For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimise our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

Going forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

– Ben Weaver, CEO, Outlook Publishing Ltd

EDITORIAL

Editorial Director: Alex Tuck alex.tuck@outlookpublishing.com

Senior Editor: Jack Salter jack.salter@outlookpublishing.com

Editor: Lucy Pilgrim lucy.pilgrim@outlookpublishing.com

Editor: Ed Budds ed.budds@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

Junior Editor: Lauren Kania lauren.kania@outlookpublishing.com

PRODUCTION

Production Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Junior Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Assistant: Megan Cooke megan.cooke@outlookpublishing.com Digital Marketing Manager: Fox Tucker fox.tucker@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

BUSINESS CEO: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Sales Director: Nick Norris nick.norris@outlookpublishing.com

Regional Director: Joshua Mann joshua.mann@outlookpublishing.com

TRAINING & DEVELOPMENT MANAGER

Marvin Iseghehi marvin.Iseghehi@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Josh Hyland josh.hyland@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

SALES MANAGERS

SALES & PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS

Alfie Wilson alfie.wilson@outlookpublishing.com

Krisha Canlas krisha.canlas@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

CONTACT

Mining Outlook

First Floor, Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom.

Sales: +44 (0) 1603 363 631

Editorial: +44 (0) 1603 363 655

SUBSCRIPTIONS

Tel: +44 (0) 1603 363 655

alex.tuck@outlookpublishing.com

www.mining-outlook.com

Like us on Facebook: facebook.com/miningoutlook

Follow us on Twitter: @MiningOutlook

Welcome to our third issue of Mining Outlook magazine. Young as we are, our ambitions here are to dig into the best stories we can find in this vital sector. We have already seen the incredible scale of mining in all its facets, including many widespread industry challenges, as well as some remarkable solutions waiting to be uncovered and shared with our global readership.

This month’s cover star is Kestrel Coal Resources, who surprised all of us with their commitment to sustainable mining. The mining titan is dedicated to reducing its carbon footprint, as part of developing responsible operations, while driving the conversion of coal-mine-related gas into usable energy.

Continuing the coal theme, we profile the entirely black-owned Nadalamo Resources, formed from the amalgamation of various mining, financial, sustainability, and social responsibility-inclined professionals and entrepreneurs in South Africa.

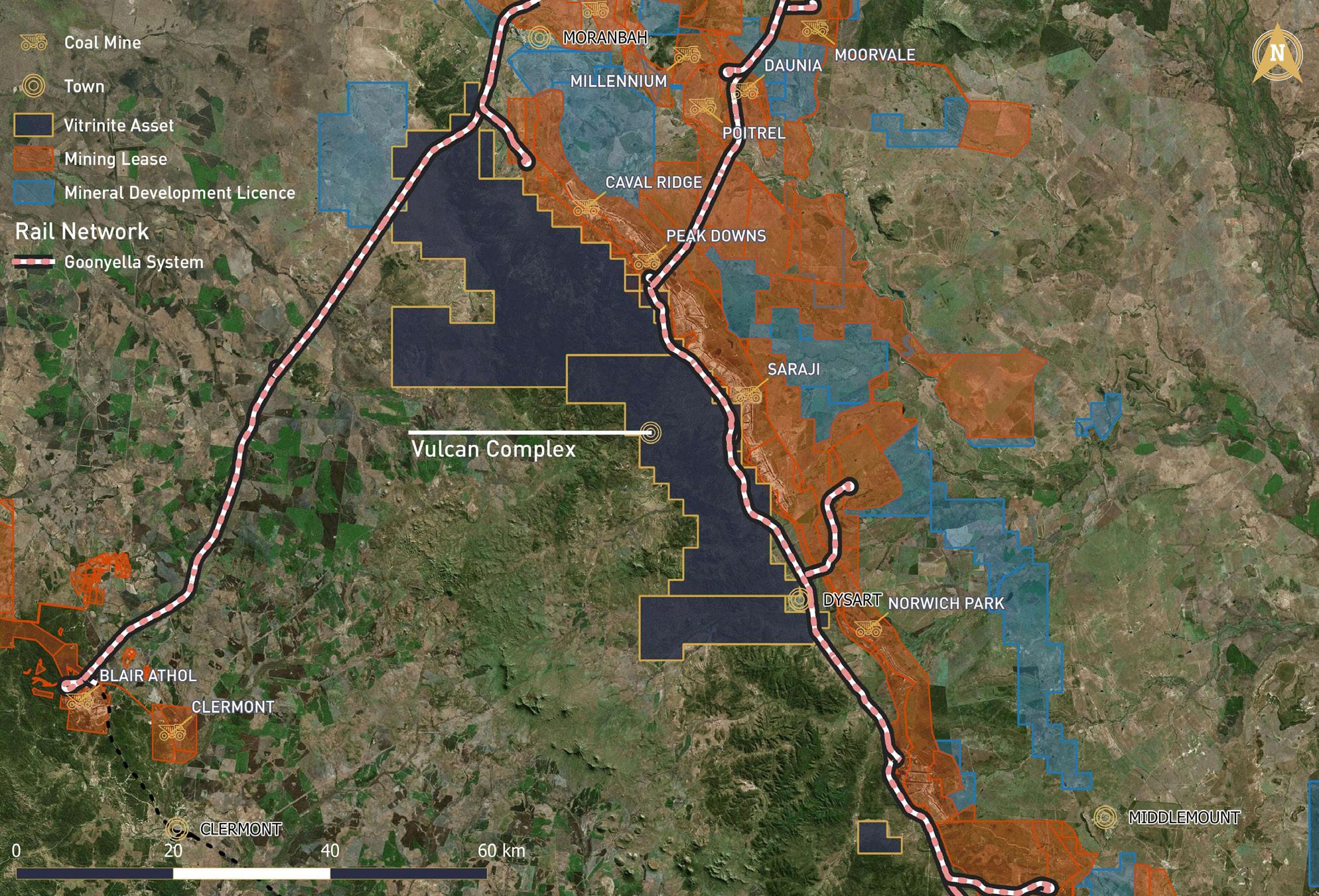

The hat-trick of coal mining features is rounded off by Bowen Coking Coal from Queensland, Australia. With mining royalties expected to feed at least AUD$6 billion a year into state coffers, it’s no wonder coal is doing so much of the heavy lifting to pay for the transition to cleaner energy.

Millions of visitors flock to Queensland every year, as it is characterised by its rugged outback landscape, dazzling sandy shores, and the magical Great Barrier Reef. And yet, the unsung hero supporting this wondrous state is the Queensland mining industry. As the representative for hundreds of mining entities, we catch up with Ian Macfarlane, CEO of the Queensland Resources Council, about the major part mining plays in not only generating revenue for the region, but also how it champions the contribution of its members by embracing innovations and guiding the industry to a greater sustainable future.

This issue also highlights top mining events to watch out for in the coming months, such as the WA Mining Conference & Exhibition in Perth, Australia, and reveals some keynotes from London’s Mining World Congress 2023, including spokespeople from Rio Tinto, Anglo American, AspenTech, KamniChain and many more.

We strive to present the major players across the mining sector, so we hope that you enjoy your read and let us know what you think on our social media pages.

Alex Tuck Editorial Director, Outlook Publishing

144 Bowen Coking Coal

Evoking Coking

Advancing Australian mining

156 Minergy Coal

Pioneering the Botswana Coal Industry

Elevating the nation’s resources

162 Ndalamo Resources

Growing a Small Seed into Sustainable Roots Investment opportunities in South African mining

178 FLSmidth

Mining for a Sustainable World Delivering solutions for tomorrow’s mine

EUROPE & MIDDLE EAST

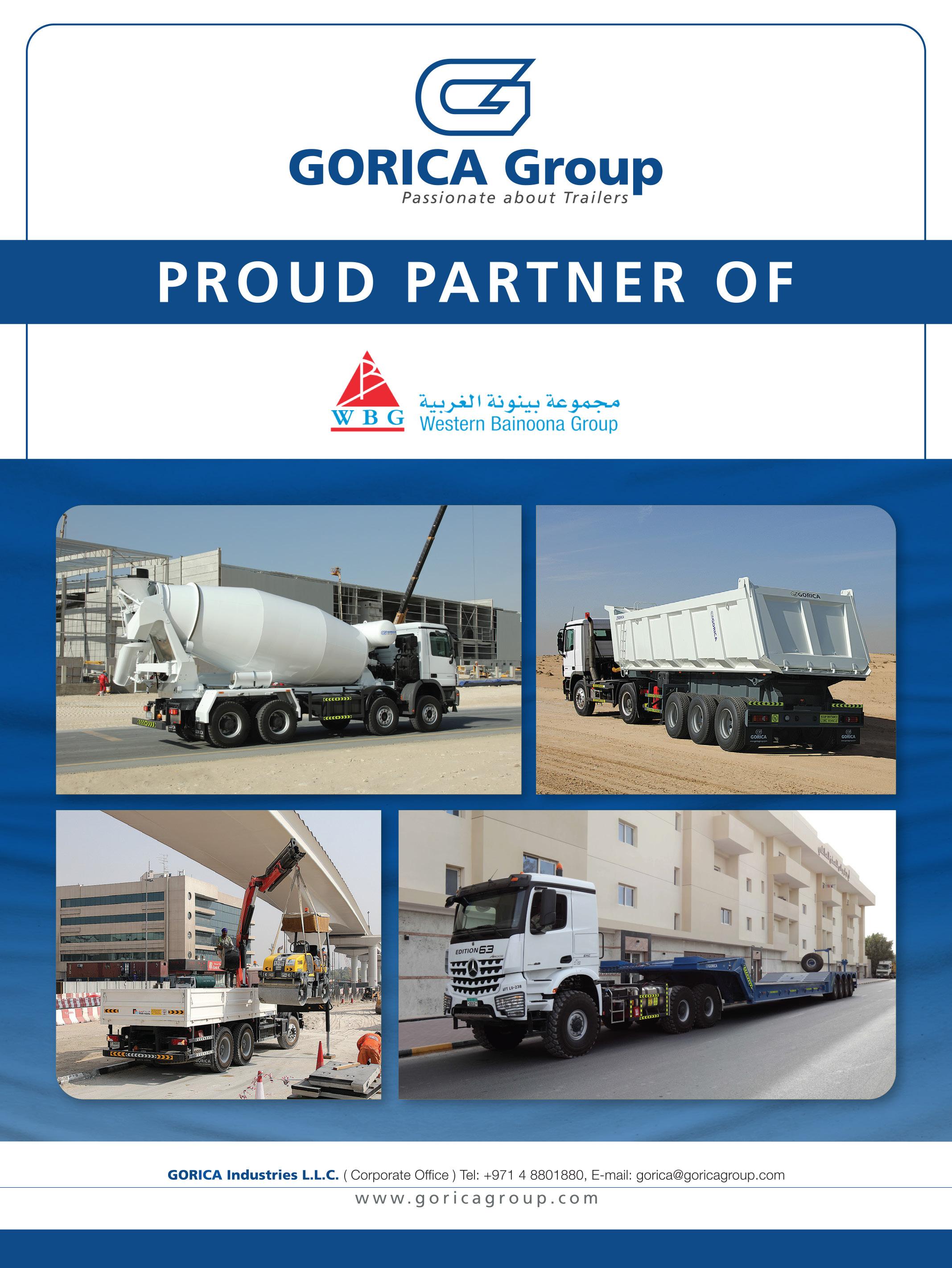

186 Western Bainoona Group

Partners in Nation Building Powerhouse engineering and infrastructure development

IRON ORE EXTRACTION

and loading are being reimagined through innovative technology at BHP’s Newman Operations in the Pilbara region of Western Australia.

The use of remotely piloted aircraft equipped with infrared cameras is being trialled by the operation’s teams to monitor the health and performance of mining equipment.

Infrared technology enables the temperature of equipment such as iron ore reclaimers to be measured, and components that may be operating outside of their normal limits to be identified.

THE FIRST PHASE of sampling and property evaluation at American Pacific Mining’s recently acquired Danny Boy project has been completed.

A total of 10 rock chip samples were collected at Danny Boy during the first phase of reconnaissance evaluation work.

Located immediately west, and contiguous to the company’s

UNDERGROUND MINING CUSTOMERS can now experience the benefits of Orica’s next generation centralised blasting system, ORBS.

Designed to provide operations with the ability to safely initiate

Tuscarora project in Elko County, Nevada, Danny Boy was acquired as part of the Clearview acquisition.

The project represents a key piece of the acquisition, allowing American Pacific Mining to complete the longawaited consolidation of Tuscarora, which now has 10 priority targets and large unexplored areas that will be mapped and sampled further in the weeks to come.

BHP is checking the temperature of components to ensure they are healthy and operating within their optimal range. For accuracy and safety, drones are fitted with laser range finders to maintain an optimal distance from the moving reclaimer.

multiple development headings and production blasts concurrently from a remote, central location, ORBS therefore enables increased productivity.

ORBS’ browser-based interface provides users with full visual oversight of all connected hardware and detonators to users.

Another key feature of ORBS is that it is a plug and play system that doesn’t require additional infrastructure to be invested in by customers. Rather, it simply connects to a mine’s communication network and is operated from an electronic device such as a PC, tablet, or phone.

Around the mining sector in seven stories

A NEW MINING code signed into law by Mali’s interim President, Assimi Goita, will enable the government to increase its ownership of gold concessions and recoup a major shortfall in production revenues.

An audit of the mining sector has shown that the shortfall is around CFA300 to 600 billion, which the state intends to recover.

RWE IS CONTINUING to progress green electricity production in the Rhenish mining district of Germany.

At the Hambach lignite opencast mine, construction has commenced on a photovoltaics plant with an integrated battery storage system (BSS).

THE WORLD’S FIRST application of Draslovka’s proprietary glycine gold leaching process in a commercial heap leaching application has been announced.

Application of GlyCat has commenced to extract gold from ores mined from Bayan Airag’s Golden Hills and Limestone Ridge pits following site-based testing.

Higher recoveries than conventional cyanidation were demonstrated at the recent heap leach trial, with overall gold recovery of 78 percent. This was achieved with a 65 percent reduction in cyanide; due to high cyanide unit costs, the total

Some 22,000 solar modules will be installed at Hambach by RWE, enough to supply more than 3,100 households with green electricity. The plant has a planned capacity of 17.6 megawatts (MW), and installation could commence as early as next year subject to planning permission.

The plant is already the fourth large solar project that RWE is launching in the Rhenish mining district within a short period of time, again in combination with a BSS.

reagent costs are also projected to be reduced by over 70 percent.

GlyCat’s use in heap leaching applications therefore demonstrates equivalent or better recoveries, and a step change reduction in operating costs.

The new code will allow state and local investors to take increased stakes of as high as 35 percent in mining projects, up from 20 percent, and could more than double the contribution of mining to the gross domestic product (GDP) of Mali, which is one of Africa’s top gold producers.

A JOINT VENTURE (JV) has been formed by Rio Tinto and First Quantum Minerals (FQM) to unlock the development of the La Granja project in Peru.

La Granja, a complex orebody located at high altitude in Cajamarca, is one of the largest undeveloped copper deposits in the world and has the potential to be a long-life operation.

A 55 percent stake has been acquired in the project for USD$105 million by FQM, who will also invest up to an additional USD$546 million into the JV to solely fund capital and operational costs to take the project through a feasibility study and towards development.

As the majority owner, FQM will now operate the La Granja project with initial work focused on completing the feasibility study.

Disruptions are the way of the world—pandemics, supply chain bottlenecks, inclement weather and wars have taught us that lesson in recent years. Grace Nam, Strategic Solutions Manager at Laserfiche, analyses the potential solutions

Written by: Grace Nam, Strategic Solutions Manager, LaserficheThe 2020-23 global semiconductor shortage arrived in a ‘perfect storm’ of economic conditions. The demand for work-from-home technology accelerated while chip production facilities shut during lockdowns; the ongoing China-US trade conflict continued; the RussiaUkraine war, and freak events like severe weather storms and factory fires further contributed to the squeeze.

Fortunately, it seems that the chip shortage is in the rearview. But while sectors worldwide are urgently returning to normal operations, semiconductor scarcity and its impact on businesses must not be ignored or forgotten—instead, it must be a crucial lesson. According to Goldman Sachs, at least 169 industries were impacted by the shortage; PlayStation 5 consoles became almost impossible to buy; Apple had to slash its iPhone manufacturing targets; Toyota was forced to cut vehicle production by as much as 40 percent.

The crisis shone a harsh light on the fragile nature of the supply chains for some of the world’s most important products. Moving forward, businesses need to ensure that their manufacturing processes are as resilient as possible so they can safely navigate any future disruption. So, let’s explore ways in which manufacturers can boost efficiency and keep up with customer demand, even as inflation and supply chain issues continue to put pressure on the industry.

A key lesson from the crisis is that agility, and the ability to pivot, have become more important than ever. The world is changing, and traditional materials, suppliers, and ways of working can often no longer be relied upon. Particularly in light of climate change and electrification, now is a good opportunity for manufacturers to review their processes from

the bottom up and bake in new or alternative approaches and materials that can be turned to in times of crisis.

One example of this is the electric vehicle manufacturer Tesla. The company uses several mission-critical chips in its control, entertainment, and even self-driving systems. However, it managed to weather the full impact of the chip shortage by pivoting to using new types of semiconductors and working to combine chips from different sources. In a 2021 letter to shareholders, the company wrote: “In Q1, we were able to navigate through global chip supply shortage issues in part by pivoting extremely quickly to new microcontrollers, while simultaneously developing firmware for new chips made by new suppliers.” A similar ‘start-up mentality’ may be required for organisations looking to ride out the next crisis.

Accurately forecasting demand for products and materials has long been an important part of strong profit levels and continuous business success. Yet back in 2020, just eight percent of organisations had implemented real-time, automated supply chain processes for ultra-

precise predictions. This lack of digital readiness was likely another driving factor behind the lingering semiconductor crisis.

From now onwards, manufacturers should look to integrate machine learning (ML) into their supply chains. This way, predictions of material demand will improve over time, resulting in more efficient stocking and production planning, building resilience into organisations’ strategies. New product anomaly-detection models can even help businesses identify whether spikes or drops in demand are relevant or coincidental, informing any required adjustments.

Semiconductor manufacturers, too, should take a step back during this time period to re-evaluate efficiency and implement technology tools that will support better data analysis, information sharing and more resilient operations. McKinsey research has found that artificial intelligence (AI) enabled supply chain management has “allowed early adopters to improve logistics costs by 15 percent, inventory levels by 35 percent, and service levels by 65 percent, compared with slowermoving competitors.” So, it’s no surprise Gartner expects that within three years, “more than 50 percent of supply chain organisations will use ML to augment decision-making capability.” Manufacturing businesses should look to follow suit.

Navigating a materials crisis isn’t solely dependent on the availability of the materials themselves. Every employee and department in the organisation must be also on the same page, from the boardroom to the shop floor, to ensure appropriate business continuity. Therefore, centralised document depositories and connected legacy systems are crucial to a mid-crisis transformation. Here, a cloud-based digital eco-

system, powered by decision-driven process automation, will prove invaluable. Businesses will be able to mitigate operational interruptions by unlocking access to important documents from anywhere, on any device. Low-code and no-code tools will enable any staff member to bridge technology gaps and create seamless connections between processes and applications, ensuring departmental alignment and transparency. Harmonised records and data will give teams access to real-time information and insights, sparking active collaboration. Plus, robotic process automation, driven by AI and ML, will take care of repetitive tasks, so human workers can focus on driving smart actions that help the organisation overcome external crises.

Even when demand is low, process efficiency is key — and can even be a competitive advantage. If a manufacturer’s process times are longer than its competitors, customers are likely to take their business to the competition. For example, optimised automated request for quote (RFQ) processes can speed decision-making and create a better first impression for prospects looking to partner with a modern, responsive manufacturer. Organisations should consider all processes — from human resources (HR) to sales, administrative to

customer-facing — when assessing operational efficiency and where it can be improved.

In the wake of the global COVID-19 pandemic and semiconductor shortage, with inflation and a recession looming, manufacturers today need to be prepared for anything. Organisations should continuously assess supply risk and communicate insights across their business, ensuring all departments and stakeholders are aligned. This requires a holistic approach to technology infrastructure strategy, prioritising operational efficiency and process automation. Real-time feedback will enable real-time adjustments, and the installation of new technologies will transform how employees tackle operational challenges.

Ultimately, no one can predict how any subsequent manufacturing crises will look. But as many organisations discovered in recent years, it’s far better to be safe than sorry. Now is the time to take steps to mitigate downstream disruptions. After all, the organisations that act decisively today can expect watertight resilience, whatever the economic conditions, long into the future.

Grace Nam, Strategic Solutions Manager at Laserfiche, is a highly motivated marketing strategies professional with progressive career experience. Fluent in both Korean and Mandarin to support domestic and international communications, Nam is skilled in strategic content and brand marketing, market research and analysis, project management, and public relations. A strong relationship builder with a team-player mentality and self-motivated to succeed, she has proven success in leading and working with regional and international teams.

www.laserfiche.com/jobs

Mining Outlook (MO): How have recent export controls imposed by China on gallium and germanium caused a surge in commodity prices?

Bindiya Vakil, CEO and co-Founder

(BV): China is the world’s largest germanium producer and controls 68 percent of global germanium refinery production in 2022, so the new restrictions will impact commodity prices. Additionally, China produces 94 percent of the world’s supply of gallium and so export controls will increase that pricing too. In fact, recent data shows a 50 percent increase in the price of gallium, so finding alternative suppliers will be critical going forwards.

MO: Owing to China’s position as the largest reserve of rare earth metals globally, is this trend expected to persist?

BV: China dominates with over 60 percent of all global rare earth oxide reserves, so the newly implemented licensing system will be an ongoing

cause for concern for many businesses and manufacturers in the high-tech and semiconductor space. It is too early to tell exactly how long the trend of increased commodity prices will continue, however, according to Resilinc’s data, 4,400 sites have been impacted by the export control measures. With just 45 alternative sites available, it will be some time before prices stabilise.

But this isn’t the first time China has restricted exports. In 2010, China restricted exports of rare earth elements to Japan as a result of a territorial dispute. This also resulted in soaring prices while Japan struggled to find alternative sources.

What’s more, there are few alternatives that perform as well as germanium and gallium. Though silicon can be used instead of gallium in low-end chip applications such as cars, it cannot be used within more advanced technology like satellites or military applications. Similarly, silicon can be used instead of germanium,

but its use is even more limited to only high-frequency electronics like infrared applications and lightemitting diodes.

Germanium and gallium are both featured on the critical minerals lists of the US and EU, so the reduced supply and resulting increase in commodity prices will only cement their reputation as highly sought after resources.

MO: What upstream impacts are Western supply chains likely to experience as a result of surging commodity prices?

BV: Currently, China typically exports germanium and gallium to companies in Japan and Europe as well as the US, with Japan and South Korea being top importers. These new export restrictions are likely to impact products like semiconductors, sensors, as well as larger products like electric vehicles (EVs) and solar panels.

Looking ahead, countries will need to increase domestic production and diversify their supply chains to reduce reliance on single-source suppliers, further reinforcing ‘China Plus One’ thinking within organisations across European countries and beyond. Some mining companies in the Democratic Republic of the Congo (DRC) and Russia are already looking to increase germanium production to meet fresh demand, however it remains to be seen if this production will be readily available to Western markets.

Following a recently released report by Resilinc, we discuss the impact of export restrictions on the global semiconductor industry with CEO and co-Founder, Bindiya VakilWestern countries that produce germanium and gallium include the US, Canada, Germany, and Japan, but it takes time to ramp up production due to the inability to process the materials, as well as environmental regulations in place preventing processing and mining due to the significant pollution it causes.

MO: Equally, what will the consequences of the latest export restrictions be for the global semiconductor industry?

BV: According to Resilinc’s data, we’ve mapped over 220,000 different parts that are impacted and have been disrupted by the export restrictions - primarily in the semiconductor, electronics, and aerospace and defence industries. Additionally, our data shows that this disruption could take an average of five weeks to recover from, and as many as seven years for some suppliers. Clearly, this adds to the already difficult picture for those suppliers and manufacturers impacted by semiconductor shortages in particular. As a result, the ‘China Plus One’ approach, whereby organisations look beyond only China to alternative suppliers to meet their

current and future demand, is one of the most likely consequences.

MO: Why are supply chain risk mitigation and AI the best methods to minimise the threat of commodity shortages?

BV: Mapping and monitoring your suppliers is the foundation to any resilient supply chain. It goes to the heart of what it means to mitigate risk, as if you don’t have visibility over who is in your supply chain and what is in your supply chain (i.e. which commodities), you cannot take the necessary actions to limit or entirely prevent the impact; after all, 80 percent of supply chain disruptions originate from sub-tier suppliers. With your supply chain mapped, you can then monitor it 24/7 for any potential threats. We track and monitor over 150 million news feeds across 200 countries and 100 languages via artificial intelligence (AI), which is fundamental to giving you the most up-to-date, clean data on what’s impacting your supply chain. Businesses then gain a head start in predicting where potential commodity disruption might occur within their supply chain so that proactive measures can be taken.

MO: What makes Resilinc an expert in how best to implement these solutions?

BV: At Resilinc, we’ve been tracking supply chain resiliency since 2010 and have mapped the supply chains of over 800,000 global suppliers down multiple tiers, covering sub-tier sites, parts, as well as raw materials. We have the largest collection of suppliervalidated data of any organisation, and we’re very proud that over 100,000 organisations use Resilinc’s resiliency solutions to protect their supply chains.

A key AI solution we offer to organisations dealing with commodity shortages is CommodityWatchAI, a predictive algorithm combining machine learning with Resilinc’s data that identifies cost opportunities and the best possible pricing across commodities, including rare earth minerals like gallium.

Africa Outlook, APAC Outlook, EME Outlook, North America Outlook, Mining Outlook and Healthcare Outlook are digital publications aimed at boardroom and hands-on decision-makers, reaching an audience of more than 800,000 people around the world; spanning the full range of industrial sectors.

With original and exclusive content compiled by our experienced editorial team, we look to promote the latest in engaging news, industry trends and success stories from across the globe.

Your company can join the leading industry heavyweights enjoying the free exposure we provide across our platforms with a free marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to help you grow your business. Visit www.outlookpublishing.com/get-involved for details on how your company can feature for free in one of our upcoming editions.

www.outlookpublishing.com/get-involved

Building on the global success of its regional titles – Africa Outlook, EME Outlook, APAC Outlook, and North America Outlook – Outlook Publishing is proud to introduce a platform dedicated to the manufacturing sector.

As manufacturing organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

A multi-channel brand, Manufacturing Outlook brings you the positive developments driven by organisations across the global manufacturing industry through our various platforms. Discover exclusive content distributed through our website, online magazine, social media channels, and dispatches delivered straight to your inbox with a bi-weekly newsletter.

Through this compelling new venture, we foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

www.mfg-outlook.com/work-with-us

The Mining World Congress (MWC) is a unique opportunity for international representatives of the world’s leading resource economies to meet, find new partners, discuss current challenges, and share the latest research, technology, and best practices.

Setting the scene for international agreements and highlevel discussions, MWC events have significantly influenced mining operations and the resource industry. This has become a truly exclusive chance for people all across the industry to join senior mining industry owners, investors, national and international government representatives, researchers, educators, regulators, suppliers, and operators in a demonstration of real leadership and presence in such a prominent sector.

This year’s mining congress is taking place in one of the cultural epicentres of the world, London, at the Kensington

Conference and Event Centre, from the 30th-31st October, and boasts 200 delegates, 25 speakers, and a plethora of mining exhibitions.

For a full rundown of all speakers across this two-day event, you can see the agenda here. With a cast-list to rival any mining event in the world, Mining Outlook shines a spotlight on the keynote speakers.

Founded in 1873, when a group of investors purchased a mine complex on the Rio Tinto, in Huelva, Spain, Rio Tinto is a British-Australian multinational company that is the world’s second-largest metals and mining corporation, focusing on finding, mining, and

The upcoming Mining World Congress 2023 is fostering debate on the wider mining industry, minerals equipment exploration, and business

MINING WORLD CONGRESS 2023 WILL BE DISCUSSING:

MINING WORLD CONGRESS 2023 WILL BE DISCUSSING:

The future of mining

Mining ESG challenges:

decarbonising the minor sector

Critical mineral and geopolitics

The role of blockchain technology in the mining industry

processing the Earth’s mineral resources.

Sam Houston, Vice President (VP) of Major Projects at Rio Tinto, is an accomplished and experienced change leader in operational engineering, construction, and mining environments. Houston relishes in propelling organisations to success by focusing on transforming commercial underperformance to profit, rationalising dysfunctional structures, and galvanising stakeholders and high-performance teams to stretch levels of accomplishment.

In the morning of the first day of the conference, Houston will be discussing the future of mining, including major projects with sustainability, technology, and people.

A British multinational mining company with its headquarters in London, Anglo American is the world’s largest producer of platinum, with around 40 percent of the world’s output, as well as being a major producer of diamonds, copper, nickel, iron ore, polyhalite, and steelmaking coal, having been an industry leader for over 100 years.

• Rio Tinto

• Anglo American

• AspenTech

• KamniChain

• Brookville Capital

• McKinsey & Company

• RheEnergise

• IGS Energy

In the afternoon of the first day, Richard Morgan, Head of Government Relations and Political Risk at Anglo American, will be leading a conversation around environmental, social, governance (ESG) in the mining industry and how it ties into political risk.

KAMNI Chain is an experienced mining industry corporation that has extensive experience of blockchain technology principles, as well as currently available solutions and providers. Offering popular webinars, KAMNI Chain has helped bridge the knowledge gap and benefits from the implementation of blockchain.

The founder of KAMNI Chain, Tanya Matveeva, is a geologist by vocation with over 25 years of experience all over the globe, focusing on exploration and data management. Since learning about blockchain technology, Matveeva realised the potential for the mining industry and is working on solving the sector’s challenges using blockchain-based solutions.

Listen to Matveeva discuss in further depth the role of blockchain technology in the mining industry in the afternoon on the first day of the conference.

Aspen Technology, Inc. (AspenTech) is a provider of software and services to process assets using safer, greener, longer, and faster methods. AspenTech’s solutions address complex environments where it is critical to optimise the asset design, operation, and maintenance lifecycle.

Marc Poualion, Senior Global Lead at AspenTech, has been working in software product management in the mining industry for over a decade, overseeing product management and R&D teams who defined and developed market-leading solutions for various parts of the mining value chain.

On the first day of the conference, Poualion will be speaking in the afternoon about mining tech – mining innovation with data, artificial intelligence (AI), and machine learning (ML).

Helping entrepreneurs invest in gold, Brookville Capital Limited works to help people retire earlier with smart investments that garner results and help secure clients’ future.

Simon Popple, Managing Director of Brookville Capital, left the world of property to invest in commodities, with MoneyWeek asking him to write a newsletter for them, and then eventually being asked to write Gold Speculator with Jim Rickards for Agora Financial. By successfully investing in the sector and regularly contributing to the IG Index, Popple has made his mark in the industry.

On day one, Popple will be leading a conversation regarding investing in recession – the case of gold!

Founded in 1926, McKinsey & Company is a global management consulting firm that offers professional services to corporations, governments, and other

organisations worldwide. The organisation is committed to the mission of attracting and developing a talented and diverse group of colleagues and helping clients create meaningful and lasting change.

As a partner at McKinsey & Company, Elizabeth Foote serves companies, governments, and social-sector organisations on a range of strategy and business topics, with a particular focus on ESG, the future of work, and organisational design.

Foote will be discussing decarbonisation and the materials transition in the morning of the second day of the conference.

Located in London, RheEnergise is bringing innovation to pumped energy storage, whilst developing technology that solves the many disadvantages of other competing energy storage and grid flexibility solutions. As one of only a handful of businesses to have been awarded grants under both the Sustainable Innovation Fund and the Small Business Research Initiative, RheEnergise is making waves in the industry.

Sophie Orme, Commercial Director of RheEnergise, is a sustainability and energy advisor, as well as a speaker and influencer. With over 16 years of CleanTech experience, Orme is an authentic, value-driven leader with director-level experience across a range of disciplines, with a common thread of developing pioneering solutions to support energy transition.

Listen to her speak about helping mines decarbonise with low-cost, scalable, long-duration energy storage on the morning of the first day.

International Geoscience Services LTD (IGS Energy) offers a highly specialised service that is entirely focused on the collection, compilation, value-adding, interpretation, and serving of geodata to incentivise and support mineral exploration.

Director of IGS Energy, Dr. Ash Johnson, is a geophysicist and business leader with over 30 years of experience in research, global business development, leadership, and corporate governance, helping companies bridge the gap between science and business.

Dr. Johnson will be leading a conversation about modern government geoscience data – a tool for exploration investment decisions, in the morning of the second day.

Timmense challenges and promising prospects, as green technologies fuel an unprecedented call for minerals like copper and lithium.

According to the World Bank, demand for these minerals is expected to rise by over 100 percent by 2050. This trend places the mining industry at the forefront of the green transition while amplifying its environmental responsibilities.

As a sector responsible for almost 10 percent of global carbon emissions, miners are under a moral and regulatory obligation to balance the scales by reducing emissions. One barrier to realising this stems from the inefficient use of heavy equipment on mining sites. The absence of best-practice CO2 benchmarking, facilitated by improved data sharing, is stifling momentum in the drive to achieve lower carbon operations. However, intelligent sensors, telematics, and data solutions can

Writer: Shweta Saxena, CEO, MachineMax

Writer: Shweta Saxena, CEO, MachineMax

serve as the linchpin for leaping this hurdle.

Crucially, if the mining industry can start to identify a standard baseline, then high-emission areas of inefficiency, like idling hotspots, can be highlighted and addressed.

Data is a valuable commodity in the mining industry, offering vast insights into operational efficiency. Recent advances in artificial intelligence (AI) and machine learning (ML) have supercharged the power of telematics and data solutions, presenting newfound potential for data. This evolution in telecommunications technology has led to enhanced on-site connectivity, and can now provide real-time data analysis that goes far beyond basic tracking.

Mining professionals can use telematics and data solutions to power automated tracking tools that monitor a wide range of metrics relating to how equipment, such as haul trucks and excavators, is being used, from performance and fuel consumption to operator behaviour. Previously, mining companies would have to manually collate this data in the field at a pace that made proactive interventions impossible.

Today, this data offers a gateway to proactively identify issues, minimise unplanned downtime, and enhance overall operational efficiency.

This pre-emptive approach can translate into real actionable improvements to operations, such as reducing idling time and fuel consumption. These aren’t just numbers on a spreadsheet, either; they produce a substantial decrease in carbon emissions, aligning with broader sustainability goals. This data-driven strategy can lead to both economic and environmental benefits.

While the adoption of telematics is widespread, the real challenge lies in the effective aggregation and analysis of data.

Three quarters of businesses use telematics for fleet management and equipment tracking, however, disparate platforms often dilute the value of the data, making it difficult to derive actionable insights.

This is where cloud-based aggregation comes into play. By consolidating data into a single platform and employing AI-driven analytics, mining firms can access critical information from the field and transform raw data into actionable intelligence.

This unified approach is the missing piece that can drive immediate, impactful change.

Looking ahead, the industry needs a comprehensive, scalable roadmap to achieve its sustainability goals. Data-driven decision making is a key steppingstone, providing miners with real-time visibility of equipment availability, performance and maintenance, thereby enabling informed strategic decisions like maintenance scheduling.

Efforts to invest in more sustainable practices are ongoing, but the sector cannot wait for wider access to renewable energy and more energy-efficient fieldequipment. The immediate priority must be to increase operational efficiency using the tools available to professionals today.

This shift, which needs to happen as a matter of urgency, will not be possible without strategic investment. In the longer term, the introduction of cleaner, alternative energy-powered equipment will help to bolster efforts. Within this journey, transparency and accountability are critical. The sector must realise the true impact of operations on climate change in order to implement robust sustainability reporting.

Only then can accurate carbon auditing mechanisms be put in place to track progress and ensure transparency and stakeholder accountability.

Mining is integral for the transition to a greener future. Telematics and data solutions offer a tangible, immediate and less environmentally destructive pathway.

As we navigate this complex landscape, the adage “If you can’t measure it, you can’t improve it” has never been more relevant.

The net-zero clock is ticking down, but while climate change has never been more pressing, miners have never been in a better position to work more efficiently. In a world demanding more from mining than ever before, it’s not the minerals but the data that will be our most valuable extraction, steering us toward a future where sustainability and profitability coexist.

www.machinemax.com

Providing indispensable resources and value whilst striving for sustainability, mining is the unheralded industry underpinning the Sunshine State

Writer: Lucy Pilgrim | Project Manager: Dave West

Writer: Lucy Pilgrim | Project Manager: Dave West

On the eastern coast of Australia, millions of visitors flock to Queensland every year, as it is characterised by its rugged outback landscape, dazzling sandy shores, and the magical Great Barrier Reef.

And yet, the unsung hero supporting this wondrous state is the Queensland mining industry, which plays a major part in not only generating revenue for the region, but obtaining the minerals and resources used in thousands of products, domestically and internationally.

As the mighty spokesperson for hundreds of mining entities, the Queensland Resources Council (QRC) is a non-governmental organisation (NGO) and non-profit organisation (NPO) that represents and promotes the interests of its members, whatever their thoughts or concerns may be. Its vital support and representation spans the fields of exploration, mining, minerals, processing and energy production.

Ultimately, QRC is working to shine a light and champion the contribution of its members by embracing innovations and guiding the industry to a greater sustainable future.

Mining Pro provides mining production and maintenance personnel, operational supervision and management to execute mining projects from a single production fleet to whole of mine solution.

LEARN MORE

Mining Pro Founder and MWG Mining Chairman Grant Wechsel says the business was purposebuilt specifically to support the Queensland Resources industry, in particular the coal sector.

In 2020, Wechsel established MWG Mining, a group of companies providing specialist mining services across a range of key core brands.

One of those brands, Mining Pro, was purposebuilt to service the Australian coal sector. Mining Pro provides mining production and maintenance personnel, operational supervision and management to execute mining projects from a single production fleet to a whole of mine solution.

“We saw a unique opportunity in the market to provide a service to coal mine owners that allowed them to keep control and responsibility of the operation, but they get a genuine mining services partner in Mining Pro. We are effectively like a mining contractor without the ultra-class equipment,” states Mr Wechsel.

Mining Pro is run by mining professionals with decades in the industry who also have a depth of knowledge in employee relations which is a key differentiator for the company in the coal industry. Mining Pro Executive Director, Grant Arnold, has spent decades working for some of the biggest coal mining companies in Australia, and not only understands what approach our clients need, but also what our teams at the ‘coal face’ want. Mr Arnold shares, “It has been important that we did what we said we were

going to do as an employer and that is provide permanent jobs, communicate well with our workforce and ensure our sites are a great place to work. I frequently get our employees thanking me for their first full-time job in the industry and others saying our site is the best they’ve worked at, which is really great to hear.”

Mining Pro proudly states they are the fastest growing full-time employer in Queensland’s coal mining heartland, the Bowen Basin. At a time when many companies have looked to diversify away from coal, Mining Pro has taken a different path. Wechsel adds, “We are privately owned and run a company that understands the coal mining industry. Our directors have been a part of the industry for many years, and we recognise that it is one of the most important industries in the Queensland economy. First and foremost, we want to provide a great service for our clients, but we also openly support an industry that does so much for us, our employees and the communities in which we operate.”

Off the back of Mining Pro’s strong reputation of delivery in open cut coal mining operations across Queensland, it is now establishing its underground coal mining services business where the team can supply a particular mining service or a whole of mine solution for our underground clients.

www.miningpro.com.au

info@miningpro.com.au

Speaking to Chief Executive of QRC, Ian Macfarlane, we learn about the association’s tenacious efforts towards achieving net zero by 2050

Mining Outlook (MO): Firstly, can you talk us through the origins of QRC, how it came about and its initial vision?

Ian Macfarlane, Chief Executive (IM): QRC was formed in November 2003, although its origins date back as far as 1910 when mineral rights were first vested in Queensland. In the 1970s, two different coal bodies merged to form the Queensland Coal Association, which then joined with

the Queensland Chamber of Mines in 1990 to form the Queensland Mining Council.

QRC’s rebranding in 2003 to a Resources Council provided a one-stop shop for advocacy on behalf of all Queensland resources – petroleum, gas, minerals, coal and metals. The intention was also to focus more clearly on both ends of the value-adding chain, from the early stages of exploration and greenfield discovery right through to refining and smelting.

The broader focus of the new QRC included the establishment of our education arm, the Queensland Minerals and Energy Academy (QMEA) in early 2005 and the public celebration of Resource Awards for Women on International Women’s Day – both early QRC initiatives that continue to grow strongly today.

Presently, QRC’s vision is to provide effective representation across the resources and energy sector as a leading corporate citizen dealing respectfully with members, governments, stakeholders, and the wider community.

QRC provides high-level policy advice and analysis to achieve the best evidence-based outcomes for industry, governments, and the community.

MO: Since inception, how has QRC developed and progressed in terms of its key objectives?

IM: From its inception, QRC has focused on strategies to secure the long-term sustainability of the minerals and energy sector. We have become a highly trusted industry peak body, recognised for our leadership role within the resources industry and among stakeholders.

QRC has established a strong track record in promoting resources, engaging with government and encouraging the highest standards in the sector.

MO: What trends are currently transforming the industry and how is QRC responding to them?

IM: The biggest trend transforming the industry at the moment is of course the move to net zero by 2050. The big resources companies that operate in Queensland

have set this as an aspirational target, and as such, are working to reduce their emissions. Companies such as BHP have made definite commitments towards using more renewable energy, whilst companies such as Anglo American are experimenting with components like hydrogen and battery trucks to try and lower their emissions and use electricity generated through solar or wind power.

As well as that, we are also seeing a rise in demand for rarer strategic metals. This is providing new opportunities, particularly in North West Queensland, and is currently in the early stages with a long way to go. Moreover, we are trying to see how we can process those minerals before we export them, and perhaps even make them into the batteries that the world is demanding.

Within the more traditional mining areas, we are seeing increased demands in copper, but also lithium, which we don’t have much of in Queensland. However, we are seeing quite a lot of prospects in this area.

Additionally, the demand for coking coal is projected to stretch out for a further four or five decades at least, alongside the significant current interest for thermal coal. Across the board we are also seeing a strong demand in the materials Queensland produces as we move to net zero, which is a goal we cannot reach without the resources we are currently mining.

MO: What do you find most interesting about the mineral and energy resources sector currently?

IM: Stretching across Queensland commodities, from new and traditional metals to coal, gas, petroleum and energy in general, the most interesting aspect currently is the innovation that is being brought into the industry, to not only lower emissions but also make it a safer and more efficient environment to work in that is internationally competitive.

We are seeing companies that have traditionally led the world with mining technology adopting new techniques in above ground operations, which is seen in the way they operate their trucks and logistics systems, plus how they generate energy and the way they move it around. Some companies in the resources sector are already building large solar and renewable energy farms, one example being the Ruby Run solar farm located in Central Queensland and operated by Bravus. Thus, companies are taking a very diverse approach to technology, using it wherever they can to improve safety, efficiency, and lower their emissions to meet Australia’s net zero target by 2050.

IM: The biggest challenge for QRC is to ensure the industry gets a fair go from governments across Australia, as we are seeing a trend that they tend to take the mining industry for granted.

We are producing billions upon billions of dollars in tax income for state and federal governments, and without the resources sector, the federal budget wouldn’t have seen the big turnaround that it did. In Queensland, the contribution from coal alone this year will be approximately AUD$13 billion, a fair distance from the original government projections of about AUD$5.5 billion. That’s a massive amount of money to go towards hospitals, roads, schools, police, and all the things that are essential to supporting communities.

In return, we therefore need recognition of the role that the resources sector is playing, not just in terms of taxes, but also the employment that we provide. Queensland’s resources sector supports the jobs of around 450,000 people across the state, many of them in regional areas. The influence and benefits of the mining industry are felt right across Queensland, from Eagle and Queen Streets, the main business streets in Brisbane, north to Cloncurry and Mount Isa, and west to Birdsville.

Mining is an industry that’s making huge economic contributions, and we want to see those contributions more openly recognised.

IM: We work very closely with numerous departments of the Queensland Government. The relationship between QRC and the Department of Resources is very strong, and it is one built on mutual respect. We’ve worked together since the inception of the department in various forms.

QRC also provides industry-wide input and feedback on policy areas, which saves the department from having talk to all our members individually. Our role is to collect their thoughts, concerns and praise and feed them back to the department.

We also work very closely with the Department of Environment and Science. Whilst at times we do have issues with some Queensland Government policies, we work efficiently at a departmental level to try and advocate for our members.

Other departments such as infrastructure, transport, and energy also rely very heavily on input from members of QRC.

working with the government on a survey of employees in the resources industry to address any misconceptions about speaking up about safety concerns.

QRC has also recently received state government funding for a new initiative to address skills shortages and create job opportunities for groups underrepresented in the resources and energy sector workforce. The project is called Resources W.I.D.E (Workforce Inclusion and Diversity Engagement) and will target Indigenous Australians, women, people from culturally diverse backgrounds, veterans, refugees, and neurodiverse people who are looking for employment in the resources sector.

MO: Does QRC have any projects in the pipeline that excite you?

IM: Safety is a core value for the resources industry and equally for QRC. We work hard to assist members operating across the minerals and energy sector, to help create a safe working environment. Currently, we’re

The resources workforce has historically been maledominated, but that is changing with QRC setting a target of 30 percent participation by women in 2026. We’ve been offering a women’s mentoring programme, in conjunction with Women in Mining and Resources Queensland (WIMARQ) for the past 10 years, as well as a mentoring programme for female students. Both have become very popular and successful in introducing women to great career opportunities in mining, from engineering to trade apprenticeships and executive leadership roles. Our

WIDER COMMUNITY”

– IAN MACFARLANE, CHIEF EXECUTIVE, QUEENSLAND RESOURCES COUNCIL

latest figures indicate women now make up 22 percent of the resources sector workforce and we are confident of reaching our target.

The industry is committed to being part of the global solution to meet the challenges of achieving a decarbonised future. QRC and its members are committed to working together to achieve energy security while taking proactive steps towards a low-emissions economy. We also support the Paris Agreement and its emissions reduction goals to limit global warming to well below two degrees Celsius (°C), preferably to 1.5°C, compared to preindustrial levels.

Coal Mine Site Rehabilitation is another important focus. Amongst other initiatives, we recently introduced Coal Mine Site Rehabilitation scholarships that will fund two university students to take up postgraduate studies in world-class environmental management.

Queensland is fortunate to have large reserves of the critical minerals the world needs to develop new technology across a range of important industries including defence, health, communications, and of course, energy. QRC is working with the Queensland Government on the development of a Critical Minerals Strategy, with a focus on regulatory reform to promote secondary processing. We now have a QRC Critical Minerals Working Group to ensure Queensland has a strong role to play in the rapidly emerging, and evolving, critical minerals market.

MO: How do you see QRC and the wider industry developing over the next five years?

IM: Traditional industries will definitely remain strong. Alongside the increased demand for coking coal, there will be heightened demand for steel, whether it’s for windfarm towers or for local infrastructure such as buildings and

cars. The coking coal industry will remain important to everything that involves steel.

To add to this, the demand for coking coal in developing countries is going to continue to rise. We are also seeing a rebound in the demand for thermal coal, and whilst our industry is focused on achieving net zero by 2050, the immediate focus for people in developing countries is to be able to turn their lights on. The industry is additionally addressing challenges stemming from the market disruptions of the Russian conflict in Ukraine.

Metals including aluminium, copper, zinc, and all the resources used in renewable energy projects, as well as traditional energy sources, will also see a substantial rise in demand. This is reflected in the demand for gas, which has become Queensland’s second most important export after coal, particularly with the extraordinary global demand for liquified natural gas (LNG), to ensure that every viable transitional fuel is being used to help achieve net zero.

Rare and strategic metals are in the very early stages of development but we are making good progress, with a multi-user processing plant being built in North Queensland and other companies opening mines for vanadium, which has been talked about for a long time.

So, I think that the future looks very strong, and our challenge is to not only make sure we reach our targets of net zero by 2050, but also have long-term opportunities for people to join and work in the industry, get a great career out of it, and make a difference in getting Queensland and the world to net zero by 2050.

info@qrc.org.au

www.qrc.org.au

“QRC’S VISION IS TO PROVIDE EFFECTIVE REPRESENTATION ACROSS THE RESOURCES AND ENERGY SECTOR AS A LEADING CORPORATE CITIZEN DEALING RESPECTFULLY WITH MEMBERS, GOVERNMENTS, STAKEHOLDERS AND THE

MINING OUTLOOK is a quarterly digital publication and media brand showcasing the latest innovations, industry insights and corporate stories from across the international mining and resources sector. Its world-class team collaborates with the biggest and most exciting brands to craft engaging and authoritative content for a global audience of industry players. As mining organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

The expertise of our in-house design and production teams ensures delivery to the highest standards, as we look to promote the latest in engaging news, industry trends and success stories from the length and breadth of the global mining sector.

As a multi-channel brand, Mining Outlook reaches an international audience through various platforms, with exclusive content distributed through our website, online magazine, social media channels, and bi-weekly newsletter.

Through this compelling venture, we intend to foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers or our Managing Director, James Mitchell, today.

Writer: Alex Tuck | Project Manager: Eddie Clinton

Soaring over the vast swathes of Queensland’s Central Highlands, the Nankeen kestrel is a common sight. Over the millennia, this native Australian bird has continuously evolved to adapt to its local surroundings, and despite its diminutive size, remains one of the region’s most successful and resourceful birds of prey.

The kestrel’s very architecture is the ultimate example of each component working in harmony as a

cohesive whole, from the black tip of its wing to its laser-focused vision, as it surveys the resource-rich coalfields of the Bowen Basin, poised to seize opportunity.

As part of the Nankeen’s regional territory, cattle graze serenely on the lush, verdant pastures that originally earnt the nearby town of Emerald its distinctive name, but unbeknownst to the bird, beneath these lands, a dynamic hive of activity awaits in the coal-rich underground realm.

Undamine Industries (Undamine) is a contracting company specialising in the black coal industry. Renowned as secondary support and longwall specialists throughout the Bowen Basin, the company’s Central Queensland base allows it to effectively serve areas such as the Galilee Basin and beyond. Company Director, Peter McPhail is considered one of Queensland’s premier secondary support specialists whilst Director, Shane Jackson is a longwall and machinery maintenance expert. Both work closely on-site with their Project Managers, Secondary Support Specialists, Longwall and Machinery Maintenance Teams. This expert turnkey workforce is constantly available around the clock. The four Directors, Peter and Karla McPhail and Shane and Renee Jackson possess a strong commitment to providing excellence in both safety and performance.

Undamine Industries is proud to be a contracting company working with Kestrel Coal Resources, commencing our long-term contract partnership in March 2021, Undamine supplies trained and skilled labour to Kestrel South Mine Site. Established in 2004, Undamine Industries specialises in the Queensland and New South Wales coal industry. We have worked throughout the industry in many different areas but have focused on labour supply for contracts in Secondary Support, Longwall Moves and Maintenance. We supply skilled and specialised labour and equipment to support mining operations throughout the industry with a focus on the Bowen Basin, operating out of Yeppoon, Queensland, Australia.

Whilst working throughout Queensland and New South Wales we have partnered with various major clients including Glencore, Fitzroy Resources, Anglo American, BMA and Kestrel Coal Resources.

We believe in partnering with the companies we service, building strong relationships with their management team and workforce. We work in a fully integrated manner operating within the structure of the operation.

Undamine Industries strives for excellence in business and puts people first, always.

Being an established company, we can take a flexible and innovative approach to problem solving. This adds significant value. One example is that we have the unique capability to deliver urgently needed underground longwall recovery services and have conducted critical auxiliary works outside the scope of contracts as required by our clients.

Our labour force is among the most highly trained, qualified and licensed in the industry. Having Coal Train a registered RTO to support Undamine ensures that the workforce competencies are maintained and updated as required by the industry and our clients.

We maintain a stable and motivated workforce, which is critical to maintaining high levels of safety and productivity. Undamine fosters healthy, positive workplaces, and as a result we have enjoyed outstanding loyalty and stability from our workforce.

Undamine is a privately owned business established in 2004. The four owners, Peter and Karla McPhail and Shane and Renee Jackson, have a strong commitment to providing excellence in both safety and performance.

We know the industry well and apply our expertise to managing safer, more cost-effective operations: Undamine has been publicly acknowledged for exceeding all of our KPI over a five-year contract period. Undamine are is proud to have an unparalleled, continuous working partnership with our contract holders for over 19 years.

Established in 2004, Undamine has one of the most outstanding safety and production records in Queensland and in 2012 was acknowledged as having zero Lost Time Injuries (LTIs) whilst also having met 100 percent of its key performance indicators (KPIs) over a five-year contract period. Additionally, Undamine are ISO9001 accredited and has worked throughout both Queensland and New South Wales (NSW) with major clients including Xstrata, Anglo American

Thanks to our reputation for quality services and our exceptional safety and production record, Undamine has grown to have over 300 employees training and manning sites at over eight different locations.

Karla Way-McPhail, highly successful businesswoman and Undamine Industries CEO, has built her success on empowering others. Whether in the workplace giving businesses and individuals the tools to prosper or out in the community providing support to the disadvantaged, Karla lives her philosophy of “people first, always.”

and BMA. The company promotes the key values of excellence, integrity, safety, accountability and teamwork in everything that is does.

Peter and Shane have both been Company Directors of Undamine since its establishment in 2004.

Undamine takes great pride in

Peter has an excess of 40 years’ experience in the underground mining sector. Shane has over

30 years’ experience in the underground mining sector.

Peter and Shane are well respected in the Black Coal Industry for their industry knowledge and outstanding safety record.

Supported by an exceptional Management and Operational Team, our streamlined organisational structure means Undamine is 100 percent compliant across all business operational areas.

Renowned as Secondary Support and Longwall Specialists throughout the Bowen Basin, Undamine hires out both labour and machinery to support mining operations. We supply to all sections of underground mining across Queensland and New South Wales.

sponsoring both senior and junior sporting clubs, providing funds for much-needed medical equipment and supporting organisations such as Legacy and The Lions.

The company also has a strong commitment to supporting non-profit organisations within the communities in which it works. Similarly, Undamine

Undamine Industries is focused on becoming the partner of choice for the mining and resources industry. Our proven operational performance with the Tier One mining houses demonstrates a customer focused business approach ensuring we establish personal relationships with our clients ensuring any successes are mutually beneficial.

As a contracting company we have the most substantial footprint in Queensland. We are the only suppliers who supply directly to:

• Anglo American

• Glencore

• BMA

• Kestrel Coal Resources

• Fitzroy Resources

• And others

We have demonstrated both longevity and endurance.

The Undamine Head Office and state of the art training facility is located in Yeppoon, Queensland. In addition to this we have regional offices and training facilities in Emerald, Blackwater, Middlemount, Moranbah, Mackay and Emerald.

Undamine Industries is very proud to be the longest contracting company in Queensland. Undamine has been supplying contacted services to major companies for over 19 years straight. This is a demonstration of the outstanding level of services we provide to contact holders.

Much like its symbolic namesake, it is in this region where Kestrel Coal Resources (Kestrel) operates with the same agility, resourcefulness and compact adaptability of the raptor, as an underground mine that keeps the cogs of our modern world turning.

“We have all the experience of a traditional mine, with the innovation and agility of a new-generation business,” introduces Kestrel’s CEO, Shane Hansen.

Acting as a custodian of the landscape, Kestrel causes little surface disturbance to the land itself, aspiring to the same minimal impact as its airborne emblem. A similarly permanent fixture of the region’s community, the Kestrel team thrives together as one, its workers dressed in shirts of the same cobalt blue as the skies in which the bird hovers above.

As a leading–edge, coking coal company, Kestrel calls on the proud coal mining heritage that defines the Bowen Basin. The Kestrel mine itself has been operating as part of this industrial legacy since 1992, after celebrating its 30th anniversary last year.

The mine can be found approximately 40 kilometres (km) north of the small rural town of Emerald – an industrious outpost that was originally established in 1879 to coincide with the mining boom that ensued when coal deposits were first reported in the basin the previous year.

With the Bowen Basin home to the largest coal reserves in Australia, these legendary, resource-rich lands have continued to provide a veritable treasure trove for the industry over the centuries. Alongside coal mining, the regional economy has evolved from depending on the exploitation of gemstones, to crop cultivation and sheep/cattle raising – both of which are able to thrive in alignment with the industry as evidenced by the Kestrel

site, where 96 percent of the surface land is in agricultural use.

Although the mine’s nearest town of Emerald may owe its name to the vibrant grasslands of its surroundings, the sparkling gem is an apt metaphor for the prosperous green future that Kestrel envisions.

“I see a future for metallurgical coal that is both sustainable and profitable,” shares Hansen.

By positioning itself as a sustainable mining company producing highquality coal destined for steel-making applications around the world, Kestrel champions the transition towards responsible mining that sustains longterm value.

Despite having a workforce of 700 people, comprising both employees and contractors on-site, Kestrel’s relatively diminutive size belies its

Kestrel is Respectful – Kestrel acts with honesty, integrity and aims to be the team that everyone else wants to work with.

Kestrel is Committed – Whether it’s safety, hitting its targets, caring for its people, community, or environment, Kestrel is committed to doing it the right way.

Kestrel is Agile – Kestrel approaches its work through a different lens. The company does it safely and gets the results few others can.

Kestrel is One – Kestrel is a diverse group with varied skills working together as one team.

vast impact – both in terms of driving long-term value within the regional community and global output.

Indeed, with approximately 6.5 metric tonnes (MT) of coal produced every year, Kestrel represents one of the world’s largest producing underground metallurgical or coking coal mines.

For Hansen, accomplishments such as this attest to Kestrel’s unwavering

“THE METALLURGICAL, ALWAYS FACING

ability to perform with the “big players” in the industry.

“We may have the feel of a smaller mining company, but we have consistently demonstrated that we have the capability to play in the big league,” he says. “Being smaller in size is not a limitation for us.”

Kestrel plays its size to its advantage by championing one of its core values – agility – since minimal

levels of bureaucracy allow for key decisions to be acted on both swiftly and effectively.

“This agility is invaluable in an industry that is as dynamic and rapidly evolving as ours,” affirms Hansen.

The company combines this agility with the energy and ambition of a young enterprise after it was established to take over the existing Kestrel mine site in 2018. The business

was formed as a joint venture (JV) between Kestrel (80 percent) and Mitsui Coal Holdings (20 percent).

As the operating entity, Kestrel has a shared ownership model between the specialist resources private equity manager, EMR Capital (EMR), and one of Indonesia’s largest coal miners, PT Adaro Energy (Adaro), both of whom are keen investors in metallurgical coal.

OR STEELMAKING, COAL INDUSTRY IN AUSTRALIA IS FACING NEW CHALLENGES, BUT WE’RE PREPARED FOR THAT”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

HBT is a world-class manufacturer and fully integrated singlesolution longwall mining equipment provider. Headquartered in Lünen, NRW, Germany, we export our high-performance equipment to every major mining market in the world and we have subsidiary and partner offices strategically located to support each region.

We offer our customers the right system for their applications — from low seams to high seams, no matter how long the face or how high the production demand. We understand the challenges faced by longwall mines today, and we’ve developed our machines to stand up to those demands. All our equipment has been designed to maximise customer value through the application of cutting-edge autonomous technology which delivers benchmark productivity and industry-leading operator safety.

We research, develop, design, manufacture and validate all our equipment in-house to ensure everything we make meets the highest standards and international regulatory requirements. We also offer high-quality parts and aftermarket support services, completing our line of end-to-end solutions for longwall mining operations.

We offer a complete line of longwall mining equipment:

• High-horsepower shearers

• Automated plow systems

• Armoured face conveyors (AFCs) / beam stage loaders (BSL) and tailends/bootends

• Intelligent conveyor drive systems

• Hydraulic roof support legs and cylinders

• Programmable mining controls

• Face automation sensors, actuators, microprocessors and computers

• High-pressure pump stations / hydraulic control valves

• Measurement and control systems for harsh environments

• Explosion and flame-proof power distribution, motor switching devices and VFD drive technology

HBT’s ancestry is ingrained in the longwall mining industry, dating back to the very beginning of mechanised longwall mining in the 1800s. Over the last 200 years, we’ve driven innovation and performance as we were shaped by a number of industry leaders — most notably Hauhinco, DBT and Caterpillar.

Hauhinco was founded in 1908 in Sprockhövel, Germany, in the cradle of the Ruhr mining area. For over 100 years, the company has adapted to new conditions while remaining true to its roots, and this experience makes us unique in the marketplace. DBT was renowned as a technology leader, with over two centuries of experience driving mechanisation and automation in the coal industry. Its innovations were instrumental in the development of the modern longwall mine — including the armoured face conveyor and the coal plow. The DBT engineers also focused on designing technology to pioneer autonomous mining. Caterpillar also has a long history in engineering and the mining industry, with impressive industrial manufacturing capability, leading-edge technology and refined demand stream processes.

We’re drawing on the strengths and advantages of all these companies as we move into the future, with a focus on driving value and helping our customers achieve their goals. We are adopting a direct service model, further enhancing our distribution capabilities, customer service and aftermarket support — all so we can deliver the best possible results for our customers.

We also have extensive aftermarket service offerings including:

> Spare parts and technical support

> Onsite maintenance and repairs

> Rebuilds and optimisation

> System performance and lifecycle monitoring

> Equipment training

YOUR IDEAL PARTNER FOR SAFE & EFFICIENT LONGWALL MINING SOLUTIONS

HBT is committed to being your single source of supply for longwall mining solutions and mining electrical engineering. We offer advanced technologies and high-performance machinery, backed by a global team of experts and the infrastructure to support customers anywhere in the world.

To learn more, visit hbt-group.com

With over 30 years of hands-on experience in the industry, Hansen began his mining career working in base metals in the well-known town of Mount Isa in Northwest Queensland. From here, he transitioned to a maintenance engineering role with BHP at the Gregory coal mine in Central Queensland at a time of enormous opportunity in the coal industry. Subsequently, Hansen went on to accept senior operations positions at various other Queensland mines, before working at Mitsui Coal Holdings with an emphasis on its global coal business and acquisitions. By positioning the company to deliver optimal returns for shareholders and providing strategic direction to facilitate growth and increased capital value, the latter led to Hansen’s current position, as CEO of Kestrel. Throughout his career, Hansen has honed specific skills in mining, processing, planning, facilities management, construction, performance management, business analysis, business growth and development.

Digging deep into the Kestrel site, the mine functions as an underground longwall operation along the German Creek seam. This location is the sweet spot for the low ash and high fluidity coal that is Kestrel’s niche product, with the company mining at a depth of 350 metres (m) to 400m along a single seam of 3m in thickness.

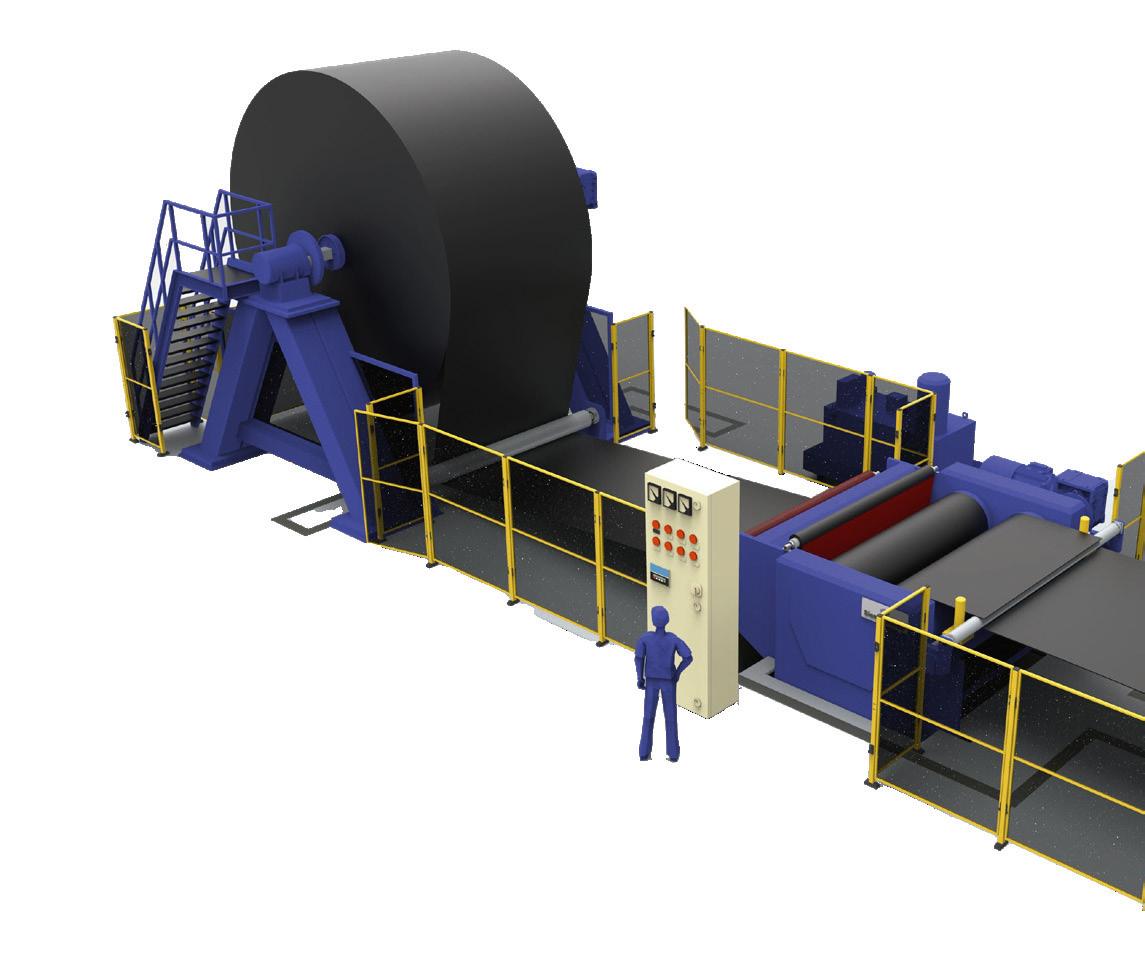

The long-life mine site consists of a single longwall, panel extraction, and a coal handling preparation plant (CHPP) where the product is washed using recycled water. Following the mining process, run-of-mine (ROM) coal is transported via a 7km overland conveyor directly to the CHPP.

From here, rail transport provides an indispensable link onwards to Australia’s premier multi-commodity port and Kestrel’s gateway to the world, the Port of Gladstone. It is from this strategic global node that Kestrel’s quality, high-energy coal is shipped to key markets worldwide.

“Our global customers use the coal to produce steel across Asia, India and Europe,” explains Hansen.

Following significant expansion efforts in 2013, the life of the Kestrel mine was extended by 20 years and increased its production capacity to 5.7MT of coking coal per annum. Of this, between 75 to 80 percent of the coal reaches the final product to minimise waste.

Today, Kestrel has an approved life of mine (LOM) until 2033, with reserves to last until 2046. However, as an exciting next step in the company’s development, there is significant potential to increase this even further.

At every level of its processes, the company maintains an unrelenting

standard of operational excellence that extends far beyond the core activity of mining itself.

“Our team’s capability covers the entire mining process, from development to extraction and processing, environmental management and sustainable rehabilitation,” he outlines.

Aside from the mine’s operational performance, Kestrel sets a new standard in longwall mining by creating a business that is communityfocused, sustainable, and ultimately, a place that people want to be.

“Our greatest strength lies in our unique blend of a respectful culture, exceptional performance, and our long history of operating in the community,” Hansen acknowledges proudly.

This has been recognised with several prestigious accolades to date. Most recently, Kestrel was voted the 2022 Australian Mine of the Year at the Australian Mining Prospect Awards, and as winner of the 2019 Mine of the Year by Australian Mining Monthly. Both achievements serve as a testament to the dedication of the Kestrel team and its underlying culture of respect, trust, and positive communication throughout the business.

Through its comprehensive capabilities, Kestrel sets itself apart by living and breathing its core values of being respectful, agile, committed, and acting as one. Permeating throughout the entire company culture, these four core tenets are the adhesive that binds all of Kestrel’s individual moving parts into a collective force that is

“OUR GOAL IS TO BE A MODEL OF SUSTAINABLE, RESPONSIBLE MINING”