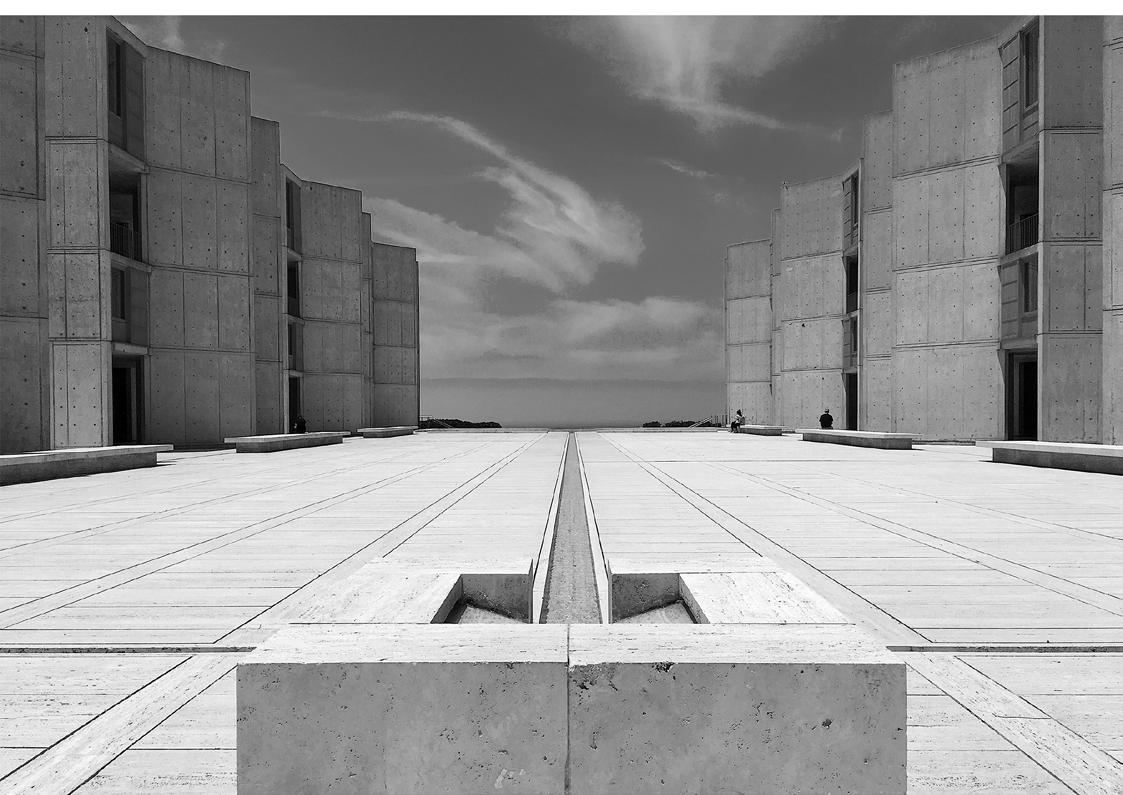

“Concrete is the material of parking garages and overpasses and highways, but in the Salk Institute, the concrete has an enormous warmth to it and changes in beautiful ways as the sun moves around or the fog rolls in.” Nathaniel Kahn

The motivation for selecting the project is to begin operating on a specific topic, and it is essential to comprehend and observe iconic examples. Salk Institute is one of the leading projects of the laboratories, and it was passionate to create a communicative atmosphere within the house during the design.

In addition, writing desks in the laboratories are positioned along the windows and are separated from the lab benches with glazed partitions. Throughout the building, the use of glass provides transparency and also corresponds well with the Research Center for Natural Sciences laboratory design principle. The Salk Institute, Louis Kahn’s most outstanding masterpieces, enlighten the way of thinking during the design of the labs. It has a substantial vision of using materials and organization of spaces. Case Study: Philosophy of Lab Design

70

Salk Institude, Louis Kahn ( 1959-1965), San Diego,CA

Fig 117: Salk Institude, Louis Kahn

Fig 119: Salk Institude,Louis Kahn

Fig 120: Salk Institude,Louis Kahn

Fig 118: Salk Institude,Louis Kahn

The laboratories, first conceived as a pair of towers separated by a garden, evolved into two elongated blocks mirroring each other across a paved plaza. The central court is lined by a series of detached towers whose diagonal protrusions allow for windows facing westward onto the ocean. 4

Kahn designed the laboratories to be easily upgraded. Support beams are restricted to the edges of each lab, allowing for greater flexibility in reconfiguring the equipment and spaces within. 4

Kahn writes, ”snugly isolated from other mentalities, needed more than anything the presence of the unmeasurable, which is the realm of the artist.” A place providing architectural quality is a complex situation that is not simply created by putting individual elements together in a refined and logic manner.

Besides the physical quality of the building, understanding Kahn`s philosophy and artistic vision provide another perspective on the way of thinking.

71

Fig 121 Salk Institude, Louis Kahn

Fig 123 PLan, Salk Institude, Louis Kahn

Fig 122 Stairs, Salk Institude, Louis Kahn

Fig 124: Salk Institude, Louis Kahn

Case Study: Philosophy of Lab Design

Fig 125: Max Planck Institute of Biophysics,Auer+Weber+Partners

Fig 126: Max Planck Institute of Biophysics , Auer+Weber+Partners

Fig 127: Plan, Max Planck Institute of Biophysics , Auer+Weber+Partners

Case Study: Philosophy of Lab Design

72

Max Planck Institute of Biophysics, Auer + Weber + Partners, (1998-2003) Frankfurt,Germany

Fig 128: Max Planck Institute of Biophysics,Auer+Weber+Partners

Fig 129: Max Planck Institute of Biophysics , Auer+Weber+Partners

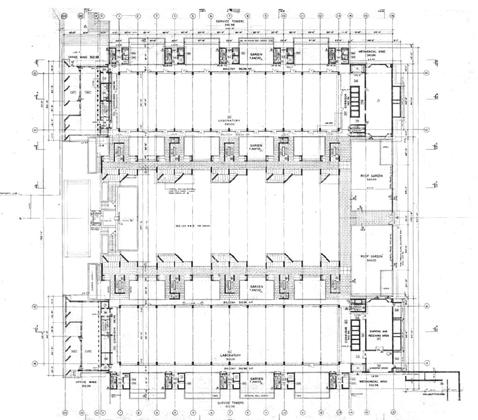

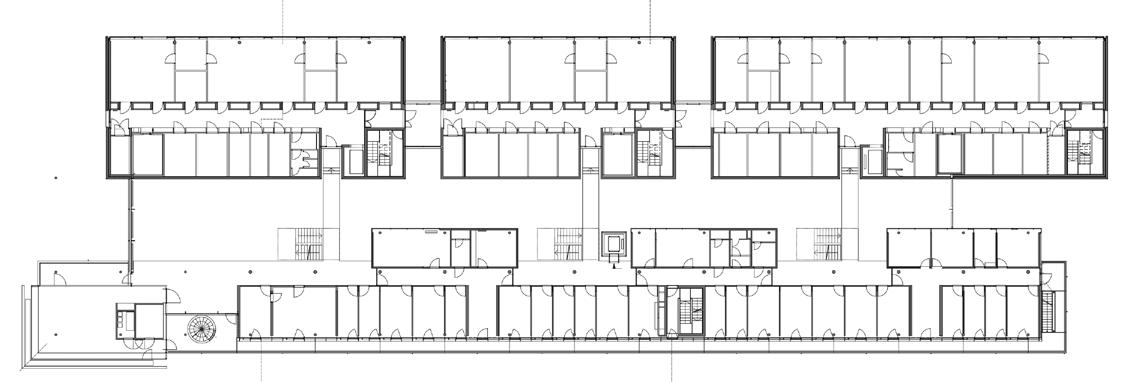

The institute’s new building is located on the natural science campus of Johann Wolfgang Goethe University in “Niederurseler Hang” next to the chemistry, physics, and biology departments, as well as other non-university research facilities. The building composes the southern border of the campus’ future central area and is placed parallel to the slope to the south. It consists of two parallel wings systematically and tightly partitioned and connected by a full-height atrium space. Laboratory departments for experimental research are placed in the north; they are readable from the exterior and form a row of three-story volumes with double-loaded passages.

The plan layout of the project corresponds pleasingly with Research Center for Natural Sciences` laboratories. Their laboratories closed filtered space, and laboratories are located on the sides of the central corridor

Fig 130: Section, Max Planck Institute of Biophysics , Auer+Weber+Partners

73

of

Case Study: Philosophy

Lab Design

132: Entry/Exit

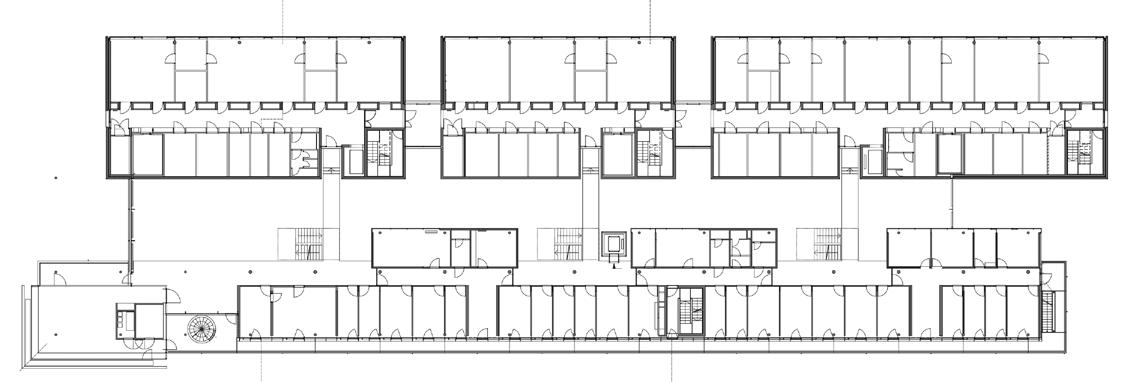

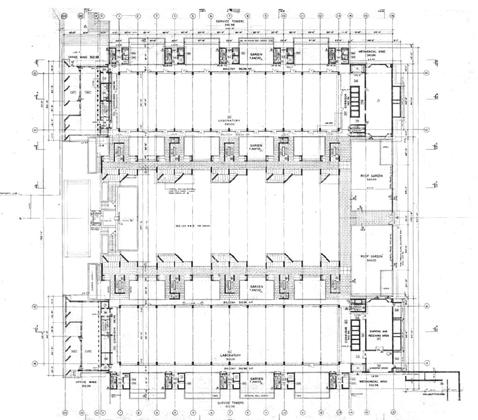

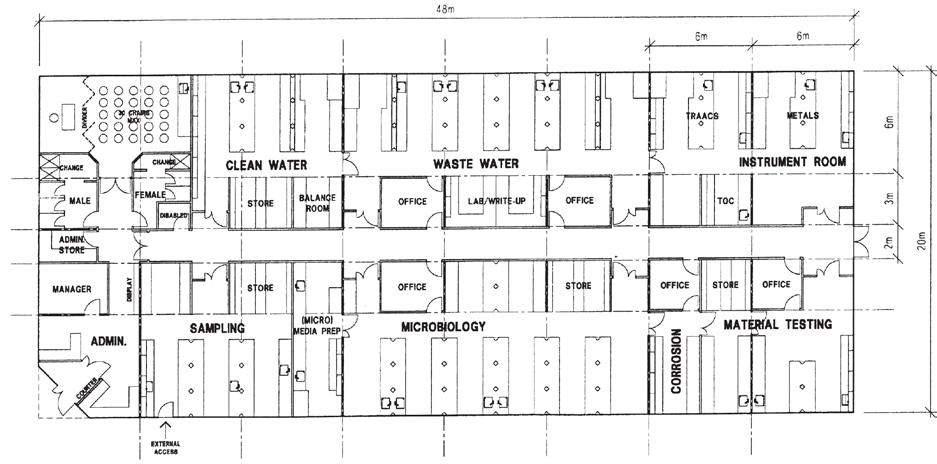

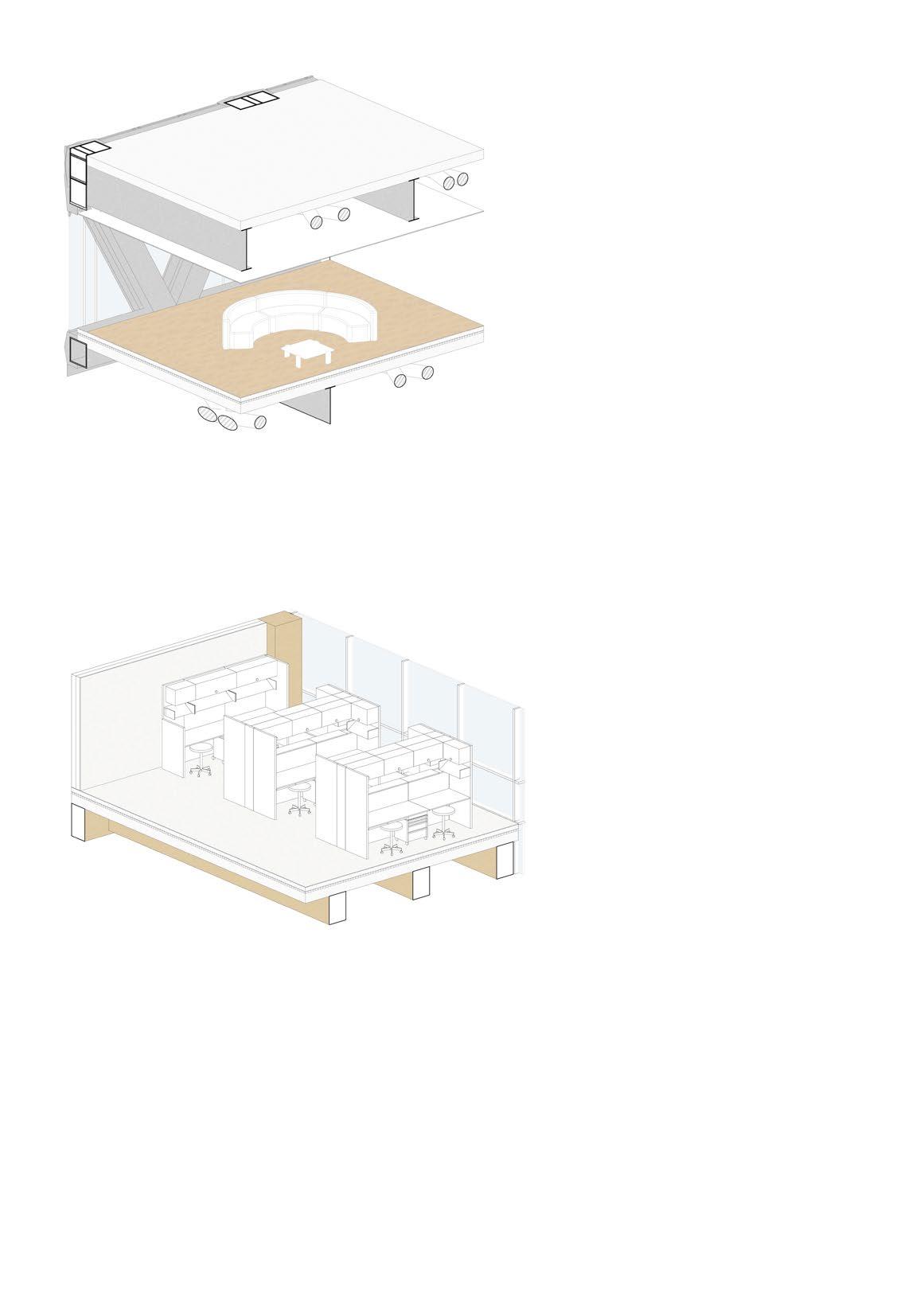

Concerning the building’s geometric features, one of the main issues was creating the layout of the laboratories. With a length of 20 m, the ideal solution was to have the central corridor and both sides laboratories. Another critical aspect was the design methods for workplaces, storage, and furniture. Designing laboratories has strict rules depending on the building characteristic and types of labs. From services design to interior design, each phase needs detailed research. Brian Griffin’s Design Guide was used in these actions during this approach.

Fundamental principles are taken from Brian Griffin,

-A good rule in interior laboratory design is to arrange the workbenches at right angles to the window walls, this arrangement creates quiet work ‘bays’ free from traffic.

Fig 133: Wet/Dry Lab modules Fig 134: Office

Fig 135: Single Corridor, Braun Griffin

- The single corridor plan is generally favored, however, as it is more flexible. The areas on bothsides should be the same width for maximum flexibility, so the single corridor should be central.

- Wall and ceiling surfaces should be impermeable, non-porous, and smooth for easy cleaning.

- Plan for storage space adjacent to the main circulation for easy access by staff replenishing supplies.

- The laboratory support facilities in this plan can be arranged immediately adjacent to the laboratory they serve.

-For maximum flexibility laboratory functions should be combined into shared open spaces.

74

Fig 131: Cool RM/CT Cabinets Fig

Laboratory Design Guide, Brian Griffin Laboratory Layout

Labs Support

Corridor Support

Lab Case Study: Philosophy of Lab Design

A Design Manual Research and Technology Buildings, Braun Gromling

Laboratory Modules

The experimental scientific working area is one of the critical parts of the laboratories. They have high-tech equipment, depending on the type. Scientists collect information, substantiate the experiments and summarize their investigations there. After these results, they discuss them with a small group of people. These procedures suppose a specific critical community and work phases. Some of the information that should follow, according to Gromling,

-Type and frequency of work processes -Number of persons working in a laboratory -Daylight/artificial lighting -Fume boards for toxic substances -Number of desks for writing and analysis -Layout and planning of service supply

Besides the investigation of Griffin`s principles, during the design of laboratory modules, we based Gromling`s laboratory module layout ( Figure 136,137,138), which is consistent with our functions.

According to the Gromling, the following design criteria of the laboratories,

-Work areas -Fixtures, furnishings and equipment (FF&E) -Grids -Structural and fit-out considerations -Zoning and required areas for apparatuses and technical equipment

Fig 136: Molecular Biology Laboratory, Gromling B.

Fig 137: Chemical Laboratory, Gromling B.

Fig 138: Physical Laboratory, Gromling B.

Fig 139: Molecular Biology Laboratory, Gromling B.

Working areas

Fig 140: Chemical Laboratory, Gromling B.

Zoning and required areas for technical equipment

Fixtures, furnishings and equipment (FF&E)

Study: Philosophy of Lab Design

Fig 141: Physical Laboratory, Gromling B.

75

Case

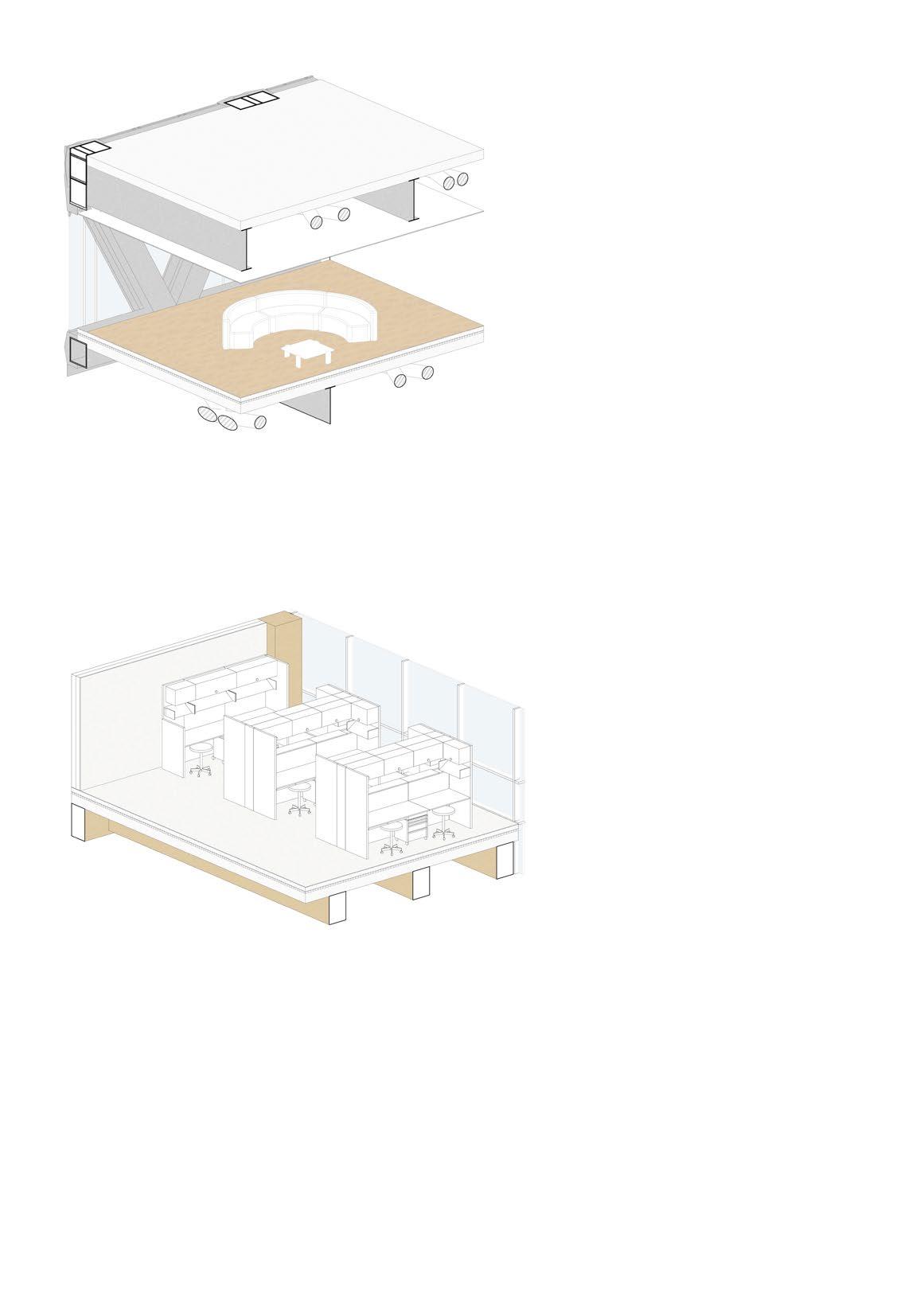

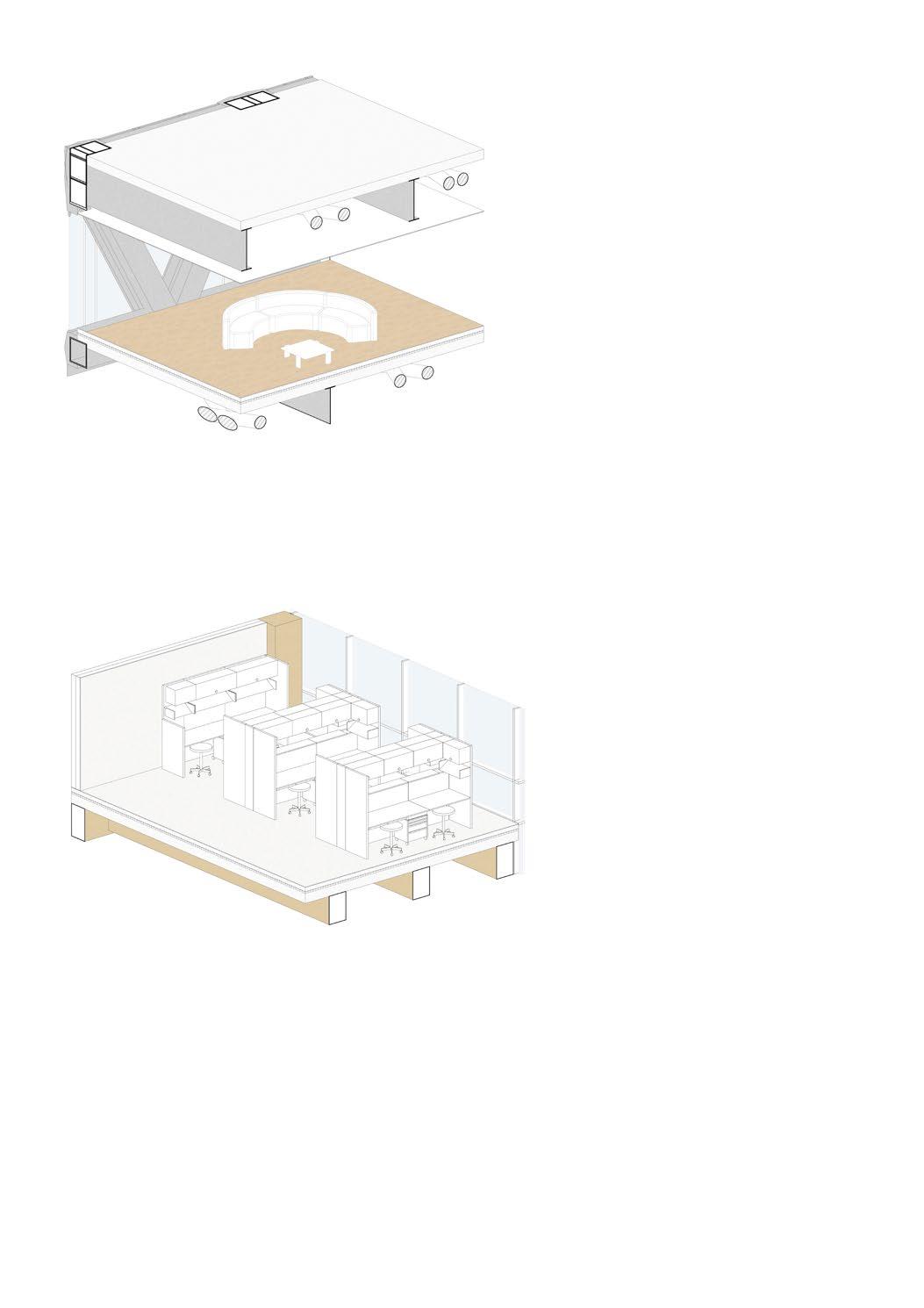

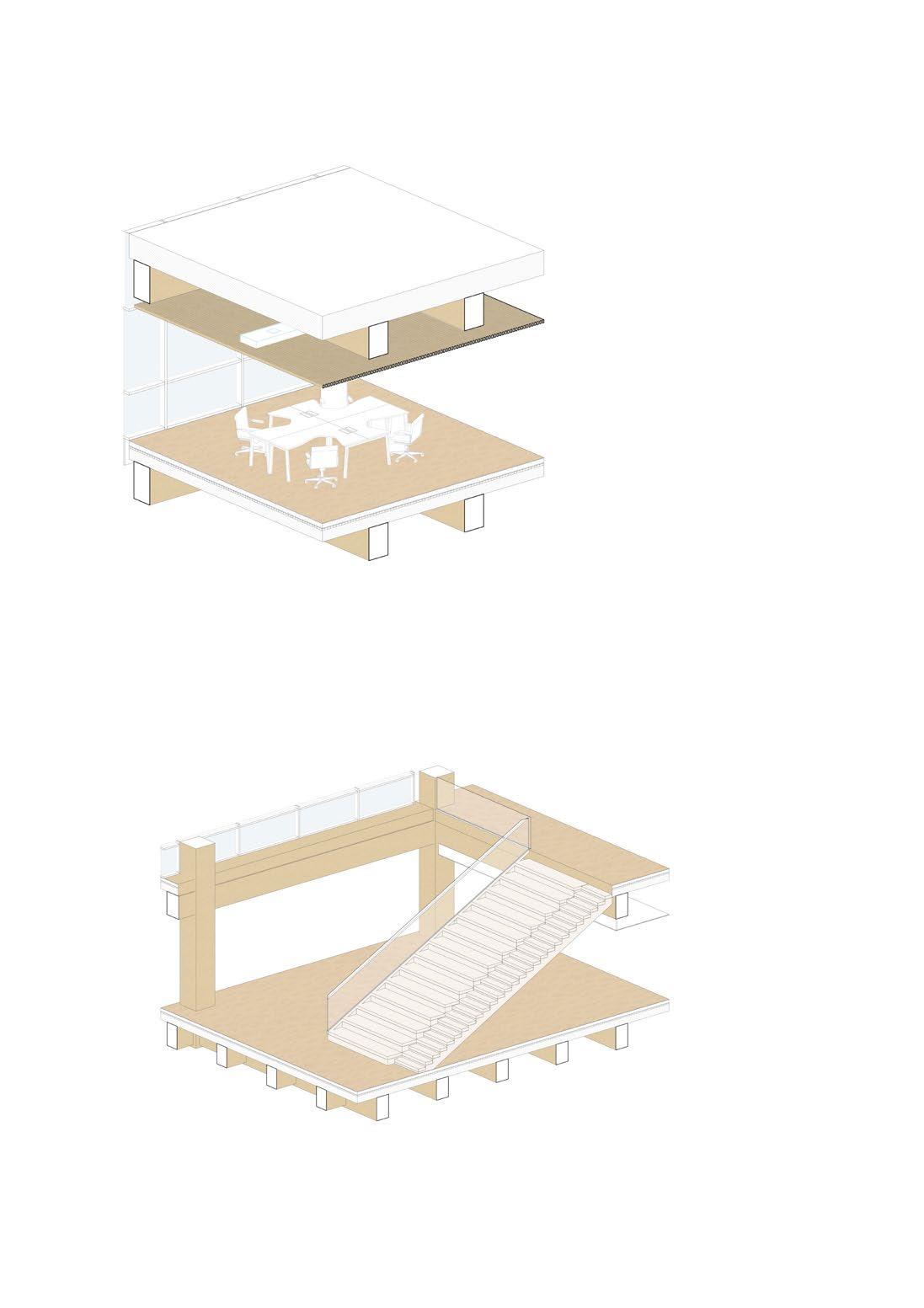

types of laboratories

Level 1 : Chemistry Laboratory

Level 2 : Biology Laboratory

Level 3 : Physics Laboratory

76

Types of Laboratories

Fig 142: Exploded axonometry diagram , Authors

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

Dangerous substances/wet area Fume cupboard,point air exhaust Cabinet for dangerous substances Cabinet for chemicals Laboratory sink

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

Working desks with ceramic tops Incubator/Dryer Refrigerator/Freezer

type 2 : research lab

single computer lab storage / archive writing desk locker

type 1 : experimental lab chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

Dangerous substances/wet area Fume cupboard,point air exhaust Cabinet for dangerous substances Cabinet for chemicals Laboratory sink Working desks with ceramic tops Incubator/Dryer Refrigerator/Freezer

type 1 : experimental lab chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 1 : experimental lab chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

Dangerous substances/wet area Cabinet for dangerous substances Cabinet for materials Laboratory sink Working desks with ceramic tops Dark room

type 2 : research lab

single computer lab storage / archive writing desk locker

type 1 experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 2 : research lab

Individual working space Storage/archive Writing desks Locker

single computer lab storage / archive writing desk locker

Break

type 2 : research lab

single computer lab storage / archive writing desk locker

break space

break space other functions : workshop server room dark room IT storage

type 2 : research lab break space other functions : workshop server room dark room IT storage

other functions : workshop server room dark room IT storage

vertical connections / bathrooms

vertical connections / bathrooms

Other functions Workshops Server room Storage Dark room

vertical connections / bathrooms

Individual

type 2 : research lab

type 2 : research lab

single computer lab storage / archive writing desk locker

single computer lab storage / archive writing desk locker

single computer lab storage / archive writing desk locker

break space other functions : workshop server room dark room IT storage

type 2 : research lab break space other functions : workshop server room dark room IT storage

single computer lab storage / archive writing desk locker

type 1 : experimental lab : chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer

type 2 : research lab

Individual working space Storage/archive Writing desks Locker

Other

vertical connections / bathrooms

break space other functions : workshop server room dark room IT storage

break space other functions : workshop server room dark room IT storage

vertical connections / bathrooms

vertical connections / bathrooms

vertical connections / bathrooms

single computer lab storage / archive writing desk locker

type 2 : research lab

single computer lab storage / archive writing desk locker

break space other functions : workshop server room dark room IT storage

break space other functions : workshop server room dark room IT storage

break space other functions : workshop server room dark room IT storage

vertical connections / bathrooms

vertical connections / bathrooms

vertical connections / bathrooms

77 Level 1

Level 2 Level

connections bathrooms type 2 research lab

space other functions workshop server room dark room IT storage

1 experimental lab chemistry dangerous substances/ Wet area fume cupboard, point air exhaust cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink storage: incubator/dryer refrigerator/freezer single computer lab storage archive writing desk locker

break

biology dangerous

exhaust cabinet

dangerous substances

tops

break space other functions offices vertical connections bathrooms

1 experimental lab physics dangerous substances/ Wet area cabinet for dangerous substances cabinet for chemicals working desks with stoneware/ceramic tops laboratory sink dark room storage single computer lab storage archive writing desk locker

Fig 143: Plan Diagram of Labs, Authors Fig 144: Plan Diagram of Labs, Authors Fig 145: Plan Diagram of Labs Authors

3 vertical

break

type

type 2 research lab

space other functions workshop server room dark room IT storage vertical connections / bathrooms type experimental lab

substances/ Wet area fume cupboard, point air

for

cabinet for chemicals working desks with stoneware/ceramic

laboratory sink storage: incubator/dryer refrigerator/freezer single computer lab storage archive writing desk locker type 2 research lab

type

1 : Experimental Laboratory Type 1 : Experimental Laboratory Type 1 : Experimental Laboratory

2 : Research Laboratory Type 2 : Research Laboratory

2 : Research Laboratory

Type

Type

Type

space

space

space

Break

Break

functions: Workshops Server room Storage Dark room Other functions: Offices

working space Storage/archive Writing desks Locker

Types of Laboratories

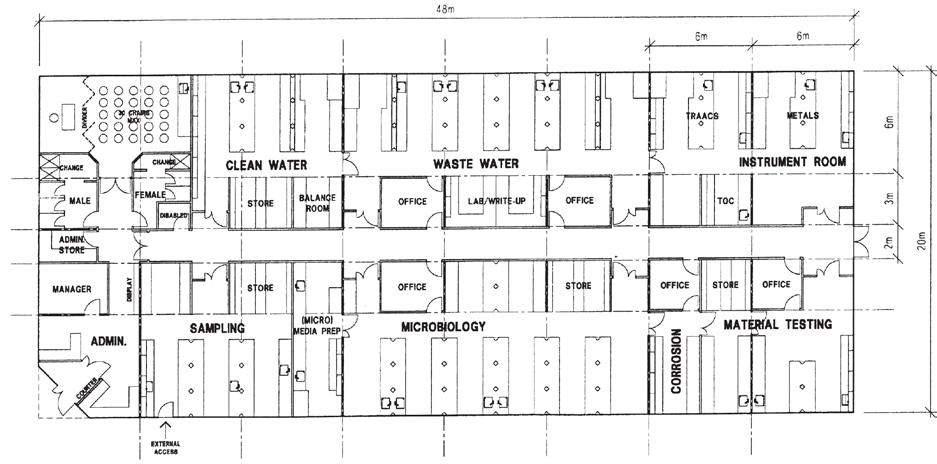

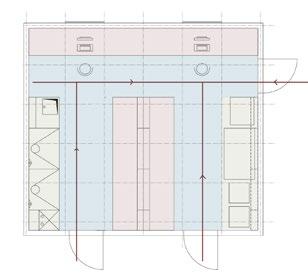

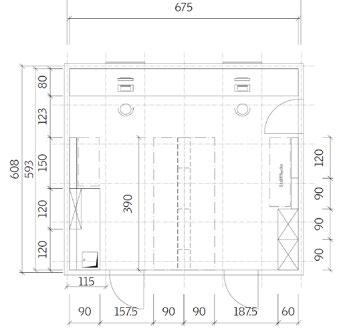

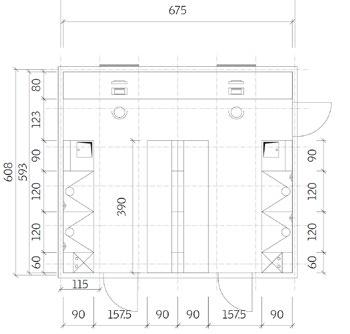

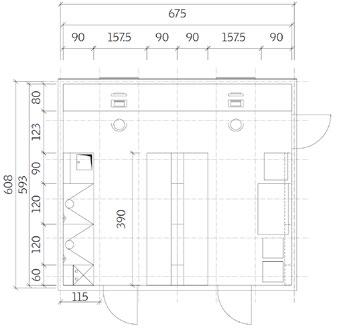

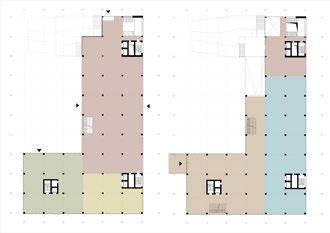

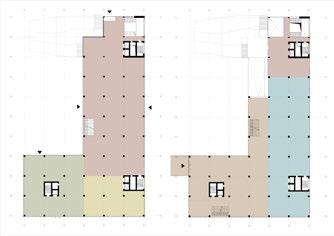

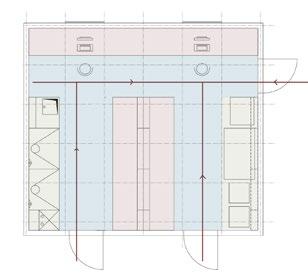

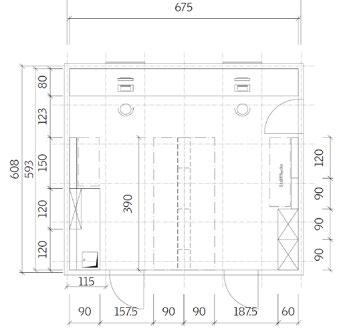

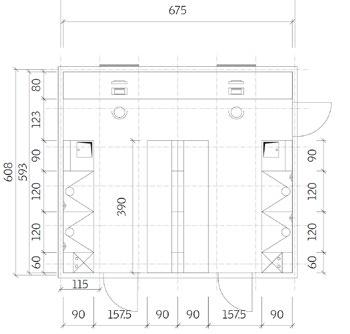

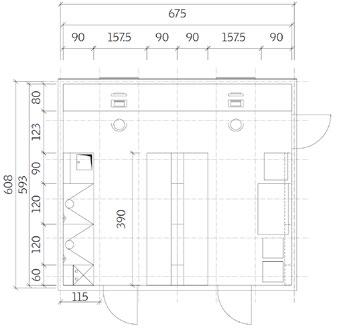

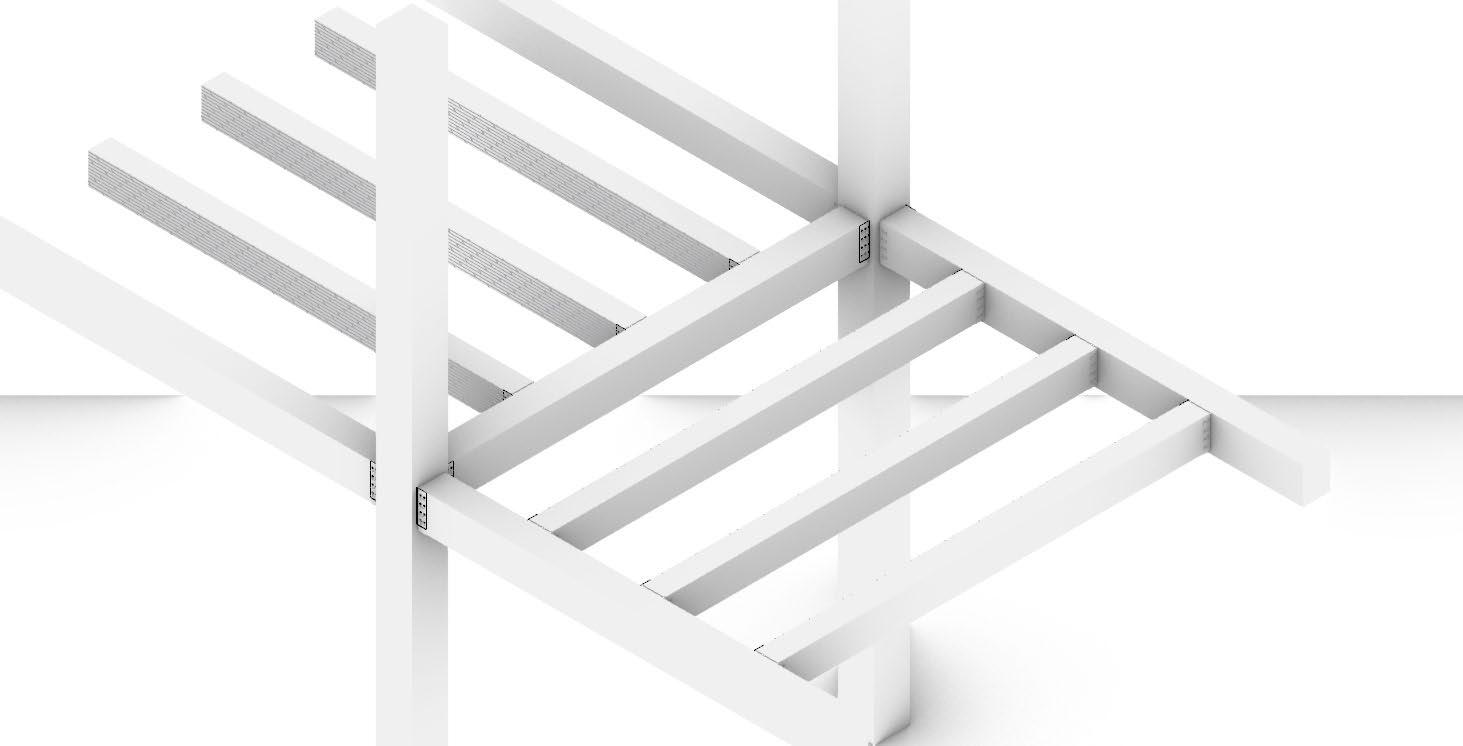

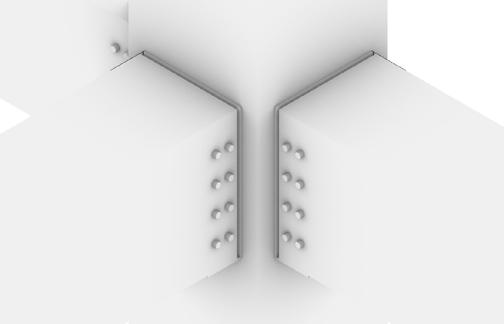

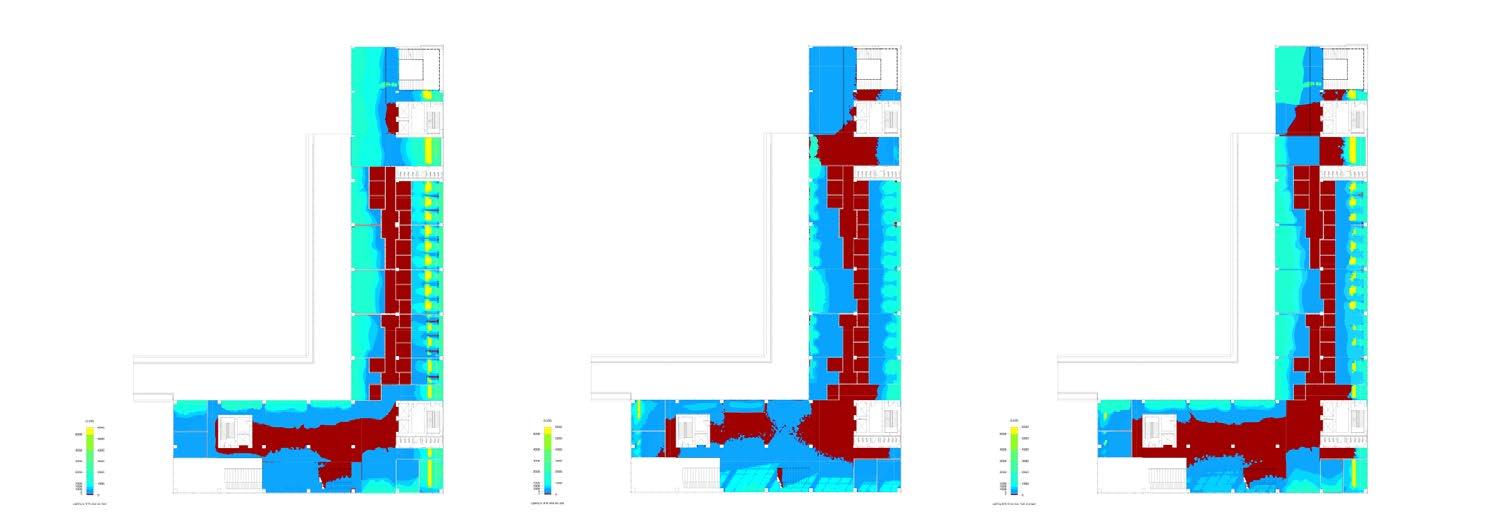

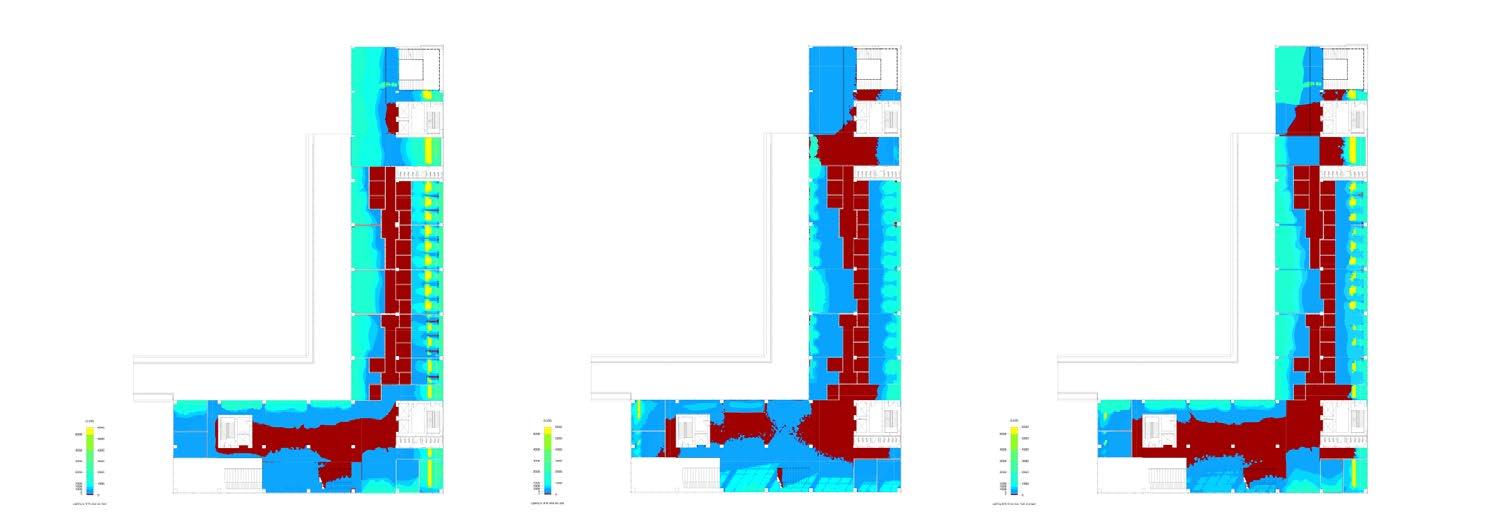

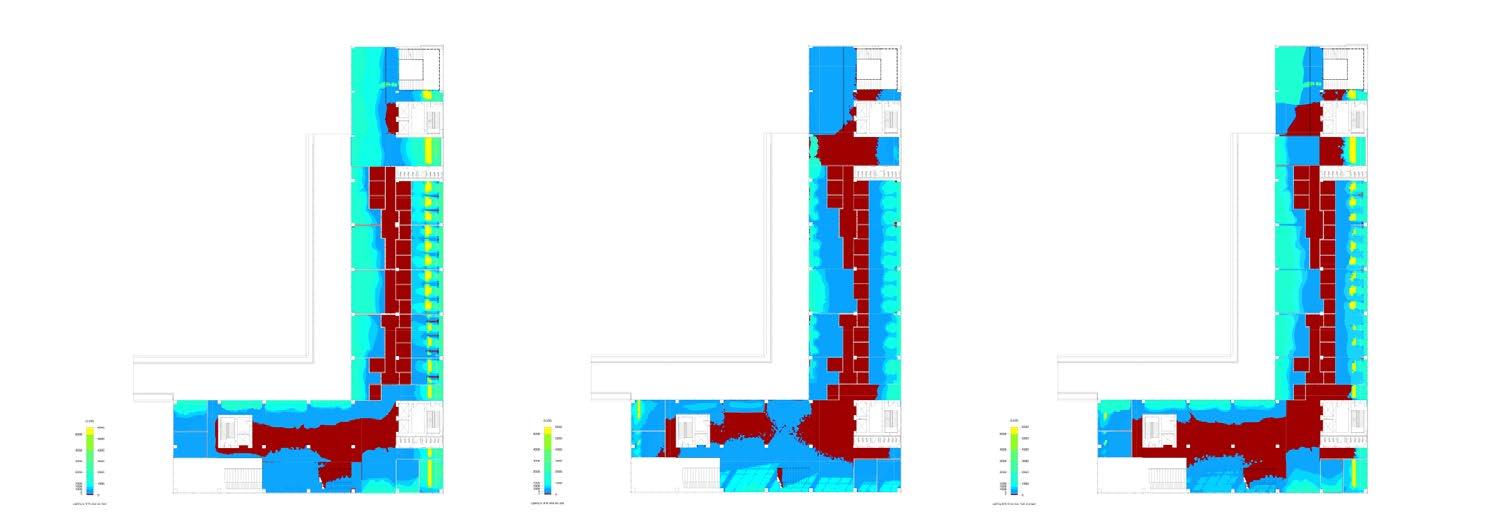

Research Center for Natural Sciences distinguishes itself from the most common lab building design with its visionary perspective. The functions of the labs are specified by considering Unimi Campus`s departments. The three building levels are dedicated to the laboratories, each with a specific function. These functions are Chemistry, Biology, and Physics. The laboratory typology is based on the central corridor, which infiltrated until the end of the space. These closed spaces are placed in between the central cores of the building to have continuous accessibility. This way, a private and healthy work environment throughout the area is provided. In light of the case study of the philosophy of laboratory design, the laboratory layout was created, and modules were developed. All levels were designed by considering community needs, and the aim was to create a vibrant atmosphere, such as having an exhibition on the first floor, lounges, and break areas inside the laboratory layout. Meeting rooms and workshop areas are also placed at the same level for working groups, usually composed of several teams.

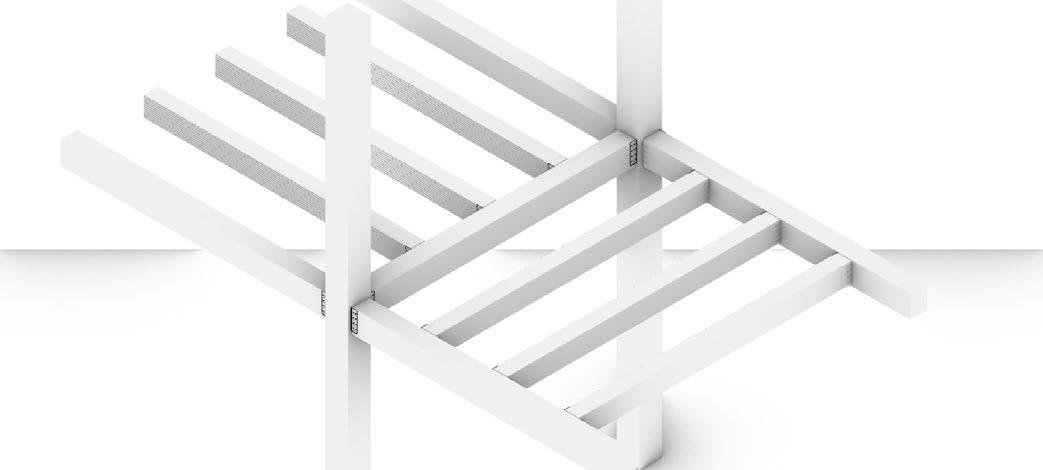

Modularity: With respect to the general grid system of the building, laboratories have the rules of the grid depending on their types. The primary configuration of the labs started by using grids and modules, depending on the building shape. All the labs are classified by using 10 meters as a vertical dimension. The horizontal dimension changes between types, and it provides to have various design perspectives and interior distinctions.

Light - Facade: Having natural light was one of the essential design goals for laboratories. The building has a curtain wall facade system and openable windows at each laboratory. Curtain wall provides also weather protection and improves performance of the building. Considered laboratories the curtain wall has openable windows to have air circulation especially for the laboratories.In addition,along the corridor, there are opposite lab types with a glass interior skin so that researchers can see each other in both labs. Shading provides by interior curtains.

78

Fig 145: Interior render of the laboratory type 1, Authors

Types of Laboratories

Type 1 : Experiment Laboratories Type 2.1 : Research Laboratories Type 2.2 : Research Laboratories

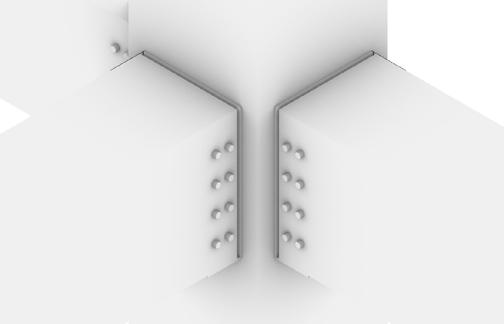

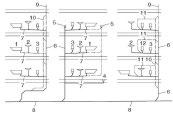

Type 1 is the experimental laboratory typology with a 10x10 grid. They consist of entry/exit from the central corridor, and it has support areas. Entry/exit work as a filtering zone between the corridor and experiment space. Chemistry and biology laboratories have cooling and incubator rooms to maintain their chemicals or other materials. Physics laboratories have a dark room for experimentation and storage of the equipment. All the experimental laboratories have working stations perpendicular to the window and separated from the walls. Distinct from the physics laboratory, chemistry and biology laboratories have fume boards. They also have a laboratory sink for sanitizing, called wet labs. Ventilation is vital for the experimental laboratories; respecting Neufert, rooms have a high rate of air exchange and frequently additional fume cupboards with air extraction. Each laboratory has airflow thanks to the ceiling, and all the equipment is hidden.

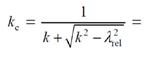

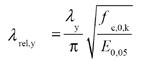

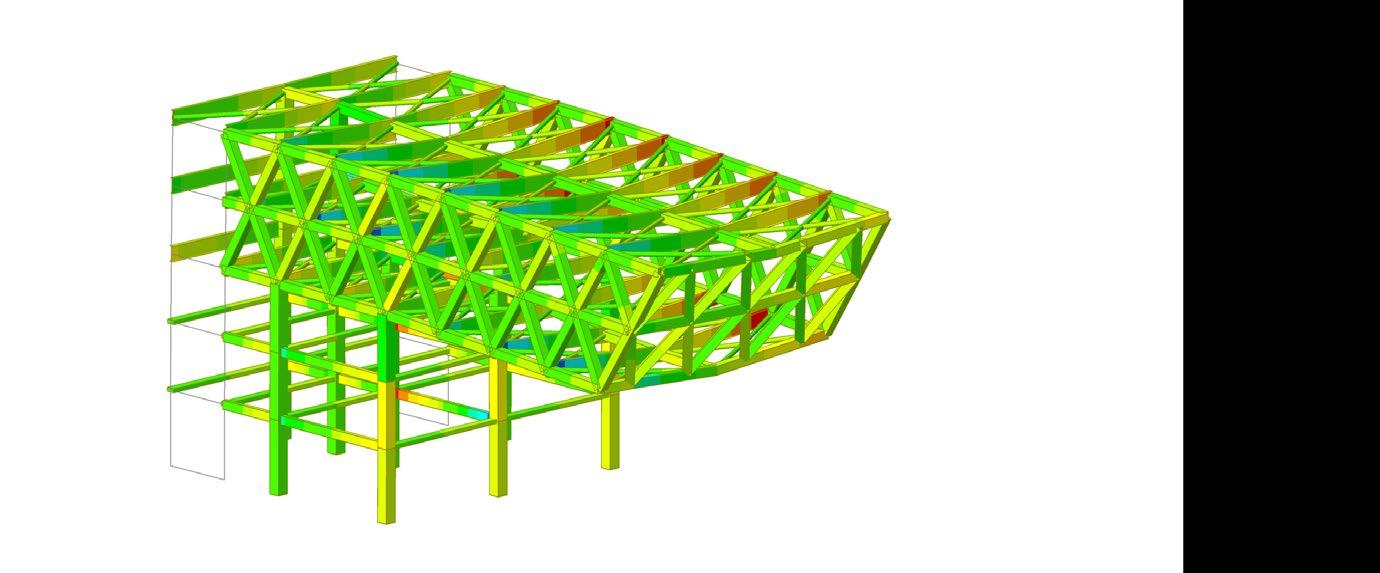

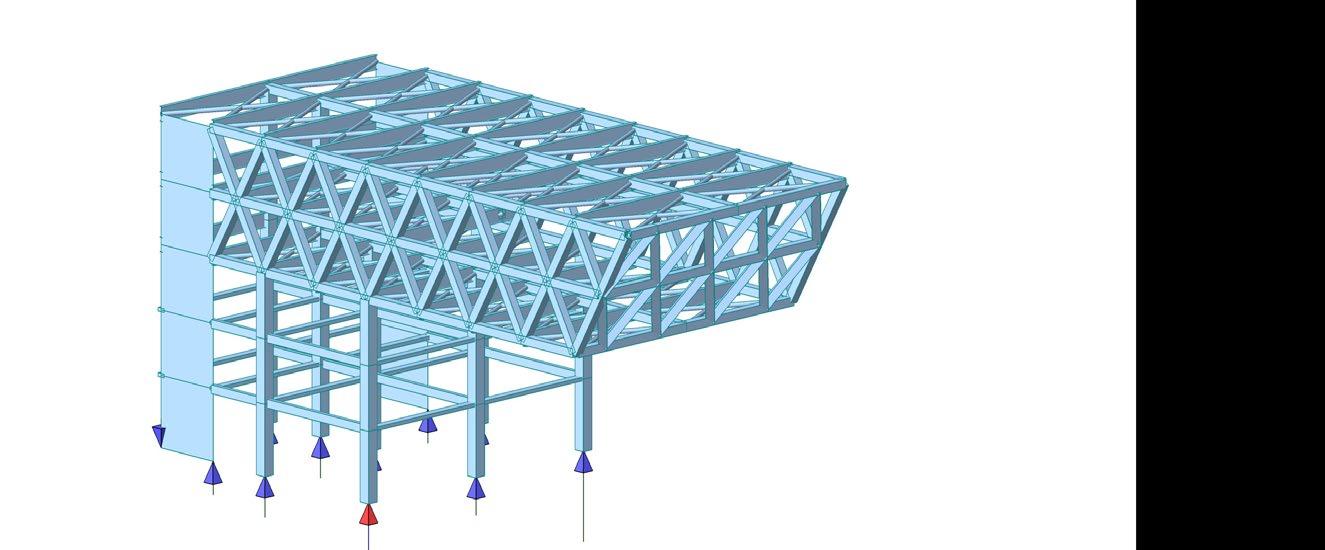

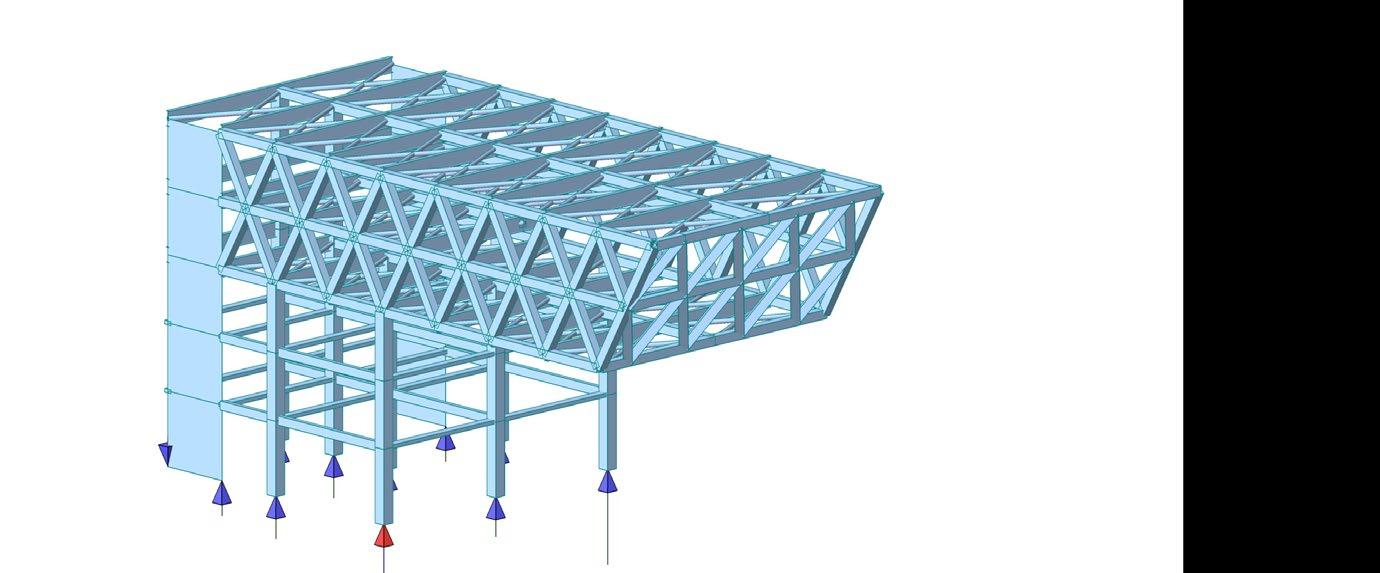

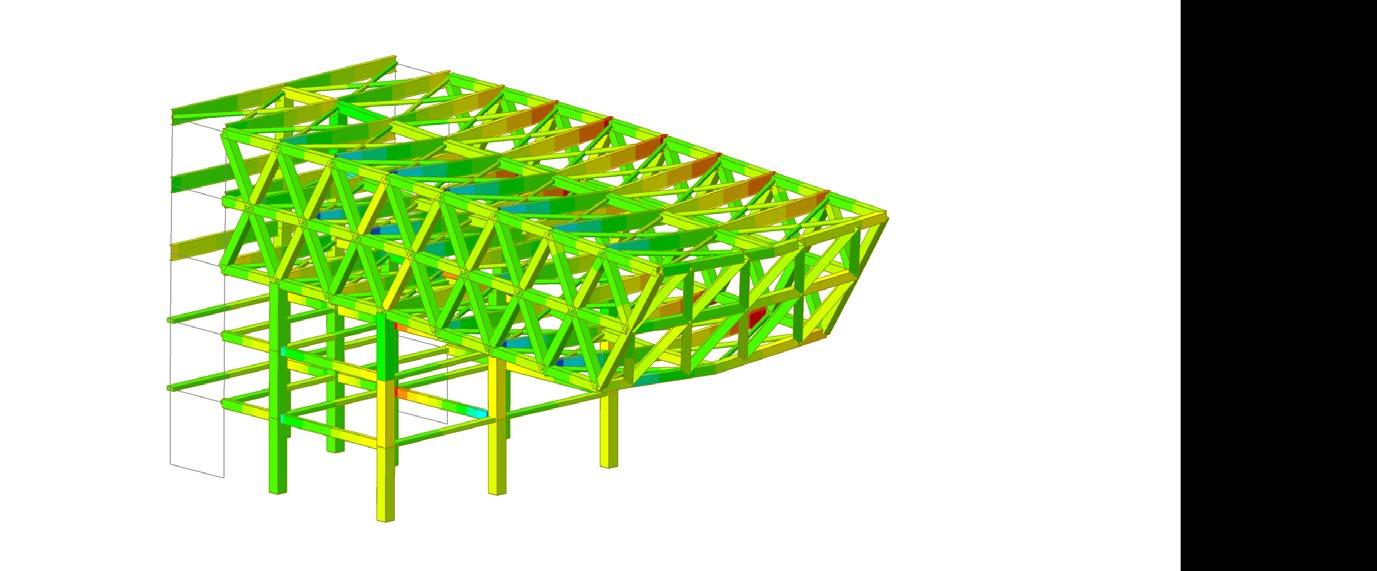

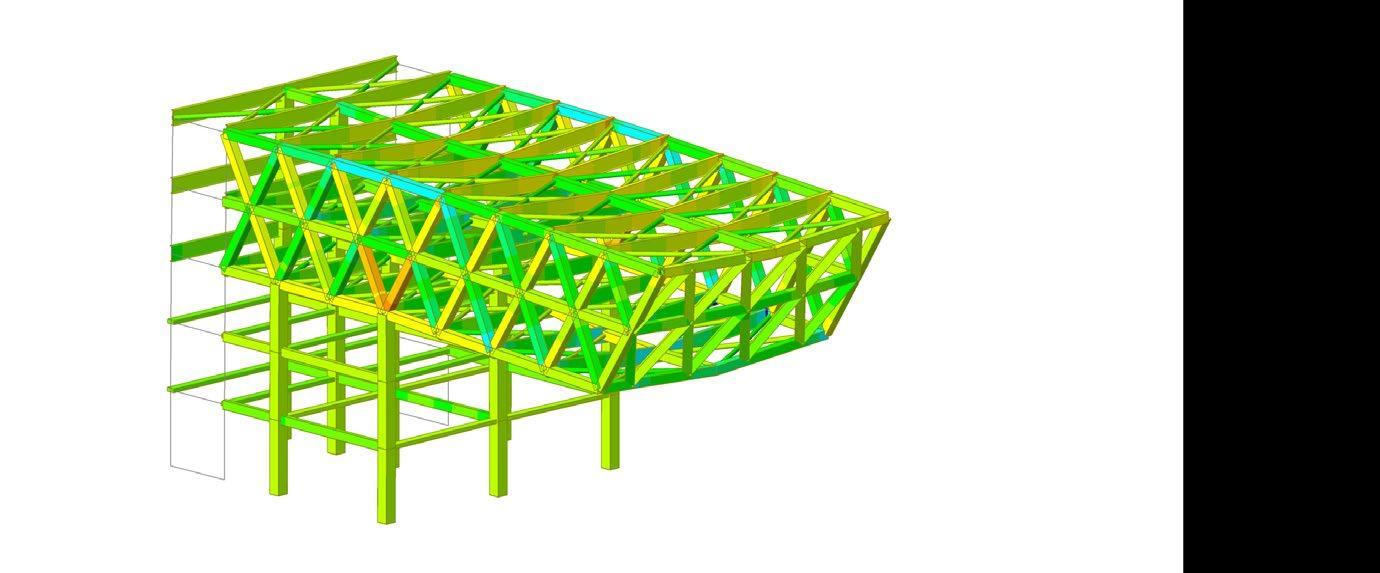

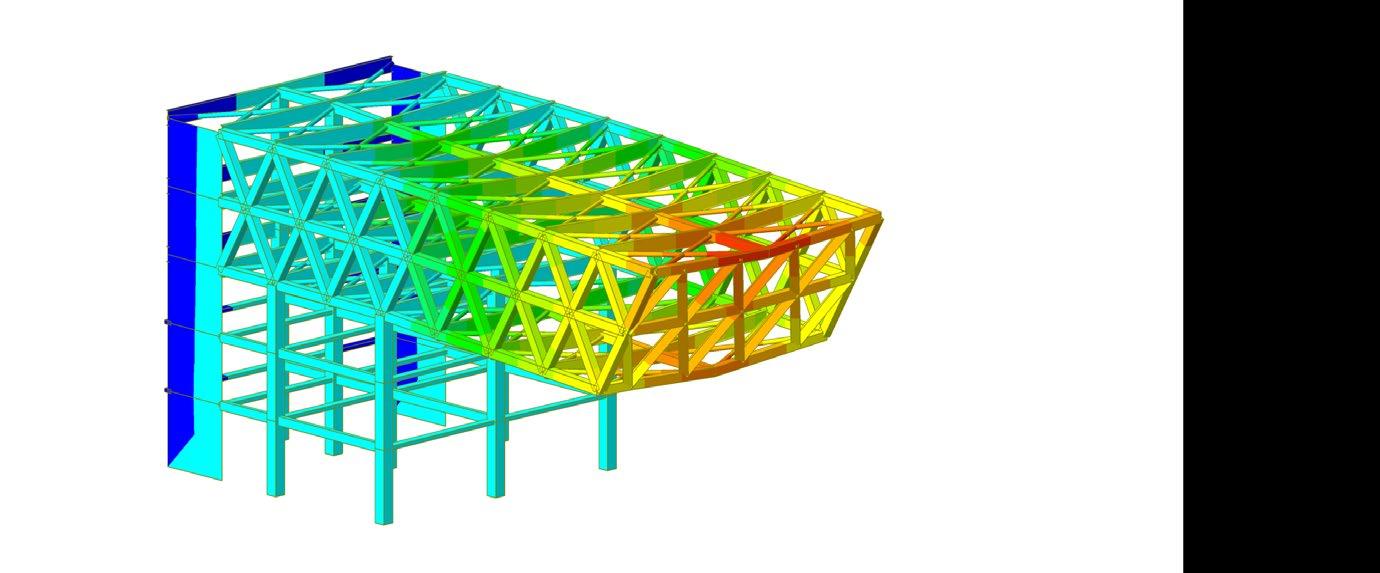

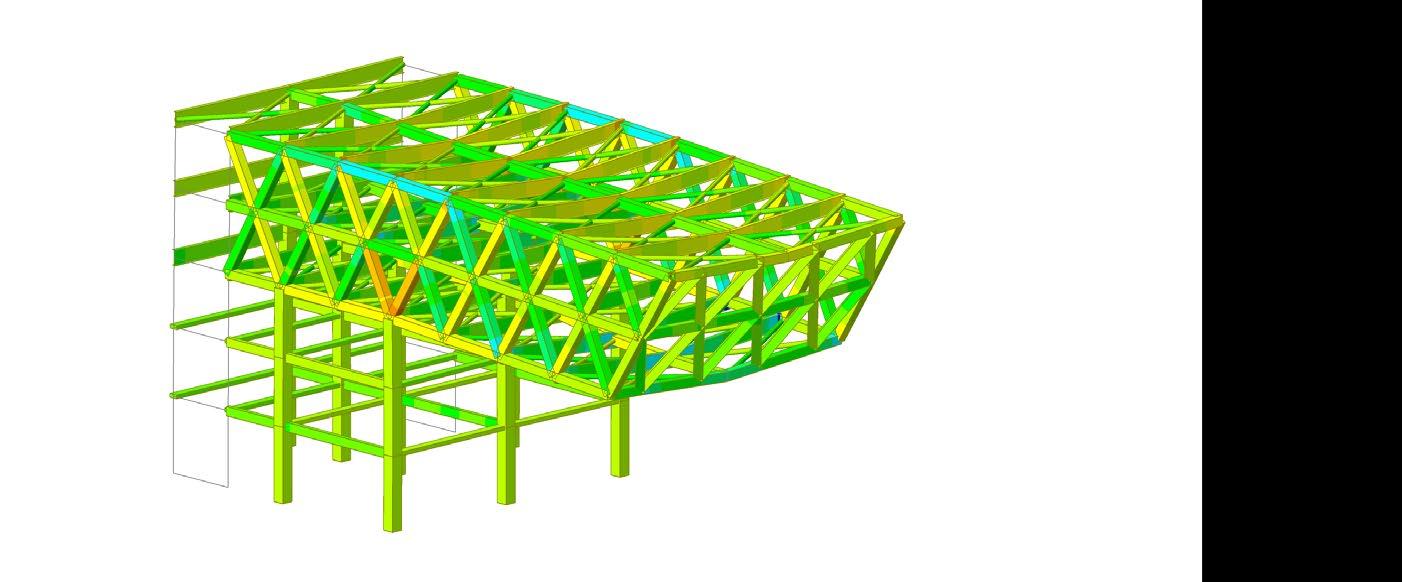

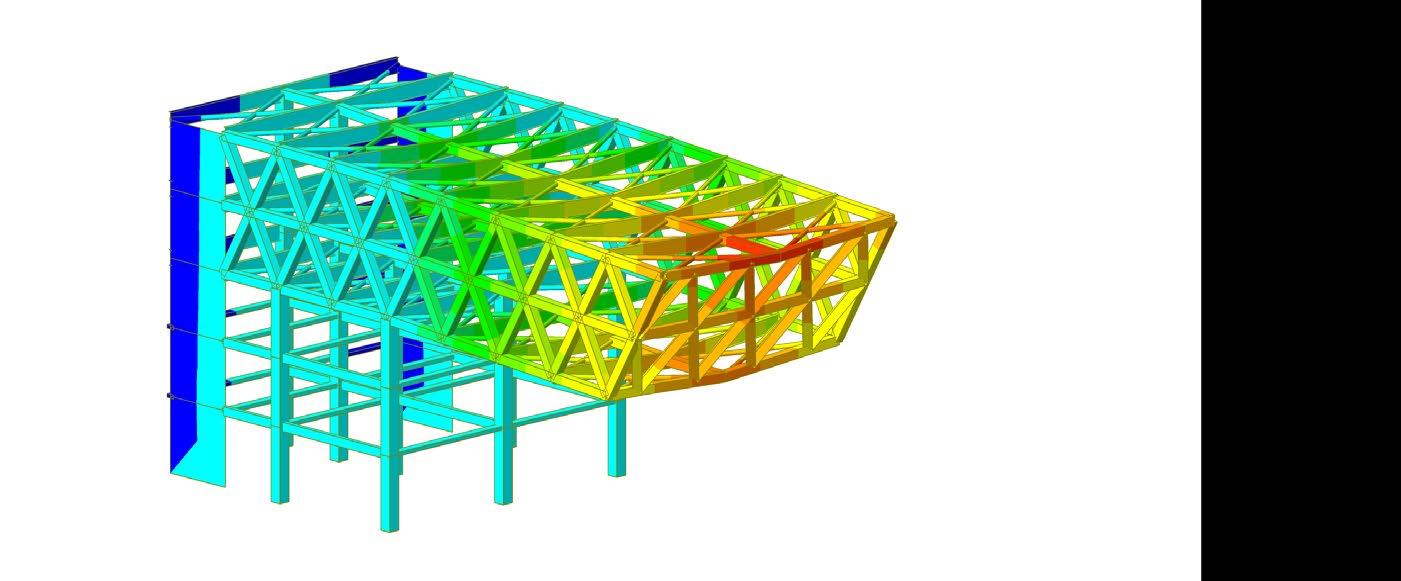

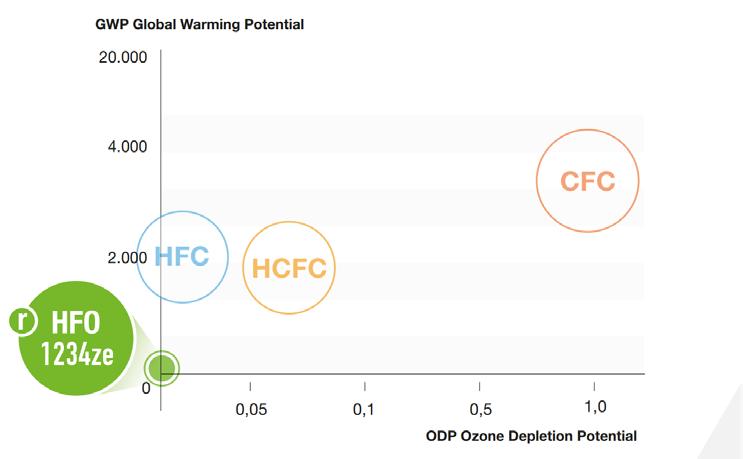

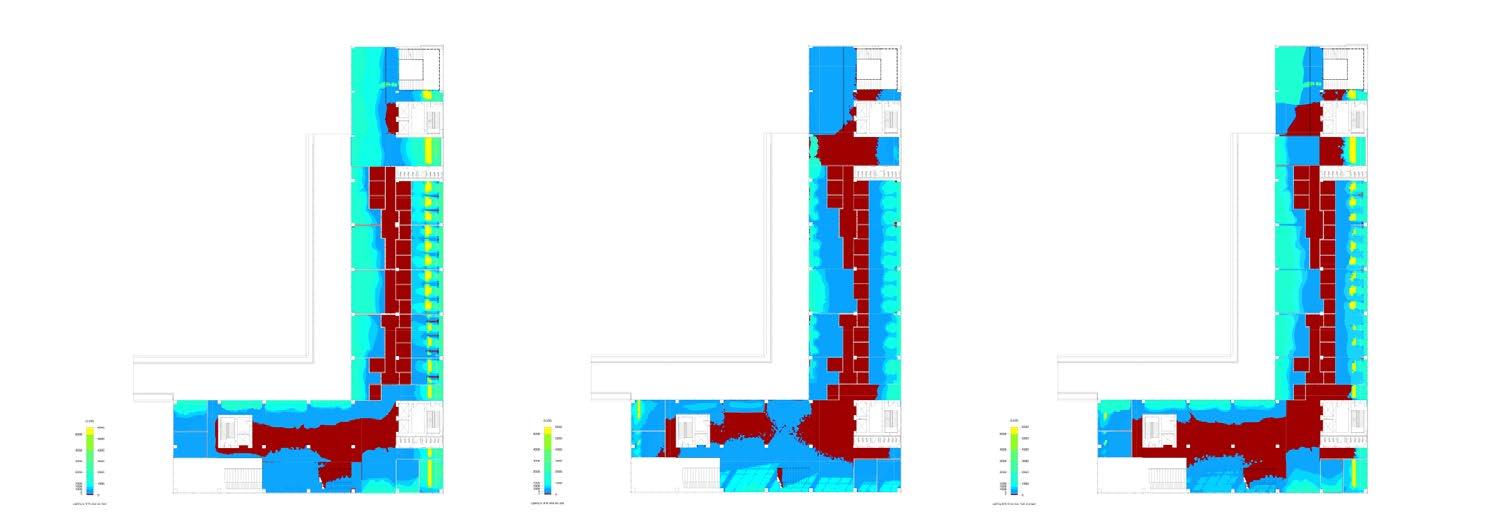

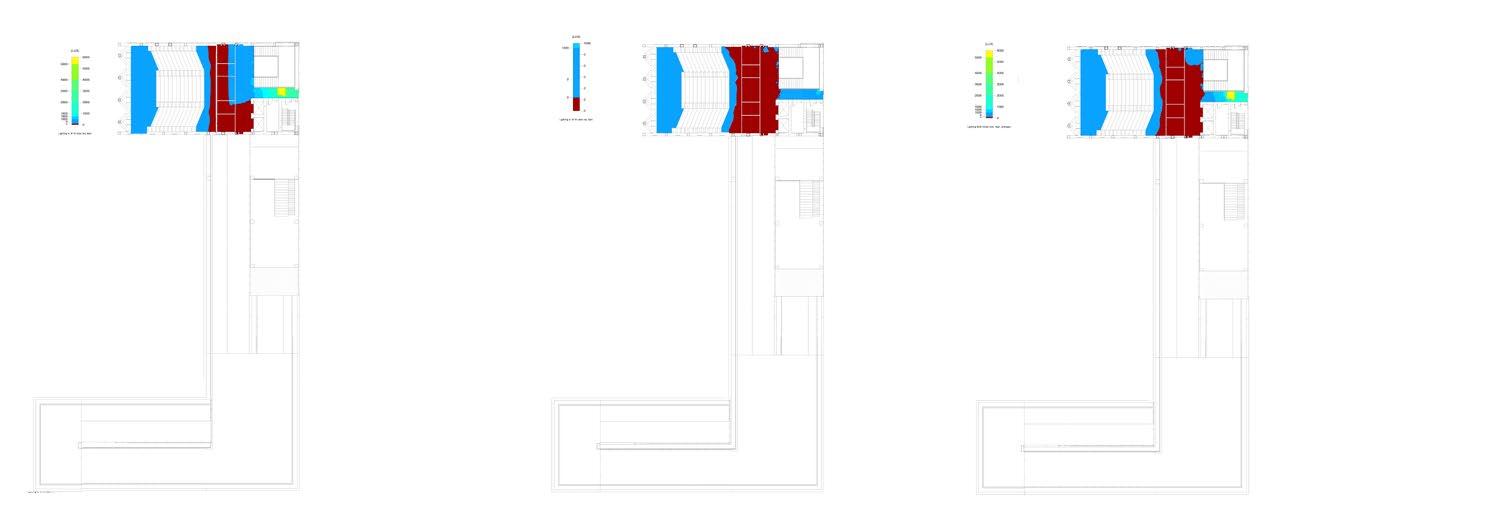

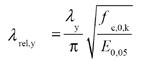

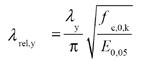

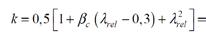

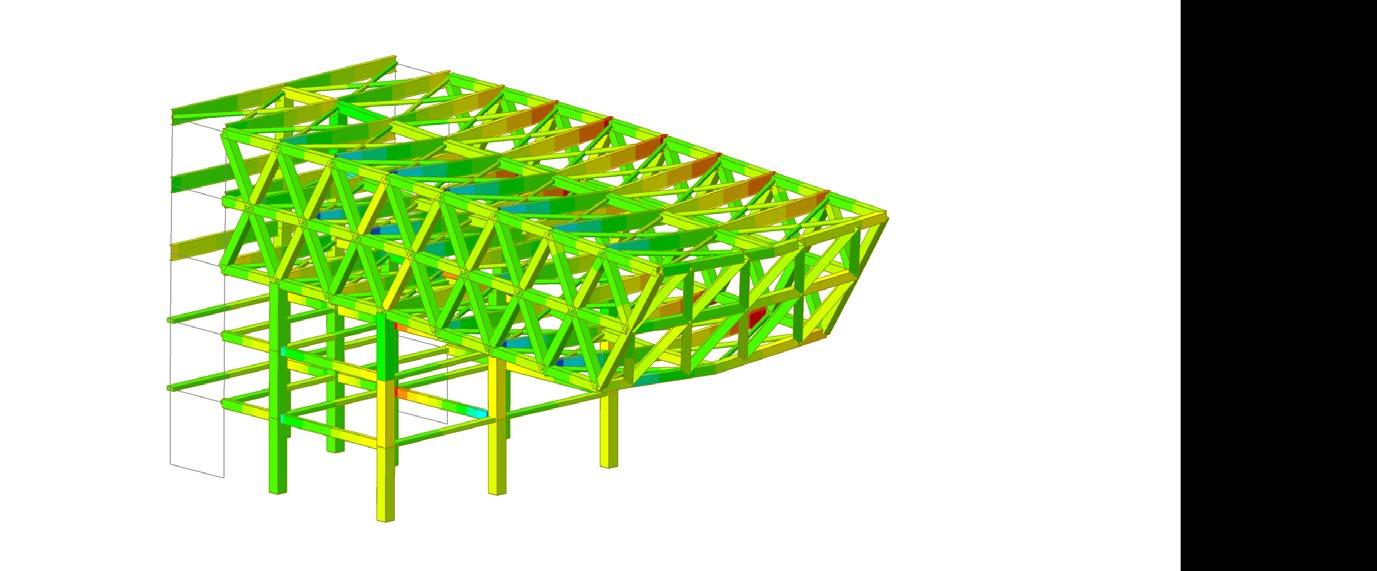

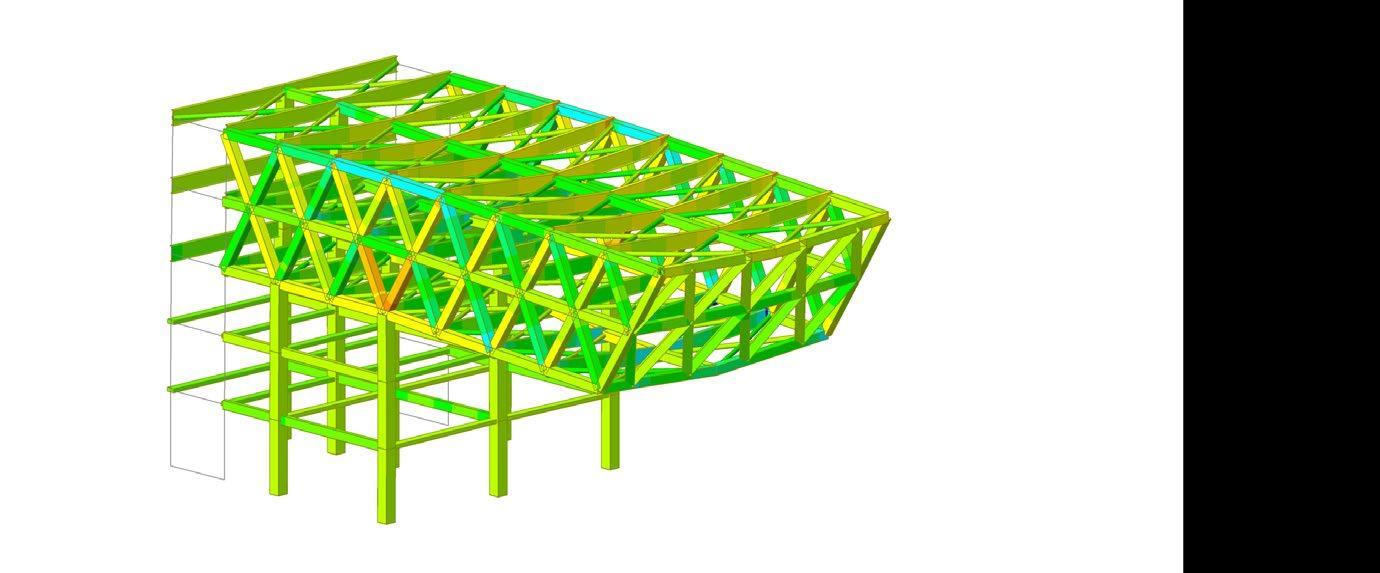

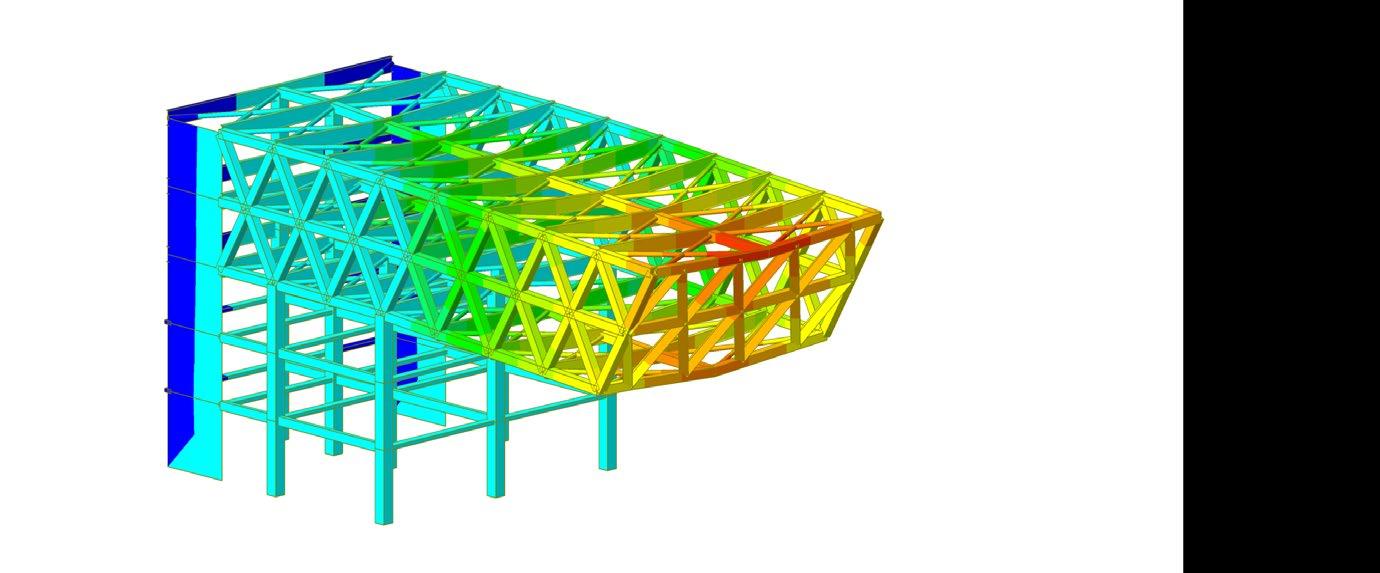

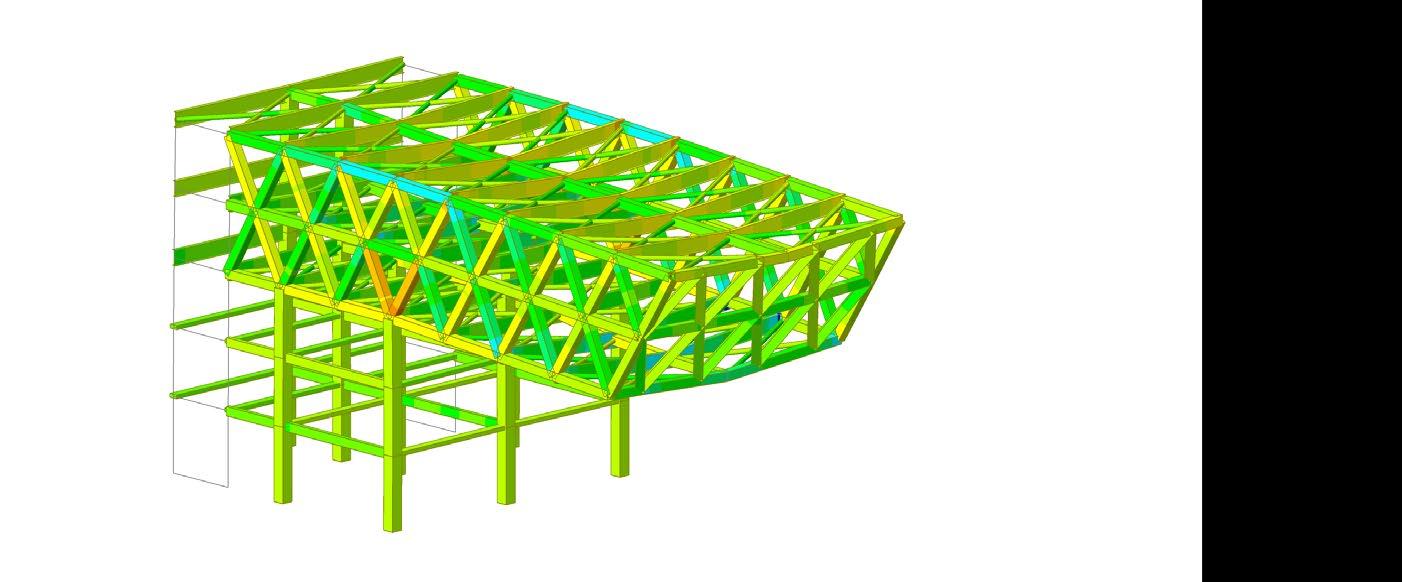

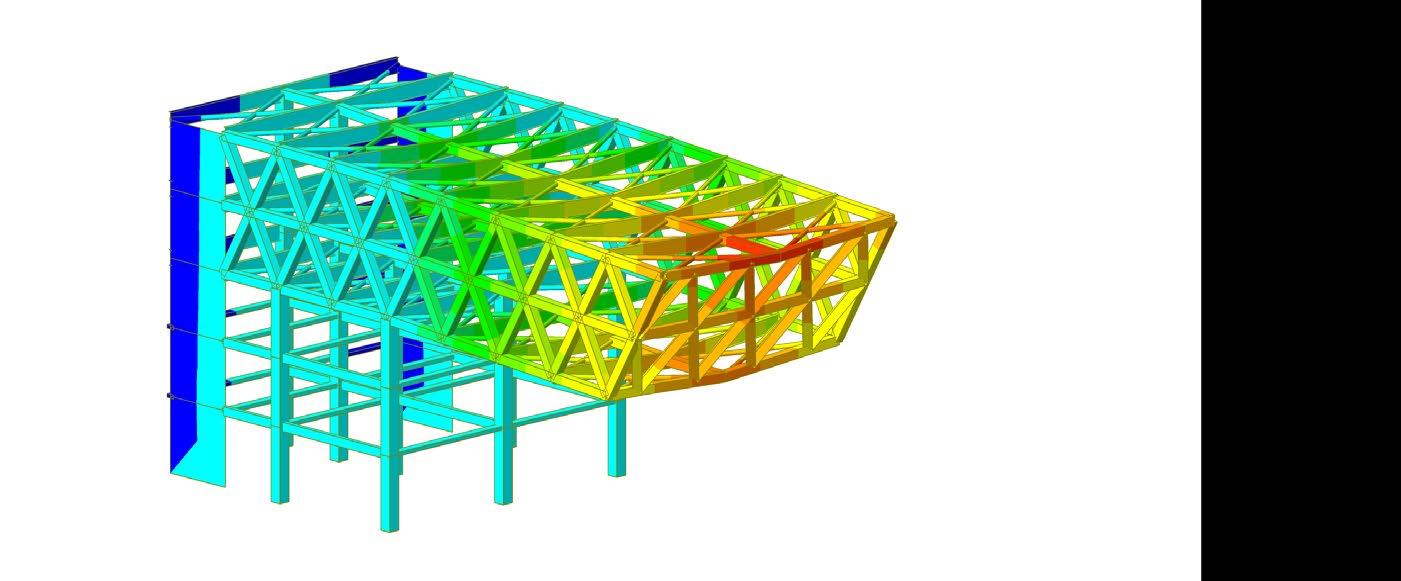

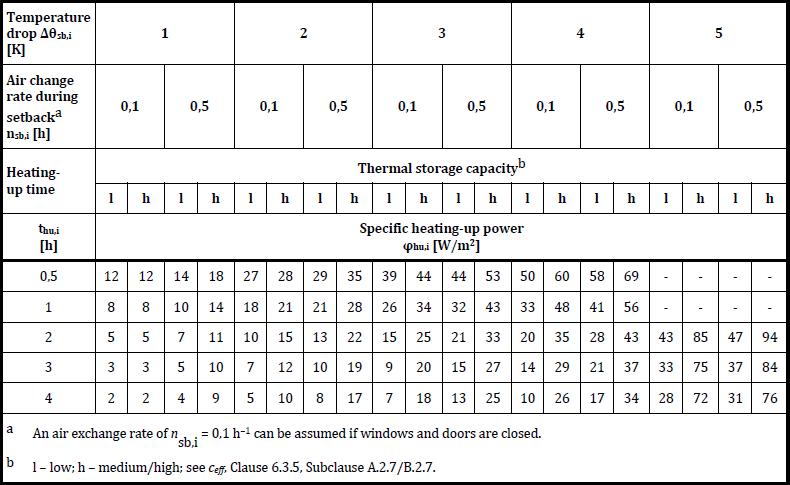

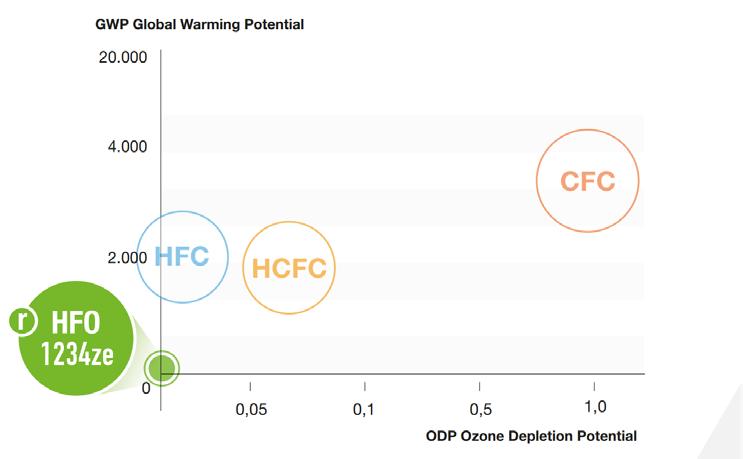

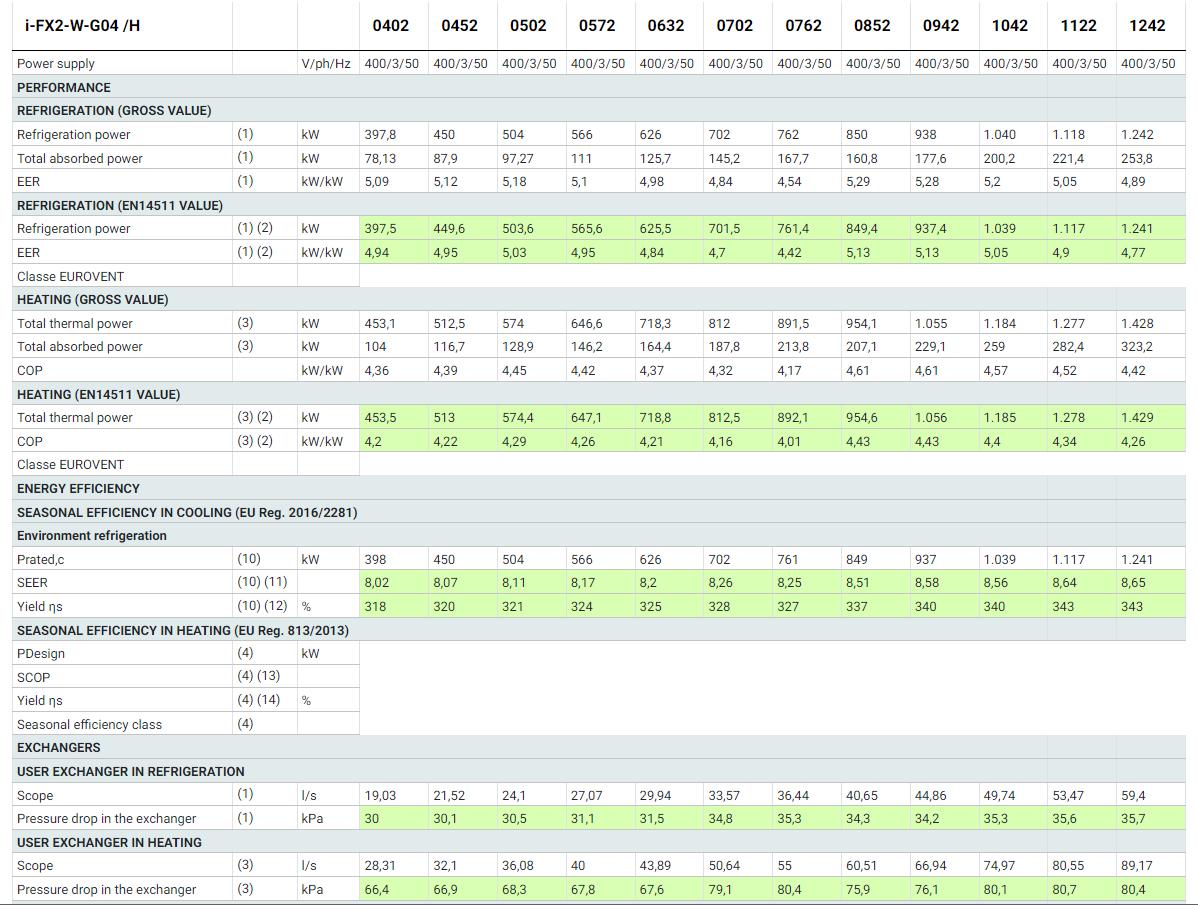

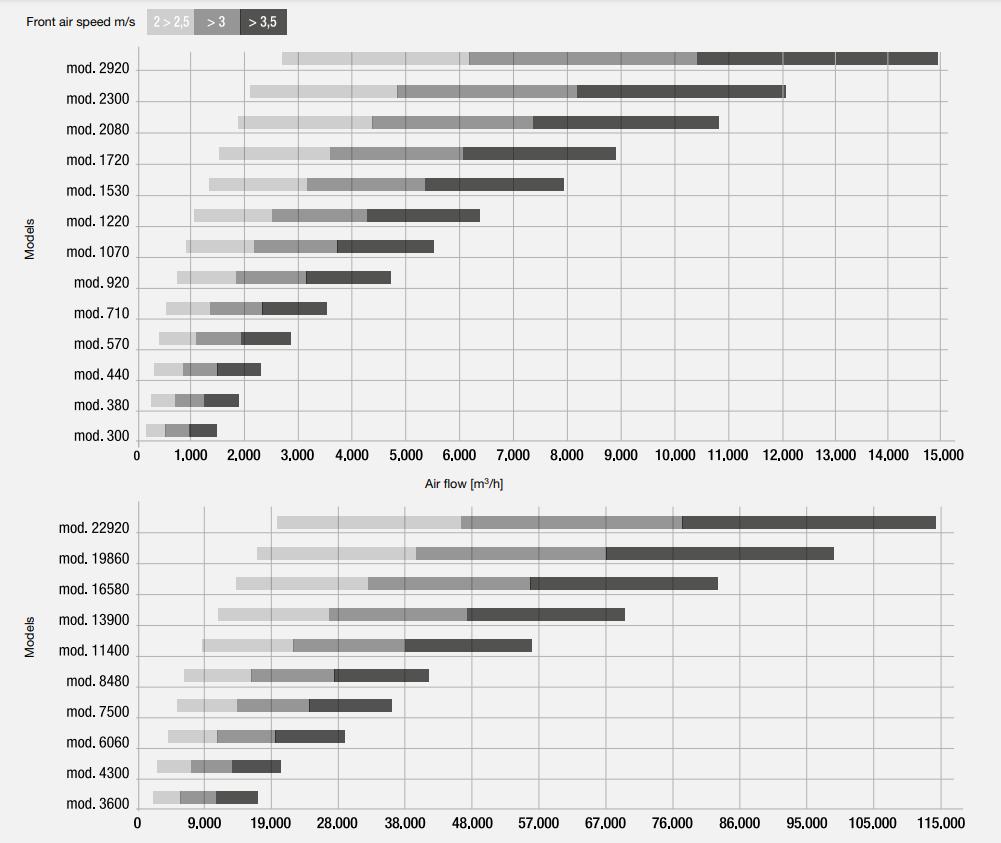

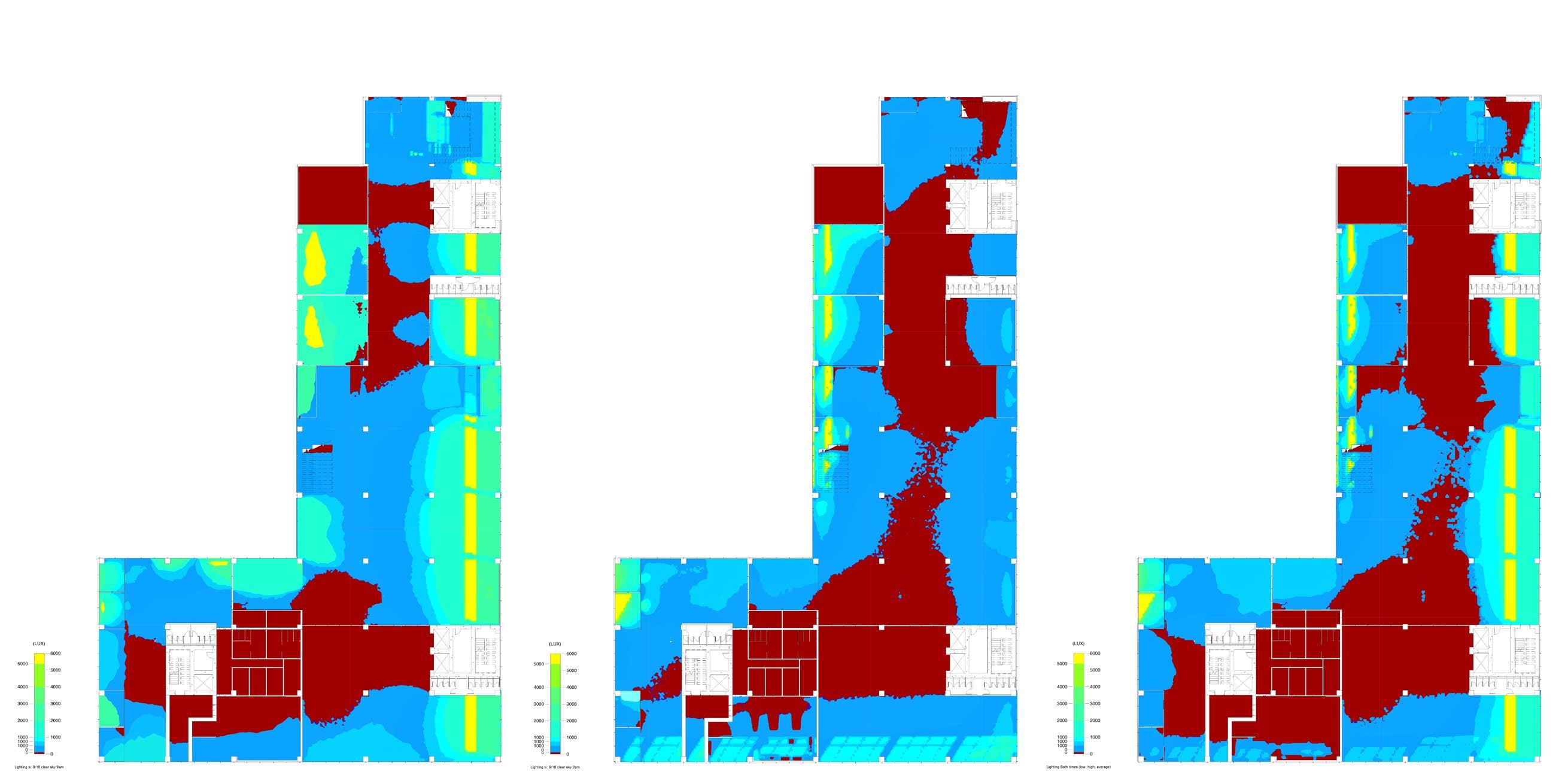

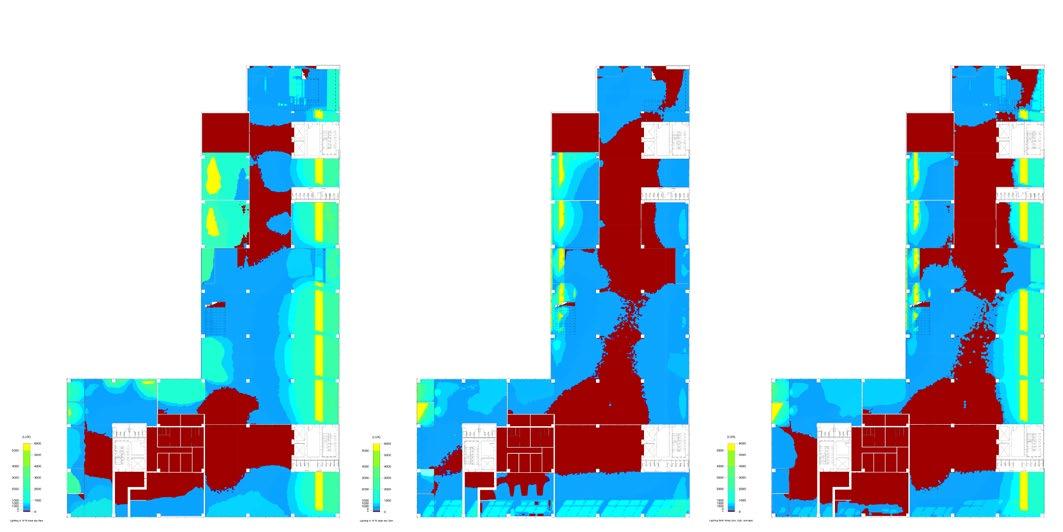

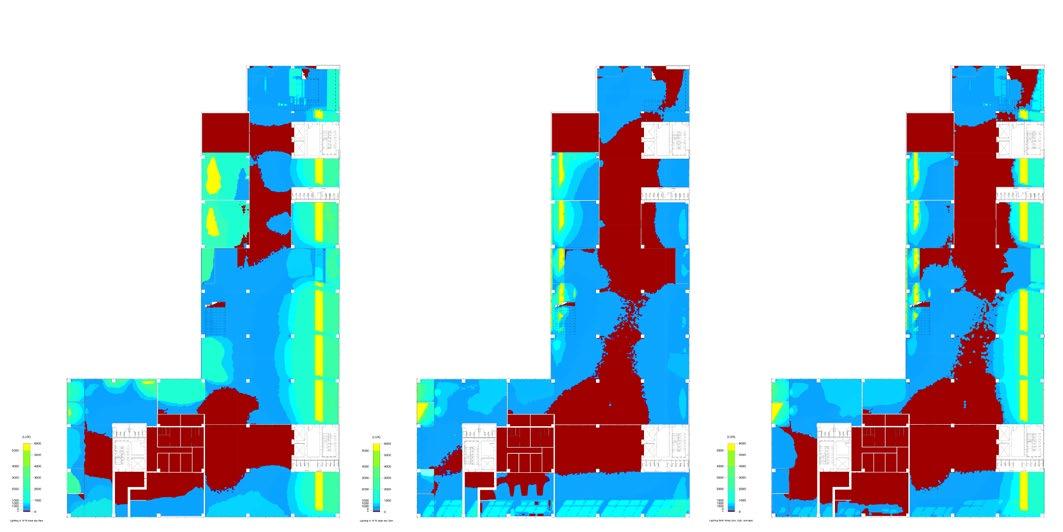

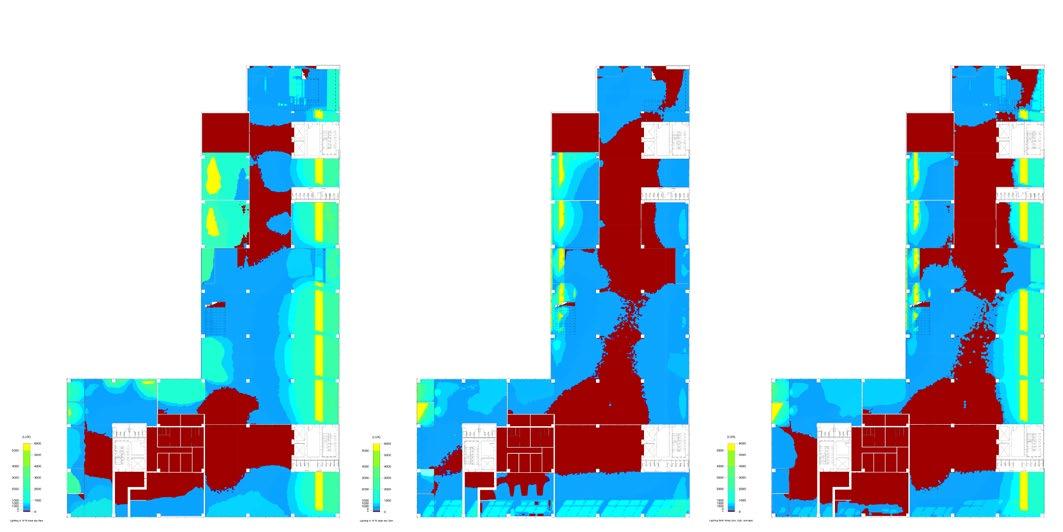

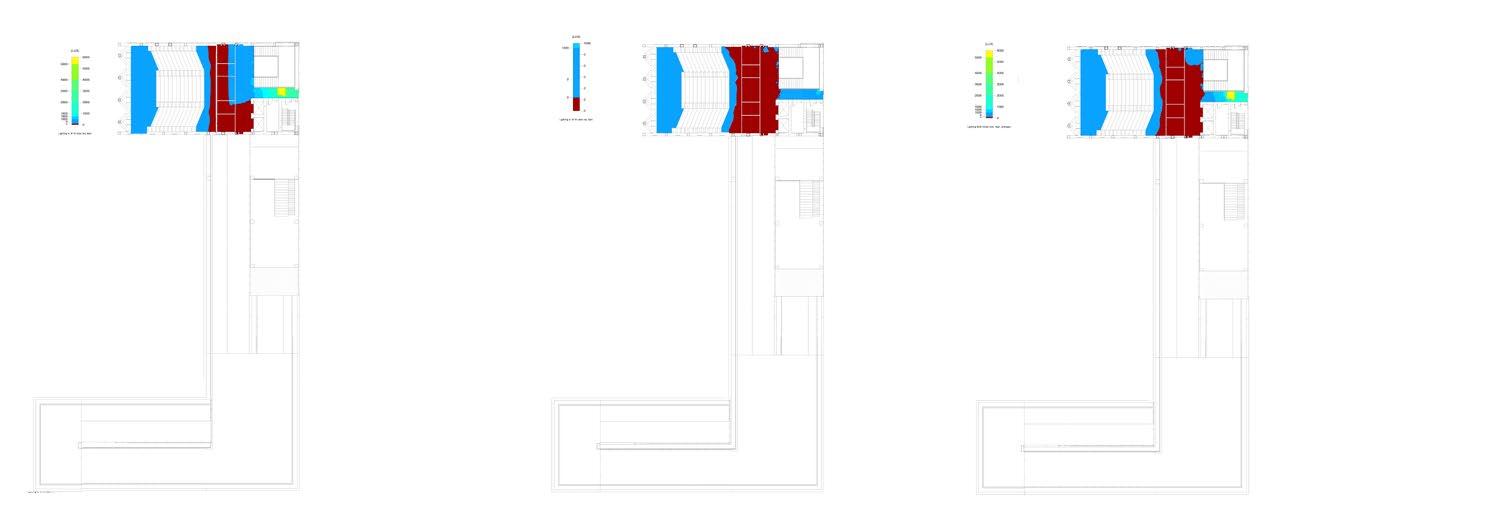

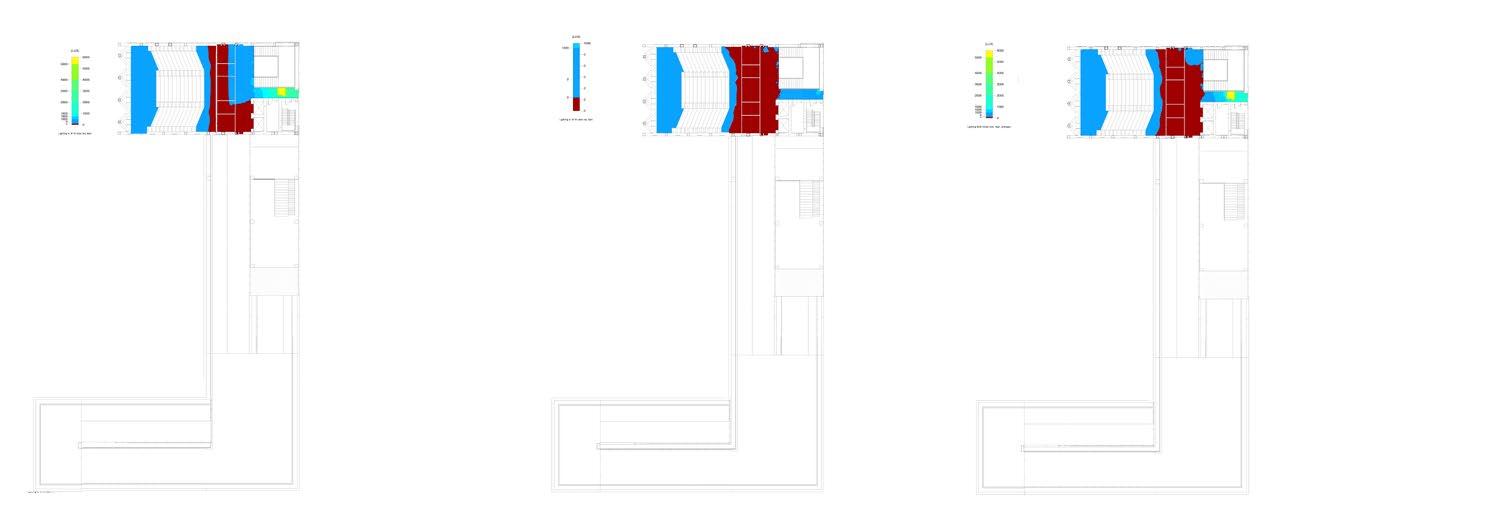

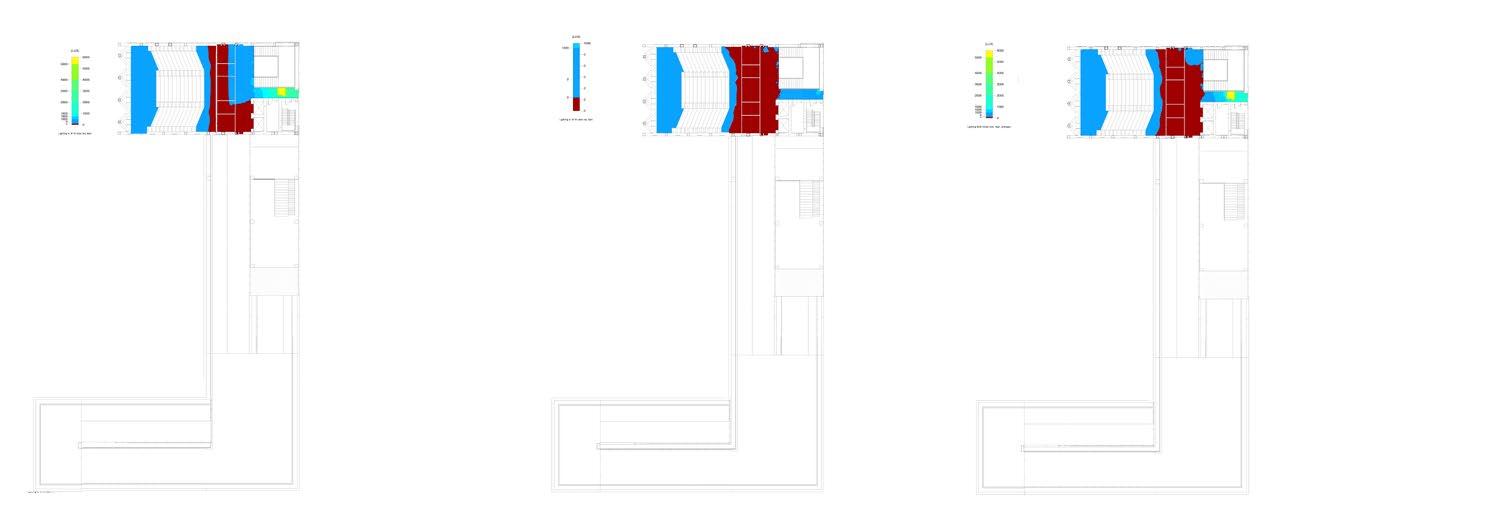

Function distibutions