MINE TRANSITION AND EXPANSION IN AUSTRALIA’S BOWEN BASIN

Vitrinite is focused on utilising an untapped tool in its open cut mines. We speak to Michael Callan, COO of the company, about the latest developments across the Vulcan Mine Complex

Writer: Marcus Kääpä | Project Manager: Eddie Clinton

Writer: Marcus Kääpä | Project Manager: Eddie Clinton

The industry has gone through quite a tumultuous past year - it has been a bit of a wild time. We had coal prices going into the 600s during the middle of 2022, which is both incredible and

source responsible for around 36 percent of the world’s electricity. Metallurgical coal, more commonly known as coking coal, is used to produce coke, an essential fuel for many modern industries such as steel production. It therefore comes down to coal mining companies to fuel this

In Australia, the mining sector is one deeply embedded in the country’s past, and coal is no exception. Yet despite its historical roots, there are new companies making their mark in an old industry,

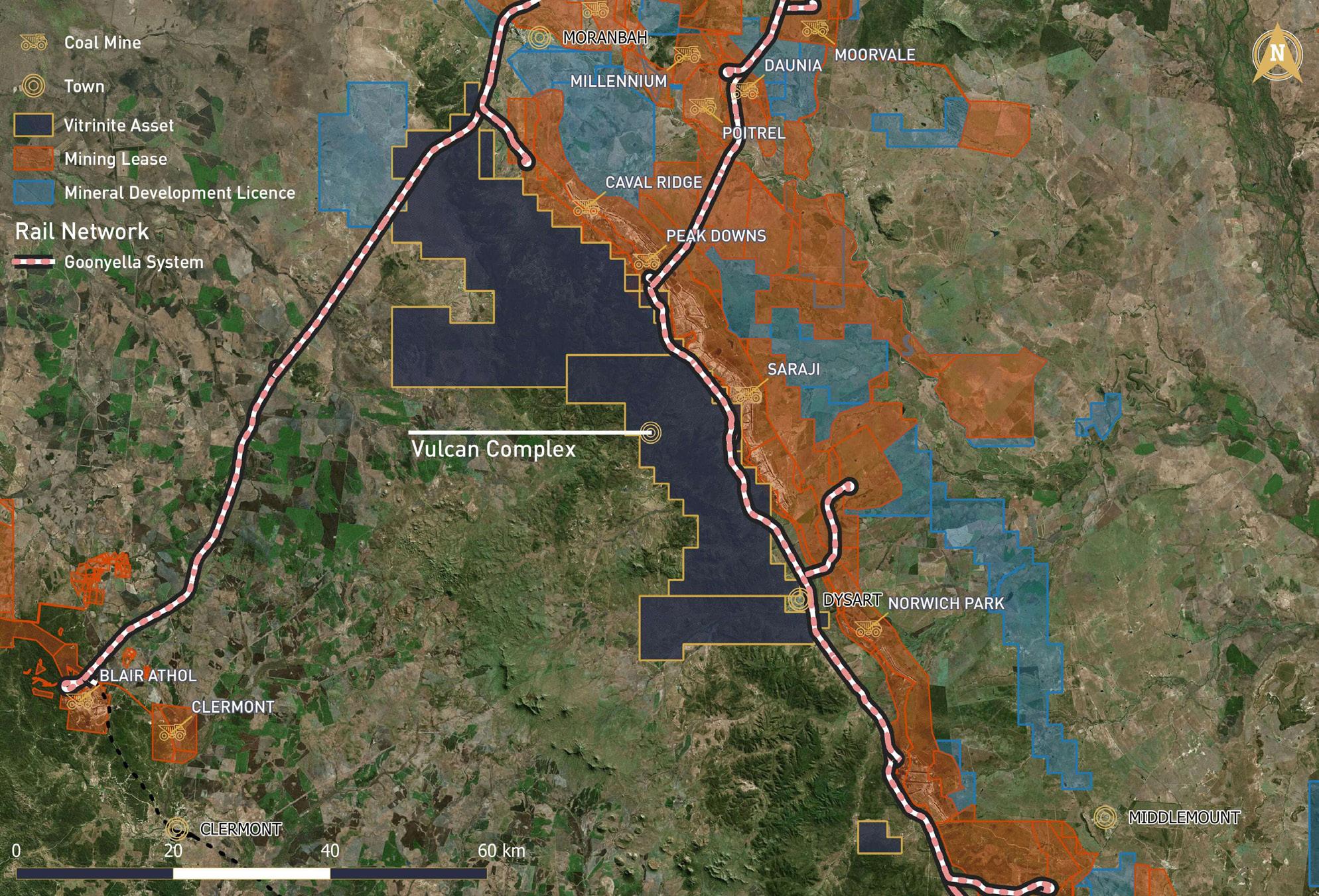

Vitrinite is one of these active and innovative companies, privately owned and holding an extensive strategic coking coal tenement portfolio within Queensland’s world-class Bowen Basin. At present, Vitrinite is primarily focusing on the well-known Vulcan Mine Complex (Vulcan). The company’s assets are situated in close proximity to operating mines, infrastructure and proven economic resources. Vitrinite is undertaking extensive exploration efforts within its holdings, identifying new deposits of premium coals in the basin.

Vitrinite is a young, progressive company insisting on excellence in every aspect of its work, and takes immense pride in the coal industry and the Australian resources sector. Vitrinite ensures stewardship of the lands and developing mineral deposits, aiming to achieve outsized returns for its shareholders and stakeholders.

From its humble beginnings to the present day, being partnered with some of the world’s most renowned and industry leading brands of mobile and fixed crushers and screens, Screenmasters (SMA) continues to grow. SMA is continually increasing its stock of machines and spare parts over four sites located throughout NSW, QLD and Victoria.

With new machines recently added to our impressive 66-unit hire fleet, the SMA team, with over 140 years’ combined experience in the crushing and screening industry, provides sales and hire, first-class technical and aftersales support, spare and wear parts back up and operator training. SMA is all too aware that downtime is lost time that hits our customers’ bottom line. We always do our utmost to dispatch units, parts and technical support in a timely manner ensuring minimum lost and downtime. Whilst this has proven problematic with the recent COVID-19 pandemic and global shipping delays, SMA is proud to state that we never lost a single day’s work throughout the 36 months of the pandemic. We kept going and our customers kept producing - that has been a winning combination!

Approaching 30 years in operation, the SMA team is well equipped to offer solutions for the majority of our customers’ needs and requests. Our warehouses, located across four locations, stock in excess of AUD$5 million of components and consumables ready to support our clients’ equipment and our expanding rental fleet.

Director, Michael McGinley, firmly believes “you have to stay ahead of the game, to stay in the game.” This has never been truer than with the current Keestrack R6 HSI Impact Crusher.

SMA has been partnered for over 20 years with one of the leading global manufacturers in mobile crushing and screening, Keestrack. Over this time the partnership continues to advance with new innovations and technologies, getting better and better with each passing year.

Keestrack Scalping Screens are proven to be the most reliable and productive on the global market. They truly stand tall when it comes to reliability, productivity, and fuel consumption.

The Keestrack R6 Impact Crusher has proven to be a game changer for many customers who think ‘outside the box’. In many applications, this single machine can, and does, replace the need for a traditional jaw, cone and screen set-up, working in a closed circuit.

Screenmasters is one of Australia’s leading distributors of mobile and fixed crushing and screening equipment solutions

“SMA offer solutions quickly efficiently and cost effectively”

“Staying ahead of the game to stay in the game”Keestrack R6 Impactor in a quarry application Feed Product: 600mm Basalt (LA15) Final Product: -40mm at 280tph

Vitrinite purchased a Keestrack R6 in July 2022, fitted with a 3.1 metre (m) double deck pre-screen with fines conveyor, 450kW engine, 6.5 tonne rotor and 16 x 5 double deck screen, all operating in a closed circuit. This set up allows the enduser to produce four products in one pass, with just one machine. The savings are enormous! Fuel and servicing one machine over its lifetime against three machines in this application, just makes perfect sense. SMA has installed the same specification into other large mining companies over the years.

The feedback and savings are impressive to say the least. One such company claims that in a 13-month production period, it saved over AUD$2.5 million in the right applications, Keestrack R6, R5 and R3 Impactors can, and do save the end user on capital purchase, maintenance, service and naturally, fuel costs. It makes sense that it would be cheaper to run one machine rather than three, allowing the end-user to lower the overall cost per tonne.

The Keestrack R3 Impactor boasts a ground breaking design which has seen it win a host of awards including the prestigious Red Dot Design Award, German Design Award and Big See Award. The R3 features include an aggressive screenbox, Volvo Engine, large access doors for easy and safe servicing, steel hydraulic pipes, load sensing hydraulics and variable displacement pumps for low fuel burn.

Driven by the global need for cleaner, cheaper and more sustainable energy sources, Keestrack has developed and introduced its ‘E’ range of hybrid, electric and zero drive models worldwide. SMA looks forward to introducing the ‘E’ Models into Australia over the coming years.

Keestrack was the first company globally to introduce and manufacture the scalping screen. Other OEMs have followed

the path Keestrack set down, but the company stands out as a proven market leader and its ‘E’ range will set a new standard in clean, efficient crushing and screening globally.

In 2002, SMA was the first company in Australia to import European made Impactors with screens attached in a closed circuit. “There were many doubters who didn’t believe these machines could save the end-user the costs we claimed, but through hard work and perseverance we proved them all wrong,” says Director, Michael McGinley. Now, two decades later every major OEM globally designs and manufactures primary closed-circuit impactors with Keestrack leading the way.

In 2023, SMA continues to push the boundaries and shift market thinking with the introduction of the GIPO Vertical Shaft Impactor, placed in an open or closed circuit. The GIPO fitted with a Magotteaux VSI Crusher has proven incredibly reliable, flexible and productive in applications from sandstone, basalt to hard rock. One GIPO VSI has replaced two cone crushers, a VSI and finishing screen. Over the last 25 years, Magotteaux, a global leading supplier of highquality wear parts, has placed 1,000+ of its crushers into fixed plant applications around Europe. Many of these units have over 70,000 hours and are still processing. SMA partnered with GIPO Crushers to place these units on a track mounted chassis (with or without a screenbox) to once again change the market thinking and lower the end user’s costs. “Don’t just play the game, change the game,” affirms Director, Michael McGinley.

Along with our global industry leading partners and OEM partners, SMA will continue to strive to stay ahead of the game. Find out more call SMA +61 1800 571 464

Produce four products in one pass, with just one machine, the Keestrack R6 Impactor Keestrack ‘E’ range of electric, hybrid and zero drive machines Keestrack R3h Impactor, the first choice for contractors worldwide“Don’t play the game, change the game!”

“The savings are enormous!”

“Keestrack are market leaders, setting new standards”

Location:

- Located north of Dysart and 15km south of Moranbah.

Nearest port:

- Hay Point Coal Terminal (approximately 200km away)

Rail line access:

- Blair Athol Mine Branch and Peak Downs Branch on Tenement.

Coal type:

- Hard coking coal

Method:

- Open cut

The company’s values embody and encourage an open and collaborative attitude, inward and outward, while its vision is to create value and wealth through the provision of energy to power world economic growth, exceeding and setting world’s best practices in every endeavour.

“Costs have risen, dropped and stabilised after major fluctuations. This stability in price spells good times ahead for Australian coal, particularly coking coal,” introduces Michael Callan, COO of Vitrinite and orator of the opening statement.

“On top of this, there are industrywide changes and scrutiny around gaining approval for projects, especially when looking at a federal level, although it is slightly easier for coking coal.”

THE VULCAN MINE COMPLEX Vitrinite is soon to be celebrating its ninth birthday, with 2023 also marking two years since the company first produced coal in the Vulcan region. For the past year, Vitrinite has been ramping up production to full capacity, including preparation work for the transition from its Jupiter pit, as well as focusing on other areas of the mining complex.

“We started Vulcan activities in June 2020, including preparation work, with the first coal production occurring in June 2021, so we have been producing coal there for two years out of the open cut and chipping pit,” Callan tells us.

“It is a really exciting time at the moment. Our ramp-up includes expanding the complex to operate in an additional area.”

Based in Clermont, Central Queensland, CBH is a privately owned company specialising in the procurement and supply of thermal coal products for domestic industrial users.

Our mission is to supply our valued customers in Queensland and New South Wales with high quality thermal coal products using our modern and well-maintained fleet of equipment. With quality assurance programmes in place, our expertly trained team strives to provide our customers with the best quality service experience. Alongside this, safety is paramount to everything we do.

Our core services include coal supply, magnetite and logistics/ haulage based in Clermont, Mackay, Gladstone and Newcastle.

Michael Callan, COO: “I completed a mining and engineering degree, and have always worked in the coal industry, primarily underground coal. I started in Queensland and ended up consulting as a geological technician in New South Wales (NSW), then moved on to work for LDO Group, the owner and operator of Chain Valley Colliery, and worked with them for 10 years on a greenfield project called Dawson West.

“One of the managing owners of Vitrinite was on the project with me and that’s how I got to know the company. When Vitrinite started to ramp up, I was asked to help out and I have been working for the company for almost five years now.”

This new location is Vulcan South, a mine in the pre-approval phase awaiting process completion for Vitrinite to move forward with mining operations. Separate from the Jupiter area, Vulcan South is still part of the greater mining complex, located only nine kilometres (km) from the Jupiter pit.

Vulcan South is not only a new area of coal exploration, but it also represents a significant transition that will see Vitrinite’s industry-leading knack for innovation taking centre stage.

“We are looking to transition from Jupiter and end the life of that mine, and to move on to Vulcan South which is another open cut operation based, as per the name, in the south of the complex. This will involve transferring the same workforce to that location as well,” Callan explains. “This is the next big step for us at Vitrinite; it’s the next mine within the Vulcan complex that we are going to be exploring and working on.”

This development consists of completely separate mining approvals and processes. According to Callan, the primary point of excitement within the project is the introduction of new and industry-innovative technology at the new site.

“We are introducing a highwall miner into our production at Vulcan South,” he reveals. “Like the Jupiter site, Vulcan South is an open cut mine similar to its soon-to-be predecessor, utilising similar mining equipment and run rates. However, we will be the first in Australia to use a highwall miner and prove its effectiveness, and we foresee this setting a trend that will echo through the industry.”

Highwall mining is not a brand-new notion; in countries such as India and the US, highwall miners are used to extract or “scavenge” mineral deposits left over from primary mining activities.

We are SGS – the world’s leading testing, inspection, and certification company. We are recognised as the global benchmark for sustainability, quality, and integrity.

With our commitment to excellence and innovation across laboratory, analytical and assay services, we have designed and developed the world’s first robotic preparation cell for mineral sample processing. Located in our Mackay lab, robotics enables resource efficiency and drives sample processing standardisation - particularly when processing high volumes.

The system effectively and efficiently manages a wide variety of laboratory processing methods and takes care of all crushing, dividing, and milling to deliver analytical services you can trust.

Thanks to the success of the fully operational system in Mackay, we are now planning to roll out the system nationally to further enable our customers access to the most accurate mineral sample processing.

Contact our expert consultants for your energy minerals solutions today.

www.sgs.com

Au.sales.EMS@sgs.com

1300 781 744

Michael Callan, COO: “What the highwall miner does is open up inner seams in the mine that would otherwise be left due to their unsuitability for underground mining, because they are too thin and shallow to continue large-scale open cut mining. Mixed with the limited value of such seams, it has simply been regarded as not worth the effort. However, the highwall miner changes the way such seams are accessed and, as a side project, makes it financially viable and advantageous to pursue.

“Mining with a highwall miner also has the advantage of being extremely low cost, so when the ever-fluctuating market inevitably faces a downturn, Vitrinite will be producing coal very cheaply which will give us some durability to handle the downturns in the industry. It is definitely an exciting time and a lot of people will be watching us, and when it succeeds it will be a game changer.”

Vitrinite has entered a contract with global supplier Gainwell Engineering Global Pte Ltd (Gainwell Engineering), to receive a GHWM300M Highwall Mining unit to support activities at Vulcan South. The equipment is manufactured by Caterpillar Inc (Caterpillar), a world leader in construction and mining equipment, among many other industrial technologies and engines.

When primary open cut (or other) mining takes place, activities contour and follow seams in the earth to extract mineral wealth until only small deposits are left over. This primary extraction inevitably creates a growing subcrop in a hill, for example, that makes mineral extraction from the smaller deposits more difficult and require a more technical solution.

“What we intend to do is dig the open cut coal until it reaches a point where it becomes too deep to

economically extract the overburden at the top - the high wall is the fresh face of rock above the coal seam,” Callan shares. “At that point, we will install a highwall miner which is an underground roadway miner pushed underground without personnel, and use it to take further amounts of coal, where traditionally people would operate machinery that goes underground.”

To be the first of its kind used in Australia, the introduction of highwall mining technology will play a significant role in the future of the nation’s mining industry, as it has in many other coal markets around the world. On top of being notably productive by providing access to coal that would otherwise be stranded, highwall miners have proven to be safe, with a low environmental impact. However, the potential of this equipment has thus far not been recognised.

“WE LOVE BRINGING PEOPLE WITH US ON OUR JOURNEY AND HELPING BUILD THESE COMPANIES VIA OUR OPERATIONS”

– MICHAEL CALLAN, COO, VITRINITE PTY LTD

Van Damme Plant Hire Pty Ltd (VDPH) is a locally owned business operating within mining, civil and rural industries. We service the Mackay, Whitsunday’s, and surrounding Coal Fields. Currently a medium size business, our vision is growth and expansion to meet the requirements of present and future clients.

LEARN MORE

“It is the reputation of this equipment being used for scavenging projects that has prevented its incorporation into Australian mining,” Callan elaborates. “A national industry that traditionally leans towards primary mining activities, mining companies view pursuing further extraction via highwall mining as unnecessary and not worth the time and financial investment.

“Utilising highwall mining is unsuccessful in Australia due to this association, being seen as a major primary mine activity effort for limited reward, instead of being viewed as a side project.”

For Vitrinite, this is exactly what highwall mining will represent. While primary open cut mining activities will be carried out at the new Vulcan South site, highwall mining will act as a secondary side operation to maximise yield.

“The way we are doing it, the

emphasis we are putting on it and the style with which we are using it can be considered somewhat novel in the industry,” Callan states. “Elsewhere, highwall miner tech is used routinely, and it is often used as a side project –installed towards the end of a project to scavenge the last traces of coal.

“The way we are using it is similar to how they utilise the technology in the US; we consider use of the highwall miner a project in itself, not a side project, and it will form a key proportion of our total overall mine production.”

Vulcan South represents a new frontier for Vitrinite, and marks the company’s focus on the expansion of open cut operations moving forward into 2023 and beyond. The introduction of highwall mining is a key focus point in this growth, opening up a promising new production and revenue stream for the company while proving the worth of the technology to the entire industry.

“The investment into this highwall miner is key for us and is the future of

“IT IS A REALLY EXCITING TIME AT THE MOMENT. OUR RAMP-UP INCLUDES EXPANDING THE COMPLEX TO OPERATE IN AN ADDITIONAL AREA”

– MICHAEL CALLAN, COO, VITRINITE PTY LTD

the mine, being a piece of equipment that has not operated in the country before, and working with the different legislation and compliance requirements,” adds Callan.

“What is equally as important to our continued growth and success is our many partners, suppliers and business relationships that keep us going, and help us achieve success.”

For Vitrinite, a selection of key contractors and suppliers is vital in the industry, and the company’s partners are critical to its operations. This is best exemplified by the company’s mining and haulage contractors, made up of multiple small familyowned businesses local to the Queensland region and familiar with Vulcan territory.

“We love bringing people with us on our journey and helping build these companies via our operations,” Callan tells us proudly. “Directly dealing with owners of those companies is

important, as is maintaining these relationships. Although we are not the largest mining company out there, we are starting to get to the scale of operation whereby smaller companies are relying on us to keep work flowing.

“Another great part of working with smaller local partners is the culture aspect of work; everyone shares a similar inclusive mindset and we bond as if we were one team. Key suppliers have the same ethos as us, so it becomes very easy for us to mesh cultures together and work effectively while enjoying what we do day to day.”

There are certainly exciting times ahead for the company. As activity at the Jupiter pit comes closer to its end, and the gradual transition to open cut operations progresses at Vulcan South alongside the incorporation of highwall mining technology, preparation for such a future is the core of current affairs at Vitrinite.

“The most exciting thing is getting prepared for this transition, and it is not just about buying equipment and getting it set to work,” Callan explains. “There is a lot of work to do in regard to setting up systems, getting prepped for it, and working with the original equipment manufacturers (OEMs) to get the construction and design completed on time, and getting it delivered.

“On top of all this, we are recruiting a team at the moment to run this, so by the end of 2023 we will be ready to accept delivery of that and fully transition over to Vulcan South and ever more prosperous years ahead at Vitrinite.”

Tel: (07) 3174 4816

www.vitrinite.com.au