As the world’s largest and most experienced supplier of grinding media, Jim Anderson, CEO of Molycop, discusses how the company’s continued investment in research, development, and advanced technology delivers improved outcomes to customers

Writer: Lauren Kania | Project Manager: Thomas ArnoldWith over a 100-year history built on reliable innovation and a conscious global footprint, Molycop is a time-tested, world-leading partner for consumable products, instrumentation, and services for the global mining industry and rail and manufacturing sectors in Australia.

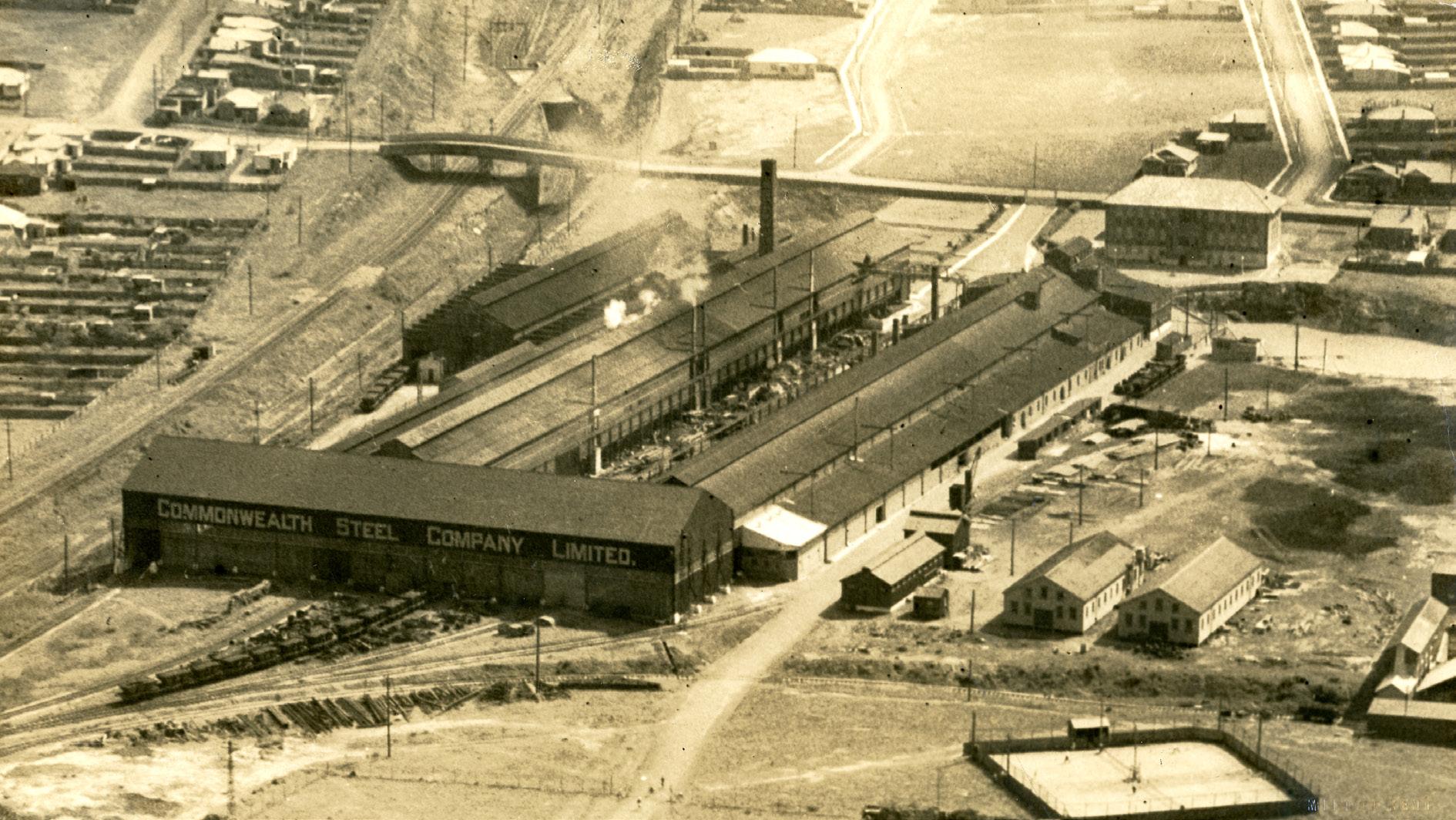

With origins tracing back to the Australia-based Commonwealth Steel and US-based Sheffield Steel

businesses, both of which independently developed grinding media products for minerals processing, Molycop prides itself on providing innovative and high-quality products, world-class technical support, and delivering outstanding supply assurance.

“We’re incredibly proud that Molycop’s strength is not one or two things in isolation; it is the sum of our parts,” opens Jim Anderson, CEO of Molycop.

“We are focused on helping our customers increase throughput and maximize recovery with our portfolio of products and services across milling, flotation, leaching, process optimization, and training.”

Coming from a rich and deep history of serving the world’s copper and gold mining segments, Molycop now operates a global business model with over 1,500 dedicated employees who service over 400 mines across 40 countries, being the largest grinding media supplier in the world.

With major operations in Chile, Peru, Mexico, the US, Canada, Australia, Indonesia, and Spain, Molycop leverages the full talent of its network to provide the best solutions for customers with a unique local nuance and expertise.

“Innovation is in Molycop’s DNA.”

Being able to call yourself an industry leader is no small feat; Molycop has been able to set these

1917: First site established under Commonwealth Steel in Waratah, New South Wales, Australia

1930s: Sheffield Steel invented and patented the first heat-treated grinding media alloyed with molybdenum and copper, giving rise to the Molycop brand name

1961: Sheffield Steel began its international expansion into Chile

1998: Commonwealth Steel expanded into Indonesia

2002: International plants were acquired by Scaw Metals Group

2007-2010: The foundation of the business as it operates today emerged, with OneSteel acquiring Commonwealth Steel through its purchase of Smorgon Steel and then acquiring the North and South American grinding media operations of Scaw Metals

2011: Under OneSteel ownership, all the business’ grinding media manufacturing facilities merged into a common Molycop organization, creating the largest grinding media company in the world

2017: Acquired by American Industrial Partners (AIP), Molycop adopted a global business model continuously improving its fulfillment and service innovation

2018 – 2019: The company embarked on further geographic expansions acquiring Donhad (Australia) and Metso Sabo and expanding its reach into Africa and the Middle East.

2020 – 2023: Molycop has developed a comprehensive instrumentation and process optimization offering through the acquisition of Mill Trakka sensor technology, Digital Control Lab (“Millslicer”) and Process IQ.

AJA Industrial Services specialise in onsite scrap metal processing and supporting scrap yards in planning and managing all scrap processing from sorting to cutting to logistics.

We are fully equipped to provide a professional yard, onsite cleanup service including fit for purpose machinery, floats and trucks.

We are experts in the deconstruction of redundant and decommissioned complex machinery across all sectors. We are the market leaders in value for money, large scale steel processing operations.

With our experience and fit for purpose equipment we are able to meet and crush quotas consistently.

We provide you with the tools, strategies, and expertise to accelerate all your processing needs and offer Short- or long-term contracts, Onsite resizing of scrap metal across all sectors for transport, FIFO, Project Management, site clean-ups and Machine Hire.

PH: 0419 899 655 | Email: jasson@ajais.com.au | info@ajais.com.au

www.ajais.com.au

– JIM ANDERSON,standards and differentiate itself as a result of its investments in research and development (R&D) and the people who work hard to make results happen – whether it be by upskilling or attracting the industry’s brightest minds.

In addition, Molycop has partnered

with some of the world’s leading universities, acquiring a competitive edge when it comes to developing and retaining people, ensuring that they are well-equipped for the future.

“Importantly, the way we collaborate with our customers and stakeholders also drives this

progress,” clarifies Anderson.

The innovation strategies Molycop provides aim to yield fast, credible solutions to the social and fiscal challenges that customers face. These strategies also enable the sustainable liberation of resources essential for a better tomorrow.

“INNOVA TION IS IN MOLYCOP’S DN A”

CEO, MOLYCOP

We are experts in on-site services, total scrap management and add value to your by-products through our innovative recovery processes.

SCE Steel Services provides the following specialist on-site solutions to the steel industry and other major metallurgical producers:

• Materials and by-product handling

• Slag handling, processing, marketing and sale

• Metal recovery, collection and steel cutting

• Dust agglomeration, for recovery of valuable elements

• Refractory removal, processing, marketing and sale

• Transport and logistics

Terrace Fabrications is a leading familyowned steel fabrication company, founded in 1979 by Victor Ruban and based in Heatherbrae, NSW.

With over four decades of experience, Terrace Fabrications now has over 20 employees and has remained a trusted partner in providing bespoke services to a diverse range of industries, including manufacturing, processing, mining, and construction across The Hunter and Upper Hunter regions.

Our unwavering commitment to quality and customer satisfaction has earned us an unrivalled reputation in the market, cementing our position as a leader.

Ph: (02) 4987 3881

E: enquiries@terracefabrications.com.au terracefabrications.com.au

We provide a variety of services that cater to the diverse needs of our clients, ensuring a comprehensive solution for their projects. These include:

• Steel fabrication

• Plate work

• Mining equipment fabrications and repairs

• Ladles

• Tank and pipe work

• Screening equipment

“Together we are able to solve the big challenges our industries face, setting new benchmarks, evolving to market trends, and ultimately delivering improved outcomes for our customers,” notes Anderson.

The future of mining, like that of any industry, is always changing, and Molycop is all about ensuring the change is for the better. By playing our part in the transformation of the mining sector and improving the ways in which everyday things get done, Molycop is always aspiring to be innovative and ahead of the curve, with a constant focus on forward momentum.

As is expected in any major industry that plays a large part in driving economic growth, the mining industry is continually evolving and facing new challenges, including pertinent subjects such as declining

Jim Anderson, CEO: “Our Molycop360 business, while Australian-centric, provides integrated logistics and waste management solutions predominantly on the East Coast of New South Wales. The business captures waste streams such as used grinding media, conveyor belts, and mining tyres. The scrap steel and rubber crumb are used in the steelmaking process to produce new products at Molycop’s site in Waratah. This is a model that Molycop is looking to globalize to deliver on our circular economy efforts.”

head grades, skillset challenges, and developing local communities.

However, technology is an enabler that allows the industry to meet these challenges head-on.

“Molycop has been the leader in our industry for over 100 years, and it’s only a natural progression and is expected we take a leadership position in working with our customers to help them solve these issues through the use of more advanced technology,” comments Anderson.

Operating with the desire for constant evolution and standing at the forefront of the industry, Molycop has established a new business portfolio under the strength and reputation of the company brand to emphasize its commitment to sustainability and innovation with the extensive range of products and services at the customer’s disposal.

For example, Molycop’s innovation team has significant research projects

Stanton is assisting Molycop with satisfying their safe use requirements for overhead bridge and gantry cranes.

In addition to routine inspection and maintenance by crane technicians, the mandatory requirements for third-party input are:

• An independent periodic third-party inspection (PTPI)

• A DWP assessment (DWP)

Stanton’s PTPI/DWP package is used by a range of large crane fleet owners.

Our package assists these crane owners in satisfying their safe use responsibilities.

We can also help with compliance auditing, fatigue/strength assessment, anti-derailment design, certification of past-DWP cranes and much more.

Phone: +61 438 523 610 | Email: cranes@stancon.com.au

Website: https://www.stancon.com.au/

Note that major inspections are not required if your crane (or hoist) has not passed 100% DWP.

If a major inspection has been recommended, talking to the crane specialists at Stanton will likely help your budget bottom line.

underway with leading universities in materials science and comminution. With a major initiative such as the development of the Molycop Digital Engine, projects such as these underpin the future product and service developments within the company.

“These new capabilities truly build on Molycop’s rich history, paving the way for a future that’s better when we create it together,” expands Anderson.

Under one strong identity, Molycop prides itself on its holistic portfolio offered to customers, continuously raising the bar for progress, accessibility, and reliability.

Molycop has placed a focus on moving beyond the accuracy and flexibility limitations of traditional

mineral processing analytical techniques, which were traditionally based on empirical models and rulebased systems, to opportunities in new powerful tools for data analysis, prediction, and optimization.

“Around the world, we are seeing a positive impact in the way Molycop’s customers are benefitting from artificial intelligence (AI) and machine learning (ML),” notes Anderson, “including real-time predictions and the optimization of mineral processing operations.”

One such example of this positive impact that has been developed to predict the behavior and optimize the performance of comminution circuits is the Molycop Digital Engine, an advanced intelligence computational framework specifically tailored for optimizing crusher-to-floatation circuits. Additionally, the Digital

Engine is integrated with Molycop’s mill monitoring system, including shell and mill sensor data with main operating variables.

Always leading the way for progress and innovation, Molycop’s Dr. Yousef Mohammadi will present a paper, eMolycop Digital Engine: Machine Learning-accelerated SAG Mill Optimization, at SAG 2023 in Vancouver. And Mukesh Singh Bisht, who is undertaking his PhD co-supervised by Molycop at Sydney University, will present a poster display titled “Heterarchical Comminution Model for Rotary Mills”. Advanced instrumentation, data capture and visualization, and data integration with AI and advanced analytics overlay are all aspects that are crucial to the future of mining and are supported by Molycop’s global team of qualified experts.

As a company with an expansive global reach, Molycop works to positively impact people, support local communities, and minimize our environmental footprint through every aspect of the company.

Committed to the pursuit of greater sustainability in a manner that allows

“OUR UNIQUE SELLING POINT IS ONE THAT PLACES US BEYOND DIRECT COMPARISON. WE’RE INCREDIBLY PROUD THAT MOLYCOP’S STRENGTH IS NOT ONE OR TWO THINGS IN ISOLATION; IT IS THE SUM OF OUR PARTS”

– JIM ANDERSON, CEO, MOLYCOP

for superior efficiency of resources and achieves the highest standard of environmental performance, Molycop is dedicated to creating lasting benefits that are responsible, transparent, and respectful to the rights of all.

Polymer Injection Technology

(PIT) is a groundbreaking initiative Molycop, in collaboration with the University of New South Wales (UNSW), is spearheading to reshape Electric Arc Furnace (EAF) steel manufacturing by partially substituting traditional coke with rubber from tyres and other sources.

“The benefits are many; however, the clear environmental stewardship is a focus area for us. Beyond financial advantages, PIT significantly reduces carbon emissions by minimizing electrical energy consumption,” expands Anderson.

Additionally, Molycop has developed a sustainability strategy to articulate priorities, provide clear actions to meet objectives and enable the monitorization of progress against agreed targets.

This strategy includes three strategic pillars: “doing better for the future, with a focus on environmental

material topics; doing what matters, ensuring our social works and people focus is maintained; and doing what’s right, managing our organization with strong ethics and governance arrangements,” explains Anderson.

Molycop also has a critical role to play in helping the industry deliver the copper it needs for a low-carbon future, as the demand for copper used for solar and wind is forecast to double by 2035. In doing this, Molycop is focusing on delivering consumable products that have increased wear life and are optimized for varying mill operating conditions – increasing the throughput and recovery in the comminution process.

With the belief that one of the best ways to promote sustainable development is to innovate new and better technologies and to change current ways of operating, the focus is always on the future at Molycop, taking the responsibility of providing for customers very seriously.

molycop.com