Equipped with a multitude of purpose-built solutions, Nulogy extracts value and facilitates real-time collaboration to efficiently solve the biggest supply chain challenges. Christine Barnhart, Chief Industry and Ecosystem Officer, delves into the company’s unmatched expertise

Writer: Lucy Pilgrim | Project Manager: Poppi Burke

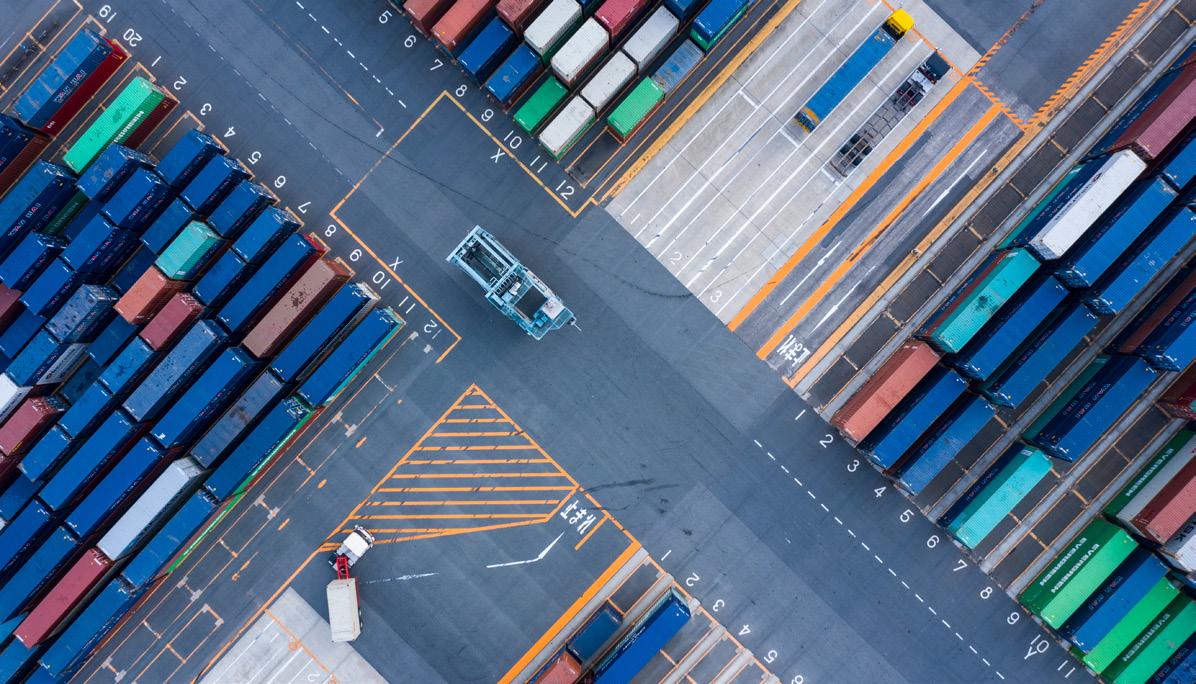

In order to operate effectively, organizations across the North American supply chain must synchronize and balance the demands of stakeholders – including customers, investors, and staff – with their needs and goals.

On top of this, companies must also consider the socioeconomic context in which they are operating, taking into consideration natural disasters, geopolitical conflicts, and socioeconomic strains.

These particular pressures have mounted in recent years, becoming an omnipresent force for supply chain professionals.

Yet, the industry is at a turning point, entering into a digital age that is introducing new processes and tools and a fresh perspective to the market, fostering greater collaboration and efficiency.

“The stressors may change from time to time and the priorities shift, but the core of what a supply chain

The company predominantly works with businesses across North America and Europe, supported by an emerging operational footprint in Latin America and Asia.

As supply chain market innovators, Nulogy’s 200+ employees primarily reside in R&D and product development, helping a diverse range of clients.

“We were born out of the supply chain base for very large, fast-moving consumer goods (FMCG) brand suppliers,” Barnhart adds.

Since then, the company has developed five core solutions within its main platform.

Firstly, Nulogy’s legacy product, sold on the shop floor, allows contract packagers and manufacturers to schedule production processes, manage labor, provide block code and batch traceability, and maintain quality, alongside many other elements that would be expected in production.

The company additionally offers its Supplier Collaboration Solution, a complementary product predominantly sold to large supplier organizations and their customers.

“This allows us to create what I call virtual vertical integration. Many big brands are equipped with great tools to manage their own supply chain, but as they go into the supply base, they lose visibility.

“Therefore, our Supplier Collaboration Solution helps build not just the integration needed but the business processes required within the context of external manufacturing,” she explains.

Nulogy’s Smart Factory Solution was also launched at the beginning of 2025, which focuses on making facilities more efficient, effective, and productive through machine monitoring, production tracking, and overall equipment effectiveness (OEE) improvement capabilities.

Elsewhere, the Connect Solution,

which is utilized across all its products, enables the company to use powerful low and no-code integrations, electronic data interchange (EDI) integrations, and application programming interfaces (API) integrations.

“This solution also allows us to provide custom workflows and build notifications. Therefore, it’s a really great complementary solution that lowers the cost of implementation across our platforms,” Barnhart expands.

Finally, Nulogy’s Data Solution captures all the data developed within its platforms and was developed in conjunction with Snowflake – a leading cloud-based data storage organization that provides a platform to make the solution accessible to customers.

Nulogy exports data into the Snowflake platform so customers can marry data with their own requirements, whether it be warehouse management systems, enterprise resource planning (ERP), or advanced planning.

“The Data Solution gives customers a lot more of a holistic view of what’s happening, not just within their facilities but their suppliers’ facilities as well.”

Nulogy is distinguished by its cuttingedge solutions that are purpose-built for the external supply chain and developed using the company’s 20+ years of experience in solving problems in this space.

“Purpose-built refers to the fact that we started the business with the question of how we solve supply chain challenges,” emphasizes Barnhart.

Indeed, Nulogy set out to support supply chain operators working with a vast range of brands, each with different processes and requirements. On top of this, the company recognized that the depths of relationships may also differ for each customer.

Christine Barnhart, Chief Industry and Ecosystem Officer:

“My involvement in promoting underrepresented demographics in the supply chain, particularly women, is something I’m pretty proud of.

“I have been one of the biggest supporters of the Women in Supply Chain Forum since its inception. I’m also a big part of the Supply Chain Leaders in Action program that helps women in the industry and an area of concentration in my position on the Association for Supply Chain Management (ASCM) board.

“I think women have come a long way in the supply chain, as I can remember being just one of two women in the room when I started out in manufacturing over 25 years ago, but there’s still a long way to go.

“At the current rate of change, it’s a question of whether the planet will be carbon neutral before women are paid equally to men.

“It’s unacceptable and something I think everyone should be challenging in order to shift the paradigm.”

Nulogy was therefore built to address these complex but all-toocommon obstacles, leveraging its rich background in supply chain challenges, which differs from the broad but limited capability of other solution providers.

“We started with a deep understanding of what it takes to be a manufacturer for somebody else, which I would say is very unique,” she highlights.

“In every decision we make, we’re adding a capability or function and asking ourselves – does the customer, brand, or brand supplier get value out of this?”

As such, the company facilitates better collaboration between customers and suppliers so both sides of the equation extract value from the solution.

Nulogy equally places great consideration into the investments it makes to deploy solutions rapidly and aid suppliers in a cost-effective way.

Typically, ERP implementations can take months or even years, particularly on a global scale. Nulogy, however, has an entirely different mindset, allowing suppliers and brands to obtain the most value.

“We need them talking to each other in a more robust and dynamic way, almost instantaneously. Therefore, we measure the return on investment (ROI) of our solutions in weeks or months to ensure both suppliers and customers are getting value quickly and efficiently,” Barnhart details.

Nulogy is most acutely differentiated by its Smart Factory Solution, an acquisition the company made last year that helps manufacturers manage their facilities more effectively with state-of-the-art machine monitoring and production and OEE tracking capabilities.

The Smart Factory Solution aptly demonstrates how solutions can be deployed efficiently and quickly. It is also incredibly scalable, allowing users to implement additional capabilities as the operation matures.

The solution is also horizontally applicable, meaning that a vast range of manufacturers can benefit from having better visibility of what’s happening at every level.

“Companies can often lose a lot of time during the manufacturing process, which can have a depreciable impact on their capacity. You want these assets to run at peak performance, because if they are not running, companies are not making money.

Nulogy’s staff base is an integral component of the company’s success. Therefore, it regularly rewards employees who go above and beyond in demonstrating Nulogy’s values.

“If you’re not good to the people that work for you and with you, you’re not going to be successful or go very far in my opinion,” Barnhart reflects.

Moreover, the company prides itself on having a flat organizational structure with strong collaboration across all levels and teams.

Nulogy also focuses on hiring people who have strong domain expertise and are humble and collaborative, making a meaningful contribution to workplace culture.

“Having never worked for a Canadian company before, I’ve found Nulogy has the easiest group of people I’ve ever worked with as they are incredibly collaborative and everybody just wants to do their best,” she smiles.

“IN EVERY DECISION WE MAKE, WE’RE ADDING A CAPABILITY OR FUNCTION AND ASKING OURSELVES – DOES THE CUSTOMER, BRAND, OR BRAND SUPPLIER GET VALUE OUT OF THIS?”

– CHRISTINE BARNHART, CHIEF INDUSTRY AND ECOSYSTEM OFFICER, NULOGY

“This is the core of what our Smart Factory Solution does, unlocking the ability to monitor machines on the plant floor, track production, and make data-based improvements,” Barnhart enthuses.

Indeed, the solution makes it quick and easy to deploy methodology, democratizing data and technology for small and medium-sized enterprises alongside big conglomerates.

This year will see Nulogy continue to explore the concept of connected planning, in which it works with key partners to deliver advanced solutions.

In today’s fast-moving world of consumer packaged goods (CPG), companies are under constant pressure to optimize production, reduce costs, and accelerate their time to market. Whether launching a new snack line, beverage, pet food, or health and wellness product, brands need more than just a manufacturer that can churn out products - they need a strategic partner that provides operational efficiency, flexibility, and industry expertise.

That’s exactly what MSI Express brings to the table.

Led by CEO Charles Weinberg, MSI Express is more than just another contract manufacturer. The company has positioned itself as a leader in the space by focusing on engineeringdriven solutions, intelligent supply chain management, and a deep commitment to helping brands scale efficiently.

“Instead of operating as a transactional vendor, we take a holistic approach to manufacturing, ensuring that clients not only receive high-quality products but also benefit from cost optimization, streamlined logistics, and reduced lead times,” says Weinberg.

Many brands enter partnerships with manufacturers expecting a simple exchange: specifications are provided, production begins, and products roll off the assembly line. But MSI Express challenges this conventional model by asking deeper, more strategic questions:

1. Can the product be manufactured closer to its final distribution points?

2. Are there ways to adjust the formulation or packaging to save costs without compromising quality?

3. Could automation be leveraged to improve efficiency without requiring a massive upfront investment?

These considerations set MSI Express apart, making it a true extension of the brands it partners with rather than just another supplier.

“Customers come to us because they trust us to address their needs”

The Power of Strategic Manufacturing

Manufacturing is no longer just about producing goods at scale. In today’s competitive market, it must be done intelligently, efficiently, and with a keen eye on the broader supply chain. MSI Express understands that costs don’t just stem from production itself - they arise from transportation, warehousing, material waste, and logistical inefficiencies.

Take, for example, a food brand which was struggling with high freight costs because its production facility was located in the Northeast while its biggest markets were in the Midwest and West Coast. MSI Express analyzed the situation and proposed a multi-facility approach, shifting a portion of production to strategically located plants. This significantly reduced shipping costs and delivery times, resulting not just in financial savings but also in faster product availability, fewer out-of-stock situations, and improved retailer relationships.

This ability to optimize manufacturing and logistics holistically is one of MSI Express’s key

differentiators. Instead of simply taking orders and producing goods, the company deeply examines a brand’s operational model, finding ways to improve efficiency at every stage of the supply chain.

“Customers come to us because they trust us to address their needs - whether related to supply, quality, pricing, or introducing new products. Our goal is to consistently deliver effective solutions and be the trusted producer of their products. Excellence in providing solutions is at the core of what we do,” says Weinberg.

MSI Express’ success has been attributed to our core principals: safety, quality, and productivity. MSI Express places a strong emphasis on quality control and food safety, operating GFSI-certified facilities that meet some of the strictest industry standards. Rather than reacting to quality issues after they arise, the company employs real-time quality monitoring systems to catch potential problems before they impact production.

For brands in highly regulated industries such as health and wellness, supplements, and pet food, rigorous quality assurance is non-negotiable. MSI Express doesn’t just meet regulatory requirements - it exceeds them, ensuring that every product leaving its facilities is safe, consistent, and ready for market success.

Looking ahead, MSI Express remains proactive, collaborating with clients to identify growth opportunities - whether through capacity expansion, new product development, or line extensions. The company’s goal is to align with customers’ long-term plans, ensuring it has the capacity and innovation needed to support future success.

MSI Express continues to set the standard for what a modern contract manufacturer should be - flexible, innovative, and relentlessly committed to delivering value.

marketing@msiexpress.com www.msiexpress.com

The company partnered with OMP and Kinaxis in 2023 and 2024, respectively, which occurred after many of Nulogy’s FMCG customers wanted better visibility of their supply chain base and therefore needed more connected planning capabilities.

As a result, Nulogy launched its Connected Planning strategy across all departments, functions, and external partners.

This acts as a key building block for end-to-end supply chain orchestration, which is critical to achieving the balance between meeting the demands of customers and needs of stakeholders.

Orchestration through the deployment of technology helps users make real-time, outcomebased decisions, paving the way for the future of supply chain and reducing their impact on the planet.

“Let’s not be a mile wide and an inch deep. By working together, we can figure out what we’re really good at and then cooperate and collaborate to solve problems for our customers in a way that is

easy for them to deploy.

“This is the journey we are on, and Connected Planning is a big part of that,” Barnhart insights.

Nulogy has a wealth of additional technology and implementation partners that are utilized in a number of ways.

For example, the company works with Snowflake for joint development and implementation of technology solutions, harnessing their rich industry knowledge.

“Historically, Nulogy has always done its own implementation, but now, as we expand our portfolio and product offerings, we are actively engaged in recruiting implementation partners to help us scale and engage industries never served before,” Barnhart states.

By working with partners that are

“RATHER THAN QUESTIONING HOW TO DEPLOY AI EFFECTIVELY, WE ASK WHAT THE PROBLEM IS AND WHAT DATA AND AI WE HAVE AVAILABLE TO SOLVE IT”

– CHRISTINE BARNHART, CHIEF INDUSTRY AND ECOSYSTEM OFFICER, NULOGY

embedded in industries the company serves, it can deliver not just the right capabilities but also the best forms of implementation to its customers.

In addition, the creation of Barnhart’s role as Chief Industry and Ecosystem Officer has become the cornerstone of Nulogy’s supply chain strategy, working with key players in the industry such as Gartner, Supply Chain Leaders in Action, and the Association of Supply Chain Management, alongside other masters of the supply chain.

“I work with industry partners and really rich supply chain thought leaders, as well as technology and alliance partners, bringing them all together in an ecosystem to determine what’s happening in the market and how best to solve problems,” Barnhart tells us.

In line with global supply chain evolutions, Nulogy is exploring the vast potential of artificial intelligence (AI) and how it can be used in the future of supply chain management.

“Rather than questioning how to deploy AI effectively, we ask what the problem is and what data and AI we have available to solve it,” Barnhart comments.

With this in mind, Nulogy is developing new capabilities, set to launch later this year, which will better leverage 20 years of historical data as well as real-time information to make better recommendations and prescriptions.

“This will allow us to confidently advise clients on how best to utilize their data to make better decisions every day.

“It will also help reduce waste and labor time while optimizing production and the cost of goods, ultimately satisfying the customer to the best of our ability.”

As Nulogy navigates the future of the North American supply chain, it hopes to expand into new, more discrete industries and verticals, particularly with its Smart Factory Solution.

Market expansion and the deepening of partnerships are also key priorities going forward.

“A big focus for us is the expansion into other parts of Europe. We have a pretty good footprint in the UK, but we believe that we can help broaden the sphere of Europe and Latin America, making geographic expansion a key pillar for the company,” Barnhart concludes.

Tel: +1 (416) 204 0427 info@nulogy.com nulogy.com