Your trusted partner for the control cabinet and beyond

Process safety is usually larger in scope, making more complex. In addition to controlling inputs some signals from the eldfi come from explosive need to be properly conditioned. Over-voltage power redundancy also become necessities process.

Functional safety management starts at the encompass an entire company strategy. In applied in two major areas: machine and process.. Machine safety can be as simple as a single to a safety relay controlling a motor, or as fail-safe PLCs with distributed safety I/O networked a factory. No matter how large your system, three pieces: inputs, outputs, and logic.

From connectivity on the machine to through-panel and in-cabinet wiring, Phoenix Contact gives you the confidence you need in your production systems.

CAPAROC is your customizable electronic circuit breaker system for overcurrent protection in 12 V to 24 V DC applications. The CAPAROC system uses data-driven power modules to customize overcurrent protection. With numerous feed-in power modules, circuit breakers, potential distribution modules, and current CAPAROC makes it easy to design an intelligent communication system.

YOUR TRUSTED PARTNER FOR THE CONTROL CABINET AND BEYOND

Safety

Learn more at www.phoenixcontact.com/us-caparoc

That was easy

The COMPLETE line system has numerous signals reliably. From controller and connectivity sensors and motors, this group of products switching at the right time.

choosing a universal product, or it might and allowing the application to dictate product

Expand your automation freedom with PLCnext Technology from Phoenix Contact. PLCnext is an open industrial automation platform with limitless possibilities that expand the use of a PLC in ways that have changed the future of automation. Open with Linux, PLCnext is IIoT ready, o ering multiple cloud connection options. Explore programming capabilities with the potential to be networked for easy monitoring. With apps available on the PLCnext Store to save programming time

PHOENIX CONTACT 2023

www.phoenixcontact.com/us-caparoc 6/22/2023 3:08:57 PM

US_2023-Four-page-North-America-Outlook-Advertorial_360x240mm_005864.indd

That was easy

Expand your automation freedom with PLCnext Technology from Phoenix Contact. PLCnext is an open industrial automation platform with limitless possibilities that expand the use of a PLC in ways that have changed the future of automation. Open with Linux, PLCnext is IIoT ready, o ering multiple cloud connection options. Explore programming capabilities with the potential to be networked for easy monitoring. With apps available on the PLCnext Store to save programming time and PLCnext Engineer software available as a free download, it’s easy to implement into your control system.

It’s a proven technology that many of our customers have already adopted. Visit www.phoenixcontact.com/open to learn more about what you might be missing out on.

© PHOENIX CONTACT 2023

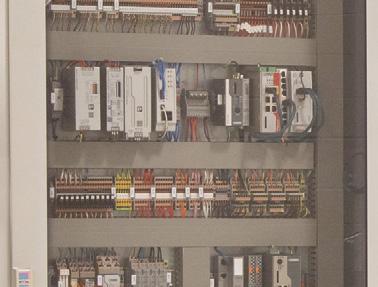

Build your control cabinet with confidence

Industrial solutions from sensor to cloud

Control cabinet designers must constantly rethink their processes to remain competitive. Since its founding in 1923, Phoenix Contact has collaborated with customers across nearly all industries to improve the reliability and e ciency of industrial applications.

Today, Phoenix Contact provides comprehensive solutions to optimize processes and save time. The COMPLETE line perfectly coordinates hardware and software to streamline processes, giving you the peace of mind and competitive edge needed to succeed in today’s highly complex manufacturing world.

Power reliability

No other function in your control cabinet impacts overall system performance more than reliable power. Phoenix Contact has all the necessary components to reliably protect, convert, monitor, and distribute low-voltage power within your system. High-performance surge protection and circuit breakers protect equipment from transient overvoltage and overcurrent disturbances. Transmission of those disruptive events to a “cloud” enables preventive maintenance.

Redundant solutions or batteries supplement the DC power supply when needed, safeguarding low-voltage power, even in critical situations. In addition, future-proof monitoring systems save energy in the overall system. Innovative solutions for AC or DC potential distribution reduce space requirements and installation times in the control cabinet.

Connectivity

Connections in the cabinet, through the cabinet, and in the field are the bridge between the field-based sensors and logic controlling a system.

The automation and control level reads inputs and drives outputs. These devices must be connected by secure discrete wiring or through networks.

These same devices must be reliably powered, which requires e cient distribution and marshaling to energize and balance loads. Loads can range from small milliamp signals to high-horsepower motor connections.

Analog signals often require special functionality at the connection point, such as testing, measurement, or fusing. Specialty terminal blocks support these functions. When >>>

Build your control cabinet with confidence

Industrial solutions from sensor to cloud

system complexity and I/Os increase, networking field signals outside the enclosure is often a more e cient way to integrate larger systems than point-to-point wiring.

Signal switching and conditioning

Every signal has a specific purpose, and not all signals are the same. Sometimes along the journey, signals may need to be isolated, amplified, or converted to serve their purpose. Ensuring the signal’s mission is accomplished can be as simple as choosing a universal product, or it might require digging deeper and allowing the application to dictate product selection.

The COMPLETE line system has numerous options to transmit signals reliably. From controller and connectivity solutions to sensors and motors, this group of products ensures the right switching at the right time.

Safety

Functional safety management starts at the top and should encompass an entire company strategy. In application, safety is applied in two major areas: machine and process..

Machine safety can be as simple as a single safety sensor tied to a safety relay controlling a motor, or as complex as multiple fail-safe PLCs with distributed safety I/O networked throughout a factory. No matter how large your system, it will always have three pieces: inputs, outputs, and logic.

Process safety is usually larger in scope, making it inherently more complex. In addition to controlling inputs and outputs, some signals from the field come from explosive areas and need to be properly conditioned. Over-voltage protection and power redundancy also become necessities in a continuous process.

Shop floor productivity

Time is money. The tools and resources used to build your control cabinet are key to controlling costs. Design software, marking systems, industrial tools, wire management, and cabinet accessories are often overlooked. Careful consideration of these products reduces errors and production time, translating directly to the bottom-line profitability of any shop floor. All aspects of your cabinet design and build will require tools and equipment on the shop floor. Wires and components in and around the cabinet will need to be processed, organized, and identified. This family of products ensures the production of a high-quality cabinet.

Automation and control

The heart of your control cabinet is the logic platform. For OEMs and control engineers alike, it has never been easier to build smaller, smarter machines fast. This lets builders free themselves from using controllers and equipment based solely on prior familiarity or specifications. Industrial PCs/HMIs and scalable controllers can streamline functionality, reduce equipment and costs, and usher in the next generation of intelligent machine automation.

Control systems can range from simple, single-function control to real-time SCADA applications.

Networking

The modern factory, driven by the Industrial Internet of Things (IIoT) and big data, must handle increased network tra c and the possibility of internal or external vulnerabilities. Phoenix Contact networking and security products support many technologies, so you can design and implement scalable, reliable, and high-functioning systems.

Ethernet infrastructure devices provide everything from basic connectivity to advanced managed switches, with options that include powering end devices, field-wiring connectivity, and converting between physical media. Network security can properly separate the IT and OT networks and protect critical assets.

Cellular remote connectivity powers communication with devices around the globe. The increasing capabilities of cloud services provide the support and data management needed for IIoT. Wireless technology enables convenient, reliable, and cost-e ective communication, either on the factory floor or to remote sites miles away.

Limited Lifetime Warranty

Phoenix Contact stands behind its products with the industry’s most comprehensive Limited Lifetime Warranty. The LLW is our promise to you that the products you install in your control cabinets are built to last.

Register today at: www.phoenixcontact.com/LLW

Trusted partners in industrial automation

Phoenix Contact and AWC work together to bring innovative products and world-class service to customers in the automation and control industry. From connectivity to control, Phoenix Contact gives you the confidence you need in your production systems.

Your trusted partner for the control cabinet and beyond

Intuitive circuit breaker system

From connectivity on the machine to through-panel and in-cabinet wiring, Phoenix Contact gives you the confidence you need in your production systems.

CAPAROC is your customizable electronic circuit breaker system for overcurrent protection in 12 V to 24 V DC applications. The CAPAROC system uses data-driven power modules to customize overcurrent protection. With numerous feed-in power modules, circuit breakers, potential distribution modules, and current rails, CAPAROC makes it easy to design an intelligent communication system.

Learn more at www.phoenixcontact.com/us-caparoc

© PHOENIX CONTACT 2023

© PHOENIX CONTACT 2023

Phoenix Contact and AWC work together to bring innovative products and world-class service to customers in the automation and control industry. From connectivity to control, Phoenix Contact gives you the denceconfi you need in your production systems.

Trusted partners in industrial automation

Register today at: www.phoenixcontact.com/LLW

Phoenix Contact stands behind its products with the industry’s most comprehensive Limited Lifetime Warranty. The LLW is our promise to you that the products you install in your control cabinets are built to last.

Limited Lifetime Warranty

Cellular remote connectivity powers communication with devices around the globe. The increasing capabilities of cloud services provide the support and data management needed for IIoT. Wireless technology enables convenient, reliable, and cost-e ective communication, either on the factory oorfl or to remote sites miles away.

Ethernet infrastructure devices provide everything from basic connectivity to advanced managed switches, with options that include powering end devices, eld-wiringfi connectivity, and converting between physical media. Network security can properly separate the IT and OT networks and protect critical assets.

Contact networking and security products support many technologies, so you can design and implement scalable, reliable, and high-functioning systems.

PHOENIX CONTACT

01952 681700

info@phoenixcontact.co.uk phoenixcontact.com

The modern factory, driven by the Industrial Internet of Things (IIoT) and big data, must handle increased network tra c and the possibility of internal or external vulnerabilities. Phoenix

Networking

Control systems can range from simple, single-function control to real-time SCADA applications.

used to build your costs. Design software, management, and cabinet consideration of production time, translating any shop oor.fl build will require tools and components in processed, organized, ensures the production

making it inherently inputs and outputs, explosive areas and Over-voltage protection and necessities in a continuous

the top and should In application, safety is process.. single safety sensor tied as complex as multiple networked throughout system, it will always have

as require digging deeper product selection. numerous options to transmit connectivity solutions to products ensures the right

to control, in your

PRODUCED BY NORTH AMERICA OUTLOOK MAGAZINE

Learn more at www.phoenixcontact.com/us-caparoc

as simple

be

© PHOENIX US_2023-Four-page-North-America-Outlook-Advertorial_360x240mm_005864.indd