‘GOING FURTHER’ IN THE UK FOR MORE THAN A CENTURY

‘GOING FURTHER’ IN THE UK FOR MORE THAN A CENTURY

For more than 50 years businesses have relied on Ford Transit to get the job done, and the Company is more determined than ever to maintain that tradition as the industry moves into the electric age

o be an outstanding global entity in a given industry is one thing, but to then hone in on more localised success over a sustained period of time is a whole other prospect; and one that Ford has achieved unwaveringly for more than 100 years in the UK.

As the renowned automotive manufacturer’s third largest global market, accounting for around 30 percent of all sales in Europe, the UK has long served as a continental flagship for the Henry Fordinitiated pioneer. But by no means is this a one-way street of country empowering company; with the latter also enriching each presence point far beyond just its products offering.

In essence, and as the Company correctly and proudly states, “Ford has a social responsibility to keep Britain moving” and this responsibility is carried out on a daily basis across more than five million customers in England, Scotland, Wales and Northern Ireland.

“People rely on us consistently delivering class-leading products and services that allow them to run their lives and their businesses,” affirms and introduces Ford UK’s Chairman and Managing Director (MD), Andy Barratt. “Our position as the UK market leader is recognised and valued, with the Company frequently asked to comment - supporting Government and industry bodies - on key issues such as the future of UK automotive manufacturing, skills, research & development, and the air quality agenda.”

A facilitator of development and multi-industry growth - as well as simply customer satisfaction - Ford has held the mantle of passenger car sales leader in the UK for 40 consecutive years; and commercial vehicle sales leader for an even more impressive 51 years.

Pepa Torres Romaguera is the current CEO of Walkerpack MPL, and under her leadership the Company aims to be the best logistic partner to Ford and its Valencia operations.

The Company currently manages part of the logistics chain, developing and implementing advanced procedures and offering the following services:

• Storage

• Sequencing

• Quality inspection

• Stock control

• Software development

All services are provided using the Company’s own transportation.

T: 0034 607 509 826

F: 0034 96 178 89 33

E: PTORRES@WALKERPACKMPL.COM

WE ARE IN THE INDUSTRIAL PARK JUAN CARLOS I AVDA DE LA FOIA, Nº 20 ALMUSSAFES VALENCIA 46440 SPAIN

Additionally, a Ford model has been officially named as the best-selling car in the UK for the past 44 years, with its flagship Fiesta brand thriving as the country’s best-selling car for eight consecutive years.

More than just a sales hub, however, the UK and Ford have formed a harmonious partnership throughout the value chain; the former lending itself as a breeding ground to the latter, and the latter repaying such hospitality with its aforementioned market dominance and consumer offering.

“The UK plays a crucial role for Ford, globally, in terms of research & development and high-value manufacturing, as the centre of excellence for the engineering, design and manufacture of low-emission powertrains as well as the design and development of commercial vehicles (CV),” Barratt emphasises. “Ford is a leading partner in the UK’s APC (Advanced Propulsion Centre), a joint

“Accelerating the development of new products that customers want and value is a key component of the One Ford plan. From fun-to-drive, fuel-efficient cars to versatile, capable utility vehicles and tough, durable trucks that work harder and last longer, Ford offers a full range of high-quality products with global appeal.”

industry and Government initiative to help the UK maintain a leading position in defining the future of personal transport.”

The notion of “defining the future of personal transport” comes with its challenges and responsibilities of course, but never has this been more pressurised and important in the UK than in the present day, as uncertainties around Brexit and the UK’s economic connection to the wider world come to the fore.

It is a reassuring comfort therefore that a name like Ford has helped to bridge international trends, preferences and manufacturing ideologies for more than a century.

“In contrast to most European markets, UK new car registrations returned to pre-recession levels in 2014 and 2015, as confidence in the economy expanded and consumer demand for the latest models and technology grew consistently,” Barratt recalls. “Last year the UK passenger car and commercial vehicle markets continued to grow, but 2017 is seeing a decline amidst mounting concerns about the UK economy and uncertainties around Brexit.”

Thankfully, Ford’s presence in the UK is established enough to both ride this wave of uncertainty, and indeed to remain a national positive amid a backdrop of largely negative business connotations.

At present, the Company can boast around the country: 110 transit centres; 187 transit service dealers, 456 car dealerships; 69 FordStores; and 472 sales points. Meanwhile, from an employment perspective; Warley, Dagenham, Dunton, Bridgend, Southampton, Halewood and Daventry are all graced with the familiar Ford logo, and are also complemented by a 788-strong Ford Financial division, and a TrustFord UK (Ford Retail) workforce of more than 3,000.

Overthe past three years, the Spanish Company, Walkerpack MPL S.L., a logistics partner of the Ford Motor Company, has developed into one of the main logistics suppliers for Ford Valencia.

Walkerpack develops real-time sequencing for production lines, in correct quantities and at the necessary time, through its proprietary system of synchronisation in sequence (SSS), for the Valencia assembly plant.

The firm currently handles more than 3,500 references in different centres. This involves supplying 5,000 parts to the point of feed (pof) every hour and at 80 different points, including the door line, trim and chassis.

Currently, Ford Valencia manufactures five different vehicles: the Transit Connect, Kuga, Mondeo, S-Max and Galaxy. It’s possible that Valencia is the most flexible plant in Europe, and possibly the world.

Walkerpack has been working for Ford in Valencia since 2005, but the past five years in particular have proven especially significant. The Company has been able to grow at the astonishing rate of 900 percent to meet Ford’s needs in the Valencia plant. Starting out with just 50 employees; today the business comprises 500 workers in the Almussafes industrial park.

Walkerpack is working on a number of Ford installations including its 2nd row seat; via a conveyor which serves both the S-Max and Galaxy models manufactured by Faurecia. All foam produced by the foam plant in Valencia also derives from this conveyor.

Pepa Torres, Walkerpack’s Chief Executive Officer, stepped up to meet the formidable challenge of serving Ford, and she’s now

working with her team to develop further improvements.

To do this, the Company has invested in more resources, the latest technology and staff training to offer the best services at the best price.

The professional team has been working in the automotive sector for more than 10 years, and both the Company’s technology and partners are capable of taking on new challenges every year.

Walkerpack is also developing and implementing advanced procedures based on continuous improvement, lean manufacturing and a corporate culture. In short, the firm’s main goal is to satisfy customers by offering ‘just in time’ solutions, as needed.

The Company´s objective is now to build a logistics centre close Ford Valencia to unify three sequencing centres, in order to obtain synergies and savings. Its intention is to be the best logistics partner in Valencia and to introduce itself to other Ford plants in Europe in the near future.

For this reason, and based on its successful experience, Walkerpack wishes to introduce the Company in the UK to potential new customers, including companies that are seeking an automotive logistics partner.

“Headquartered in Brentwood, Essex, we have more than 14,000 people employed across our UK operations, which includes TrustFord, a dedicated Ford dealer group,” Barratt affirms in defining the sheer scale that Ford enjoys in the UK. “Our research & development centre, the Dunton Technical Centre, also in Essex, is one of the largest of its type in the UK.

“Home to more than 4,000 highly skilled designers, engineers and support staff, it is Ford’s global Centre of Excellence for Powertrain and Commercial Vehicle engineering and design.”

In terms of the Company’s manufacturing footprint in the UK there are two engine plants; Bridgend, in South Wales, and Dagenham. Between the two, there is the capacity to produce more than two million engines a year; a target that reached

almost 75 percent accountability in 2016 when Ford UK’s plants rolled more than 1.4 million engines off the production line.

“85 percent of the engines built were exported,” Barratt adds, “with a combined export value exceeding £1 billion.”

The MD continues: “In 2014 we also began a transformation of the customer experience with the creation of FordStores, which offer a new way to shop and experience Ford.

“Designed to make buying a new Ford easy and enjoyable, the dealerships arrange vehicles in distinct zones and, with the growth of personalisation, customers can use our life-size configurator. The technology allows near life-size configurations to be shown on an HD Power Wall, viewable inside and out, from all angles to ensure that it’s exactly what they want.”

Since 1984, ALUDEC has engineered and produced decorative solutions for the automotive industry.

The Company’s core capabilities involve the design, engineering and manufacture of high quality parts for vehicle interiors and exteriors.

The Company owns all processes (plastic injection, chrome plating, in-moldforming, assembly, and silk screening) and has expertise of all materials (steel, aluminium, plastics, resins, adhesives and inks) involved in the productions of emblems, monograms, interior trims and protection bumpers amongst other parts.

The Company’s premises are conveniently located close to our clients’ decision centres in Spain, France, Germany, Sweden and the USA. Hence, the Company is able to deliver parts to more than 600 assembly plants worldwide.

ALUDEC engineers and produces automotive interior components and exterior decorative parts meeting the highest industry demands of the world’s car manufacturers. Our objectives are aligned in order to deliver superior value through operational excellence. www.aludec.com

It is this customer-oriented ethos that has driven Ford’s continuous improvement over the years, both in the passenger car sales and commercial vehicle sales domains. The latter in particular has seen a doubling of Ford’s CV sales since 2011, coinciding with the introduction of the Ford Transit Centre.

The word ‘transit’ is so intrinsically linked to the Ford name, and this latest unveiling has capitalised on the brand’s popularity through the creation of a one-stop shop for commercial vehicle customers.

Barratt details: “With repairs, maintenance and support all under one roof, plus extended opening hours for greater flexibility, Transit Centres are designed to maximise the productivity and efficiency of people who rely on our products to run their businesses.

“We also rolled out our Ford Mobile Service programme, nationwide, following a successful trial around Greater London.”

The programme was initially developed to minimise disruption to fleet operators by reducing vehicle down time, and already the Company’s initiative has now evolved to comprise more than 100 speciallyliveried Ford Transit units; all equipped to handle a wide range of servicing, maintenance and repairs.

“It means, for example, a plastering company or landscaping business can continue to earn money on site while we service their van in the car park,” Barratt explains.

‘Continuous improvement’ in this sense, and indeed in most Ford applications, focuses largely on a refinement of service and customer interaction as opposed to simply improving internal processes and end products. In essence, all aforementioned factors are intertwined, with the latter manufacturing enhancements

Axalta Coating Systems, a leading global supplier of liquid and powder coatings, congratulates the Ford Motor Company on its 100-year milestone in the UK. Axalta is proud to have a decades-long global relationship with Ford and is the exterior coatings supplier to the production of the Ford GT. Ford and Axalta developed eight colours synonymous with Ford: Shadow Black, Frozen White, Ingot Silver, Triple Yellow, Liquid Red, Liquid Blue, Liquid Gray and Matte Black. Axalta’s coatings have been formulated to meet the specifications of the Ford GT’s carbon fibre body. A special Axalta primer followed by a topcoat brings the colour to life. A clearcoat gives gloss and protection.

In 2017 the relationship between Ford and Axalta took another step forward: Axalta became an Official Associate Sponsor of Ford Chip Ganassi Racing. Under the agreement, the Ford GT race cars feature Axalta’s logo as they compete in the International Motor Sports Association (IMSA) WeatherTech SportsCar Championship and the FIA World Endurance Championship (WEC) series.

With 150 years of experience in the coatings industry, Axalta supplies its more than 100,000 customers in 130 countries with innovative, colourful, sustainable and technically-advanced solutions that are designed to prevent corrosion, to increase productivity and to enable the coated materials to look better and to last longer.

For more information visit www.axalta. com or follow us on Twitter @axalta and on LinkedIn

driven by the commitment to meet - and exceed - customer needs and expectations.

The One Ford strategy is a further example of this bridging of the manufacturer-consumer gap, as well as highlighting the advantage that Ford has as a truly global entity.

Barratt explains: “The One Ford strategy has allowed us to benchmark global best practices and leverage our current portfolio; bringing products like Edge, Mustang and KA+ to the UK.

“Similarly, it’s enabled us to export our expertise with the introduction of the Transit, designed and engineered here in the UK, and now launched in the US.”

Simply outstanding

Just as 100-plus years of industry development lends itself to enhanced

modern-day operational excellence, the resultant continuous improvement strategies have similarly catalysed ongoing product improvements; completing a successful, and profitable, cycle.

In the UK, this process is epitomised by the evolution of the Fiesta which has been ever-popular on the country’s roads since 1976 in different guises; each model further cementing its status as a national automotive icon.

“As the UK’s best-selling car ever, and the market leader for the past eight years consecutively, the Fiesta has to be the product that has driven the Company forward in the UK,” Barratt affirms. “The very first Fiesta was groundbreaking - as the first front-wheel drive Ford, the first transverse-engined Ford, and the smallest capacity Ford since the 1950s

“Henry Ford has changed the way of life for many people with his vision to make owning a car both practical and affordable. The moving assembly line and mass production techniques that he developed, set the standard for worldwide industrial practice in the first half of the 20th Century.”

Brugola OEB Industriale SpA is a leading critical fasteners supplier of any fixing element to the automotive industry worldwide. The Company was founded in 1926, has four production plants in Italy, a brand new production facility in Michigan, USA and 11 logistic centres worldwide.

The Company produces 800 different types of bolts and manufactures seven million bolts every day and 420 employees contribute every day to the Company’s success.

The Company provides full support in engineering and development from the first stages of the project to the launch of the programme, including full logistics service from material production to line feed.

For more than 30 years, the Company have proudly supplied automotive manufacturers worldwide and are a full service provider for the Ford European Powertrain plants.

In May, 2016, the Company received Ford’s 2016 World Excellence Award for Supplier Performance within the “Special Recognition” category, which is reserved for those suppliers that delivered results that exceeded expectations.

With a strong belief in its values, the Company continues to evolve constantly, obtaining important results which it is very proud of.

The Company is building its future with quality and defends it with the utmost commitment, “Always”.

Brugola OEB Industriale SpA is a leading critical fasteners supplier of any fixing element to the automotive industry worldwide The Company was founded in 1926, has four production plants in Italy, a brand new production facility in Michigan-USA and 11 logistics centers in the world. We produce 800 different types of bolts and we manufacture 7 million bolts every day 420 employees contribute every day to the success of our Company

Brugola OEB provides full support in engineering and development from the first stages of the project to the launch of the program including full logistic service from material production to line feed

automotive manufacturers worldwide and we are F u l l S e r v i c e P r o v i d e r f o r t h e F o r d E u r o p e a n Powertrain Plants.

In May last we received the 2016 Ford’s World E x c e l l e n c e Aw a rd f o r S u p p l i e r ’s p e r f o r m a n c e within the “Special Recognition” category which is reserved for those suppliers that delivered results that exceeded expectations.

With a strong belief in its values, Brugola OEB Industriale spa has continued to evolve constantly, obtaining, throughout the years, important results which we are proud of We build our future with Qual ity and we defend it with our commitment, always”

with 957cc and 1,117cc engines - and it quickly became Europe’s fastest-selling car.

“Every successive Fiesta model has improved on the one before, and this year we have launched an all-new Fiesta range. Not only it is it our most technologically-advanced Fiesta ever; it is also the most expansive model range. From the sporty looking ST-Line and luxurious Vignale models, to the hotly anticipated ST and - for the first time in its history - a crossover model: the Fiesta Active.”

The latter milestone model delivers “rugged SUV-inspired styling including raised ride height” and will arrive in the UK in 2018.

“The all-new Fiesta is simply outstanding,” Barratt continues. “It has the most sophisticated range of driver assistance features ever in a small volume car in Europe and is the first Ford in Europe to benefit from computer simulation crash tests of a complete vehicle.

“We have a market share of around 12 percent on passenger cars and more than 30 percent on commercial vehicles.”

CARS: Ford 11.8 percent Vauxhall 9.3 percent VW 7.7 percent Nissan 5.7 percent

LCV: Ford 30.6 percent VW 12.3 percent Mercedes 9.4 percent Vauxhall 10.1 percent

TOTAL VEHICLES: Ford 14.2 percent (436,316 vehicles)

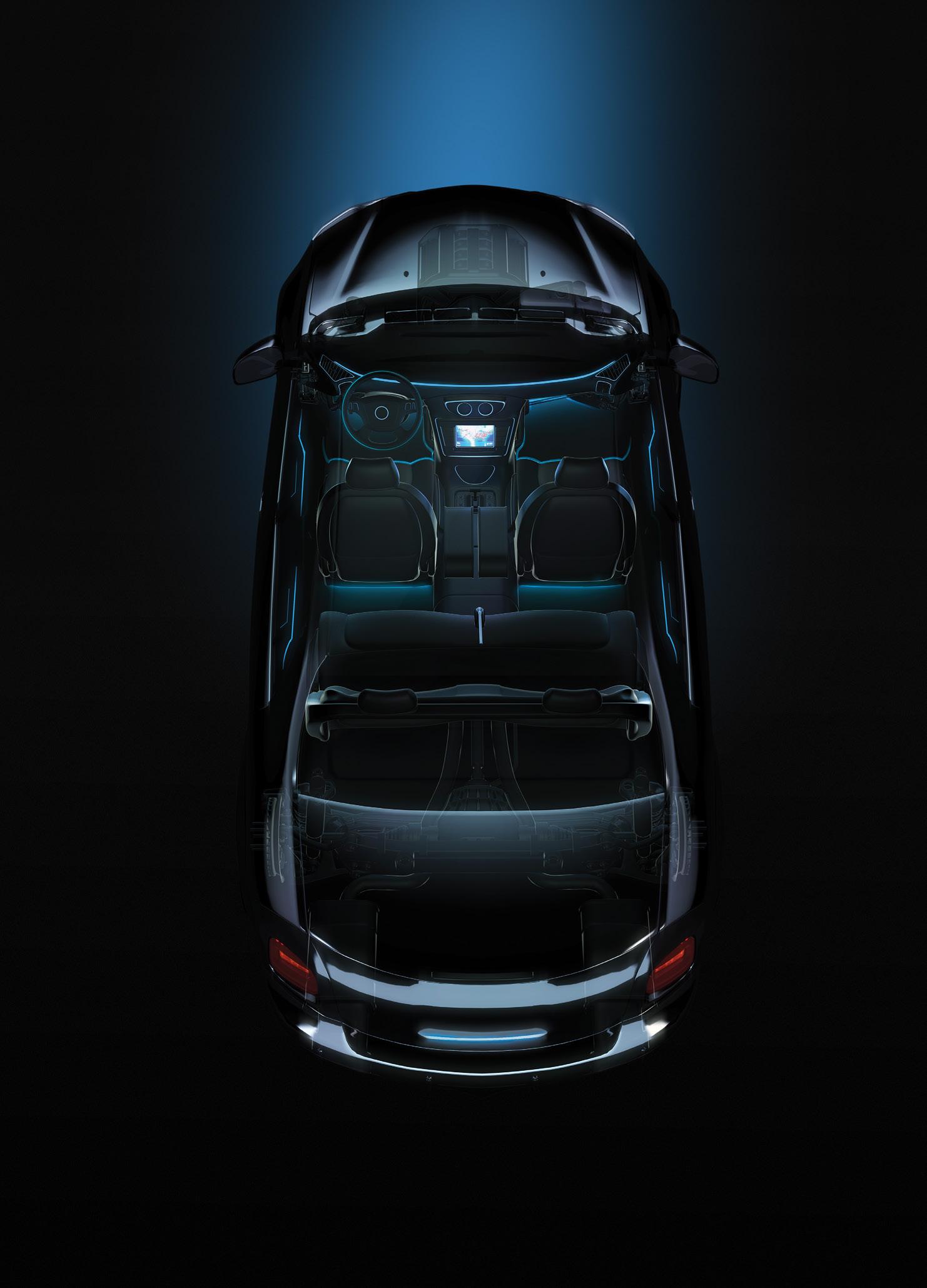

Hanon Systems is a full-line supplier of automotive thermal energy management solutions. Products include heating ventilation and air conditioning; powertrain cooling; compressors; fluid transport; and thermal and emissions solutions for conventional and electric, hybrid, fuel cell and autonomous vehicles.

Automakers rely on Hanon Systems as an expert in the field of automotive thermal management, creating value in an endless commitment to innovation and striving for excellence. Through its differentiated product portfolio, abundant experience and business acumen, the Company is focused on strengthening its position as a leader in innovative thermal and energy management solutions in the global automotive market.

The Company is committed to delivering automotive solutions that address government, consumer and industry trends through connected, integrated, controlled and optimised designs that meet individual needs of automakers in the development of next-generation vehicles. The value Hanon Systems brings is in the supply of solutions that not only deliver cabin comfort and enhance powertrain efficiency, but also maintain optimal operating temperatures for these devices.

With deep technical expertise and a suite of solutions to respond to the changing demands of the fast-paced automotive industry, Hanon Systems is continuously expanding its scope of product innovations to reinforce mechatronics and eMobility solutions that are designed to deliver even greater value to automakers and lead the technology of tomorrow.

The Company operates 40 manufacturing and 18 engineering sites across 20 countries, and employs more than 16,500 people. To learn more, visit www.hanonsystems.com or email info@hanonsystems.com.

May your 100+ years of leadership in the U.K. continue to be a successful, never-ending journey.

CONGRATULATIONS, Ford Motor Company, on over a century of success in the U.K. We appreciate our long-term partnership with you, and look forward to the road ahead.

“It is also the first Ford vehicle to feature an exclusive, premium B&O PLAY sound system, and for the first time offers an opening panoramic glass roof.

“It is part of the most comprehensive Fiesta range ever, meeting growing consumer demand for greater choice and more personalisation. Put simply, it is a brilliant new car, bringing style, technology and refinement that has never been seen in a small car before.”

As always, the new Fiesta models reflect the ongoing research & development that occurs behind the scenes at Ford, but more poignantly epitomise the Company’s dedication to customer satisfaction; something which also shines through its luxurious Vignale range.

The Vignale’s recent introduction was specifically in response to the growth in customer demand for the highest specification series’ available; Barratt noting that buyer feedback regularly called for an even higher spec and service.

“The Mondeo Vignale was our first offering and we’ve added it to the S-MAX, Edge, Galaxy, Kuga and now the all-new Fiesta,” he notes. “We know that buyers consider high levels

of customer service a key difference between a mainstream and upmarket experience, while showroom appearance and quality of hospitality are factors that influence customer expectations.”

The past two years has seen Ford launch its widest ever range of products. The iconic and oft lustedafter Mustang finally arrived in the UK for the first time in its 50-year history; complete with right-hand drive for the full UK experience.

In addition, the Company also launched its flagship SUV, the Edge; laden with modern driver-assist technologies.

Barratt adds: “We also have a line-up of vehicles that truly demonstrate our performance prowess and innovation. The all-new Ford GT and the third generation Focus RS are two cars that showcase our strength and credentials for delivering pure driving pleasure; truly exemplifying the Ford DNA.

“More recently we announced the plan to introduce a new plug-in hybrid electric (PHEV) Transit Custom van, designed to help improve local air quality by running solely on electric power for the majority of city journeys.”

The ‘electric age’ represents the next era for global automotive

Industrias Alegre S.A was founded in 1953 as a plastic injection and mold workshop, and these activities still continue today under 100 percent family and Valencian ownership. This, together with the expertise of its engineering team, makes the Company an excellence reference in its sector.

From its Spanish headquarters, the Company manufactures and supplies parts for customers across Europe and non-European countries such as Russia, Mexico, Brazil and India.

Its core business as a manufacturer and global supplier of plastic parts for the automotive sector focuses on the creation of interior plastic parts. From the upper and lower pillars and boot pieces to components of the instrument panel, consoles and seats, the range of plastic parts manufactured by the Company covers the total plastic content of the interior of the vehicles.

In addition, the Company’s R&D department has developed a packaging solution called HybridBox, which is a packaging solution that is reusable and waste free. Pieces are placed in individual cells when manufactured, optimising the space of the packaging in its folded position as well as unfolded, saving time and money in addition to being respectful to the environment.

The first Fiesta that Ford manufactured at the Valencia plant in 1976 already carried parts made by the Company, and it has continued to offer its products and services to the model range since then, including the latest generation Fiesta, launched at the Ford Cologne plant in April this year.

manufacturing so it comes as no surprise that Ford is plotting its route into the sub-sector with great care.

To this end, the PHEV Transit Custom van is scheduled for volume production in 2019, as part of the wider Company’s global promise to provide customers with not just access to the electric vehicle world; but affordable and realistic access to this new technology.

“Ford is the first volume manufacturer to offer PHEV technology in this segment and the vehicles will start testing at the end of this year,” Barratt says. “The London fleet trial project is supported by Transport for London, and features a cross-section of city-based businesses, including Metropolitan Police, British Gas and Clancy Plant, that will integrate the vans into their day-today operations.”

Prior to production, Ford has gone to extensive lengths to analyse the

significance of PHEV Transits in the UK, kick-started by the trial of 20 units mounted with an advanced telematics system.

Subsequently gaining an understanding of the benefits that electric vehicles present, and how these benefits can be further maximised, the system will provide real-time data on the vans’ performance; ultimately ensuring that Ford fully understands each customer’s needs.

“We, of course, continually monitor trends and adapt to the needs of consumers and anticipate future customer requirements,” Barratt emphasises to this end. “The growth in SUVs, for instance, continues and we’ve strengthened our product line-up with EcoSport, Kuga and Edge, which will be joined by the Fiesta Active next year.”

Technology also - predictably, yet importantly - continues to play a crucial role in Ford’s continuous improvement psyche; with special emphasis now placed on making “smart and connected” vehicles.

The dimmed headlights, the rain sensor, the anti-pinch protection system for electric windows, the first automatic emergency braking function based on a mono camera: KOSTAL invented them all.

KOSTAL Automotive Electrical Systems is the largest of the four divisions of the KOSTAL Group: a Company run by the fourth generation of the family that owns it and with headquarters in Lüdenscheid, in Germany’s Sauerland region. It would be hard to find a car on the road anywhere in the world that doesn’t have a single KOSTAL product installed in it.

The Company develops and manufactures innovative, reliable and cost-optimised products for the global automotive industry. With more than 17,000 employees in 21 countries on four continents and an annual turnover of €2.4 billion KOSTAL is among the top 100 automotive suppliers in the world.

The Company’s history goes back more than 100 years and is visible evidence of the long-term, reliable and cooperative relationship that KOSTAL Automotive Electrical Systems enjoys with its customers, employees and everyone connected to us.

The three business fields of Mechatronic Modules, Switch Panels & Switches and Electronic Control Units act with corporate responsibility in a way which is not only quality, customer and product-oriented, it is also costefficient. This guarantees smooth and comprehensive cooperation between all participants in the global process chain.

With its innovative focus in areas such as autonomous driving, electric mobility and new HMI concepts, KOSTAL is shaping the future today.

Barratt continues: “We are pursuing more transportation research partnerships to look at the cities of the future, and how people, goods and services will move in the future.

“We continue to expand our resources in autonomous vehicle research, with the recent announcement of our partnership with Lyft and the $1 billion investment in Argo AI combining Ford’s autonomous vehicle development expertise with Argo AI’s robotics experience and artificial intelligence software to further advance autonomous vehicles.”

Ford has also opened a new Ford Smart Mobility Innovation Office on the former Olympic Park at Stratford in London.

Once again addressing the trend of smart mobility and advanced technologies, the new office has provided a dedicated team of ford specialists - led by smart mobility Director, Sarah-Jayne Williams -

easy access to world-class digital companies, leading academic institutions, nimble start-ups, and existing partners.

“Ford continues to work on projects with the city to help improve air quality, ease congestion and broaden mobility for Londoners,” Barratt affirms. “Having an office in London offers Ford close proximity to its projects and partners; including the plug-in hybrid Transit trial due to launch later this year.”

Methode Electronics, Inc. is a US Chicago-based international global developer of engineered user interface, sensor, switch, power and ambient lighting solutions with design, testing and manufacturing facilities in the United States, Canada, Germany, Malta, Belgium, Mexico, China, Egypt, India, Italy, Lebanon, Singapore, Switzerland, the United Kingdom.

The Company’s products are in the primary end automobile markets, designed and produced for worldwide renowned brands. This includes the FORD Motor Company with whom the Company nurtures an excellent long standing relationship.

Methode Electronics supplies FORD worldwide from its three main campuses in China, Malta and Mexico. From its European location in Malta, Methode has supplied hidden switches to FORD since the early 1980s and continues to do so until today.

By the end of 2018, Methode Europe will have supplied more than 65 million ignition starter switches to Ford worldwide, ever since the launch of the first Focus (C170) in 1997. Methode Electronics Europe pioneered the first integrated centre stack assembly with Aston Martin of the Premier Automotive Group and later launched Electronic Face Plates for various US car lines from its plant in Mexico.

Today, the product capabilities have broadened to include interior and exterior mechatronic and electronic modules and endless modular solutions for every part of the automobile.

MECHATRONICS AND AMBIENT LIGHTING SOLUTIONS

Endless sensor and ergonomic solutions for interior and exterior user interface controls, pedal box, ignition, chassis, suspension, transmission and powertrain.

GET IN TOUCH AND DISCOVER HOW ANYTHING IS POSSIBLE.

Methode is possibilities...

The concept of ‘responsibility’ can often be seen as a tenuous one in the industrial world, with financial implications and business success understandably taking precedence for the majority of SMEs and even larger, but less-established businesses.

For Ford though, once again, the ability to act responsibly in the UK - and indeed across its entire footprint - has been integral to its longevity; whether as a natural contributor to the country’s talent pool and engineering acumen, or through less industrial-focused initiatives that are often associated with the Ford of Britain Trust.

Barratt describes: “A wide number of initiatives are supported through the Ford of Britain Trust, which was established in 1975 and provides funding for local charities and NGOs.

“We pay special attention to projects focusing on education, the environment, children, the disabled, youth activities, and projects that provide clear benefits

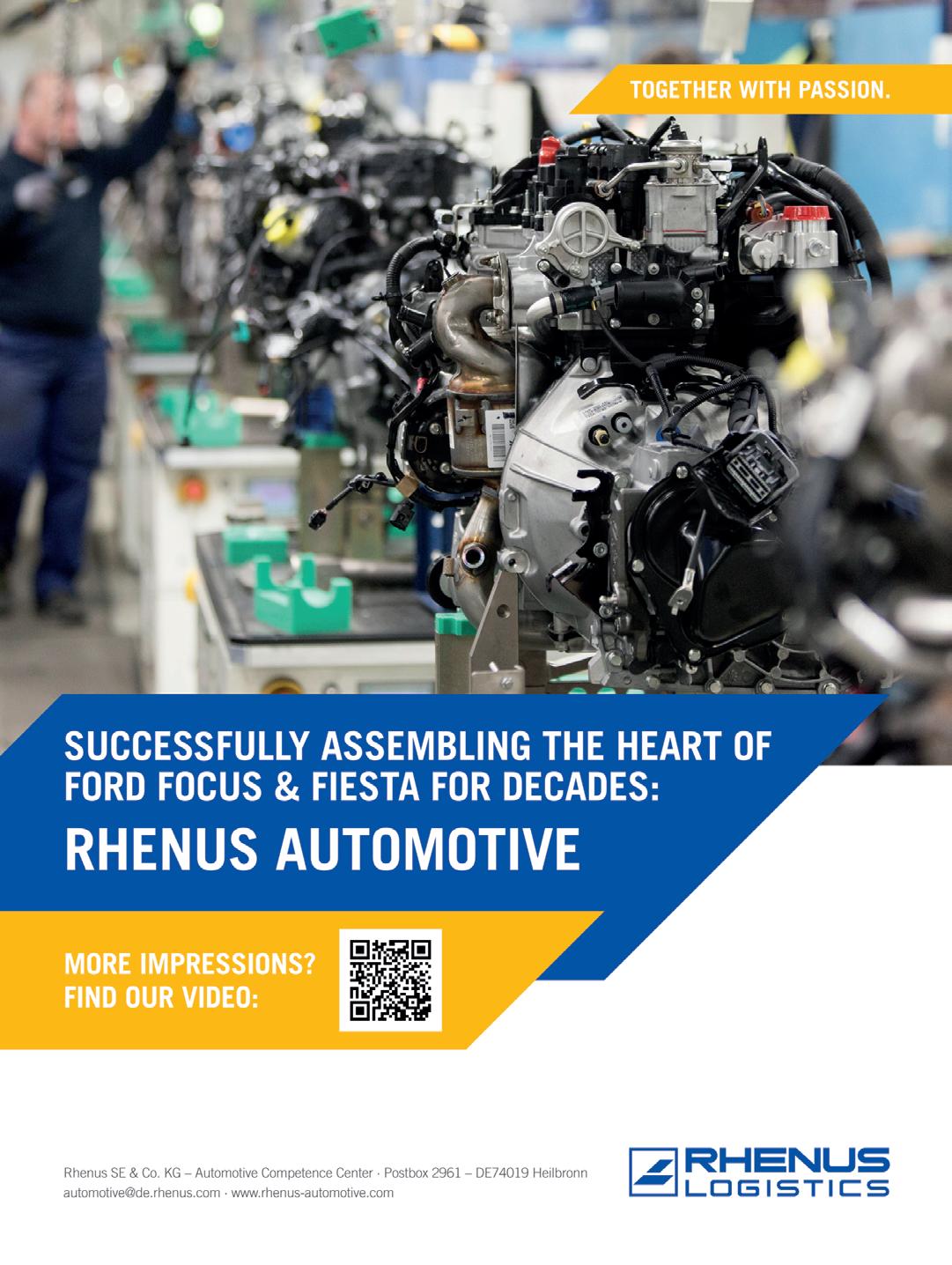

Rhenus Automotive is an international service provider of logistics, assembly and engineering services. We focus on high quality and flexible services to create value for our customers in the US and Europe. Decades of strong cooperation shaped the trust that enables us to develop new ideas and create efficient solutions with our partners: the leading automotive producers and innovative automotive suppliers.

Our assembly expertise includes a vast range of modules

pony pack, engine dress-up

front and rear axles, front corner

headliner, cockpit, center console

exterior and interior parts

auto glass

Our mission is to reduce complexity for our customers through innovative logistics and value-added assembly solutions. Our technologies and business practices build sustainable, long-term partnerships. By improving our processes day by day we are able to deliver better performance at all our sites. Rhenus Automotive constantly invests in innovation; aiming to identify, develop and implement ideas that support our customers’ success.

Ford always had an important role for our growth in Europe. Due to decades of tight partnership in Cologne, Saarlouis, and Valencia we are able to contribute a high level of value to most of the Ford models seen on the streets today. Strong bonds to Ford are the basis for highest performance – every day.

to the local communities close to our UK locations.”

One recent example showcases Ford UK’s partnership with Primary Engineer, a non-profit organisation that runs a variety of engineeringbased courses for children of primary school age. Collaborating with 20 schools across Essex, Ford’s engineers work with each to provide teacher and project support to help make the idea of engineering fun and exciting to inspire the next generation of industrial artisans.

“Another example is Ford’s work with Enactus, a global non-profit organisation and community of students, academics and business leaders,” Barratt adds. “In the UK, the Ford UK Innovation Challenge supports young people by encouraging social entrepreneurship through the implementation of sustainable community solutions.

“It’s also part of the global Ford College Community Challenge (Ford

The Ford Fund also provides Ford Driving Skills for Life (DSFL), a global advanced safety training programme specifically designed for newly licensed drives, aged 18-24.

Barratt comments: “The free training helps young drivers to develop skills in four key areas: hazard recognition, speed and space awareness, vehicle handling, and driver distraction including the simulated effects of drugs and alcohol.”

Such corporate social responsibility adherence - like most aspects of Ford’s operations - hasn’t gone unnoticed, and in 2017, Ethisphere Institute named the Company in its list of the World’s Most Ethical Companies for the eighth year in a row.

Recognising not only Ford’s personnel and community enrichment

With more than five decades of experience, The Sertec Group has become renowned as a manufacturer of excellence in aluminium and steel.

Quality and customer satisfaction is at the heart of Sertec and it is no surprise that growth has been dramatic in recent years through strategic expansion, acquisition and new customer gains.

With six factories in the UK, one in each of Germany and Hungary and a tooling operation in China, Sertec is a major force in automotive manufacturing supply. A recent £16 million investment in a brand new press shop in Birmingham has increased its stampings capacity, with transfer and progression presses ranging from 250 to 1,000 tonnes. But expertise extends to a much broader range of capabilities than purely presswork.

Sertec is leading the way in lightweight joining technologies, with both robotic and manual operation of welding and riveting processes. From raw material to OEM delivery of complex assembled components, Sertec has the project management expertise and the quality engineering performance required to supply the most stringent of global automotive manufacturers.

Wire frame assemblies for seat structures is a further speciality at Sertec, alongside other wire forming capabilities in bending wire from 0.1mm up to 17mm diameter. Add to this, expertise in deep drawing, tubular assemblies, fine blanking and precision stampings; Sertec is the complete supplier in Body In White engineering to the automotive market...globally. T

(0)1675 436600

E sertec.group@sertec.co.uk sertec.co.uk

The Sertec Group has a 20 year history of supplying The Ford Motor Company. Once recognised primarily for Stampings, winning both Silver and Gold in Ford’s World Excellence Awards, Sertec has grown to become a world class manufacturer in many other disciplines.

A leading exponent of lightweight material joining technologies for assembled components, plus wire frame structures, precision engineering and much, much more, Sertec is a major force in automotive manufacturing supply in the UK and beyond.

initiatives, the accolade also sheds light on the Company’s ongoing commitment to environmental sustainability.

Inevitably set to strengthen even more in the coming years through the inception of its electric range of vehicles, Ford has already proven itself as an ecopioneer; especially by virtue of its supply chain management strategy.

Driven by the Company’s role within the ‘Partnership for a Cleaner Environment’ (PACE) programme, Ford proudly operates as en entity committed to creating a better world.

“As a company, it’s important that we make quality products and minimise the impact on the environment by doing things the right way,” said Mary Wroten, senior manager of Ford Supply Chain Sustainability upon the 2017 unveiling by the Ethisphere Institute. “Having suppliers that want to share that responsibility shows we can work together to reduce our collective environmental footprint, while still continuing to deliver great products.”

PACE encourages consistency in best practices as well as supplier transparency and sustainability; subsequently working collaboratively throughout the value chain to save an estimated 550 million gallons of water over the next five years according to 2016 data.

SEGURA

GRUPO SEGURA is an industrial Group dedicated to the design, development and manufacturing of metal components for automobiles, mainly using stamping, welding and assembly processes.

The design allow its clients to manufacture safer, lighter and more ecological vehicles, contributing to optimising gas consumption and minimising environmental impact.

Having grown in partnership with Ford, developing its own culture and values, the Company is now stronger and more sustainable.

The Company would like to thank Ford for their support over the last 100 years, and look forward to many more exciting years ahead!

T +34 963 465 090

E mmontalban@fsegura.com

www.fsegura.com

With a long history of automotive sensor and module development, Casco offers a wide range of invehicle electronics for an enhanced driving experience. The Company’s tradition of innovation continues today with cutting-edge products for power delivery and management, environmental sensing, connectivity and electromechanical interfaces.

From sensing when to turn your headlights on, to charging your cell phone on the way home, to helping your vehicle manage the energy of its 48V battery system, the Company’s global footprint and over 1,200 dedicated employees support its customers with truly “power-full” solutions.

“Asacompany,it’s importantthatwe makequalityproducts andminimise theimpactonthe environmentbydoing thingstherightway”Clay modelling the Transit at Dunton

To play its part, Ford provides suppliers with a ‘PACE toolkit’ which consists of 350 leading practices across areas of energy, water, air emissions and waste.

One such supplier, DENSO has participated in the PACE initiative alongside FORD in 38 countries since 2014 and the Company’s Senior Manager for Safety, Health and Environment in North America, Jim Laney further commented on the relationship and vision during this year’s unveiling.

“We are serious about protecting lives and preserving the planet, and sharing best practices with Ford helps further that mission to sustain the environment globally,” he said.

Putting the customers at the heart Wider industry involvement and collaboration has been pivotal to Ford’s knowledge expansion and its influence on the sector over the years, and has been compounded in

recent times by becoming the first automotive manufacturer to join the Electronic Industry Citizenship Coalition (“a non-profit organisation dedicated to improving social, environmental and ethical conditions in their members’ global supply chains”).

Such adherence to sustainability - and environmental enrichment especially - can largely be attributed to Ford’s ‘Blueprint for the Road’ motto which homes in on outstanding fuel economy and the reduction of greenhouse gas emissions from its products.

“They’re very much part of our corporate responsibility policy, too,” Ford UK elaborates on its website.” So we’re always researching, evaluating and developing initiatives that create value; value that’s consistent with the long-term preservation and enhancement of environmental, social and financial capital. To define these actions and incorporate many other

ILUNION, the group of social enterprises of ONCE and its Foundation, is a socially responsible business project that develops its activity with criteria of economic and social profitability. It has a workforce of 36,540 employees, of which 40.8 percent are people with disabilities.

ILUNION Servicios Industriales

Automoción was founded in 2002. With 1,065 employees, of which 90 percent are people with disabilities, it is the TIER 1 logistics service provider of Ford España. Its centre is in Valencia province and takes up a total area of 40,000m².

T +34 902 90 41 11

E contacto@ilunion.com

www.ilunion.com

programmes, we established our ‘Blueprint for Sustainability.’

“This Blueprint encapsulates our sustainability strategy as a whole, reflecting the fact that sustainability issues are part of a complex system that interconnects our products, plants, people and the communities in which we operate.

“As well as being the right thing to do, sustainability is a core part of Ford’s business strategy. With smart and sustainable manufacturing solutions and an exciting range of technologically advanced, fuel-efficient vehicles, we’re creating foundations that will ensure our long-term success in Europe.”

By virtue of this philosophy, Ford also enforces its core, initial vision to bring long-term benefits and satisfaction to a customer base that has become so familiar with the brand’s innovation and influence over the decades.

And as the business now looks forward to replicating its dedication to

C\ Albacete 3

28027 Madrid, Spain

T: +34 902 90 41 11

E: contacto@ilunion.com

W: www.ilunion.com

development over the coming years, its UK operations will continue to serve as an example of Ford’s global competitive advantage.

“Our overarching strategy is putting the customer at the heart of everything we do. Our dealer network in Britain is one of the strongest in the world and remains a competitive advantage,” Barratt concludes. “[In the coming years] there will certainly be growth in digital and connectivity trends with the likes of car-to-car and car-to infrastructure communications. Increasing demand for the development and implementation of smart mobility solutions that are right for the consumer will certainly shape and transform our business.

“As an industry we therefore need to ensure that manufacturers and retailers are positioned to meet the needs in a rapidly changing world, where traditional models may no longer be valid.

“As such, customers will move even further into the heart of everything we do.”

Alberto Durán Vice President of ONCE Foundation and President of Ilunion

“We simply need to WANT IT, believe it is possible; find the way and CONQUER IT.”

BBB SERVICES LTD