HANDCRAFTED

HANDCRAFTED

With a rich history and unrivaled passion, Cruisers Yachts creates American-made boats for the world. We speak to Josh Delforge, Vice President of Engineering and Operations, about the company’s first-class fleet and commitment to innovation

Writer: Ed Budds | Project Manager: Michael Sommerfield

The global yacht building industry presents a unique blend of adventure, luxury, and freedom.

It is a vast and diverse sector that attracts designers, engineers, and builders from across the world but has the feel of a much smaller community, and for many, it exists as a lifelong passion.

At present, the US continues to be the main focus of yacht builders worldwide.

Within this expanding market, some builders may only produce one or two bespoke boats a year, whereas others are producing that same quota every hour.

“With the US being a key market, we see a continuous flow of new products introduced which fuels new design

trends. As a designer and builder, we’re excited by the challenge of creating unique solutions for clients with each of our vessels,” introduces Josh Delforge, Vice President of Engineering and Operations at Cruisers Yachts.

“The main market trends we are seeing today focus on increasing the ease of water interaction and giving our customers more flexibility with how they can utilize our yachts,” he continues.

After graduating from the University of Wisconsin-Madison in 2003 with a degree in engineering mechanics, Delforge was hired as a design engineer at Carver Yachts, where he was first introduced to the nautical world.

“OUR RICH BOAT-BUILDING HERITAGE DATES BACK TO 1953 AND WE HAVE SINCE BECOME ONE OF THE WORLD’S PREMIER PROVIDERS OF MID-SIZE LUXURY PLEASURE YACHTS”

– JOSH DELFORGE, VICE PRESIDENT OF ENGINEERING AND OPERATIONS, CRUISERS YACHTS

Cruisers Yachts has been building boats for over 70 years in Northeast Wisconsin and today boasts production plants located in both Oconto and Pulaski, with a total of just under 400 employees.

“As a young engineer, I was drawn to the combination of creativity and technical skills needed to be successful.”

Today, time is such a valuable commodity, and with families having less free time, Cruisers Yachts wants to give its customers the ability to cruise, anchor, entertain, overnight, and everything in between on its state-of-the-art vessels.

As such, one of the company’s goals is to find avenues to open up boating to new customers and audiences.

To do this, Cruisers Yachts is constantly looking at new materials, suppliers, building processes, and equipment to improve its products and allow it to offer more boats at a lower price.

“Additionally, in the near future, we predict that technology will grow to the point where we start seeing more electric and hybrid solutions in larger production yachts. Today, we only see this in small pockets, but we are getting closer each day,” Delforge explains.

What started as a production base for small wooden vessels has now evolved into the home of multi-million-dollar luxury yachts.

“Our rich boat-building heritage dates back to 1953 and we have since become one of the world’s premier providers of mid-size luxury pleasure yachts.

“Each model is crafted with industry-leading design, manufacturing, and amenities. Every part, texture, and element has been hand-picked to provide our clients with unparalleled comfort and performance,” Delforge prides.

JOSH DELFORGE, VICE PRESIDENT OF ENGINEERING AND OPERATIONS:

“As a major employer in both cities where we operate, we are always looking for ways to expand our reach within the community. We sponsor local events, donate to local charities, and connect with local schools.

“Additionally, as a boat builder, we are a member of the National Marine Manufacturers Association (NMMA), in which we strive to educate and promote safety on the water.

“At a local level, we are members of the North Coast Marine Manufacturing Alliance (NCMMA) and the Northeast Wisconsin Manufacturing Alliance (NEWMA). These groups focus on promoting manufacturing through connections with local schools, universities, workforce development boards, chambers of commerce, and state organizations. To date, NEWMA has sponsored over $500,000 in college scholarships over the past 20 years.

“Elsewhere, at corporate level, MarineMax has been such a positive influence with their focus on employee and community outreach. A great example is their newly-created Crew Care Relief Fund, an amazing program to help team members who need financial assistance following an unforeseen disaster or personal hardship. Their commitment to employees has been evident since day one and goes a long way in building trust with the entire team and community.”

In 2021, the company was purchased by MarineMax, the world’s largest retailer of recreational boats and yachts.

Through this key partnership, and ongoing relationships with independent dealers, Cruisers Yachts distributes its products and interfaces with customers.

“While distribution of our yachts is mainly focused across the US, we ship products all over the globe,” he confirms.

Over the past three years, the company has invested close to $15 million in new equipment, facility upgrades, and expansion, with a focus on employee safety, plant cleanliness, product quality, internal capabilities, and output capacity.

In addition, Cruisers Yachts has recently implemented new systems and processes that are designed to

foster a culture that understands the importance of receiving feedback.

This valuable feedback loop allows the company to make changes to improve its end products and increase efficiency.

Cruisers Yachts currently has three key product lines of vessels ranging from 34 to 60 feet (ft) in size.

“Our Grand Luxury Sport (GLS) line-up ranges from 34 to 50ft and is categorised in the bow rider segment. These models have a focus on exterior entertainment with spacious interiors,” Delforge sets out.

Meanwhile, the company’s Cantius models are cabin cruisers that range from 42 to 60ft. These vessels feature a larger enclosed interior volume but maintain a focus on exterior entertainment.

General Hydraulics (GHS) is a marine manufacturer specializing in swim platform lifts and side door hinge assemblies.

“Our swim lifts and side doors are manufactured and assembled here in the US at our plant in Clearwater, Florida. We have thousands of products out in the field, proving our experience and understanding in what this industry demands.”

GHS also manufactures all its lift and hinge components inhouse, including its stainless hydraulic cylinders which are manufactured and assembled at its primary facility.

“This process allows us to maintain the highest quality standards, enhancing GHS’s ability to quality control (QC) every aspect of lift and side door operation prior to delivery. Each component is comprehensively tested with its hydraulic pump package to its fullest capacity ensuring trouble free installation and operation.

“We are known in the industry for our innovative yet simple designs with reliability at the forefront of each concept.”

Over the last 25 years, GHS has developed proven QC and testing procedures.

The company’s QC processes are derived from the experience of over 15,000 swim lifts and more than 4,000 side doors installed in operation on vessels around the world.

“We are proud of our resolute zero-defect policy from the factory, and we are constantly adapting to ensure this industry leading standard is maintained.”

GHS has earned its place as the world’s largest original equipment manufacturer

(OEM) supplier of hydraulic platform lifts by delivering the best selection, proven quality, and unmatched customer service.

Family owned and operated for 35 years, the company has, to date, built, shipped, and installed over 19,000 hydraulic swim platform lifts for happy boaters and boat manufacturers around the world.

“Because our personal guarantee and professional reputation rides with each swim platform lift that we build, all mechanical parts are created in-house at our state-of-the-art manufacturing facilities. These

parts are never outsourced.

“Additionally, our huge product line of multi-purpose platform lifts means we have the perfect lift for every boat and for every boater. Furthermore, GHS’s extensive warranty and responsive customer service professionals ensure your complete and total satisfaction.”

GHS was created in 1998 to design and build reliable, durable, and multi-function hydraulic platform lifts for boaters and boat manufacturers.

“Our company got its start by filling a need for sea ray boats for a transom mounted hydraulic swim platform lift. The product sea ray used at the time was a telescoping lift that proved to be unreliable and needed to be replaced and upgraded.”

Through extensive research and firsthand feedback from OEMs and customers of the existing style lift, GHS engineered and developed a panographic lift. This design eliminated the complexity of a telescoping lift and over time has proved to be the reliable, flexible platform swim lift demanded by boaters around the world.

GHS manufactures a large array of hydraulic platform lifts and platform lift packages for boats 36 feet and larger. “All of our current model lifts are built using our original, proven designs and advanced technology. Years of experience and utilizing skilled craftsmen have allowed us to become very efficient and successful at adapting our technology to fit most of the various and complex transoms of today’s boat market without a drastic increase in price to the consumer.”

Regardless of boat manufacturer, GHS can build the Right Swim Lift or Side Door for your application.

Since its beginning, GHS has built and released more than 19,000 units worldwide, firmly establishing the company as the world’s largest OEM supplier of hydraulic platform lifts and side-door assemblies. GHS’s design capabilities and manufacturing expertise has earned it a growing customer list featuring the most recognized boat manufacturers in the business.

“Our customers include Sea Ray Boats, Marquis Yachts, Carver, Four Winns, Cruisers, Regal, Chapparral, Scout, Tiara, Aquila, Intrepid, Formula, Pursuit, Mastercraft, and many other premier boat builders around the world.”

GHS is a subsidiary of Southcoast Marine Products, one of the nation’s largest manufacturers of custom, production-type marine hardware. The company’s state-of-the-art facilities house the latest in manufacturing and machining technology and tools including:

• Over 65,000 square feet of manufacturing space

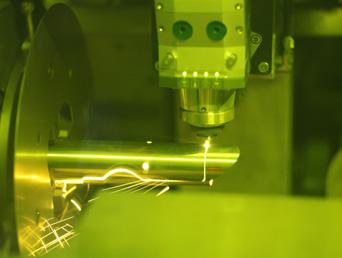

• 6000 and 10,000 watt Bystronics & BLM Plate and Tube Laser cutting Systems

• Bystonic 150-ton and Strippit 120-ton 5 axis press brakes

• 350-ton press

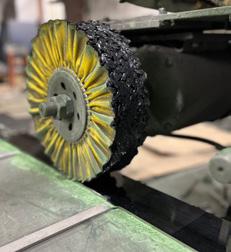

• Computer numerical control (CNC) robotic welding and polishing

• BLM CNC Tube Bender Elect 80B

• Hand benders, hand polishing, and CNC machining capabilities

“Our combination of tooling capabilities and experienced craftsmen allows GHS to be the

only platform lift manufacturer to manufacture all mechanical aspects of its lifts in-house. This provides an unmatched level of quality control throughout the building process.”

Each GHS platform lift includes:

• Complete mechanical lift assembly

• Adapter bracket assembly (if needed)

• Bulkhead fittings

• Hydraulic pump assembly with anti-float (as needed) backup alarms, backup hand pump

• All required interior hoses

• All required exterior hoses

• All required installation fasteners, fittings, and backup washers

• Detailed owner’s manual

• Hard-wired handheld control with required harness

• Rocker switch with switch panel and required harness

• One gallon of hydraulic oil

“AS A DESIGNER AND BUILDER, WE’RE EXCITED BY THE CHALLENGE OF CREATING UNIQUE SOLUTIONS FOR CLIENTS WITH EACH OF OUR VESSELS”

– JOSH DELFORGE, VICE PRESIDENT OF ENGINEERING AND OPERATIONS, CRUISERS YACHTS

customer requests, changes in market trends, or interruptions in the supply chain without disrupting production.

Another vital differentiator is Cruiser Yachts’ commitment to its customers and their boating experience, which is overseen by a service team at both dealer and corporate level.

“We often talk about how the yachting world is small, yet we have many customers who have owned multiple boats and built a relationship with the service team over time,” Delforge reveals.

With a majority of its customers located in the US, a simple phone call to the factory in Wisconsin provides clients with the answers or parts needed to keep them happy and on the water.

“The newest addition to the fleet is our 57 FLY, which debuted in November 2024. The new FLY series redefines on-water luxury with a bold design, unmatched flybridge entertainment, seamless water access, and an interior created in collaboration with superyacht designer, Luiz De Basto,” he excites.

Elsewhere, one critical element that defines Cruisers Yachts’ portfolio of

boats is vertical integration.

“We design and fabricate 99 percent of our own tooling, fiberglass, cabinetry, metal components, electrical wiring, and upholstery.

“This gives us control and visibility of the build process from start to finish, ensuring the highest levels of quality.”

This also gives the company the required flexibility to react to

As a yacht builder, the company’s goal is to provide its customers with a wonderful boating experience at all times.

“To do that, we rely on having strong partners when we source parts, many of which we have done business with for decades,” Delforge expresses.

As such, Cruisers Yachts is always striving to find creative solutions

BOMON Marine is a trusted, family-owned company based in Montreal, Canada, with a rich history that spans over four decades. Founded in 1982, BOMON Marine has been a leader in the production of high-quality, custom-made windows, doors, and hatches for a wide range of applications, including pleasure crafts, commercial, and industrial sectors. Now run by the second generation of the founding family, BOMON Marine continues its legacy of craftsmanship, innovation, and commitment to meeting the diverse needs of boat owners, builders, and businesses alike.

The company’s focus is on providing versatile and tailored solutions for marine and industrial applications. BOMON Marine specializes in crafting bespoke products that meet both the aesthetic and functional demands of its customers. Whether you need an individual replacement door, window, or hatch for your boat or are a major boat builder looking for high-volume custom solutions, BOMON Marine offers products designed with precision and durability in mind.

Over the years, BOMON Marine has expanded its offerings and expertise to include a variety of custom doors, windows, and hatches. These products are built to stand the test of time, engineered with advanced materials and cutting-edge techniques that ensure they perform under the toughest conditions. The company’s extensive experience in manufacturing bespoke products allows it to meet a wide array of requirements for both small vessels and large commercial projects, ensuring quality and reliability across the board.

A key feature of BOMON Marine’s product line is its madeto-measure approach. No matter the boat’s make, model, or year, BOMON Marine has the expertise and extensive database to find the perfect solution. Clients simply need to provide details about their boat, and BOMON Marine will take care of the rest, ensuring that the custom windows, doors, or hatches fit perfectly and function flawlessly.

BOMON Marine offers a variety of window types, including fixed, sliding, porthole, and hinged designs, each crafted to provide ease of use, optimal visibility, and enhanced durability. The windows are designed for easy installation, requiring no screws or holes to be drilled through the hull of your boat, which minimizes the risk of leaks and preserves the integrity of your vessel.

Whether you are looking for a single replacement window or outfitting an entire fleet of boats, BOMON Marine’s ability to deliver high-quality, custom products tailored to your specific needs sets them apart. Their dedication to craftsmanship, innovation, and customer satisfaction has earned them a loyal following and a reputation as one of the most reliable providers of custom marine windows and doors in the industry.

From its humble beginnings in Montreal to its continued success as a second-generation family-run business, BOMON Marine has stayed true to its roots of delivering exceptional products and service. With a rich history of producing custom, high-performance solutions for the marine industry and beyond, BOMON Marine remains committed to maintaining its leadership in the field of custom windows, doors, and hatches for years to come.

In a world where quality and precision matter, BOMON Marine stands as a beacon of trust, providing customers with reliable, made-tomeasure solutions that ensure their vessels are equipped with the best products available.

and the best possible materials for its vessels.

“It is very easy to find someone to sell you materials, but we value a partner that is focused on getting us the right materials for the applications. We also take into account the technical support services that many of our partners offer,” he tells us.

Across the entire sector, there has been an explosion in the use of new outboard drives, with the technology becoming more accessible and

integrated throughout the wider yachting industry.

As Cruisers Yachts develops new features, the ultimate goal is to find partners willing to think outside the box and get creative in finding the best possible solutions.

“For our fold-down beach doors, we partnered with the team at General Hydraulic Solutions (GHS). They have always been great to work with and they embraced this new challenge.

“Their system is extremely robust,

which gives our doors a solid feel; at the same time, we achieve a very clean look because of the internal pin mechanism. As a builder, any supplier as open and willing to take on new projects as GHS would be considered a win,” Delforge gushes.

The primary focus for Cruisers Yachts in 2025 is on new product development and continuous improvement throughout its operations.

“Keeping our product line current and staying on top of trends is a key priority. With a five-year plan to spend over $25 million on new product development, much of our focus is on design and engineering,” Delforge elaborates.

As of today, the company remains in the build phase of three new models with a further two in the concept stage. These new yachts will play a big role in continuing to diversify Cruisers Yachts’ product line

going forward.

Furthermore, continued investment into design and engineering shows the company’s resolute commitment to long-term growth.

“Our teams understand the business and have suggested many improvements, implemented methods to enhance and develop our products, found efficiencies in the building process, and curated a culture of pride,” he concludes.