INNOVATIONS IN COLD CATHODE TECHNOLOGY AND GEOGRAPHIC EXPANSION

We return to Varex Imaging, whose Senior Vice President and General Manager of X-ray Sources, Mark Jonaitis, elaborates on the company’s ongoing innovations in the cold cathode X-ray market and geographic expansion into India

Writer:

Lucy Pilgrim | Project Manager: Poppi Burke

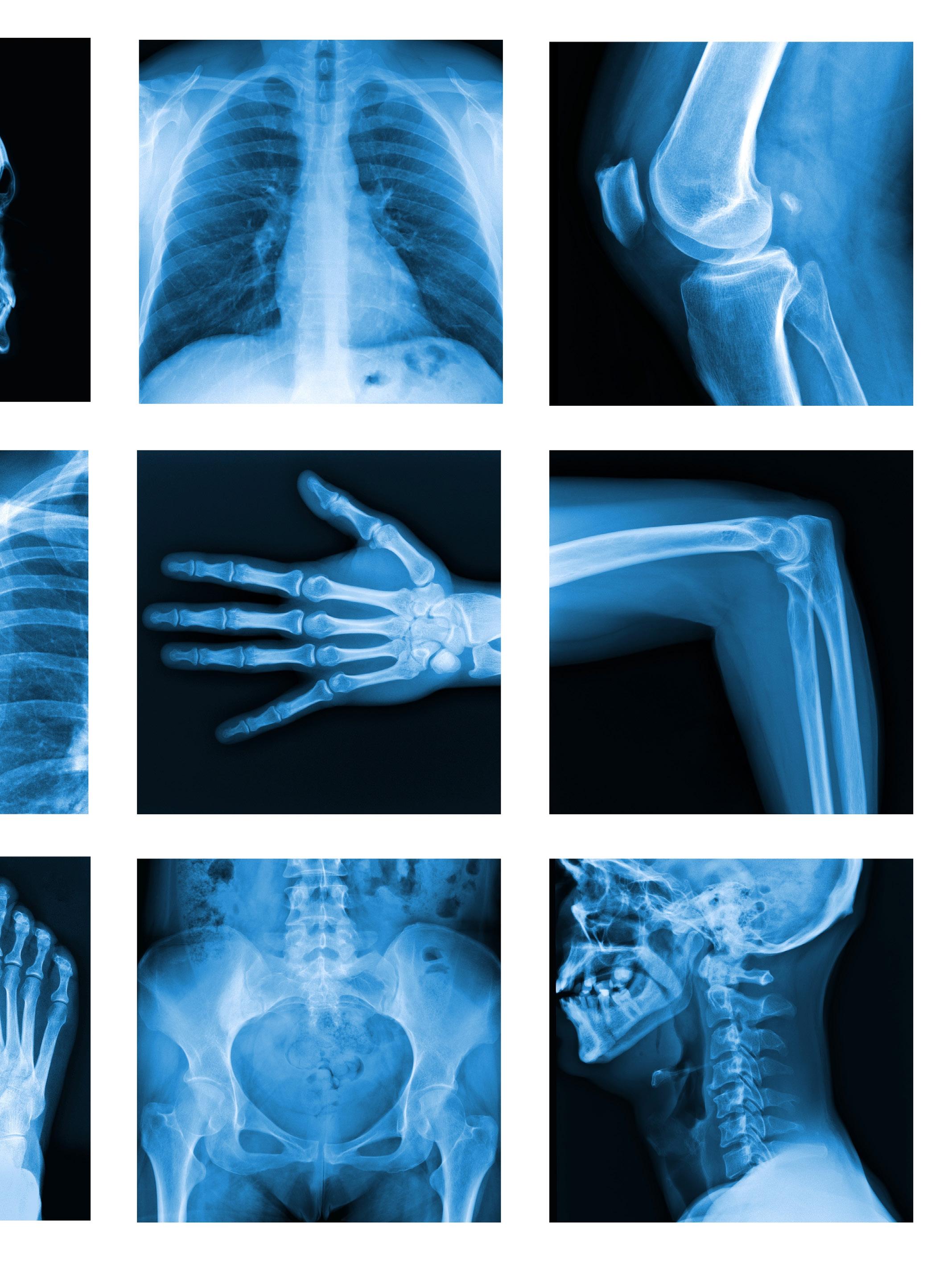

During the past year, the X-ray imaging sector across North America has witnessed some notable changes in cold cathode technology.

Namely, the gradual industry acceptance of liquid metal bearing (LMB) X-ray tubes, particularly in computed tomography (CT) and cardiac diameter (CD) modalities, indicates a shift from conventional ball-bearing X-ray tubes utilized in recent decades.

This move continues to strengthen big healthcare corporations, including GE HealthCare, Philips, and Siemens, who have migrated to the fabrication of LMB X-ray tubes.

In recognition of this evolution, Varex Imaging (Varex) has adopted the technology for its continuing exploration of cold cathode X-rays over the past year, catering to the needs of its customers and industry transformation.

“Varex is developing its own LMB X-ray tubes to have a full offering of what customers want or need,” opens

Mark Jonaitis, Senior Vice President and General Manager of X-ray Sources.

Varex’s recent transition to the use of cold cathode technology means it is able to streamline and improve its X-ray imaging process, paving the way for major transformations in healthcare and diagnostics.

“WE’RE ON THE LEADING EDGE OF GETTING CUSTOMERS TO UNDERSTAND THE TECHNOLOGY; IT’S GOING WELL, AND WE’RE VERY OPTIMISTIC”

– MARK JONAITIS, SENIOR VICE PRESIDENT AND GENERAL MANAGER OF X-RAY SOURCES, VAREX IMAGING

The technology involves putting multiple field emitters in a single tube, thus extracting more electrons.

Cold cathode technology therefore offers many advantages as it allows multiple emitters to be fired in sequence and in close proximity because they don’t generate any heat when creating an X-ray, meaning that accurate images can be created quicker and more efficiently.

Since we last spoke to the company 12 months ago, it has continued the live testing and verification of cold cathode technology to ensure its compatibility and reliability once it enters the commercial stream.

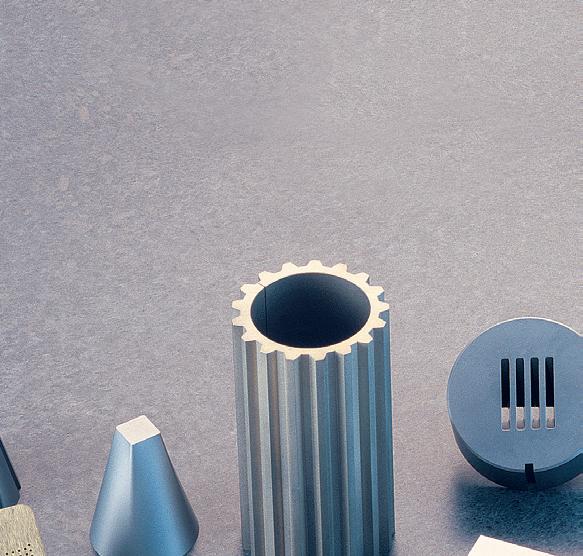

A number of globally-recognized corporations have already progressed in making cold cathode technology commercially viable across a multitude of industries.

Alongside building a new site, Varex has taken the initiative to establish a training cell facility for X-ray imaging, thus reducing long lead times for cells to be used in microscopy techniques.

This is particularly beneficial for the company’s greenfield factories, significantly reducing the time it takes to prepare cells.

Varex presets the cells to be functional and operational in its brownfield facility, allowing the company to easily uproot and place them in the greenfield facility when ready, streamlining the entire X-ray manufacturing process.

For instance, Sino-US joint venture NuRay Technology has incorporated it into baggage scanning devices for security inspection, alongside other medical and dental diagnostic applications.

Elsewhere, Australia-based Micro-X has used cold cathode technology to create lightweight mobile X-ray units, which offer much greater flexibility.

Many of Varex’s customers, meanwhile, are increasingly adopting cold cathode technology and showing an interest in the company’s demonstrator unit.

This lets them explore and learn about the technology’s advantages and gives them the opportunity to decide on specialized focal spots, such as the target angle and pitch, to fit their specific requirements.

“VAREX IS DEVELOPING ITS OWN LMB X-RAY TUBES TO HAVE A FULL OFFERING OF WHAT CUSTOMERS WANT OR NEED”

– MARK JONAITIS, SENIOR VICE PRESIDENT AND GENERAL MANAGER OF X-RAY SOURCES, VAREX IMAGING

“We’re on the leading edge of getting customers to understand the technology; it’s going well, and we’re very optimistic,” Jonaitis shares.

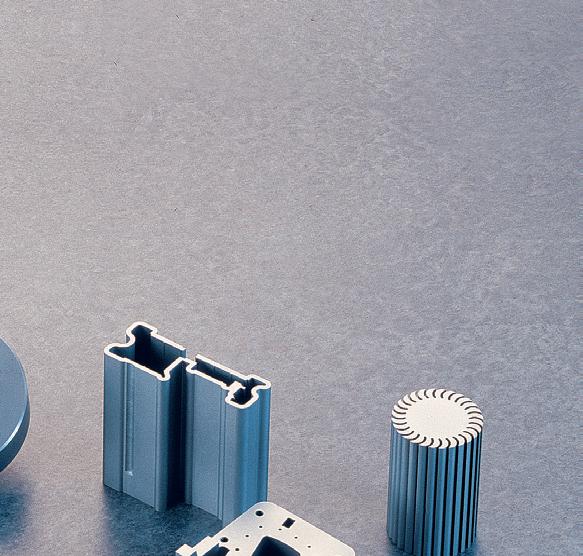

Varex’s geographical expansion continues to be its biggest endeavor as it hopes to capitalize on the significant population growth in India, where it is establishing a brownfield facility with a specialized service center.

“You can’t hide from the fact that the most populous country in the world is going to need a lot of different services, including healthcare,” Jonaitis affirms.

The service center will be part of an extensive worldwide network, which means the company can send inserts

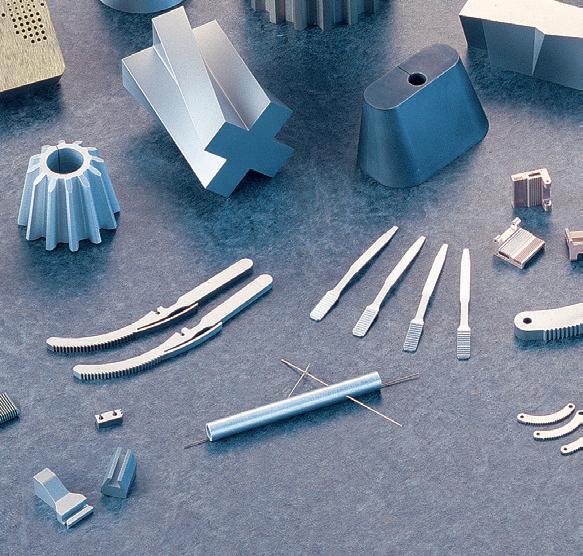

Varex is strongly committed to environmental, social, and governance (ESG) practices, with sustainability remaining a particularly important focus, as it firmly believes in recycling materials from both an ecofriendly and financial standpoint.

The company therefore utilizes a vast range of rare earth metals as part of its operations, including tungsten, and prides itself on being able to use reclaimed metals rather than labmanufactured ones.

“If it’s good for the planet, then it’s good for us!” Jonaitis states.

and load them in the country where they are being used, while any repair products can be easily distributed, thus streamlining the manufacturing and application process.

Varex’s facility in India complements the company’s factory in Wuxi, China, built over 70 years ago, which loads inserts sent from Salt Lake City in the US.

Unlike its Chinese facility, the company has committed to creating a more comprehensive operation in India by establishing an end-to-end LMB X-ray tube manufacturing facility.

“It’s going to be a factory for raw materials all the way to inserts and loaded units – we’ve never done that level of venture before.

“As the world becomes more of a competitive landscape, you can’t afford to pay the middleman for

things you can or should do yourself,” Jonaitis reflects.

The brownfield facility in India will not only enable greater vertical integration but also service localization, which is crucial to Varex’s success in a changing economic environment.

Historically, the company’s dedication to localization stems from its Wuxi facility, which was developed following anticipated population growth in China and major international investments in Chinese medical equipment.

With this in mind, much of the local population was employed in the factory as Varex wanted to be part of the area’s growth.

However, given its worldwide presence has grown considerably in recent decades, the company strives to reduce its dependency on imports

from China and instead utilize regional suppliers.

“We feel we can’t depend on China like we did in the past when we did a huge sourcing push and developed our factory there.

“I don’t believe that was misplaced because it was a great move for the localization of services and allowed us to serve Chinese customers. However, with the current tariff environment, it doesn’t make sense to use Chinese suppliers in places like the US,” Jonaitis discusses.

With this in mind, Varex is developing a more regional supplier network to cater to its global presence and ensure a fair cost structure while maintaining high-quality products.

Localizing the supply chain is no mean feat as it involves establishing many new partnerships.

they listen to and incorporate your feedback,” he concludes.

As such, creating a brand-new supply chain for the latest facility will take substantial effort, but Varex is prepared to tackle this head-on and achieve significant growth.

This commitment aligns with the company’s mission to remain up-todate in the X-ray imaging sector while also meeting the needs of its customers across the globe.

“The reason you have established suppliers is because they make it easier to work with them and Tel: +1 801 972