DELIVERING ON THE EYE HEALTH NEEDS OF PATIENTS AROUND THE WORLD

Committed to delivering the eye health needs of patients around the world, Johnson & Johnson has vision solutions for patients at every stage in their lives. Ryan Reinhardt, Vice President, Supply Chain, Johnson & Johnson, Vision tells us more about how the company collaborates, innovates, and works seamlessly together to care for patients at every stage in their eye health journey

Writer: Lily Sawyer | Project Manager: Michael Sommerfield

Fueled by innovation at the intersection of biology and technology, Johnson & Johnson (J&J) prioritizes delivering on the eye health needs of its patients around the world.

“We understand that eye health evolves over a lifetime, from contacts to cataracts,” introduces Ryan Reinhardt, Vice President, Supply Chain, Johnson & Johnson, Vision.

As such, J&J has built a unified, global organization that collaborates, innovates, and works seamlessly together to care for patients at every stage of their eye health journey.

Providing vision solutions for patients throughout their lives, the company’s portfolio is vast.

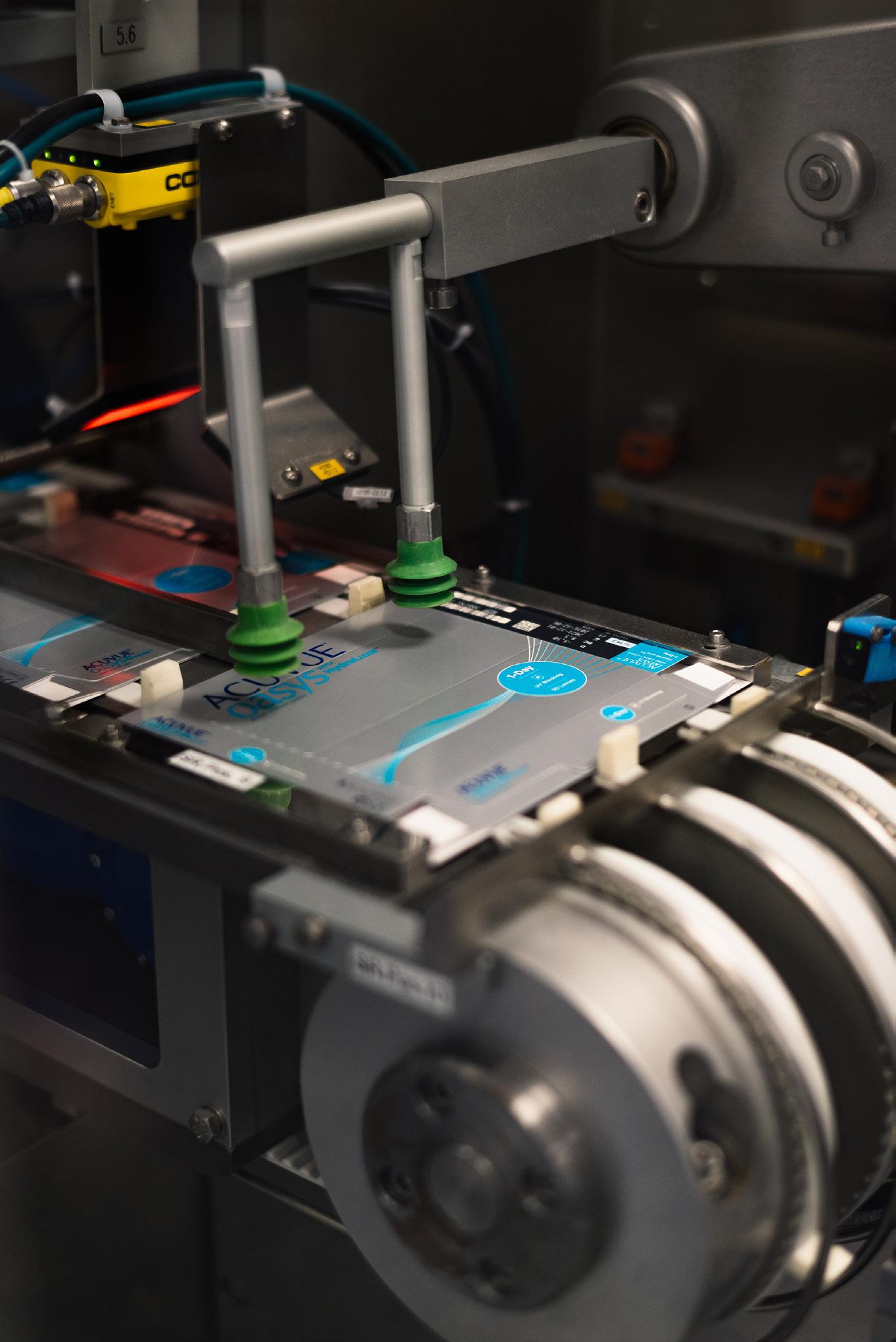

Its ACUVUE® contact lens portfolio is the most trusted by eye doctors

globally (1) and is the number one selling contact lens brand in the world (2)

Meanwhile, J&J’s refractive surgery solution, iLASIK, has been used in over 25 million patients worldwide, delivering exeptional visual quality with a patient satisfaction rate exceeding 96 percent.

Having started his career journey in engineering in Buffalo, New York, Reinhardt’s own journey into healthcare is an interesting one. His strong foundation in the industry sparked a hunger to pursue an MBA to broaden his skillset – sponsored by his company at the time.

This led to him moving abroad to lead aftermarket, spare parts, and distribution operations, which turned out to be a transformative move both

professionally and personally.

“I took this as an opportunity to not just deliver on the work I was undertaking but also enrich my life; I wanted to immerse myself in the culture and committed to learning the local language. What began as a three-year assignment evolved into a decade-long journey,” he smiles.

During Reinhardt’s time working abroad, he held several leadership roles, expanding his scope beyond his initial work overseeing aftermarket, spare parts, and distribution operations.

“I led a factory before transitioning to a healthcare company, where I took on new challenges,” he shares.

While working with at the

WAS IT AN INTENTIONAL MOVE WHEN YOU TOOK ON THE ROLE AT J&J TO LEAD THE VISION SUPPLY CHAIN BUSINESS?

Ryan Reinhardt, Vice President, Supply Chain, Johnson & Johnson, Vision: “I’ve always seen J&J as one of the great American companies, with a unique position in both the pharmaceutical and medical technology sectors.

“This dual presence across such critical industries is what sets J&J apart and makes it an exciting place to work. The opportunity to step into a leadership role within one of their MedTech businesses, where I could truly make a meaningful impact, was incredibly appealing.

“I saw this as a chance to not only contribute to a company with a rich legacy but also to shape my career trajectory within an organization that offers immense growth potential.

“The combination of J&J’s strong reputation, its broad reach in healthcare, and the opportunity to lead in the MedTech space were key factors that motivated me to make this move.”

healthcare company, Reinhardt became responsible for larger sites. As such, this period of his career became defined by leading and managing factories and supply chains, providing an opportunity to glean insights into the intricacies of a global logistics operations.

After 10 years working abroad, Reinhardt had the opportunity to return to the US, assuming a new role in Seattle.

“Here, I led the end-to-end supply chain for the ultrasound business. My responsibilities continued to evolve,

and from that point on, I focused on overseeing end-to-end supply chains for different business sectors,” he explains.

Two years ago, Reinhardt assumed his role at J&J, where he now leads end-to-end supply chain operations for vision.

While his technical roots in engineering have always played an important role, Reinhardt’s focus has shifted over the years toward business leadership – particularly in the realm of managing complex supply chain functions.

“IT’S NOT EVERY DAY YOU GET TO BE PART OF A COMPANY THAT PRODUCES BILLIONS OF CONTACT LENSES A YEAR. THE SCALE IS PHENOMENAL, AND IT’S INCREDIBLY EXCITING TO BE INVOLVED IN A SUPPLY CHAIN THAT OPERATES AT SUCH HIGH VOLUMES”

– RYAN REINHARDT, VICE PRESIDENT, SUPPLY CHAIN, JOHNSON & JOHNSON, VISION

As the company continues to advance its sustainability efforts, J&J is tackling climate change by reducing its carbon footprint and increasing the use of renewable energy across facilities.

It is also reducing waste, optimizing packaging, helping customers and patients recycle more, and protecting natural resources by finding alternative solutions to protect the environment.

J&J’s manufacturing plant in Jacksonville, Florida was awarded Leadership in Energy and Environmental Design (LEED) status, recognizing its sustainable design.

Meanwhile, the company’s intraocular lens manufacturing sites recycle wherever possible, including its product boxes, cardboard cartons, and swabs, with its Dutch manufacturing facility receiving Zero Waste to Landfill certification.

“This evolution reflects my growth from an engineer to a business leader overseeing global supply chain operations,” he prides.

Having always been drawn to processes, science, and math, engineering seemed the perfect way for Reinhardt to channel his passions.

“It helped me to develop strong problem-solving skills and allowed me to work in a field that matched my analytical mindset,” he observes.

However, after gaining more experience in the workforce, Reinhardt’s interests began to shift. He realized he had a growing passion for business leadership – specifically gaining an understanding of how a business operates at a larger level.

“I wanted to focus on driving outcomes that benefited the business, employees, shareholders, and ultimately its customers or patients.”

This small shift in focus led him to explore new avenues where he could merge his technical background with leadership and strategy.

Thus, Reinhardt’s decision to move into the healthcare supply chain was deliberate and thoughtful.

“Before joining the healthcare industry, I worked in the capital equipment manufacturing sector, where we sold products to healthcare companies,” he informs.

Reinhardt found this intersection of business and healthcare intriguing, and with several friends already working in the healthcare industry, the opportunity to make a noticeable difference in patients’ lives piqued his interest even further.

Today, Reinhardt also wants to be part of an industry that has a direct, positive impact on the world.

Whether improving the health of children, adults, or anyone along the healthcare continuum, the ability to make meaningful contributions to people’s well-being is a daily motivator.

Our engineers drive innovation in eye health by turning patient insights into advanced products. Help us pave the way:

“KNOWING THAT THE DECISIONS I MAKE IN MY ROLE CAN HAVE SUCH AN IMPORTANT IMPACT MAKES IT INCREDIBLY FULFILLING, AND THAT’S WHAT ULTIMATELY DREW ME TO THIS PATH IN HEALTHCARE”

– RYAN REINHARDT, VICE PRESIDENT, SUPPLY CHAIN,

JOHNSON

& JOHNSON, VISION

“Knowing that the decisions I make in my role can have such an important impact makes it incredibly fulfilling, and that’s what ultimately drew me to this path in healthcare,” Reinhardt states.

Working in various roles across different regions throughout his career has provided Reinhardt with invaluable personal and professional insight.

“Each step along the way has broadened my understanding of the role that manufacturing and supply chain play within a business,” he tells us.

In the early stages of his career, Reinhardt’s focus was very much on optimizing individual factories or distribution centers, ensuring operations were running smoothly and driving the right outcomes at a micro-level.

As his career progressed, he began to see how all these roles fit into the larger picture.

Transitioning from leading a factory to overseeing end-to-end supply chains allowed him to view how these functions tied into broader business objectives.

“My thinking evolved and moved up the value chain as I assumed more responsibility and began to

ACUVUE® Contact Lenses are available by prescription only for vision correction. An eye care professional will determine whether contact lenses are right for you.

Although rare, serious eye problems can develop while wearing contact lenses. To help avoid these problems, follow the wear and replacement schedule and the lens care instructions provided by your eye doctor.

Do not wear contact lenses if you have an eye infection, or experience eye discomfort, excessive tearing, vision changes, redness or other eye problems. If one of these conditions occurs, remove the lens and contact your eye doctor immediately.

For more information on proper wear, care and safety, talk to your eye care professional and ask for a Patient Instruction Guide, call 1-800-843-2020, or visit www.acuvue.com

understand the deeper connections between the supply chain and overall business success,” he recalls.

One of the most important things Reinhardt learned from living and working abroad was the value of understanding and connecting with local culture.

“I spent a lot of time immersing myself by learning the language, forming friendships with local people, and understanding what motivated them,” he passions.

This led to a deep belief that relationship building is key to achieving desired outcomes and that these connections often transcend geographic boundaries.

Being open, curious, humble, and willing to learn from different cultures was essential to Reinhardt navigating his time working and living in different regions and leading teams successfully across continents.

When he returned to the US, he was able to apply this broader worldview, approaching problems and devising strategies in new ways.

“This cross-cultural exposure expanded my horizons, allowing me to think more creatively and strategically when facing challenges,” he informs.

Ultimately, it was these experiences that shaped the way Reinhardt approaches leadership and problemsolving today.

With its approach to bridging the gap between two very different industries – fast-moving consumer goods (FMCGs) and medical devices – working in vision presented an opportunity to tackle a unique set supply chain operations.

“It’s not every day you get to be part of a company that produces over five billion medical devices a year. The scale is phenomenal, and it’s incredibly exciting to be involved in a supply chain that operates at such

high volumes,” he excites.

J&J’s process starts with getting products off the production line, directly into its warehouses, and then swiftly to customers around the world.

On the other end of the spectrum, the equipment side of the business involves a much more assemblydriven process and is focused on electromechanical assembly.

This is the typical medical device approach when dealing with lowvolume, high-complexity products sold to the likes of surgeons and hospitals.

Two distinct models – one focused on high-volume FMCGs and the other on more specialized medical devices – demand very different supply chain solutions.

“We have these models existing alongside each other within Johnson & Johnson Vision. Being able to manage and optimize both in one supply chain is truly special,” he says.

J&J also has a high level of automation on site which, in Reinhardt’s opinion, is world-class.

With significant advantages afforded by J&J’s end-to-end supply chain network model, especially in terms of alignment with the organization, there’s no ambiguity when it comes to its end goal.

“We all know what we’re working toward, and this clarity enables us to develop strategies that drive business outcomes rather than just functional ones,” Reinhardt confirms.

Everyone at J&J works together to achieve these goals, and this unified approach allows for quicker, more effective decision-making.

Because the whole company is aligned in terms of its understanding of business objectives, it can make decisions more closely linked to customer needs.

“Ultimately, this leads to better outcomes for the eye care professionals we work with, as well

as the patients who rely on our products,” he outlines.

One of the key benefits of J&J’s model is that it helps executives understand and respond to customers better.

“We can link our decision-making directly to customer needs, which strengthens our ability to deliver the right products at the right time.”

However, with such a contained business model, Reinhardt notes how important it is to be mindful of what’s happening outside the immediate vicinity.

“We have to make sure we’re not overlooking best practices or innovations happening in other parts of J&J,” he explains.

To mitigate this, it focuses on creating centers of excellence through which J&J teams can collaborate with other parts of the company to share insights and learn from each other.

“This approach allows us to bring best practices from across the organization into our supply chain processes, ensuring we’re always striving for continuous improvement while still maintaining full ownership of our mission to deliver the best possible outcomes for customers, patients, and the business,” Reinhardt confidently concludes.

Tel: (904) 443-1000

sa-visus-viseyesite@its.jnj.com www.clearvisionforyou.com

Intended for US audiences