For over a decade, our portfolio of in-house magazines has been lovingly produced, printed, and distributed to our esteemed subscribers across the globe from our headquarters in the UK.

But now we are moving with the times, adopting a digital-first approach by producing online-only publications. A major factor in this decision is to minimise our environmental footprint, reducing the carbon emissions involved in the logistics of print magazine distribution and the resources required therein.

Going forward, we will provide print orders of any magazine in-line with the requests of our featured companies, subscribers, and conference & expo partners.

Please get in touch for a print-on-demand quote or visit our website to find out more.

“We always planned that when our digital subscribers consistently accounted for 85% of our total magazine subscribers, we would cease printing our publications in-line with our environmental and sustainability goals.”

– Ben Weaver, CEO, Outlook Publishing Ltd

EDITORIAL

Editorial Director: Phoebe Harper phoebe.harper@outlookpublishing.com

Senior Editor: Marcus Kääpä marcus.kaapa@outlookpublishing.com

Editor: Jack Salter jack.salter@outlookpublishing.com

Junior Editor: Ed Budds ed.budds@outlookpublishing.com

Junior Editor: Rachel Carr rachel.carr@outlookpublishing.com

PRODUCTION

Production Director: Stephen Giles steve.giles@outlookpublishing.com

Senior Designer: Devon Collins devon.collins@outlookpublishing.com

Designer: Sophs Forte sophs.forte@outlookpublishing.com

Junior Designer: Louisa Martin louisa.martin@outlookpublishing.com

Production Assistant: Megan Cooke megan.cooke@outlookpublishing.com

Digital Marketing Manager: Fox Tucker fox.tucker@outlookpublishing.com

Social Media Executive: Bria Clarke bria.clarke@outlookpublishing.com

Web Editor: Oliver Shrouder oliver.shrouder@outlookpublishing.com

BUSINESS

Chief Executive Officer: Ben Weaver ben.weaver@outlookpublishing.com

Managing Director: James Mitchell james.mitchell@outlookpublishing.com

Sales Director: Nick Norris nick.norris@outlookpublishing.com

Commercial Director: Joshua Mann joshua.mann@outlookpublishing.com

HEADS OF PROJECTS

Josh Hyland josh.hyland@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

TRAINING & DEVELOPMENT MANAGER

Marvin Iseghehi marvin.iseghehi@outlookpublishing.com

SALES & PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS

Alfie Wilson alfie.wilson@outlookpublishing.com

Cameron Lawrence cameron.lawrence@outlookpublishing.com

Dave West dave.west@outlookpublishing.com

Dennis Morales dennis.morales@outlookpublishing.com

Jordan Levey jordan.levey@outlookpublishing.com

Kierron Rose kierron.rose@outlookpublishing.com

Kyle Livingstone kyle.livingstone@outlookpublishing.com

Nicholas Kernan nicholas.kernan@outlookpublishing.com

Liam Pye liam.pye@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

EME OUTLOOK

Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +45 (0) 1603 363 631

Editorial: +45 (0) 1603 363 655

SUBSCRIPTIONS Tel: +45 (0) 1603 363 655 phoebe.harper@outlookpublishing.com www.emeoutlookmag.com

Like us on Facebook: facebook.com/emeoutlook

Follow us on Twitter: @eme_outlook

The European construction sector is big business, contributing approximately nine percent to the EU’s overall GDP and providing over 18 million direct jobs. Within this major economic driver, our cover star is Bouygues Travaux Publics, the innovative French contractor with a leading commitment to sustainable construction. Building better, through the added-value of “shared innovation”, we speak with Executive Vice President, Vincent Avrillon, in an exclusive interview for an update on the latest developments from an iconic name in construction.

“We are very proud of our design approach, as when we look at a project, the first thing we do is try to challenge the design, change it, modify it and find alternatives that will save time and money, and we regard this as our greatest strength,” he shares.

Elsewhere, building back, we delve into the meteoric comeback of leading Italian electricity provider, Tirreno Power. Re-emerging from the ‘perfect storm’ of 2015, we speak with General Manager, Fabrizio Allegra, to celebrate the company’s transformation to a renewable energy leader commemorating 20 years of operation in 2023.

“We have had to face many challenges in these 20 years, but we have come out stronger and with greater resilience and awareness of our skills and knowledge,” Allegra tells us.

Finally, building forwards, LTP Group is the garment and textile manufacturer embracing a ‘Consciously Crafted’ concept, in creating durable, functional, and premium products on behalf of the world’s leading brands with its choices determined by environmental and ethical accountability.

“We are committed to significantly improving LTP Group’s overall sustainability performance and to driving positive change across our industries,” says one-third of LTP Group’s modern leadership team, CEO for the Furniture Division, Henrik Holmgaard Olsson.

Meanwhile, discover thought-provoking corporate stories based on insightful interviews with Swiss Blue Salmon, the Port of Helsinki, the industry association behind the UK’s vaping industry, and many more.

We hope that you enjoy your read.

Phoebe Harper Editorial Director, Outlook Publishing

26 SHOWCASING LEADING COMPANIES

Tell us your story and we’ll tell the world

CONSTRUCTION

28 Bouygues Travaux

Publics

Fabricating Solid Future Foundations

Construction experts tunnelling to success

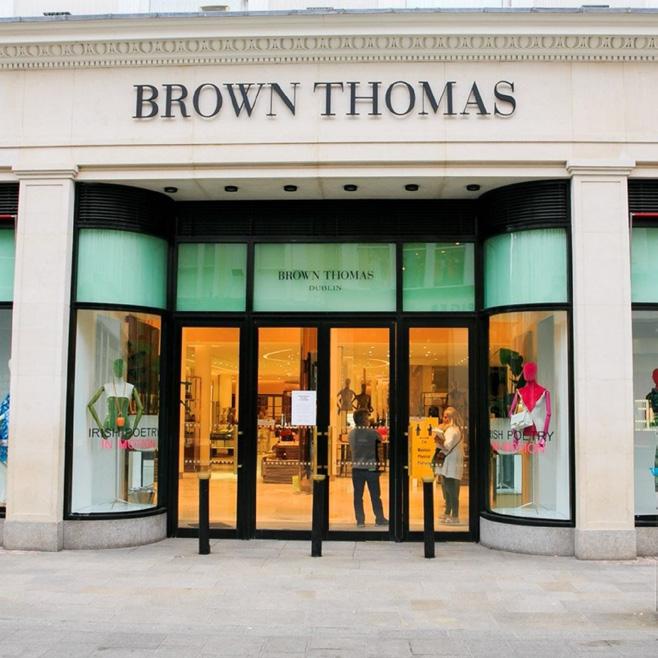

42 Knightsbridge Development Corporation

Construction Across Continents

6 NEWS

Around Europe and the Middle East in seven stories

8 EXPERT EYE

Global digital commerce powering Europe’s economic recovery

BUSINESS INSIGHTS

10 Technology

Digital for Green

Leveraging digital technologies to improve sustainability performance

1 4 Supply Chain

The World’s Shipyard

Managing the largest ship repair facility in the Middle East

TOPICAL FOCUS

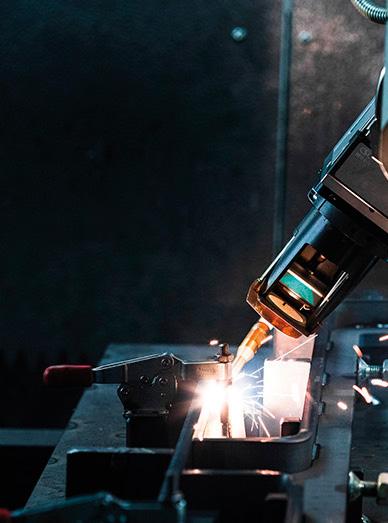

18 Manufacturing

Data-Powered Manufacturing

The key to driving successful AI projects

50 Collegiate UK

Studying, Socialising and Sleeping in Style

A new concept in student living

ENERGY & UTILITIES

56 Tirreno Power

Recharging an Energy Renaissance

The comeback powering Italy’s sustainable future

MANUFACTURING

70 LTP Group

Future Facing Textile Manufacturing

The innovators of consciously crafted textiles and garments

20

INDUSTRY SPOTLIGHTS

20 UK Vaping Industry Association (UKVIA)

A force for good in the fight for a smokefree UK

114 THE FINAL WORD

How do you encourage diversity in the workplace?

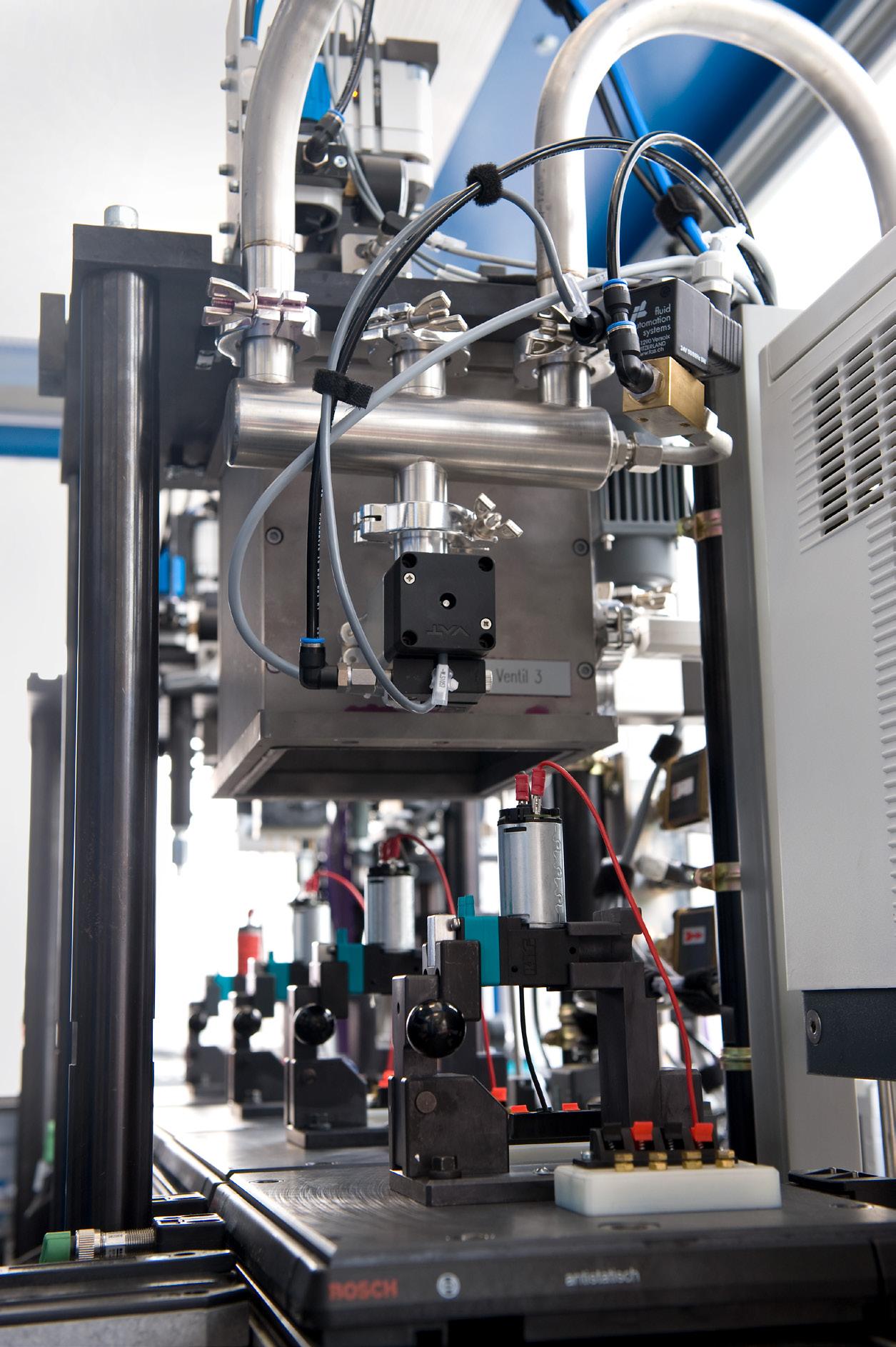

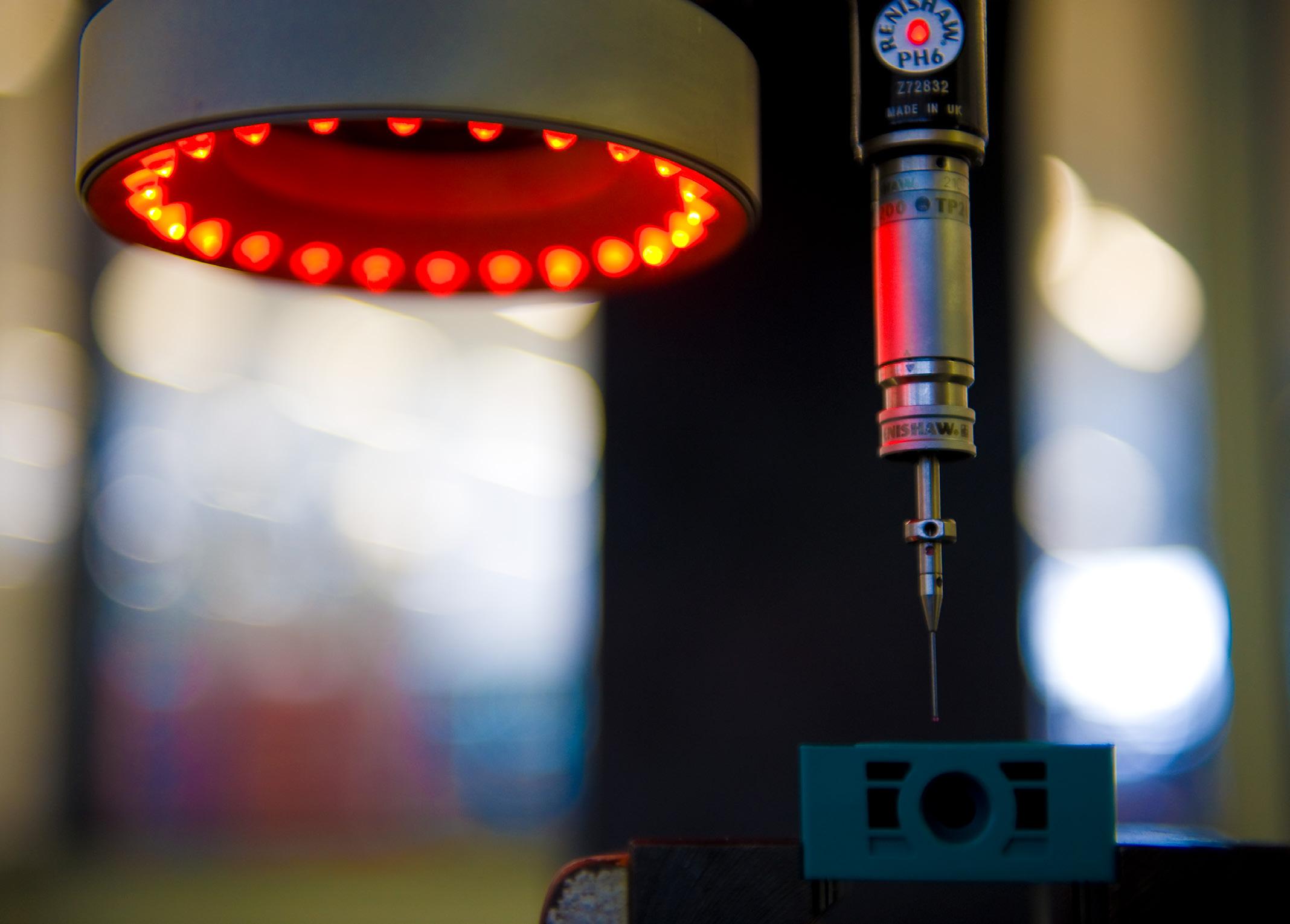

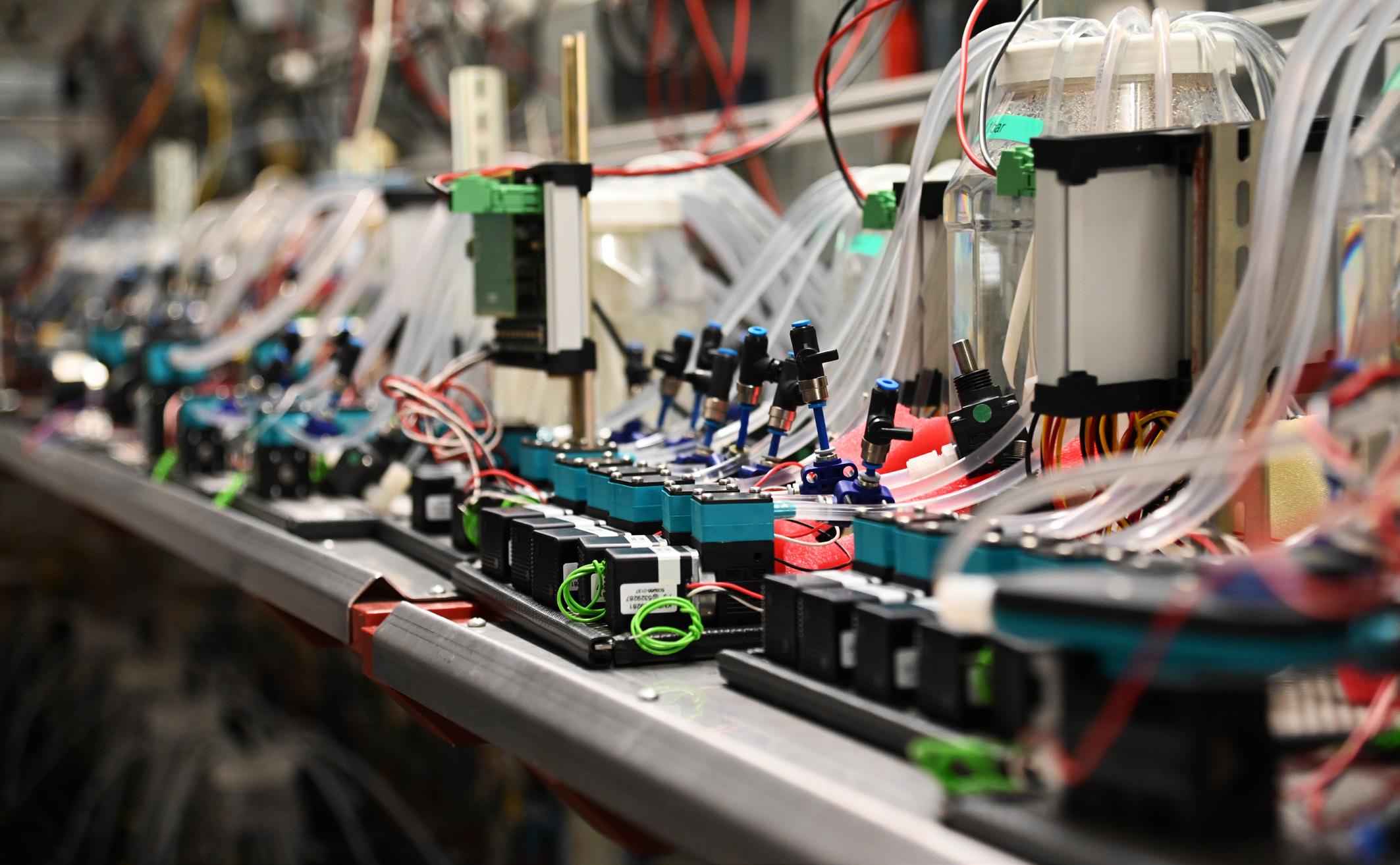

80 KNF Flodos AG

Delivering Unmatched Proficiency

Concentrated know-how and constant innovation

88 Bremsen Technik Group

Braking New Ground

The relocated home of automotive brake friction products

SUPPLY CHAIN

94 Port of Helsinki

The Gateway to Finland

Recovering passenger and cargo traffic in the Baltic Sea

102 Interbrands Orbico

Agility and Sustainability with a Global Distributor

Romania’s largest logistics network

FOOD & BEVERAGE

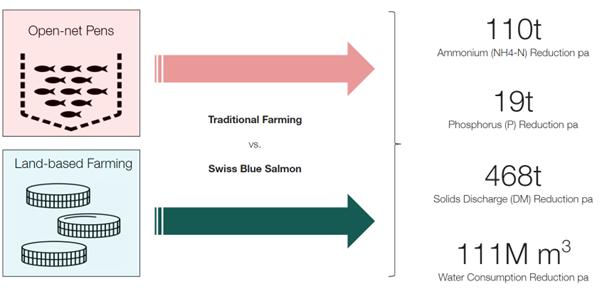

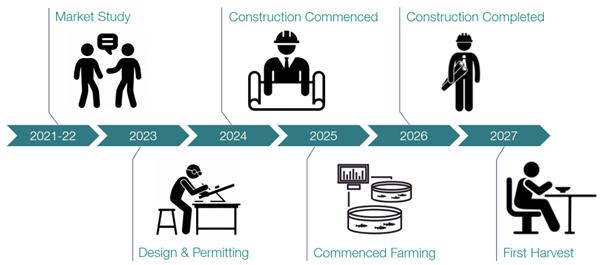

108 Swiss Blue Salmon

Smart Aquaculture in the Alps

Raising healthy and sustainable salmon on land

CREDIT SUISSE HAS been bought by rival investment bank UBS in a Swiss government-backed rescue deal.

Amid growing fears about the health of the global banking sector, following the collapse of Silicon Valley Bank in the US, the last-minute deal aims to restore the confidence of financial markets and manage risks to

the economy.

Experts are, however, not forecasting a repeat of the 2008 financial crisis when a global recession was sparked by the failure of a number of big banks.

UBS will pay three billion Swiss francs (CHF) for the 167-year-old bank, and assume losses of around CHF5 million.

RESEARCH BY ROLLS-ROYCE into how nuclear power could be used to support a future Moon base for astronauts is being backed by the UK Space Agency.

To develop technology that will provide the necessary power for humans to live and work on the Moon, scientists and engineers at RollsRoyce are working on the MicroReactor programme.

£2.9 million of new funding has been announced for the project, which will deliver an initial demonstration of a UK lunar modular nuclear reactor.

All space missions depend on a power source, and nuclear power has the potential to increase the duration of future lunar missions as well as their scientific value. It is also expected to create new skilled jobs across the UK to support its burgeoning space economy.

MERCEDES IS REPORTEDLY investing in the modernisation of its plants in Rastatt (Germany), Kecskemet (Hungary) and Beijing (China).

The German carmaker is preparing to go electric by the end of the decade when market conditions allow, in line with EU emissions reduction targets.

Work is set to commence on the Rastatt plant over the coming months, and the facility will produce the first model of the compact vehicle platform, MMA, from 2024.

Mercedes will also be modernising its painting systems in Rastatt, as well as Bremen and Sindelfingen, with the aim of cutting energy and water consumption. It will additionally address the system’s reliance on gas rather than carbon-free energy.

A DEAL ALLOWING millions of tonnes of grain to be exported by Ukraine through the Black Sea has been extended, despite the ongoing conflict with Russia and a disagreement between the two countries over how long it will last.

Ukraine is pushing for a 120 day extension whilst Russia is only calling for 60 days, warning that it will not allow the deal to be prolonged any further unless sanctions ease against Moscow.

NEW PLANS TO stimulate and support investment in sustainable hydrogen production have been set out by the European Commission. Hydrogen can contribute significantly to ending EU dependence on Russian fossil fuel imports in the coming years and achieving the union’s climate neutrality ambitions by 2050.

The United Nations (UN) and Turkey originally helped to broker the export agreement in July 2022. It came in response to worries over food shortages, given Ukraine is one of the world’s top producers of grain and access to Black Sea ports was blocked by Russian warships after the invasion.

IN RESPONSE TO increasing customer demand, the inaugural flight of Maersk’s new air freight service has been announced with scheduled flights between Billund, Denmark and Hangzhou, China.

Commencing on 20th March with three weekly flights operated by Maersk’s internal cargo airline, the inaugural flight also marks the first scheduled air cargo operation between Denmark and Asia.

The European Hydrogen Bank (EHB) aims to accelerate investment and bridge the investment gap for the EU to reach domestic REPowerEU production targets of 10 million tonnes (mt) of renewable hydrogen by 2030, coupled with 10 mt of imports.

The EU is a research and innovation powerhouse, and the EHB will establish a full EU hydrogen value chain alongside the Net-Zero Industry Act, which seeks to boost manufacturing of clean technologies.

Access for high value and time sensitive cargo between Scandinavia, Northern Europe, and the entire Asia-Pacific region is expected to increase significantly in the corridor from Billund Airport.

Additionally, Maersk’s newly opened air freight hub at Billund Airport enables customers to avoid the congestion and delays that are commonplace at larger airports.

FOOD & BEVERAGE

A FURTHER £13 million canning line investment has been announced by leading soft drinks business, Britvic.

The investment takes Britvic’s Rugby factory into the top five largest soft drinks manufacturing sites in Europe, and will increase the production of some of the UK’s favourite brands such as Tango and Pepsi Max by 14 percent.

It follows a £27 million canning line investment in the factory in 2021, bringing total investment in the factory to £40 million over the last two years.

Writer:

Writer:

There is no denying that the challenging economic environment that we find ourselves in today has impacted the technology sector. The ongoing inflationary impact of the war in Ukraine means that some investors are pulling away from the sector, which can stall innovation. However, there is light among the dark. We are still living through a rapid digital payments revolution as commerce continues to shift from offline to online.

In the emerging world of digital commerce, there are significant growth opportunities for SMBs. This comes at a critical time not only on the journey of those businesses and entrepreneurs but also for local economies across the region. The key word here is growth, and that is what is on offer for SMBs who are ready to look beyond the traditional and across borders.

We are now living in an environment where digital commerce innovation has been thrust upon the global population down to an initial necessity. Crucially for SMBs, there is still a lot of room for growth. E-commerce is expected to make up 24.5 percent of global sales by 2025[1]. This represents a monumental expansion of the digital commerce ecosystem but importantly there is headroom. People have rediscovered the benefits of face-to-face interaction, but we are all living digital lives. For SMBs in Europe, and indeed across the world, this represents an opportunity to broaden the customer base and achieve global growth.

For the region, the opportunity must be seen as the sum of many parts. For

example, SMBs produce 58 percent of European Union GDP and provide 67 percent of jobs across the region. This means that in an environment in which ambitious business owners can tap into the world of digital commerce, the positive impact on a country’s economic health cannot be underestimated. Fortunately, the barriers to entry are lower than they have ever been. E-commerce’s only prerequisite is access to digital networks, and with over four billion mobile phone users in the world [2], the digital gap is closing.

We have also seen trends emerge concurrently which are creating the perfect environment for innovation in online commerce, with one of the key elements being a truly borderless workforce. We’ve seen countries like Portugal and Spain welcome the digital nomad revolution with attractive Visa programmes. This is in response to a vibrant community of digital freelancers. We recently published our 2023 Global Freelancer Report which is based on responses from over 2,000 freelancers across

122 countries and revealed that almost half (46 percent) of freelancers report an increase in demand for their work from the global businesses that hire them compared to 2021. The growth of the borderless freelancer workforce means that SMBs are now not only being introduced to new customers across the world ,but are able to hire a team which reflects today’s global digital economy.

Moving from a domestic focus to looking at business growth across borders is often totally new territory for business owners. It’s an exciting prospect but it is important to consider the complex challenge ahead. For example, in Europe there remains different currencies and receiving funds in those different currencies can be a challenge. It is also vital to operate in a way that is compliant with local laws and regulations – there will be areas that are consistent and those where deviation and nuances are found. Looking beyond the technical and

operational, there are also distinct cultures and languages. It is important that global expansion is backed up by a clear understanding of how your business or product is going to be received in different countries.

The breadth of the European region also means that whilst digital commerce growth is a global phenomenon, the pace of change varies across the region. The maturity of each market within the region is also a vital consideration with Northern and Western Europe having a higher percentage of e-commerce sales than both Southern and Eastern Europe.

Digital businesses in more mature markets like the UK are likely to see the opportunities in digital commerce - we recently published research into UK sellers which found that 46 percent consider direct-to-consumer sales to be the biggest opportunity for their business in the next 12 months and 38 percent say social commerce presents the biggest opportunity. This openness to innovation is something that we are seeing emerge across Europe and it will be exciting to see the period of

innovative growth that lies ahead in countries like Serbia and Hungary.

In today’s global digital economy, the lines between competitors, partners and customers are blurred. At Payoneer for example, we partner with retailers, marketplaces, banks, and the wider payments and FinTech ecosystem. This is a global effort, but in Europe specifically, we are lucky enough to have a vibrant technology and FinTech community which is collaborating to bring innovative digital commerce solutions to SMBs. There have also been a number of positive steps taken across the region by policymakers to create a supportive environment. For example, the UK chancellor recently announced R&D tax credits for businesses looking to invest in innovation in FinTech. This is a positive step and coupled with the growth already taking place in the global digital commerce ecosystem will further drive the digital revolution.

James Allum is SVP and Regional Head of Europe at Payoneer, a financial technology company empowering the world’s SMBs to transact, do business and grow globally. Allum also heads up Payoneer’s global banking partnership strategy. Payoneer’s mission is to enable anyone anywhere to participate and succeed in the global digital economy. Since being founded, the company has built a global financial platform that has already made it easier for millions of SMBs, particularly in emerging markets, to pay and get paid, manage their funds, and grow their business.

Intentionally applying technology to advance environmental, social, and governance (ESG) goals is gaining traction, but challenges remain for business leaders aiming to successfully use digital innovation to boost sustainability.

Using digitalisation to measure and improve ESG performance, an approach that recognises the largely untapped opportunity for technology and data to drive sustainability goals, is sometimes called the ‘twin transition’, and the approach is becoming increasingly structured.

In its report “Digital for Green: Leveraging Digital Technologies to Improve Sustainability Performance”, The Conference Board, a global think tank delivering trusted insights for what’s ahead, interviewed multinational firms in Europe and the US to discover the ways leading edge companies are adopting the twin transition and how other organisations can benefit from what

they’ve learned. The report explains that a successful twin transition requires dedicated attention and efforts on three levels: envision, enable, and engage.

Successfully transforming a company culture to emphasise a sustainable approach to business and innovation requires considerable time and investment and must start at the top. Leadership at the board and C-suite level must set a clear direction toward sustainability, integrating the company’s ESG goals with its business goals, and incorporating both efforts into the organisation’s overall strategic plans.

Ideally, employees are incentivised to reach twin transition goals and leadership will need to continually revisit and reaffirm the company’s purpose and mission, to make it happen. Because twin transition goals can take time to bear fruit, one popular dynamic is for businesses to rely on long-term and non-financial metrics at board level, rather than rely solely on year-on-year profit and

loss data. Additionally, the incentives to prioritise and accelerate the twin transition need to incorporate longer term and more comprehensive financial and non-financial metrics.

Of course, all the incentives in the world will not boost sustainability unless employees have the right tools, methods, and authority to make the necessary changes. First, companies must ensure their information systems are up to the task. The Conference Board’s discussions with executives revealed that this effort is frequently focused on infrastructure and data management.

Infrastructure must be reliable internally as well as with shared external partners. Some new digital infrastructure, such as accounting and reporting systems, facilitates this joint participation. Additionally, as new accounting standards could require broader and more systemic environmental reporting,

firms will have to adapt or upgrade systems to fulfil these mandates. In parallel, data informs decisions, supports optimisation efforts, and enables the development of more sustainable business models, so data management systems must be structured, stable, and advanced enough to deal with real time data, all of which require a mature information system.

The Conference Board also found top executives are considering

methods and end-to-end thinking when approaching a twin transition. Leaders interviewed for the report mentioned holistic work approaches that incorporate circularity, as well as efforts to make the design and development of the products themselves more environmentally friendly through their entire life cycles, from production to use to waste. Firms also emphasised communication, indicating that integrity and transparency are

“AS RECENTLY AS A FEW YEARS AGO, SUSTAINABILITY AND DIGITISATION INITIATIVES WERE STILL APPROACHED VERY MUCH SEPARATELY FROM ONE ANOTHER, BUT NOW, THE TWO ARE SEEN AS COMPLEMENTARY FORCES THAT CAN EXPONENTIALLY IMPROVE DESIRED OUTCOMES”

– JOHN METSELAAR, THE CONFERENCE BOARD

important, especially when measuring and reporting on the progress of sustainable development. Not only does this bring clarity to stakeholders, but it helps them understand the added value of digital investments for sustainability. Companies are also considering the reputational impact of ESG, affirming that a positive societal impact and an upstanding reputation are indispensable for future growth and success.

Finally, the entire organisation must be engaged and empowered in the company’s strategy for green digital, both internally among employees and externally in terms of other players in the ecosystem. In their interviews with The Conference Board, executives firmly asserted that there are no structural obstacles to implementing the twin transition embedded in their

with digital and sustainability transformations and have an understanding of the related challenges, executives are leveraging additional ways to accelerate change. Some companies place the customer at the centre of their strategies while others adhere to a science-based approach, but a consistent theme was supporting experimentation and agility. The ability to navigate ongoing changes and innovate based on fast iterations builds resiliency and unlocks competitive advantages, according to executives. When tackling the digital aspect of a twin transition, some companies rely on small communities of digital champions to inspire and drive change, while others are exploring innovative methods such as reverse mentoring, where younger generations coach their older colleagues.

While internal collaboration is critical to digital and sustainability transformations, companies must also look outward, cooperating with suppliers, start-ups, and sometimes even competitors on the sustainable development of their shared ecosystem. These efforts vary widely, from opening data access to partners for digital innovation to teaming up with peers to develop sustainability standards for their sectors.

the vision and identifying roadblocks to drive workforce buy-in to the organisation’s twin transition. Ongoing, transparent dialogue is a commonly cited tool for establishing and maintaining a digital and sustainable mindset across and outside an organisation.

As recently as a few years ago, sustainability and digitisation initiatives were still approached very much separately from one another, but now, the two are seen as complementary forces that can exponentially improve desired outcomes. Envisioning the transformation at the strategic level, enabling the organisation to execute it, and engaging and empowering internal and external stakeholders to contribute are all key components to a successful twin transition.

company cultures besides mindset and a willingness of the workforce to implement the changes. Incentives are a solid way to build the right mindset, and in addition, companies are working on raising awareness of digital and sustainability issues, upgrading the workforce through hiring or training, and providing more time for employees to learn about initiatives related to the twin transition.

Once employees are on board

As with internal initiatives toward a twin transition, external efforts must also be underpinned by an organisational structure where the transition strategy is centralised and supported from the top. Some companies are approaching this by assigning dedicated teams to break down departmental silos and simplify processes that may have become too complex for rapid change.

Companies must also tackle mindset related challenges externally, ensuring a clear understanding of

John Metselaar is The Conference Board’s Centre Leader of the Economy, Strategy and Finance Centre, Europe. He also coleads its Innovation and Digital Transformation Institute and leads its European and Asian Innovation Councils, as well as the European Chief Technology and Innovation Officers Council. He additionally serves as Senior Fellow. Metselaar is also Professor at the Solvay Brussels Business School for Economics and Management (ULB) for which he teaches his course and modules of “Leading and Living Innovation”. Previously, Metselaar held a 30-year VP-level career leading Innovation at Procter & Gamble (P&G). He has worked in Cincinnati, US, and Kobe, Japan, and served as the CTO of P&G’s Brussels Innovation Center.

Drydocks World has worked relentlessly to establish itself as a leading provider of marine and offshore services to the shipping, oil and gas and energy sectors. We delve deeper into the key to success and the exciting future of the company with CEO, Captain Rado Antolovic

Writer: Ed BuddsDrydocks World provides unrivalled shipbuilding and repair services, as well as expert ship maintenance, rig building, refurbishment, and offshore fabrication services from its industry leading facilities in Dubai, UAE.

Conceived as an ambitious project under the guidance of H.H. Sheikh Rashid Bin Saeed Al Maktoum, the late ruler of Dubai, the yard has grown spectacularly over the past 40 years.

We find out more with Captain Rado Antolovic, CEO of Drydocks World.

EME Outlook (EO): Could you briefly introduce us to Drydocks World?

Rado Antolovic, CEO (RA): Strategically located in Dubai, a rapidly developing region of the world, we have been able to take advantage of the Emirates’ political and economic stability to grow our reputation as a reliable,

cost-efficient one-stop shop solution for our customers. On average, we complete over 300 projects a year, with a record of handling 42 refurbishment projects simultaneously. Located next to Dubai’s Port Rashed, our yard is spread over 200 hectares, and includes three dry docks, one wet and dry basin for docking small vessels and a floating dock, as well as more than 3,700 metres of berth space. It also boasts an in-house-built floating crane, which can lift 2,000 metric tonnes, including the weight of lifting gear for all types of heavy lift operations.

Our workforce can only be described as a beehive: we currently employ 9,000 employees. As we are constantly looking for the best possible talent, we also employ over 3,000 subcontractor

personnel – making our total workforce of 12,000 some of the best talent in the industry. Our specialised project management team, comprised of marine engineers, naval architects, and ex-classification society surveyors, have the expertise and training to deliver projects on time and service clients locally and globally. This comes in handy, as our clientele is truly global, spanning from the Middle East and Europe to South America, Africa, and Asia. Aside from the retrofitting, new-build, and conversion services that we offer at our yard – including complete solutions for fabrication of offshore projects, turret systems, modules and specialised vessels –we’re able to provide global offshore services at short notice at any location.

These facilities have allowed us to break records in constructing some of the largest new build offshore fabrications in the world. But we also know that while reputation is hard won, it’s also not easy to keep. That’s why we aim to consistently deliver excellence and position ourselves as an international yard of choice by constantly upgrading our facilities and investing in expanding our capabilities. Overall, we like to think of ourselves as a piece of the UAE maritime industry’s success story.

EO: What is your take on the shipping industry in Europe at the moment?

RA: Europe’s trade development is deeply intertwined with shipping, and it remains central to the region’s economic outlook today. Whether that’s making use of the rivers that run through the region or its access to trade-prone seas such as the North and Mediterranean basins, its economy lives and breathes trade. In terms of trends, I’ve identified two that will affect the rest of the global shipping industry in some capacity – the turn towards “green” shipping, and geopolitical energy strategy protection, or the shortening of the energy supply chain, further concentrating trade within the region. Both these trends are full of opportunity for private businesses to innovate, so it’s a space we’re excited to see grow and develop.

EO: What are the most challenging elements of the business and how are you overcoming them?

RA: The main challenge in the industry and for our own business is meeting the increase in demand for our services post-pandemic. However, to pre-empt these capacity pinch points, we have been investing to expand and upgrade our yard’s facilities for years so we’re confident that we will be able to navigate these headwinds. Our South Yard expansion has been one of the recent developments which will increase our fabrication capacity area by 70,000 square metres, which is set to add one more load out facility in the yard.

We have also made sizable investments in equipment including recent purchases of new cranes, as well as hydro blasting and other equipment, to increase our efficiencies.

Alongside our hardware upgrades, we are also in the process of implementing a new state of the art Internet of Things (IoT) system that will help us streamline our production and project management planning and execution to avoid capacity congestion. The aim of our digital transformation journey is to digitalise the existing processes that are currently being done manually, to increase productivity, optimise costs, enhance staff performance, and provide real-time data for immediate business decision making.

EO: Are there any ongoing or recent projects that the company is particularly excited about?

RA: There are several projects we are excited about, including our own business transformation and work we are undertaking for our valued customers.

We are set to begin work on upgrading the Petrojarl Knarr floating production storage and offloading (FPSO) vessel for deployment at the Rosebank field offshore of the UK. The contract is a joint venture with Aker Solutions, and under the agreement, we’ll be responsible for the construction and life extension of the FPSO vessel, which will operate for 25 years at the Rosebank field without drydocking.

Among our FPSO and FSO conversions, we are working on a few retrofitting and upgrading projects with various sustainable technologies. The FPSO Firenze is getting ready to sail away from our yard, set

we’re looking to expand our capabilities in the maritime energy construction sector. To echo DP World, our parent company, the international maritime and energy sectors need smart, integrated solutions to ensure sustainable production and to successfully transition equipment and vessels for the future.

EO: What differentiates your company from the competition?

to operate in the Baleine Field, off Ivory Coast. This major renovation project was a huge undertaking by the Drydocks team and had crossed four million Lost Time Injury (LTI) free manhours by January 2023.

Our contract with Malaysian FPSO specialist Yinson in 2022 to upgrade, refurbish and convert a vessel due to be deployed at Enauta’s Atlanta field offshore Brazil is another one we’re proud of, as it is truly symbolic of our global reach and our growing importance for customers around the world.

Last year, we also signed a contract with Norwaybased Kanfa to deliver a topside module for a floating production storage and offloading vessel, scheduled for delivery in Q2 2023. The module will be used to process crude oil received from oil wells and will be placed on the main deck of the FPSO.

On the business transformation side of our work,

RA: Drydocks World’s unique value proposition is a result of a mix of factors, including our service offering matrix, our strategic location in the UAE, and our standard for excellence. We are constantly investing in increasing our yard capacity and upgrading our technology to better service our customers, which, coupled with an everexpanding range of services offered, make us uniquely placed to handle even the most bespoke requests. Being located in Dubai, and part of the DP World portfolio of companies is also a huge advantage for us. Not only is the UAE’s strategic location connecting us with the rest of the world through important trade routes, but Dubai is also renowned for being an economically, politically, and socially stable country. This means that we’re able to work on projects that take multiple months to complete without interference.

Lastly, our reputation precedes us. We are known in the industry for our punctuality, standard of excellence, and thoroughness. This is our business card in the industry and is one that we take great pride in, but we also know that without our people’s talent, our restless drive to innovate, and our ambition to expand into more areas of the market, we wouldn’t be where we are today.

EO: What does the next year look like for the company?

RA: The industry at large may face some headwinds in the next 12 months, but I’m excited about the opportunities that lie ahead. We’re expanding our yard, investing in new technologies to grow our service offering, and working with new clients to venture into new markets.

Writer: Kirsty Biddiscombe, UK Head for AI, ML and Analytics

Data is like water; it’s always flowing, you cannot survive without access to it, and it’s constantly being used, cleaned, and recycled.

But dirty water, is largely unusable – left to stagnate in water tanks or storage, it’s quickly forgotten and got rid of. When we treat that water with care and ensure it’s clean, we allow for the reallocation and consistent use and re-use of it in different ways in everyday life.

Data is the same. If firms do not have accessible, clean, secure and consistent data, artificial intelligence (AI) projects will not survive.

With the release of a series of ground-breaking models, in recent times, the popularity in AI language models has increased. This has led many on the internet to question whether we’re on the edge of an

android apocalypse.

However, AI’s true potential lies in its ability to serve as a tool to streamline processes – no matter the size or scale of the project.

Proof of AI’s increasing integration was highlighted in McKinsey’s 2022 State of AI report. It demonstrated that AI adoption has more than doubled since 2017, with 50 percent of organisations saying they now use AI in at least one business area.

This adoption has been helping

businesses in industries such as retail and utilities to innovatively serve the needs of their organisations and customers. However, it’s in manufacturing where AI is having the biggest impact.

AI-based products such as machine learning (ML) and deep learning (DL) are facilitating smart factories that can optimise increasingly complex, multi-stage processes. These tools are enabling them to become more sustainable, efficient and cost-effective.

But questions for businesses looking to integrate AI into their manufacturing processes remain - where do I start? And how do I ensure clean data is at the heart of the process?

High performing AI solutions within manufacturing require secure and clean data. That is because of the long-standing dependence on legacy systems which have meant that data storage has dropped down the priority list.

Luckily, we’re starting to see a mindset shift thanks to the digitalisation of the manufacturing industry. Manufacturing CIOs now understand the importance of not just collecting and inputting data, but storing it in a safe and clean way, which is necessary when it comes to storing industry leading secrets or people’s data, for example.

By promoting the belief that effective manufacturing applications begin with data, and this data needs to be cleaned and stored in a safe and secure way, businesses will be able to plan and deliver more successful AI-powered projects.

As many leaders within the manufacturing industry know, how you choose to approach your data

management can make or break a project. Currently, data scientists lose around 80 percent of their working hours on collecting, clearing, and detecting defective data – instead of creating actionable insights.

As mentioned previously, like water, clean data is essential for training AI algorithms so it can make more accurate predictions around priorities such as impending plant breakdowns or machine downtime.

When it comes to training AI algorithms, using unclean data can be detrimental. Better data hygiene helps businesses seamlessly integrate information into existing software programmes. They can then deploy AI to automate the process – driving better efficiency and productivity.

But the success of AI projects in manufacturing rests heavily on the quality and quantity of the data it processes – the better the data, the better the results.

When implementing any technology tools into your tech stack, they should bring strategic value and add to the day-to-day functioning of your business. It’s no different for AI.

Leaders should consider what’s needed for AI integration to be successful, such as the costs, challenges and any limitations. But the right approach, with the right partner on board, should have an immediate, cheaper and more sophisticated impact.

Across manufacturing, AI integration might look like introducing intelligent machine maintenance, improving the efficiency of quality control, becoming more agile

with supply chain management or increasing AI-powered automation for running better processes.

Ensuring success in these areas is also about the people using the technology – how they use it, the way they embed it into the process, and whether they use it to its full potential. So, leaders need to ensure they’re leading from the top and showing their employees that these tools are useful in order to ensure the success of the deployment. Implementing sometimes complex technology can be daunting, but ensuring your people understand it and are able to use it to their best ability is vital. Leaders need to focus on investing in training so the whole business can embrace the innovation.

In today’s market, AI has the potential to provide a huge competitive advantage for companies in manufacturing, but only if it’s set up and used in the right way. Starting with the right data set – which is clean and secure – is essential. Truly transforming a business’ approach to data and technology will prove AI’s potential.

Kirsty

Biddiscombe is the AI, ML and Analytics Lead for NetApp’s UK and Ireland business. She plays a crucial role in driving successful engagement in AI, ML, and Data Analytics, supporting organisations to achieve their business objectives around their AI presence.

Writer: Phoebe Harper | Project Manager: Dave West

Writer: Phoebe Harper | Project Manager: Dave West

As the largest growing consumer goods sector in the UK, we tackle the contentious topic of vaping and the pressing need for an evidence-based approach to promote a healthier alternative to smoking

Although a phenomenon that has exploded in recent years, vaping is an undeniably controversial issue.

In a media storm that continues to favour clickbaithorror stories frequently plagued with misinformation and falsities, the true purpose and value of the industry – as an undeniably healthier alternative for adults looking to quit smoking – is being obscured in an endless game of smoke and mirrors.

As a result of an overwhelmingly negative media barrage, it has been reported that only a third of adult smokers are aware that vaping is a significantly less harmful option to smoking, despite widespread agreement from both medical professionals and the government confirming the same. Indeed, in 2022 data from the Office of National Statistics showed that smoking rates are now at their lowest levels since records began, crediting vaping as playing a ‘major role’ in that decrease, a conclusion further bolstered by the Office for Health Improvement and Disparities.

Nevertheless, the industry today must confront the stark reality of the environmental issues and waste implications of a habit that primarily relies on singleuse devices, and the fact that the number of children vaping aged between 11-17 has doubled within the past two years alone (as reported by a YouGov survey for Action on Smoking and Health).

The latter represents the industry’s greatest hurdle, as it seeks to impose more stringent regulations regarding the illegal sale of vaping devices to children, and the policing of marketing tactics that are at risk of targeting a young audience. In addition, manufacturing innovation is needed to promote the use of environmentally-friendly materials and recyclable alternatives, steering consumers away from disposable models.

The comparative health benefits of vaping to smoking make the industry a critical public health tool if the UK is to reach its ambition of being smoke-free by 2030. In addition, its economic benefits cannot be understated – not just in terms of revenue, but also in terms of saving costs for our overburdened public health system. In 2019, this translated to an estimated cost saving of over £300 million (as reported by the UK Vaping Industry Association).

However, the advantages that vaping can bring to the UK’s well-being, both in terms of public health and economically speaking, can only be realised both sensibly, and sustainably, if we fully acknowledge an evidence-based approach over misinformation – one that paves the way for regulating industry activity, and keeping vapes out of the hands of children.

Championing the vision of a smoking-free future for the nation, we highlight the work of the leading trade association behind the UK’s £1 billion vaping industry

Founded in 2016 as a non-profit trade organisation to support, educate and inform its key stakeholders, while also acting as a unified voice for the industry, UKVIA is run by its members, for its members. Director General, John Dunne, tells us more.

EME Outlook (EO): Firstly, could you introduce us to the association – when were you founded and what is your vision?

John Dunne, Director General (JD): We are proud to have grown to become the UK’s biggest vape trade association working for our members to champion our industry and help fully realise the enormous potential for change that vaping can bring to adult smokers.

The UKVIA regularly engages with government officials, regulators, parliamentarians, trading standards departments, the media and other interested stakeholders to promote the industry and call for fair and sensible regulation.

With vaping gaining record levels of media coverage –much of it negative, misleading or just out-and-out false – as well as politicians facing demands to introduce even more regulations, our role is more vital than ever.

Our vision is quite simple. We want smoking to become

a thing of the past in the UK. There are between 5.6 and 6.6 million adult smokers in the UK and we want every one of them to be aware that vaping could be the one thing that helps them quit cigarettes.

We can help do this by cutting through all the negativity in the mainstream media about vaping and providing the evidence-based facts about vaping so that the public health benefits of switching from smoking are fully realised.

EO: What is your current take on the UK’s £1.3 billion vaping industry? Is it facing many challenges, such as the media’s perception of the health effects of vaping?

JD: When it comes to encouraging adult smokers to quit and regulating the vaping industry, the UK is often held up as the ‘gold standard’ for other countries to follow.

The Government, the NHS, regulatory authorities and influential members of the scientific community recognise that vaping plays a major role in helping adult smokers quit – in fact, for many former smokers, it has been the only method that has ever worked.

It is crucial that the Government continues to support vaping. The review by Dr Javed Khan into the Government’s smokefree goals said it would miss the

target by at least seven years unless it took decisive action, including ‘the promotion of vaping as an effective tool to help people to quit smoking tobacco’.

The latest Office of National Statistics (ONS) data shows that smoking rates are at their lowest levels since records began and describes how ‘vaping has played a major role’ in this decrease.

In 2015 Public Health England (PHE) concluded that vaping was ‘at least 95 percent less harmful than smoking’ and PHE’s replacement, the Office for Health Improvement and Disparities (OHID), confirmed the figure last year and concluded that it was clear that ‘vaping poses only a small fraction of the risks of smoking’.

But this does not match with how the mainstream media reports on vaping. The red tops in particular seem content to chase clicks by printing vaping horror stories which have no basis in fact.

Not only is this irresponsible, but it is costing lives by discouraging smokers from switching - only a third of adult smokers are aware that vaping is a far less harmful alternative.

Concerns about the environment and youth uptake are big challenges for the industry, but we are working hard to find solutions to these while working to realise the full potential of vaping to help smokers quit.

EO: What role does research play in the association’s work?

JD: Research is fundamental to the UKVIA’s work and a lot of our time and effort goes into making sure that our members, regulators, government agencies and other key stakeholders have evidence-based facts at their disposal.

We have seen how disinformation in the media about vaping is having a negative effect on smokers and the same, sadly, is true about other interested parties including the medical profession, politicians and the public.

It is of vital importance to state the facts about the relative risks of vaping compared with smoking – backed up by hard evidence – so that smokers can make informed decisions about how they consume nicotine.

But the vaping industry is much more than just a tool to help smokers quit, which is why we recently commissioned the Centre for Economics and Business Research (Cebr) to produce an Economic Impact Report on the value the industry added to the economy.

Among the findings of the report were that the UK vape industry’s aggregate turnover was valued at £2.8 billion last year; the sector supported almost 18,000 full time equivalent jobs in retail, manufacturing and the supply chain, and the estimated cost saving to NHS of smokers switching to vaping was over £300 million in 2019 alone.

We also do a lot of our own internal research to plan our activities, keep our members informed and come up with evidence-backed policies to help the industry fulfil its potential to assist the Government in meeting its smokefree 2030 ambitions.

The UKVIA regularly provides evidence to support the industry for Government consultations on vaping

regulations such as our ‘Blueprint for Better Regulation’, which drew heavily on published research and data to highlight how UK vaping regulations could be amended to encourage more smokers to quit.

EO: Could you tell us more about VApril Awareness Month?

JD: VApril is the hugely successful UKVIA-led annual month-long campaign to promote vaping awareness amongst UK smokers.

Over the last six years it has established itself as the largest vaping education campaign in the world as countries around the globe use our resources to cut through the misinformation about vaping and give their smokers the facts they need.

Created and delivered by the UKVIA, VApril is dedicated to helping smokers choose the right vaping device, flavours and nicotine strengths that will give them the best chance to quit smoking.

We have full information on our VApril.org website and during the month we will run a paid social media campaign aimed at answering the most common questions that smokers have about vaping.

For 2023 we have produced a new guide to vaping responsibly – which covers everything from how you can take a responsible approach to vaping in public to disposing of your device in an environmentally-friendly way.

We also encourage vapers to give advice to current smokers looking to switch by using #VapingWorks on social media, and there is an easy-to-follow five-step ‘start vaping – quit smoking’ plan on the VApril.org website.

EO: Are there any other initiatives, events or projects the UKVIA is working on that you would like to highlight?

JD: We have just held the first ever environmental summit for the vaping sector which brought together political, regulatory, environmental, recycling, consumer and vape industry experts to help deliver a ‘Greenprint for Sustainable Vaping’.

This is a very emotive issue, and we recognise that more must be done to help mitigate the effects on the environment without impacting the proven ability to help smokers quit.

This virtual summit brought together stakeholders with a key role to play in the greening of the vaping sector and put the spotlight on the whole supply chain from product innovation through to the waste being handled and dealt with.

Some of the best scientific minds in the industry are working hard to find more environmentally friendly materials for vaping products, especially single-use devices, but this is not exclusively an issue for the vaping industry to solve as regulators, policymakers and consumers all have a role to play.

Youth vaping is another topic which is gaining massive media attention and the UKVIA is clear that vaping is an

adult-only activity designed to help smokers quit. This is why we have recently updated our ‘Preventing Underage Sales Guide’ for UK retailers and why we are calling for fines of up to £10,000 per instance for those who deliberately sell to children.

Finally, on 10th November in London, we will be hosting our annual UKVIA Forum and Industry Recognition Awards where we debate pressing issues, celebrate our successes and recognise those who have made an exceptional contribution to vaping over the year.

EO: How do you see the industry developing over the next decade or so?

JD: Given that so much can happen in this fast-paced industry over a few weeks or months, it is very difficult to predict what things will be like in a decade or more.

I can certainly see more of a push into the convenience sector with expanded product offerings. Technological advances will no doubt continue, and the industry will also respond to both consumer demand and any changes required by regulators.

EO: Finally, what are the UKVIA’s key priorities within that future?

PB: Our priorities will remain the same which are to represent our members, speak up for the industry, highlight the great power for good that vaping has to transform the lives of adult smokers for the better, and to push back against excessive or unreasonable regulation.

We will continue to fully engage with governments, the media, regulators and all relevant stakeholders so that smokers can be better informed about vaping and to give the UK the best possible chance to finally become smoke free.

“OUR VISION IS QUITE SIMPLE. WE WANT SMOKING TO BECOME A THING OF THE PAST IN THE UK”

– JOHN DUNNE, DIRECTOR GENERAL, UKVIA

EME OUTLOOK is a digital product aimed at boardroom and hands-on decision-makers across a wide range of industries in Europe and the Middle East regions. With content compiled by our experienced editorial team, complemented by an in-house design and production team ensuring delivery to the highest standards, we look to promote the latest in engaging news, industry trends and success stories from the length and breadth of Europe and the Middle East.

Reaching a combined audience of more than 395,000 people, EME Outlook covers a full range of industrial sectors: agriculture, construction, energy & utilities, finance, food & drink, healthcare, manufacturing, mining & resources, oil & gas, retail, shipping & logistics, technology and travel & tourism. In joining the leading industry heavyweights already enjoying the exposure we can provide, you can benefit from FREE coverage across our digital platforms, a FREE marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to grow your business.

To get involved, please contact Outlook Publishing’s Managing Director, James Mitchell, who can provide further details on how to feature your company, for FREE, in one of our upcoming editions.

As an innovative construction business with a diverse workforce underpinning a creative approach to its extensive project portfolio, Bouygues Travaux Publics is thriving. We explore further with Executive Vice President, Vincent Avrillon

Writer: Ed Budds | Project Manager: Ryan Gray

Independent Substation Services Ltd (INDSS) was established in 2011 as a specialist High Voltage and Low Voltage electrical engineering company. We offer a varied range of services such as:

• Transformer and switchgear maintenance

• Transformer and switchgear supply, installation, commissioning and testing

• Cable jointing and terminating

• Fault finding / emergency call out

We work within private networks offering services to end users and operators of electrical equipment. Our customer base varies from biomass sites, high rise buildings and hotels to construction projects and everything in between. Recently our larger projects included a major HV and LV systems retrofit at the Lanesborough Hotel in London whilst keeping the hotel operational; and the installation and commissioning of the entire HV supply to the HS 2 South Portal site in Rickmansworth.

Europe’s construction industry is intrinsically bonded to the prosperity of the European economy.

This plentiful sector provides 18 million direct jobs, contributes to around nine percent of the EU’s overall GDP, and possesses the crucial ability to create new employment opportunities, drive economic growth, and provide solutions for social, climate and energy challenges.

Part of this vast network is Bouygues Travaux Publics (BYTP), who has evolved efficiently to secure its esteemed standing as a global player in construction. Founded in 1952, BYTP remains family owned to this day.

The vastly experienced company designs, builds and operates projects in the building, infrastructure and industrial sectors, and as a responsible and committed leader in sustainable construction, BYTP sees innovation as its primary source of added value. This crucial quality is viewed by the company as “shared innovation” that benefits its customers, whilst simultaneously improving its productivity and the working conditions of its 32,400 employees.

“I was immediately attracted to the construction industry, as it’s

As a local development player, BYTP is committed to the following principles:

• Respecting the fundamental human rights, interests, cultures and values of its employees and the communities in which it operates.

• Developing and valuing the skills, diversity, quality of work life and cohesion of all its employees.

• Participating in the social and economic development of the territories where it operates through employment, integration, training and community partnerships.

• Addressing environmental issues at every stage of the company’s projects, in particular by reducing carbon footprint, preventing pollution, preserving biodiversity and sourcing responsible resources.

• Limiting waste through the promotion of the circular economy.

The construction and infrastructure industries are undergoing a massive shift. With pressure from shareholders and the need to comply with a growing raft of legislation, work sites are increasingly insisting on net zero and carbon neutral operations. One way to help achieve this is to choose site welfare products which minimise fuel use and emissions.

Over the past two years, UK manufacturer Boss Cabins has been helping sites to go carbon-free with their patented Deep Green 2030 range of welfare cabins and portable toilets, proven to operate almost entirely from solar energy, slashing fuel use and producing virtually zero emissions. Also incorporating rain harvesting, water recycling and vastly reducing the need to visit the site to service the cabins, the Deep Green range has had its carbon savings verified by respected independent industry watchdog Carbon Footprint as well as being shortlisted for two prestigious sustainability awards –edie’s ‘Net Zero Product of the Year’ and ‘Product Innovation of the Year’.

Now after 24 months of data proving how successfully Deep Green units reduce fuel use and emissions on site, Boss Cabins has taken its solar innovation one step further with the launch of the patent-pending GenFree range. This 100 percent silent running welfare cabin range is the world’s first towable welfare range with no on-board generator at all. With all electrical power supplied by an advanced solar system with extendable arrays and vertical panels, this breakthrough in site welfare is available for demo now.

For more information, contact Boss Cabins on 01778 300475.

bosscabins.co.uk

something that I believe some people just have in their blood,” introduces Vincent Avrillon, Executive Vice President of BYTP.

“I started off by resisting many other career paths, such as joining a car manufacturer or chemistry company. Banks at that time were also starting to recruit lots of engineers, but I was attracted by construction only, and the nature of seeing the things being built every day was really important to me.”

Having joined the company in 1990 as part of an overseas training programme, launched as a specific French opportunity, Avrillon travelled to Australia to continue his development, later moving to Hong Kong, then back to Australia once more, before

returning home to Paris with BYTP.

“I now focus on managing tenders, delivering projects, trying to build success and training people to be the future of the company,” he sets out.

Avrillon believes that the European construction market finds itself in a difficult position at present. The UK, for example, is having to navigate the ever-increasing difficulties left in the wake of the complicated fallout from Brexit and now more recently, the war in Ukraine.

These challenges continue to have a negative effect and slow progress on all current projects for the entire construction industry.

Victor Products Ltd is the world’s leading manufacturer of electrical connectors and lighting for the global mining and tunnelling industry.

Trust is Earned, Never Given. Nowhere is this truer than at the bottom of a mine shaft. Victor Products Ltd, established in 1929, has over 90 years’ experience offering world class customer service, technical support and outstanding engineering services and support. Victor Products is able to specify and provide the specific solution to suit our customer’s requirements.

The electrical connector range covers voltages up to 11,000V and currents up to 750A. Victor Products Ltd has developed a range of LED lighting designed specifically for the arduous environments found in mining and tunnelling.

www.victor.co.uk

“I WAS IMMEDIATELY ATTRACTED TO THE CONSTRUCTION INDUSTRY, AS IT’S SOMETHING THAT I BELIEVE SOME PEOPLE JUST HAVE IN THEIR BLOOD”

– VINCENT AVRILLON, EXECUTIVE VICE PRESIDENT, BOUYGUES TRAVAUX PUBLICS

Find

Victor Products Ltd.

Unit 3A

Tyne Dock East Side

Port of Tyne

South Shields

Tyne & Wear

NE33 5SQ

Tel: +44 (0) 191 280 8000

Email: sales@victor.co.uk

Web: https://www.victor.co.uk

Victor Products Ltd manufactures an extensive range of explosion protected electrical connectors and lighting primarily for the underground coal mining and tunnelling industry We have been proudly nominated as a key partner by Vincent & Anne-Sophie DUC DODON, Project Management Officer of ALIGN JV & Bouygues. Our products for the tunnelling industry increase efficiency and improve safety. This further recognition increases Victor’s reputation throughout the mining/tunnelling industry that the products we design, and manufacture are second to none.

Victor Products Ltd is the global headquarters of the Victor Group of companies with manufacturing facilities in the UK and South Africa. In addition, there is a network of agents available throughout the world to supply local solutions. Research and development are a constant, with the portfolio of products expanding, and the addition of individual country’s approvals of the existing product range.

One of the most distinguishing features of Victor Products is its quality level which is recognised throughout the world. In addition, customers regularly comment on the depth of product knowledge the team at Victor Products Ltd can draw upon to provide engineering solutions.

Victor Products is a wholly owned subsidiary of the Federal Signal Corporation of Chicago. Registered Office: Victor Products Ltd, Unit 3A, Tyne Dock East Side, Port of Tyne, South Shields, Tyne & Wear, NE33 5SQ. Reg. in England No. 06531201.

“Despite these obstacles, the French market remains prosperous, mainly thanks to the Grand Paris Metro Project. Apart from that, however, it’s not a booming market across Europe right now,” he explains.

Ever since it was founded, BYTP has consistently sought to bring people together by combining aesthetics, technicality, practicality, and safety for users through total mastery of all the techniques involved in the construction of bridges, tunnels and other projects.

“We have always tried to be at the forefront of the market in terms of innovation, safety, the equipment we

are using on site, and design,” Avrillon informs us.

“We are very proud of our design approach, as when we look at a project, the first thing we do is try to challenge the design, change it, modify it and find alternatives that will save time and money, and we regard this as our greatest strength.”

Some of the bridges that BYTP has built have become casebook examples for the construction industry, such as the Hong KongZhuhai-Macao Bridge, the world’s longest sea bridge between Macao and Hong Kong, the Avignon Viaducts and the New Coastal Road viaduct,

TANKS-UK has successfully partnered with Align JV to provide Firewater Reserve Tank Systems. In addition, they have supplied the HS2 project and other large construction projects with Portable Bowsers for Water or Fuel Dispensing, Combination units with AdBlue®, Trailed Bowers for dust suppression and Static High-Volume Storage Tanks in plastic or steel.

To provide a seamless and complete service, TANKS-UK carries a comprehensive range of pumps, fittings and accessories, giving turnkey liquid handling solutions for your requirements.

We look forward to your call. Sales helpline +44 1953 665 948 or sales@ tanks-uk.com

www.tanks-uk.com

linking Saint-Denis to La Grande Chaloupe.

One particularly successful project that remains very special to the company is the Grand Paris Express, Metro Line 15.

“Paris is our garden, so we definitely wanted to be involved with building the Grand Paris Metro. When the project started five years ago now, we had not built tunnels in France for maybe 10 years, so one of the challenges for us was to upskill a new generation of tunnellers, workers and young engineers,” Avrillon illustrates.

“Traditionally, we are very good at design and building when we work overseas, but we were not always so successful in France, so it’s the start of a new era and a new way of delivering major projects in France,” he details passionately.

Another key area of development for the company is through investment in the offshore wind farm business.

Bulk Fuel

TANKS-UK is the leading supplier for a range of Tanks and Liquid Handling Systems across Construction, Agriculture, Industry and Domestic

Supported by a wide selection of pumps, fittings and accessories, we tailor systems to meet each customer’s requirements on request. We provide free technical support, friendly advice and unrivalled service levels.

Ducrocq Engineers specialises in the design and manufacturing of equipment dedicated to extremely challenging environments, including infrastructure construction projects (tunnels and railway works), energy markets (oil, gas and hydroelectricity) and industry.

Learn more

“We acquired a design concept of a floating solution last year, as the offshore wind farm market is an important target for us. It is a marine works, heavy concrete structure, and will allow industrialisation of the construction as well as being a way to demonstrate our ambition in terms of our ongoing carbon emissions reduction strategy.”

Above all, BYTP is committed to building a workplace in which all individuals feel supported and respected. To get the best from its highly valued staff, the company knows that it must nurture a culture and an environment that embraces difference.

“To remain competitive and to differentiate us in the construction market, we know that our people will be more productive and engaged if they feel ‘well’ at work,” explains Avrillon.

“We aim to educate all members of staff about the importance of a diverse and inclusive workplace to achieve business success, and we focus on providing career opportunities for all key talent in a fair and equitable way,” he adds. BYTP’s diversity and inclusion goals are supported by graduate schemes and comprehensive learning and development programmes throughout the employee life cycle, including mentoring and recruiting activities.

“To be even more specific, in a male dominated industry, we aim at realising gender equality throughout

all key employee experiences including recruitment, performance and remuneration reviews and development opportunities,” Avrillon elaborates further.

Additionally, BYTP has envisioned several key gender balance objectives, as the company remains convinced that it needs to change. Today, all executive leader bonuses are tied to different targets, including gender balance goals, as BYTP strives to ensure that its workforce is free of any harassment or discrimination.

As a company, BYTP believes that whatever the level of someone’s profession within its structures,

“WE MUST SEDUCE US CONTRACTORS TO WORK WITH US AND DEMONSTRATE WHAT WE CAN BRING TO THE TABLE”

– VINCENT AVRILLON, EXECUTIVE VICE PRESIDENT, BOUYGUES TRAVAUX PUBLICS

you need to achieve your goal with the support of our expert team.

Whether you are starting from a trench, working your way up, or giving a structure a new lease of life, we can provide you with the support you need to bring your structure to life in the most efficient, cost-effective and safe way.

training is a key driver in the development of people. In this way, careful attention is paid to every individual’s needs to help them develop towards their highest potential. Everyone’s career path is treated in an individualised way, which opens the maximum number of opportunities for career development within the group.

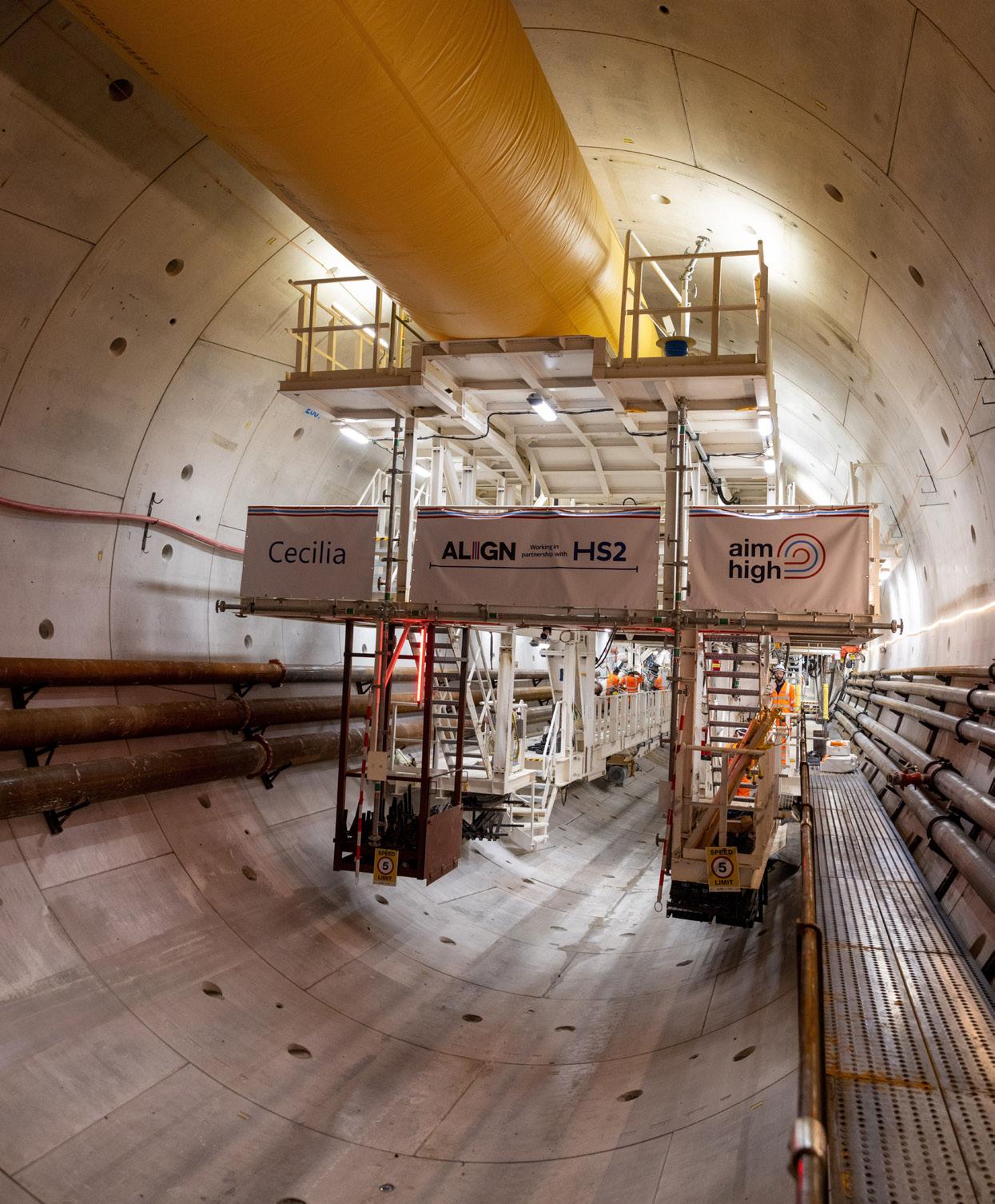

One of the signature projects of BYTP’s ever-expanding portfolio is HS2, a high-speed rail line that will provide a non-stop link between Birmingham and London, UK, which

is a prosperous market for the company.

The Align joint venture, consisting of BYTP, Sir Robert McAlpine and Volker Fitzpatrick, is managing the design and construction of the 21.6 km Central 1 (C1) section, to the northwest of London, which includes a 3.4km viaduct over the Colne Valley and a twin-bore 16km tunnel through the Chiltern hills.

“HS2 is the longest tunnel we have ever built, and together with the viaduct it is quite a sophisticated and iconic project. The project is on-track with reference to budget and timing, so it’s a real success in the UK, and we are very proud of it“ Avrillon acclaims.

Align is using variable-density tunnel boring machines, a technology that has already been used by BYTP across projects in Hong Kong and on the Grand Paris Express project, which adapt excavations to the specific geological conditions of the terrain. The complex work carried out also included the construction of cross passages between the two tunnels, as well as the installation of five ventilation shafts.

Also located in the UK, BYTP is particularly proud of the Hinkley Point C (HPC) project. This sizeable undertaking consisted of the construction of a power station that

©

HS2 Ltd

©

HS2 Ltd

houses two nuclear reactors.

EDF Energy awarded the project to BYTP, working as part of a larger consortium with the British company Laing O’Rourke, taking on the contract to construct the buildings that will house the two European pressurised reactor (EPR) nuclear reactors at HPC. With a total capacity of 3.2 gigawatts, the plant will supply a staggering seven percent of the UK’s electricity consumption and provide power to over five million homes.

BYTP has identified that the key to growing the business further, is to constantly endeavour to develop a diverse pool of international talent.

“The construction industry is not what it once was, and we now need to make sure that our partners, suppliers and contractors will stay in the business with us for 10, 20 or even 30 years to help build mutually advantageous

relationships,” Avrillon outlines.

Looking forward, North America will certainly play a crucial part in BYTP’s expansion strategy for new projects, as the company has collectively decided to focus more on the US market.

Now, with a strong team established in Miami, BYTP has secured several ongoing tenders, which are mainly tunnels because of the positive reputation that the company has forged in this project category.

“We are well established in Australia, Hong Kong, France and of course the UK, so now the focus is on the US,” he continues.

“The competition is sophisticated, with many local and European contractors working out there, and the level of the financial returns is good so it’s a place where we really want to work more regularly. We must seduce US contractors to work with us and demonstrate what we can bring to the table.”

Continuing to build prosperous

relationships with local partners will be at the forefront of the new strategy across the US. Similarly, thanks to the HS2 and HPC projects, BYTP now boasts an impressive and growing pool of talent in the UK, and offers to relocate staff to the US, Australia, Hong Kong or elsewhere for future jobs and new contracts if they are interested.

“Ultimately, we need to make sure that we are not only a French contractor employing French people working overseas. Instead, we must be seen as a more international company with international talents at our disposal,” he concludes.

Knightsbridge Development Corporation is championing social housing and large-scale project development from Canada. We speak to Will Smith, President and CEO, about the company’s central mission and its latest developments across the world

Writer: Marcus Kääpä | Project Manager: Nicholas Kernan

Writer: Marcus Kääpä | Project Manager: Nicholas Kernan

We are at a point in our industry where technology is taking us to new heights in sustainability, the race to carbon neutrality, and timber construction, all with the assistance of truly talented architects, engineers and owners dedicated to building better buildings - it’s an exciting time to be in Canadian construction.”

For Will Smith, President and CEO of Knightsbridge Development Corporation (KDC), the construction sector across the North American region is one of bountiful opportunity and incredible potential, spearheaded by a digital drive that is seeing technology assist development like never before. Digital tools such as building

information modelling (BIM), artificial intelligence (AI), and 3D printing have broadened the ability to enhance creativity and streamline construction operations throughout the industry.

With offices across Canada, KDC is part of a larger group of companies that includes KDC UK in England, as well as Desarrollos Knightsbridge (Desarrollos) and PanAm Construction Managers (PanAm) both with a presence in South America, which allows KDC to service the whole American continent on top of the UK and Europe.

In all geographic regions, KDC offers development management, construction management, project management, advisory services, and facilities management services as a

third-party provider.

“We have represented and continue to represent major publicly traded real estate investment trusts (REITs), RioCan, Allied Properties, ExxonMobil, Haworth International, Selfridges, and many others, as well as private companies,” Smith explains.

KDC’s primary focus is on largescale projects in the areas of office towers, mixed-use development, hospitality, and high-street retail projects, which support sustainability, innovation, and environmental stewardship both from a construction perspective and a developmental point of view. Typically, this means repurposing rather than demolishing existing structures wherever possible,

WILL SMITH, PRESIDENT AND CEO: “My educational background was in civil engineering, however after graduation, I quickly determined I did not want a career solely as a consulting engineer. I was fortunate to find an entry role in the development and construction industry, which, combined with my family’s construction businesses, created the base for my career. From there I built on the opportunities that arose through roles as a Project Manager, Director and Vice President, before ultimately reaching the level of President and CEO at KDC, at which time I also received my master’s in real estate. The culmination of these experiences resulted in my ability to work on construction projects in North America, Latin and South America, Europe and the UK as well as Asia over the past 30 years.”

or alternatively re-using building elements such as old timbers, significant architectural components, and multiple other facets.

“We carry out this work through talented teams of people, working locally in their markets, and utilising what we learn globally across all the offices,” Smith adds. “Our teams are small, tight-knit communities who embrace not only our clients and the projects, but one another, in an environment of collaboration, respect, and diversity.

“Our company mission is to provide client-focused real estate advisory services through world-class intellectual capital and resources, and to design and execute customised solutions that create value for our clients by locally applying what we learn globally. We provide our clients with a flexible and effective platform to support current and future opportunities and challenge the status quo with thoughtful consideration of a better future.”

KDC’s impressive work is exemplified by the broad portfolio of projects

that it has undertaken in Canada and abroad. One such Canadian project is The Well, made up of offices, retail space, condominium and rental apartments located close to Toronto’s bustling waterfront and business district.

The Well sets the standard for work-live-play developments in North America by creating a seamless coexistence of office, retail and residential uses through high-quality design supported by exceptional public transit connectivity, with an overall focus on sustainability that includes incorporating district energy and LEED Platinum and Gold Building Design.