For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimize our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

Going forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

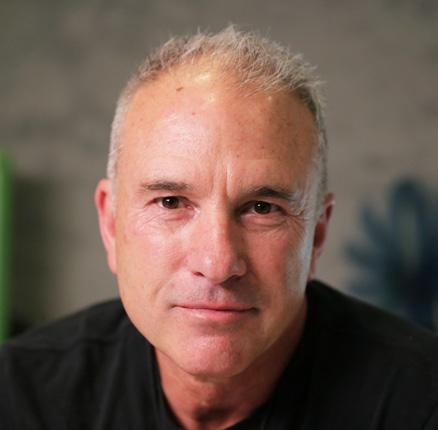

– Ben Weaver, CEO, Outlook Publishing Ltd

EDITORIAL

Head of Editorial: Marcus Kääpä marcus.kaapa@outlookpublishing.com

Senior Editor: Jack Salter jack.salter@outlookpublishing.com

Editor: Phoebe Harper phoebe.harper@outlookpublishing.com

Editor: Lucy Pilgrim lucy.pilgrim@outlookpublishing.com

Editor: Ed Budds ed.budds@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

PRODUCTION

Production Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Designer: Sophs Forte sophs.forte@outlookpublishing.com

Junior Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Assistant: Megan Cooke megan.cooke@outlookpublishing.com

Digital Marketing Manager: Fox Tucker fox.tucker@outlookpublishing.com

Social Media Executive: Bria Clarke bria.clarke@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

BUSINESS

CEO: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Sales Director: Nick Norris nick.norris@outlookpublishing.com

Commercial Director: Joshua Mann joshua.mann@outlookpublishing.com

REGIONAL DIRECTORS

David Knott david.knott@outlookpublishing.com

Tom Cullum tom.cullum@outlookpublishing.com

PROJECT MANAGERS

Felix Revell felix.revell@outlookpublishing.com

Lauren Robinson lauren.robinson@outlookpublishing.com

Louis Locke louis.locke@outlookpublishing.com

Michael Sommerfield michael.sommerfield@outlookpublishing.com

Scarlett Burke scarlett.burke@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT DIRECTOR

Marvin Iseghehi marvin.Iseghehi@outlookpublishing.com

SALES & PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

SALES MANAGERS

Alfie Wilson alfie.wilson@outlookpublishing.com

Jordan Sibley jordan.sibley@outlookpublishing.com

Krisha Canlas krisha.canlas@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

CONTACT

North America Outlook Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +44 (0) 1603 363 631

Editorial: +44 (0) 1603 363 655

SUBSCRIPTIONS

Tel: +44 (0) 1603 363 655 marcus.kaapa@outlookpublishing.com www.northamericaoutlookmag.com

Like us on Facebook: @northamericaoutlook

Follow us on Twitter: @NA_Outlook

Welcome to our latest issue of North America Outlook magazine!

In this 18th edition, we take a look at the pressing importance of industrywide decarbonization developments. Whether operating in the transport, healthcare or technology sectors, efforts exist to bring about a low carbon future for the region and build a healthier and happier world.

Beyond the sustainability space, our cover feature is one that truly encapsulates happiness; Canada’s Wonderland has been creating amusement all year round since 1981 and has entered this decade with a bang, bringing with it fun for everyone.

“We have great thrill rides and exciting roller coasters, but we also provide great experiences for families with our children’s areas and 20-acre water park,” opens Phil Liggett, Vice President and General Manager. “Helping to create that fun and those memories is the best part of what we do at the park every day.”

On top of this, and fitting with this month’s July 4th celebrations, we take to the freedom of the waves with Saltchuk Marine, proudly serving the US with its seafaring fleet of reliable, versatile and responsive tugboats.

“We provide rescue tows around the world and emergency response when called upon. As proven by the COVID-19 pandemic, we are an essential service that keeps the wheels of commerce turning,” details Jason Childs, President and CEO.

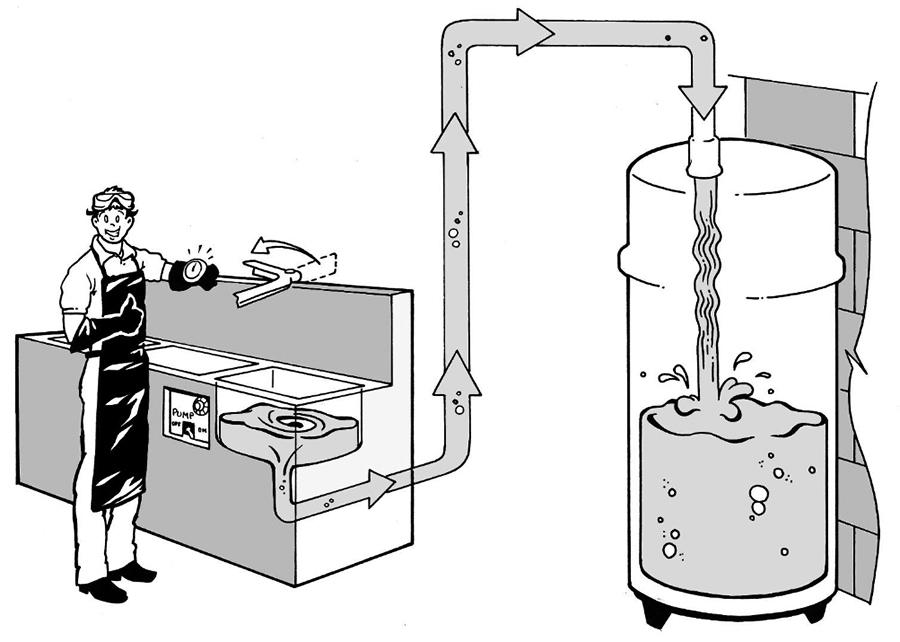

Elsewhere, dive into the secrets of logistical streamlining with UPS Supply Chain Solutions®, sustainable foodservice practices with Mahoney Environmental, aircraft turbine applications with Moeller Aerospace, innovative gas systems with Galileo technologies, and many more.

We hope you enjoy your read.

Marcus Kääpä

Head of Editorial, Outlook Publishing

FOLLOWING A GLOBAL crackdown on account sharing from brands such as Netflix, Costco has decided to follow suit and take preventive measures into its own hands.

The US retail behemoth is clamping down on shoppers craftily sneaking into its stores and trying to do their shopping with other people’s membership cards.

Having always employed the policy

of asking shoppers for their membership cards at the cash registers before they pay, customers will now be asked to show a photo ID to prove the membership is their own.

Costco stands apart from most retailers because of its unique business model, as the bulk of its earnings stems from membership fees, which help to keep product prices extremely low.

THE AUTOMOTIVE INDUSTRY isn’t the only sector going electric. A new environmentally friendly trend is sweeping the US in the form of battery-powered leaf blowers, grass mowers, and string trimmers. These electric-powered outdoor tools have started to dominate neighborhoods and golf courses around the country, as part of the transition away from gas power.

Home Depot recently estimated that the market for electric tools and related battery sales is $32 billion and counting. However, there are still obstacles to adoption as batterypowered leaf blowers and mowers can be much more expensive than their predecessors.

DELTA HAS BEEN crowned the best US airline at the ‘Oscars of Aviation’, the Skytrax World Airline Awards.

The ceremony was hosted at the Paris Air Show and ranks 325 airlines across a variety of comprehensive categories, using data from survey responses.

The 23rd iteration of the annual

awards ceremony at the Air and Space Museum in Paris featured numerous senior figures in the aviation industry and airline CEOs in attendance.

Delta Air Lines took home the award for number one carrier in North America for the second year in a row, climbing the overall global rankings from 24th to 20th.

So far 2023 has welcomed several prestigious accolades for Delta, with the Wall Street Journal declaring it the top US airline of 2022 back in January.

AUTOMOTIVE FOLLOWING DRAMATIC PRICE slashes, Tesla has delivered a record number of vehicle sales in its second quarter, topping all market estimates, as its strategy to lower prices has paid off and US consumers have taken full advantage.

The American carmaker has comprehensively beaten market expectations and delivered 466,140 cars in three months, an increase of 10.4 percent in the first three months of the year.

Affordability was previously identified by CEO, Elon Musk as a key factor that was limiting sales. As

AEROSPACE

AMERICAN SPACEFLIGHT

COMPANY, Virgin Galactic’s rocket ship has taken passengers more than 50 miles above the Earth’s surface to the edge of space. Furthermore, British billionaire Sir Richard Branson’s private company has finally completed its maiden commercial flight.

a result, the cost of Tesla’s vehicles was reduced to keep the company competitive with rivals, as traditional carmakers continue to boost their electric vehicle production.

to the experience of around five minutes of weightlessness, allowing them to float freely around the cabin.

Branson wants to give people the opportunity to explore the universe through his spaceflight brand after completing a similar trip himself back in July 2021, and becoming the first owner of a private space company to jet into space.

Flights will soon initiate for the 800 people who’ve bought tickets for the rocket so far, with each seat costing

ACCORDING TO THE latest environmental analysis, four of the five cities with the worst air quality in the world are in North America, including New York City, Toronto, Montréal, and Washington D.C.

This shocking discovery has not been helped by the devastating forest fires across Canada that have sent smoky air swarming across the continent, engulfing many cities.

New York City now possesses the second-worst air quality in the world with a recorded air quality index of 162, behind only Jakarta in the rankings. At present, anything exceeding an AQI of 150 is considered unhealthy and potentially harmful air.

FOOD & BEVERAGE

FOR PIZZA LOVERS craving a taste of their favorite takeaway while sunbathing on a beach or relaxing in a public park, Domino’s Pizza is aiming to transform its delivery service to be as easy and accessible as it is when at home.

With the unveiling of its new pinpoint delivery service, customers can now order Domino’s nationwide across the US to locations without a standard address. Pizza lovers can fol low their orders in real-time using the company’s tracking service, access a driver’s GPS location and receive text alerts about the delivery’s progress.

delivery technology in Australia in 2017, but the pinpoint delivery rollout will make the feature available for the first time in US markets.

As the US confronts the urgent need to tackle climate change and transition to a low-carbon future, the development of gigafactories – industrial plants which produce advanced lithium-ion batteries – has emerged as a pioneering solution. Gigafactories are state of the art facilities that have the potential to decarbonize crucial sectors of the economy where lithium-ion batteries can provide power. These sectors include transport, data centers, and renewable energy infrastructure.

Heading up the American transition to a low-carbon future, Lars Carlstrom, Founder and CEO of Statevolt and Italvolt, discusses one of the most impactful developments underway today –gigafactories

Written by: Lars Carlstrom, Founder and CEO of Statevolt and Italvolt

Written by: Lars Carlstrom, Founder and CEO of Statevolt and Italvolt

The future success of decarbonization in the US will rest upon the ability of the country to dramatically cut the emissions from highly polluting sectors. A prime example is transport; the sector accounted for 29 percent of greenhouse gas (GHG) emissions in the US in 2021, significantly exceeding emissions from industry, which accounted for 23 percent. Producing lithium-ion batteries at scale will be crucial to support the decarbonization of the US economy. Furthermore,

ensuring the US can meet its energy transition goals independently is essential to guarantee the security of supply and remain competitive on a global scale. Establishing a strong US footing in the battery production field will help counter China’s dominance in the electric vehicle (EV) supply chain and manufacturing process.

Gigafactories can lay the foundation for modern, future-proof industry in the US. As large-scale and technologically advanced battery plants, gigafactories have the potential to redefine the industrial landscape for states that build them. The highly complex and technological process for battery development requires specialist skills which can help attract talented workers to the facility’s location and help create opportunities for existing workers in the region – each factory can create thousands of highly-skilled jobs. This is especially true for gigafactories planned for development in the industrial heartlands of the Southern and Midwestern US, where workers possess deep existing knowledge in automotive or heavy industries, allowing them to upskill or develop entirely new capabilities.

In addition to upskilling workers, gigafactory development can provide wider economic benefits in the communities where they are built. Statevolt, the company I founded and currently run as CEO, is building its gigafactory in Imperial Valley, California, and will serve to illustrate how gigafactories have the potential to revitalize underdeveloped communities. Due to their scale and highly advanced manufacturing processes, gigafactories can be economic engines that empower local communities and create highquality jobs. Statevolt is focused on supporting growth and regeneration in the area, with an ambition to provide direct employment for up to 2,500 people in the Imperial Valley community.

To further reduce carbon emissions from gigafactory and lithium-ion battery development, Statevolt is pioneering a ‘hyperlocal business model’, which aims to rely on local sourcing, processing, and production to produce lithium-ion battery cells that are made in the US from start to finish. The result will be a local and reliable supply chain that eliminates dependence on foreign sources while reducing the net carbon footprint. Given the level of capital required to start a gigafactory, each project represents a huge investment in the region. GlobalData research estimates that between $106 billion and $177.6 billion is set to be invested in gigafactories worldwide between 2020 and 2030. Gigafactories can provide significant direct and indirect economic opportunities for local communities, as well as adjacent industries which supply gigafactories and the needs of their employees. The gigafactory Statevolt is currently developing aims to create 2,500 full time jobs for people in the Imperial Valley region.

The plan to build gigafactories across the US will not be without its challenges, notwithstanding the large capital expenditure required to kickstart production. However, as the demand for EVs and energy storage rises over the coming decades, there is a strong imperative to accelerate gigafactory development. States such as California have implemented bans on the sale of new petrol and diesel cars from 2035, as a means of accelerating the switch towards battery powered EVs by 2035. As such, lithium-ion powered EVs are the only realistic alternative.

According to the International Energy Agency’s (IEA) Sustainable Development Scenario, for the world to meet climate and sustainable energy goals, close to 10,000 gigawatt hours (GWh) of batteries and other forms of energy storage will be required worldwide by 2040, which is around

50 times the size of the current market. For us to meet net zero targets while securing a just transition, we must look towards gigafactories as the solution.

The development of gigafactories across the US will make the shift to net zero a sustainable and efficient reality while strengthening the US’ automotive industry.

A hyper-local business model which narrows the distance between producers and consumers can further advance these aims, creating a positive, long-term economic future for people and economies throughout the continent.

Lars has over 30 years’ experience in the automotive and batteries sector, including as the Former Chairman of Britishvolt. He is currently the Founder and CEO of Statevolt and Italvolt

Statevolt

Founded in 2021, Statevolt’s vision is to be a leading player in the energy transition for a more sustainable future. Statevolt’s mission is to ensure that American communities and workers reap the benefits of the clean energy economy by building battery gigafactories in strategic US locations and pioneering a hyperlocal model that prioritizes sustainability and a domestic supply chain.

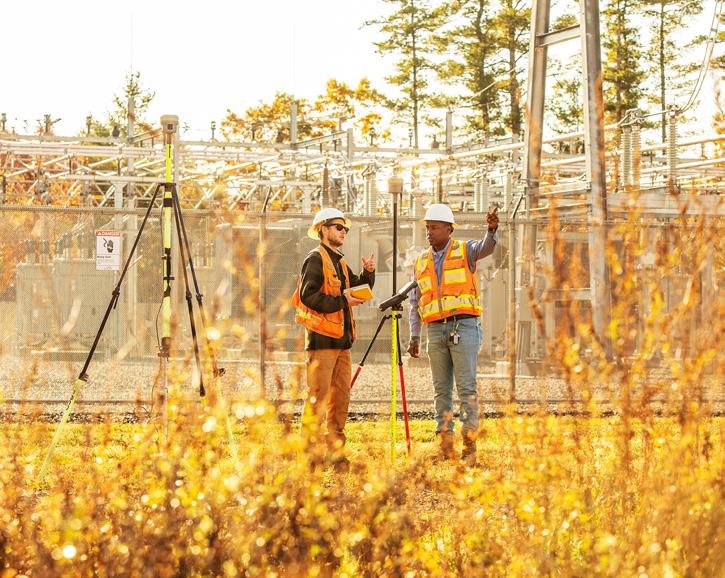

We speak to Richard Matonich, Regional Division Manager for Large Motors and Generators at ABB, about the latest decarbonization technologies for industries across North America

Writer: Marcus Kääpä

Writer: Marcus Kääpä

Electric motors are essential to a multitude of industries, but they are also major consumers of the world’s energy. Fortunately, high-efficiency motor technology is now available that is both good for sustainability and profitability.

It comes as no surprise that global industries are a major contributor to carbon emissions. Four in every 10 tons of coal are burned to power industry, and 42 percent of all electricity generated worldwide is used by industrial facilities. Decarbonization to reach net zero carbon emissions by 2050 therefore requires industry activity around the world to adapt.

Yet there is no single solution that will transform industries. Instead, it will be a combination of many technologies and approaches. Some, like the large-scale implementation of hydrogen, are not yet mature. Others, such as energy efficiency, are available for businesses to act on today, bringing us significantly closer to net zero. The International Energy Agency (IEA) calls energy efficiency “the first fuel –the fuel you do not have to use”.

“Fortunately, according to March 2023 Energy Insights report, 97 percent of the 2,300 leaders of industrial businesses surveyed plan on improving energy efficiency,” begins Richard Matonich, Regional Division Manager for Large Motors and Generators at ABB. “There exist steps that businesses can take today to bring us closer to net zero.”

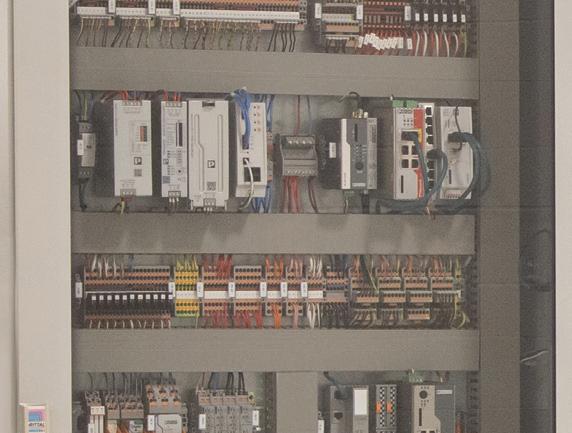

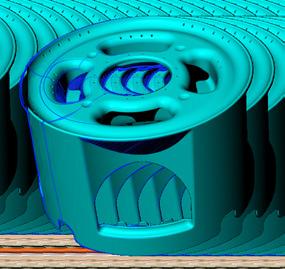

When looking for opportunities to improve efficiency, the electric motor is a logical place to start. Electric motors are common across industries – they power fans, compressors, pumps, conveyors, and all sorts of other machinery – and are highly energy-intensive.

“Collectively, the world has more

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s 105,000 employees are committed to driving innovations that accelerate industrial transformation.

ABB not only advocates for a decarbonized future but also develops innovative solutions to reduce carbon footprint and minimize environmental impact. For example, the company recently launched the new generation AMI 5800 NEMA modular induction motor, which offers energy efficiency and reliability in demanding applications across various industries. Additionally, ABB has introduced the Top Industrial Efficiency (TIE) initiative, ensuring the availability of optimal large motor and generator solutions that offer the highest efficiency without compromising reliability or utilizing unproven technology.

the machines they power consume approximately 45 percent of all electricity generated. Further, the number of motors is expected to double by 2040,” Matonich tells us.

“Large industrial motors, in particular, must be a focus of efficiency efforts. Although these motors account for less than one percent of all electric motors, they use 23 percent of the electricity. In many cases, the larger the motor, the greater the potential for energy efficiency measures.”

Fortunately, motor technology has advanced rapidly. Today’s motors are even significantly more energy efficient than models from just five to 10 years ago, enabling facilities to greatly reduce the amount of power they use. This also has significant benefits in terms of energy security and operating expenditure (OpEx), especially during periods when electricity prices are high.

The global drive for more efficient motor technology is, in part, advanced

by authorities implementing minimum efficiency standards. These create market pressure for more efficient solutions, and many manufacturers work to develop solutions that exceed the minimum. This futureproofs end users against potential additional legislation and enables even greater energy savings.

For example, the latest generation AMI 5800 True NEMA motor is designed specifically for the North American market and achieves outstanding energy efficiency. All AMI 5800 configurations meet North American energy efficiency standards, and most configurations exceed them. Some even achieve efficiency greater than the IE4 equivalent “super-premium” level while still meeting NEMA standards.

However, unlike small and mediumsized motors, large motors in the tens of megawatts are not subject to minimum energy performance standards (MEPS). This is unfortunate, as efficiency is especially important in large motors – their power ratings are so high that tens of kilowatts can be saved with even relatively small efficiency improvements. Small decreases in the amount of power used also add up over time, which is significant as many large motors run for over 8,000 hours each year.

To address the lack of MEPS, ABB has launched the Top Industrial Efficiency (TIE) initiative to provide motors that meet the highest efficiency standard. TIE motors are no-compromise solutions that rely on proven technologies.

A common misconception is that energy efficiency is expensive –according to the Energy Insights Report, 33 percent of businesses list cost as a major obstacle to efficiency. Yet, in reality, greater energy efficiency results in direct savings.

“This design also offers a range of other benefits, including rugged reliability. It has a welded steel frame, which lowers stress on the motor and reduces vibrations. As a result, it is suitable for highly demanding applications, such as within the oil and gas, mining, cement, and metal industries,” Matonich explains.

“The AMI 5800 NEMA is compatible with common mechanical mounting standards and entirely modular in terms of cooling methods, bearing, shaft extensions and terminal boxes. This makes it ideal for new installations and retrofits of existing ones.”

“For example, 97 percent of the total cost of ownership (TCO) of a motor goes to the electricity required to power it. Considering motors typically last for 15 to 20 years, the potential savings are significant. Therefore, while more efficient motors may be slightly more expensive up front, they are far cheaper in the long term,” Matonich concludes.

“In this way, businesses can play their part in our global journey to net zero and reduce the operating costs associated with energy consumption – a genuine win-win. All we need now is for forward-thinking operators to take the initiative and begin making energy efficiency a top priority on the road to decarbonization.”

Writer: Jack Salter

Writer: Jack Salter

North America Outlook (NA): Why is pressure growing on the US healthcare industry to lower its carbon footprint?

Reeve Benaron, co-Founder and co-CEO (RB): Being honest, the US healthcare industry (and the global one for that matter) has historically been overlooked in terms of its environmental impact. Medicine packaging, COVID-19 test kits, and the medical instruments used in hospital settings are typically seen as exempt for their negative green impact (plastics, nonbiodegradable chemicals in products). Saving lives takes priority and precedent.

But things have been intensifying and changing for a while in terms of environmental scrutiny on private medical product suppliers and the practices of US hospitals, which is a good thing. The US healthcare industry is reportedly responsible for 8.5 percent of total carbon emissions in the country, with pollution rates from the sector increasing.

A large bulk of this is from the initial supplier side of products and services. Immense carbon emissions generated from energy-intensive facilities in drug production is commonplace (medicine manufacturing plants also often run 24/7). Then, you have the constant production of new medical devices, i.e., pacemakers, cardiovascular monitoring equipment, hemodialysis machines, and CT scanners, and manufacturers are always trying to outdo one another and lead the way in competitor innovation. Medical devices are always quite quickly upgraded if the budget is available from the healthcare setting and older versions of MedTech are disposed of quite quickly, leading to mass volumes of healthcare e-waste across the US industry.

Also, with the obvious focus being on saving people’s lives, healthcare settings are typically quite wasteful and discardable with their medical implements. This is usually for sanitation reasons, but it has strong recycling

hospital kitchens.

With this in mind, and the touted 8.5 percent of US carbon emissions generated by the country’s healthcare industry, it’s clear we have problems to address. That’s why we’ve seen the National Academy of Medicine (NAM) launch the Action Collaborative on Decarbonizing the US Health Sector initiative, and huge US MedTech providers such as Cardinal Health and pharmaceutical firms like Eli Lilly and Company really ramping up their carbon emission sustainability programs, mainly to negate carbon footprints causing issues in RFP/tender processes.

NA: How is climate change affecting the ability of the US health system to deliver safe, effective, and efficient care?

RB: Naturally, it is making provision of medical products and healthcare supply more complicated, as it’s another factor for healthcare boardrooms to tackle for external stakeholders. Pharmaceutical companies will have the biggest challenges from regulators, given the scale of pollution created in mass market drug production. But like I say, we can’t stop delivering life-saving

DIAGNOSTICS

DIAGNOSTICS

person-centered healthcare for the service user. The pressure from regulatory bodies and ‘green consumer movements’ should push healthcare providers (mainly hospitals) to further invest in MedTech such as e-appointment bookings, e-prescription services, telehealth products, and health information technology portals. This will help healthcare providers overserving and over-medicating service users, or more ideally, help to give US consumers information on healthy lifestyles and self-management of their ailments and personal health, avoiding having to treat them in the first place. Preventive health services are key for efficient US healthcare and for healthcare sustainability initiatives.

NA: What benefits are there to reducing the carbon footprint of the healthcare ecosystem, and what are hospitals in the US doing to lower

Carbon curbing initiatives, such as e-waste audits on medical utensils and medical devices, naturally help achieve cost savings in healthcare settings, so that’s pretty obvious. Social benefits in my eyes will mainly be a company’s marketing strength – where MedTech/pharmaceutical companies are able to prove green credentials to secure tenders or contracts and achieve more revenue. healthcare industry will look like better preventive, personalized,

“TRUE SUSTAINABILITY IN THE HEALTHCARE INDUSTRY WILL LOOK LIKE BETTER PREVENTIVE, PERSONALIZED, PERSON-CENTERED HEALTHCARE FOR THE SERVICE USER”

– REEVE BENARON, CO-FOUNDER AND CO-CEO, INTRIVO

Tighter recycling processes and policies in US hospitals are steadily coming along. Reusable personal protective equipment (PPE) is pretty significant nowadays, and tendering processes for suppliers to supply drugs and medical devices are tightening up too. Some US hospital kitchens are trying ‘Meatless Mondays’, but I’m not sure what the carbon efficacy of that will be!

NA: How much more needs to be done to decarbonize the industry?

RB: Quite a lot is required I believe, and regulatory bodies need to interject with tighter policy enforcement if possible. The

Driving forward the nation’s sustainable commitments, the U.S. National Blueprint for Transportation Decarbonization strives to cut all greenhouse gas emissions by 2050, an ambitious but achievable objective

Writer: Lucy PilgrimThe US government has begun to take bold steps in transforming the environmental footprint of the transportation sector, as set out by the recent implementation of the U.S. National Blueprint for Transportation Decarbonization (Blueprint). The influential policy proposed by the Biden administration sets an international precedent for a governmental commitment to decarbonizing the transport sector by 2050.

Implemented in September 2022, the historic memorandum of understanding (MoU) champions a

synergy between the Environmental Protection Agency (EPA), the Department of Energy (DOE), Department of Transportation (DOT), and the Department of Housing and Urban Development (HUD). Following a targeted approach, the Blueprint seeks to address the transportation sector as the greatest contributor to carbon emissions. It covers all forms of transportation – including land, air or sea – and accounts for a third of the country’s green house gas (GHG) emissions. Evidently, the holistic approach of the Blueprint signifies how the

environmental responsibilities of the nation have become a primary focus in recent years, emphasizing that the commitment is not an aspiration, but an eventuality.

The Blueprint tackles three strategic areas to reach a state of decarbonization by 2050, which span all passenger and freight transportation elements. For each branch of the Blueprint, a short, medium and long-term goal is established, divided into 10-year segments.

Furthermore, it is projected to be a valuable resource for the multitude of stakeholders involved in the US transportation industry, as companies have begun to work in tandem with federal agencies. This is encouraged through necessary research, publicprivate partnerships, and training schemes, amongst other initiatives. Consequently, the Blueprint ensures that the revitalized transport sector will yield benefits such as reducing air pollutant emissions, enhancing sustainable urban planning and

advancing environmental justice objectives.

The short-term initiatives outline greater funding and authority implemented by the Blueprint, to spur a sector-wide transition to zeroemission vehicles and the increased use of sustainable fuels. Subsequently, the medium and long-term objectives herald the increased use of sustainable transportation solutions, brought to the helm by new policies, targeted investment, partnerships, and programs.

Convenience: The Blueprint supports community design, at both a regional and local level, through diligent land-use planning. Subsequently, common amenities and infrastructure such as shops, schools, offices, entertainment and more are purposefully located close to densely populated areas.

Efficiency: Alongside this, public transport and rail, would be restructured to improve efficiency, accessibility and affordability.

Clean: The Blueprint drives the

The first instruction of the Blueprint stands as a widespread transitioning to clean vehicles, conducive to the fact that the large majority of generated emissions stem from light, medium and heavy-duty vehicles, as well as buses and aircraft.

As such, the adoption of batterypowered vehicles is one of the most dynamic and effective strategies to decarbonize the transportation sector. This also aligns with President Biden’s environmental objective stated in 2021, in which 50 percent of vehicle sales will be zero-emission by 2030.

As the primary solution of meeting net zero by 2050, the use of batterypowered and electric vehicles (EVs) is supported by the by the long-term option of using hydrogen and biofuels, particularly for heavyduty vehicles and in more rural communities.

In regard to aviation, a similar ethos of using biofuels, hydrogen and methanol is encouraged as fossil fuel alternatives. The Blueprint absorbs many targets proposed by the Biden administration’s Sustainable Aviation Fuel Grand Challenge Roadmap, which dictates targets of reducing aviation emissions by 20 percent by 2030.

A significant Blueprint component

document calls on local governing bodies to incorporate sustainability into community decision making. This means consolidating different modes of transport and navigating the balance in the movement of people, goods and services. As a result, commuting burdens will be reduced, with improved walkability and cycling services.

The Blueprint further proposes federal agency intervention in local decision making around transportation and planning. In fact, it bolsters ideas around ‘smart planning’ - outlined as the relocation of renewable infrastructure including public vehicle charging stations and renewable energy facilities.

The final subsector to the Blueprint is the advancement of vehicle and system initiatives that increase the frequency of environmentally friendly passenger transportation, ranging from trains to personal vehicles.

The document suggests an expansion in funding and incentives for the use of sustainably efficient vehicles, compounded with greater investment in the advantages of rail and mass passenger transit.

Due to the fact that individual modes of transport are typically decided through personal choice, the Blueprint advocates for employers and schools to adopt policies and programs which incentivize

NORTH AMERICA OUTLOOK is a digital product aimed at boardroom and hands-on decision-makers across a wide range of industries on the continent.

With content compiled by our experienced editorial team complemented by an in-house design team, the resultant Outlook Creative Services department ensures delivery to the highest standards in promoting the latest in engaging news, industry trends and success stories across the length and breadth of the US & Canada.

As a bi-monthly publication, North America Outlook constantly has its finger on the pulse of the latest trends, biggest developments and business successes from each corner of the region, epitomized by the diversity displayed across each magazine. It incorporates an annual calendar-tailored front-of-book section, a showcasing segment dedicated to the most fascinating success stories in North America, and an event focus assortment sure to fill executives’ diaries throughout the year. The aligning North America Outlook website is also honed and ready to serve as a host for these facets and much more.

To get involved, please contact Outlook Publishing’s Managing Director, James Mitchell, who can provide further details on how to feature your company, for FREE, in one of our upcoming editions.

Diving into the Caribbean region, we take a look at Curaçao as a tranquil and strategic gem for investment, connecting Europe to the Americas

Writer: Marcus Kääpä | Project Manager: Krisha Canlas

Writer: Marcus Kääpä | Project Manager: Krisha Canlas

Blessed with the enthralling beauty of azure Caribbean waters, white sand beaches, and a divine climate, Curaçao is marked out as a unique country within the paradisal region by a blend of European influences.

In centuries past, Portuguese sailors injured or stricken with illness were left to recover in the care of the island. Diseases such as scurvy were remedied by a change in diet, likely one that included vitamin C, with the country taking its name from the Portuguese curação, meaning “cure”.

From its status as a place of rest and recovery and its nickname as the “Island of Healing”, Curaçao’s historically strategic location off the northern coast of Venezuela marks it as a hub between the Americas and Europe. Indeed, the island has long drawn European attention, with a lasting Dutch colonial past apparent throughout the nation’s architectural footprint.

Today, Curaçao presents itself as an excellent destination for visitors wishing to experience the island’s natural tranquility and Dutch-Caribbean culture, yet the country also attracts attention from businesses seeking investment opportunities in the region. Based outside of the hurricane belt, Curaçao benefits from many ports, a natural and well-developed deep-water harbor, and frequent flights connecting the island to multiple continents. Curaçao’s economic stability and multilingual culture are bolstered by the island’s significant digital infrastructure, boasting 86.7 percent internet penetration, multiple data centers including the only Tier 4 data center in the Pan-Caribbean region, and a highly skilled talent pool.

With attractive offers available to tourists and businesses alike, Curaçao continues to position itself as an investment opportunity for international enterprises and an active hub within the Caribbean.

North America Outlook (NA): Could you briefly introduce us to CINEX?

Jeanette Bonet, Interim CEO (JB): As the authorized investment and export promotion agency for the government of Curaçao, CINEX focuses on attracting foreign investments and promoting the export of local products and services. Since its establishment in 2014, CINEX has been dedicated to fostering economic growth and development on the island. Its approach integrates investment and export promotion under one umbrella, allowing for a coordinated strategy to drive economic progress.

Investment promotion involves providing comprehensive information and assistance to investors throughout the entire investment process while promoting the country's investment opportunities, incentives, and positive image. CINEX aims to attract investment by facilitating and guiding investors in establishing their businesses in the country. We promote the country as an appealing investment destination, target investors based on identified needs, and advocate for policy reforms to facilitate investment on a broader scale.

Export promotion, on the other hand, supports

We speak with Jeanette Bonet, Interim CEO of CINEX, about bringing business and international investment interest to Curaçao

and promotes exports from local companies. CINEX assists domestic businesses in expanding globally by helping them identify new markets, providing market intelligence and research, and offering support with export documentation and logistics. They also encourage participation in international trade fairs and exhibitions to showcase products and services to a global audience.

CINEX works closely with the Ministry of Economic Development, the Curaçao Chamber of Commerce and Industry, Curinde, and other governmental entities to implement government policies on international trade and investment. CINEX also participates in regional investment promotion through its membership in the Caribbean Association of Investment Promotion Agency (CAIPA). This collaboration ensures streamlined efforts and the fulfillment of our mandate.

Finally, CINEX emphasizes the importance of promoting sustainable development. We are committed to encouraging socially responsible and environmentally sustainable investments, ensuring that economic benefits derived from foreign investment align with these principles.

CINEX’s mandate has remained unchanged over the years; rather, it has grown stronger and more firmly established as the organization has evolved.

NA: Why should entities invest in Curaçao, and how does CINEX attract investment to the island?

JB: Curaçao offers various investment incentives including favorable corporate tax rates, tax holidays for investment in most businesses, e-zone regimes, preferential access to the EU (OCT) and US (CBI), and zero percent profit tax for intangible assets. Considering these combined benefits, including its vibrant culture and natural beauty, Curaçao is becoming increasingly popular as an investment destination for entities looking for long-term success, and there are many sectors that hold significant investment opportunities on the island.

The tourism and hospitality sector plays a crucial role in the island's economy, with a focus on luxury resorts, cruise tourism, and eco-tourism. Elsewhere, investment opportunities exist in hotel development, resort expansion, recreational facilities, and eco-friendly tourism initiatives. In the finance sector, Curaçao is also a well-established international financial center, providing a range of services, including offshore banking, insurance, trust management, and international trading. Investors can explore opportunities in banking institutions, insurance companies, financial technology (FinTech) start-ups, and support services.

Curaçao's own research showcases the growing information and communication technology (ICT) sector on the island, supported by modern telecommunications (telecoms) infrastructure and a highly skilled workforce. According to this research, various governments around the world, including Anguilla, Dominica, Peru, Ghana, Greenland, Marshall Islands, Samoa, and Vanuatu, are already utilizing software systems developed and supplied by companies in Curaçao. This serves as a testament to the abundant talent available in Curaçao. Investment opportunities are particularly promising in areas such as software development, data centers, information technology (IT) consulting, cybersecurity, e-commerce platforms, and telecoms services.

The island’s advantageous geographic position in the Southern Caribbean makes it a prime hub for logistics and international trade. With its expansive deep-water port, Curaçao offers abundant prospects in shipping, transshipment, warehousing, distribution, and logistics services, catering to the needs of businesses operating in the region. Curaçao boasts two free economic zones and one industrial park, with plans underway to establish an additional industrial park any time soon. Our e-zone regime presents an attractive opportunity for companies seeking to utilize Curaçao as a strategic hub for operations spanning the Americas, Europe, or other global destinations.

Despite its arid climate, Curaçao is also actively promoting agricultural diversification and sustainable farming practices. Investment opportunities exist in hydroponics, aquaponics, organic farming, agroprocessing facilities, and the production of specialty crops for local consumption and export.

NA: Can you tell us about the advantages of Curaçao's location for sustainable business and creative industries?

JB: The country is making significant strides in reducing its reliance on fossil fuels and embracing sustainable energy sources. Currently, 40 percent of Curaçao's energy production is derived from renewable sources, specifically wind and solar power. This achievement marks a substantial milestone in Curaçao's transition towards cleaner energy. Moreover, the nation has set its sights on reaching the 50 percent mark in the near future.

Curaçao's commitment to renewable energy is further exemplified by its recent signing of a Memorandum of Understanding (MoU) with the government of the Netherlands. This collaboration aims to promote the development of renewable energy and facilitate the establishment of offshore wind turbines. By undertaking such initiatives, Curaçao is poised to become a trailblazer in the Caribbean region, leading the way in sustainable energy practices.

“CINEX EMPHASIZES THE IMPORTANCE OF PROMOTING SUSTAINABLE DEVELOPMENT”

-JEANETTE BONET, INTERIM CEO, CINEX

Over the past 38 years, Curoil has evolved from a local fuel distributor to a regional supplier of fuel products and services, with a strong foothold in the Southern Caribbean region. Curoil has fuel operations on the islands of Aruba, Bonaire and Curaçao (The ABC Islands). As the company continues to expand its wings throughout the region, Curoil is committed to maintaining the same high standards that have earned it the reputation of being a reliable fuel supplier in the Caribbean.

At present, the commercialization of fossil fuels remains Curoil’s dayto-day focus, however it acknowledges that the world is transitioning from fossil-based systems to renewable energy sources. Hence, the company continues to invest in research on alternative energy, stimulate the dialogue on environmental laws and contribute to policy change on a local level. Curoil’s aim is to be the preferred choice among the top-rated Caribbean suppliers of energy products and services while creating sustainable value for its stakeholders and the communities in which it operates.

As we navigate the challenges of the 21st century, Curoil is committed to being part of the transformation of the energy sector for a better and more sustainable future. By investing in renewable energy solutions and exploring alternative fuel options, Curoil is setting the stage for a greener and more sustainable future for Curaçao.

STRATEGIC VISION:

After conducting a comprehensive strategic analysis, Curoil has identified three key areas of focus that will shape its path towards a sustainable future:

1. Production of green hydrogen and other energy carriers by offshore floating wind for export

Curoil recognizes the immense potential of green hydrogen and other energy carriers generated through offshore floating wind technology and shares the vision of the government, for Curaçao to become the regional leader in the production and export of green energy.

Looking ahead, Curoil’s participation in this government-led project, which focuses on offshore floating wind technology, highlights the company’s dedication to innovation and research. By actively engaging in this initiative, Curoil aims to advance offshore wind technology and the large-scale production of green hydrogen and

energy carriers, driving progress and accelerating the transition to a sustainable energy landscape in the Caribbean region and connecting to increasing global demand for renewable energy sources.

2. Feedstock import for biodiesel production and export

As part of its commitment to diversifying its energy portfolio, Curoil will prioritize the import of feedstock for biodiesel production. This initiative aligns with Curoil’s dedication to environmental responsibility while simultaneously positioning the company as a leading player in the global biodiesel market.

3. Expansion of wind and solar energy

Recognizing the growing significance of wind and solar energy in the global energy transition, Curoil aims to expand its investments in these renewable sources. Through financing for instance solar solutions, the company seeks to accelerate the adoption of solar energy systems, paving the way for more availability and affordable renewable energy resources. This strategic direction underscores the company’s determination to promote renewable energy and reduce reliance on conventional fossil fuel-based power generation. In addition to these three areas, Curoil is actively exploring other renewable products, such as waste oil processing plants. Also, the company is conducting additional market research to meet the growing demand for E-Methanol in the maritime sector and Sustainable Aviation Fuel (SAF) in the aviation sector.

In conclusion, Curoil’s strategic analysis has laid the foundation for a forward-thinking and sustainable future. Through its focus on green hydrogen, biodiesel production, wind and solar energy expansion, and collaboration with waste oil processing plants, Curoil is poised to significantly impact the energy sector while ensuring environmental responsibility. With these strategic pillars in place, Curoil is leading the way towards a cleaner, greener, and more prosperous tomorrow.

Ideally located at the crossroads of trade routes between South America, the US and Europe, Curinde believes that Curaçao is the prime logistical hub for successful business in the Caribbean

What makes Curaçao one of the most prosperous islands in the Caribbean?

As an autonomous country in the Kingdom of the Netherlands, Curaçao offers a balanced business and leisure environment. Curaçao is considered a politically stable and safe country that offers ISO certified business parks, a good financial sector, state of the art telecommunication infrastructure and a multilingual population, making it a safe place for conducting business.

developer of four business parks in Curaçao, Curinde guides and assists those interested in establishing a company with fast and accurate advice regarding the procedures for incorporating and starting a business in one of its business parks. Its philosophy is to provide the highest quality facilities to businesses on the most competitive terms.

By reaching their objectives, how do trading and production companies contribute to the sustainable economic and social growth of Curaçao?

Free Economic Zone, or the Industrial Zones?

How does Curinde attract, assist and stimulate trading and production companies to reach their objectives?

Curinde is committed to providing professional guidance to investors interested in establishing a company in one of its business parks.

As the managing company and

First, they contribute by creating jobs. People with jobs have spending money, which has a spin-off effect, resulting in more jobs. These employees pay income taxes and social security fees, which means more income for the government and a greater contribution to the social insurance bank. Furthermore, these companies contribute to the country’s foreign exchange reserves. All in all, an increase in export and trading activities will contribute to a sustainable growth of the economy.

What professional seamless support and qualitative facilities does Curinde provide to parties interested in operating in the Curaçao Airport Free Economic Zone, the Curaçao Harbor

Curinde’s team is formed of highly trained specialists who give quick and precise advice about the operations and procedures of the Free Economic Zones and Industrial Zones in terms of compliance with its activities. According to its CEO, Jacqueline Jansen, Curinde’s services reach out as far as referrals to legal, customs and financial advisors, as well as to engineers, specialists and technicians. The guidance that Curinde offers is complimentary. In addition, Curinde has access to an extensive network of international organizations of which it is a member, including the Free Trade Zones Association of the Americas (AZFA), the World Free Zones Organization (WFZO), and the World Association of Investment Promotion Agencies (WAIPA).

Why does Curinde believe that Curaçao is the prime logistical hub for successful business in the Caribbean?

There are some key factors that play a role:

1. The strategic location of Curaçao; it is ideally located at the crossroads of trade routes between South America, the US and Europe.

2. Curaçao is an autonomous country within the Kingdom of the Netherlands.

3. Curaçao is a politically stable country.

4. Daily connections to the Caribbean, North and South America, and Europe.

5. ISO-certified business parks with 24/7 security, offering a secure and safe environment where business can be conducted at ease.

6. Attractive incentives are offered by the government to businesses established in the Free Economic Zone: zero percent import duties and zero percent sales tax.

7. Good financial sector with a reliable banking sector, and the fact that the Guilder is pegged to the US Dollar.

8. Multilingual population that is able to communicate in four languages.

9. State of the art telecommunications infrastructure with a Tier IV Data Center.

10. Curaçao lies conveniently outside the hurricane belt.

How will Curinde achieve its vision of being an internationally recognized facilitator of international production and trade of highvalue goods by 2030?

By creating more alliances with other entities and Free Zones around the world that can be a significant partner for Curinde and Curaçao, which in turn will benefit the companies established in Curinde’s business parks.

Curinde’s focus will also be on client satisfaction, which will result in attracting more investors to establish in one of its business parks.

Curinde believes that it is of utmost importance to develop business parks that offer:

• Excellent service by

stakeholders involved in the logistic chain

• Diversification of activities

• Continue doing promotional activities, especially in the region in combination with the use of Curinde’s international contacts.

• E-commerce activities which are the new trend of doing business.

For more information:

E: info@curinde.com

W: www.curinde.com

Through these efforts, Curaçao is not only reducing its carbon footprint but also fostering a more environmentally conscious and resilient energy infrastructure. This transition towards sustainable energy sources reflects the island's dedication to mitigating the adverse effects of climate change and creating a greener future for its residents and the wider Caribbean community.

Investment opportunities exist in renewable energy projects such as solar, wind, and wave energy, as well as energy-efficient technologies, green infrastructure development, and waste management.

Additionally, the island possesses a vibrant artistic and cultural scene, making the creative industries sector a potential area for investment. This includes film production, music, design, fashion, advertising, and the development of creative spaces and events.

Curaçao is home to several reputable educational institutions, attracting students from around the world. Investing in the expansion of educational facilities, vocational training programs, and specialized courses can cater to the growing demand for quality education and skill development.

The Curaçao Ports Authority manages all ports in Curaçao ensuring development, quality nauucal services, safety and security in the ports in an environmentally responsible manner. With modern infrastructure and the experienced port cluster, the ports of Curaçao offer mariume and logisucal service excellence.

Investing in a foreign country can be a daunting task and comes with its own set of risks.

But what if we told you that there is a way to ensure that your investment remains safe and secure? Look no further than Curaçao!

By investing through Curaçao, you will have access to industry-leading help to properly structure your investment and protect it from political risk. This means that you won’t have to worry about the unjust revocation of your license, harmful unexpected changes in the law, or even disguised or outright expropriation of your assets. This will guarantee that you receive fair and equitable treatment in a court of law.

Curaçao is known for having strong regulations and laws regarding traditional trusts and private foundations. This, paired with an impressive list of bilateral investment protection treaties, makes it the perfect destination for your investment. Trust us, Sadekya always takes these factors into consideration when structuring the financial affairs of our valued clients.

So if you want advice you can trust and an investment that is truly protected, choose Curaçao. Don’t let political risks come between you and your investment.

www.sadekya.com

Invest through Curaçao and let us help you secure your investment.

NA: Can you tell us about any recent milestones CINEX has celebrated?

JB: Recently, the government signed an MoU with Proteus Ocean Group. This collaboration aims to develop the world's first underwater research habitat of its kind, with Mr. Fabian Cousteau, the grandchild of the late famous Jacques Cousteau, leading the project. This will put Curaçao at the forefront of the blue bioeconomy and technology spheres.

The renowned and exclusive luxury hotel, Sandals, opened in Curaçao in 2022. This project has been in the works for a long time and has successfully attracted a niche group of tourists to the island that we wanted and will continue to target in the future, promoting Curaçao as a luxury destination.

Thanks to its aforementioned benefits and incentives, Curaçao has caught the attention of many business process outsourcing (BPO) companies over the years. This year, Concentrix, a prominent company in the field, established its presence in Curaçao, creating numerous job opportunities.

Furthermore, there are several upcoming investments in the hospitality, IT, and sustainable energy sectors scheduled for the next year. These investments will put Curaçao on the map for potential investors.

NA: How has the promotion of Curaçao been impacted by increasing digitalization?

JB: We found that the shift towards an increasingly digital environment has presented both challenges

“WE ASPIRE TO BE THE LEADING AND RELIABLE DIGITAL HUB FOR THE AMERICAS”

-JEANETTE BONET, INTERIM CEO, CINEX

and opportunities for the promotion of our island as a destination for foreign investors.

On one hand, challenges arise from the abundance of information available online, making it more difficult for specific destinations to stand out and capture the attention of potential investors. At CINEX, this difficulty has necessitated a change in our approach to promoting and selling Curaçao. We are currently in the process of gradually implementing this new approach with the support of our marketing department and external experts.

On the other hand, the digital environment also presents significant opportunities. With the use of data-driven strategies, we are able to reach a larger portion of our target audience simultaneously. By leveraging data and analytics, we can identify the right audience segments

and tailor our promotional efforts to their specific needs and interests. This allows us to maximize the impact of our marketing campaigns and increase our chances of attracting foreign investors to Curaçao.

Furthermore, the digital landscape provides us with various online tools that enable us to effectively engage with potential investors. Through social media platforms like Instagram, Facebook, Twitter, and LinkedIn, we can showcase Curaçao's business-friendly environment and investment opportunities through engaging and highquality content. These platforms not only provide us with a wider reach but also facilitate direct communication and interaction with potential investors, allowing us to share valuable information and build relationships more easily.

This year, Curaçao will be introducing the Digital Hub Americas (DHA) platform during the CANTO 2023 conference, aiming to officially establish Curaçao as the go-to solution for all ICT endeavors.

We aspire to be the leading and reliable digital hub for the Americas. To achieve this, DHA aims to empower businesses in co-creating solutions at a local level while facilitating global delivery. Situated in the Caribbean as part of the Dutch Kingdom, and with our advantageous legislation, central location that minimizes the risk of natural disasters, and a multilingual population that

URBAN DESIGN Sustainability

We design neighborhoods, not bricks and pavement. We design new ways of living. Literally green, local, and adapted to the weather conditions of the island, we create that place to connect, with each other, with your inner soul and with nature.

ARCHITECTURE Creative ideas We consider architecture as the built concept that is an answer to different problems. Architecture is more than a shelter, it is the experience, what you can touch, visualize, imagine and how it makes you feel.

INTERIOR DESIGN Creating ethos

The environment we reside in, has to make us feel safe, inspire us to get the most out of our brains, inspire us to create, to relax, to share the moments, to enrich our experience. The space we create will create us.

CONSULTANCY Creating a resilient environment for everyone Having worked as a policy maker at the Ministry of Traffic, Transport and Urban Development, we understand the tension between public interest, developers and economic factors and know how to come to resilient and sustainable win-win solutions.

ZARJA@ZARJA.NET | 599-9-519-2173 | ZARJA.NET | |

URBAN DESIGN Sustainability

We design neighborhoods, not bricks and pavement. We design new ways of living. Literally green, local, and adapted to the weather conditions of the island, we create that place to connect, with each other, with your inner soul and with nature.

ARCHITECTURE Creative ideas We consider architecture as the built concept that is an answer to different problems. Architecture is more than a shelter, it is the experience, what you can touch, visualize, imagine and how it makes you feel.

INTERIOR DESIGN Creating ethos

The environment we reside in, has to make us feel safe, inspire us to get the most out of our brains, inspire us to create, to relax, to share the moments, to enrich our experience. The space we create will create us.

CONSULTANCY Creating a resilient environment for everyone Having worked as a policy maker at the Ministry of Traffic, Transport and Urban Development, we understand the tension between public interest, developers and economic factors and know how to come to resilient and sustainable win-win solutions.

ZARJA@ZARJA.NET | 599-9-519-2173 | ZARJA.NET | |

facilitates communication, we truly serve as a gateway to the Americas and Europe.

The sector and its active participants acknowledge the immense potential present on the island and recognize the significance of highlighting Curaçao's importance in this regard. Through this platform, we aim to promote Curaçao as a hub for innovation, technology, and cutting-edge ICT services.

NA: Are there any key internal investments or developments you would like to highlight?

JB: In 2019, Curaçao embarked on a project to develop a national export strategy (NES), with a primary focus on seven distinct sectors revolving around technology and electronic government. The NES vision reflects the country’s ambition to transform its economy into

one that is driven by entrepreneurship, efficiency, costeffectiveness, quality, and innovation. The strategy focuses on transforming the economic makeup of the country by upgrading and creating new value chains, particularly in service exports. As a result, the forthcoming five years will prioritize attracting investments for these sectors and recognizing that investment is a prerequisite for successful exports. These sectors include the blue bioeconomy, creative industries, IT services, financial services, and port and maritime services. Presently two additional strategies are in the making, one for the health tourism sector and renewable energy.

Curaçao offers a distinct work-life balance. In 2020, another project called @HomeinCuraçao was launched. The government of Curaçao provides an opportunity for remote workers who hold Dutch or US citizenship to live and work on the island for an extended period. To take

advantage of this opportunity, all you need to do is request a judicial declaration through the provided link. Nowadays if you are not a Dutch or US citizen, but still desire to reside and work in Curaçao, you can find the conditions and registration details by visiting the website. So, while staying connected to your colleagues and workplace during the day, the lively island provides ample opportunities for relaxation and rejuvenation whenever you need a break from your desk. Curaçao is renowned for its multicultural community, ensuring there is always a place for you. With a wide range of workspaces you can relate to other remote workers and immerse yourself in the culture by engaging with the community, Curaçao has it all. Moreover, regardless of whether you speak Dutch, Spanish, English, or Papiamentu, you will always feel at home. For additional information, please visit www. athomeincuracao.com

JB: Since we’ve been in the industry for almost a decade, we have seen tremendous growth. In this sense, we aim to keep growing and creating more investment opportunities in Curaçao. This is also done by expanding our services to provide potential clients with the best possible solutions. As the investment landscape continues to evolve, CINEX wants to stay ahead of the curve by keeping up to date with the latest trends in investment promotion, which includes exploring innovative technologies and developing new strategies for marketing and customer acquisition. Moreover, CINEX is committed to providing quality customer service that ensures clients receive the highest level of satisfaction when working with them.

The future of investment promotion is looking bright for CINEX as we continue to strive toward our goals. With our focus on providing top-notch services and support for foreign investors, we aspire to become a leader in the field of investment promotion in Curaçao. Thus, going forward, we can expect CINEX to continue expanding its services and offerings to meet the ever-evolving needs of investors around the world.

Let us help you fulfill your investment and export dreams!

Canada’s Wonderland has been creating memorable thrills for over 40 years. We speak to Phil Liggett, Vice President and General Manager, about dedication to family fun and the park’s latest investments

Writer: Marcus Kääpä | Project Manager: Callam Waller

Canada is a source of natural and cultural wonder, boasting landscapes that are equally dramatic and beautiful, and large enough to find true adventure amid forests, lakes and mountainous rises. But the marvels don’t cease there. Canada is a hub of monumental celebration, with festivals being held throughout the year and amusement parks for all the family available across the country.

The largest of these is Canada’s Wonderland; located in Vaughan, Ontario, the country’s premier amusement park features more than 200 attractions, including two children’s areas and 18 roller coasters, one of which is the world recordbreaking dive coaster, Yukon Striker.

New for 2023, is the one-of-akind thrill ride Tundra Twister and the family launch coaster Snoopy’s Racing Railway. The park also features a 20-acre water park with Canada’s largest outdoor wave pool, 17 water slides, exhilarating cliff jumping, water playgrounds and more.

The four-season amusement park also hosts world-class entertainment, live shows and special events including Camp Spooky, Halloween Haunt and the immersive holiday event WinterFest. The park is situated on approximately 300 acres and is one of 11 amusement parks owned and operated by Cedar Fair Entertainment Company.

Its key products include daily

admission tickets and three-tiers of Season Pass - Platinum, Gold and Regular – plus add-on products such as dining plans, drink plans and fast lane passes.

“Since 1981, Canada’s Wonderland has been the premier destination in Ontario for thrills, family fun, and world-class entertainment,” begins

Phil Liggett, Vice President and General Manager of the park.

Phil Liggett, Vice President and General Manager of the park.

“The smooth running of the amusement park comes down to our 150 dedicated full-time staff and the substantial number of seasonal staff, approximately 4,000, through the operating season which runs from late April to the end of December

Marvin Candy & Displays was incorporated in 1990 and has been developing and servicing high volume confectionery programs since that time. Today we are the largest marketer of confectionery products within the Fun and Leisure sector in Canada. We are the exclusive Canadian distributor for Pucker Powder products and authorized distributor for many industry leading brands. Our knowledge of equipment, products and positioning is gained by having a hands-on approach. This allows us to maximize sales and profits for our customers. We develop confectionery programs that have a proven success record. Add custom equipment and graphics, the result is a perfect marketing solution. Marvin Candy & Displays conducts business across Canada and in several US states. Our broad customer base covers all areas of the Fun and Leisure sector including: candy stores, water parks, zoos, museums, science centers, amusement facilities, ski resorts and theme parks. Our nationwide programs and fixtures are exposed to millions of visitors annually.

each year. These are the people at the heart of the process who ensure the happiness of everyone who visits!”

People are the focus of Canada’s Wonderland. For Liggett, customer experience, operational excellence and employee well-being stand above all else. In light of this, Canada’s Wonderland is continuously evolving its people-centric offerings, the latest of which is the highly popular Lazy Bear Lodge.

“Lazy Bear Lodge is the largest dining facility in the park and represents the most significant investment we’ve made in food and beverage since Canada’s Wonderland opened in 1981,” Liggett tells us. “It’s one of the latest additions to our growing Canadian-themed collection of venues and attractions, with two levels, a sprawling stone patio with an amazing view of our fireworks show, and seating for 500 guests.

“Its gourmet menu of smoked brisket, barbecue chicken and

healthy vegetarian options supports our ongoing efforts to elevate our amusement park dining experience. We’re not just about hot dogs and pizza. We’ve developed a diverse offering of locally sourced, quality food and drink items that cater to the increasingly sophisticated preferences of our park guests.”

Thus far, the response to the Lazy Bear Lodge, its architecture, the menu and the speed of service has been very positive as it helps Canada’s Wonderland deliver a memorable dining experience.

Canada’s Wonderland is a place dedicated to creating fun and great memories in a safe environment. For the park’s management and teams, it is the unique experiences the park offers, and the fostering of fun for friends and families, that drive passion to deliver.

“The smile on a child’s face as they experience their first ride; the terrified screams of friends as they encounter the first drop on a roller coaster; taking family photos with Snoopy or Charlie Brown after ice skating under

“SINCE 1981, CANADA’S WONDERLAND HAS BEEN THE PREMIER DESTINATION IN ONTARIO FOR THRILLS, FAMILY FUN, AND WORLD-CLASS ENTERTAINMENT”

– PHIL LIGGETT, VICE PRESIDENT AND GENERAL MANAGER, CANADA’S WONDERLAND

NORTH AMERICA OUTLOOK: CAN YOU TELL US ABOUT YOUR CAREER TO DATE AND YOUR INTRODUCTION INTO THE AMUSEMENT PARK SPACE?

PHIL LIGGETT, VICE PRESIDENT AND GENERAL MANAGER:

“I started my career in the amusement park industry 40 years ago when I joined Canada’s Wonderland as a seasonal supervisor in food and beverage. Prior to that, I had been working in a few different restaurants and eventually became aware of opportunities for students in supervisory and leadership roles at the park.

“The size of the park operation, the team and the fun atmosphere were all compelling factors in applying at the park and reasons I have never wanted to do anything else. I worked at the park from 1984 through 2006 in a variety of roles and disciplines including food and beverage, park operations and human resources. After that, I was fortunate enough to hold General Manager roles at several other amusement parks in the US and Canada before returning to my true home park –Canada’s Wonderland, in January of this year. This is truly a great business and re-joining the team here as General Manager has been a highlight of my career.”

enjoying our classic strawberry funnel cake at the end of the day – these are only some of the unique experiences the park offers,” Liggett tells us fondly. “Helping to create that fun and those memories is the best part of what we do at the park every day.”

Each year, it is the management teams at Canada’s Wonderland that implement developments designed to attract customers, create thrills and produce that “wow” factor.

offer both a new thrill ride and a new family ride in the same season to cater to the interests of different guest demographics,” Liggett continues. “We’ve had the chance to do this a few times in the last decade and guests always respond well.”

One such development is the park’s all-new Tundra Twister, a thrill ride in the Frontier Canada section of the park. This consists of a giant swinging pendulum that takes

BIG THRILLS – Canada’s Wonderland is home to the most exhilarating collection of rides and coasters in North America! Scream your face off on Leviathan, Behemoth and the world recordbreaking dive coaster, Yukon Striker.

KID’S AREA – Featuring two familyfriendly areas, KidZville and Planet Snoopy, kids will enjoy more than 25 rides and attractions, plus meet and greets with Snoopy, Charlie Brown and the rest of the Peanuts gang!

FOUR SEASONS – There is plenty to see and do for guests of all ages through the spring, summer, fall and winter at Canada’s premier amusement park.

LIVE ENTERTAINMENT – Enjoy world-class live shows like Ultimate Thrill Circus, Fall Out Stunt Dive Show, dance parties with the Peanuts gang, and more!

SPLASH WORKS – 20 acres of refreshing summer fun including slides, water playgrounds, a lazy river, wave pool and exhilarating cliff jumping at Mountain Bay Cliffs!

guests 360 degrees, upside down to heights of 47 meters and speeds of up to 75 kilometers per hour (kph). The gondola seats fit 40 people and rotates spontaneously, which delivers a unique ride experience every time. It is a prototype designed by Mondial, a rides manufacturer in the Netherlands, which makes it the only one of its kind in the world.

Another key attraction is the highly popular Snoopy’s Racing Railway, the park’s 18th roller coaster and the

newest addition to Planet Snoopy, one of the children’s areas. This ride is a family launch roller coaster built by ART Engineering, accelerating from zero to 50kph in a matter of seconds before taking guests through the dips and turns of a wild railway adventure.

“Snoopy’s Racing Railway is a great addition for kids and families. It can accommodate guests as small as 36 inches tall (three feet), so we’re excited for our youngest thrill seekers who may find Snoopy’s Racing Railway to be their very first roller coaster experience,” Liggett shares.

Snoopy’s Racing Railway is a perfect example of Canada’s Wonderland diversifying its offers to cater to a wider customer base. This diversification of the guest experience is critical to ensuring that there is something for everybody when they visit the park.

“We have great thrill rides and exciting roller coasters, but we also provide great experiences for families with our children’s areas and 20 acre water park,” Liggett explains. “In addition to this, we have a full line-up of world-class events and live entertainment throughout the year, including cirque-style shows, international food festivals and special events like the week-long Celebration Canada and KidZfest with popular TV characters and Marvel superhero meet and greets. This keeps our entertainment offerings fresh and gives guests – particularly our Season Passholders – a reason to visit often.”

In the fall, Canada’s Wonderland features a daytime Halloween program for children on weekends called Camp Spooky, and at night Halloween Haunt thrills the park’s older guests with monsters, haunted mazes and sinister shows. The fun continues in November and December with the park’s immersive holiday event WinterFest, featuring millions of lights, ice skating, festive

food, holiday shows and interactive family experiences.

While open through all four seasons, Canada’s Wonderland sees its busiest time during the summer months when schools in Ontario gain leave during July and August. Annually, the park hires for thousands of seasonal positions across all departments, with recruitment efforts beginning as early as January. These seasonal associates play a vital role in the park’s mission delivering amazing experiences to all guests, and Canada’s Wonderland offers highly competitive wages, amazing perks and an opportunity to make lifelong friends and develop essential leadership skills to help build future

careers for all those who join.

This people-centric skills development and experience is just one of the park’s continuous aims, with future goals also enveloping multi-faceted business objectives.

“We have revenue and attendance targets but our success in meeting them depends heavily on our attention to certain key areas. These include guest satisfaction, the expansion of entertainment and attraction offerings, and ensuring awareness to emerging demographics,” Liggett concludes.

“Our Season Passholder base is an important part of our business, so we make sure to add substantive value to those passes each year, through

expanded perks programs, exciting new rides and events to give those guests plenty of things to do.

“We’re a four-season park and want to give customers great reasons to visit all year long!”

Tires distributed by Canada Tire Inc have been providing value to customers for almost a century. CEO, Gabriel Granatstein, details the company’s dedication to distribution, its team and its values

Writer: Jack Salter | Project Manager: Callam Waller

The consolidation of Canada’s tire industry has seen many local and regional distributors rolled up into larger national players.

However, one regional distributor that has proudly stood the test of time – 95 years to be exact – and played a major role in shaping the industry, is Canada Tire Inc (Canada Tire).

Gabriel Granatstein, CEO, along with his brother-in-law, Director of Sales, Chris Moody, represents the fourth generation of the family business, which was founded in 1928 by his great grandfather, Louis Wiseman.