AN

INNOVATIVE ARCHITECTURAL VISION

With a visually striking landscape comprising towering skyscrapers and luxurious, futuristic buildings, Dubai’s opulent architecture is both captivating and unique.

The construction industry in the city is thriving, with many buildings

primarily composed of glass and some even featuring fully glazed façades. Glass manufacturing companies are flourishing as they adapt to the high demand for energyefficient and innovative products.

As we revisit Emirates Glass, the company demonstrates a keen

awareness of the increased industry requirements.

“We have been proactive in enhancing our production capacity to meet the surging demand for high-performance architectural glass, targeting a market share of 27 percent this year,” introduces Rizwanulla Khan,

AN UNBREAKABLE COMMITMENT TO EXCELLENCE

With a crystal-clear objective of meeting evolving customer needs, Emirates Glass has undergone a significant transformation since we last spoke with the company in 2018. Executive President, Rizwanulla Khan, highlights its leading position in the architectural glass industry

Writer: Rachel Carr | Project Manager: Josh Whiteside

Executive President.

“In 2024, the company achieved its highest revenue and profit to date, contributing over 1.3 million square metres (sqm) to our total production – an eight percent increase year-on-year.”

The growth was propelled by the

commissioning of state-of-the-art machinery, including a jumbo glass panel processing system and a glass digital printing line, as well as scaling up bullet-resistant glass production by 15 percent.

Additionally, Emirates Glass successfully launched its fire-related

glass product line, Emfire, cementing its position in the passive fire protection sector.

The company has also embraced diversification, with notable expansions into fire-rated glass and architectural and automotive bulletresistant glass, ensuring alignment

with market trends and sustainability goals whilst developing its portfolio.

“Our bulletproof glass segment had a productivity boost last year, providing unparalleled safety solutions for high-security projects. Meanwhile, the newly installed jumbo glass processing line caters to specialised projects requiring oversized panels, offering both aesthetic and functionality for iconic architectural structures,” he adds.

CAPABILITIES AND FACILITIES

In 2024, Emirates Glass integrated cutting-edge technologies into its manufacturing processes, with key highlights including advanced tempering and lamination systems, as well as a sophisticated digital printing line which enhances the decorative glass segment.

The technologies ensure precision, quality, and efficiency whilst meeting diverse customer requirements.

“We have invested in equipment to bolster the company’s capabilities, enabling increased productivity and thereby expanding our portfolio with innovative products, such as fire-rated and bulletproof glass,” notes Khan.

HOW DOES EMIRATES GLASS ENSURE CUSTOMER SATISFACTION AND MAINTAIN STRONG CLIENT RELATIONSHIPS?

Rizwanulla Khan, Executive President: “At Emirates Glass, we prioritise customer satisfaction by fostering strong, trust-based relationships and delivering innovative solutions tailored to our clients’ needs.

“By maintaining open communication channels and providing technical expertise, we ensure seamless project execution and customer confidence. Our commitment to quality, timely delivery and precision reinforces these relationships, making Emirates Glass a reliable partner for both standard and specialised projects.

“Our continuous improvement and responsiveness to market demands further enhance the customer experience.”

“In addition, we are in the process of setting up a curve tempering facility, which will further expand its specialised offerings and allow for greater flexibility in high-performance architectural applications.”

This strategic addition reinforces Emirates Glass’ commitment to technological advancement and market leadership.

The investments reflect a key approach to growth, diversification, and operational excellence.

Whilst the commissioning of stateof-the-art jumbo-sized processing equipment has enhanced production capacity, there have also been substantial investments beyond

“We recognise that innovation is driven by expertise and have actively invested in human resources, tapping

workforce. By fostering a dynamic and skilled team, we ensure its ability performance architectural glass and

This focus on both technological

long-term industry

STRATEGIC AND SUSTAINABLE PARTNERSHIPS

partnerships have been fundamental to Emirates Glass’ success, driving excellence, and market expansion.

“Collaborating with globally

recognised certification bodies such as Intertek ensures rigorous product testing and compliance, reinforcing industry credibility and customer trust,” Khan emphasises.

“We have also established strong relationships with leading industry players, including Schott, Vetrotech Saint-Gobain, Aluprof, Kuraray, and Tremco. Our partnership with the latter has been long-standing, playing a vital role in advancing high-performance glazing solutions, particularly in fire-rated and speciality applications.”

These alliances have significantly contributed to Emirates Glass’ ability to deliver cutting-edge architectural and safety glass solutions.

Furthermore, the company maintains robust supplier relationships, ensuring operational efficiency, consistent material quality, and seamless production workflows. These strategic collaborations continue to fuel its growth, innovation, and leadership in

“WE HAVE INVESTED IN EQUIPMENT TO BOLSTER THE COMPANY’S CAPABILITIES, ENABLING INCREASED PRODUCTIVITY AND THEREBY EXPANDING OUR PORTFOLIO WITH INNOVATIVE PRODUCTS, SUCH AS FIRERATED AND BULLETPROOF GLASS”

– RIZWANULLA KHAN, EXECUTIVE PRESIDENT, EMIRATES GLASS

the global glass industry.

“By fostering long-term relationships with suppliers, we ensure consistent material quality, timely production, and enhanced customer satisfaction – key factors in maintaining our market leadership. We emphasise efficient supply chain management to meet growing demands,” explains Khan.

Sustainability is also a fundamental pillar of Emirates Glass’ operations, with a strong focus on reducing environmental impact through advanced glass solutions. The

company has developed energyefficient glass products that optimise thermal insulation, minimising energy consumption in buildings.

“We actively promote sustainability by integrating Total Solar panels into our product offerings, enhancing energy efficiency and supporting renewable energy initiatives,” he assures.

Total Solar is the name given to the solar panels installed by TotalEnergies in partnership with Emirates Glass as part of a joint effort to harness the sun’s natural energy and reduce carbon emissions.

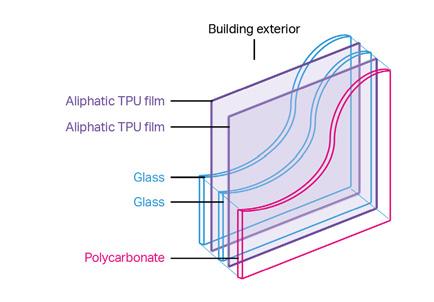

Covestro TPU films set new standards in security glazing

We are a world-leading manufacturer of high-quality polymer materials. With innovative products, processes, and methods, we improve quality of life and drive our vision of becoming fully circular.

Briefly introduce us to Covestro Films GmbH (formerly Epurex).

Covestro Films GmbH (Covestro) is a subsidiary of Covestro AG - a global leader in high-performance polymer materials. Headquartered in Leverkusen, Germany, Covestro operates 46 production sites worldwide and employs approximately 17,500 people.

Covestro specialises in manufacturing and developing advanced thermoplastic polyurethane (TPU) films under Platilon® and Dureflex® brands for industries such as mobility, construction, electronics, and healthcare. These solutions support technical performance with a focus on sustainability and innovation.

Committed to becoming fully circular, Covestro targets for climate neutrality for Scope 1 and 2 emissions by 2035, and for Scope 3 emissions by 2050, driving long-term sustainable growth and a resource-conserving economy.

What differentiates Covestro?

Covestro sets itself apart through its vertically integrated raw material production, global manufacturing footprint, and decades of technical expertise. These strengths enable us to deliver consistent, high-quality TPU film solutions tailored to unique customer requirements.

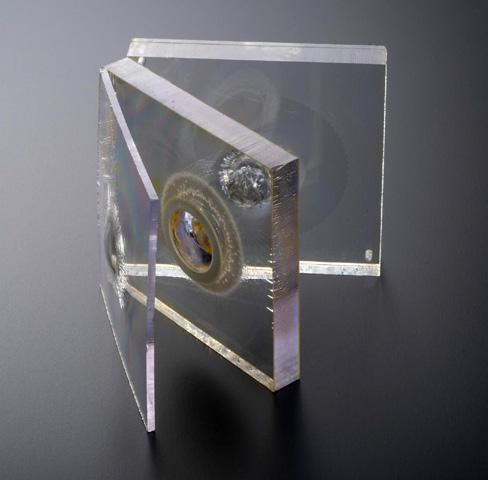

One key application area for Covestro’s film solutions is security and bullet-resistant glazing. These applications require materials that deliver robust protection without compromising appearance.

Covestro’s aliphatic TPU film portfolio is designed to meet the high demands of the bullet-resistant glazing market, offering excellent durability, UV resistance, and optical clarity. These films are used in adhesive applications for glass-clad and glass-plastic laminates, including polycarbonate (PC) and acrylic (PMMA). Free from plasticisers, the films maintain long-term stability, while the lightweight construction of glass-plastic laminates helps reduce overall weight. This innovative solution particularly excels in addressing ballistic threats.

The film’s properties effectively slow bullet penetration and retain glass shards, making it ideal for security glazing that protects against debris.

How does Covestro push for the circular transformation of the industry by developing new ideas?

In line with our vision to become fully circular, we expanded our Specialty Films portfolio by partly consisting of bio-based content or partly recycled raw materials, as well as ISCC PLUS-certified films, where recycled and renewable feedstock has been attributed via a mass balance approach.

As a result, our innovation strategy follows two complementary paths: we actively develop pioneering solutions that set industry trends and shape the future direction of sustainable film technology, positioning ourselves as thought leaders in the industry.

Simultaneously, we maintain close partnerships with industry leaders, collaborating to create sustainable, tailor-made solutions that precisely address their specific challenges and requirements.

Bullet-resistant glass is essential for vehicle safety and protection against attacks. ©alex-stock. adobe.com

Glass-clad polycarbonate employs TPU film to bond glazing layers together, where polycarbonate provides protection from flying glass in the interior of a building.

(Photo courtesy of Covestro)

Justus Kaiser, Director of Commercial Operations Specialty Films EMEA, Covestro

This balanced approach of driving innovation independently and co-creating with partners ensures we deliver cuttingedge solutions while meeting real-world market demands for sustainability.

What projects would you like to showcase?

We recently collaborated with Emirates Glass, a leading manufacturer of energy-efficient architectural glass in the Middle East. This partnership aims to elevate safety and performance standards in architectural glazing. This collaboration reflects a shared commitment to innovation, quality, and sustainability in the construction industry. By combining Covestro’s material expertise with Emirates Glass’s regional market leadership, the project demonstrates how collaborative innovation can drive the development of safer, more efficient, and environmentally conscious building materials.

The incorporation of Covestro’s TPU films into Emirates Glass’s products has led to significant advancements:

• Enhanced Safety: Improved resistance to impact and ballistic threats, ensuring occupant protection.

• Durability: Increased longevity of glazing systems due to superior UV and weather resistance.

• Design Flexibility: Ability to create complex, multi-layered glazing solutions that meet specific architectural requirements.

Beyond technical benefits, the project aligns with both companies’ sustainability goals. Covestro’s TPU films are designed to reduce environmental impact without compromising performance.

Please tell us more about the materials that you provide and how they serve key sectors on their transformation journeys towards circularity and climate neutrality.

Our films play a vital role in enabling key industries to the transition toward more sustainable practices:

• Textiles: Our TPU films provide excellent bonding, flexibility, durability, and recyclability for breathable, long-lasting fabrics.

• Automotive: We deliver advanced UV-resistant, lightweight films that enhance design and support fuelefficient, electric vehicles.

• Construction: Our films support sustainable solutions for sanitary applications and insulation, boosting building durability and efficiency.

An excellent example of our contribution to circularity and performance is the use of aliphatic TPU films in laminated glass applications. Architectural and automotive glazing demands have become more complex. Traditional interlayer materials like polyvinyl butyral (PVB) have shown limitations. This is especially true when paired with thermoplastics such as polycarbonate.

To meet these new requirements, next-gen aliphatic TPU films, such as Dureflex® A4700, offer an excellent alternative:

• Optical clarity: Maintains transparency over time without yellowing, ensuring clear visibility.

• Impact resistance: Provides robust protection against ballistic threats by absorbing and dissipating energy.

• UV stability: Resists degradation from ultraviolet exposure, extending the lifespan of glazing systems.

• Flexibility: Accommodates thermal expansion differences between glass and polymers, preventing delamination.

These advanced materials enable high-performance, sustainable glazing, helping customers achieve safer, more circular, climate-neutral solutions.

Looking ahead, what are your key priorities for the coming year?

Our future vision at Covestro is built on three fundamental pillars.

First, we will continue excelling at developing innovative materials that create real value for our customers. Second, we aim to maintain and strengthen our position as a trustworthy, long-term partner, just as we have done throughout our history. We firmly believe that true innovation and value-adding products come from lasting, trust-based partnerships.

This brings us to our third crucial objective: sustainability. As products increasingly need to meet stringent environmental standards, we are committed to making a significant contribution to this global challenge.

Multilayer polymer laminates using TPU interlayers provide bullet resistance with reduced weight and ease of fabrication.

(Photo courtesy of Covestro)

“Additionally, we prioritise responsible sourcing and raw glass processing, ensuring material optimisation whilst reducing waste. A key initiative includes our recycling programmes, where excess glass is repurposed, contributing to a circular economy and minimising our environmental footprint,” Khan informs.

Emirates Glass further reinforces its commitment to transparency

and sustainability through Environmental Product Declaration (EPD) certifications, demonstrating compliance with global environmental standards and providing clients with data-driven insights into the impact of its products.

“Through these efforts, we continue to lead the way in sustainable innovation, aligning with industry advancements,” he highlights.

GLOBAL GOALS

Looking ahead, Emirates Glass is focused on the continuous development of existing products and the introduction of new innovations to meet evolving market demands.

The company is seeking to expand its footprint beyond current markets and remains dedicated to broadening its international presence.

“With a strategic focus on meeting the global demand for

Photo: © Kuraray

high-performance architectural glass, we are exploring new opportunities in emerging and established markets alike,” shares Khan.

Through innovative product offerings, state-of-the-art production facilities, and strategic collaborations, the company aims to reinforce its position as a global leader in the industry whilst ensuring adaptability to regional needs and trends.

“We aim to scale up production capacity even further, targeting

ICONIC PROJECTS

ONGOING

• SAADIYAT LAGOONS – EmiCool Sun NN30 DSL coating ensures enhanced performance in solar control and thermal insulation.

• DISTRICT ONE – Supplied EmiCool DSR II coating, offering superior energysaving capabilities whilst complementing modern architectural designs.

• OPAL GARDEN – Provided EmiCool Sun NN40 coating on clear glass substrates, combining solar control with architectural brilliance.

• ELORA – Integrated EmiCool Super Vision 60/32 coating, ensuring optimised daylight management and energy efficiency.

COMPLETED

• IMPERIAL AVENUE – Supplied EmiCool Sun NN30T coating on clear glass substrates, ensuring superior solar control and thermal performance.

• ADDRESS RESIDENCES – EmiCool Superlite 70/40 coating on grey glass substrates enhances the façade with its excellent light transmission and solar protection.

• MOHAMMED BIN RASHID CITY – Provided EmiCool NN35 coating, delivering optimal energy efficiency and visual clarity.

• GOLF HEIGHTS TOWER – Contributed EmiCool Super Vision 50/25 coating, striking a balance between solar performance and elegant aesthetics.

• NOYA VILLAS – The EmiCool Solite Jar coating offers outstanding insulation and durability, providing a refined residential experience.

• AZIZI RIVERA – Supplied EmiCool DSR II coating on grey glass substrates, reinforcing sustainability and thermal regulation in this iconic waterfront development.

“At Emirates Glass, we take pride in delivering high-performance architectural glass solutions tailored to the unique demands of prestigious developments across the region. Our expertise and commitment to excellence have positioned us as a trusted partner in shaping modern skylines, providing innovative coated glass solutions that enhance aesthetics, energy efficiency, and durability in landmark projects,” Khan impassions.

“Each of these projects reflects our commitment to delivering innovative, high-quality glass solutions that redefine modern architecture and enhance sustainability. As we continue to expand our portfolio, we remain dedicated to excellence, ensuring our products contribute to the future of the built environment,” he adds.

27 percent of the market share. Our plans include expanding our fire-rated glass segment, investing in additional cutting-edge machinery, and reinforcing our commitment to sustainability through energy-saving solutions.

“These priorities reflect Emirates Glass’ strategic vision for growth, technological advancement, and industry leadership,” Khan concludes emphatically.

As Dubai undergoes a remarkable transformation, marked by ambitious construction projects and a strong emphasis on energy efficiency,

Emirates Glass is strategically poised to expand its market presence by providing exceptional highperformance architectural glass solutions.

The company’s unwavering commitment to cutting-edge technological advancements, combined with its strategic alliances with esteemed global certification bodies, positions it at the forefront of industry standards and innovation, ensuring it remains a leader in the dynamic glass manufacturing landscape.

Tel: 00971 4 709 4700

info@emiratesglass.com

emiratesglass.com