Have you ever wondered where the ingredients in your toothpaste, sunscreen, and makeup come from? Or where the pigments found in paints, inks, or clothing originate? Many would be surprised to discover that these everyday items are heavily reliant on rutile – an oxide mineral found in deep red crystals.

Sierra Rutile, a global leader in natural rutile production, mines the crucially important mineral from its site in southwestern Sierra Leone.

The company boasts an established operating history of over 50 years and supplies approximately 20 percent of the world’s natural rutile.

The industry titan extracts titanium feedstock minerals, namely rutile alongside ilmenite and zircon, which contain high-grade titanium dioxide (TiO2) – a critical mineral heavily relied upon across the world.

Sierra Rutile’s principal activities revolve around a multi-deposit mineral sand mining operation located in the small West African

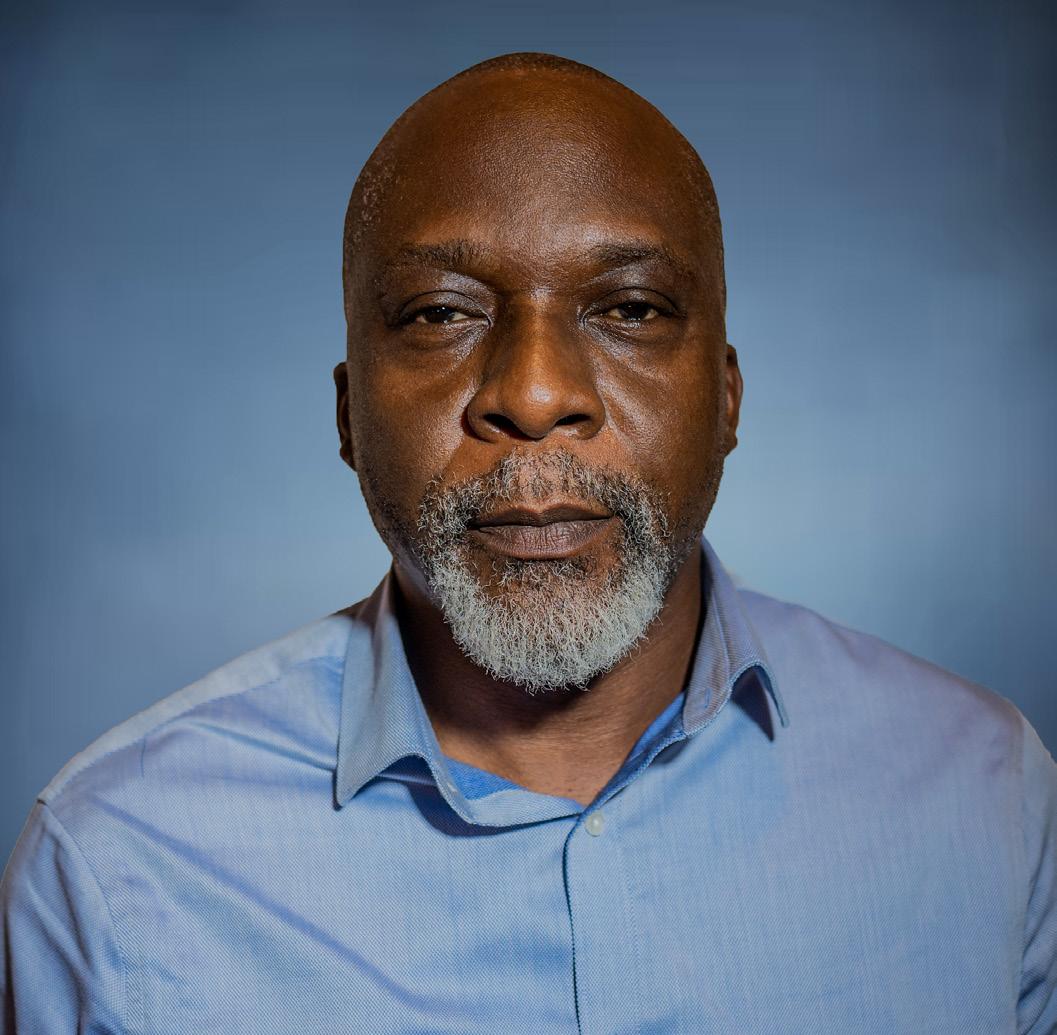

A leading international mineral sands producer renowned for its cutting-edge operations, Sierra Rutile is the world’s largest producer of natural rutile. Lima Sufian-Kargbo, CEO, tells us more about the company’s vast experience and plans for a successful, sustainable, and supportive future

Writer: Lauren Kania

Project Manager: Thomas Arnold

nation. It then ships standard-grade rutile (SGR) products directly to major customers globally and stores industrial-grade rutile (IGR) at its warehouse in Amsterdam to sell to welding customers.

With a client base that spans North America, Europe, and Asia, Sierra Rutile serves a plethora of industries ranging from chemicals and aerospace to welding and pigments, all of which are dependent upon the company’s products.

“We’ve proudly been in operation for over five decades, and with around 1,500 employees, Sierra Rutile is one of the country’s largest private sector employers. We are deeply committed to local economic empowerment and community development,” introduces Lima Sufian-Kargbo, CEO.

Currently, the mining operation is positioned to significantly extend its mine life and reduce the cost of operations with the Sembehun development – one of the largest highgrade natural rutile deposits in the world.

LIMA SUFIAN-KARGBO, CEO:

“The company’s main objective this year is to become profitable, which will put us in a stronger position for the long-term development of Sembehun.

“This will be achieved through cost efficiency in our operations, power supply improvements, people and cultural effectiveness, stakeholder relations improvements, prioritising safety, mining responsibly, and preserving the environment for future generations.

“Every aspect of how we operate and conduct our business will be scrutinised to find efficiencies and improvements.”

If the proposed project proceeds, it will have a 15-year mine life based on the definitive feasibility study (DFS) completed in 2024.

“At the heart of our operations lies Area 1, a flagship mining and mineral processing hub showcasing not only four wet concentrator plants but also a mineral separation plant continuously being upgraded to improve mineral recovery,” details Sufian-Kargbo.

“We also have other associated infrastructure, such as our dedicated Nitti River Port Terminal.”

Although not one of the most commonly recognised minerals, rutile serves as a crucial component to many products used across the globe on a daily basis.

Specifically, rutile is the highestgrade naturally occurring TiO2 feedstock used in the manufacture of pigment found in paints, laminates, plastic pipes and packaging, inks, clothing, sunscreen, toothpaste, and the cosmetic industry. The mineral

is sized and processed to create a bright white powder that serves as the main source of white colouring in everyday products.

It is also prized as a welding electrode alongside being used to manufacture titanium metal, which has the highest strength-to-weight ratio of all commercial metals and is found across a diverse range of applications, such as aeronautics, medical implants, defence, and sporting goods.

As a whitening agent, light reflector, and provider of ultraviolet (UV) and chemical resistance, TiO2 offers unparalleled performance durability, and as a result, has become an indispensable resource for industries that require highquality, long-lasting products.

In addition to being used as a pigment, the mineral can be manufactured to create titanium – a chemically resistant metal with a high melting point and low conductivity. These exceptional qualities make it an ideal choice in industries where weight is crucial,

such as aerospace.

Implementing titanium in aeroplanes helps lessen fuel consumption, resulting in improved efficiency and cost-effectiveness.

Equally, rutile plays a pivotal role as an element in welding electrodes by ensuring their ease of use and effectiveness in the construction, manufacturing, and shipbuilding industries. Rutile in welding electrodes increases the safety, durability, and strength of steel joining and remains a primary component in the production of safe, reliable, and long-lasting welds.

Natural rutile has many benefits as it is the cleanest and most pure form of TiO2 and considered a superior titanium product with environmental benefits and high purity.

The latter stems from the low amount of contaminants found in the product, making it a preferred feedstock for producing high-quality chloride pigment and titanium metal.

Natural rutile has a reduced environmental footprint as less ore is required and less waste is generated

in landfill and waste treatment, in addition to the product’s lower transformation energy and carbon consumption.

With over 25 years working in civil engineering and project management across Europe and Africa, SufianKargbo is a chartered engineer whose journey began in infrastructure, working on major rail and road projects in the UK.

“As a project manager, delivering the €350 million Makeni Ethanol and Power Project in Sierra Leone was what steered me into the energy

sector and expanded my perspective on large-scale industrial projects in Africa,” he specifies.

Prior to Sierra Rutile, SufianKargbo led Centurion Engineering as Managing Director. There, he gained valuable experience in managing an outfit in the tough business environment of Sierra Leone, where there is a dearth of supporting industries and industrial operations over-reliant on the importation of critical components.

Equally, risk management, governance, and compliance can be challenging with constantly changing requirements and legislation.

“Transitioning into the mining

industry felt like a natural progression, allowing me to bring my expertise in project delivery and infrastructure development into the world of resource extraction. Today, my focus remains on fostering growth and innovation,” he details.

Currently, Sufian-Kargbo views the industry as an exciting space to be involved in.

“From my experience at the 2025 Investing in African Mining Indaba, it’s clear the sector is evolving quickly, making way for innovation, collaboration, and investment opportunities across the value chain.”

Could you tell us about some of the major challenges faced within the industry and the business itself and then detail how these have been overcome?

The rutile mining industry, which primarily extracts titanium dioxide for use in pigments, welding rods, and other industrial applications, faces several major challenges. Whilst Mano Mining is not directly involved in the processing of the rutile final product, it’s operations could be impacted by these challenges as the company is one of the leading contractors at Sierra Rutile Limited, engaged in ore mining. Below are the major challenges based on current trends and insights:

• Environmental Impact and Regulation –Rutile mining, often done through open pit as in the case of Sierra Rutile Limited, can lead to deforestation, soil erosion, and water contamination. In order to overcome this challenge, Sierra Rutile Limited operates under strict environmental regulations, being monitored by Sierra Leone’s Environmental Protection Agency. Over the years, Sierra Rutile Limited has invested heavily in mitigation measures, such as rehabilitation of mined land and water management systems.

• Resources Depletion and Accessibility –High-grade rutile deposits are becoming harder to find, pushing companies to explore remote locations. Mano Mining through its client Sierra Rutile Limited is also facing these challenges. As the resources within the current mining areas continue to deplete, we have had to mine remnant mining blocks which leads to high extracting costs. In order to address this challenge, Sierra Rutile Limited, which is holding one of the world’s largest and highest quality known natural rutile deposits, is working on the development of the Sembehun Project. This project presents an attractive development opportunity with a longer life of mine, good grades, contagious deposits, and additional exploration potential that can all leverage on the current infrastructure investment.

• Labour and Community Issues – Mining operations often face resistance from local communities over land use, displacement, or environmental concerns. Mano Mining, working under the Sierra Rutile Limited framework has overcome this by securing a “social licence to operate”. This has been achieved through negotiations, compensation, and community development programmes. Over the years, Mano Mining has provided food aid to communities within its operational areas, employment of youths to work at the mines, and has embarked on a series of human capital development projects such as the Community Youth Apprenticeship Programme.

What are your major future ambitions going forward and how will these goals be achieved?

The future ambition going forward is to be a world-class mining company, to grow and expand beyond the boundaries of Sierra Leone. To achieve this, we will continue to effectively deliver on current mining contracts which will enable us to build a long-term relationship with clients.

At Mano Mining, we believe that our employees are our greatest assets and have a significant role to play in our future ambitions. To attract and retain talent, we have robust training programmes where we train our operators on effective equipment usage, ensuring safety whilst maximising on production.

and puts us on track to achieve our future ambitions.

Could you tell us more about any environmental initiatives that you have in place?

Our environmental management initiative is a structured framework designed to minimise and mitigate the environmental impacts of our mining operations while ensuring compliance with regulatory requirements and promoting sustainability. Our environment management strategies entail the following:

• Water Management – protect water quality by ensuring that we install sedimentation ponds and filtration systems to manage runoff from the mining activities.

• Air Quality and Emissions – reduce dust using water sprays for dust suppression.

• Waste Management – minimise and safely dispose of mining waste through the segregation and recycle of non-hazardous materials.

• Biodiversity Protection – preserve local ecosystems and wildlife through supporting our client’s implementation measures to restore vegetation, support local biodiversity and reclamation of disturbed land.

• Community and Social Impact – addressing community concerns and enhance local benefits through the training of local workers in environmental stewardship roles.

What are you most proud of in relation to the company overall?

We are proud to be the first Sierra Leonean owned mining company to be awarded such a contract at Sierra Rutile Limited, after more than 50 years of operating. We are also incredibly proud that we have been able to deliver for our clients, supporting them to maximise production whilst maintaining a safe operation.

What does the next 12 months look like for the business?

Our focus over the next 12 months will be on cost control and operational efficiency, ensuring that we achieve the production targets set by clients whilst we maintain high safety standards.

+232 99 00 0100

+232 79293949

Info@manomining.com

www.manomining.com

“AS WE LOOK AHEAD, OUR DEDICATION TO INNOVATION, ENVIRONMENTAL STEWARDSHIP, AND RESPONSIBLE GROWTH WILL CONTINUE TO DRIVE THE FUTURE OF SIERRA RUTILE”

– LIMA SUFIAN-KARGBO, CEO, SIERRA RUTILE

The industry as a whole is pushing towards sustainability and environmental, social, and governance (ESG) compliance, with a growing demand for critical minerals as the world shifts towards cleaner energy sources.

This offers new opportunities for operators like Sierra Rutile, who has a portfolio of untapped resources to meet the demand.

However, as expected, there are challenges facing the sector, such as rising costs, regulatory changes, and geopolitical instability.

“The mining industry is in a transformative phase, and it’s a pivotal time to be a part of it. There’s a lot of

potential to make a real difference, not just in business, but in how we approach mining in a responsible, sustainable, and inclusive way,” insights Sufian-Kargbo.

Sierra Rutile works to distinguish itself in a variety of ways. What serves to set it apart in the mineral sands industry is not only its focus on being a leading producer of high-quality rutile, ilmenite, and zircon, but the manner in which it is able to do so.

The company operates in Sierra Leone, where it has access to some

of the world’s highest-grade deposits located in some of the most remote and deprived regions of the country.

“We don’t take our location for granted. We’ve worked hard to integrate sustainability into every part of our operations, from minimising environmental impacts to being deeply commited to in the communities where we operate, investing in areas such as education, healthcare, infrastructure, and livelihood support,” impassions Sufian-Kargbo.

“It’s about making a positive impact that lasts long after our mining activities have ceased.”

Equally, the company prioritises the safety, well-being, and long-term development of its workforce to ensure it continues to be competitive and maintains a market-leading position.

In short, Sierra Rutile’s commitment to sustainable practices, investment in local communities, and track record of operational excellence truly differentiate it within the industry.

For the past nine years, A. Yazbeck & Sons Limited (AYS) has proudly served as a trusted partner to Sierra Rutile, delivering dependable machine maintenance and rental services. Despite operating in a challenging environment, including the global logistical disruptions caused by the COVID-19 pandemic, we have consistently achieved over 85% equipment availability. This accomplishment underscores our commitment to supporting SRL in meeting its operational objectives with minimal downtime and maximum efficiency. Our success is rooted in the strong relationships we maintain with our esteemed principals, Volvo Construction Equipment, Mercedes-Benz, Dressta, Mitsubishi, Wolf Oil, HBM-NOBAS, Magni, and Beta Tools. By representing these globally recognised brands, we bring cutting-edge technology, high-quality products, and unparalleled technical expertise to our clients. These collaborations have played a pivotal role in ensuring the efficiency, reliability, and durability of the equipment we provide, empowering SRL to operate seamlessly and deliver exceptional results in a demanding industry.

At AYS, we place a strong emphasis on safety, workforce development, and local content inclusion. Our impeccable safety record reflects our unwavering commitment to maintaining a secure and hazard-free working environment for our employees, partners, and clients. We believe that safety is not just a priority but a core value embedded in every aspect of our operations. Additionally, we are passionate about developing local talent and engaging with local suppliers. Through the use of advanced simulators, we provide operators at SRL with state-of-the-art training to enhance their technical skills, promote safe operations, and improve equipment productivity. This approach not only fosters a highly capable workforce but also contributes to the socioeconomic growth of the communities we serve. As we look to the future, AYS remains steadfast in its commitment to upholding the highest standards of service, safety, and operational excellence. We are proud of the trust placed in us by our clients and partners and will continue to go above and beyond to deliver solutions that drive success, innovation, and sustainable progress.

Just as important to the company’s journey is being locally owned.

In a truly historic moment for both operator and nation, Leonoil Company – a Sierra Leonean-owned organisation with a strong presence in the country’s petroleum sector – acquired Sierra Rutile in October 2024 through an off-market takeover of its parent company, Sierra Rutile Holdings Limited, on the Australian Stock Exchange (ASX).

“For over five decades, Sierra Rutile had been owned by foreign investors, but this acquisition marked a monumental shift, putting us firmly in local hands,” expands Sufian-Kargbo.

This change represents a major leap forward and offers the company the opportunity to ensure that the people of Sierra Leone are the primary beneficiaries of its mineral resources.

THE COMPANY IS AN ESTABLISHED GLOBAL SUPPLIER OF A RANGE OF HIGH-QUALITY PRODUCTS, INCLUDING:

SGR – Considered an industry-leading, high-quality product consumed primarily in manufacturing TiO2 pigment and titanium sponge, SGR accounts for 85 to 90 percent of the company’s annual rutile production.

IGR – Well-suited to high-quality flux core wire applications due to its excellent packing density and low contaminant level, IGR trades at a premium compared to competing rutile products.

High-grade chlorine ilmenite – Suitable for direct chlorination into TiO2 pigment and transformation into titanium slag.

Zircon in concentrate – A by-product steam typically containing 20 to 25 percent zircon as well as other heavy materials. Zircon is extracted and consumed in applications such as ceramic tiles, sanitary ware, foundry coatings, refractories, and the chemical industry.

SIERRA RUTILE – SIERRA LEONE TURNKEY PROJECT

“THE SEMBEHUN EXPANSION PROJECT IS A GAME-CHANGER FOR SIERRA RUTILE, BEING ONE OF THE MOST INTERNATIONALLY SIGNIFICANT AND HIGH-QUALITY NATURAL RUTILE DEPOSITS LOCATED JUST 30 KILOMETRES FROM OUR EXISTING AREA 1 OPERATIONS”

– LIMA SUFIAN-KARGBO, CEO, SIERRA RUTILE

It also positions the country as an even more attractive destination for private investment in mining and other sectors.

“For us at Sierra Rutile, this means greater control over our future endeavours and the strategic direction of the company, with decisions being made closer to home and a renewed focus on creating longterm value,” states Sufian-Kargbo.

Currently, Sierra Rutile’s medium to long-term vision is to operationalise its rutile mine, Sembehun, by 2028.

Thus, the company’s strategic objective is to extend the life of its current mining area – Area 1 – and operate it profitably through costefficiency measures, ensuring it can continue to meet global rutile requirements ahead of Sembehun coming online.

This will be key to securing the mining operator’s position as one of the world’s most established producers of natural rutile and maintaining a supportive off-take environment with its international customers.

“The Sembehun Expansion Project is a game-changer for Sierra Rutile, being one of the most internationally

significant and high-quality natural rutile deposits located just 30 kilometres from our existing Area 1 operations,” explains Sufian-Kargbo.

With its exceptional scale and grade, Sembehun offers the potential to substantially reduce the company’s production costs and generate attractive returns.

Insights from the Sembehun DFS, completed in April 2024, highlight the strategic value of the deposit, with an anticipated production of 175,000 tonnes per annum of rutile between 2028 and 2038, which will be critical in addressing the imminent supply gap of natural rutile in global markets.

The project will ultimately leverage the existing Area 1 infrastructure, including processing facilities and transport networks, ensuring a smooth and cost-effective transition to steady-state operations at Sembehun.

“This development will extend our mine life, further cementing Sierra Rutile’s position as a global leader in rutile production and playing a pivotal role in industries that rely on highquality titanium feedstock,” he notes.

• Sierra Leone’s name stems from the Lion Monument near the capital city of Freetown.

• It is a tropical country on the West African coast bordered by Liberia, Guinea, and the Atlantic Ocean.

• The country’s landscape offers a flat coastal belt, with the east covered by hills and mountains.

• Sierra Leone has a population of approximately seven million.

• Spoken languages consist of English, Krio, and a range of West African languages, predominantly Mende and Temne.

• For the past two decades, Sierra Leone has operated as a stable democracy, achieving moderate annual economic growth.

• Agriculture and mining are key contributors to the country’s exports, GDP, and employment.

• The nation is an established mining jurisdiction with a long history of mining and an existing regulatory framework.

Local procurement and relationships with suppliers, businesses, and contractors are a top priority for Sierra Rutile.

“We’re focused on empowering Sierra Leonean businesses as we see them as essential to the success of our operations and long-term growth of the local economy,” divulges Sufian-Kargbo.

Through initiatives such as its ‘Bridging the Gap and Empowering Local Businesses’ workshops, the company has had the chance to engage directly with local contractors and suppliers, fostering collaboration and addressing challenges together.

Sierra Rutile spends approximately 65 percent of its procurement budget with local companies and proactively formulates strategies to increase opportunities for them within its supply chain.

“These partnerships are central to what we do by ensuring local businesses grow with us and that we create a positive and lasting impact on the economy,” details Sufian-Kargbo.

“It’s all about building a sustainable, mutually beneficial relationship where everyone wins.”

In parallel to its procurement initiatives, Sierra Rutile emphasises local content within its workforce, with 97 percent of employees being Sierra Leonean citizens – nearly half of whom are from the communities surrounding the company’s mine.

The mining operator believes in creating a diverse and inclusive work environment where everyone has equal opportunities to thrive.

For instance, gender equality is integral to the company’s operations and taken very seriously. Sierra Rutile has, therefore, established a gender task force to drive diversity and inclusion, with a focus on ensuring women have equal opportunities to be part of all operational aspects and at the forefront of key decision-making.

“This is not just about ticking boxes or meeting quotas – it’s about creating an environment where both men and women can contribute, grow, and succeed in our business equally,” insights Sufian-Kargbo.

“THE MINING INDUSTRY IS IN A TRANSFORMATIVE PHASE, AND IT’S A PIVOTAL TIME TO BE A PART OF IT. THERE’S A LOT OF POTENTIAL TO MAKE A REAL DIFFERENCE, NOT JUST IN BUSINESS, BUT IN HOW WE APPROACH MINING IN A RESPONSIBLE, SUSTAINABLE, AND INCLUSIVE WAY”

– LIMA SUFIAN-KARGBO, CEO, SIERRA RUTILE

“Ultimately, promoting local content and gender equality helps us build a stronger, more diverse local workforce, and that is key to our longterm success.”

As demonstrated, Sierra Rutile considers engaging with local communities in a structured and inclusive manner as an important responsibility.

The company is proud of its long-standing association with its communities and makes a significant contribution to the neighbouring people through wages, local sourcing and supplies, social investment, and numerous other commitments. It aims to enable community growth with lasting positive contributions to the nation, having impacts that will prove fruitful long after the company exits operations.

“The focus of our ESG initiatives is to entrench responsible and sustainable practices in every aspect of our mining operations and continue to play a key role in Sierra Leone’s development through job creation, community development, local content promotion, and paying the taxes and royalties that support the economy,” voices Sufian-Kargbo.

“Pivotal to this will be improving the lives of our host communities through investments in education, healthcare, infrastructure, and livelihoods.”

For over three decades, Ibrahim Shour Auto Spares has been Sierra Leone’s trusted supplier of genuine Toyota spare parts, tyres, batteries, lubricants, PPE, and power tools. As official distributors for leading brands like Good Year Tyres, Rymax Lubricants, Dimas Oil, Yato Tools & Safety, and Sailun Tyres, we offer high-quality products to meet all your automotive needs.

We take pride in being the go-to supplier for businesses, including Sierra Rutile Ltd, for more than 20 years, ensuring reliability and excellence. Whether you’re maintaining a fleet or handling personal vehicle repairs, our extensive range of top-tier products, combined with expert customer service, guarantees you’ll always find exactly what you need.

Visit us today and experience the best in auto parts, tools, and accessories!

Contact Information: Mobile: +23279121211 - +23276634451

Email: ibshour@hotmail.com

Facebook: Ibrahim Shour Auto Spares

The safety of all employees, contractors, and visitors is of the utmost importance to Sierra Rutile.

Committed to providing a safe environment for all, the company implements safety training, guidance, and initiatives.

These initiatives include:

• Sierra Rutile’s Life Saving Commitments campaign.

• The Incident Causal Analysis Methodology (ICAM).

• Pre-start safety checks, driver training and competency assessments, and integrated traffic management plans.

• Investment in a health and safety management system.

• Mandatory risk assessments for all non-routine tasks.

• Fire response training for emergency responders.

• Fully integrated tailings management.

• Mandatory daily alcohol testing across all sites and shifts.

• Lifting, guarding, fatigue management, and hazard reporting procedures.

In 2021, Sierra Rutile partnered with the International Finance Corporation (IFC) on a community development programme to develop a range of social investment projects.

As a result of the social risk and impact assessments, four social investment focal points – livelihoods, health and well-being, education, and community building – were identified.

Furthermore, the company has been actively investing in primary healthcare since 2018, leveraging existing infrastructure to provide healthcare to employees and their dependents alongside emergency care to local community members.

The Sierra Rutile Clinic, which was established in the 1970s, is one of the best-equipped medical facilities in the country with a dedicated team of staff providing medical services to employees and their families.

The clinic’s initiatives and resources have allowed an effective early warning surveillance and intervention system to respond to outbreaks of infectious diseases.

Ultimately, the mining operator and its renowned clinic allow individuals to access well-equipped and advanced healthcare in an area where the impacts of a challenged medical system are pronounced, aptly displaying its contributions to the development of a healthy and vibrant community.

Zafco International Inc., a Canadian-based engineering solutions provider, specialises in delivering highperformance industrial and mining technologies to optimise productivity, efficiency, and equipment reliability. With a commitment to innovation and technical expertise, we provide cutting-edge solutions that meet the rigorous demands of the mining, cement, and oil and gas industries.

Through our Ghanaian subsidiary, Mintech Resources LTD, we extend our engineering and technical support across Western and Central Africa, ensuring on-the-ground service, equipment integration, and operational optimisation for our clients.

Sierra Rutile is proudly committed to implementing effective ESG practices, as the company recognises it has a duty to regularly review its sustainability-related procedures and ensure it protects the environment long into the future.

The company actively complies with the Environmental Project Agency of Sierra Leone and makes sure its environmental management practices are aligned with and go beyond the country’s regulatory requirements.

“At the core of our operations is a focus on sustainability, ensuring we meet global market demands whilst creating shared value for all our stakeholders and leaving a positive and lasting impact on the communities in and around our concession area,” furthers Sufian-Kargbo.

Sierra Rutile upholds its commitment to minimising the

Our Engineering Solutions:

• Continental – Engineered conveyor belting systems for high-capacity bulk material handling.

• Belt Conveyor Servicing – Comprehensive inspection, maintenance, and repair solutions to maximise belt performance and reduce downtime.

• Ingersoll Rand – Rotary screw and reciprocating air compressors, industrial power tools, and fluidhandling pumps for heavy-duty applications.

• Air Compressor Servicing – Preventative maintenance, diagnostics, and repairs to ensure optimal efficiency and longevity of compressed air systems.

• Lubricants and Maintenance Solutions –High-performance lubricants designed to reduce friction, enhance thermal stability, and extend equipment life.

• MLT – Belt scrapers, tracking systems, and accessories to enhance conveyor efficiency and reliability.

• Mining Chemicals – Advanced reagents and flotation aids for ore beneficiation and mineral recovery.

• Taurus Weartex – High-quality rubber lining sheets for wear protection in mining, processing, and material handling applications.

• Tecman – Hydraulic rock breakers and hammers for efficient fragmentation and reduced operational downtime.

At Zafco International Inc., we don’t just supply equipment - we engineer solutions that maximise uptime, enhance efficiency, and drive long-term success in the most demanding industries.

environmental impact of its mining operations through relentless efforts to preserve wildlife and rehabilitate mined-out areas, having successfully exceeded its annual land rehabilitation targets in 2023 and 2024.

This progressive rehabilitation takes place during the operational phase of the mining life cycle in order to prevent or minimise adverse longterm environmental, physical, and socioeconomic impacts.

The mining operator has rehabilitated approximately 809 hectares of land since 2016, supported by the ongoing efforts of the nursery team. Equally, there is an annual rehabilitation plan published to showcase the company’s many environmental achievements.

“As we look ahead, our dedication to innovation, environmental stewardship, and responsible growth will continue to drive the future of Sierra Rutile,” concludes SufianKargbo.

Zafco International Inc. – Canada: +1-289-752-2678 | zafco@zafco.ca www.zafco.ca

Mintech Resources LTD – Ghana: +233-020-325-2246 info@mintechresources.net