Soaring over the vast swathes of Queensland’s Central Highlands, the Nankeen kestrel is a common sight. Over the millennia, this native Australian bird has continuously evolved to adapt to its local surroundings, and despite its diminutive size, remains one of the region’s most successful and resourceful birds of prey.

The kestrel’s very architecture is the ultimate example of each component working in harmony as a

cohesive whole, from the black tip of its wing to its laser-focused vision, as it surveys the resource-rich coalfields of the Bowen Basin, poised to seize opportunity.

As part of the Nankeen’s regional territory, cattle graze serenely on the lush, verdant pastures that originally earnt the nearby town of Emerald its distinctive name, but unbeknownst to the bird, beneath these lands, a dynamic hive of activity awaits in the coal-rich underground realm.

Undamine Industries (Undamine) is a contracting company specialising in the black coal industry. Renowned as secondary support and longwall specialists throughout the Bowen Basin, the company’s Central Queensland base allows it to effectively serve areas such as the Galilee Basin and beyond. Company Director, Peter McPhail is considered one of Queensland’s premier secondary support specialists whilst Director, Shane Jackson is a longwall and machinery maintenance expert. Both work closely on-site with their Project Managers, Secondary Support Specialists, Longwall and Machinery Maintenance Teams. This expert turnkey workforce is constantly available around the clock. The four Directors, Peter and Karla McPhail and Shane and Renee Jackson possess a strong commitment to providing excellence in both safety and performance.

Undamine Industries is proud to be a contracting company working with Kestrel Coal Resources, commencing our long-term contract partnership in March 2021, Undamine supplies trained and skilled labour to Kestrel South Mine Site. Established in 2004, Undamine Industries specialises in the Queensland and New South Wales coal industry. We have worked throughout the industry in many different areas but have focused on labour supply for contracts in Secondary Support, Longwall Moves and Maintenance. We supply skilled and specialised labour and equipment to support mining operations throughout the industry with a focus on the Bowen Basin, operating out of Yeppoon, Queensland, Australia.

Whilst working throughout Queensland and New South Wales we have partnered with various major clients including Glencore, Fitzroy Resources, Anglo American, BMA and Kestrel Coal Resources.

We believe in partnering with the companies we service, building strong relationships with their management team and workforce. We work in a fully integrated manner operating within the structure of the operation.

Undamine Industries strives for excellence in business and puts people first, always.

Being an established company, we can take a flexible and innovative approach to problem solving. This adds significant value. One example is that we have the unique capability to deliver urgently needed underground longwall recovery services and have conducted critical auxiliary works outside the scope of contracts as required by our clients.

Our labour force is among the most highly trained, qualified and licensed in the industry. Having Coal Train a registered RTO to support Undamine ensures that the workforce competencies are maintained and updated as required by the industry and our clients.

We maintain a stable and motivated workforce, which is critical to maintaining high levels of safety and productivity. Undamine fosters healthy, positive workplaces, and as a result we have enjoyed outstanding loyalty and stability from our workforce.

Undamine is a privately owned business established in 2004. The four owners, Peter and Karla McPhail and Shane and Renee Jackson, have a strong commitment to providing excellence in both safety and performance.

We know the industry well and apply our expertise to managing safer, more cost-effective operations: Undamine has been publicly acknowledged for exceeding all of our KPI over a five-year contract period. Undamine are is proud to have an unparalleled, continuous working partnership with our contract holders for over 19 years.

Established in 2004, Undamine has one of the most outstanding safety and production records in Queensland and in 2012 was acknowledged as having zero Lost Time Injuries (LTIs) whilst also having met 100 percent of its key performance indicators (KPIs) over a five-year contract period. Additionally, Undamine are ISO9001 accredited and has worked throughout both Queensland and New South Wales (NSW) with major clients including Xstrata, Anglo American

Thanks to our reputation for quality services and our exceptional safety and production record, Undamine has grown to have over 300 employees training and manning sites at over eight different locations.

Karla Way-McPhail, highly successful businesswoman and Undamine Industries CEO, has built her success on empowering others. Whether in the workplace giving businesses and individuals the tools to prosper or out in the community providing support to the disadvantaged, Karla lives her philosophy of “people first, always.”

and BMA. The company promotes the key values of excellence, integrity, safety, accountability and teamwork in everything that is does.

Peter and Shane have both been Company Directors of Undamine since its establishment in 2004.

Undamine takes great pride in

Peter has an excess of 40 years’ experience in the underground mining sector. Shane has over

30 years’ experience in the underground mining sector.

Peter and Shane are well respected in the Black Coal Industry for their industry knowledge and outstanding safety record.

Supported by an exceptional Management and Operational Team, our streamlined organisational structure means Undamine is 100 percent compliant across all business operational areas.

Renowned as Secondary Support and Longwall Specialists throughout the Bowen Basin, Undamine hires out both labour and machinery to support mining operations. We supply to all sections of underground mining across Queensland and New South Wales.

sponsoring both senior and junior sporting clubs, providing funds for much-needed medical equipment and supporting organisations such as Legacy and The Lions.

The company also has a strong commitment to supporting non-profit organisations within the communities in which it works. Similarly, Undamine

Undamine Industries is focused on becoming the partner of choice for the mining and resources industry. Our proven operational performance with the Tier One mining houses demonstrates a customer focused business approach ensuring we establish personal relationships with our clients ensuring any successes are mutually beneficial.

As a contracting company we have the most substantial footprint in Queensland. We are the only suppliers who supply directly to:

• Anglo American

• Glencore

• BMA

• Kestrel Coal Resources

• Fitzroy Resources

• And others

We have demonstrated both longevity and endurance.

The Undamine Head Office and state of the art training facility is located in Yeppoon, Queensland. In addition to this we have regional offices and training facilities in Emerald, Blackwater, Middlemount, Moranbah, Mackay and Emerald.

Undamine Industries is very proud to be the longest contracting company in Queensland. Undamine has been supplying contacted services to major companies for over 19 years straight. This is a demonstration of the outstanding level of services we provide to contact holders.

Much like its symbolic namesake, it is in this region where Kestrel Coal Resources (Kestrel) operates with the same agility, resourcefulness and compact adaptability of the raptor, as an underground mine that keeps the cogs of our modern world turning.

“We have all the experience of a traditional mine, with the innovation and agility of a new-generation business,” introduces Kestrel’s CEO, Shane Hansen.

Acting as a custodian of the landscape, Kestrel causes little surface disturbance to the land itself, aspiring to the same minimal impact as its airborne emblem. A similarly permanent fixture of the region’s community, the Kestrel team thrives together as one, its workers dressed in shirts of the same cobalt blue as the skies in which the bird hovers above.

As a leading–edge, coking coal company, Kestrel calls on the proud coal mining heritage that defines the Bowen Basin. The Kestrel mine itself has been operating as part of this industrial legacy since 1992, after celebrating its 30th anniversary last year.

The mine can be found approximately 40 kilometres (km) north of the small rural town of Emerald – an industrious outpost that was originally established in 1879 to coincide with the mining boom that ensued when coal deposits were first reported in the basin the previous year.

With the Bowen Basin home to the largest coal reserves in Australia, these legendary, resource-rich lands have continued to provide a veritable treasure trove for the industry over the centuries. Alongside coal mining, the regional economy has evolved from depending on the exploitation of gemstones, to crop cultivation and sheep/cattle raising – both of which are able to thrive in alignment with the industry as evidenced by the Kestrel

site, where 96 percent of the surface land is in agricultural use.

Although the mine’s nearest town of Emerald may owe its name to the vibrant grasslands of its surroundings, the sparkling gem is an apt metaphor for the prosperous green future that Kestrel envisions.

“I see a future for metallurgical coal that is both sustainable and profitable,” shares Hansen.

By positioning itself as a sustainable mining company producing highquality coal destined for steel-making applications around the world, Kestrel champions the transition towards responsible mining that sustains longterm value.

Despite having a workforce of 700 people, comprising both employees and contractors on-site, Kestrel’s relatively diminutive size belies its

Kestrel is Respectful – Kestrel acts with honesty, integrity and aims to be the team that everyone else wants to work with.

Kestrel is Committed – Whether it’s safety, hitting its targets, caring for its people, community, or environment, Kestrel is committed to doing it the right way.

Kestrel is Agile – Kestrel approaches its work through a different lens. The company does it safely and gets the results few others can.

Kestrel is One – Kestrel is a diverse group with varied skills working together as one team.

vast impact – both in terms of driving long-term value within the regional community and global output.

Indeed, with approximately 6.5 metric tonnes (MT) of coal produced every year, Kestrel represents one of the world’s largest producing underground metallurgical or coking coal mines.

For Hansen, accomplishments such as this attest to Kestrel’s unwavering

“THE METALLURGICAL, ALWAYS FACING

ability to perform with the “big players” in the industry.

“We may have the feel of a smaller mining company, but we have consistently demonstrated that we have the capability to play in the big league,” he says. “Being smaller in size is not a limitation for us.”

Kestrel plays its size to its advantage by championing one of its core values – agility – since minimal

levels of bureaucracy allow for key decisions to be acted on both swiftly and effectively.

“This agility is invaluable in an industry that is as dynamic and rapidly evolving as ours,” affirms Hansen.

The company combines this agility with the energy and ambition of a young enterprise after it was established to take over the existing Kestrel mine site in 2018. The business

was formed as a joint venture (JV) between Kestrel (80 percent) and Mitsui Coal Holdings (20 percent).

As the operating entity, Kestrel has a shared ownership model between the specialist resources private equity manager, EMR Capital (EMR), and one of Indonesia’s largest coal miners, PT Adaro Energy (Adaro), both of whom are keen investors in metallurgical coal.

OR STEELMAKING, COAL INDUSTRY IN AUSTRALIA IS FACING NEW CHALLENGES, BUT WE’RE PREPARED FOR THAT”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

HBT is a world-class manufacturer and fully integrated singlesolution longwall mining equipment provider. Headquartered in Lünen, NRW, Germany, we export our high-performance equipment to every major mining market in the world and we have subsidiary and partner offices strategically located to support each region.

We offer our customers the right system for their applications — from low seams to high seams, no matter how long the face or how high the production demand. We understand the challenges faced by longwall mines today, and we’ve developed our machines to stand up to those demands. All our equipment has been designed to maximise customer value through the application of cutting-edge autonomous technology which delivers benchmark productivity and industry-leading operator safety.

We research, develop, design, manufacture and validate all our equipment in-house to ensure everything we make meets the highest standards and international regulatory requirements. We also offer high-quality parts and aftermarket support services, completing our line of end-to-end solutions for longwall mining operations.

We offer a complete line of longwall mining equipment:

• High-horsepower shearers

• Automated plow systems

• Armoured face conveyors (AFCs) / beam stage loaders (BSL) and tailends/bootends

• Intelligent conveyor drive systems

• Hydraulic roof support legs and cylinders

• Programmable mining controls

• Face automation sensors, actuators, microprocessors and computers

• High-pressure pump stations / hydraulic control valves

• Measurement and control systems for harsh environments

• Explosion and flame-proof power distribution, motor switching devices and VFD drive technology

HBT’s ancestry is ingrained in the longwall mining industry, dating back to the very beginning of mechanised longwall mining in the 1800s. Over the last 200 years, we’ve driven innovation and performance as we were shaped by a number of industry leaders — most notably Hauhinco, DBT and Caterpillar.

Hauhinco was founded in 1908 in Sprockhövel, Germany, in the cradle of the Ruhr mining area. For over 100 years, the company has adapted to new conditions while remaining true to its roots, and this experience makes us unique in the marketplace. DBT was renowned as a technology leader, with over two centuries of experience driving mechanisation and automation in the coal industry. Its innovations were instrumental in the development of the modern longwall mine — including the armoured face conveyor and the coal plow. The DBT engineers also focused on designing technology to pioneer autonomous mining. Caterpillar also has a long history in engineering and the mining industry, with impressive industrial manufacturing capability, leading-edge technology and refined demand stream processes.

We’re drawing on the strengths and advantages of all these companies as we move into the future, with a focus on driving value and helping our customers achieve their goals. We are adopting a direct service model, further enhancing our distribution capabilities, customer service and aftermarket support — all so we can deliver the best possible results for our customers.

We also have extensive aftermarket service offerings including:

> Spare parts and technical support

> Onsite maintenance and repairs

> Rebuilds and optimisation

> System performance and lifecycle monitoring

> Equipment training

YOUR IDEAL PARTNER FOR SAFE & EFFICIENT LONGWALL MINING SOLUTIONS

HBT is committed to being your single source of supply for longwall mining solutions and mining electrical engineering. We offer advanced technologies and high-performance machinery, backed by a global team of experts and the infrastructure to support customers anywhere in the world.

To learn more, visit hbt-group.com

With over 30 years of hands-on experience in the industry, Hansen began his mining career working in base metals in the well-known town of Mount Isa in Northwest Queensland. From here, he transitioned to a maintenance engineering role with BHP at the Gregory coal mine in Central Queensland at a time of enormous opportunity in the coal industry. Subsequently, Hansen went on to accept senior operations positions at various other Queensland mines, before working at Mitsui Coal Holdings with an emphasis on its global coal business and acquisitions. By positioning the company to deliver optimal returns for shareholders and providing strategic direction to facilitate growth and increased capital value, the latter led to Hansen’s current position, as CEO of Kestrel. Throughout his career, Hansen has honed specific skills in mining, processing, planning, facilities management, construction, performance management, business analysis, business growth and development.

Digging deep into the Kestrel site, the mine functions as an underground longwall operation along the German Creek seam. This location is the sweet spot for the low ash and high fluidity coal that is Kestrel’s niche product, with the company mining at a depth of 350 metres (m) to 400m along a single seam of 3m in thickness.

The long-life mine site consists of a single longwall, panel extraction, and a coal handling preparation plant (CHPP) where the product is washed using recycled water. Following the mining process, run-of-mine (ROM) coal is transported via a 7km overland conveyor directly to the CHPP.

From here, rail transport provides an indispensable link onwards to Australia’s premier multi-commodity port and Kestrel’s gateway to the world, the Port of Gladstone. It is from this strategic global node that Kestrel’s quality, high-energy coal is shipped to key markets worldwide.

“Our global customers use the coal to produce steel across Asia, India and Europe,” explains Hansen.

Following significant expansion efforts in 2013, the life of the Kestrel mine was extended by 20 years and increased its production capacity to 5.7MT of coking coal per annum. Of this, between 75 to 80 percent of the coal reaches the final product to minimise waste.

Today, Kestrel has an approved life of mine (LOM) until 2033, with reserves to last until 2046. However, as an exciting next step in the company’s development, there is significant potential to increase this even further.

At every level of its processes, the company maintains an unrelenting

standard of operational excellence that extends far beyond the core activity of mining itself.

“Our team’s capability covers the entire mining process, from development to extraction and processing, environmental management and sustainable rehabilitation,” he outlines.

Aside from the mine’s operational performance, Kestrel sets a new standard in longwall mining by creating a business that is communityfocused, sustainable, and ultimately, a place that people want to be.

“Our greatest strength lies in our unique blend of a respectful culture, exceptional performance, and our long history of operating in the community,” Hansen acknowledges proudly.

This has been recognised with several prestigious accolades to date. Most recently, Kestrel was voted the 2022 Australian Mine of the Year at the Australian Mining Prospect Awards, and as winner of the 2019 Mine of the Year by Australian Mining Monthly. Both achievements serve as a testament to the dedication of the Kestrel team and its underlying culture of respect, trust, and positive communication throughout the business.

Through its comprehensive capabilities, Kestrel sets itself apart by living and breathing its core values of being respectful, agile, committed, and acting as one. Permeating throughout the entire company culture, these four core tenets are the adhesive that binds all of Kestrel’s individual moving parts into a collective force that is

“OUR GOAL IS TO BE A MODEL OF SUSTAINABLE, RESPONSIBLE MINING”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

community-centric, and purpose driven.

Much like the coal entrenched in the ground on which it operates, by firmly embedding these values into its everyday actions and conversations, Kestrel builds the foundation from which the company prospers.

Embodying its value of oneness, Kestrel is one company supporting the world’s largest industries and economies, as one community sharing the same set of values through one crew.

“We have fostered a one-team approach that resonates deeply within our organisation,” comments Hansen. “Our team understands that every job, no matter how small,

contributes to the bigger picture of making our mine successful. Everyone digs deep to get it done and make Kestrel a great place to work.”

Hansen credits this approach as a major contributing factor to the company’s many “remarkable achievements”, including being Australia’s highest-producing underground metallurgical coal mine for the past four years.

“This accomplishment instils a sense of pride in our people and serves as a daily motivator for everyone to bring their best – not just at work, but also in their personal lives,” he continues.

Under the empowering mantra of ‘We Are One’, Kestrel cherishes each individual as a valued member of the team who brings the varied skills,

experience and behaviours that are essential to the company’s success.

For Kestrel’s Strategic Sourcing Manager, Damian Cavill, it was this inclusive approach to teamwork that originally attracted him to the company.

“The reason I came to Kestrel is twofold - the people, and the culture,” he says. “The Kestrel team are some of the most experienced and technically proficient people I have met in the industry.”

Much of this team calls on the experience of Queensland’s esteemed mining legacy, which represents a colourful tapestry of strong characters and individuals with a potential that Kestrel seeks to unleash and encourage. This is done by honouring respect as a two-way

street that guarantees appreciation for ideas, skills and solutions.

“There is a genuine respect for one another and when things get tough, we have each other’s backs, which makes everyone feel like a valued member of the team,” observes Hansen.

The internal sense of coherence and resilience fostered by the one-team approach combines with Kestrel’s agility to serve the company in good stead despite challenging industry conditions. Remaining united and adaptable helps Kestrel stay buoyant, as it continues to soar in the face of major recent headwinds.

“The challenges this industry faces are significant, with global economic conditions, changing energy policies and ongoing public scrutiny around carbon emissions,” Hansen observes. “However, these challenges also bring opportunities to innovate, adapt, and thrive.”

The mining of fossil fuels and the wider industry’s carbon footprint have become contentious issues within the fraught context of the ongoing climate crisis. However, Kestrel advocates a bright future for Australian coal mining, one in which the industry can evolve to operate more sustainably while holding the answers to the brave new world of the energy transition.

“With modernisation, the industry has responded swiftly to artificial intelligence (AI) and automation, which makes it an exciting place for people to start their careers and become part of urbanisation and decarbonisation,” he remarks.

On a path of constant innovation, Kestrel navigates the quandary that exists between the widespread negative environmental perception of mining, and the inescapable necessity of extraction to provide the resources needed to fuel our modern world. This is best defined by its stance as a company that seeks

THE 1. People - Embedding Kestrel’s culture today, to solidify its foundation for future growth. 2. Health and Safety – Protecting its people from harm so that everyone goes home in good physical and mental health. 3. Community and Indigenous Development – Connecting with its communities and cultures to build a lasting legacy. 4. Environment and Heritage – Committed to continual improvement in minimising impacts to the environment and land.to provide resources responsibly, as evidenced by its continually maturing environmental, social and governance (ESG) strategy and comprehensive annual sustainability reports that transparently outline its progress.

Aside from its ongoing internal efforts in carbon reduction, the very nature of Kestrel’s flagship product contributes to driving wider, positive change on a global scale.

“The intrinsic connection of metallurgical coal with the broader process of decarbonisation makes for an exciting future,” hints Hansen optimistically. “The metallurgical, or steelmaking, coal industry in Australia

is always facing new challenges, but we’re prepared for that.”

More than just a coal mine, Kestrel actively contributes to building the framework of our contemporary world by providing the core ingredient of one of its most important materials – steel. Coking coal is the lifeblood of steelmaking, which is an industry that is powering the transition to a renewable future.

“Metallurgical, or coking, coal is an essential ingredient in steel production, which continues to be

indispensable in our modern society,” adds Hansen.

Aside from being a core element in the construction of wind turbines, solar panels, and electric vehicles (EVs), steel is used in a number of technologies that are instrumental to carbon reduction. Using the example of a wind turbine, approximately 250 tonnes of metallurgical coal are required to build a single model, since steel is needed to manufacture each individual component, from the generator and the blades to its very foundation.

Unsurprisingly, the ongoing energy transition has resulted in a booming demand for the resources necessary to fuel a future that uses renewable technologies and provides the robust infrastructure to house an evergrowing global population.

“Despite often being unappreciated, the resources sector has been a cornerstone of our economy and continues to play an integral role, particularly

“WE MAY HAVE THE FEEL OF A SMALLER MINING COMPANY, BUT WE HAVE CONSISTENTLY DEMONSTRATED THAT WE HAVE THE CAPABILITY TO PLAY IN THE BIG LEAGUE”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

For over a decade, Field Solutions Group has gone where other telcos haven’t to connect the underserviced and bridge the digital divide between metro and rural Australia.

Field Solutions Group (FSG) is reshaping telecommunications and digital solutions. Engaging with businesses along with local and state governments, FSG continues to invest in and employ innovative technologies that meet and exceed the needs of its clients.

Over 100 highly qualified staff are currently employed by FSG, who prides itself on locating its team as close to customers as possible to provide timely services and remediation even in the most remote locations, as it expands its operations into new states and territories. The head office of FSG’s Mining & Resources division is in Brisbane, supported by its primary regional hub in Emerald.

Elsewhere, FSG also maintains a physical presence in New South Wales, Tasmania, and Western Australia, along with multiple regional locations. With the proven experience, resources and technical capabilities, FSG provides a unique, future-proof suite of ICT solutions for all mining companies.

FIELD Mining & Resources provides innovative and customised IT solutions to mining companies enabling them to withstand IT challenges in the industry. An IT company’s role is to ensure uptime is at the highest percentage possible for mine sites and offices so there is zero downtime, and FSG supplies critical services to achieve this.

“We are a network operator providing bespoke solutions for our mining customers. We have a dedicated FIELD Mining & Resources team providing support with on-site team members; essentially, we are a one-stop shop for all your IT needs,” says Jody Barlow, Head of the FIELD Mining & Resources division at FSG.

FIELD Mining & Resources partners with its clients to provide end-to-end managed IT services in the mining industry.

Recent contracts with Kestrel Coal Resources (Kestrel) are developing the company’s delivery of managed IT services going forwards.

“We have the capacity and skilled staff to fulfil both remote and on-site duties, backed by our network engineering and security team.”

FIELD Mining & Resources offers a full project management construct across all mining clientele requirements and liaises with third-party vendors and contractors, ensuring there is only one point of contact for mining customers.

For Kestrel specifically, FIELD Mining & Resources has a dedicated team working in their Brisbane CBD office and on-site at both their North and South sites, supported by FIELD Mining & Resources’ shared services team.

“We are a trusted partner and advisor to Kestrel, and we act as an intermediary between Kestrel and all third-party suppliers,” says Barlow.

“We ensure Kestrel has one contact and liaison point. Our FIELD Mining & Resources project management office (PMO) team brings this together to ensure everything is delivered on time, within budget, and in scope.”

As a result, FIELD Mining & Resources allows Kestrel to do what they do best – mining and selling coal –ensuring guaranteed uptime on all their services and ensuring productivity.

FIELD Mining & Resources has the capability to provide bespoke projects.

At Bowing Coking Coal’s mine camp in Burton, for example, it recently provided the 650-man site with unlimited data.

Through its strategic partnership with Cambium, FIELD Mining & Resources provided a Wi-Fi connectivity solution to not only the residents but the surrounding work offices.

“This allowed the bandwidth to be optimised, provided complete network coverage, and enabled Bowen Coking Coal to retain important staff on an on-call roster,” Barlow elaborates.

FIELD Mining & Resources also offers 24/7 helpdesk support focused on ensuring issues get resolved in a timely manner.

For example, it provided Ravenswood Gold with remote hands, level 1-3 desktop support, and the functionality to provide networking and security where required.

With IT specialists and experts on the ground to support its mining clients, FIELD Mining & Resources, therefore, acts as an extended member of their mining teams, handling all their managed services, desktop support, and security needs so they can focus on their core business.

• Jody Barlow, Head of FIELD Mining & Resources – Barlow brings considerable knowledge in the mining vertical, having successfully managed large accounts in the industry and developed deep expertise in the unique challenges and opportunities facing mining/resources organisations.

• Jamie Black, Mining Operations Manager –An accomplished IT professional with extensive proficiency in the mining industry, Black possesses a broad range of technical expertise and deep understanding of delivering complex IT projects on time and within budget.

• Lee Gillam, PMO Manager - Gillam has proven experience in executive and c-level management roles all focused on service and delivery functions within several state and national organisations.

• Michael Beaumont, Network Architect –Experienced in both service provider and enterprise networking, with a heavy focus on mining verticals.

• Alex Kamrath, Service Delivery Manager

– Kamrath has worked in the IT industry for 14 years in various roles, including Tier 1/2 IT support, IT project management, and as a software developer.

Going forward, FSG’s focus is to ensure the FIELD Mining & Resources division is recognised as a connectivity partner and a partner that provides end-toend customised solutions for its mining customers.

“Growth will be exponential for FIELD Mining & Resources as we continue to engage with like-minded mining clientele who regard innovation and on-site support as key factors to their mining operation’s success,” concludes Barlow.

Jody Barlow

Head of FIELD Mining and Resources

T 1300 000 488 | M +61 0434 483 144 fieldsolutions-group.com/mining

• Kestrel operates a low disturbance footprint. Its infrastructure areas cover only four percent of its tenements, with the remaining areas impacted with subtle subsidence at the surface.

• Kestrel minimises disturbance to land and progressively rehabilitates throughout mine life. 60 percent of its mining footprint is established rehabilitation, with 571ha certified rehabilitation.

• The company manages tailings to the GISTM and ensures quality of management in construction, operation and closure.

• Kestrel actively looks to reduce its carbon footprint and continuously improves energy efficiency and waste management.

• Kestrel supports biodiversity and land management and contains and minimises potential environmental harm and pollution sources.

• The company implements effective risk management processes and systems.

as we navigate the challenges and opportunities associated with global changes in the way that energy is consumed and produced,” Hansen confirms.

Consequently, the demand for steel – and by extension, metallurgical coal – continues steadily, running in parallel with the global need for urbanisation and infrastructure development. Fortunately for Kestrel, it is a demand that shows no sign of abating.

“For decades to come, steelmaking coal will be required to help facilitate the transition to a greener and more sustainable global economy,” he comments.

Crown Technologies has raised the bar with its innovative approach to the design and manufacture of gas drainage and monitoring equipment used at Kestrel Coal Resources and other mines in the Bowen Basin.

Cutting-edge industry leading practices such as:

• Goaf and blower skid TARP control,

• Gas drainage and ventilation network interaction and response

• Field-based multi-point gas monitoring systems

The result is improved safety, visibility and performance standards targeted at maintaining longwall operations.

Pre-drainage skids feature technological improvements such as automated water and gas drawdown processes, environmental compliance monitoring, generator control and advanced downhole equipment protection.

Crown Technologies also specialises in gas analysis, custom made switchboards, conveyor and pump starter packages through to HV substations. Crown Technologies’ professional and practical team of Hazardous Area Engineers, Instrumentation Electricians and High Voltage Protection Engineers will deliver your project requirements.

Crown Technologies proudly builds long-term relationships by delivering high-quality products and supporting customers with a service that extends long past the initial supply.

Contact the team at Crown Technologies to learn how they can assist with your next project.

Contact Details:

P: (02) 4956 7455

E: email@crowntech.com.au

W: www.crowntech.com.au

Cognisant of the impact of steel on the global economy, Kestrel leverages a robust network of international markets where the demand for its metallurgical coal is high. Thanks to the product’s low impurity levels and niche coking properties, Kestrel coal is coveted by steel and coke makers across Asia, Europe and South America.

“Our Kestrel team has great relationships with our global customers and the growth potential in emerging markets is extremely exciting,” shares Hansen.

For Kestrel, India is a prime example of a new and developing market where the appetite for industrialisation has introduced a rapidly escalating need for steel.

According to a report by the Economic Times, India produces approximately 126MT of crude steel per year and consumes 106MT. These statistics make the country the second-largest global producer of crude steel, second only to China. Consequently, India now represents Kestrel’s largest market, followed closely by North-East Asia.

“Kestrel is well-positioned to meet India’s increasing demand for steel,” he asserts.

The company’s agency on the global market reflects its internal philosophy, which acknowledges that Kestrel operates in a world that is shared and interconnected across people, environments, cultures and economies.

Kestrel may be global in its reach, but it is local in its everyday. Closer to home, this emphasis on locality translates to supporting the community and local, state, and regional economies wherever possible.

In the same way that the impact of Kestrel’s coal elevates developing

markets around the world, the company places explicit emphasis on supporting and unleashing the full potential of its surrounding communities.

A business that both lives and buys local, Kestrel has been a mainstay of the Central Highlands community for over 30 years. Indeed, 67 percent of its full-time workforce consists of local employees, many of whom reside in nearby Emerald.

Consequently, Kestrel takes pride in its commitment to positively contributing to the region in myriad ways and upholds this value as a key point of difference. The careful

1. Grow presence and connection in Emerald 2. Structured opportunity through Kestrel 3. On-country opportunity 4. Education and culture opportunity“EVERYONE DIGS DEEP TO GET THE JOB DONE, HAVE EACH OTHER’S BACKS, AND MAKE KESTREL A GREAT PLACE TO WORK”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

Australian company ABM Contractors (ABM) is strengthening domestic mining operations with its comprehensive range of services – an offering that puts strong partnerships at the forefront.

Based in Queensland, the company has become well-known for its high-quality project management, supplementary labour, shotcrete services and longwall support, as well as its work in ground consolidation and coal development.

Through the veteran company, clients can access first-rate drill and blast services, secondary support, VCD installations, fault driveage, equipment hire and repair as well as major conveyor installations and recovery services.

ABM Director, Jamie Abraham describes his highly experienced team as specialists in fall recovery, drifts and ground stabilisation, which positions the company as an ideal partner to many operators within the mineral resources sector.

The company is proud of its work at the Kestrel Coal Mine, one of the world’s largest producing underground coking or metallurgical facilities.

During this project, a key ingredient of ABM’s successful relationship with Kestrel Coal Mine was its shared commitment to local community support, and to improving host communities and embracing environmental sustainability goals, meaning it was critical for the company to partner with service providers that had a similar vision.

First established in 2000, ABM has gained a nationwide reputation for tackling tough jobs headfirst both on time and on budget.

The family-owned business is also poised to start a new venture providing underground specialised shotcreting services, cutting-edge ground consolidation products, and a range of ventilation control devices to operators within the coal industry.

ABM PROMISE

Health and Safety – During the execution of its projects, ABM takes particular care to ensure that all risk is evaluated and managed effectively.

Social Responsibility - ABM’s vision is to enhance the quality of life for the host communities in which it operates.

Environmental Stewardship - Conservation and the continued health of our planet is everyone’s responsibility, and ABM will continually strive to facilitate the least possible harm during operations.

Quality - ABM’s commitment to quality flows from the fact that long after project completion, its reputation will continue to be influenced by the work and service provided. People - A core set of values binds ABM together and provides the ethical framework for conducting business day-to-day.

Community – ABM fosters open and honest

communication and contributes to the sustainability of the communities it operates within.

ABM VALUES

Integrity - To be honest and reliable, reflecting the highest ethical standards in all business practices.

Respect - To trust and treat people with respect and dignity.

Leadership - To recognise the unique contribution and intrinsic worth of each individual and provide an inclusive environment focused on consistently delivering value.

Value Creation - To focus on doing the simple things really well.

Collaboration - Promote open communication as the key towards influencing and inspiring high-performance outcomes.

For more information, visit www.abmcontractors.com.au Phone (07) 4982 2174

General enquires email: admin@abmcontractors.com.au

Employment opportunities email: careers@abmcontractors.com.au

• 220 participants

• Administrators to CEO

• Mixed cohorts

• Mixed delivery mode

• 12-month programme

UNLEASHED’s intent is to build the capability of Kestrel’s people across nine key elements of leadership:

• Unleashing One Kestrel

• Nurturing your potential

• Leading your team

• Expectations and accountabilities

• Approaching planning and priorities

• Safety, every day

• How to motivate and influence

• Engaging communication

• Driving improvement

So far, UNLEASHED has seen an average uplift of 19 percent across diagnostic competencies. Standout results include:

• 33 percent uplift in leaders’ ability to develop and execute innovative improvement ideas within teams

• 24 percent uplift in feeling they can effectively coach others

• 22 percent uplift in being able to put plans in place to improve engagement and performance

• 16 percent uplift in their ability to lead change

consideration of its impact on the wider community remains at the forefront of every single decision that Kestrel makes, as a true partner in local development.

“The passion and the commitment that the Kestrel team has not only for the company but for the regions we operate in is second to none,” states Cavill.

On the understanding that community equates to connectivity, Kestrel’s level of investment is not just economic – rather, by building relationships and creating

opportunities for growth, it creates an avenue for lasting connections.

As a largely residential-based entity, income is fed back into local businesses, schools, not-for-profit organisations (NPOs) and other community bodies or initiatives of all sizes surrounding the mine. This not only strengthens Kestrel’s connectedness with nearby communities, but also reinforces the internal cohesiveness of its culture.

“We maintain a heavy focus on supporting local businesses, as it’s always been,” echoes Hansen.

“WITHOUT THE SUPPORT OF OUR SUPPLIERS IN THE LOCAL COMMUNITY, WE COULD NOT ACHIEVE OUR GOALS AS A BUSINESS”

– DAMIAN CAVILL, STRATEGIC SOURCING MANAGER, KESTREL COAL RESOURCES

As reported in its latest Sustainability Report, in 2022 this equated to AUD$122,000 invested in direct community support.

Kestrel’s dedicated community approach centres on the four pillars of community partnerships, keeping communities safe, cultural heritage, and indigenous development. True to Kestrel’s own one-team ethos, respect is the common ground on which all these concepts are founded.

“Our relationship with the township is a testament to the mutual support and respect we’ve cultivated, and we are motivated to contribute positively to create a lasting legacy,” Hansen surmises.

• 5.67 Mt – saleable production

• 305 – number of local and regional suppliers

• AUD$237 million – spent on local and regional suppliers

• AUD$122,000 – direct community support

• 67 percent – local workforce (full-time workers)

• 10 percent – gender diversity

• AUD$650,000 – cultural heritage investment

• 270ha – area surveyed for cultural heritage

• 0.24t - CO2 e/t coal product

• 116l – raw water usage per tonne of coal product

• 571ha – rehabilitated land certified

• 17.6 TRIFR (one million working hours)

The legacy that Hansen alludes to centres on creating opportunities for sustainable local development. This means providing jobs and supporting the local economy, but also focusing on healthy environmental management and promoting social programmes and initiatives that will benefit the community for generations to come. However, this also involves respecting the cultural legacy that predates the mine. In this regard, Kestrel works closely with the registered Native Title Claimants of the land on which it operates - the Western Kangoulu. As the Traditional Land Owners, the landscape surrounding Emerald and the Kestrel mine is intrinsically linked to the history of Indigenous people, and these deep connections are acknowledged, honoured, and considered in every decision.

This respect for cultural heritage informs Kestrel’s approach to community relations, but it also impacts environmental management in a physical sense. Paying respect to Australia’s Indigenous people and Elders past, present and future, Kestrel positions itself as a partner working in the best interests of protecting the land’s heritage.

The 17,000 hectares (ha) of land that Kestrel occupies is rich with stone artefacts, resources, shelters and cultural areas, quarries, and scarred trees. There are over 80 of the latter spread across the Kestrel site, with each tree indicating a poignant historical reminder of where Aboriginal Australians would have stripped bark to be used for toolmaking amongst other purposes.

To ensure that Kestrel continues to work in alignment with the aspirations of the Western Kangoulu and honour their connection to the land, a Cultural Heritage Investigation and

Kestrel Coal Resources are pleased to be supported by the Energy Power Systems team for their underground site cooling requirements.

Manage heat stress and fatigue improving your operations uptime with Energy Power Systems, your leading Mine Cooling Solution in Australia.

With over 15 years of underground Mine Cooling expertise Australia wide, Energy Power Systems leads the way as a trusted provider of Mine Cooling, Power and Compressed Air solutions.

Offering custom designed solutions to provide optimal cooling performance under any condition, including surface Bulk Air Cooling through to Spot Cooling, our systems are installed with integrated maintenance systems to help increase uptime and reliability of underground cooling packages.

Get in touch with us today to discuss your Mine Cooling needs.

ONE NETWORK. ONE CALL 1800 800 441

Kestrel Coal

Kestrel Coal

Ethical Business Practice –Conduct business with honesty and integrity supported by the highest standards of governance.

Valuing People – Ensure Kestrel’s people can fulfil their potential in a safe, healthy and rewarding environment.

Connected Communities –Collaborate with stakeholders to build enduring relationships and long-term successful outcomes.

Responsible Environment

Stewardship – Continuously find ways to improve production efficiency, sustainably manage natural resources and take strong action on climate change.

Management Agreement (CHIMA) exists between both parties.

“We have continued developing a strong partnering approach with our Traditional Land Owners, the Western Kangoulu,” comments Hansen.

The CHIMA entails the contribution of technical advisors who undertake stringent data-led assessments that aim to deliver proactive outcomes for heritage. As part of this work, over the course of 2022, Kestrel directed AUD$650,000 into cultural heritage investment, surveying over 270ha of land for cultural significance.

Working in partnership with both the Western Kangoulu and the wider Emerald community, Kestrel actively promotes Indigenous development. This is reflected by the creation of an Indigenous development hub, where guidance is provided on different career choices and ways of life for the Indigenous community.

Operating under the mantra of ‘Make it Real – Respect, Inspire, Develop’, the hub aims to increase local employment levels and enhance training development and procurement opportunities both across the community and within the company itself.

The ‘Make it Real’ strategy consists of a pillared approach, whereby the company aims first to grow its presence and connection throughout Emerald, then provide structured opportunities within the company, followed by on-country opportunities, and finally by offering further opportunities in education and culture.

As another example of Indigenous development in practice, last year, Kestrel launched the CONNECT programme in partnership with the Western Kangoulu. With both parties collaborating throughout its development and delivery, CONNECT has been designed to provide all

Eickhoff Australia Pty Ltd. (EAP) provides the supply and service of shearer loaders for underground applications and specialised industrial gearboxes within the Australasian region.

Utilising the same technology and manufacturing techniques deployed in the mining sector, we also design, manufacture, supply, and service industrial gearboxes for multiple uses, such as:

• Armoured face conveyors (AFCs) in the mining sector

• Stacker reclaimers

• Bucket wheel excavators

• Water locks and dams

• Large-scale roller press applications

We encounter different mining conditions at each new location around the globe. Our machine range has no problem adapting to these varying conditions thanks to our experience in developing made-to-measure machine concepts, suitable for the operative range of 1.4m up to 7.2m. As such, EAP offers shearer loaders from the Eickhoff SL 300, SL 750, and SL 1000 ranges.

All ranges offer the latest technology and their performance levels are constantly improved. Productivity, reliability and, consequently, cost-efficiency is measured via:

• Our maintenance and service-friendly modular system • Standard ranges which can be adapted flexibly to individual customer requirements

EAP is a wholly owned subsidiary of Eickhoff Bergbautechnik GmbH, a globally operating, family-owned company rooted in Bochum, Germany since its founding back in 1864. With its core business in the manufacturing of machines and gearboxes, it has proven itself worldwide under extreme conditions. Additionally, EAP’s mining machines for potash significantly contribute to resourcesaving food production.

• Cement and sugar mill drives and processing equipment

• Sheet metal working

EAP’s customer base now has the advantage of having its entire product range built and overhauled at the Eickhoff Life Cycle Management Centre (LCMC) located in Braemar, approximately 90 kilometres (km) south of Sydney. The LCMC is a 19,600 square metre (m²) state of the art facility, offering product support, as well as repair and overhaul services. The workshop has 5,500m² undercover with a crane capacity of 130 tonnes, more than sufficient to lift the largest fully assembled shearers in the market. Outside the fully covered work bays, there is a 4,600m² concrete pad in order to facilitate longwall system mini-builds and compatibilities.

• Tough machine bodies at minimum dimensions (tension rod technology)

• A modern, decentralised gearing concept (transverse engine concept)

• Reliable high-performance motors

• Efficient direct current (DC) winch drives, and alternatively rotary current winch drives

• Protection of motors and gearboxes through safety installations

• Control and monitoring through modern micro-processors

• Different optional dust prevention systems

• Automation possibilities through memory cut and data transfer

Kestrel Coal Resources is a private Australian company that is ultimately owned by EMR Capital (52 percent) and PT Adaro Energy (48 percent). EMR Capital is a specialist resources private equity manager, while PT Adaro Energy is an integrated coal mining and energy company, with businesses spanning over eight pillars in the coal, energy, utilities, and supporting infrastructure sectors. Kestrel Coal Resources is the 80 percent owner and manager of the Kestrel Coal JV, with the remaining 20 percent owned by Mitsui Coal Holdings.

members of the Kestrel workforce with a thorough understanding of their responsibilities towards cultural heritage. That same year, Kestrel also deployed a series of schoolbased workshops to enhance local education on the same topic.

Another prime demonstration of Kestrel’s commitment to development and education is the company’s internal UNLEASHED programme. As a scheme that has been designed for Kestrel, by Kestrel, UNLEASHED

is a leadership scheme that aims to unlock even more strength within the company’s operations by investing in the potential of its own people.

The programme takes place over 12 months and is a comprehensive course in leadership capabilities.

“WE HAVE PROUDLY BEEN PART OF THE CENTRAL HIGHLANDS COMMUNITY FOR OVER 30 YEARS, AND WE ENVISION BEING AN INTEGRAL PART OF IT FOR MANY MORE”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

Leading provider for technical support and overhaul of hazardous area equipment.

Gricon Industries is an innovative company specialising in technical solutions and automation support for hazardous area equipment. Established in 2019, Gricon Industries is a reliable family-owned business, providing comprehensive services from concept design to maintenance and repair for all underground electrical and automation equipment.

Gricon strives to provide our customers with the ‘full package’ from concept and design to manufacture and overhaul, commissioning and testing, to on-site implementation and production handover.

Through various modules, the programme covers nine key objectives, ranging from the concept of ‘Unleashing One Kestrel’ to ‘Safety, Everyday’. Throughout, participants are encouraged to lead from the front, providing both feedback and constructive ‘feedforward’, all while nurturing a psychologically safe workplace.

UNLEASHED channels the idea that a leader’s job is to bring out the best in other people, and arms participants with the skills that enable them to do so – both in the workplace and within their personal lives.

Over the course of 2022, 220 employees – almost a third of the entire workforce - participated in the UNLEASHED programme and the results continue to exceed expectations. This is reflected by an average uplift of 19 percent recorded across all diagnostic competencies.

The programme is an effective way of perpetuating the continuity of Kestrel’s distinctive culture as an

• Risk management – Risk and opportunity management for Kestrel is to provide business resilience; protection from loss and sustainability of things it values, including people, community, stakeholders, environment, ongoing operation, and business viability to prosperity.

• Tailings management – Kestrel is committed to responsible management of our tailings facilities to prevent adverse impacts on people and our environment.

• Modern slavery and human rights – Kestrel acts in accordance with the UN guiding principles on business and human rights and the modern slavery act 2018 (Cth).

• Anti-bribery and corruption – Kestrel is committed to providing a workplace that fosters mutual respect, honesty, and trusting working relationships.

• Code of conduct and whistleblower – Everyone has the right to a fair and inclusive working environment of which they are proud to be part of. The company is committed to a culture of respect and ethical conduct in the way everyone works and relates to each other. Kestrel recognises the value of keeping the laws and procedures that apply to the company and its work and encourages everyone to report misconduct.

above the line differentiator, with the company being built on a foundation of trust and respect, where open and honest conversations are always encouraged.

Kestrel’s investment in the development of its future leaders is just one of the ways in which it upholds ‘People’ as the first pillar of its sustainability approach. By growing its own people, Kestrel sustains the wider growth of the company itself.

With an increasing emphasis on diversity and inclusion, the company fosters an environment of equal opportunity and is making steady progress toward greater gender representation. In 2021, female employment at Kestrel was reported as 7.4 percent. As of last year, this number has increased to 10 percent. Although the underground workforce is still dominated by male employees,

JA Engineering Group Pty Ltd (JAE) manufactures and refurbishes equipment for the Australian mining industry with a unique specialisation in the underground coal sector.

Established in 2007 in Rockhampton, QLD, we initially focused on gear cases and components, leveraging our knowledge of South Africa and built relationships with key customers. Some 15 years later, we’ve emerged to become a keystone provider of machinery restoration and support services for Continuous / Bolter Miners, Shuttle Cars, Feeder Breakers and Mobile Bolters.

JAE is structured to operate using lean business principles that allow us to remain responsive and open to innovation. The key to our model is identifying value for the customer and delivering it with as little waste as possible.

We are one of only a few organisations globally that offers alternative manufacturing for aged, difficult to get or unreasonably expensive legacy parts – wheel units, gear cases and cutter drum assemblies to name a few. Our in-house expertise extends to gearcase reconditioning or replacement, line boring and structural welding, in addition to professionally certified mechanical services.

In 2020 we entered the market as an OEM of the Wildcat JAE42 continuous miner, capable of transforming high installed cutting power through the machine weight into real production and cutting performance. The Wildcat JAE42 is engineered to be used in a room and pillar coal mining operation, where a high cutting force is required. We will continue to establish ourselves as a full systems OEM provider over the next phase of the business.

greater numbers of women are now represented in management positions and the company actively supports events including International Women’s Day and Women in Mining.

The business expresses its pride and recognition of employees with the COAR Awards. An acronym for Committed, One, Agile and Respectful, each nomination for an award entails a donation of AUD$20 to a nominated community group in the Central Highlands, thereby creating a direct bridge between team performance and contributing to the community. In 2022, the total funds raised through these donations equated to AUD$3,898.

Providing both empowerment and motivation, the awards are designed to reward individuals who truly embody the company’s values and acknowledge those who go above and beyond the expectations of their roles. They represent one of the many ways in which Kestrel lives, breathes, and enacts its values, rather than simply talking about them.

OUR DESIRE TO NOT ONLY CONTINUE EVOLVING OUR ESG MATURITY BUT ALSO IDENTIFY HOW WE AIM TO CREATE A LEGACY WORTH LEAVING”

Working in a high-risk industry such as mining, Kestrel marries this peoplecentric philosophy with an unrelenting commitment to safety, as the second pillar of its sustainability approach. By setting the standard for best practices in health and safety, Kestrel fulfils its ultimate priority – to protect its people from harm and ensure that everyone can return from a day’s work in good health, both physically and mentally.

Through building trust and motivating its team, Kestrel encourages individuals to adopt, interpret and connect to the company’s safety culture as their

own. The Kestrel vision of ‘making the right way, the easy way’ results in the obvious benefits of fewer injuries and less downtime, but also in solidifying a safety mindset that coexists alongside high-performance levels.

Adopting a multi-pronged approach to safety, Kestrel implements training compliance and innovation with contractor management to ensure streamlined operations with a capable employee and contractor workforce. In addition, the company maintains its world-class operations by incorporating critical controls, conducting internal and external audits, and championing safety innovation by partnering with

“THROUGH KESTREL’S LATEST ESG STRATEGY, WE REAFFIRM

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

Jemtec Civil Services is a vibrant company which specialises in civil construction, mining, urban construction, and agricultural development.

Jemtec Civil prides itself on being integral and the focus being on the client, which we believe develops true partnering relationships. Our ability to autonomously deliver safe turnkey solutions sets us apart from other contractors.

Our strength derives from our diverse approach to providing clients with a “one stop shop” package, from all aspects of earthmoving, civil construction to agricultural development.

All these are possible due to our hard-working team of employees and late model equipment.

We specialise in:

• Remote projects and operations

• Onsite concrete batch plants

• Onsite mobile crushing plant

• Bulk and detailed earthworks

• Roads and drainage

• Tailings dams and levees

• Rehabilitation and remedial work

• Vegetation management

PO BOX 384 Emerald QLD 4720 0428 983 776

admin@jemtec.com.au www.jemtec.com.au

business units (BUs) to strive towards safe production through ongoing improvement.

At the apex of the Kestrel safety pyramid, the business enables growth through the continuous simplification of its safety and health management system (SHMS). Through this scalable solution and a high-functioning health and safety team, the SHMS facilitates company growth without compromising on this core priority.

With significant time and money consistently invested into perfecting such systems, Kestrel is rewarded by continually reducing risk.

Another major effort that reflects Kestrel’s concern for employee wellbeing was introduced last year with the ‘Kestrel Lifestyle Challenge’. This scheme was designed to encourage employees and contractors to adopt positive exercise habits and offered expert advice in terms of promoting sustainable and nutritional meal choices.

Thriving hand-in-hand with the company’s emphasis on positive mental health, the programme’s success was highlighted as the Winner

of the Health Program Award at the 2022 Queensland Mining Industry Health and Safety Conference.

Alongside health and safety, people, community and Indigenous development, and governance, the environment is a strategic segment in Kestrel’s dedicated sustainability approach. This spotlights the company’s journey of continual improvement to minimise its impact on the environment and the land.

“We continue to invest significantly into leading-edge technology to reduce our impact on the environment,” shares Hansen.

For Kestrel, sustainability encompasses a holistic vision that honours the mine’s past, present and future, as it seeks to contribute to its place in the world, operate a meaningful place of employment, and grow its value to stakeholders. Its approach endeavours to create a Legacy Worth Leaving – an idea that relies on ethical business practice that values people, builds connected communities, and

promotes responsible environmental stewardship.

“We are creating a high level of awareness around what sustainability means and the importance placed on getting it right,” Hansen continues.

Kestrel continuously measures its sustainability performance against International Council on Mining and Metals (ICMM) Sustainable Mining Principles. These 10 core principles are common to the global mining community as an industry benchmark, incorporating both the Paris Agreement mining targets and the United Nations (UN) Sustainable Development Goals (SDGs).

“We established a solid foundation through releasing our first publicly available Sustainability Report in 2021,” he informs us. Since that time, Kestrel’s annual Sustainability Report has served as a transparent outline of exactly how the company creates and sustains long-term value in a rapidly changing world.

For Kestrel, ESG represents an ongoing journey – one where its strategies, objectives and priorities are constantly in flux as they mature and develop.

Across the primary areas of ESG significance, the company actively manages risk and identifies areas where it must strive to improve. These include diversity and inclusion, decarbonisation, heritage protection, and biodiversity and water conservation.

Here, Kestrel channels the spirit of agility by looking ahead and adapting its decision-making accordingly, to ensure that it is consistently operating in the best interests of its people and the community.

“Our ESG Strategy mirrors our business approach of balancing sustainability and takes into account the impact we have on our stakeholders, community, and the environment,” says Hansen.

As a trusted freight and logistics provider to resource companies like Kestrel Coal, we understand the critical need to minimise downtime, maximise uptime and keep business moving. That’s why we offer integrated logistics solutions over Australia’s only multi-modal network – operated by dedicated teams around the country – to deliver reliable, resilient and unparalleled reach through road, rail, air and sea.

YOU CAN’T STOP PROGRESS

The company’s first ESG Strategy was officially launched in 2022 after being endorsed by the Board. It came to life through a comprehensive process consisting of employee interviews, industry benchmarking, listening to the concerns of the local community, and an extensive review of current and emerging ESG issues. This also led to the identification of the four pillars of the aforementioned Legacy Worth Leaving. Since that time, ESG has been positioned at the core of the company’s operations.

“Although Kestrel is in the early phase of its ESG journey, I am immensely proud of the results that we have achieved to date,” he expresses. “Through our latest strategy, we reaffirm our desire to not only continue to evolve our ESG maturity but also how we aim to create a Legacy Worth Leaving.”

A major aspect of this includes the ongoing pursuit of innovative solutions that will make Kestrel

more sustainable, environmentally considered, and energy efficient. Over the course of 2023, key actions in ESG development include conducting an independent third-party audit of the Kestrel SHMS, reviewing and updating the company’s Modern Slavery Statement, and developing a five-year implementation plan dedicated to the progressive rollout of the overall strategy.

“We will challenge ourselves to ensure our ESG Strategy continually evolves and keeps pace with what matters most regarding our role in society, the impact we have, and the value we create,” Hansen concludes.

As an advocate of proactive environmental management, water conservation is a vital element within Kestrel’s ESG Strategy. The company’s efforts in water stewardship reflect its concern for maintaining a clean, and reliable water supply within the

Fitzroy River Basin where it operates.

To conserve and protect this precious and scarce resource while sharing it with other users in the catchment, Kestrel combines transparent water governance with an effective management system.

The mine’s raw water supply is directed from a river water source on the Nogoa-McKenzie system. As a variable supply, each year, the company prepares a dedicated wet season plan to ensure that it is ready to respond by both containing water on-site and actively pursuing methods to reduce water demands. Major strides were made in this regard in 2016 with the launch of a water reduction programme that saw Kestrel’s raw water demand plummet by a staggering 65 percent.

The trend of declining raw water demand continues today. In 2022, Kestrel recorded a raw water usage of 657 megalitres (ML) at a rate of 116 litres (l) per tonne of coal product.

This represents a reduction of 220ML in raw water usage compared to 2021 (877ML).

Thanks to this drop in raw water demand, in addition to supplementary bores and dewatering usages, Kestrel’s overall total site water in 2022 was reduced to 3,628ML. The company did not rely on water from supplementary bores throughout this period and supplemented its raw water usage with output from its reverse osmosis (RO) plants.

The 2016 plan also effectively integrated water reuse across the mine site. Currently, all water on-site is recycled through a dam system for reuse, with the exception of sewage and water for human consumption.

Across its operations, Kestrel maintains a comprehensive groundwater monitoring network to oversee water levels and quality. This extends to site areas (including tailings), the mine’s periphery, neighbouring wells and regional locations further afield.

Set to continue this promising trajectory in 2023, Kestrel proposes various improvements in water stewardship, including assessing the recent optimisation of the RO plants against new or additional infrastructure, pursuing options for further raw water usage reduction from the Selma Weir, and continuing to optimise the performance of its dry tailings’ disposal process.

From water to the land, Kestrel takes its role as an environmental steward equally seriously, particularly when considering that 96 percent of the 17,000ha that the site occupies consists of active cattle farms.

The land is maintained through an existing lease between Kestrel and the Australian Agricultural Company (AACo), which operates as a fully separate productive cattle property.

As such, there are several factors contributing to the notion of full

land productivity which Kestrel endeavours to uphold. These include the agricultural productivity of cattle farming, the values intertwined with the cultural heritage of its Traditional Owners, but also the biodiversity that must be maintained.

Indeed, the biodiversity that thrives on its surface makes the Kestrel site an area of great environmental importance. This includes high-value areas such as riparian habitats, waterways, remnant habitation, and endangered species like the native Queensland King

Bluegrass community (Dichanthium queenslandicum) that require various conservation efforts.

In addition, the area attracts an abundance of insects and birdlife, including, of course, the company’s symbolic Nankeen kestrel.

In 2023, Kestrel will continue its involvement in several restoration projects with funding towards improving the bluegrass diversity of Central Queensland through the rehabilitation of areas that were previously assigned to agricultural activity.

“WE’RE SETTING NEW STANDARDS FOR LONGWALL MINING – NOT ONLY IN OPERATIONAL PERFORMANCE, BUT ALSO IN BUILDING A PLACE WHERE PEOPLE WANT TO BE”

– SHANE HANSEN, CEO, KESTREL COAL RESOURCES

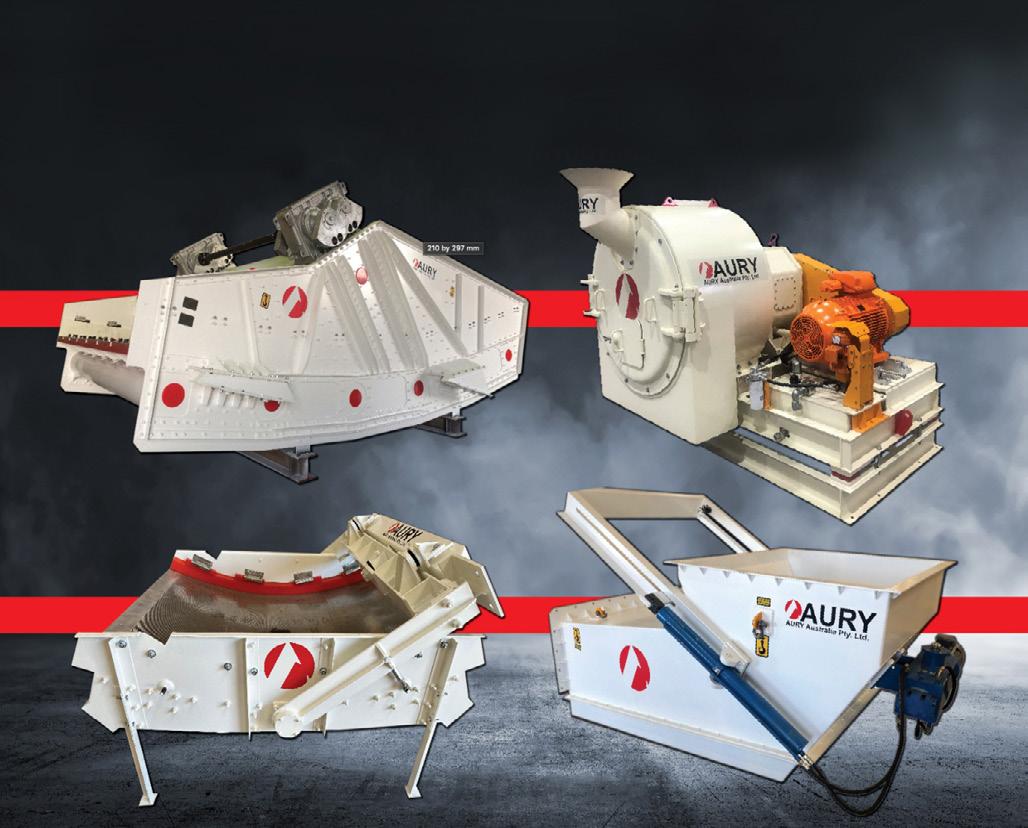

Aury Australia is committed to providing world-class screening and vibrating equipment solutions and services. Backed by a team of industry professionals, we pride ourselves on being the leading mineral process equipment and service provider with a global footprint in Australia, Asia, North America and Africa. As an organisation, Aury prioritises advanced technology, practical output and customer satisfaction to deliver the best possible service to our clients.

sales@auryaustralia.com.au

auryaustralia.com.au

Across the Kestrel landscape, the progressive rehabilitation of disturbed land to its full productivity is a key objective. In 2015, the company marked a proud moment when it became the first Queensland coal mine to achieve certified rehabilitation status for 571ha.

As Kestrel’s Sustainability Manager, Colleen Fish maintains this area of certification as a key focus going forwards.

“We are currently seeking additional certification to add to our 571ha of certified rehabilitation,” she tells us.

This falls into the company’s Progressive Rehabilitation and Closure Plan (PRCP), which has been granted an extension by the Department of Environment and Science (DES). Kestrel will formally commence the certification of new areas that are ready to be certified as fully rehabilitated pending the PRCP’s submission to the DES later this year.

All land disturbance at Kestrel is undertaken through a spatial and conditioned disturbance permit process that takes into account major factors including water, soils, ecology and heritage. Progressive rehabilitation is then implemented in alignment with the cycle of land as and when it becomes available. Depending on rainfall levels, Kestrel aims to manage all temporary land disturbances back to a rehabilitated state within 15 to 30 months.

As each mine site ceases operation and enters into closure, these areas are given new life through appropriate land use. The same also applies to legacy landforms. By doing so, Kestrel perpetuates post-mining regeneration that creates value, whether for the environment, the economy, or the local way of life.

In the consideration of how land should be re-purposed post-mining,

Kestrel is now exploring ways in which this might further the company’s decarbonisation efforts by putting certain areas to good use for the generation of clean energy.

For Hansen, a potential foray into renewable energy represents an exciting avenue for the company to capitalise on.

“As we continue to plan for site rehabilitation, we see a significant opportunity for the development of renewable energy projects, particularly in the form of energy storage systems,” he shares.

“These sites have the necessary space, infrastructure, and location to support such initiatives, and repurposing these areas in this way would be a win-win situation – for us, the local community, and the environment.”

This idea of repurposing introduces another major environmental endeavour currently being undertaken by Kestrel, as the company continues its investigation of converting the gases related to coal mining into new, usable energy. As part of its prevailing commitment to reducing its carbon footprint through responsible operation, the potential impact of such a scheme in terms of

decarbonisation at Kestrel could be enormous.

As Hansen affirms, “we are actively exploring ways to re-utilise gas derived from our mining activities for energy generation.”

As with any underground mining operation, harmful gases must be extracted to create safe working conditions. Coal-related gas emissions are the greatest contributor to Kestrel’s carbon footprint, with 88 percent of carbon emissions generated directly by the coal resource.

Consequently, the carbon impact of these gases takes priority over other means of emissions reduction such as diesel or electricity consumption, due to their relatively small impact on Kestrel’s overall footprint.

Of these coal-related gases, the need to mitigate vented-air methane (VAM) emissions is a major focus, since this particular gas is 28 times more potent a greenhouse gas (GHG) than CO2. With Kestrel now mining the deepest section of its deposit, this means that it is confronting heightened concentrations and densities of methane.

In an effort to mitigate negative impact, Kestrel is currently exploring the possibility of using this waste gas to achieve circularity by generating clean energy that can be used to power the mine’s operation.

A major step forward in this regard is Kestrel’s upcoming Waste Coal Mine Gas Power System (WCMGPS). This involves the construction of a 20-megawatt (MW) facility that will repurpose this gas to create clean energy. The facility will be fuelled by the mine’s existing system which drains gas directly from the coal seam and is connected to the mine’s existing 66 kilovolt (kV) electricity network, which in turn is connected to Ergon’s network at the Lilyvale Substation.

“The system will convert the WCMG to electricity and supply it to the mine to power mining operational requirements and reduce its demand on the Ergon network,” explains Fish.

Constructed over two phases, Phase 1 will establish a grid connection and achieve 4MW, while Phase 2 will see expansion to 20MW. Phase 1 takes advantage of shorter grid connection approval processes for small generators to start generating sooner and prepare the ground for the more ambitious Phase 2.

“This initiative is not only environmentally conscious, but it also allows us to utilise what we have and effectively turn waste into sustainable energy,” elaborates Hansen.

The construction of the WCMGPS falls into Kestrel’s Decarbonisation Plan, as part of the company’s wider ESG Strategy. This provides an LOM vision and implementation plan for ongoing decarbonisation to meet both legislation and expectation.

“We intend to advance the

continuous progression of our LOM decarbonisation strategy,” affirms Fish.

Within this, Kestrel is focused on exploring other opportunities to reduce its coal mine waste gas emissions, specifically in finding technologies that will allow the conversion of VAM to or other usable methane concentrations, as its biggest single possible reduction in carbon emissions.

As a result, the company is actively looking to secure energy partners with whom it can work towards gas reuse, in addition to achieving energy efficiency across the site and sourcing components of its electricity usage from renewable sources.

“We’re looking at harnessing new technologies and processes to further enhance our efficiency, with a focus on minimising our environmental footprint,” Hansen informs us.