M

THROUGHPROTEINPOULTRYProtobrandstobeaone-stopshop,”opensKelfoodsCOO,SotiMichael.Donna’sEggsarepower-packedwithproteinandthereforeattheheartofKelfoods,whosegoalistoconsistentlysupplyeggstoMalawianconsumersandincreaseAsoneofthemostpopularsourcesofprotein,Kelfoodshashatchedsuccessfromhigh-qualityeggsinMalawi.COO,SotiMichael,givesusthedetailsWriter:JackSalter|ProjectManager:KyleLivingstone 2 | Africa Outlook issue 98 KELFOODS FOOD & DRINK

In Malawi, eggs are a necessity. Most alternative protein sources are seasonal and in decline, whereas eggs are available throughout the year.

Addressing the shortage of protein in Malawi is Kelfoods, a leading integrated poultry business that farms, produces and markets table eggs, day-old chicks and animal feeds through its extensive retail and distribution network.

alawi, one of the world’s most densely populated countries, has a debilitating protein shortage.Protein is an important nutrient that the body needs to grow and repair cells, and to work properly. It is found in a wide range of foods, such as eggs, and is crucial to a healthy diet.

“Kelfoods has Lohmann layer breeders and Ross broiler breeders, who feed our hatchery. From there, we sell our day-old chicks, while our pullets are reared on our rearing farms,” Michael tells us.

Kelfoods is also Malawi’s biggest supplier of day-old chicks under the Proto Chicks brand, selling up to 200,000 per week, the majority of which are delivered to small-scale farmers across the country. The highly regimented production systems at Kelfoods’ hatchery enhance the genetic potential of each chicken, through internationally accepted hatching standards in line with strict animal welfare practices.

“The main business of the company is the production and sale of table eggs, branded as Donna’s Eggs, as well as day-old chicks (Proto Chicks), commercial animal feed (Proto Feeds), and poultry equipment and vaccines (Proto Vet). We have combined our Donna’s Eggs and

annual consumption to 80 eggs per person, sufficient to sustain child development and ensure sustainable physiological growth.

Currently, an impressive one million eggs are produced by Kelfoods each day, and with its own bio-secure broiler and layer farms, the company is well equipped to meet current and future table egg demand.

Ross® 308

“We cover all the main towns and markets across Malawi, however we are constantly evolving and expanding into new townships and population growth areas.”

To be successful in the poultry industry, whether you are a small-scale farmer or a commercial farmer, you need good quality, consistent feed.

“We have invested in a state-of-theart feed mill in Dalein, which every hour produces 25 metric tonnes of mash feed and six metric tonnes of pellet feed to drive our expansion in both the layer and broiler business,” outlines Michael.

Proto Feeds is the brand name under which animal feed is produced and sold by Kelfoods, and the feed mill is the catalyst for growth throughout the company’s business value chain.

By specifically grading eggs for their interior quality, weight, cleanli ness, shell construction and freshness, Kelfoods puts only the best quality eggs on the market and sets the stand ard for food safety in Malawi.

KELFOODS – AT A GLANCE

As such, a key investment in Kelfoods’ expansion strategy is the company’s new feed mill.

Kelfoods has also recently upgraded its facilities with state-ofthe-art grading equipment. Grade requirements for eggs are set to protect the consumer from undue risk, and to ensure a uniform and appealing product.

VISION: To sustainably grow the business, being the best-cost producer of animal protein and feed to Malawi and immediate regional markets through superior product quality and availability.

MISSION:

• Continuously improve and grow the production of high-quality products to internationally accepted social and environmental standards at the best cost.

rcaexports@rossafrica.com

• Employ and develop skilled employees who are passionate and committed, creating a culture of excellence.

Chicks Feeds Vet

NEW FEED MILL

4 | Africa Outlook issue 98 KELFOODS FOOD & DRINK

Customers across the region choose Ross because it meets the requirements they are looking for, specifically in FCR and yield, which in turn maximises their profit, making Ross the breed of choice in the region.

“This includes a batch weighing scale, mixer and discharge hoppers, and a feed pellet crumbler, making it a fully integrated system.”

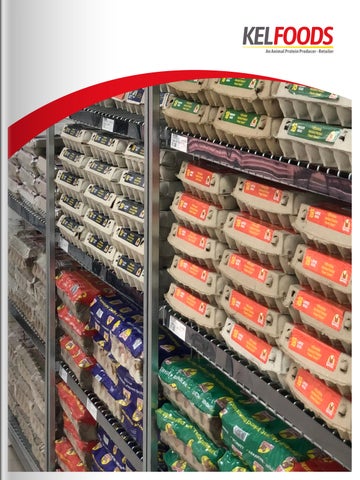

70 percent of Kelfoods’ products are marketed and sold through its 101 branded retail outlets, strategically positioned to support local vendors and small business owners.

• Produce and sell products at affordable prices.

The Ross 308 is the leading broiler worldwide, with its unparalleled and renowned performance in both open and closed-housing environments.

The Ross® 308 satisfies the demands of customers who require a bird that performs consistently well and has the versatility, robustness and cardiovascular strength to meet a broad range of end-product requirements and environments.

Construction of the new mill commenced in January 2018, doubling Kelfoods’ feed milling production capacity to 10,000 tonnes per month, the largest in Malawi.

• Maximise growth and profitability for all stakeholders in a responsible and sustainable manner.

• Improve product availability and customer satisfaction, supported by an expanding retail and distribution network.

VALLI S.r.l. - via Cimatti 2, 47010 Galeata (FC) - Italy Tel: +39 0543 info@valli-italy.com975311 MADE IN www.valli-italy.comITALY Africa Outlook issue 98 | 5 KELFOODS FOOD & DRINK

Our tradition is quality without compromise. IS A LIFESTYLE

5 Years of BalancedImprovementsGeneticAnnuallyDelivered 2.5 to 3 ImprovementChicks 0.5g inImprovementADG 2.5 to 3 Point ImprovementFCR 0.25% Improvement in Livability 0.2% Improvement in White Meat Yield IN THE LAST 5 YEARS, THE ROSS 308 HAS DELIVERED: For more information contact us at rcaexports@rossafrica.com 2022 - 0820 Ross Central Africa Half Page Ad.indd 1 8/24/22 11:32 AM R

All of our history, all of our experience, all of our work is dedicated day by day to improve the design and performance of our equipment in order to provide our customers with a "quality they can depend on".

WHERE QUALITY

Since its origins the company has been dedicated to the manufacture of top quality "cage" systems for the poultry industry.

Excellence in poultry equipment since 1956.

We design complete turnkey packages with all the internal equipment, ventilation and electrical controls required and have the back up of well-trained installers and supervisors to ensure your build is of the best quality and functionality.

Valli offer a very wide range of products for laying birds from traditional "A" frame cages for tropical climate countries, to manure belted systems with/without manure drying and new "enriched" multitier systems to match the requirements of EEC welfare regulations. We also supply rearing, parent stock, broiler cages and aviary systems.

STRICT BIOSECURITY

“All of our eggs are graded by Kelfoods’ state-of-the-art packing station and distributed to shops, supermarkets and customers across Malawi,” Michael tells us.

Reducing the risk of disease on its farms is imperative to Kelfoods, who

The first step in preventing disease is to protect flock from exposure to disease agents, by following very strict biosecurity guidelines to the letter.Biosecurity comprises the likes of flock healthcare, timely and effective vaccination programmes, balanced nutrition, enclosed and ventilated housing, high standards of farm and bird management, and poultry disease control, all of which are key to produce high quality products for the consumer.“Biosecurity is our perimeter fence, and is one of the cornerstones of our success,” acknowledges Michael.

personnel must dip their feet and all cars are Kelfoods’disinfected.”breeders, hatchery and rearing sites are even more restricted when it comes to biosecurity, with showers required before entry and only on-site clothing and shoes worn, whilst serology and microbiology laboratories ensure healthy flocks for healthy food.

“We don’t take any shortcuts towards biosecurity, and all of our sites are fully enclosed. Every site has only one point of entry, whereby all

FullyLayerAutomatedFacility

implement and maintain rigorous biosecurity measures as part of its farm management practices.

KELFOODS FOOD & DRINK

Through Proto Vet, experienced Kelfoods veterinary teams are also available to develop or fortify biosecurity, vaccine, and/or therapeutic treatment protocols for businesses.Kelfoods offers a complete animal health and hygiene range, including vaccines to protect livestock from today’s commercial

“We pride ourselves on having wellmaintained, clean, and smart farms with constant disinfection, rat bait, and wild bird proofing programmes.”

Also included is an abolition block, classroom, and seven model broiler houses each with the capacity to grow 200 broiler birds that illustrate the various stages of farming up to five“Theweeks.three-day course combines practical and theory, so whatever is

With tailored logistics, Kelfoods’ new fleet of custom-equipped trucks are configured to supply products to customers on time and offer an efficient logistical backbone.

Kelfoods allows all employees to take on new positions first before recruiting from the open market

Tel: +265 993 993 333 +265 994 994 444

www.kelfoods.netinfo@kelfoods.net

According to the World Health Organization, eggs are the most sustainable and acceptable source of animal protein in infant and child diets. Whether soft or hardboiled, fried or whisked into an omelette, eggs appear to give even infants a boost.

along with our standard operating procedures and key performance indicators, will help us to grow into neighbouring countries. Our strategy is to eventually set up similar operations in these countries, starting with Northern Mozambique.”

“After successfully finishing the course, farmers will take away our theory booklet with them and be awarded a Certificate of Completion. The entire course is provided for free by Kelfoods, including transport to and from anywhere in Malawi, accommodation and food.”

“We believe that our professionalism and teamwork,

It could also be a cost-effective way to prevent stunting in young children, according to researchers.

taught is shown in practice. Farmers will get to experience and understand what is required for the entire five weeks of broiler farming, from receiving day-old chicks to selling and cleaning the house to restart the process,” Michael explains.

and invest in broiler poultry farming. The company’s demonstration farm focuses solely on equipping local poultry farmers, with up to 1,000 new poultry farmers trained per year at no cost to the individual.

Direct engagement with Malawian farmers, and the growth of smallscale poultry farmer training, is one of Kelfoods’ key priorities for the year ahead, as it continues to supply high-quality, affordable animal protein throughout Malawi and into immediate regional markets such as Mozambique, Tanzania and Zambia.

production challenges, water soluble medications and supplements, and custom-developed disinfectants and detergents formulated to offer the highest level of protection against diseases without risk to users or livestock.“Wehave an extension service for all farmers with our own technical vets, who work with our retail outlets and cover all regions throughout Malawi under the Proto Vet brand,” states Michael.

One single egg contains a high amount of protein, anti-oxidants, vitamins and Wholeminerals.eggs are among the most nutritious foods on the planet, with Omega-3 enriched or pasteurised eggs an even healthier option.

“Our supply chain and logistics network operations have to be consistently efficient 365 days of the year, and we value all of our suppliers and partners whereby we build longterm relationships based on a win-win approach with open communication and understand to grow together.”

Great emphasis is placed on local employment by Kelfoods, with internal training provided at all times and local staff having equal opportunities to learn and grow within the“Wecompany.openthe door for each Kelfoods employee to empower one another and motivate each other to grow and develop. We allow all employees to take on new positions first before we recruit from the open market,” reveals Michael.

LOGISTICAL BACKBONE

“We provide a healthy mix of our own fleet for specialised deliveries and external third-party contractors, so we are flexible and nimble to market,” Michael observes.

THE POWER OF EGGS

Likewise, Malawians are empowered by Kelfoods to learn

Africa Outlook issue 98 | 7

Kelfood’s shop

Across the supply chain, from farm to customer, Kelfoods prides itself on providing the highest quality products to the market through more than 1,500 valued employees.

PRODUCED BY AFRICA OUTLOOK MAGAZINE KELFOODS Protopoint, Robert Mugabe Highway, Bangwe, Limbe , Malawi Tel: 0991 917 www.kelfoods.netinfo@kelfoods.net675