Vehicles are incredibly complex and technologically advanced machines.

A number of important parts immediately spring to mind, from fundamentals such as brakes, engines and wheels, to modernday luxury accessories including satellite navigation and parking sensors.

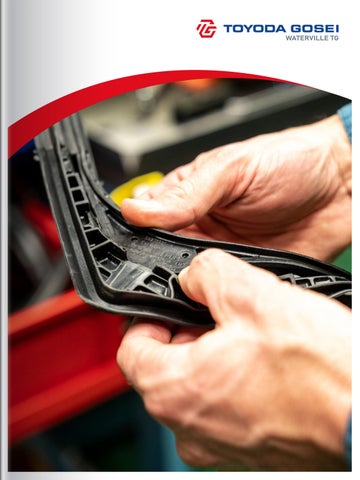

But one component that often gets forgotten about, yet serves a vital purpose in protecting a vehicle, is weatherstripping.

The rubber material that seals the

edges of doors, windows, windshields and more, weatherstripping is responsible for retaining warmth and keeping rain, dirt, and bugs out.

The world’s biggest automotive manufacturers, including Ford, General Motors, Honda, Stellantis and Toyota, continue to choose customized weatherstrips designed and manufactured by Waterville TG (Waterville), whether for their massmarket or more luxurious models.

“We are a supplier of dynamic and static weatherstrip systems for the automotive industry,” says Benoit

Benoit Tetreault, President

Benoit Tetreault, President

Tetreault, President of Waterville.

“We offer a turnkey service to our customers, from the custom design, through to material development and the manufacturing process, up to the mass production of these parts.”

It was Tetreault’s interest in understanding these multidisciplinary aspects of the business, and the challenges of design and manufacturing, that allowed him to be promoted to President in 2017, having worked in the automotive sealing industry since 1994.

“Throughout my whole career, my

technical expertise combined with my market knowledge and appetite for the future of sealing systems brought me to where I am today,” he reflects.

The history of Waterville, a wellestablished company celebrating its 70th anniversary this year, is one defined by the search for the best solutions.

From its founding in 1952, Waterville stood out by becoming the first producer of sponge rubber in North America.

Since then, the company has become a key player in the design and manufacture of weatherstrip seals and systems, today employing more than 1,100 members of staff and operating three production plants, as well as one distribution center, across Quebec and Ontario.

For Tetreault, longevity is one of Waterville’s biggest competitive advantages.

“We have continuously improved our materials, manufacturing methods, and processes to provide the best products,” he tells us.

“That know-how keeps us one step ahead of our competitors, and we can build on these foundations. We have several employees with more than 30 years of seniority!”

Many trends have come and gone over the last seven decades, in which time Waterville has also developed a strong understanding of the market by working with multiple customers, even the likes of Ferrari and Porsche, across various product types.

Indeed, the company has been recognized internationally as a convertible vehicle sealing specialist, with the quality and reliability of Waterville’s products setting it apart from the competition.

“We have the capability to develop the full product, from design to dayto-day support and delivery, and a very strong program development team that supports our customers

through the complete lifecycle of their vehicles,” Tetreault says.

“Furthermore, we have an experienced material development team that can quickly develop new formulations, ensure compatibility between various materials, and our chemists ensure the support of our sister companies as well.”

Waterville’s engineering team is just as integral to the organization, special izing in various fields of expertise from artificial intelligence (AI) and robotics to manufacturing and engineering.

“This team is leading the way towards global competitiveness and developing new technologies,” adds Tetreault.

As an active member of the community, being a good corporate citizen is a priority for Waterville.

Transportation is racing forward, evolving at its fastest pace in more than a century. Electric, hybrid and autonomous vehicles are reshaping our world and how we will travel, requiring advanced solutions to meet the challenges of individual and societal mobility.

To meet these rapidly evolving needs, Dow partners with key players in the value chain to develop solutions for targeted automotive application needs including weather seals. For example, NORDEL™ EPDM is used in high performance weatherseals today, and Dow continues to develop the materials for the next generation of ultra-lightweight, color stable, and high-performance weather seals aimed at meeting the needs of battery electric vehicles (BEVs).

Furthermore, Dow created its MobilityScience™ Studios which offer a collaborative workspace that features a world-class suite of testing capabilities focused on acoustic and powertrain solutions for fast-moving automotive applications.

“Understanding that vehicle requirement needs are in transition, MobilityScience™ Studios is always looking for ways to develop next generation materials for a variety of applications,” said Beth Talaga, Dow Transportation Marketing Manager. “These studios, located in Midland, Michigan and Lake Jackson, Texas, combine unparalleled expertise and a broad product portfolio, offering a comprehensive development network with access to experts and a focus on formulation, fabrication, and testing capabilities.”

Whether companies are looking for solutions for electric or autonomous vehicles, Dow customizes solutions to drive enhanced safety, performance, reliability, and sustainability.

Looking for lighter weight? Amazing acoustics? Improved weatherability? Increased manufacturing efficiency? Enhanced sustainability…from raw materials selection through end-of-life options?

Backed by MobilityScience™ Studios – our exclusive, comprehensive development network – we’re working side-by-side with customers and NORDEL™ EPDM to help create a new generation of weatherseals for BEVs and beyond.

Want to get in on the excitement? Let’s talk.

Please contact a Dow representative or visit us at www.dow.com/nordel to learn more.

“For us, social responsibility is about the positive impact our company can have on preserving the environment, creating pleasant workspaces, and helping to build communities that people want to live in,” Tetreault emphasizes.

“Our company contributes to the local economy by providing quality and stable jobs for hundreds of families locally. We also partner with local engineering firms, develop new suppliers, and purchase tools and components from local vendors.”

Waterville’s commitments to the community include support for organizations such as Centraide Estrie (United Way), taking part in the nonprofit’s awareness campaign every year.

Many employees also make donations to Centraide Estrie through automatic payroll deductions, with special prizes given out to donors by Waterville to encourage employee participation.

Elsewhere, the company makes financial and material donations to the likes of Blue Massawippi and FSWC Québec, and supports a variety of projects in the city of Waterville.

“We also like to encourage university students by supporting their engineering projects and competitions, as well as sports organizations.”

Equally, Waterville’s Better Health program is centered on wellness and allows staff members to enjoy a fulfilling lifestyle.

Better Health focuses on physical and mental wellbeing in five specific areas: Eat Better, Breathe Better, Be Safer, Live Better, and Move Better.

“We try to implement different types of activities so that the program appeals to everyone,” Tetreault shares.

“For example, we have a massage therapist that comes to the Waterville plant every week, we have several gym and spa discounts, and we hand out fresh apples in the fall.”

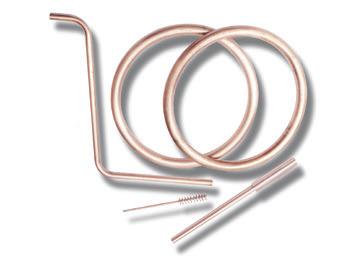

Acrolab provides thermal, design and sourcing solutions for several manufacturing applications and industries. Partnering with us brings you full optimization of thermal engineering and supply chain management.

Speed, precision, profit and sustainability are key features of Acrolab. We develop thermal management technologies and manage discrete industry partnerships with reliable suppliers that result in superior comprehensive technology solutions for our customers.

Our products and services optimize output, resources, cost and carbon footprint. Acrolab operates along the principles of Sustainable Development Goals (SDGs) to maximize output while reducing contributions of environmental emissions.

For more than 75 years Instron has been a world leader in the materials testing industry, offering cutting edge solutions for tensile, compression, flexural, fatigue, impact, dynamic, melt flow, HDT, Vicat, and torsion testing applications as well as structural durability and crash simulation testing.

Instron materials testing systems are used in industry, academia, and government to evaluate the mechanical properties and performance of raw materials, components, and final products.

The extensive Instron product line is backed by a global infrastructure offering a broad range of local service capabilities including installation, calibration, verification, training, technical support, and onsite service. www.instron.com

Production process

Production process

To minimize its environmental footprint, and eliminate the landfilling of production waste, Waterville has recycled waste weatherstrip rubber processed outside the factory for almost 20 years.

“We have surrounded ourselves with processors, and brought our technical expertise with rubber into the equation to allow a significant reduction of material going to waste,” outlines Tetreault.

More recently, the company was awarded the Eastern Townships environmental excellence prize and is now recycling 70 percent of its residual materials.

Waterville is also constantly opti mizing its coating systems to reduce landfilled waste, lowering the amount of silicone used and alleviating volatile organic compound (VOC) emissions.

Numerous recycling projects, meanwhile, have been implemented to prevent other materials from going to landfill, including paper, cardboard, glass, metal, wood, and plastic.

“We also promote composting, and in our recycling business relationships, we prefer local businesses in order to reduce our carbon footprint to the maximum,” Tetreault notes.

Another of Waterville’s environmental goals is to increase the reuse of reclaimed EPDM rubber in compound mixing, based on a new ‘cradle-to-cradle’ mantra.

This year, the company will be pursuing an R&D project with the intent of increasing the ratio of reclaimed material inside new batches of rubber.

“The end goal is to revalorize products by reintroducing them into the production process. One of the challenges is the reclaiming process itself, to design the product with reuse in mind and the collection of material following its usage.”

Waterville has a track record of environmental leadership, having been a member of the Canadian

Industry Program for Energy Conservation (CIPEC) since 2004.

CIPEC recommends best practices in energy management, and encour ages reductions in the consumption of energy per unit of production whilst improving economic return. Waterville has subsequently had an electricity management system (EMS) in place since 2014, enabling the implementation of systematic energy management.

The company has also been involved on the Board of Directors of the Fondation Estrienne en Environnement (FEE) since 2007, promoting environmental protection and sustainable development in the Eastern Townships region.

As a FEE member, Waterville has now participated in expert networks and drafted guidelines dealing with the adoption of best practices in the industry for several years.

“Waterville participates in the sharing of knowledge, with the goal

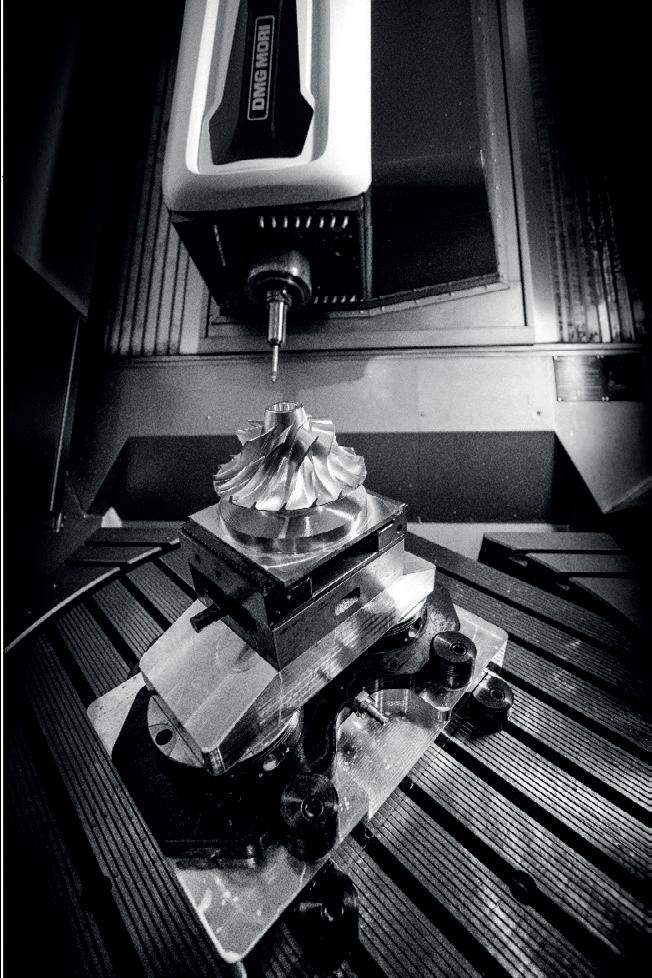

Established since 2017 in Sherbrooke, Quebec, Usinage Blaxes CNC has been known to compete and help the big companies of this market.

We have made our name strong by making quality parts at a good price and by shipping them promptly.

Usinage Blaxes CNC specializes in CNC manufacturing, now possessing two 5-axis milling, one 3-axis milling, an EDM Wirecut and recently a 4-axis lathe.

We are now able to help our customers more than ever. This is why we are a major asset for Waterville TG in the process of making their molds. www.blaxes.com

Rubber productionof having a positive impact on the industry,” Tetreault states.

“We are also involved on the CSMO Caoutchouc Board of Directors, participants in Elastomer Valley, members of the Association des Élastomères du Québec (AEQ), and have participated in the Maison régionale de l’industrie (MRI) for more than 30 years.”

For the year ahead, Waterville’s big focus will be on supporting its customers in the disruptive Battery Electric Vehicle (BEV) environment.

The company is collaborating with manufacturers, who are facing fresh challenges associated with BEVs, to

reduce mass, improve acoustics, and comply with new regulations.

“As car manufacturers start to master BEV powertrain technologies and competition increases, we think their focus will change to improve noise, vibration, and harshness (NHV) and weight saving,” Tetreault says.

“We would like manufacturers to recognize the technical complexity of quality weatherstrip sealing systems, the benefits of which will show in this new era of mobility.

“Our parts need to withstand not only doors and windows opening and closing, but also exposure to external elements. The body sealing system has an impact on a vehicle’s perceived quality from an NHV perspective; the

importance of weather seals to block airborne external noise and manage squeaks and rattles is considerable,” he continues.

It comes as Waterville continues its efforts towards automation, having invested heavily in manufacturing robotics over the last few years to ergonomically improve its processes and increase global competitiveness.

“This vision makes even more sense now in the context of labor shortages.

“However, the challenge here for automated operations is the fact that weather seal parts are soft,” Tetreault acknowledges.

On the cutting edge since 1952, the next 70 years of automotive rubber weatherstripping at Waterville is set to be as exciting as the first.

Tel: 1 (819) 837-2421 isabelle.tremblay@wtg.ca www.watervilletg.com

“WE ARE A SUPPLIER OF DYNAMIC AND STATIC WEATHERSTRIP SYSTEMS FOR THE AUTOMOTIVE INDUSTRY”

– BENOIT TETREAULT, PRESIDENT, WATERVILLE TG