A CHAMPION OF BRITISH ENGINEERING

CAPABILITY SOVEREIGN

A champion of British engineering, Rheinmetall UK is committed to ensuring the country remains a global leader in defence innovation as we find out from Deputy CEO, Rebecca Richards Writer: Jack Salter | Project Manager: Cameron Lawrence

CAPABILITY CAPABILITY

Rebecca Richards, DeputyCEO

Defence has always played a vital role in ensuring national security, but in today’s increasingly complex and uncertain global landscape, its importance has only intensified.

That said, the value of defence extends far beyond security alone; it’s a catalyst for economic growth, innovation, and regeneration, particularly in areas that benefit from long-term investment, skilled employment, and industrial revitalisation.

In Europe and the Middle East (EME) specifically, modernisation and innovation across the sector is being driven by increased defence spending, evolving security threats, and a renewed emphasis on NATO collaboration.

“It’s a truly dynamic environment – one that’s pushing boundaries, advancing technologies, and fostering stronger partnerships between

governments and industry,” notes Rebecca Richards, Deputy CEO of Rheinmetall UK (Rheinmetall).

Proud to be at the forefront of this shift, Rheinmetall is delivering next-generation capability through programmes like the Boxer Mechanised Infantry Vehicle (MIV) and Challenger 3 Main Battle Tank (MBT).

These systems will not only enhance the British Army’s capabilities but also strengthen interoperability with NATO and allied forces.

Another of the key changes in the region has been the growing need for speed and agility in procurement; today, responding quickly to operational requirements is critical.

A great example of this is Rheinmetall’s delivery of 500 HX 8x8 military trucks to the UK Ministry of Defence (MoD) in just seven months – demonstrating the company’s efficiency and unwavering focus on readiness and mission success.

“With significant investment flowing into the sector, increasing cross-border collaboration, and a strong focus on capability development, this is a genuinely exciting time to be working in defence,” Richards observes.

“At Rheinmetall, we’re playing an active role in shaping the future of land warfare by driving innovation, building strategic partnerships, and delivering mission-critical solutions at pace.”

INVESTING IN THE UK

Rheinmetall is a multi-domestic prime contractor, generating intellectual property, creating jobs, and driving economic growth within the UK defence sector.

From concept and design to production and long-term sustainment, the company offers a full-spectrum capability, ensuring mission-ready solutions.

“WITH A STRONG INDUSTRIAL FOOTPRINT AND COMMITMENT TO DEVELOPING SOVEREIGN DEFENCE SOLUTIONS, RHEINMETALL IS ENSURING THE BRITISH ARMED FORCES AND OUR ALLIES ARE EQUIPPED FOR THE FUTURE BATTLEFIELD”

– REBECCA RICHARDS, DEPUTY CEO, RHEINMETALL UK

It has been operating in the UK for nearly two decades across seven sites in Telford, the Isle of Wight, Newcastle, Bristol, London, Bovington, and Southampton.

Rheinmetall House, the Rheinmetall UK headquarters in Bristol, includes the Collaboration and Innovation Centre, a hub for advancing battlefield technology through partnerships with the UK MoD, small to medium-sized enterprises (SMEs), and academia.

Its Telford facility, meanwhile, is home to Rheinmetall BAE Systems Land (RBSL), a defence engineering

joint venture, and has undergone a £56 million investment to support major UK defence programmes, including Boxer and Challenger 3 production.

“With a strong industrial footprint and commitment to developing sovereign defence solutions, Rheinmetall is ensuring the British Armed Forces and our allies are equipped for the future battlefield,” Richards tells us.

The Telford site has been transformed into a world-class armoured vehicle manufacturing hub, ensuring the UK retains a leading role in land defence systems.

END-TO-END EXPERTISE AND WORKFORCE DEVELOPMENT

From concept and design to production and long-term sustainment, Rheinmetall offers a full-spectrum capability, ensuring mission-ready solutions.

With over 1,000 highly skilled employees and strong investment in apprenticeships, graduate schemes, and industrial placements, the company is securing the future of defence engineering and long-term sustainability of defence skills in the UK.

“Our approach not only sustains critical skills but also supports defence exports by integrating British SMEs into our global supply chain, reinforcing the UK’s position in global security,” outlines Richards.

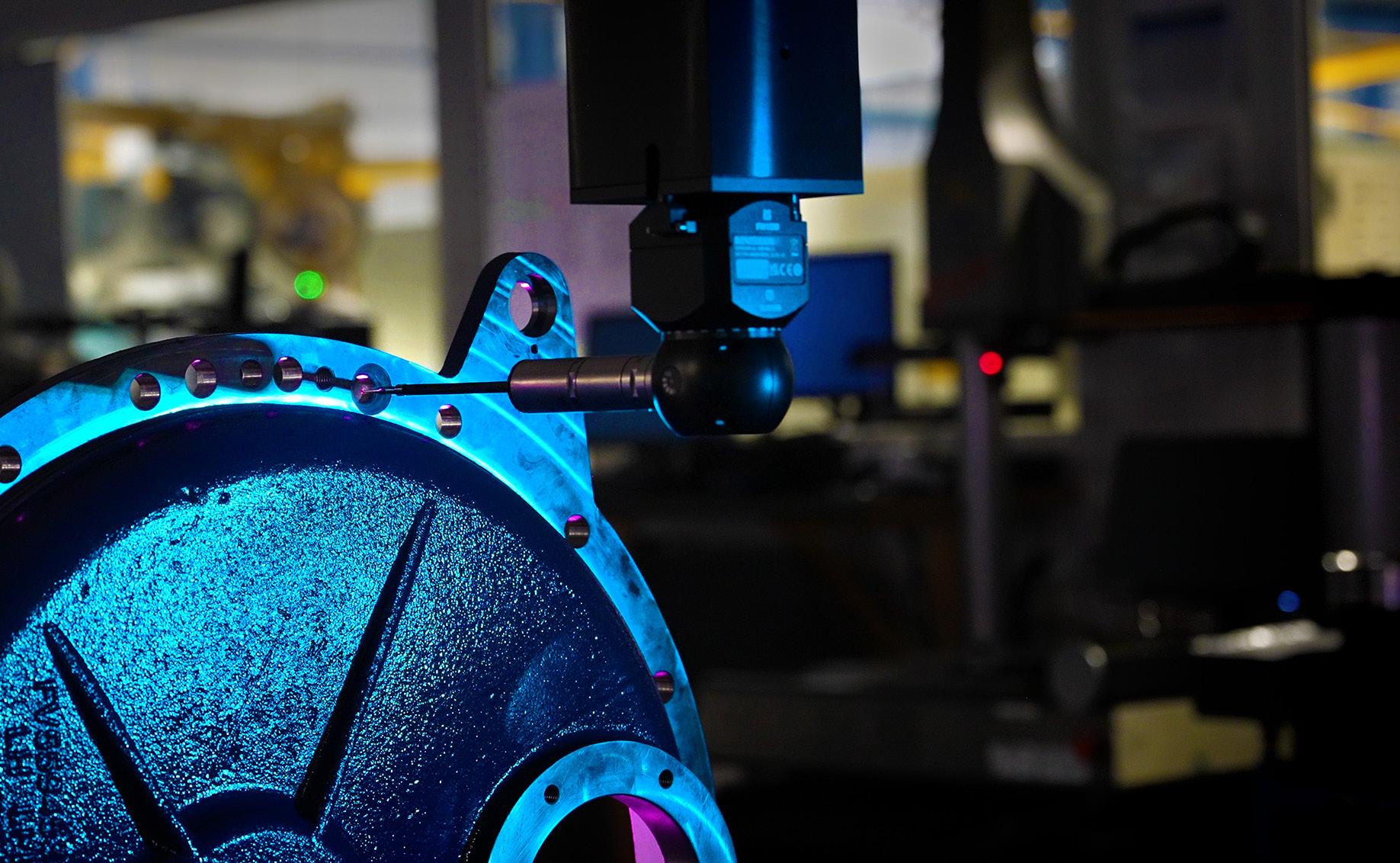

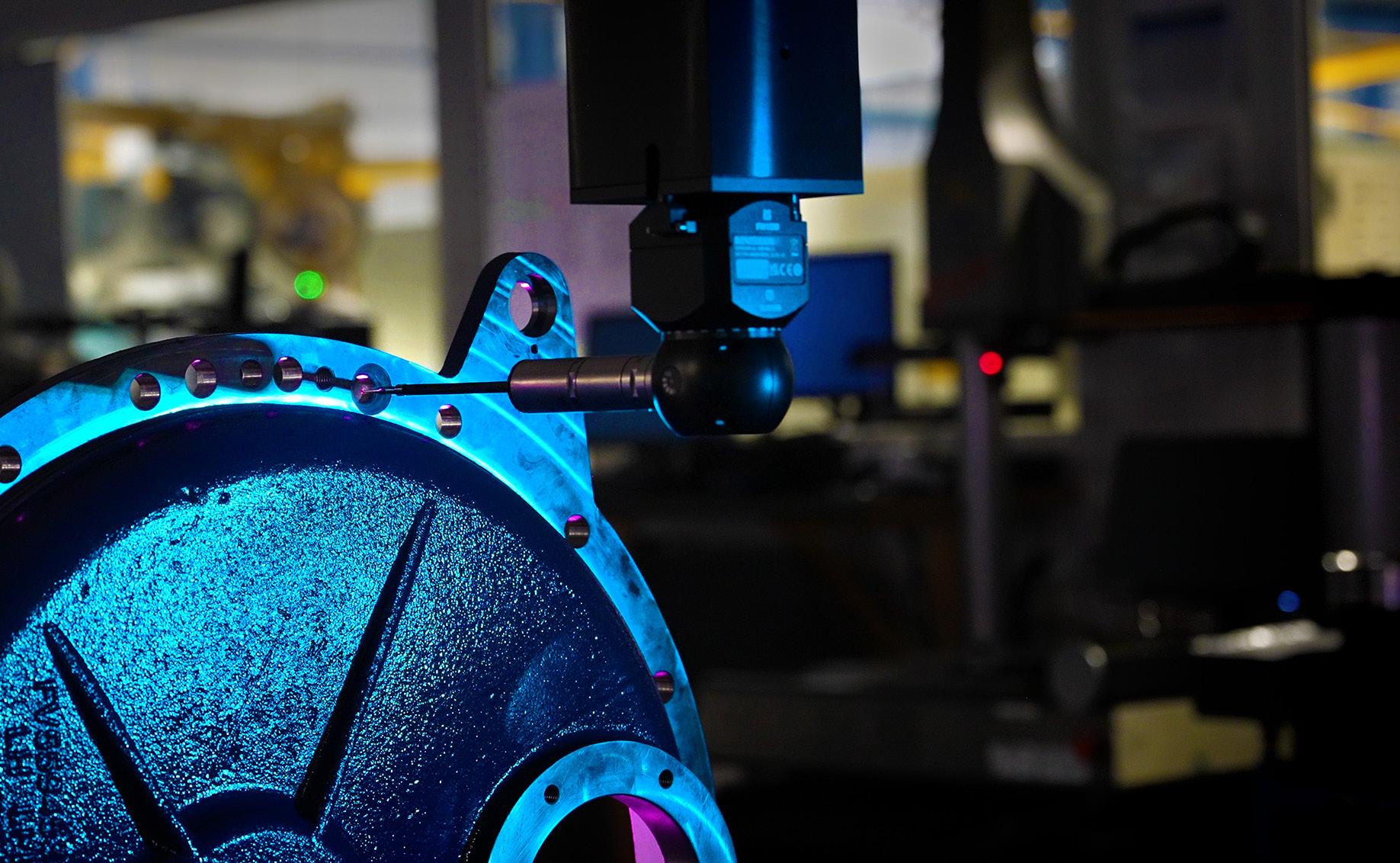

PRECISION ENGINEERING

Llanelec is a precision engineering company which specialises in manufacturing integral parts for vehicles operating in defence and high-precision titanium parts for aerospace.

I understand Llanelec specialises in precision CNC machining of running gear and the supply of solid compound wheels for military vehicles. Could you provide a brief overview of your day-to-day activities, locations across the UK, and the client base you typically serve?

Founded in 1984 in Neath, South Wales, we pride ourselves on our commitment to quality and reliability. Our state-ofthe-art facilities and dedicated team of experts allows us to deliver products that meet the rigorous requirements of the sectors we work in. Our reputation is built on a foundation of reliability, precision, and a relentless commitment to excellence.

With a global customer base and diverse product portfolio, we are proud to be recognised as the partner of choice for many leading manufacturers. We have also been a trusted supplier for the Ministry of Defence for more than 35 years. Our expertise lies in crafting vital products for military vehicles and solid compound wheels, with our extensive product portfolio covering everything from road wheels and gears to final drive components and potential capacity to undertake armour plating for vehicles.

We use advanced CNC machinery and the latest software to produce precision components with exceptional reliability. Our commitment to continuous improvement and innovation ensures that we stay ahead of industry trends and consistently meet our customers’ evolving needs. This guarantees that we not only meet but exceed our customers’ demands in quality, delivery, and cost efficiency.

By partnering with leading manufacturers and using cuttingedge technology, we deliver solutions that enhance the performance and durability of military vehicles and the aerospace market.

Our dedicated team of engineers and technicians work tirelessly to refine our processes and develop new techniques, ensuring that every product we create is of the highest standard. Through rigorous testing and quality control measures, we ensure that our components withstand the most demanding environments.

Our customer-centric approach and strategic investments in research and development enable us to provide innovative and cost-effective solutions, solidifying our position as a trusted leader in the industry

Having been in business for more than 40 years, how have you seen the UK’s industrial machinery manufacturing landscape evolve? How has this impacted your business?

Llanelec have endured over 40 years in the defence sector and witnessed the highs and lows that coincides with the industry. We have seen many changes in that period, a major one being the advances in technology, not only in the plant that is used for milling and turning but the significant improvements in our measuring capacity as implements become more sophisticated. This has in effect led us to drive back into the design phase the requirement for tighter tolerances and more complex interfaces to be achieved.

Another major shift over the years has been the dramatic change in manpower and personnel skill level. We saw the move from traditional apprenticeships being very attractive to the youth of that day to a desire to have more officebased job roles around the millennium years. This had an impact on the engineering and manufacturing pipeline, causing a shortage in the system. Whilst this trend is starting to change with manufacturing again coming to the fore, the infrastructure to support the development will need to keep pace.

“The Iron Triangle is what Llanelec prides itself on: quality, cost, and delivery.”

We see this point as fundamental and key, and as such we have a strategic goal to support.

Finally, as the defence sector can be quite niche, we have been subjected to the ebb and flow of defence needs.

We have worked through defence thinking and shrinking during the 80s and 90s post-Cold War with less reliance and need for heavy armour, through the 90s and 00s with the Gulf Wars requiring more agile vehicles, to the recent RussiaUkraine conflict that has stretched defence manufacturing capacity to its limits.

What, in your opinion, is the company’s key differentiator? What do you do to stand out from the competition?

Whilst our company absolutely recognises the need for agreements, contracts, and agreed terms and conditions as the framework to do business, at Llanelec we place a great deal of importance on how we manage a change to the plan. We believe that it is more important for customers to have a supplier who will collaborate, and problem-solve effectively without reaching for the contract in the first instance. We welcome a close relationship with both our customer and supply base and have a long-standing track record of keeping calm under adversity, with a laser focus on solving

the problem to achieve the aim. We think that is the essence of engineering and manufacturing. To have the solutions to the problems, Llanelec has built up a strong capability over the years. This means that we have a broader scope within the value chain and can deliver most projects as a turnkey solution, keeping the links in the chain to a minimum and having more control.

Llanelec prides itself on being a problem solver to OEMs and prime defence and aerospace companies.

Can you talk about your work with Rheinmetall Vehicle Systems International, and any recent projects or jobs you have collaborated on?

The first project that comes to mind was a recent problem that RVS International had with a component that was required for a high-profile programme to deliver a vehicle which, without the component, would have compromised the planned roll-out. Llanelec were contacted at the beginning of December 2024 with the notion that it was probably impossible to source the component from anywhere other than the current supplier. Technical specifications were shared which identified that it would be unachievable to source the required raw material in the timeframe.

Llanelec identified a suitable alternative material that was available, RVS International assessed the request and issued approval within 24 hours and the material was sourced.

Llanelec expedited the request, whilst carrying out other operations out of sequence, to benefit the overall delivery time of the finished component. The result was that the components were delivered to RVS International by midJanuary, successfully meeting their need date. From original enquiry to delivery was no more than six weeks, quite remarkable in the current manufacturing sector where there is a real lack of widespread capability and capacity. This is a classic example of how Llanelec solves problems for OEMs and prime defence companies.

How do your values of reputation, quality, flexibility, reliability, expertise, and cost-effectiveness allow you to consistently provide precise, high-quality solutions that surpass expectations?

Almost all business and project plans will change. We believe that embedding our values throughout our organisation, at all levels, is a key facilitator to our ability to deliver consistently to our customers. The values we set and actively reinforce daily basis are what set our high standards. It creates a sense of pride in what we do and for whom we do it.

Throughout all our organisation, individuals and teams challenge themselves and others to go that extra step.

The values are there as the standard to remind the business what we stand for and how we have all agreed to operate.

The Iron Triangle is what Llanelec prides itself on: quality, cost, and delivery.

Could you tell us more about your long-held vision to grow the business, and how being awarded contracts such as UK MOD Land Forces and Babcock International Group have endorsed recent investments in resources, infrastructure, capability, and capacity?

Being awarded contracts provides an element of certainty, which is crucial to support business cases, particularly in a small to medium-sized enterprise (SME) family-owned business.

Our vision is to grow the business year on year, and to achieve this the business must invest in Llanelec and its infrastructure. The contracts awarded to us provide that stability to not only invest in our equipment but also our staff. We also look to use the contracts to leverage the political desire to level up the surrounding areas, rejuvenating what once was.

The area was once a hotbed of engineering and manufacturing, and the company’s vision is to play an active part in developing that once again.

Llanelec has grown 400% 0ver the past 5 years in revenue, size and capabilities; the new 8.5 acre site, with a state-ofthe-art 120,000 sqft multi-disciplined manufacturing facility allows a further 400% for future growth.

A truly one-stop shop servicing aerospace and defence.

Finally, what are your key priorities, targets, and goals for the year ahead?

Our Strategic Plan describes how we wish to continue to grow the business whilst continuing to maintain our standards. We have several goals contained within, but the one we are most focused on and will be proud of when we deliver is our plan to create an Engineering Training Centre.

Llanelec have planned a new engineering school for both young apprentices and local skills; it will provide quality labour, which is key to our growth, whilst supporting the local community in replacing jobs lost from Tata Steel - Port Talbot.

This will not only support the development of our growing number of apprentices but also provide an opportunity for local people to retrain and attain new skills. We believe that this opportunity will not only benefit the affected people but also increase the manufacturing capability and capacity in the area supporting the defence requirement for many years.

In addition, Llanelec plans to expand its product range internationally in supporting all NATO countries within defence. Our aim at Llanelec is to become a centre of excellence within the defence and aerospace industry!

“Our

aim at Llanelec is to become a centre of excellence within the defence and aerospace industry!”

COMMUNITY ENGAGEMENT

Rheinmetall encourages and supports employees who give back to their communities, whether by mentoring, coaching local sports teams, or volunteering as scout leaders.

This commitment to community engagement is an integral part of the company’s culture.

“Through strategic partnerships with universities and STEM initiatives, we are helping to shape the next generation of engineers and innovators, thereby strengthening the UK’s defence talent base,” Richards sets out.

One key partnership is with the University of the West of England’s Formula Student team – a group of skilled STEM students who design and build a race car for international competitions.

Rheinmetall’s sponsorship not only strengthens its relationship with a leading academic institution but also connects the company with talented engineers and innovators who may become part of its future workforce.

Rheinmetall stands out through its sovereign manufacturing capability and has strategically invested over £70 million in its UK production facilities, demonstrating the company’s commitment to British-designed and manufactured military vehicles.

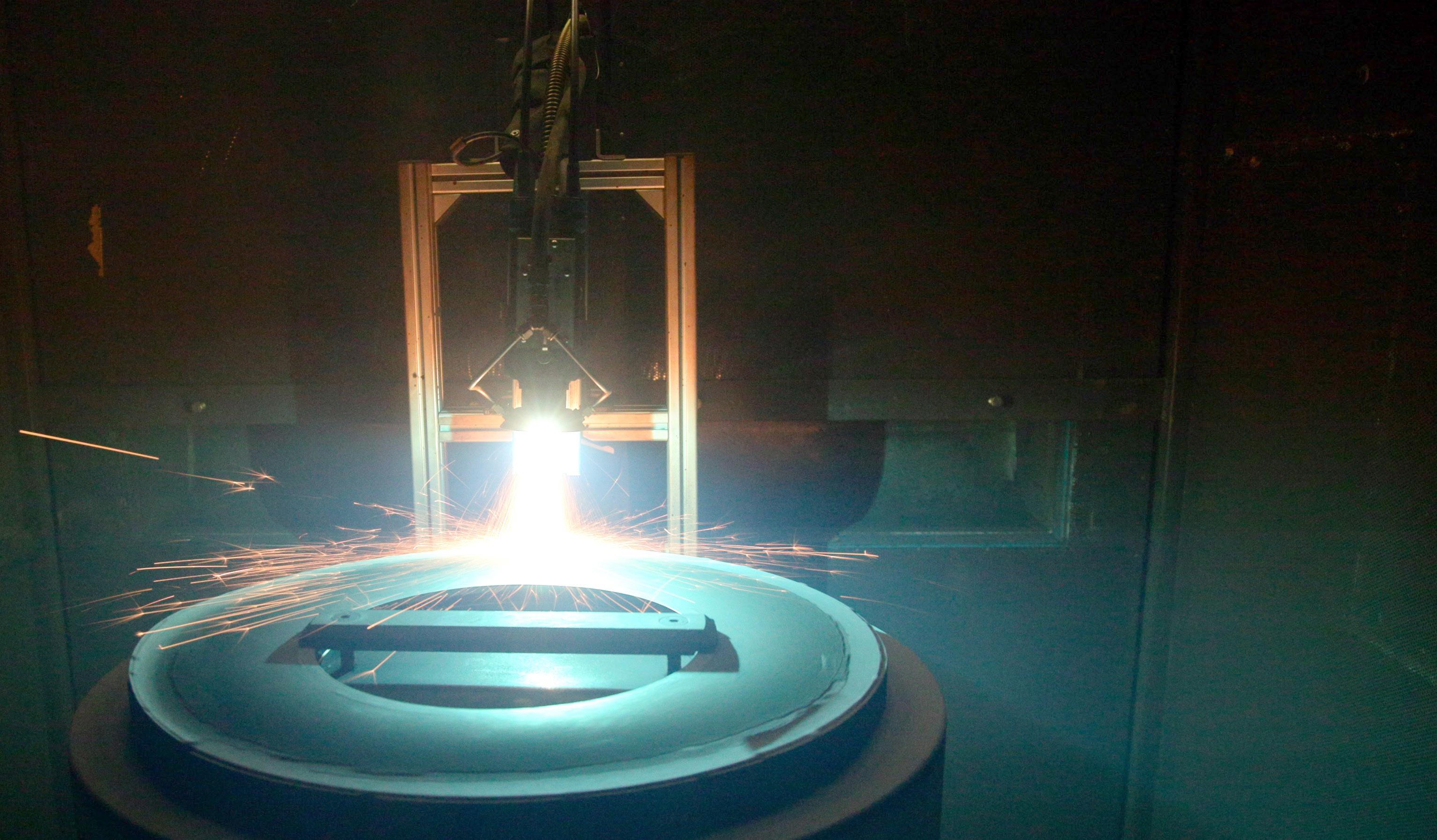

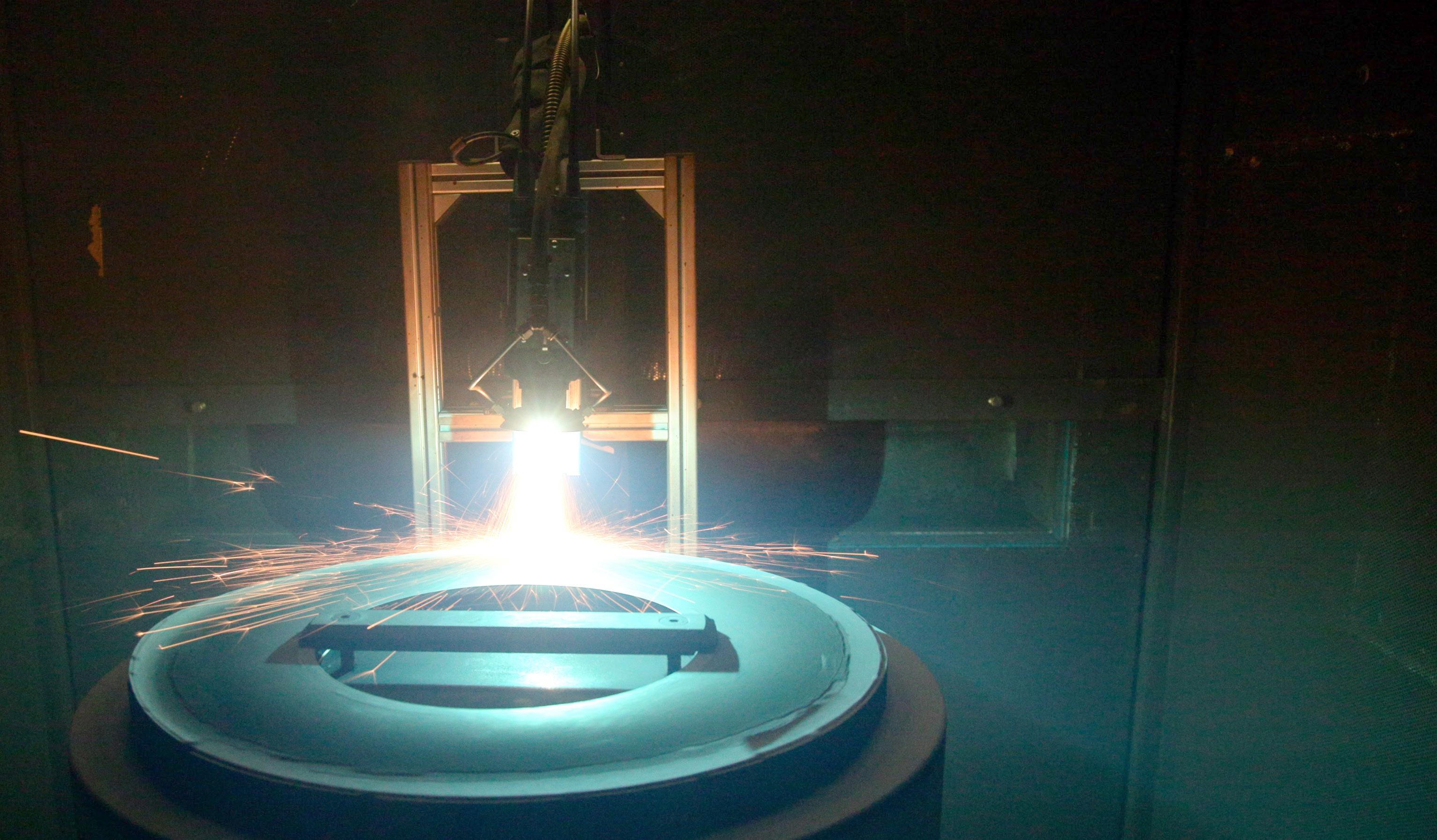

In addition to Rheinmetall House and the Telford facility, key areas of this investment include a new largecalibre gun hall and expanded military vehicle production.

“These underpin critical defence programmes and position the UK as a global leader in land defence manufacturing,” adds Richards.

In May 2025, Telford was confirmed as the home of Rheinmetall’s new gun hall, marking a bold step in re-establishing sovereign defence manufacturing in the UK.

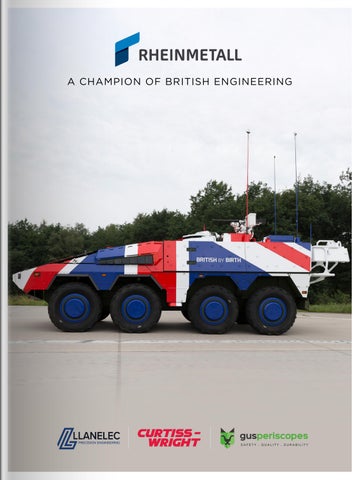

BUILT IN BRITAIN

The unveiling of the first British-made Boxer at the International Armoured Vehicles Conference in January 2025 by Maria Eagle, Minister of State for Defence Procurement and Industry, marks a major milestone for Rheinmetall and the UK defence industry, signifying the return of armoured vehicle manufacturing to the UK.

Built at its Telford facility, the achievement highlights Rheinmetall’s investment in sovereign capability, industrial growth, and long-term defence manufacturing.

“It also reflects our commitment to skills, infrastructure, and cutting-edge manufacturing, underscoring the importance of industry-government collaboration in delivering worldclass military capability,” Richards highlights.

One of the world’s most advanced wheeled armoured vehicles, the Boxer offers unmatched mobility, protection, and modular adaptability.

“Its reconfigurable design allows for multiple mission roles, ensuring the British Army’s evolving operational requirements are met whilst

delivering battle-proven survivability,” she acclaims.

The Boxer has undergone extensive live-fire exercises, mobility trials, and extreme environment testing to ensure peak combat effectiveness. By exceeding performance benchmarks, the Boxer will deliver

game-changing capability to the UK Armed Forces.

The country’s defence industry and economy have been strengthened as a result of this milestone with over 1,000 domestic jobs created, reinforcing its manufacturing base and engineering expertise.

75 percent UK supply chain integration also ensures British SMEs play a central role in Boxer production, whilst its export potential positions domestic suppliers for international contracts.

As production scales up, the Boxer MIV programme will continue to strengthen UK industrial sovereignty, defence capability, and economic prosperity, solidifying Britain’s leadership in global armoured vehicle manufacturing.

A NEW CHALLENGER

Equally, the Challenger 3 MBT programme represents a major leap forward in armoured warfare, ensuring the British Army remains equipped with a world-class tank for decades.

Under an £800 million contract, Rheinmetall is leading the design, development, and production of 148 Challenger 3 tanks through RBSL, with full operational capability targeted for 2030.

Put innovation in motion

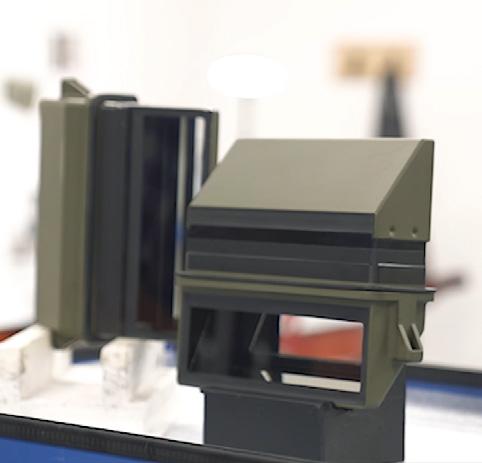

Curtiss-Wright Defense Solutions is a leading provider of comprehensive solutions for various rugged applications, with a complete portfolio of cost-effective engineering and support services.

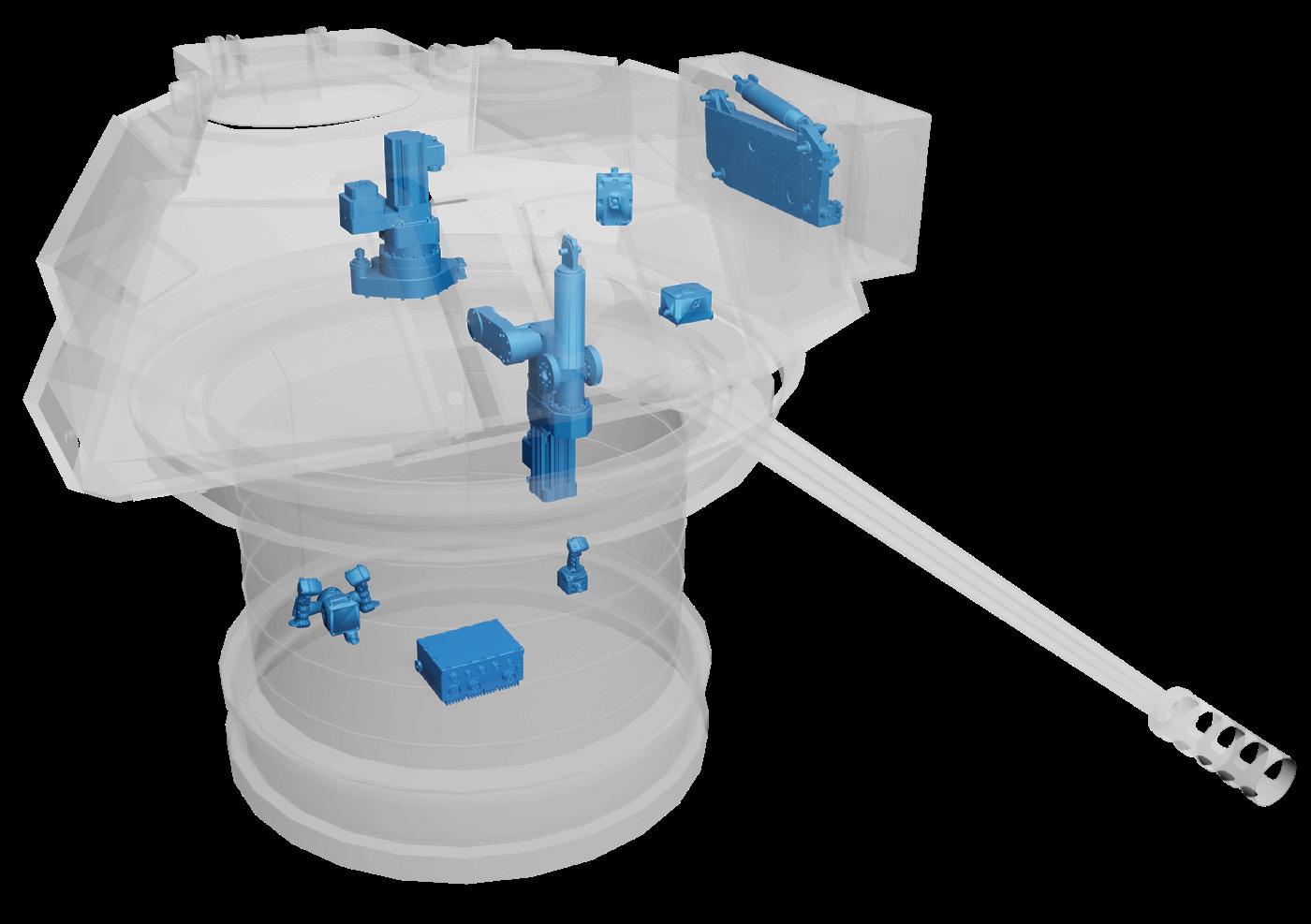

Modular and scalable motion control solutions, built and designed in the company’s facility in Switzerland, are used in a wide range of military platforms, from Remote Weapon Stations (small-calibre solutions) and Infantry Fighting Vehicles (medium-calibre solutions) to Main Battle Tanks (large-calibre solutions).

Our high-speed, highly precise solutions are also used in applications such as train tilting systems and Hollywood camera crane drive and stabilisation systems.

Tell us about Curtiss-Wright’s motion control business.

We have been a trusted and proven partner in the field of motion control for over 70 years. In the last 30 years, we have become a global leading supplier of electromechanical drive systems for the industrial and defence industries. A significant part of our business is focused on turret drive stabilisation. We are a one-stop shop system integrator with excellent customer and field integration support.

Turret Drive Stabilisation System (TDSS) solutions are globally recognised for their high performance, quality, and reliability. When customers require a high-speed motion control solution that must operate in harsh environments, we provide a single point of contact to solve their problem. Examples include ammunition flow systems, auto-loader systems, and missile launchers, which our customers integrate into their overall solution. On the industrial side, examples include the tilting train system for the Swiss inter-city railway that enables higher speeds and better performance on the track. Another application is a motion picture camera crane drive and stabilisation system, which is used on different vehicles during the production of numerous feature films.

What are some recent projects the company is proud of?

We are proud to be a preferred supplier of Rheinmetall BAE Systems Land (RBSL) and were selected by them to provide the TDSS for the British Army’s Challenger 3 main battle tank. We have long been a leading supplier for medium-calibre system infantry fighting vehicles, but this represents our first electro-mechanical TDSS on a main battle tank. What’s more, this business provided the foundation for our recent selection to support the development of Germany’s next-generation main battle tank.

Looking forwards, what are the key priorities and goals for the year ahead?

Our highest priority in 2025 is supporting the development phase of Germany’s new main battle tank, with the critical design review at the end of this year. We have invested significant IRAD to support the tank’s high weight and load turret within the platform’s limited space. Our innovative, modular approach uses two parallel azimuth drives. Compared to a single large drive, this saves weight, helps balance the payload, and enables operation in limited performance mode if a single drive fails.

What is the company’s vision?

We are committed to being the number one preferred TDSS supplier and integrator in the world. The market for armoured fighting vehicles is growing. With strategic uncertainty and growing international tensions fuelling the need to bolster military capabilities, this trend is likely to continue beyond 2025. We also see growing opportunities in the power management market. Examples include the DC/DC converters with energy power packs we developed for an Air Defence System and opportunities for our DC/DC converters with intelligent safety power management, ruggedised with an EMI filter, on platforms such as UUVs.

What differentiates you?

Having delivered over 5,000 electromechanical turret systems in the last two decades, we have unmatched experience in the design, development, and production of ruggedised solutions that meet military specification for use in harsh environments. Our renowned field support customer service team consults with customers to find better solutions and ensure flawless integration. We also have expertise in meeting requirements to enhance local economic benefits for customers. We have partnered with Rheinmetall and other customers in multiple countries to support local content programmes, such as our successful participation in Australia’s Land 400 Phase 2. We are especially proud to be known as one of the most supportive, forward-thinking, and agile suppliers.

“We are committed to being the number one preferred TDSS supplier and integrator in the world.”

Christian Kopp, Managing Director, Curtiss-Wright Antriebstechnik GmbH

Tailored to Meet Mission Needs

Precision Target Location and Shot Stabilization

Single Axis Gyroscopes

Rotary Gear Drive

Two Hand Controller

Electrical Motion Actuator

Dual Axis Gyroscopes

Linear Gear Drive

One Hand Controller

Motion Controller

Motion Controller

Suited for use on weapons stations or main battle tanks and designed for the most demanding dynamics and precision requirements.

Electrical Motion Actuator

Designed to meet the demanding requirements for future and legacy land systems for missile launchers and radar applications.

Single Axis Gyroscope

Ultra-fast and low noise fiber optic gyro developed for high-performance military applications.

Dual Axis Gyroscope

Equipped with ultra-low noise sensors and engineered to withstand extreme environmental conditions.

curtisswrightds.com/motion-control

Rotary Gear Drive

Define system performance with a configurable gearbox while maximizing stiffness and minimizing friction and backlash.

One Hand Controller

One-handed operation optimized for user comfort. Connector handles can hold up to 12 independently sealed switches.

Linear Gear Drive

Designed to provide smooth linear motion to defense applications operating in harsh environments.

Two Hand Controller

Engineered for both horizontal and vertical handling, ensuring precise control and a firm grip over challenging terrain.

RHEINMETALL KEY PROJECTS – AT A GLANCE

• Boxer MIV – Over 600 vehicles for the British Army, strengthening the UK’s armoured fleet.

• Challenger 3 MBT – The most advanced tank ever operated by the British Army, providing unmatched lethality and survivability.

• HX trucks – 500 delivered in under five months, adding to the 7,000 already in UK service.

• Large-calibre weapon production – Investment under the Trinity House Agreement to enhance UK and NATO capabilities.

• Electronic systems and digitisation – Rheinmetall is expanding its capabilities, ensuring future armoured vehicles are fully networked and interoperable with cutting-edge battlefield technology.

• Autonomous revolution – The company is launching three brand-new Advanced Land Autonomy Centres of Excellence in Germany, the Nordics, and the UK, whilst also expanding its current Canadian Autonomy Centre of Excellence.

“Manufacturing is underway at our advanced facility in Telford, reinforcing our commitment to sovereign UK manufacturing and industrial capability,” reveals Richards.

The Challenger 3 is the most advanced MBT ever fielded by the British Army, with Rheinmetall’s advanced technology at the core, delivering next-generation firepower, survivability, and digital capability.

It features a state-of-the-art, 120-millimetre smoothbore gun capable of firing the latest NATOstandard ammunition for enhanced range, accuracy, and firepower.

It also boasts modular armour, developed in collaboration with UK defence experts, offering superior protection whilst maintaining high mobility.

A fully digitised turret and fire control system provides real-time battlefield awareness and precision targeting, whilst advanced survivability systems ensure crew protection in high-threat environments.

Beyond its battlefield superiority, the Challenger 3 MBT programme delivers long-term benefits to the UK.

These include sustaining and creating highly skilled jobs across engineering, manufacturing, and systems integration; strengthening the country’s defence supply chain with key components sourced from British industry; and enhancing the UK’s defence export potential, positioning the Challenger 3 as a next-generation MBT for allied nations.

“With prototype vehicles undergoing rigorous trials, the programme remains on track, ensuring the British Army retains cutting-edge armoured capability for the future,” Richards details.

INNOVATION AND COLLABORATION

Along with its sovereign manufacturing capability, Rheinmetall’s competitive edge is defined by technological innovation

We protect those who protect us.

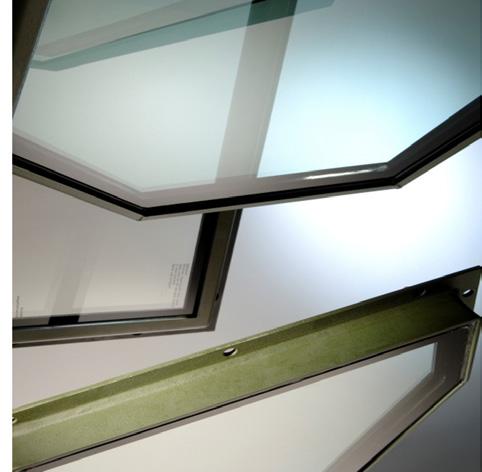

EXPERTS IN MILITARY PERISCOPE TECHNOLOGY

GuS Periscopes Ltd (GuS UK) is a UK-based defence company with extensive expertise in Military Periscope Technology. Based in Cwmbran, South Wales, within an 11,000 sqft facility, GuS UK specialises in the design and manufacture of both standard and custom observation systems, including periscopes, hybrid electronic periscope systems, episcopes, and vision blocks for armoured fighting vehicle applications.

As the only UK manufacturer of both PMMA (acrylic) and optical glass periscopes, GuS UK is passionate about providing the best performance and value solutions to its end users, actively engaging and encouraging end user input during the design and development process. GuS UK’s talented team of engineering, manufacturing, and supply chain management specialists are agile and reactive, using the latest 3D CAD software, in-house optical simulation tools, and rapid prototype techniques to produce products quickly and effectively for customer delivery and end user feedback. This design and supply chain expertise also allows GuS UK to reverse engineer and repair legacy OEM products that can no longer be sourced new.

Significant investment is planned for 2025, including a £250,000 CNC polisher and extensions to the bonding department and engineering offices. This investment supports the unique GuS UK bonding process that provides near-glass optical quality and superior environmental quality to traditional laminated PMMA (acrylic) periscope.

GuS UK has developed strategic alliances with companies who offer complementary, specialist capabilities - such as optical coatingsto ensure GuS UK can offer a true “one-stop shop” service and is

continually adapting to meet the evolving technological demands of the modern defence landscape. GuS UK provides a comprehensive service that spans the entire design and manufacturing process.

The GuS Family

GuS UK is proud to be a part of the GuS family. The GuS brand is synonymous with safety, quality, and durability. Leveraging the 45-year heritage of the GuS family, GuS UK can offer ballistic windows using the ballistic glass manufactured at GuS Glass and Safety in Germany and acts as a distributor of fully ruggedised electronic display screens from the sister company Lucius and Baer in Munich.

Working with the electronics capability within the GuS group, new design electronic hybrid periscopes have increased the scope of GuS UK’s offering, allowing the end user to integrate the camera feed into the the company’s state-of-the-art hybrid periscope systems.

The systems combine the standard periscope technology with new innovative digital technology, offering the end customer enhanced reversionary mode in the digital age. The GuS EP range of hybrid periscopes includes IR, day, lowlight, and fusion capability alongside the direct view vision. GuS UK can work with the end user to offer the optimum system for each customer requirement.

GuS UK’s Mission.

GuS UK’s mission is to “protect those who protect us” and the team is dedicated to fulfilling this.

GuS Periscopes UK is proud to be the periscope supplier to Rheinmetall for the Boxer programme in the UK and the Land 400 Boxer programme in Australia.

+44 (0) 1633-495043

and deep-rooted partnerships.

The company is pioneering the future of armoured warfare, investing in lethality, survivability, and digital systems integration.

“We are expanding our capabilities in electronic systems and digitisation, ensuring future armoured vehicles are fully networked and interoperable with cutting-edge battlefield technology,” Richards informs us.

“This focus on digitisation is critical to enhancing command-and-control capabilities and supporting the integration of artificial intelligence (AI)-driven decision-making tools.”

The company is also launching its Advanced Land Autonomy Centres of Excellence in Germany, the Nordics, and the UK, whilst additionally expanding its current Canadian Autonomy Centre of Excellence.

These pioneering hubs will serve as the core of Rheinmetall’s autonomous systems strategy, providing advanced

“I BELIEVE STRONGLY IN BEING VISIBLE, NOT ONLY FOR MY DAUGHTERS BUT FOR OTHER WOMEN LOOKING TO BUILD SUCCESSFUL, FULFILLING CAREERS IN DEFENCE. I’VE BEEN TOLD I’M LOOKED UP TO FOR MY PERSONAL STYLE – BRIGHT COLOURS AND BOLD PRINTS IN A WORLD OF DARK SUITS; IT’S ALWAYS BEEN A CONSCIOUS DECISION”

– REBECCA RICHARDS, DEPUTY CEO, RHEINMETALL UK

integration, testing, and national control over next-generation solutions, with a strong focus on the PATH Autonomous Kit.

Close collaboration, meanwhile, ensures future-proof solutions, as demonstrated by the company’s Challenger 3 modular armour system which was co-developed with the Defence Science and Technology Laboratory (DSTL) and Defence Equipment and Support, an

arm’s-length body of the MoD.

“Additionally, the Trinity House Agreement, signed in 2024, further strengthens UK-Germany defence industrial ties by expanding largecalibre weapon production,” shares Richards.

DRIVING DEI

Aside from the Boxer MIV and Challenger 3 MBT programmes, Rheinmetall takes great pride in its

commitment to the Armed Forces community and fostering diversity, equity, and inclusion (DEI) in the workplace.

The company actively recruits veterans and works closely with specialist organisations to help ex-service personnel transition into civilian careers.

“In 2024, we formalised this commitment by signing the Armed Forces Covenant, providing additional leave for reservists and Cadet Force Adult Volunteers and supporting military families through flexible employment opportunities,” Richards confirms.

Beyond employment, Rheinmetall is a proud corporate friend of SSAFA, the Armed Forces charity, engaging in fundraising and initiatives that support veterans, service personnel, and their families.

On driving DEI, Richards firmly believes diversity is essential for

Oldham Engineering is a UK Premier manufacturing service provider for all Industrial Sectors, including Nuclear, Defence, Oil and Gas, Subsea, Aerospace, Rail and Renewables.

Operating from it’s UK manufacturing site based in Oldham and Sheffield, the company has premium engineering facilities totalling over 150,000 sqft. The business is ISO9001 certified and holds the ‘Investors in People’ accolade. Oldham Engineering’s Competitive Advantage is driven by three key elements;

• a highly skilled and competent workforce,

• investment in the latest machining technology, and

• a business culture of continuous improvement.

better decision-making, broader perspectives, and innovative problemsolving – critical factors in today’s defence industry.

“Different viewpoints lead to stronger outcomes, and we must foster new ways of thinking to address the evolving challenges we face,” she emphasises.

Rheinmetall’s progress in DEI wouldn’t be possible without the full support of its executive leadership, who continue to champion and drive this work forwards.

“We are committed to creating a workplace where every individual feels valued, empowered, and supported.”

As part of this commitment, the company is developing a comprehensive well-being strategy that aims to enhance its focus on employee health, resilience, and an inclusive culture that promotes work-life balance and family-friendly policies.

The strategy will build upon existing support structures to ensure Rheinmetall’s workforce remains motivated, engaged, and equipped to succeed.

“Beyond the workplace, I am deeply passionate about driving gender diversity and inspiring future talent. I want to show my daughters that they can achieve anything they set their minds to, even in traditionally male-dominated industries,” Richards affirms.

“To help achieve this, I volunteer at local schools, mentor young people, and encourage more females to pursue STEM careers. I am also dedicated to raising aspirations in deprived communities.”

As part of its broader commitment to gender diversity, Rheinmetall has signed the Women in Defence Charter, pledging to increase female representation in senior leadership roles.

The company has made great strides in ensuring women are wellrepresented at all levels, creating a culture where everyone has the opportunity to thrive and contribute.

It is also proud to have recently been endorsed by Work180, which recognised the company’s commitment to gender equality – a milestone that reflects the impact of policies such as 26-week paid parental leave and flexible work options that support parents in returning to the workplace after the birth of a child.

Additionally, the company invests in STEM engagement, apprenticeships, and graduate programmes, ensuring it nurtures a diverse pipeline of future talent for the defence sector.

“I’ve worked closely with schools, universities, and STEM outreach initiatives to help inspire the next generation – especially young women – to consider careers in a sector that has traditionally been male-dominated. Over time, I’ve seen greater diversity emerging across the

defence industry, and I’m proud to be part of that shift,” she impassions.

“I believe strongly in being visible, not only for my daughters but for other women looking to build successful, fulfilling careers in defence. I’ve been told I’m looked up to for my personal style – bright colours and bold prints in a world of dark suits; it’s always been a conscious decision.”

Evidently, Rheinmetall recognises the importance of actively engaging with communities that have historically been underrepresented, prioritising initiatives that support veterans, promote STEM opportunities, and address gender equality in a meaningful way.

PASSIONATE PEOPLE

With DEI deeply embedded in its values and how the company operates every day, the greatest strength of Rheinmetall is its people, including some of the most talented engineers, technicians, and defence

specialists in the country.

These individuals are not only highly skilled but also deeply passionate about innovation and excellence.

Whether developing cutting-edge military technology, supporting the Armed Forces, or strengthening Britain’s sovereign defence capability, everyone at Rheinmetall plays a vital role in delivering real-world impact.

“I’ve come to appreciate that every member of the team brings unique strengths. High-performing teams are built on diversity of thought and experience; it’s about understanding, balance, and compromise – not oneupmanship,” acknowledges Richards.

“We’ve built a genuinely supportive and friendly workplace culture. It’s the small, thoughtful moments –people checking in, sharing a laugh, or showing a genuine interest in one another – that make a big difference. We’re a motivated, passionate team, and that positive energy is what makes it such an inspiring and

dynamic place to work.”

As a growing business, Rheinmetall is investing heavily in the UK and planning for the future, not just in military capability but also in creating high-value jobs and meaningful careers.

With that growth comes the opportunity to help shape the company culture, ensuring it remains a place where people want to work, develop, and stay.

“Being part of that journey is incredibly rewarding. Early in my career, I believed everything in work had to be perfect – contracts had to be flawlessly negotiated and bids had to be won – but as I progressed, I realised that true success comes from building long-term, fair partnerships,” Richards reflects.

“It’s not about winning but achieving the right outcomes for everyone involved. No two days are the same, especially in defence, and even with years of experience there’s always something new to learn.”

THE JOURNEY INTO DEFENCE

Despite having this extensive experience in the industry, Richards’ journey into defence was an unconventional one.

She initially studied law and began her career in a solicitor’s firm before moving in-house to the legal department of an iron and steel company.

When the opportunity arose to move back home, Richards came across a role at military vehicles and communications company General Dynamics, which opened the door to the world of defence.

“That role marked my first real exposure to the industry, and I was immediately drawn in by the scale and complexity of the programmes,” she recalls.

“Defence enabled me to contribute to significant projects whilst remaining rooted in my local community.”

As her career progressed, Richards became increasingly passionate about the wider impact of the industry – not just on national security, but on local economies and social mobility.

Indeed, it plays a valuable role in supporting regional development, particularly in areas that benefit from skilled jobs and long-term investment.

Having progressed to Commercial Vice President of General Dynamics in 2016 – a milestone Richards believed would be the pinnacle of her career – a new chapter soon opened at Rheinmetall when she joined as Managing Director in 2019.

Initially tasked with overseeing key programmes and strategic partnerships across the UK, Richards is now proud to serve as Deputy CEO.

“My focus is on strengthening sovereign manufacturing capability and delivering world-class military vehicle systems to the British Army,” she summarises.

“I have been fortunate to work on some of the UK’s most

significant defence programmes, which has provided me with a deep understanding of defence procurement, manufacturing, and the supply chain landscape –knowledge that is instrumental in shaping Rheinmetall’s future.”

PIVOTAL PRIORITIES

The future includes a number of priorities for the company, with 2025 being a pivotal year as Rheinmetall expands its operations and advances key defence programmes.

These priorities include scaling Boxer production capacity, advancing Challenger 3 trials, and operationalising its new large-calibre gun hall.

Rheinmetall is also investing in advanced defence technologies and expanding both the UK defence supply chain and the autonomous revolution.

By 2030, the company aims to be the nation’s leading armoured vehicle manufacturer, not just meeting domestic defence needs but also positioning Britain as a key exporter of advanced military vehicles.

“Our long-term investment in workforce development, infrastructure, and sovereign defence capabilities will be instrumental in achieving this vision.

“Through continued collaboration with the UK government, industry partners, and international allies, we remain focused on delivering world-class defence solutions that strengthen Britain’s strategic position on the global stage,” Richards closes.

Tel: 07707853374

uk.communications@rheinmetall.com https://www.rheinmetall.com