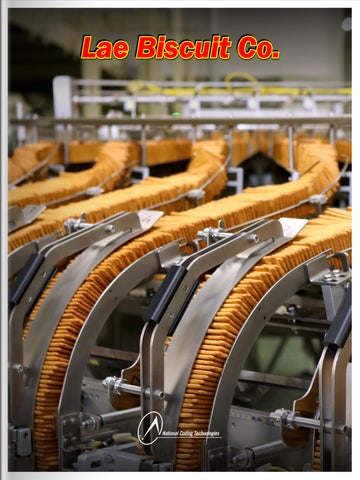

Starting from humble beginnings and a simple desire to create a flavourful snack, Edwin Wong, General Manager of Lae Biscuit Co. Ltd., discusses how the company has now become the largest biscuit producer in the Pacific and is only continuing to grow

Writer: Lauren Kania | Project Manager: Liam PyeNearly everybody can look back and vividly remember spending time in the kitchen with family: the smell of fresh ingredients wafting through the air, the sound of clanking pots and pans, the sight of steam rising from a freshly cooked meal, and the feeling of warmth and serenity as you gather with those you love.

Edwin Wong, General Manager

Cooking for people you care about brings forth a passion like no other, and this evident devotion and commitment is no more visible than in the core foundation of Lae Biscuit Co. Ltd. (Lae Biscuit).

Having grown to become the Pacific region’s largest biscuit and instant noodle producer for over the past 50 years, Lae Biscuit is a family-owned and family-run business started by Sir Henry F. Chow in 1972 out of a humble bakery located in

Voko Point in Lae, the second largest city in Papua New Guinea (PNG).

Edwin Wong, General Manager of Lae Biscuit, has been with the company for over a decade and has always held a sense of excitement when it comes to the food and beverage industry, particularly biscuits.

“I always had a passion for eating biscuits when I was a little kid, and even up until now, I still make sure to have a packet of biscuits beside my bed for midnight snacks,” he opens.

Boasting over 30 years of experience within fast-moving consumer goods (FMCG), Wong is an expert in food and beverage manufacturing and notes that in times of crises, biscuits are always the first thing people will pick in a grocery store to bring them immediate comfort.

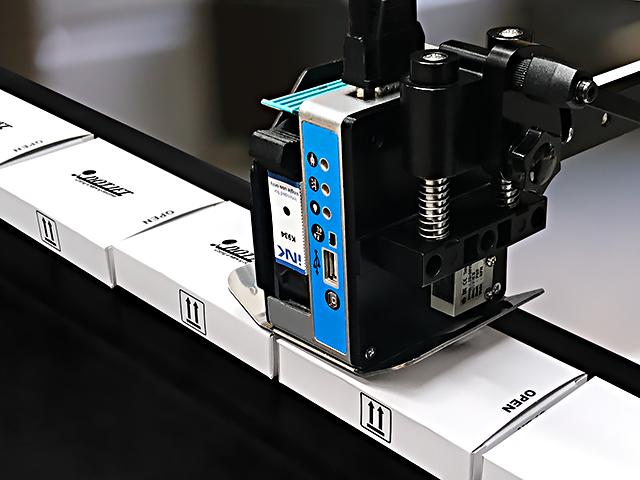

We have a diverse suite of products providing total solutions such as:

• Industrial inkjet printers

• Industrial laser printers

• Hi res printers

• Desktop thermal printers

• Thermal transfer printers

• Conveyors

• Turntables

• Carton tapers

• Label applicators

• Colour label printers

• Label rewinders

• ID tag printer

• Card feeders

• Roller coders

• Bottle labellers

• Desktop conveyors

National Coding Technologies P/L offers first class ongoing support for your business through a range of servicing, parts and accessories. Our intellectual machines alert you that a service is due or accessories are running low which enables companies to run seamlessly without any downtime to production. We also offer more specialised services on recommendation and request to suit your business needs.

• Feeder systems

• Printing consumables such as inks, labels, printing ribbon etc. We also have a network of global partners who can provide a high level of automation to suit most companies.

National Coding Technologies P/L are regional suppliers of a large range of industrial coding, marking and automation equipment. 07 3201 2640 / 0411 708 219 sales@nationalcoding.com.au www.nationalcoding.com.au

dedicated employees spread across its offices in Lae and Port Moresby, along with its various branches in the Southern, Momase, Islands, and Highlands regions of PNG.

The company’s services include promotion and marketing, delivery of finished goods, sporting events, and product donations to sports and church communities.

Dealing only with main product distributors, supply chain and supplier relationships are of the utmost importance.

“Taking into account the limited shipping schedule of international vessels, the supply chain is paramount,” expands Wong.

“We need suppliers who can provide our overseas materials in a timely manner and have an accurate tracking system to trace the status of incoming containers or air cargo shipments.”

These relationships are crucial to ensuring that Lae Biscuit is able to

continuously produce its delicious products to high standards and meet customer expectations.

From its humble beginnings to today’s grand openings, Lae Biscuit has maintained its belief in creating employment opportunities for those in PNG and supporting the local community by assisting with community projects, events, sporting events, and disaster relief.

Currently, the company is contributing to 26 sporting clubs, various churches, and myriad charitable organisations that assist people in need.

Lae Biscuit’s corporate social responsibility (CSR) has been a long-established practice since its inception, and the foundational principles that guide its CSR have resulted in sustainable economic development while nurturing a grounded

• Snax Chicken flavoured cracker

• Snax Beef flavoured cracker

• TOTI Cheese and Tomato savoury cracker

• TOTI Beef and Tomato savoury cracker

• Cabin Bisket

• Navy Bisket

• Hard Navy Bisket

• Wheatmeal Biscuit

• Large Navy Biscuit

• Snax Chicken instant noodles

• Snax Chicken and Onion instant noodles

• PNG Hani raw, unpasteurised honey

relationship with the community.

During the height of the COVID19 pandemic, Lae Biscuit took the initiative to help those working on the frontline during the state of emergency and donated approximately K200,000 worth of household products. Additionally, the company donated 200 cartons of biscuits to the women’s correctional facility in Madang, 250 cartons of instant noodles to the students at the University of Technology in Lae, and 1,600 cartons of biscuits to the Catholic Highlands Diocese.

Lae Biscuit always strives to give

back to the community by providing unparalleled customer service, employment opportunities to the local community, and extremely delicious biscuits and instant noodles.

Having started out processing only five bags of biscuit flour per day to produce the first hard biscuits, Lae Biscuit has seen incredible growth and development over the past 50 years that has manifested in state-ofthe-art products and the company being a staple of the community.

Having built a world-class biscuit

plant and instant noodle line as part of an expansion project, and introduced new products across PNG, Lae Biscuit is looking to grow even further.

“Our priority is to diversify new product lines and open export markets to Australia, New Zealand, and the Melanesian Spearhead Group (MSG) region,” comments Wong.

“Additionally, we are excited to see the new line for a variety of sweet products and to pack our new “bitesize” items using a fully automatic vertical packaging machine, ensuring a high-quality product and overall packaging efficiency.”

Beginning in November of this year, installation of additional cracker and cookie lines are being constructed to cater to increasing demand and provide space for a new variety of sweet cookie products.

Lae Biscuit has recently achieved a new milestone in its adherence to the highest standards in its facilities.

“I am incredibly proud that Lae Biscuit has become the first PNGowned food manufacturing company to receive Food Safety System Certification (FSSC), based on the standard and technical specifications of ISO 22000, ISO 9001, ISO/TS 22022, and the FSSC 22000,” states Wong.

In addition, after a process that took nearly three years, Lae Biscuit met internationally recognised and approved food safety and control measures when awarded the Hazard Analysis Critical Control Point (HACCP), a milestone accomplishment resulting from the tireless work of all team members.

This, along with the unrivalled achievements and time-tested history that the company has worked hard to earn, has certified Lae Biscuit as a producer of high-quality, trusted brands that will only continue to grow as time goes on.

Tel: 475 9988 / 475 9966

laebiscuit.com.pg

LAE BISCUIT CO. LTD.

LAE BISCUIT CO. LTD.