WBHO’S UNWAVERING COMMITMENT TO SAFETY, QUALITY, AND RELIABILITY

2 | Africa Outlook Issue 101

An iconic name in construction, WBHO Construction (Pty) Ltd can be relied on to move the earth for its clients. Berto Smit, Managing Director of Civils, sets in stone the prevailing culture behind a contractor of choice, and its ambitions to become a cross-continental leader in renewables

Writer: Phoebe Harper | Project Manager: Taylor Green

I believe that there is no other construction company in South Africa (SA) that can consistently offer what we do. Our safety record is impeccable, and the quality that we deliver, on time, is just in another league.”

By name alone, WBHO Construction (Pty) Ltd (WBHO)

is synonymous with quality construction of international renown. The foundations of the iconic company were originally laid in 1970, with the inception of Wilson-Holmes (Pty) Ltd – a construction business formed by John Wilson and Brian Holmes.

Since that time, following several mergers that saw the

Africa Outlook Issue 101 | 3

MARINECONSTRUCTIONANDDIVINGSERVICES

Katlantic(Pty)Ltdisa100%BlackOwnedproviderofunderwatercivilconstruction,dredging, diving,inspection,wreckremovalandmechanicalrepairservices.TheCompanywasfounded byZainKathradain2017withafocusonPortsandDamsinSouthAfrica.Ourmainobjectiveis todelivercosteffectiveandqualityresultstoourclients.Weofferaworld-classservicethatis bothinnovativeandtailoredtosuittheneedsofourclients.WeareanISO9001:2015accredited companythatholdsdivinglicencesinallthemajorSouthAfricanPortswithareachintoAfrica andabroad.

In2018KatlanticwasgivenanopportunitytosupportWBHOonamarineprojectinthePortof Durban,beingachallengingemergencyrepairWBHOrecognisedourabilitytoinnovatively overcomechallengesearlyonwhichcontributedtotheoverallsuccessoftheproject.Sincethen, wehaveworkedcloselywithWBHOonotherProjectssettingourrelationshipin“concrete”. TheseprojectsincludethenewlybuiltTugJettyBasininDurbanwhereKatlanticexecutedawide scopeincludingbutnotlimitedtoDredging,Diving,MarineSupportandScourProtection.

KatlanticwouldliketotakethisopportunitytothankWBHOfortheirongoingsupportandwish themwellinthefuture.InthewordsofAmericanauthorNapoleonHill: "StrengthandGrowth comeonlythroughcontinuouseffort."

•MediumTHSD •CutterSuction •LongReachExcavator •PumpDredging •DiverHandHeld •AirLift•GrabDredge JettyandQuayConstruction •Dredging •CaissonBeds•SubseaPipeInstallation •JettyDemolitions • UnderwaterDemolitions •UnderwaterConcreting •Piling •GabionInstallation •SeawallConstruction •GeobagandGeotubeInstallation •UnderwaterclassCCTVSurveys • UnderwaterPipelines •CableLaying •Hydro-electricdaminspection,repairs&maintenance •Epoxyinjection •Dock,wharfandpiererection&repairs •Pilerepairs •Dredgingandjetting •DryDockExtensions •UltrasonicThicknessMeasurements •GasDetection •MagneticParticleInspection •Dye-PenetrationInspection •XRay •Radiographic Testing •VacuumBoxTesting •AnchorChainCalibration We excelattheseservices: KATLANTIC(PTY)LIMITED MarineConstructionandDivingServices 1DevonRoad,Pinetown,3610 Tel.0312660189 zain@katlantic.co.za www.katlantic.co.za Weareopentopartnershipsandjointventuresofanyscale.Feelfreetomakecontactwithusfor yournextriver,damormarineproject. StayUpdatedonourProjects •ShallowWaterWreckRemoval •SpecialCargoHandling •Pumping •PollutantsRecovery •EnvironmentalCare •HarbourClearance •Refloating DivingServices Non-Destructive Testing Marine Construction WreckRemoval Dredging

entity assume the WBHO Construction name in 1996 and complete a successful league of projects, WBHO has continued to advance and blossom into the largest construction company in southern Africa, listed on the Johannesburg Securities Exchange (JSE). In addition, WBHO boasts an extensive footprint in the UK after entering the space in 2017, and counts myriad projects undertaken within geographies all over the world.

Across the enterprise, WBHO’s extensive and wide-reaching

expertise spanning a full gamut of construction services is split into three strategic operating divisions: Building Construction, Roads and Earthworks, and Civil Engineering (Civils). The latter is proudly presided over by Berto Smit, orator of the opening statement, and Managing Director of WBHO Civils since 2010, from its base in Johannesburg.

ABILITY YOU CAN RELY ON

For Berto, the past 27 years spent working with WBHO reflect a

passion for construction that was ignited during childhood and further enhanced while studying Civil Engineering at the University of Stellenbosch.

“I have always been interested in building things and fell in love with it at a young age when my dad was building houses,” he recalls fondly.

As with all members of the WBHO management team, Berto’s own career trajectory within the company reflects the extensive industry experience channelled across the

6 | Africa Outlook Issue 101 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

PWC Core

board, having previously worked as a director of WBHO’s Cape Division, before eventually transferring to the Managing Director position in Johannesburg.

“The last 50 years have seen people climb up the ranks in the business. Our present CEO has been with the company for over 27 years, and it’s the same for me,” says Berto. “Our current Chairman has been with WBHO for almost 40 years, and prior to that, their predecessors had progressed in the same vein.”

This equates to an unsurpassed knowledge of the business itself, and an invaluable familiarity with the SA construction market.

“That level of experience and continuity within the business really makes a massive difference for us. When I originally came to Johannesburg, there was always talk of ‘the Big Five’ in terms of contractors in SA. Today, there are only two of us left – of which WBHO is

one,” he observes.

“When you look at those companies, compared to WBHO, what really differentiates us is that level of continuity and experience in our senior management.”

Indeed, for WBHO, it is the people behind the company – whether those in management positions or the construction and engineering teams on the ground – that make all the difference, both in terms of capabilities and in securing the sustainability of the enterprise itself.

“We understand the business and we understand the industry, and it is important for us that WBHO gets run by engineers,” Berto shares.

CIVILS EXPERTISE

Within the specific context of WBHO Civils, the division offers a wide range of services and capabilities that span myriad sectors, boasting a diverse portfolio of projects either undertaken or in the pipeline - all of which are

brought to life by the strengths of the WBHO team.

“We have exceptional teams out on-site that are experienced and well-trained. Our teams are hugely important to us, since at the end of the day, this is a business built around people,” shares Berto.

Primarily, WBHO’s civil engineering works are within mining infrastructure to support the industry across both SA and Africa as a whole, which Berto describes as, “our real bread and butter.”

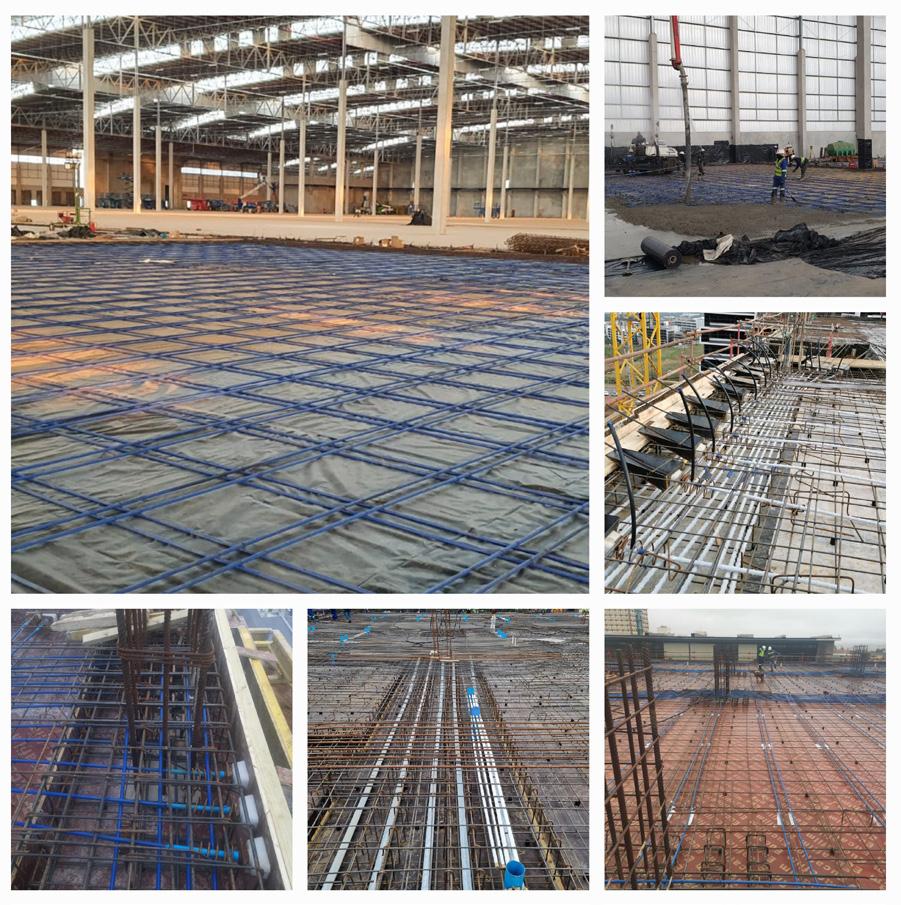

Elsewhere, the WBHO Civils team is well-equipped to oversee heavy industrial plants for major entities such as the electric public utility company Eskom, and other clients including SA Breweries. This field of work also extends to industrial buildings, as seen across many of the mines where WBHO operates and a swathe of other clients such as Twinsaver – a manufacturer of tissues and toilet paper.

“WE INTEND TO REMAIN THE CONTRACTOR OF CHOICE IN SOUTH AFRICA”

– BERTO SMIT, MANAGING DIRECTOR, WBHO CIVILS

Africa Outlook Issue 101 | 7

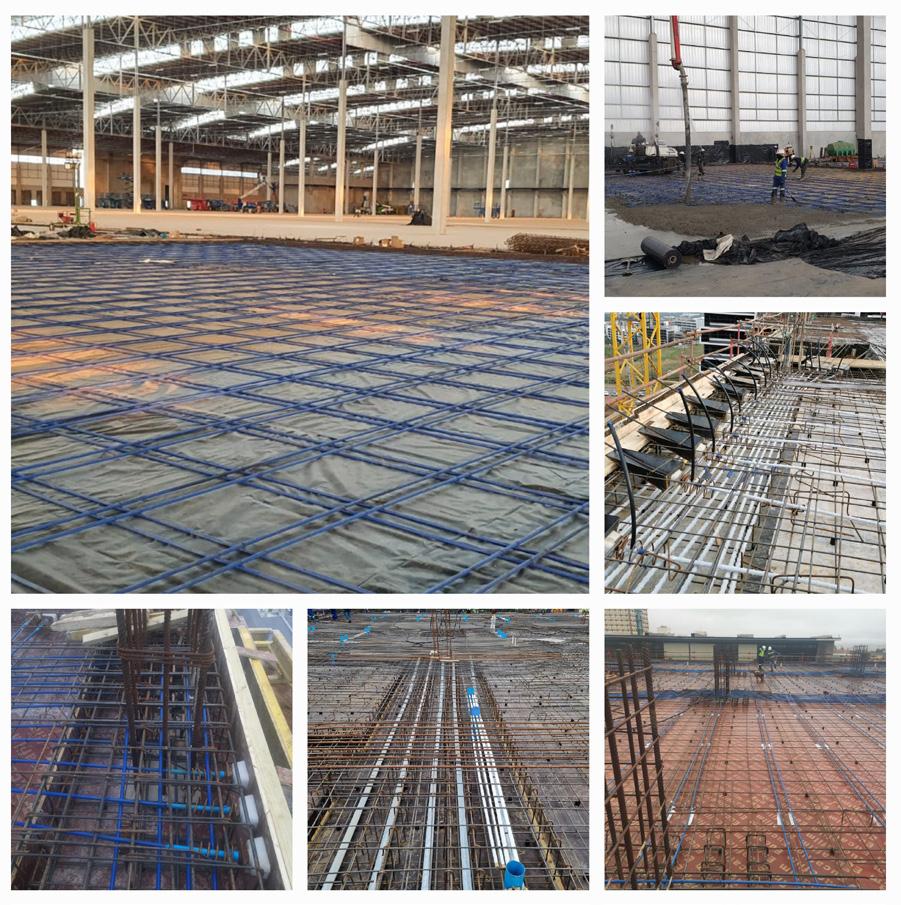

SAB Alrode Matling Plant

Creating Solutions Together

RMS Steel and VSL Post Tensioning

BUILDING TOG ETHER

Successful construction projects involve combining multiple elements to make one cohesive whole. While this applies to the actual materials used, it is equally relevant in the case of the different service offerings provided by the various contractors and suppliers involved. Sister companies RMS Steel and VSL Construction Solutions provide the perfect example of different specialties that can be combined to deliver exceptional outcomes, on time and on budget.

VSL CONSTRUCTION SOLUTIONS

VSL Construction Solutions offers multiple solutions to developers, all based on systems delivered by the Licensor, VSL, in Switzerland. The proprietary Vorspann System Losinger (VSL) system has been successfully used worldwide and is based on the process of posttensioning.

Unlike reinforced concrete, the steel elements in post-tensioned concrete (known as tendons or strands) are not in direct contact with the concrete that surrounds them. Instead, they are contained within a protective sleeve and then firmly anchored in place where they emerge from the concrete slab.

BENEFITS OF USING POST-TENSIONED CONCRETE

There are several advantages to this approach – because the steel tendons are cast into the concrete before they are tensioned, a wider range of profiles can be created. When tension is added, and the concrete is simultaneously compressed, the hardened concrete is exposed to reaction forces. These in turn help the completed concrete elements to resist tensile forces once they are in position. Essentially, the concrete is pre-stressed before it is used. Using post-tensioned concrete means that greater spans can be achieved. Crucially, both time and money can be saved through the typical resulting reduction in propping time as well as the reduction in concrete thickness, while the VSL system is also

compatible with designs utilising stay cables, external cables and ground anchors.

VSL also provides construction solutions including retained earth walls, bridge bearings and heavy lifting services. It is its posttensioning offering, however, that can make the biggest different in large-scale construction projects.

TWO FORMS OF POST-TENSIONING

VSL Construction specialises in both bonded and unbonded posttensioning systems. The key differences between the two are the number of steel strands (tendons) employed, and the applications to which they are best suited.

Unbonded systems utilise just a single plastic-sheathed strand, which is tensioned after being cast into the concrete (as described above). Unbonded post-tensioned concrete is most useful as slab or beam elements in buildings built from reinforced concrete. In contrast, bonded post-tensioned concrete is better applied to heavy civils projects like bridges, however, in the modern era they are now more suited to suspended structures where services are

a predominant component of the structure such as in hospitals and both residential and commercial offices. Each cast-in duct can contain multiple steel strands or tendons, with the bonding (and corrosion protection) being supplied by the addition of cementitious grout.

A SOLUTION FOR EVERY NEED

VSL Construction’s service offering has evolved in response to industry needs, with customers able to choose from bespoke solutions that begin with the supply of materials, and can extend all the way to a holistic supply and installation service. Their portfolio of solutions also encompasses supplying equipment and training, as well as design services (either wholly in-house or in collaboration with external engineers).

RMS STEEL

RMS Steel complements VSL Construction through producing and supplying high-quality steel reinforcement in the form of rebar and welded mesh.

Founded in 2002, RMS Steel has made great strides towards achieving its goal of becoming South Africa’s leading supplier of reinforcing steel bars and mesh. Quite literally, they’re helping SA to build back stronger.

RMS Steel is closely allied to the construction industry, which is the market for the vast majority of its output. Its steel reinforcing products are used in structural building components in structures on a wide variety of scales.

Quality, affordable steel reinforcing elements are a mainstay of the construction industry as they make buildings stronger and safer.

QUALITY STRUCTURAL COMPONENTS

Welded steel mesh has multiple applications – primarily as a means to reinforce concrete being used in building. Incorporating steel mesh into walls, floors and roofs increases their load-bearing capability and eliminates issues like cracking.

Steel rebar also offers multiple, lasting benefits. As it’s rustresistant, corrosion will not be an issue, and the strength added by rebar can be counted on in the long-term. It’s a cost-effective solution, and easy to use. Specialist companies like RMS Steel

provide bending and shaping schedules that enable customers to produce the exact rebar shapes they need to align with the original engineering diagrams.

Steel rebar can be used in almost any construction project, from individual houses to major industrial or commercial structures –indeed, anywhere that heavy loads and higher levels of stress will be encountered.

Leveraging its knowledge of construction, steel and load management, RMS Steel has expanded its offering to cover other rebar-related products. These include piling cages, rib and block slabs, accessories and Ancon products

THE VALUE OF KNOWLEDGE

RMS has years of experience in rebar and other steel elements for construction. In addition to providing comprehensive bar bending schedules, it also provides expertise to help customers resolve challenges encountered during construction projects. RMS also offers a pre-assembled rebar service – customers simply have to supply their specifications to receive their custom reinforcing steel elements.

THE STRENGTH WITHIN

Both RMS Steel and VSL Construction – either separately or together – play a key role in supporting the construction industry in South Africa and beyond. In addition to providing elements for new-build structures, VSL Construction can also assist with existing structures, structural concrete scanning and assessment, plus repair and strengthening services.

STRONGER TOGETHER

Whatever your concrete reinforcing needs, VSL Construction and RMS Steel are ideally positioned to support you.

rms-sa.co.za

PROJECT SNAPSHOT: SALDANHA OIL STORAGE FACILITY

The client appointed WBHO to build 12 oil storage and blending tanks at the end of 2016. Full go-ahead for the project was received during February 2017 and it was completed in October 2020.

Each concrete tank is 110 metres (m) x 110m x 17.5m deep and can hold 1.1 million barrels of crude oil.

Major quantities include:

• Formwork - 271,000m2

• Concrete - 156,000m3

• Rebar - 19,000 tonnes

• Earthworks - 1,250,000m3

• Pipework - 36,300m

• Electrical cabling - 245,743m

WBHO undertook the entire construction scope on this project. Find out more here.

“We are also heavily involved in water retaining structures, whether it’s for drinking water or waste water. That’s an area that we have a lot of experience in,” Berto informs us.

Meanwhile, WBHO is an expert in slipforming construction techniques, and also has a dedicated marine division in-house that works with private clients and major names such as Transnet, and most recently through a joint venture (JV) with CCS-JV in northern Mozambique. WBHO Civils is a significant player within the oil and gas sector, and is equally involved in supporting SA’s nuclear activities.

Finally, the Civils division is playing a burgeoning role in driving the clean energy transition, with a swathe of renewable energy projects under its belt and in the pipeline

for development. This work mainly centres on the balance of plant works and concrete keystones necessary for the construction of wind turbines across Africa.

Regardless of the industry or the project at hand, WBHO combines its unparalleled prowess in civil engineering with an outlook centred on accurate pricing that holds the client’s best interests at heart.

“We ensure that every tender we submit is of the highest quality and 100 percent compliant,” Berto comments. “We take enormous pride in the standard of our tenders, no matter what the project and who the client is.”

A LEADER IN RENEWABLES

Returning to the significance of WBHO’s burgeoning role in laying the foundations of SA’s renewable energy

10 | Africa Outlook Issue 101 WBHO CONSTRUCTION

CONSTRUCTION

Saldanha Oil Storage and Blending

(PTY) LTD

MORETHANJUSTREBAR…

Barnes Reinforcing Industries (BRI) was established in 2007, to serve the growing requirements for Reinforcing Steel products within the Southern African, and now global, construction industry. BRI provides Reinforcing Solutions to the construction, mining and associated industries, which include the supply, cut, bend and installation of reinforcing steel and mesh.

State of the art manufacturing, backed by a professional, highly skilled BRI Team, ensures a world class customer experience.

LEARN MORE

infrastructure, Berto highlights this as an area of major attention for future development, with the potential to make waves beyond the country and across the wider African continent.

“South Africa is definitely a bit behind Europe and many other parts of the world in terms of renewable energy and this is a focus point due to the ongoing issues we have with Eskom and power security,” he says. “However, the country has an

abundance of wind and sunshine, and the industry is taking off. It’s something that we all want to be a part of as contractors.

“It’s exciting, it’s new, it’s the right thing to do and it’s a massive market that we can see coming.”

WBHO’s Projects division has a proven track record and vast experience in delivering private public partnerships, concession arrangements and turnkey design

AFRICA OUTLOOK: CAN YOU UPDATE US ON YOUR ONGOING INVOLVEMENT IN THE TWO RIVERS PLATINUM MINE PROJECT WITH AFRICAN RAINBOW METALS (ARM)?

Berto Smit, Managing Director: “This project started in April 2022 and the plan is to finish by August 2023. We are undertaking all the main civil works for ARM’s new concentrator, and so far the project is proceeding very well, and the ‘big ticket’ items are behind us. These higher risk elements all went exceptionally well.

“Now that we are finishing off the major structures, we are helping the client by getting involved with local contractors. This is a massive focus throughout construction in SA, to work more with local contractors on all projects. This is something that we have always done on almost all of our projects, but here we are taking it to the next level. We have mobilised one of our directors to the site to help manage these partnerships with local contractors to ensure that they run smoothly and contribute to the overall successful operation of the new concentrator.”

and construct solutions and is now applying this knowledge in the renewable energy sphere.

A seminal project in this area came in 2014, when WBHO undertook a contract on the Ressano Garcia Gas Fired Powerstation in Mozambique for Gigawatt Africa. This entailed the construction of a 100-megawatt (MW) gas fired plant with 13 Rolls Royce gas engines, three transformers, a gas conditioning station, earthworks, civil

Roggeveld Wind Farm

Roggeveld Wind Farm

12 | Africa Outlook Issue 101 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

Macsteel reinvented the construction landscape with our innovative Novotexi 440® product range and Sky Former. However, we aren’t only about robust roofing solutions, our side panels, beams and cold formed sections provide the same level of durability, strength and convenience on any industrial, commercial or building projects. Offering a turnkey solution.

macsteel.co.za

For strength and durability, we have you more than covered.

PROJECT SNAPSHOT: COPPERTON AND GAROB KEYSTONE FACTORY

WBHO built the factory and produced 1,360 concrete keystones for these two windfarms in SA. These keystones are the building blocks for 80 wind turbine towers.

Major quantities include:

• Concrete - 26,000m3

• Rebar - 3,845 tonnes

• Cast-in items - 74,720

• Contract duration: Factory construction – four months, and keystone manufacture - six months

works, buildings and a high-voltage (HV) switchyard.

Similar engineering, procurement and construction (EPC) contracts ensued within solar power projects, such as Kathu Solar in SA (81MW), Ngonye Solar in Zambia (34MW), a 256MW private solar project in the North West province of SA and working as a subcontractor to Nordex Energy on the Nxuba Wind project (147MW), to name just a few.

“As a company, we can give a onestop shop solution to our clients on the renewable side,” says Berto. The Civils division’s work within renewable energy largely consists of the aforementioned keystone factories where WBHO’s concrete experience and specialities are put to good use in the construction of the sections used to build the towers for the wind turbines.

“These are large projects in the region of ZAR500-700 million,” he continues. “We have recently finished one such project successfully and have begun another working with a new turbine supplier.”

WBHO also works on both the civil balance of plant (CBOP) and electrical balance of plant (EBOP) - the former involving all the earthworks and turbine foundations, followed by the electrical work.

“By combining the keystone works with both CBOP and EBOP, we can give the client the full package.”

Elsewhere across the business, the WBHO building team specialises in the construction of 5-Star Green Buildings across SA, with numerous constructions under its belt. In addition, WBHO works closely with a selection of its larger clients in an effort to advise and guide them on ways to reduce the project’s carbon footprint during construction and beyond. This includes the analysis of power consumption and greenhouse gas (GHG) emissions associated with each project.

TRAINING AND TALENT DEVELOPMENT

Not only does the expertise that WBHO brings to each new undertaking ensure a guaranteed level of quality and reliability for its clients, but it also contributes to the culture behind the company as a rewarding crucible for professional development and growth.

The same longevity and level of stickiness within the company evidenced by Berto and other members of the management team, is encouraged amongst all WBHO employees, who are rewarded with an empowering workplace environment that prioritises training and nurturing talent to ensure that the business grows and develops future leaders from within.

Training and staff development is a major focus of investment in allowing

Copperton and Garob Keystone Manufacture

14 | Africa Outlook Issue 101 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

Dredging Africa has proven itself to be a leader in the field of clearing inland dams and harbours of silt, sand, and invasive water plants.

The recent partnership between Dredging Africa and WBHO to carry out the Durban Tug Jetty project, is a significant milestone in the African infrastructure development landscape.

Implementation of specialized dredging technologies made the successful completion of the groundwork for the construction of the new tug jetty possible. However, their success is not only due to their advanced

technology and equipment but also the expertise and professional skills of their dredging operators. These skilled professionals operate the dredgers with precision and efficiency, ensuring that the dredging process is carried out accurately and effectively. The expertise and innovative technologies employed by Dredging Africa have raised the bar for future water infrastructure projects on the African continent. The successful completion of this project is a strong indication of the fruitful collaboration between Dredging Africa and WBHO in delivering top-notch solutions to address the challenges facing Africa.

Our mission is to use technology responsibly to serve the underserved

Tembo Investment Group (Pty) Ltd is a pan African company, founded in 2014 with interests in Information & Communication Technology, Retail Value-Added Services, Digital & OOH Media and Retail Solutions.

We are passionate about developing seamless, tailored and low-cost digital payment solutions for Africa’s unbanked mass market. Our technology intensive corporation is geared to deliver state of the art FinTech solutions for retail, micro enterprises, banks and insurance companies.

We have over 20 years working experience in the Financial Services and Grocery Retail sectors, developing affordable micro-investment, savings, microlending and Value-Added Services products for the bottom scale market.

www.tembointernational.com

Tel: +27 (0) 12 443 6573 | www.dredging-africa.co.za

Africa Outlook Issue 101 | 15 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

PROJECT SNAPSHOT: VLAKFONTEIN RESERVOIR

WBHO constructed this 210 megalitre (ML) reservoir for Rand Water in South Africa with one of its Voluntary Rebuilding Programme (VRP) partners. It is the biggest circular post tension reservoir in the world at 160m diameter and 12.5m deep.

Major quantities include:

• Formwork - 39,000m2

• Concrete - 24,300m3

• Rebar - 2,230 tonnes

• Post tension cable - 256,600m

Contract duration: March 2020 to December 2022. WBHO undertook the entire construction scope on this project. Find out more here.

WBHO to securely and sustainably deliver the levels of quality, safety, and reliability that its name is synonymous with.

“For us, it starts at the very beginning, investing a lot of time with those on our bursary schemes,” Berto explains. “Our Managing Directors will go to universities to conduct the interviews and ensure that we award bursaries to the most suitable candidates; people who we believe will flourish in the construction industry and who will be a real asset to our business. Some companies will send a different representative to do that, but we believe it’s only right that our most senior people are involved in the selection of the talent that we get through those schemes. Construction is a tough industry and we need special people in our company to make a success of it.”

Successful candidates then embark on mentorship programmes with more senior candidates, who

follow their progress on the scheme and regularly check-in on them, both professionally and personally. They also undertake vacation work on WBHO projects, where they gain invaluable on-site experience. After graduating from the bursary schemes and joining WBHO full time, individuals will attend Engineering Schools, beginning with an initial and extensive introduction to both the company itself and the wider industry.

Progressing to the next level of Engineering School, employees are guided through more advanced topics in a similar format, learning the ropes of contractual and commercial matters and other necessities before the advanced Engineering School puts individuals firmly on the path to becoming successful project managers. By this stage, those pursuing the advanced Engineering School will have been in development for close to 10 years.

“Here we dig deep into the commercial, contractual and financial

Vlakfontein 210ML Reservoir

16 | Africa Outlook Issue 101

Form-Scaff is a division of Waco Africa Pty Ltd and is South Africa’s market leader in the hire and sale of scaffolding, formwork, falsework and associated services. The operation provides products and services to a wide range of construction and civil engineering industries. With over 60 years of experience and worldclass expertise, Form-Scaff also provide design skills, technical advice and support through more than thirty branches in South Africa and on the continent.

The Division is a major manufacturer of formwork and scaffolding and Form-Scaff’s products have been widely accepted as the benchmark in South Africa. Highly innovative, Form-Scaff has maintained its position among other global suppliers.

The Form-Scaff team are renowned for their versatility and always finding a solution for projects that have planning challenges, changing requirements and difficult deadlines. formscaff.com

BUILDING A BETTER FUTURE

With over 100 stores in South Africa, and neighbouring countries too, we are conveniently placed to service any construction or civils project. From large-scale construction equipment to site safety consumables, we offer a wide range of highquality products backed by the knowledge of our experienced team of Hire Specialists.

Exclusive Distribution Partner for Doka in Sub-Saharan Africa. Support Where You Need It Most

Call us now: 00258 84 566 6080 BUILDING A BETTER FUTURE | WWW.TALISMAN.CO.ZA 0861 87 87 87 | WWW.TALISMAN.CO.ZA

CHOOSE TALISMAN AS A RELIABLE

HIRE PARTNER Africa Outlook Issue 101 | 17 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

EQUIPMENT

side of the business, and our directors are very much involved throughout,” says Berto.

In addition, young engineers and quantity surveyors are offered further guidance with various support systems within WBHO to become professionally registered through the South African Council for the Project and Construction Management Professions (SACPCMP), ECSA, and with MDP courses to help encourage management development.

“We send our brightest employees on these MDPs to really enhance and complete their managerial side,” he continues.

Finally, sponsorship programmes for engineers and quantity surveyors are also designed to pair directors with trainees as a means of further progression.

On the production side of the business, WBHO has a structured training programme whereby foremen attain a South African National Qualifications Framework (NQF) registration or follow an accredited skills development course.

“These are people who typically don’t have a diploma or a degree, but they have many years of construction experience and came up through our ranks. We have a huge push to get them through these programmes and currently, more than 80 percent of our foremen have these accredited qualifications.”

These comprehensive programmes ensure that all WBHO talent is well-equipped and prepared to hit the ground running, with a solid understanding of what is expected of them and how to perform their work safely in an environment that respects them and their contributions.

SAFE AND SECURE

“A lot of people will talk about zero tolerance on safety, and zero tolerance on quality, but for us, it’s more than just talk,” states Berto.

To maintain its stringent safety

standards, the WBHO Civils team performs weekly safety ‘stand downs’, whereby directors will oversee the teams on site paying particular attention to any safety or quality issues, constantly questioning if certain tasks could be performed in a safer, or better way, as a means of constant evaluation and improvement.

The company’s prevailing emphasis on safety reflects a level of empowerment that WBHO aspires to champion within its employees, ensuring that the right people are

matched with the right projects. The company is willing to compromise on the size and scope of the projects it chooses to work on, if it provides an avenue for growth and development for junior members of the workforce.

“Although we are a big company, we put a lot of effort into selecting some of the smaller projects, which might not be where we want to play, but are equally important since they provide an opportunity for our younger engineers and quantity surveyors to experience and understand how a complete project works, but on a much

Dr Petrus Rantli Molemela Soccer Stadium

18 | Africa Outlook Issue 101 WBHO CONSTRUCTION (PTY) LTD CONSTRUCTION

Mopani Concentrator, Zambia

smaller scale,” Berto explains.

“If you only undertake megaprojects, which is our niche, you will find that some youngsters within the company will start to disappear since they’re not yet experienced enough to run these big jobs and will never get the opportunity to develop. The smaller projects offer us the opportunity to teach the young site managers all the facets of a project, in a less challenging environment.”

Aside from nurturing and encouraging professional growth and experience, the individual well-being of staff is also a constant concern, with staff checking in with each other both on their professional capabilities or challenges, but also connecting on a personal level.

“Members of the Civils team will have one-on-one sessions with me as the Managing Director where I check in with them to understand where they are at in terms of work, and what their expectations are in terms of their own progression. But I also take an interest in their personal lives, asking

about their home situation and what they’ve got going on outside of work. We find that helps a lot,” he shares.

BUILDING THE FUTURE

Turning to talk of the future, Berto has a concrete set of priorities that remain top of the agenda - both for WBHO’s Civils division and the wider company.

“We intend to remain the contractor of choice in South Africa. This is a goal that we have always, and will always, strive towards.”

This involves maintaining an unrelenting emphasis on safety and on the people laying the groundwork both of WBHO’s impressive physical footprint, and its company culture.

“The immediate priority for us is always to complete the year without any serious injuries or incidents on any of our projects,” he shares.

With these people-centric concerns in place as priorities, it is only then that WBHO considers growth and turnover as the essentials of business prosperity.

“Of course, we want to grow the

business, but we have never been a company that just chases turnover. For us, it’s more about growing and developing our people, since we always want to promote from within and give our people those opportunities to grow with us,” elaborates Berto.

When it comes to growing the business’ footprint in terms of projects and new undertakings, for the Civils team, the future is looking green.

“We have been actively busy with our renewable projects in SA for the past eight years, but now we want to establish ourselves as a market leader in renewables throughout Africa. We are seeing more and more projects cropping up outside of SA, and our high-level goals are to target them, and ultimately make them a success.” WBHO

CIVILS Tel: +27 11 321 7200 www.wbho.co.za

Africa Outlook Issue 101 | 19

TNPA Head Office - Coega

53 Andries Street, Wynberg, Sandton, South Africa. Tel: +27 11 321 7200

www.wbho.co.za

WBHO’S UNWAVERING COMMITMENT TO SAFETY, QUALITY, AND RELIABILITY

PRODUCED BY AFRICA OUTLOOK MAGAZINE

WBHO CIVILS

Roggeveld Wind Farm

Roggeveld Wind Farm