Translating as ‘cornerstone’ in Hebrew, Rosh Pinah Zinc is, indeed, the cornerstone of Namibian mining, working to achieve its vision to become the nation’s most innovative, sustainable, and safe underground mining operation. Alex Mayrick, General Manager, outlines how the company is efficiently extracting minerals in partnership with its stakeholders

Writer: Lily Sawyer | Project Manager: Thomas Arnold

Spanning 400 years, Namibia’s mining landscape boasts a rich and multifaceted history.

Whilst evidence of copper smelting by Indigenous peoples predates European arrival, modern commercial mining operations began in the mid-1800s with the opening of the Matchless Mine and the Pomona Mine in 1856 and 1864, respectively.

Today, Namibia’s mining sector is

widely considered the backbone of the nation’s economy, contributing significantly to GDP and attracting widespread foreign investment.

As such, the country has emerged as a major global producer of diamonds, uranium, gold, zinc, and copper, amongst other minerals and precious metals.

Mining has also created numerous employment

opportunities across the region, providing livelihoods for a large percentage of the population.

The industry also contributes to national and local government funding through corporate taxes, royalties, and export levies, which are often used to finance public and community development initiatives such as schools and healthcare facilities.

In certain regions, investment in the mining sector has spurred the development of critical national infrastructure – including roads, ports, and utilities – from which many have benefitted.

It’s important to note that, as Namibia’s economy is heavily dependent on mining, the government is also actively pursuing strategies to future-proof the industry and bring it in line with modern global requirements.

For example, it is investing in the long-term sustainability of mining by promoting eco-friendly activities and is prioritising environmental, social, and governance (ESG) practices due to the advantages afforded by safer, greener, and more efficient mining techniques.

Nevertheless, Namibia’s mining sector has not been without its challenges, which include fluctuating commodity prices and a growing

need for a skilled workforce.

Efforts are being made to address these factors through policies promoting sustainable development –such as the Minerals Policy of Namibia – alongside investment in national workforce expansion programmes and collaboration with Namibian educational institutions to promote local skills development.

One company operating within this complex landscape is Rosh Pinah Zinc (RPZ) – primarily a zinc mining business – whose preeminent and lasting contribution to Namibia’s mining legacy extends beyond economic benefits, shaping the country’s reputation as a stable and resource-rich region.

A long-standing player in Namibia’s mining sector, RPZ has roots tracing back to the early 1960s when the Rosh Pinah ore deposit was discovered,

comprising rich base metals.

The mine itself was established in 1969, following the discovery of highgrade zinc and lead deposits in what is now the Tsau Khaeb National Park – formerly known as Sperrgebiet – in southern Namibia.

The site subsequently became one of the country’s most important sources of zinc concentrate, contributing significantly to the national economy.

However, in 1993, the global market price of zinc fell substantially, and the mine began making a loss – forcing it into liquidation.

It was subsequently acquired by Ispat Iscor Limited (formerly Iscor Limited) through its mining division, Kumba Resources (Kumba), which acquired a 95 percent interest and management control. Kumba also partnered with PE Minerals (Pty) Ltd, which ceded the mining rights.

In 2011, Glencore – the global

Predominantly, RPZ’s operations comprise the processing of lead and zinc ore. Considered important within various contexts, the numerous uses of these metals are wide-reaching, as is their impact on everyday life.

Zinc

A chemical element, zinc is a brittle transition metal at room temperature but malleable at higher temperatures. It is also known for its anti-corrosive properties.

An important metal with many applications, it is primarily used as galvanising material for steel structures like bridges and buildings since it provides more superior protection against corrosion than iron or steel.

Zinc oxide can be found in cosmetics like sunscreen lotions because it helps absorb ultraviolet rays from the sun.

Lead is a heavy metal that is denser than most common materials. Soft and malleable, it has a relatively low melting point.

Lead has been used throughout history for a variety of purposes – in ancient Rome, it was used to make water pipes and acted as a component of solder. The metal was also used in medieval Europe to make stained glass windows. Today, it is predominately used for producing car batteries, radiation shields, bullets, pipes, bearing alloys, solder, and can be used to protect electrical components such as cables and wires against corrosion.The material is also commonly used in paints due to its ability to resist corrosion.

commodity trading firm – acquired a controlling interest in RPZ which it subsequently sold to Trevali Mining Corporation in 2017.

In June 2023, funds advised by Appian Capital Advisory Limited (Appian) – the investment advisor to long-term value-focused private capital funds specialising in metals, mining, and adjacent industries –acquired RPZ.

Appian has a global track record in responsible resource extraction, community engagement, and environmental stewardship.

Throughout the changes in ownership and operational structure over recent decades, RPZ has maintained a similar capacity. However, Appian’s acquisition and investment in the asset is now unlocking its full potential through the development of the RP2.0 expansion project, which is expected to nearly double the mine’s output.

“Even amidst ongoing change, RPZ has consistently produced high-grade zinc and lead concentrates, making a

Reinforcing Steel Concrete (Pty) Ltd (RSC) provides total reinforcing solutions to the construction, civil, mining, fencing, agricultural and engineering business sectors. This includes delivery, cutting, bending, and wiring into position of steel reinforcing products.

The company has a recognised and acknowledged industry track record of service excellence and delivering products of the highest quality.

RSC operates to international standards and is ISO 9001, ISO 14000 and OHSAS 18000 compliant and certified.

Original Equipment Manufacturers – Mining, Civil and Construction Industry

RSC includes the following industry-related companies: BRC Mesh Reinforcing, Steeledale Mesh, and RSH Mining & Duraset Strata Control.

All mining product manufacturers are subsidiaries of RSC. It has a proud legacy of successfully conducting business in the African mining industry for over 40 years.

Both BRC Mesh Reinforcing (situated in Vereeniging, Gauteng, South Africa) and Steeledale Mesh (situated in Meyerton, Gauteng, South Africa) are industry leaders, producing and delivering customer-focused products and solutions, locally and internationally, to major mining and construction houses.

The businesses are committed to sustainable development by finding solutions that are good for the environment, relevant stakeholder communities and employees.

Operating to international standards, both mesh manufacturing facilities prioritise the research and development of new products, resulting in recognition as an industry innovator. Partnering closely with stakeholders and customers is fundamental to this process. The two companies employ the latest plant and technology in the manufacture of their products. This capability, combined with excellent management and staff, has proven to be a very successful formula.

The range of products produced is extensive, catering to both industrial customers and private consumers.

BRC and Steeledale manufacture and supply gusset welded mesh to the mining industry for underground roof support.

The businesses are ISO 9001, ISO 14001 and ISO 45001 certified and compliant. BRC is additionally SABS approved to produce welded steel fabric to SANS 1024:2012 and ACRS certified to manufacture Steel Reinforcing Mesh for Australia to AS/NZS 4671:2019 specifications.

Duraset Strata Control, with its premises situated in Alrode, Gauteng, South Africa, is a well-diversified supplier of engineered support solutions to the mining and geotechnical industries.

With very well established research and development facilities, manufacturing plants and commercial services for each of our market-focused divisions, Duraset has positioned itself over time as a well-branded and leading supplier of safety-critical products to the mining industry.

Duraset manufactures a comprehensive range of high-quality mining underground products such as resin bolts, roof bolts, dynamik yielding bolts and cable anchors to only mention a few. They also supply ground support materials to the infrastructure and construction sector.

Mining is an established roof bolt manufacturing business with its premises situated in Olifantsfontein, Gauteng, South Africa.

The manufacturing plant is a fully automated facility, allowing RSH Mining to offer its customers the best quality at competitive pricing.

RSH Mining is an ISO 9001:2015 and ISO 45001:2018-certified company offering high-quality manufactured components and products to its customer base. RSH is highly automated and positioned to be a leading supplier offering excellent customer service that will exceed the industry’s most demanding requirements.

Roof bolt assemblies for resin anchoring (chemical anchoring) comprise the stud, nut, bearing plate washer and a selection of accessories and modifications which can be configured to suit particular installation and rock support requirements. Roof bolt assemblies are packaged as complete, ready-to-install units.

In line with its vision to become the most innovative, sustainable, and safe underground mining operation in Namibia, RPZ has defined a core set of values which help it to deliver on this. These include:

• Care and safety – The company cares for the safety and wellbeing of its workforce, the surrounding environment, and the communities it touches.

• Integrity – Accountable and responsible, RPZ vows to always deliver on its promises.

• Partnership – The company believes it is stronger when it bands together and embraces differences within the company, community, and with stakeholders.

• Performance –innovative, and agile, RPZ takes on challenges and continues to deliver.

significant contribution to Namibia’s export revenue and local economic development,” says Alex Mayrick, General Manager at RPZ.

“The RP2.0 expansion project will drive innovation, boost efficiency, and support sustainable growth, firmly establishing RPZ as a leading operation for years to come.

“At the same time, RPZ remains committed to regional economic development by providing employment, supporting local businesses, and investing in education, infrastructure, healthcare, and youth programmes within surrounding communities,” Mayrick adds.

One of Namibia’s flagship mining operations, RPZ under Appian places a strong focus on safety, sustainability, and innovation, and continues to proudly contribute to the country’s economic growth.

At the helm of one of the largest and most important zinc mines in Namibia, Mayrick notes the versatility of the material and its wide range of industry applications.

“Zinc’s primary use is in galvanisation where it coats steel to prevent rust, making its use vital

in construction and infrastructure contexts,” he tells us.

Also used to create alloys like brass and die casting metals for appliance and vehicle parts, zinc is a crucial component in the automotive industry.

In the health and agriculture sectors, meanwhile, the material has emerged as an essential dietary supplement and a micronutrient in fertilisers to boost crop yields.

“It also plays a key role in battery technologies, including alkaline and zinc-air batteries, and in the production of zinc oxide, which is used in rubber, cosmetics, and sunscreens,” Mayrick points out.

Alongside zinc, RPZ’s considerable deposit also includes lead and silver, both of which have a plethora of uses.

Lead’s excellent ability to store and release energy has seen it commonly used in car batteries.

It is also useful in radiation shielding for medical and nuclear applications due to the material’s effectiveness in blocking harmful rays and can be found in some types of solder, cable sheathing, and weights.

Silver, a by-product of the mine, in addition to being a valuable precious metal, has industrial and clean energy

applications, often used in solar power and electronics thanks to its electrical conductivity and ability to catalyse chemical reactions.

As such, demand for the metal has become particularly prevalent in recent years, given the increasing global demand for renewable energy.

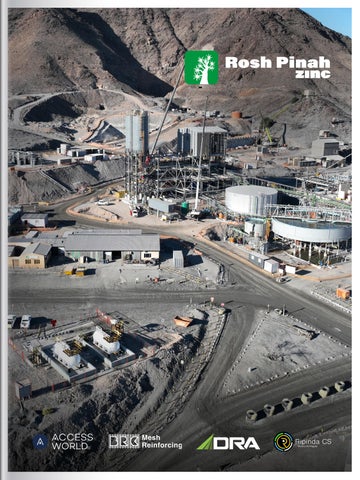

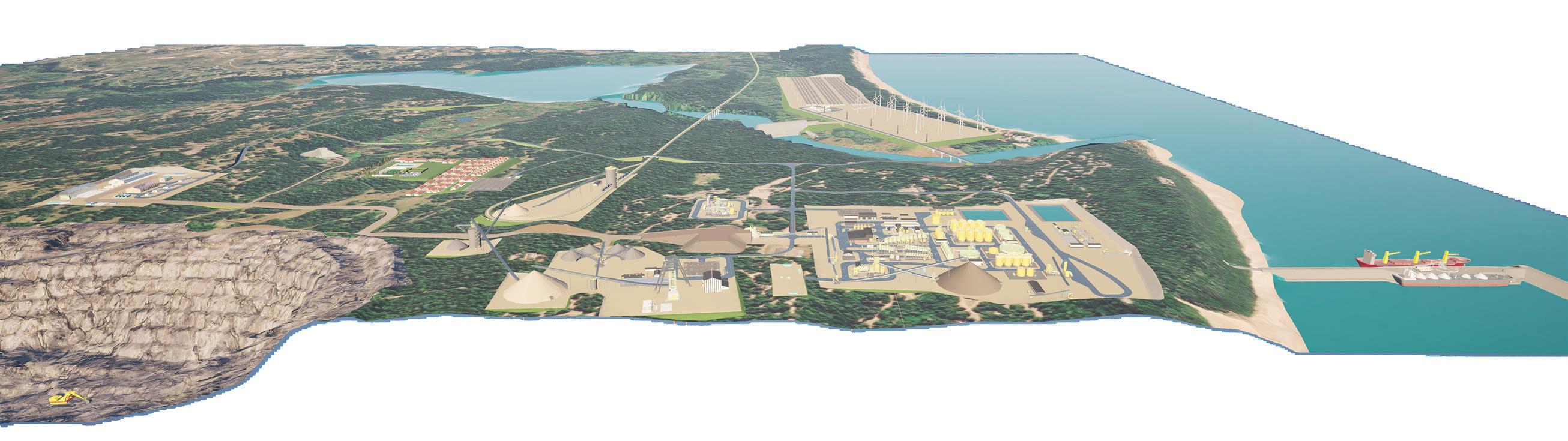

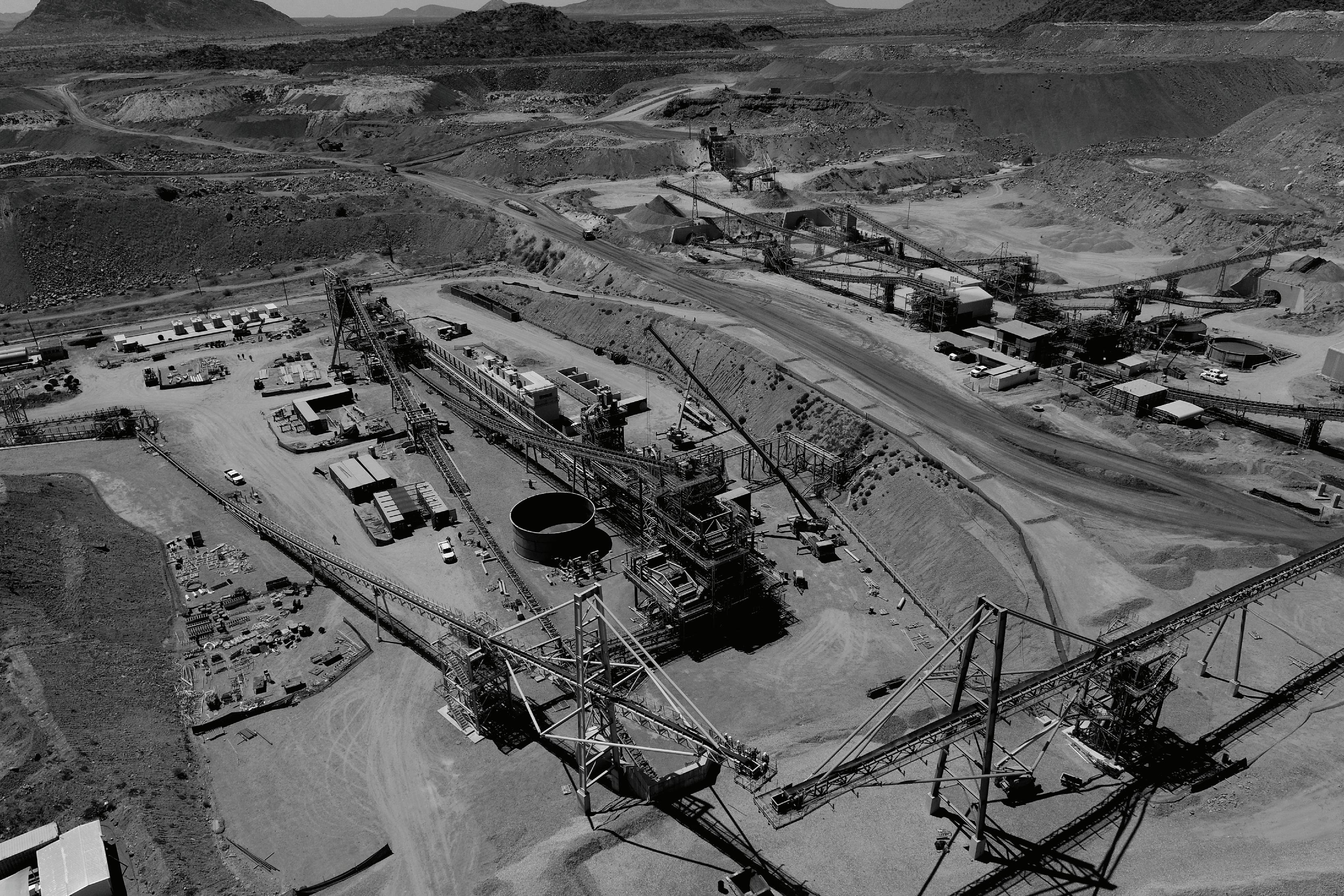

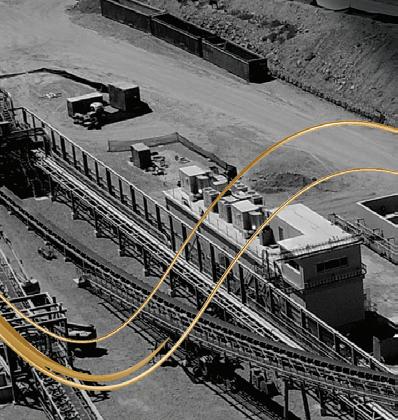

RPZ is currently focused on optimising its ongoing operations whilst progressing the RP2.0 expansion project – a major initiative aimed at nearly doubling the mine’s ore processing capacity to 1.3 million tonnes of ore per year, resulting in an annual production of 170 million pounds (lb) per year of contained zinc metal.

Specifically, the project comprises further development of the existing underground mine, as well as the construction of new and modernised surface facilities.

A cutting-edge processing plant, for example, alongside the addition of a paste backfill and water treatment plant will be implemented to manage tailings and waste materials from ore processing.

A new access decline (tunnel) from the surface to the bottom of the mine is being developed. This will bypass historical access routes and create a direct and efficient production corridor to support and enable

increased production capacity.

The construction of RP2.0’s surface facilities is now over 77 percent complete and remains within budget, demonstrating the company’s commitment to the project.

“Completion is expected in Q3 2026, with ramp-up commencing in quick succession,” Mayrick explains.

Employing over 1,800 dedicated staff and contractors across its operations, approximately 600 of

“EVEN AMIDST ONGOING CHANGE, RPZ HAS MAINTAINED CONSISTENT PRODUCTION OF HIGH-GRADE ZINC AND LEAD CONCENTRATES, MAKING A SIGNIFICANT CONTRIBUTION TO NAMIBIA’S EXPORT REVENUE AND LOCAL ECONOMIC DEVELOPMENT”

–

ALEX MAYRICK, GENERAL MANAGER, ROSH PINAH ZINC

Ripinda Communication Systems is a technical services provider which deals with surface and underground communication systems such as two ways radios, Leaky feeder, Wi-Fi, fibre optics splicing, networking, CCTV to list but a few.

As Ripinda Communications Systems we noticed that having a good product doesn’t necessarily guarantee that you will make good sales and that the clients will come to your door step if you do not have support for the products or a way of maintaining the systems as well as a good customer service.

Ripinda Communications Systems was formed to bridge the gap between the brand and the customer by providing the much needed technical and customer support services for most of the products that we supply and install.

Tel: +2711 882 0144

info@ripindacs.co.za www.ripindacs.co.za

RPZ’s team are currently focused on the development of RP2.0.

“As the expansion project progresses, we are looking to build our internal capacity as well as expand our team to support the mine’s

growth ambitions,” he states.

In addition, 99 percent of RPZ’s fulltime employees are Namibian.

“Our workforce reflects the scale and complexity of our current operations and ongoing expansion,

With the utmost respect for the communities in which it operates, RPZ’s activities follow industry best practices and international standards in areas including:

• Waste management – All hazardous and non-hazardous waste is handled according to regulatory guidelines and disposed of through licensed service providers.

• Water use and protection – The company operates under a water abstraction permit and continuously monitors its use and discharge to prevent contamination of surface and groundwater.

• Air quality control – Dust and emissions are managed through dust suppression systems, paved access routes, as well as ite roads rehabilitation and air quality monitoring.

• Climate change – RPZ uses renewable energy from solar parks controlled by Appian to provide 30 percent of its power.

• Rehabilitation and biodiversity – Implementing progressive rehabilitation plans, the company protects indigenous vegetation and works to limit its footprint within the sensitive Tsau Khaeb National Park.

reinforcing RPZ’s role as a key economic player in Namibia.”

As a company that prioritises the growth of local communities, RPZ is proud to have a forward-looking procurement strategy in place, which includes a supplier development programme.

“Through the establishment of the programme, we are committed to ensuring local businesses not only benefit from current projects but are also positioned for long-term success,” Mayrick prides.

As a result, in 2023-24, over 27 percent of the company’s goods and services were proudly procured locally.

“Our goal is to cultivate a thriving, self-sustaining local industry that extends well beyond the life of mine, transforming Rosh Pinah into a recognised hub for goods and services,” he continues.

In addition, the programme unlocks opportunities for regional suppliers to grow, compete, and ultimately export their products and services across Namibia and even internationally.

Chefe Grande Trading CC is a Namibian-owned consulting, engineering, andconstruction firm based in Rosh Pinah, southern Namibia. Established in 2021, the company delivers innovative and cost-effective solutions across infrastructure development, industrial services, and eventmanagement. Driven by a team of experienced professionals, commitment to quality, integrity, and client satisfaction.

Chefe Grande Trading CC offers a variety of Engineering and Consultancy services, including:

• Utility and infrastructure planning

• Civil and construction engineering

Project management

Feasibility studies and design

The transition to clean energy technologies places higher demands on mining companies to extract more minerals even more efficiently without compromising on safety or sustainability. An impossible equation? Not if you dare to think new We are constantly developing new intelligent technologies that accelerate this transformation.

United. Inspired.

Epiroc Namibia

Visitor’s address: 6 Jan Marais Street, Northern Industrial Area, Windhoek Phone: (+264) 84 000 9400

epiroc.com/en-na

By fostering an internal culture of continuous improvement and professional development, RPZ recognises that investing in its staff is an essential factor in sustaining excellence.

“We provide comprehensive training programmes spanning technical mining operations, safety protocols, environmental stewardship, and leadership development, granting employees the opportunity to grow and advance within and beyond their current role,” Mayrick outlines.

“These initiatives collectively create a dynamic environment for career advancement and skills development,” he explains.

Meanwhile, through various mentorship programmes, bursaries, and placements for students from the University of Namibia, RPZ cultivates local talent whilst attracting experienced professionals from the mining industry.

Deeply committed to social responsibility, RPZ actively supports community development as a core part of its operations.

The company believes progress lies in the ability of local communities to stand on their own two feet and thrive. It is therefore on hand to facilitate this level of autonomy amongst the communities it serves.

To achieve this ambition, RPZ continues to support programmes that empower personal development, build local capacity, and create meaningful change.

In 2024, RPZ invested over NAD$7 million in community initiatives.

One such project is the Obib Training Centre (OTC), which provides vocational training and skills development opportunities for local residents, facilitating access to meaningful employment and improving their livelihoods.

OTC’s mission is to initiate and sustain efficient and effective

“WE PROVIDE COMPREHENSIVE TRAINING PROGRAMMES SPANNING TECHNICAL MINING OPERATIONS, SAFETY PROTOCOLS, ENVIRONMENTAL STEWARDSHIP, AND LEADERSHIP DEVELOPMENT, GRANTING EMPLOYEES THE OPPORTUNITY TO GROW AND ADVANCE WITHIN AND BEYOND THEIR CURRENT ROLE”

– ALEX MAYRICK, GENERAL MANAGER, ROSH PINAH ZINC

community development, working to deliver on the physical, mental, emotional, and spiritual needs of local people.

Elsewhere, RPZ has invested in equipment and contracted a new teacher to provide a computer science course in a secondary school, elevating the workforce of tomorrow’s digital education.

It is also actively delivering a learnto-drive programme that includes lessons, vehicle hire, and test fees –supporting approximately 40 drivers per year.

“These initiatives contribute to the broader economic growth and social well-being of the surrounding

communities,” Mayrick notes.

In addition to adhering to social responsibility regarding community outreach, RPZ also takes sustainability very seriously, operating in full compliance with Namibia’s environmental legislation.

RPZ closely follows the Environmental Management Act of 2007 – which promotes sustainable environmental management and natural resource use – and its associated regulations.

“We also continue to maintain a valid Environmental Clearance Certificate issued by the Ministry of Environment, Forestry, and Tourism, and conduct regular Environmental

AA-COMPLIANT TRANSPORT SPECIALISTS WITH 15 YEARS’ EXPERIENCE ACROSS SOUTH AFRICA & NAMIBIA FOR CONSTRUCTION, INDUSTRIAL & RENEWABLE ENERGY.

Abnormal Load Specialists | General Transportation | Hazardous Why Choose Us:

Extensive Regional Reach

Professional End‑to‑End Service

Customer-Centric & Transparent

AA Compliant & Trusted

Trusted by Rosh Pinah Zinc for Over a Decade

Specialised mining chemicals delivered with proven reliability across Southern Africa.

30+ Year Track Record Strong Technical Expertise Dedicated Customer Service

Products Supplied

Sodium Cyanide, Activated Carbon, Bulk Liquid Chemicals, Flocculants, and Other Chemical Reagents.

+27 (0)11 873 2117 www.marlyn.co.za

Impact Assessments and audits to monitor our performance,” he emphasises.

The company complies with mining governance laws such as the Minerals (Prospecting and Mining) Act of 1992, which regulates the prospecting, exploration, and mining of minerals in Namibia.

Moreover, it reports frequently to regulatory authorities, engaging with the local community and stakeholders on environmental concerns.

“Internally, our environmental management plan guides all operations to ensure risks are minimised and sustainability is prioritised throughout the mine’s lifecycle.”

Having rebranded in 2023, RPZ’s ethos of responsibly extracting minerals in the most innovative,

Following months of meticulous planning and surveys between surface, collar point, and the underground holing position, RPZ drilled a pilot hole to create a new shaft for ventilation. Proving RPZ’s technical excellence, the team successfully met the parameters required with a final deviation of just 0.27 percent at a total final drilling depth of 220 metres.

The company’s achievement was supported by technology solutions provided by Dwyka Mining Services – a results-driven business offering technical solutions and consultancy for all manner of mining environments.

sustainable, and safe way is now clearer than ever.

“Our new logo is a bold and modern representation of our company’s identity,” Mayrick reflects.

The stylised quiver tree depicted in RPZ’s updated logo represents its heritage, whilst the blue and green colour scheme signifies the company’s commitment to environmentalism.

“The logo is designed to evoke a sense of strength and stability, which is important to us as we work to build a successful and sustainable future,” he adds.

A new tagline – ‘sustainable beyond mining’ – is a clear statement that distinctly lays out the company’s mission.

“Recognising zinc as a critical mineral for a sustainable future, RPZ is committed to mining and processing it responsibly, minimising

Our TrenTyre Namibia on-site maintenance teams have provided 24-hour operational support for RPZ since 2001.

Our team draws from our hands-on knowledge of client operations in Namibia combined with highly skilled technical expertise to help RPZ achieve their specific cost and productivity targets for operations.

Tyres are one of the most significant costs for mining operations and we understand the importance of increasing productivity whilst reducing the total cost of tyre ownership. Our team achieve these results through skilled expertise underpinned by a continual focus on safety first.

environmental impact, and enhancing benefits for the local community.”

Mayrick believes that the company’s new branding is a positive embodiment of RPZ in a new age of mining.

“It reflects our values, mission, and commitment to supporting local communities,” he insights.

Looking to the future, RPZ is making great advancements towards becoming the most innovative, sustainable, and safe underground mining operation in Namibia.

“As we progress with the RP2.0 expansion project, we are excited to see the impact it will have on our output, innovation, and sustainability,” Mayrick enthuses.

The next milestone for this project will be completing commissioning of the paste backfill and water treatment

trentyrenam.com

plants, which will be the first of their kind in Namibia.

To achieve this breakthrough, RPZ will continue to actively upskill its workforce, procuring locally where possible.

Upon completion, RPZ will backfill mined voids underground with cemented tailings (backfill), reducing tailings placement to surface tailings facilities.

This will increase ore extraction from underground and reduce future surface impact with reduced tailings volumes. The water treatment plant, meanwhile, will be used to recycle mine process water, helping to minimise RPZ’s water usage from the nearby Orange River.

Furthermore, Appian has acquired Rosh Pinah Solar Park (RPSP) from Emesco Energy to exclusively supply clean energy to RPZ.

Appian plans to increase the solar

and

plant’s output from 5.4 megawatt peaks (MWp) to 16.3MWp, providing 30 percent of the energy supply required for RP2.0.

In parallel to the RP2.0 project, RPZ is undertaking an expansive exploration drilling campaign to extend its mine life for many decades to come.

“These efforts collectively demonstrate our unwavering commitment to responsible mining practices and continuous improvement across all facets of our operations for the long term,” he passionately concludes.