CUTTING EDGE FLOWSHEET

SOLUTIONS FROM PIT TO PLANT

SOLUTIONS FROM PIT TO PLANT

Uniquely positioned as an early adopter of sustainable mining practices, we foreground the full flowsheet solution provider at the vanguard of an evolving industry. Members of FLSmidth tell us more

Writer: Phoebe Harper | Project Manager: Eddie Clinton

Writer: Phoebe Harper | Project Manager: Eddie Clinton

We are proud to offer the solutions of tomorrow, for the early adopters of today.”

A giant of the modern mining industry, FLSmidth (FLS) is the full flowsheet technology and service supplier driving sustainable productivity. In terms of both its portfolio and geographical footprint, few can rival its sheer scope and reach with the amount of both plants and equipment captured under the FLS banner.

Indeed, as a global leader in a high number of its total product portfolio, FLS has either equipment or services in practically every major mine site across the APAC region, regardless of the operator.

Although a Danish company with a presence worldwide, this particular geography is a dynamic area of operation for FLS with over 500 technical, services, product development, sales, project management and R&D teams serving the entirety of Australia, whilst also supporting countries such as Papua New Guinea and New Zealand.

For Jason Elks, FLS’ APAC Regional President and orator of the opening statement, it is a region undergoing a “significant transformation”, as the industry navigates a shifting global outlook influenced by the choppy currents of macroeconomic and geopolitical issues, regional instability and high inflationary pressures, all while answering the resounding demand for the green transition and sustainable economies.

“Whether in terms of government policy or resource sector implementation, APAC is a late adopter to the movement,” shares Elks. “However, we have a significant push here because it’s a region where the International Monetary Fund (IMF), the World Bank, and others are more than aware that sustainable mining builds education, healthcare, infrastructure, and essentially develops countries.”

As FLS’ Head of Sustainability, Wouter de Groot acknowledges the shortcomings of the wider industry in articulating mining’s relevance and necessity in driving the transition to net zero.

“As an industry, we haven’t done

Mikko Keto, Group CEO: “We know that we are one of the best in the market for our technology, but when we evaluated our portfolio, we saw gaps that could be filled with acquisitions. HPGR is one such area that is going to become increasingly important as a future technology. As the market leader for HPGR, TK Mining was an obvious choice for us. The company also had other products to advance our sustainability journey including

a very good job in making it visible just how instrumental mining really is,” he admits. The reality is stark and demands action from responsible players.

“To put it simply, to enable a transition towards a net zero society, we need the same amount of copper in the next 40 years as we have mined in the history of humankind, and about three times as much lithium as we are currently exploring,” de Groot continues.

In advancing the green transition of the mining industry, FLS established itself as a frontrunner in the space by taking a stance on accelerating sustainability in 2019 with its MissionZero commitment.

“While we are on an exciting journey with some of our early adopting partners, by and large the industry has not embraced the evolution,” echoes Elks. “FLS is wellpositioned, since for the past five years we have moved in a space that differentiates us as a market leader in innovation for sustainable practices.”

As the hotly anticipated target years of both 2030 and 2050 steadily approach, the pressure is on as mining players must meet escalating demand while remaining current and competitive, or face the consequences of being late adopters with a backlash of taxes, tariffs, and negative community perception.

In this charged environmental context, combined with the industry-specific demands of declining ore grades, cost pressures, and increasing demands on raw materials, FLS stands out as comprehensive solutions provider on hand to meet evolving customer needs.

“Major innovators such as FLS have the products available today to meet the objectives of 2030 and 2050,” Elks attests.

Speaking with FLS Group CEO, Mikko Keto, two core advantages transpire as the company’s most competitive differentiators.

Mikko Keto, Group CEO: “Through evaluating our portfolio, we identified that we add the most value to our customers through our products and technology. We are not an EPCM house – our core competency is technology and integrating it to give our customers a performance guarantee. This led us to exit certain parts of the business under this strategy that didn’t fit with where we add the most value.

“As part of this review, we decided to focus our portfolio on core technology, our products and our aftermarket service. Equally, we want to be the best partner for the full life cycle of a mine, which can last for decades. We provide our technology and support our customers from the mine’s design and build and throughout its life.

“The third pillar of CORE’26 is our sustainability commitment –MissionZero – where we help our customers to reach net zero targets. Within this, we also want to become a leader in environmental, social, governance (ESG), health and safety, and diversity. Our final fourth pillar is performance, since we need healthy financial performance to continue investing in the technology that ultimately supports our customers.”

Supplying all industries in Australia and overseas for over 30 years.

Are you looking for a high-quality engineering company that can provide reliable machining for your plastic parts? Look no further than our team at Polymer Engineering!

With over 30 years of experience in the industry, our skilled engineers and technicians have the expertise and equipment necessary to create precision parts for a variety of applications. We specialise in machining plastic parts for use in industries such as automotive, aerospace, mining, medical, and consumer products.

Our state of the art facilities are equipped with the latest machinery, allowing us to tackle even the most complex projects efficiently and effectively. We are committed to providing our clients with personalised services and flexibility, ensuring that their projects are completed on time and to their exact specifications.

At Polymer Engineering, we pride ourselves on our commitment to excellence and our dedication to customer satisfaction. Whether you’re looking for a custom part or need help with a large-scale production run, we’re here to help. Contact us today to learn more about our services and how we can help your business succeed.

Contact our Sales Team: sales@polymerengineering.net.au www.polymerengineering.net.au

02 9979 8645

Unit 12/No 2 Apollo Street, Warriewood NSW 2102

“Over the years, we have built a position of having the most complete portfolio in the industry, combined with our full flowsheet competency which allows mines to be configured in an optimal way,” he introduces.

As an original equipment manufacturer (OEM), FLS is in a rare position by operating across the entire mining flowsheet, offering its customers a full set of solutions from pit to plant. This comprehensive technological prowess thrives alongside a commitment to driving sustainable productivity that cements FLS’ status as a true industry leader and innovator.

“We see a significant opportunity and believe we have a responsibility to enable the green transition,” comments de Groot.

Running parallel to this core aim is FLS’ unrelenting commitment to delivering quantifiable value over the life cycle of a mine through its core service offering as a partner to its customers. In both sustainability and productivity, Qasim Abrahams, Head of Spare Parts and Aftermarket Service, recognises FLS’ standout strengths.

“Due to our expertise and the technology, we are uniquely equipped and positioned to create this value by increasing asset life and throughput, reducing downtime, and mitigating emissions, energy and water usage through process solutions,” he says.

The process solutions that FLS have developed seek to combat the most environmentally damaging facets of mining, with energy and electricity consumption, comminution, flotation, tailings and water as the problematic areas calling for the most improvement across the flowsheet. By seeking to minimise these contributors as much as possible, FLS preserves essential mining business in a responsible way.

“The global green transition depends on minerals, and to achieve climate targets, we need more commodities and processing plants. Our commitment is to help our customers do that in the most sustainable way possible,” states Keto.

By leveraging its well-advanced expertise and comprehensive product range to drive environmental footprint mitigation, the inception of MissionZero placed FLS firmly ahead of the curve in this regard.

“MissionZero was born from the recognition that we needed to use our expertise to help mining companies meet their targets and move the overall industry to a more sustainable production set up,” says de Groot. This entails a commitment to reaching zero energy waste, water waste and zero emissions by 2030, in line with the wider industry’s pledge for carbon neutrality by 2050.

“FLS will essentially be a shop where any mining operator can find all the competencies, people, and technologies that will enable you to operate with zero emissions by 2030,” he continues.

“Our MissionZero efforts and end to end flowsheet technology for lithium and other battery and critical minerals is at the forefront, but we are also focused on the traditional core and have innovated considerably in gold, copper and iron ore flowsheets to assist and fast track those commodity groups’ achievements for a sustainable future,” adds Elks.

MissionZero’s success is intrinsically bound to the technological solutions designed to enable the fruition of that ambition across the flowsheet.

This is evidenced by FLS’ vision of the MissionZero Mine and its flowsheet of the future which highlights the impact of solutions and optimisations across the mine site. With progress well underway, Elks elegantly describes the future MissionZero Mine as, “a global example in the art of the possible.”

The site leverages key technologies including in-pit crushing and conveying, low impact grinding, coarse flotation, eco-beneficiation, dewatering, tailings management, and digitalisation, all of which combine to keep energy consumption to a minimum.

“At FLS we take a holistic approach to our sustainability solutions to ensure they always have a net positive impact as we work towards our net zero targets,” shares Abrahams.

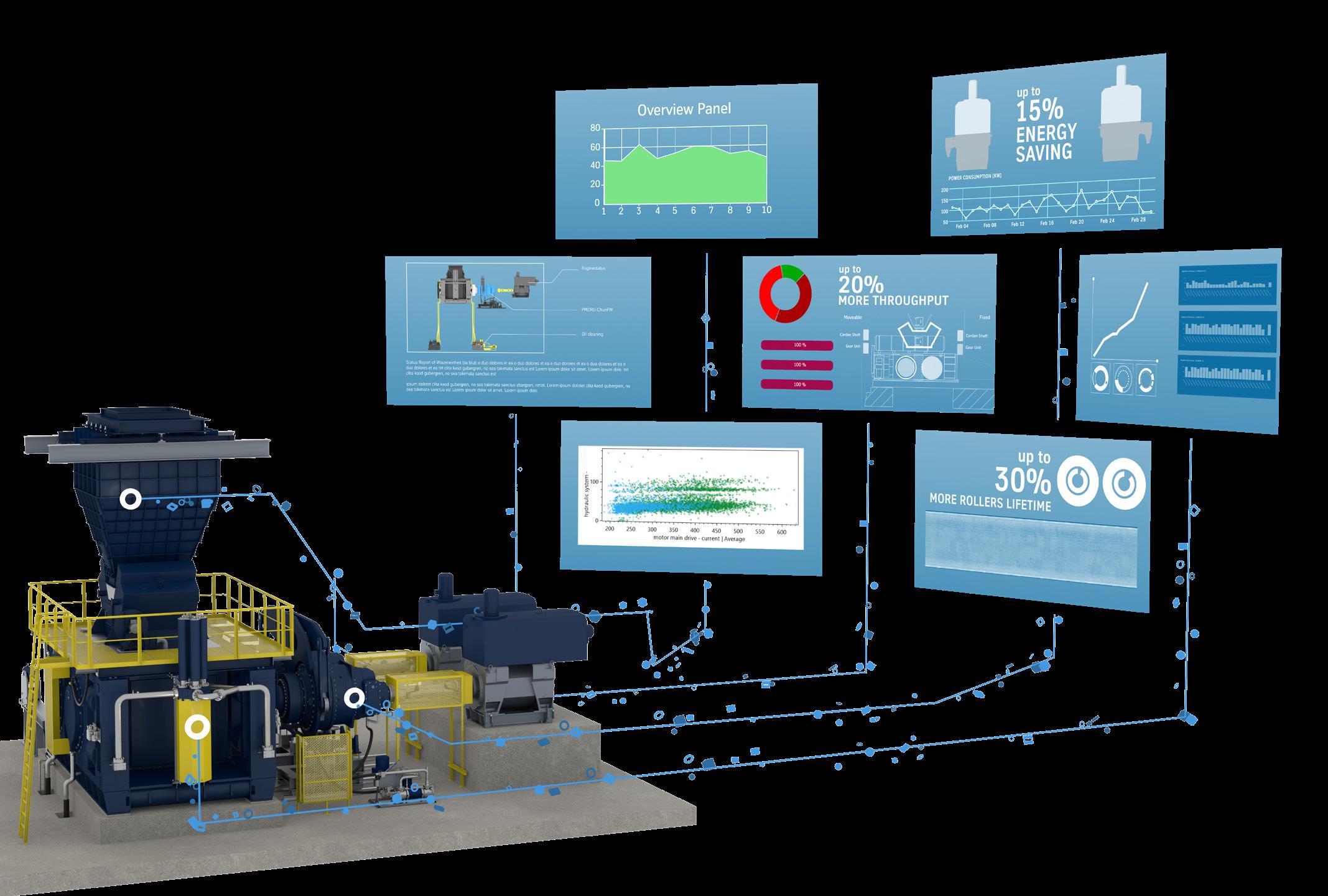

Such solutions include a market leading high pressure grinding roll (HPGR) - the HPGR Pro - which has been proven to optimise energy efficiency in milling circuits by up to 30 percent.

“WE SEE A SIGNIFICANT OPPORTUNITY AND BELIEVE WE HAVE A RESPONSIBILITY TO ENABLE THE GREEN TRANSITION”

– WOUTER DE GROOT, HEAD OF SUSTAINABILITY, FLSMIDTH

GLOBAL PROVIDES COMPLETE DESIGN AND MANUFACTURING SOLUTIONS

In water management, FLS’ automation filtration process can recycle 90 percent of the water used, offered in combination with a dry stack tailing solution. With many mines located in water-starved areas, the reuse of this precious resource is critical in minimising freshwater consumption.

Elsewhere, state of the art flotation technologies have been introduced

For Vice President, Head of Digital Services, Rebecca Siwale, the innovation of FLS’ flotation advanced process control (APC) system “pushes the envelope” of technology by leveraging deep learning to drastically enhance applications.

“Our APC systems mimic how the human brain processes visual input. These deep learning technologies bring machine vision into an application where highly subjective decisions become instantaneous,” she tells us.

As reflected by Siwale’s role at FLS, the company’s digital offerings of connected equipment and expertise in analytics are fundamental in providing value to customers through remote monitoring, predictive maintenance, and support services.

“The digital transformation effort requires working with the customer across the mineral processing value chain to identify opportunities for improvement and implement

– QASIM ABRAHAMS, HEAD OF SPARE PARTS AND AFTERMARKET SERVICE,

“AT FLS WE TAKE A HOLISTIC APPROACH TO OUR SUSTAINABILITY SOLUTIONS TO ENSURE THEY ALWAYS HAVE A NET POSITIVE IMPACT AS WE WORK TOWARDS OUR NET ZERO TARGETS”

FLSMIDTH

solutions that drive business value,” she says.

Digital services are deployed across the mineral processing flowsheet in comminution, sizing, flotation, separation, and dewatering to positively impact productivity, cost, and environmental footprint through real-time data, analytics and algorithms.

“We leverage such technologies where systems will self-train themselves from the continual analysis of data and create models for effective sustainable decisions,” Siwale continues.

“We are confident that building solutions on such innovative and breakthrough technologies for continuous and real-time optimisation and health monitoring of mining assets will greatly lower the impact and make our environment safer - be it through operational efficiencies, reduction in emissions and carbon footprint, savings in energy usage or protecting our water reserves.”

To uphold this industry-leading position at the forefront of technological innovation, FLS maintains an emphasis on performance to guarantee the steady

stream of investment that fuels the R&D necessary for future endeavours.

“If we don’t make sufficient profit, then we can’t invest anything back into the business,” says Keto. “Without healthy financial performance, there is no R&D, innovation, or new develop ment. This is extremely beneficial to our customers since it is this continual investment into R&D that makes us a leading technological supplier.”

In terms of delivering customer benefit, FLS prides itself on working in partnership with its customers,

“WE ARE PROUD TO OFFER THE SOLUTIONS OF TOMORROW, FOR THE EARLY ADOPTERS OF TODAY”

– JASON ELKS, APAC REGIONAL PRESIDENT, FLSMIDTH

optimising operations and supporting their growth as an end-to-end process solution partner.

“By working directly in partnership with our clients, rather than through an engineering, procurement and construction management (EPCM), they can see and understand so much more of our product range,” elaborates Elks.

Aside from the environmental advantages, partnership with FLS simply makes good business sense.

“The value that we deliver has a direct positive impact to our customers’ bottom line,” affirms Abrahams.

Siwale highlights one particularly effective example of this, where FLS’ use of advanced analytics, machine learning (ML) and artificial intelligence (AI) can increase a customer’s mill efficiency by up to 10 percent, an advantage which improves their bottom line tremendously.

“We use digital technologies that

quickly and efficiently to improve the uptime of our customers’ assets, but also to support improving their supply chain and optimising their capital committed on inventory levels. Having the right critical parts available with little or no lead time is crucial to ensure profitability,” she continues.

FLS continues to grow and develop the business through its partnerships, approaching acquisitions as a means to fill in any gaps or make improvements in areas within its already impressive portfolio as per its CORE’26 strategy “It’s always a win/ win relationship if both parties commit and align on the overall goals of a partnership,”

Incorporating a range of technological firsts for minerals grinding, HGPR Pro achieves higher throughput with less energy, maintenance, and environmental impact than similar technologies.

SAG Mill controls

SAG Mill controls

As a committed partner to its clients, FLS provides comprehensive aftermarket services including workshop, maintenance, repair, upgrades and overhaul, spare parts, retrofitting, and performance optimisation services.

“The most important factor for the customer is that we can support them over the full life cycle of the mine,” Keto says.

These run alongside the digital support solutions that are fundamental to modern mining, including remote monitoring, analytics, predictive maintenance, process control and automation solutions.

REBECCA SIWALE, VICE PRESIDENT, HEAD OF DIGITAL SERVICES, FLSMIDTH

“As technology develops, so too do customer expectations of what service should be delivered. Gone is the era of service merely keeping mines up and running and minimising downtime,” says Siwale. “We are committed to innovative aftermarket service offerings to meet the evolving needs of our customers.”

Such needs range from improving maintenance efficiency, equipment reliability and overall uptime to maximising the lifespan of assets resulting in increased production and optimised operational expenditure. With customer needs integral to the company’s operations, the entire structure of the FLS group has

been formatted to emphasis its dedicated service organisation, thereby elevating its focus on this specific area.

“Our strategic service priorities and initiatives have been developed using a customer-centric lens, getting feedback from our customers looking forward to improving their journey and experience, while creating more value than before,” says Abrahams.

This crucial customer feedback is the fuel that drives new product development, continually innovating and improving based on their demands.

“WE ARE CONFIDENT THAT BUILDING SOLUTIONS ON SUCH INNOVATIVE AND BREAKTHROUGH TECHNOLOGIES FOR CONTINUOUS AND REAL-TIME OPTIMISATION AND HEALTH MONITORING OF MINING ASSETS WILL GREATLY LOWER THE IMPACT AND MAKE OUR ENVIRONMENT SAFER”

–Maximising water management: Achieving sustainable practices through tailings water reduction and thickener upgrades

For Keto, the service area will be the focus of much investment in the years ahead through continued exploration into digital technologies to enhance FLS’ capabilities and offerings, particularly by improving on its strengths in consumables and wear parts.

“On the service side of the business, our immediate priority is to strengthen our technological position and grow,” he tells us.

Looking ahead, FLS’ overriding ambition across the whole group is one of rapid growth, to facilitate the equally rapid transition required to champion a more sustainable resources sector, working with and influencing policy and governmental considerations on a wider scale.

“I am confident that we will grow rapidly,” affirms Elks. “Our end-toend flowsheet solutions and product range will revolutionise the transition

and rapid growth that sustainable mining demands to keep up with the early adopters.”

Within the APAC region, this growth has seen FLS open a new office in Indonesia in April of this year, a country that Elks identifies as a “thriving resources hub and economy” poised to become the powerhouse of Southeast Asia and the broader region. In addition, the company seeks to develop its existing presence in Vietnam where there are great opportunities for critical minerals and metals of the future.

Continually perfecting its technology portfolio, FLS will simultaneously pursue growth through the strong and innovative partnerships that the green transition demands.

“As an industry, we need to increase the speed of adaptation to bring new technologies on board, working together to develop

them in joint fashion,” concludes de Groot.

With a recent rebrand in place reflecting the group’s reputation as a united company and provider of full flowsheet solutions with everything needed for productivity and sustainability, FLS continues the journey to 2030 one step ahead.

Phoenix Lining Services (PLS) is the leading specialist in industrial rubber lining and protective coating services and processes. Working closely with major global mining companies and engineering firms, the experienced team at PLS also engages with a range of Tier 2 and Tier 3 organisations.

Established in 2017, PLS has swiftly garnered a reputation for delivering excellence in its results while successfully achieving robust quality, safety and environmental management systems. Currently, PLS is one of the few companies in its field to have completed a comprehensive assessment and to be independently certified. This achievement further demonstrates the company’s commitment to maintaining the highest possible service, quality, environmental and safety standards. This is achieved through a fully qualified and well-equipped team that is reliable and trustworthy. No matter how complex a project is, the PLS team of experts has the resources and expertise required to execute and meet client requirements successfully. In this way, the company is fully adaptable with mobilised equipment to work in the most extreme climate conditions, and the PLS team is always ready to undertake jobs at the most remote sites, both within Australia and overseas.

PLS adheres to a specific set of crucial core values, upon which the ethos of the entire company is built and held together.

Most importantly, the company regards safety as its main priority. PLS consistently complies with industry safety standards as a highly safety-driven organisation. Every team member has completed comprehensive training in health and safety procedures within the organisation and off-site.

The highly motivated and expert team employed by PLS consistently achieves outcomes of the highest quality whilst also continuing to strive for improvements in its products. It is this premium quality of service that is at the very heart of everything PLS does and stands for.

Additionally, accountability is another crucial element of PLS’s success. Reliable and trustworthy, its team is committed to delivering what it promises, ensuring high-quality outcomes for any project undertaken.

Never satisfied and always striving for growth, PLS aims for continuous improvement. In this way, the company takes customer feedback seriously to continually provide excellent service and outstanding results.

Elsewhere, PLS champions integrity as a key element to achieving ongoing success. The company believes in open and honest discussions with both its clients and suppliers.

As PLS updates its clients on issues or problems, it simultaneously works towards achieving a solution. This is because it is a company that aims to do the right thing even when no one is watching.

In order to outperform the competition, a meticulous approach is employed alongside attention to detail for every project. This ensures that PLS exceeds all project requirements. Finally, trust and respect remain foundational elements of the PLS core values. The entire team believes respect is vital and promotes healthy relationships, fosters empathy and understanding, and creates a more inclusive and harmonious work environment. Employing teamwork as a core value promotes a culture of collaboration, mutual support, and shared success. It helps to build strong and resilient teams that can achieve more together than they could as individuals, as is the case at PLS.

Our mission is to provide end-to-end project management, exceeding our client’s requirements for their rubber lining and specialised protective coating application requirements, regardless of location or climate conditions to protect and extend the lifespan of industrial equipment. We strive to be a reliable partner for our clients, delivering innovative and costeffective solutions that meet their specific needs and exceed their expectations.

To be the industry leader in Australia and overseas by delivering results with the highest standards set by our comprehensive ISO accreditation in safety, environmental management and quality. Here at Phoenix Lining Services, we have a clear and compelling vision of our purpose and values. Our Management Team are passionate and visionary leaders who inspire and empower their fellow employees to achieve greatness. Innovation and creativity are encouraged and rewarded. Our company is constantly exploring new ideas and technologies to improve its offerings and stay ahead of the competition. All our employees are proud to come to work each day and are motivated to contribute their best efforts to achieve the company’s goals.

PLS works closely with many of its major clients such as FLSmidth, to achieve positive outcomes and to guarantee customer satisfaction. Additionally, by working closely with customers and suppliers to understand their needs and challenges, the company has gained valuable feedback and insights that have helped drive innovation and improvement. This feedback has also been used to develop new products and services that better meet the needs and requirements of customers and help PLS stay ahead of its competitors. By striving for customer satisfaction and repeat business, the company has built customer loyalty and brand recognition, which has ultimately contributed to fantastic levels of long-term success.

www.phoenixlinings.com.au