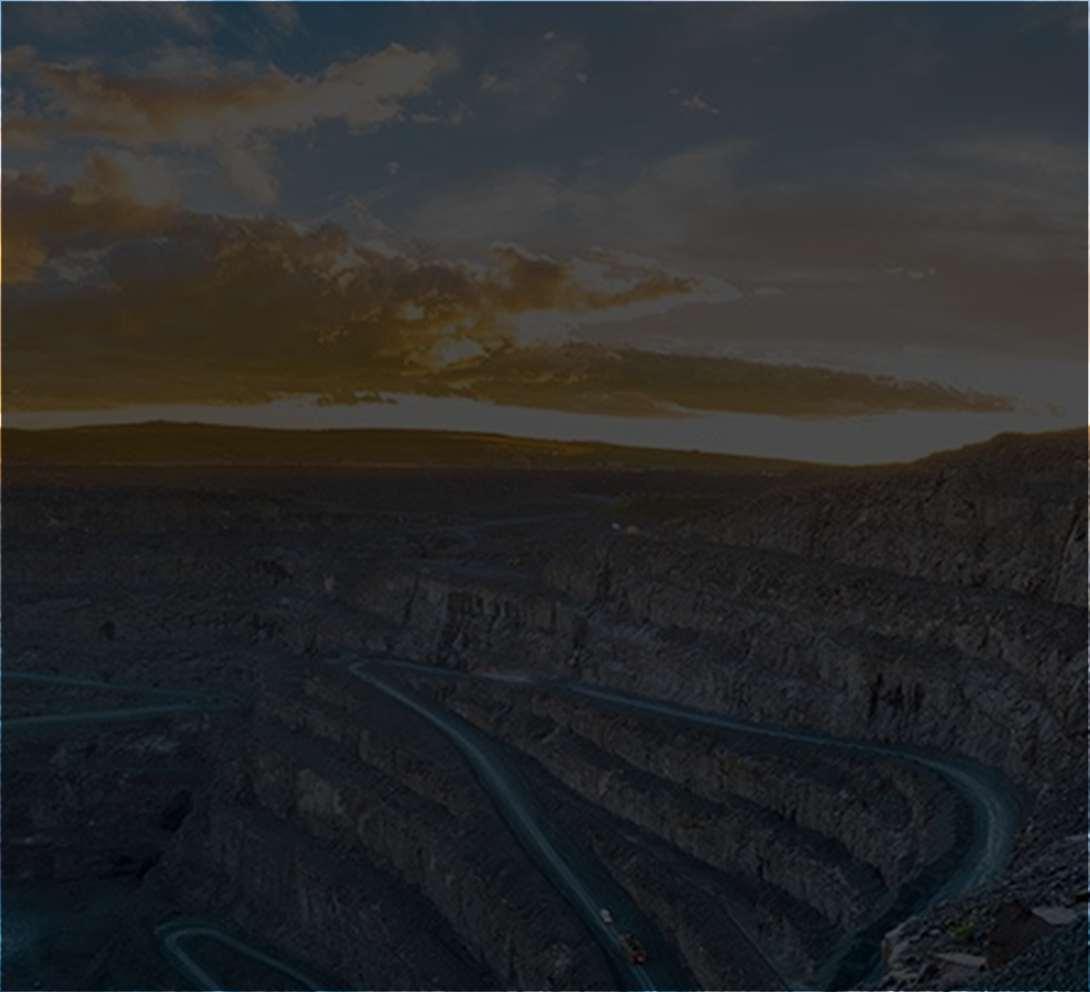

SHINING BRIGHT IN THE HIGHLANDS OF LESOTHO

Uniquely located at an altitude of over 3,000 metres, Letšeng Diamonds is in the business of mining, producing, and selling rough diamonds. CEO, Motooane Thinyane, updates us on the mine’s latest developments from the highlands of Lesotho, including its transition to an owneroperator model

Writer: Jack Salter | Project Manager: Thomas Arnold

Owned by Gem Diamonds (70 percent) and the Government of Lesotho (30 percent), Letšeng Diamonds (Letšeng) is renowned for its unique position as a mine that produces the highest average US dollar per carat value from its diamonds, albeit at the lowest grade.

Most of the mine’s revenue is derived from large diamonds (10.8+ carats), which conversely constitute less than 20 percent of the total volume of production.

Letšeng’s CEO, Motooane Thinyane, who we previously interviewed in 2023, notes that the diamond mining industry is going through similar changes to what is currently being experienced internationally.

“Mining operations continue to face pressure from a general downturn in the industry due to macroeconomic factors,” he tells us.

“Most notably, of the four operational mines in Lesotho, one went into care and maintenance in October 2024 whilst the remaining three continue to operate marginally.”

There is also pressure on the natural diamond mining industry as a result of lab-grown diamonds, which impact the former’s contribution to communities in terms of job creation, infrastructure development, education and training, social and environmental support, and economic growth.

As such, the industry is making concerted efforts to highlight the inherent value of natural diamonds as a finite commodity and the significant contributions producers make to the communities and economies in which they operate.

“In the case of Lesotho, Letšeng produces diamonds in a sustainable and economic manner that enables it to continue to make significant contributions via employment, focused community projects, local procurement, and government taxes, royalties, and dividends,” Thinyane states.

One major development since we last featured Letšeng is that the mine is now an owner-operator.

Indeed, its load and haul mining operations went into owneroperator arrangements in November 2023, whereby Letšeng reached an agreement with the previous contractor for the insourcing of mining activities.

Under this agreement, Letšeng acquired the mining equipment and absorbed the contractor’s employees in line with operational requirements.

“This transition enabled us to continue seamlessly with mining activities and created the opportunity to implement further operational changes to improve efficiencies and reduce costs,” Thinyane explains.

Regarding its processing operations, Letšeng then transitioned into an owner-operator model a year later in November 2024.

It followed a lengthy review and careful consideration as part of a drive to improve efficiencies and reduce costs, better positioning itself for longer-term sustainability.

“There remain further opportunities to transition to an owner-operator model in other aspects of our operations,” reveals Thinyane.

Alongside this transition, Letšeng’s ore and waste profile has changed over the last couple of years, resulting in leaner, more efficient processes.

The mine’s deepening ore pits and tougher economic circumstances forced a complete review of the conventional mine plans.

“Our focus has been on reducing the stripping burden whilst still enabling safe access to ore at the required rates over the life of mine,” Thinyane informs.

To this end, a number of options were considered, ranging from steepening pit slopes to underground mining.

Many initiatives to reduce haulage distances and improve fleet

productivity have yielded a revised mining plan, with a much-reduced waste stripping ratio and better overall economics going forwards.

Meanwhile, Letšeng has successfully improved efficiency, increased productivity, and reduced costs in all areas of its mining operations.

These value-adding changes, together with a strong and positive workplace culture, have set the mine up to navigate the challenging conditions currently facing the diamond mining industry.

“We are specifically excited about the significant unit cost reduction that has been achieved whilst maintaining our carat production profile,” acclaims Thinyane.

The mine is committed to zero harm to people and property, minimising environmental impacts, and the continual improvement of its health, safety, and environment (HSE) management programme and efficient use of resources.

Letšeng’s approach to occupational health and safety is focused on the management of operational risk and change, legal compliance, sound management of corrective and preventative actions, and visible felt leadership.

“THERE REMAIN FURTHER OPPORTUNITIES TO TRANSITION TO AN OWNER-OPERATOR MODEL IN OTHER ASPECTS OF OUR OPERATIONS”

– MOTOOANE THINYANE, CEO, LETŠENG DIAMONDS

Another area that Thinyane updates us on is the progress of Letšeng’s corporate social responsibility and investment (CSRI) programme.

The mine’s approach to CSRI is to establish and maintain strong relationships with local communities, stakeholders, and the entire nation of Lesotho as part of its business strategy.

“Our CSRI programme is always engaging as it reflects one of our core values – to participate in and positively

contribute to the communities where we operate,” he prides.

In the period since we last spoke, the mine has embarked on and implemented a number of projects that continue to support community livelihoods.

This includes infrastructure projects designed to address access to decent roads, ablution facilities, and potable water supply for neighbouring communities, a symptom of the remote, mountainous area where Letšeng is located.

“Rehabilitation of the gravel access road to the main A1 road down to some of the key neighbouring villages was completed after it was destroyed by heavy rain and flooding,” Thinyane confirms.

Water supply projects from natural springs have also been carried out, supplying the villages of Phuthalichaba and Maloraneng from the borehole, whilst a total of five classrooms have been constructed at Ntlholohetsane and Tšepong Primary Schools.

“OUR CSRI PROGRAMME IS ALWAYS ENGAGING AS IT REFLECTS ONE OF OUR CORE VALUES – TO PARTICIPATE IN AND POSITIVELY CONTRIBUTE TO THE COMMUNITIES WHERE WE OPERATE”

– MOTOOANE THINYANE, CEO, LETŠENG DIAMONDS

Elsewhere, in the Mokhotlong district, Letšeng continues to support dairy and poultry projects aimed at creating alternatives to employment and improving livelihoods in communities.

“Farmers are supported in the areas where they already operate and excel by providing the required infrastructure, seed capital, and technical expertise to assist them with transitioning from subsistence to commercial farming,” outlines Thinyane.

“The farmers supply major operators in the Mokhotlong district, such as the Lesotho Highlands Development Authority and other mines. Currently, the two projects employ eight people on a permanent basis.”

Letšeng has also demonstrated care for the environment and wellbeing of communities affected by its mining operations with the successful introduction of a bioremediation facility, which significantly reduces nitrates from mine waste dump seepage.

Electronic Sorting Services is a pioneer in advanced diamond recovery. The development, manufacture and supply of our Small Particle Sorter for reconcentration of primary concentrates is the latest addition to our list of successful developments with cutting edge solutions that significantly boost recovery rates by efficiently sorting fine particles from +0.5mm to -12mm.

Contact us for on-site and off-site Flowsort Recovery Machine support to benefit from our more than 30 years’ experience in the industry, or for the manufacturing/repair of X-ray generators, X-ray cables and Tracer Recovery Systems along with Concentrate bins all designed to deliver secure and reliable sorting solutions .With decades of experience, we deliver tailored solutions that optimize recovery and enhance operational efficiency at every site we serve.

Moreover, Letšeng offers educational scholarships to Basotho students to study courses related to the development of Lesotho’s natural resources.

MISSION – To maximise shareholder value and be a safe, sustainable producer of exceptional diamonds.

VISION – A world-class diamond company respected globally for optimising shareholder value through quality diamond processes, products, and social responsibility.

Upon completion, they attend a compulsory internship at the mine that is also open to other students, however preferential employment is provided to those sponsored by Letšeng.

55 students have been awarded scholarships to date, of which 18 are now full-time employees at the mine, with some even occupying senior management positions.

Currently, Letšeng directly employs around 850 members of staff and a further 300 through contractors who will play a vital role in achieving the mine’s targets for 2025.

“We are continuing our focus on operational efficiency, streamlining workflows, reducing costs, building staff capacity, and further growing Letšeng’s safety, social, and environmental workplace culture across our operations,” Thinyane closes.

“On the marketing side, our parent company continues to look for the best opportunities to maximise the revenue realisable from the sale of the diamonds.”

Tel: +266 2222 1800 info@letseng.co.ls www.letsengdiamonds.co.ls

TRANSMISSION X-RAY PEOPLE SCREENING TECHNOLOGY

South African company Xscann produces full-body scanners that reduce the theft-related losses of precious metals.

Xscann has made a significant change to how mining companies operate by enforcing effective methods of safeguarding the invaluable minerals they produce.

Unaccounted for, the potential loss of precious metals through employee theft should worry producers.

Cumulatively, it could lead to a considerable loss of revenue.

Xscann Technologies offer a sure-fire way for producers to mitigate this risk by employing its X-ray Full-Body scanning solution, which has excelled in different mining sites.

• Repairing of tyres

• Supplying all OTR branded tyres

• Supplying and repairing rims

• Offering tyre consumables and accessories

• Site studies and completed surveys

We provide services that include all types of tyres including passenger vehicles, LDV, trucks, forklifts, telescopic handlers and earthmoving tyres. Call Stephen