DERMOT 0427 580 467 11-13 Lomax St, Millmerran QLD 4357 For all You Earthmoving & Excavation Needs Take control of your fleet • Track tyre usage: Gain insights into performance and usage. Rim certification: Ensure the safety and reliability of your rims to prevent accidents and downtime. • Prevent premature tyre failures: Identify and address issues early to avoid costly problems. Operator training and on-site feedback: Empower your team with the right skills and provide real-time insights to management. Track performance and actual cost per hour • Tread utilisation: Ensure efficient usage. • Customised reports: Get the data that matters most. Supply security forecasting: Stay ahead to keep operations running smoothly. Save through effective tyre management Enhance performance and profits through customised reports: • Interactive graphical analysis: Visualise data for quick insights. Evaluation of tyre-related issues: Identify potential problems and take corrective action. • Productivity and cost efficiency recommendations: Benefit from expert advice to optimise operations. • Initiative implementation: Use findings to maximise operational value. In today’s ever-changing business environment, optimising your tyre and wheel assets is crucial, whether you have a large fleet or just a few vehicles. KEEP YOUR WHEELS TURNING Talk to the experts today about transforming your tyre and wheel management. 1800 897 336 | tyredoctor.com.au BRISBANE BLACKWATER KALGOORLIE LEETON MACKAY SINGLETON SERVICES Tyre repairs • Tyre bay tooling Rim testing and repair Valving & components Tyre fitting • Tyre & wheel management Inspections

INNOVATION IN EXCAVATION

Since the beginning of civilisation, earth’s resources have been mined and subsequently used to make energy, manufacture, and create wealth and trade. Contract Mining has been a part of this in some form or another.

Fast forward to the 21st century, and the global mining industry is booming, as a multitude of elements and rare minerals are in high demand as a direct result of the introduction of new technologies, energy solutions, and goods that are required across

the world. Today, contract mining services play a major role in mine site development, the extraction of ore, and mine site rehabilitation – through to mine closure works.

Mining in Australia is a vast industry that remains famous worldwide due

2 | Mining Outlook Issue 6

UNEARTHING AUSTRALIA’S MINING POTENTIAL

BUMA Australia has a vision to build a modern mining and rehabilitation company, that drives growth, sustainability, and prosperity. We dig deeper into the company’s story with COO, Russell Taylor, and General Manager –Rehabilitation, Ngaire Tranter

Writer: Ed Budds | Project Manager: Eddie Clinton

to its fascinating history, power in the export market, and its role as a trendsetter in ‘futureproofing’ the wider mining sector.

Furthermore, the high quantity of mining sites in the country means that the industry provides a sizable

prospective job market for Australian citizens, as well as for the number of foreign workers who want to work in the field due to its esteemed global standing.

The Australian mining industry has become more efficient at extracting

maximum product but in a more sustainable way. No longer is mine site rehabilitation an afterthought to mine development, it is planned for at the pre-feasibility stage of the mine life cycle. New technologies are being embraced in rehabilitating mined

Mining Outlook Issue 6 | 3 BUMA AUSTRALIA ASIA PACIFIC

Back to The Future in Transportation

Acompany with old-fashioned values is delivering modern and innovative approaches to BIBO services and mine fleet hire with environmental standards at the forefront.

L&F Transfers are in the business of getting people where they need to be, safely, in comfort, and on time.

At a time when the safety and wellbeing of staff is at the forefront of every procurement manager’s mind, choosing a company that prides itself on safety, reliability and professionalism is essential.

L&F provides not only this, but a flexible and dynamic approach to transport solutions and a focus on building strong relationships with clients.

L&F offers total passenger solutions and management.

Currently servicing Queensland and South Wales, with a strong presence in Central Queensland.

Our depots and workshops

• Yeppoon

• Blackwater

• Emerald

• Charters Towers

• Gin Gin

Founder and CEO Lindsey Ward’s foundation partnership was with the John Holland Group at the Jellinbah Plains mine, owned by the Jellinbah Group. Today the partnership is stronger than ever with an ongoing commitment that will see them through to 20 years of collaboration. Thanks to continued partnerships with industry leading companies such as Jellinbah, BUMA, Sojitz, NQM and Evolution to name a few, the Yeppoon based business continues to thrive and grow.

General Manager, Nathan Turner, has been with the company for five years and in that time, he’s overseen rapid growth and the expansion from bus services exclusively into mine fleet hire. L&F Fleet Hire has grown to more than 80 fleet hire vehicles from five to 57 seaters.

“We have focused on providing highly adaptable and reliable workforce transport solutions to support the mining and resources industry and local communities,” Nathan said.

“We do not keep coaches older than five years in our fleet. In fact, we aim to turn our fleet over at three years. We do this to ensure reliability, safety, and lower emissions. This year we’ve taken ownership of six Yutong C12 Clean Euro 6 emission compliant engine coaches.

“These coaches are equipped with state-ofthe-art technology including advanced safety systems and the best fuel efficiency on the market resulting in a minimum of 20 percent reduction in emissions. In every new bus we also install a Guardian driver monitoring system, a driver fatigue, distraction and accident prevention solution. We also have the ability to access live stream CCTV.

“It is undeniable that our partnership with our customers is our strength and superpower.”

“We take the view that every person on every seat is our client and it’s our responsibility to get them home safely” Nathan said.

L&F Transfers gives back to the communities in which it works, providing thousands of kilometres of bus and coach transfers every year.

VALUES:

• Safety is our number one priority: we ensure everyone makes it to their destination safely.

• We’re on time, every time – 15 minutes leeway is our limit, or it’s free

• We’re available around the clock, 24 hours a day, 365 days a year.

• We’re professional - you can expect honesty, integrity and transparency when dealing with us.

• We provide good old-fashioned service that is personal, courteous, genuine, and friendly.

SAFE, RELIABLE, AVAILABLE, PROFESSIONAL AND GREAT SERVICE

L&F forming partnerships and relationships 1300 731 528 | enquiries@lftransfers.com.au | www.lftransfers.com.au

L&F Fleet Hire’s main operation is in Central Queensland, but it offers services right across Queensland and New South Wales, providing:

• Mine-compliant light vehicles

o 4WD Wagons

o 4WD Utes

o 4WD and 2WD HiAce’s

• Buses and coaches

• Tailored fleet solutions

• Network of mechanical workshops

• Highest standards for safety, reliability, and functionality

• 4WD bus conversion kits – they are the Central Queensland dealer for EnduroCo.

L&F Fleet Hire provides safe, efficient and adaptable fleet hire to support the mining and resources industry and local communities.

MINING OUTLOOK: HOW DO YOU EMPOWER YOUR STAFF AND RECOGNISE THE VALUABLE CONTRIBUTIONS THAT THEY MAKE?

Ngaire Tranter, General Manager

– Rehabilitation: “People are our greatest strength at BUMA and remain central to our ongoing success. We provide meaningful career development opportunities for our employees so that they feel both challenged and fulfilled at work.

“We are a beliefs-driven organisation, and we believe that our commitment to our core values of safety, integrity, progress, collaboration, and people further facilitate the process of creating a positive work experience for all of

areas and also in the monitoring and maintenance of the rehabilitated land.

The mining industry currently finds itself in a dynamic period of change, as the collective focus has turned to developing efficient mechanisms to manage environmental and social considerations, whilst maximising resource extraction.

Additionally, the industry as a whole is striving for an enhanced quality of rehabilitation as opposed to a focus simply on obtaining quantity.

BUMA Australia (BUMA) is well placed to provide this high-quality rehabilitation delivery and practices, which is demonstrated by the work it has conducted for clients in the past, and present and will continue to do so in the future.

“With the increase in prescriptive compliance in environmental licensing, we’re currently working closely with our clients in the implementation space to essentially operationalise planning documentation that is designed for

seeking environmental approvals and associated licensing,” introduces Ngaire Tranter, General ManagerRehabilitation of BUMA.

AUSTRALIA: A HISTORICAL MINING GIANT

At present, approximately 1.2 million people are employed in the Australian mining industry, with the sector’s net worth of exported resources totalling an estimated AUD$160 billion.

Existing as a nation with an abundant supply of metals and materials, the country has naturally enjoyed a long and successful mining history, dating back to its first human habitation around 60,000 years ago.

The First Nations people initiated Australia’s first-ever mining operations, which included fossicking for stones suitable for weapons and tools and digging for ochre. This was then used for making pigments for the paint used in rock art and body painting, forming an integral part of their culture and distinctly unique heritage.

8 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

AUSTRALIA’S TOP MINING RESOURCES

As seen throughout its past, Australia is home to a wealth of materials that the nation has mined and exported to help drive its economy. Historically, the top four mining resources have been:

IRON ORE – Australia has been exporting iron ore, its most significant source of export revenue, since the 1960s, first helping to support Japan’s post-war redevelopment.

COAL – Australia is the biggest coal exporter in the world. As well as being vitally important to the export market, coal helps fuel the country and is primarily used to produce around 80 percent of the nation’s electricity needs.

Australia’s biggest coal mine is Peak Downs, located in the Bowen Basin in Queensland.

GOLD – With a history of gold rushes and an abundance of gold resources, it is no surprise that Australia continues to be a prominent focus in the world’s growing demand for gold. In 2021 alone, the country’s gold exports totalled 257 tonnes.

Its biggest gold mines are in Western Australia (WA), including the Boddington Gold Mine, and the Kalgoorlie Super Pit. As the country holds the title of the largest gold mine reserve in the world, there is no sign of Australia’s gold mine industry slowing down any time soon.

URANIUM – Australia is the world’s fourth largest producer of uranium, behind Canada, Namibia, and Kazakhstan, and holds 28 percent of the world’s known recoverable uranium resources. Due to the potential uses of the material, Australia exports it worldwide to countries that have agreed to use uranium for peaceful purposes only.

Later, upon the arrival of European settlers to Australia, the process of large-scale mining truly began. The first reported discovery of coal occurred in 1791 and was found by a family of escaped convicts, William and Mary Bryant, and their children.

This defining discovery was unearthed just three years after the arrival of the first fleet of settlers. The exact location of the find is unknown, but it is believed to have been located in Glenrock Lagoon in the Newcastle and Hunter regions of New South Wales (NSW).

Eight years later in 1799, coal was being exported with shipments that were sent regularly to India, thus initiating a long and prosperous history of exporting mined materials.

Lead mining began in 1841, which was shortly followed by copper in 1842. Both resources were regarded as monumental developments for the Australian economy, with the subsequent gold rush era in the 1850s catapulting the nation firmly onto the global map.

Mining Outlook Issue 6 | 9

Finding the Right Mining Solution for You

Over the past six years, Ostwald Steele Electrical Pty Ltd (OSE) has operated heavily across the East Coast of Australia as one of BUMA Australia’s key partners through delivering high-quality professional trade labour, developing safety improvement products, efficiency solutions, and being utilised as the leading electrical contractor on various infrastructure projects within its operations.

Having developed and continually growing a solid team of value-driven professionals, OSE covers much more than just mining equipment maintenance. The company is known for its ability to resolve complex issues through ‘Expanding Solutions’ paired with the belief that anything is possible.

OSE’s mission to provide elite maintenance trade services and industry solutions for mining, commercial, industrial, and residential operations and contractors is achieved alongside BUMA Australia and has played a huge part in the growth and diversification of OSE’s services offered to BUMA and the wider industry.

Having diversified teams specialising in their own unique fields - mining maintenance, electrical contracting, and product R&D, OSE’s team comprises multiple trades and industryrelated talent, i.e., electricians, HD fitters and mechanics, auto electricians, refrigeration mechanics, servicemen, and apprentices. Externally, OSE partners with quality and valuealigning companies as a strength in its product development and infrastructure fields.

Having a permanent workforce allows OSE to invest in its people and their careers, resulting in a team of professionally developed tradespeople who remain consistent in innovation, quality, and efficiency while greatly assisting with closing the trade shortage gap by cross-training and upskilling its workforce in overlapping trade and industry fields.

MINING MAINTENANCE

OSE prides itself on machine availability and increasing companies’ overall productivity.

What sets the company apart is knowing and understanding the value and importance attached to having a wellmaintained and readily available fleet of equipment operating at maximum capacity on a consistent basis. Having internal targets clearly communicated to both the team and clients, OSE delivers results from the ground up, maintaining a smooth mining and production operation for every client.

Specifically, the company has a professional focus on electrical technology and equipment advancements across various industries and a solution focus on upskilling its workforce to align with the evolving needs of its clients. OSE invests heavily in cross-training electrical and mechanical fields, offering dual trade apprenticeships to ensure its people are as technically skilled and knowledgeable as possible on heavy equipment electrical adaptation. OSE is known for providing extra value to its client’s maintenance operations and always maintaining a positive company culture.

With a deep understanding of defect management, machine

With a deep understanding of defect management, machine schedules, and thorough preventative maintenance, OSE reliably ensures the highest level of maintenance for every mining fleet. With continuous advancement and innovation, the OSE team operates with the utmost attention to detail to achieve fast diagnosis and repair of any and all breakdowns, ensuring minimal downtime and protecting operational yield. With values that include the promotion of integrity and transparency, solutions and success, risk management and a safe environment, and the professional development of the people who encompass OSE, the company is set to be the leading global resource for professional trade skills and industry solutions within the energy sector.

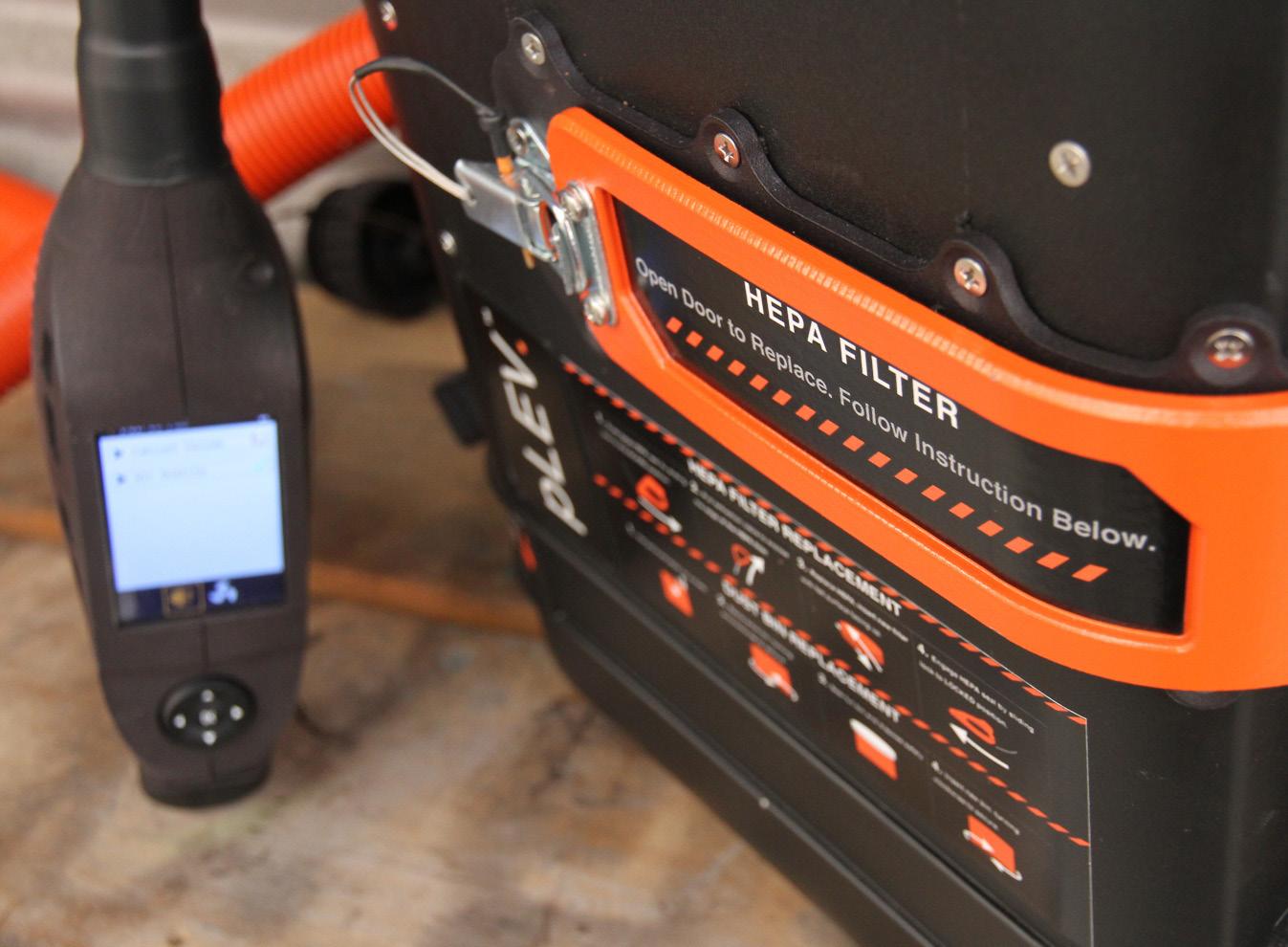

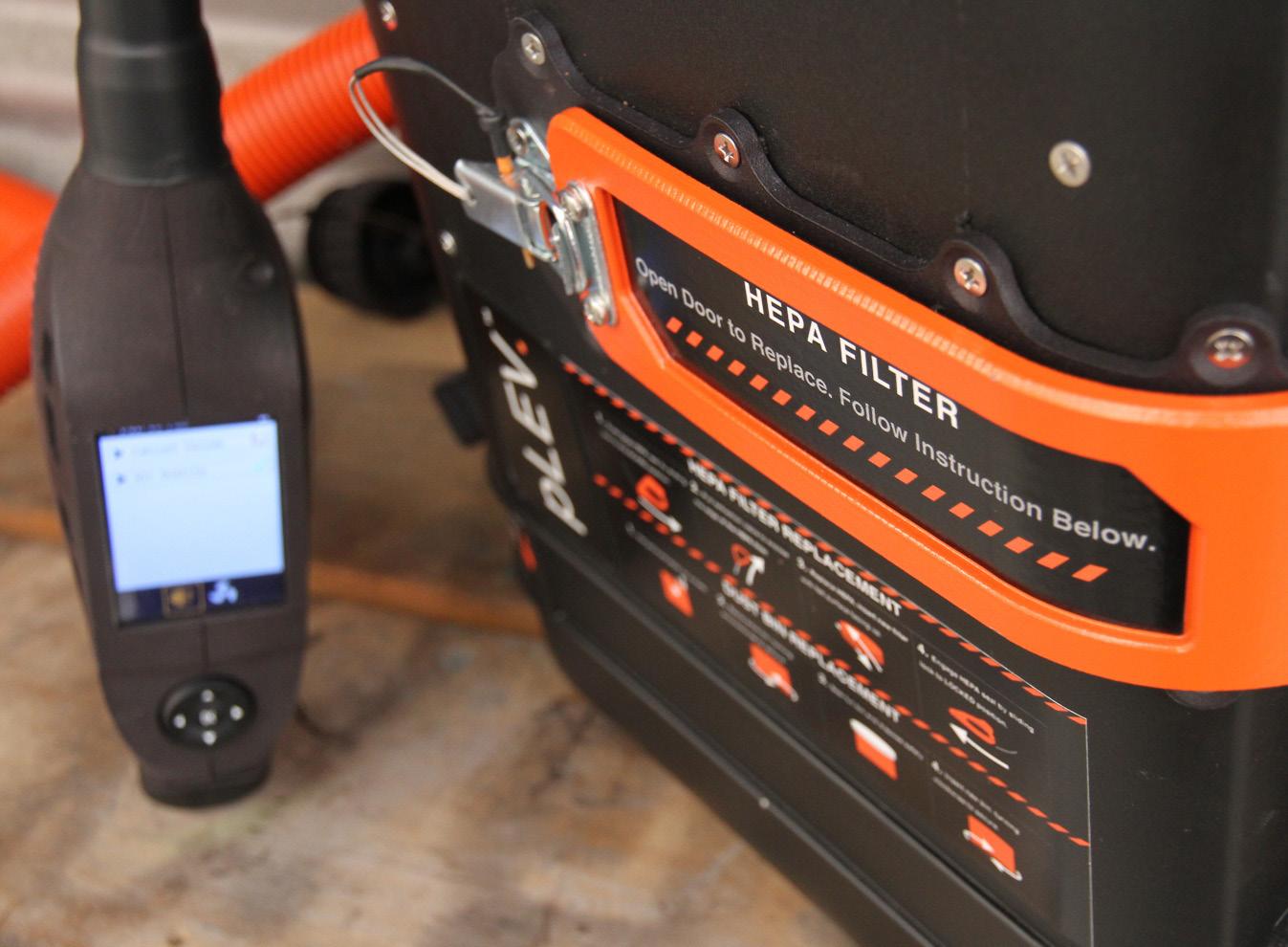

PROTECTING PEOPLE WITH pLEV™

With silicosis currently playing a dominant role in mine workers’ health deterioration, professional bodies, including the QLD mines inspectorate and regulatory bodies, identified an area of high exposure to hazardous respirable substancesthe practice of cleaning fine dust from electrical components. After this discovery, OSE went searching for a solution to ensure the protection of its team and industry professionals.

Co-developed with Australia’s leading air quality engineers Synergetics, the pLEV™ system (portable Local Exhaust Ventilation) is an air-operated cleaning system used to effectively clean electrical cabinets and components on electro-mechanical mobile plant and mining equipment. pLEV™ can be adapted to most mining air cleaning tasks where dust exposure is a concern, including:

• Electrical cabinets

• Switchboards

• Electric motors

• Alternators

• MG sets

• Drive motors

• Grids

The pLEV™ system works by creating negative pressurecontrolled environments in electrical cabinets. Dust is disturbed using the pLEV™ SmartLance and extracted safely and effectively using the pLEV™ Extractor.

pLEV™ Extractor is responsible for creating the negative pressure environment and the safe extraction of airborne dust. It has a dual-stage extraction fan that directs airflow through a HEPA-13-rated filtration system before then being released into the atmosphere as clean air. The portable extraction unit weighs under 14kg, is easy to work with and light to wear.

pLEV™ SmartLance HP (high pressure) enables the use of compressed air in the extraction environment. It features illumination, multivariable sensors for failsafe operation and optional cloud-based reporting. The SmartLance monitors particle exposure through air quality sensors with failsafe shutdown technology at the ready if an unlikely exposure event occurs. Negative pressure sensors are fitted to the SmartLances to prevent use outside the operational environment and to avoid accidental exposures.

pLEV™ SmartLance EX (exhaust) houses all the same safety and failsafe technology as the SmartLance HP but uses exhaust air directly from the Extractor to dislodge dust. Intended for use as a field unit, this air supply option allows for easier transportation due to the elimination of the need for compressed air.

pLEV™ Covers are lightweight, durable, and tailored to most common electrical cabinets and components. The covers are used to seal the cabinet to create a negative pressure extraction environment and minimising the risk of potential dust exposure. pLEV™ Covers are designed to give the operator a clear view of inside the cabinet so that they can see what they are cleaning.

The pLEV™ system improves the health and safety of all those who work daily in mining maintenance by preventing hazardous dust exposures that occur through traditional cleaning practices on electrical cabinets and components.

EXPANDING SOLUTIONS

At its core, OSE is driven by the purpose of expanding solutions, dedicating itself daily to the growth of skills, safety, and technical expertise among its team. With a forwardlooking approach, OSE has evolved its services to align with the global shift towards cleaner living, emerging as a leader in comprehending, maintaining, and repairing electro-drive equipment and technology across various industry sectors.

The company’s commitment to sustainability is complemented by its investment in a permanent workforce.

This strategic choice not only fosters a team of consistently innovative and skilled tradespeople but also positions OSE at the cutting edge of technology. Through continuous research and development, OSE tackles challenges with a solution focused mindset, producing new technology and equipment that expands solutions and delivers optimal outcomes for clients.

The heart of OSE’s success lies in its unparalleled expertise in maintaining operational fleets and enhancing machine availability through defect management, machine schedules, and preventative maintenance, thus boosting overall

OSTWALD STEELE ELECTRICAL PTY LTD SERVICES

MINING AND INDUSTRIAL

• OSE offers a comprehensive range of services to industrial and mining companies, including electrical infrastructure projects and electrical contracting to specialised mining equipment maintenance contracts.

• With nearly a decade of experience in mining and remote electrical work, the company confidently offers everything from basic electrical installations to complex electrical repairs and system upgrades including renewable energy options and standalone power gen systems.

COMMERCIAL

• OSE is a trusted provider of commercial electrical services, offering quality electrical installations, repairs, and maintenance for businesses of all shapes and sizes.

• With experienced and certified electricians on staff, OSE provides comprehensive and reliable electrical solutions to meet any commercial need.

RESIDENTIAL

• With expertise in lighting, power, maintenance, and smart home systems, OSE offers comprehensive solutions tailored for homes, sheds, and outdoor areas.

• Whether it’s a new build, renovation, landscaping, or electrical upgrade, the team has the knowledge to bring any idea to life.

productivity for its clients. Internal targets, transparently communicated, serve as guiding lights, ensuring seamless mining and production operations. OSE’s unique focus on electrical technology advancements, workforce upskilling, and cross-training amplifies the company’s commitment to staying ahead in the ever-evolving landscape of technology and safety standards.

In response to the industry-wide challenge of silicosis and OSE’s commitment to protecting people, OSE collaborated with partners, including Synergetics, to pioneer the groundbreaking pLEV™ system. This portable Local Exhaust Ventilation system redefines safety standards, offering a meticulous solution for cleaning electrical cabinets and components, vastly minimising the risk of hazardous mining dust exposure from these tasks. Components like the pLEV™ Extractor, SmartLance HP, SmartLance EX, and Covers truly showcase OSE’s dedication to health and safety advancement.

OSE’s journey is marked by the cultivation of a team of value-driven professionals, a testament to its commitment to ‘Expanding Solutions’ and fostering a positive company culture. This ethos propels the company beyond the confines

of mere mining equipment maintenance, positioning it as a leader in resolving intricate challenges with an unwavering belief in the attainability of anything. OSE’s scope now spans mining, commercial, industrial, and residential sectors, made possible by a permanent workforce committed to unwavering innovation, quality, and efficiency.

0475 365 321 | mining@ostwaldsteele.com | www.ostwaldsteele.com |

BUMA COMPANY VALUES

BUMA’s vision is to build a modern mining and rehabilitation company, that drives growth, sustainability, and prosperity. The basis of this vision is the core values of safety, integrity, collaboration, people, and progress.

PEOPLE – BUMA’s greatest strength is its people, and the company recognises their history and values how they shape its future.

SAFETY – BUMA is dedicated to working safely and believes this is a mindset, a way of thinking, and a commitment to the well-being of its people, communities, and the environment.

INTEGRITY – The company is founded on good people doing good things. “We do what we say we are going to do” isn’t just a tagline for BUMA, as the company always deliver on its promises.

COLLABORATION – BUMA actively seeks collaboration with all stakeholders to find common solutions and positive outcomes.

PROGRESS – The company pursues growth and sees change as an essential part of its journey.

Gold was first discovered in NSW in 1823, and in the decades following, more and more influential finds were dug up across Australia.

The exciting news of the discovery of gold spread worldwide, and as people began emigrating to the country in huge numbers, population growth increased exponentially alongside fresh agricultural and industrial development. The transformations of the 1850s saw Australia producing approximately a staggering 40 percent of the world’s gold supply.

However, during the first half of the 20th century, the nation witnessed

14 | Mining Outlook Issue 6

a steady decline in mining activity, with new mineral finds becoming more and more scarce. Subsequently, during the second half of the century, Australia once again witnessed a resource boom, with discoveries including nickel, oil, natural gas, and uranium. These prominent discoveries prompted a resurrection of global interest in the country’s mineral resources.

AUSTRALIA: KEY MINING LOCATIONS

With abundant resources, it is no surprise that mining is so prevalent throughout Australia.

Specifically, Western Australia (WA) is widely considered the epicentre of Australian mining and a major force in the industry worldwide. It is home to a vast number of natural resources and some of the country’s largest mines

WA currently plays host to 98 percent of Australia’s iron ore and 60 percent of the country’s gold reserves. These plentiful resources mean that at present, more than 20,000 people in WA work in the mining industry.

These are particularly exciting times for the Queensland mining sector, as growing demand has meant that explorations for new mines have begun in the north and east of the state, with the potential to create even more jobs in the future.

In the 2021/22 financial year, the Queensland mining industry contributed a record AUD$94.6 billion to the Australian economy.

Staggeringly, despite its large number of mines and impressive economic contribution, the industry only takes up 0.1 percent of the state’s surface area.

Victoria, meanwhile, continues to play a significant part in the country’s mining history. In 1851, gold was discovered in Ballarat, which triggered the gold rush that gripped the country and the wider world. It is still a key location for the production of gold, brown coal, mineral sands and antimony today, and is filled with great potential for future mineral exploration.

Mineral projects play an important role in regional development within Victoria, whilst mining creates lucrative employment for regional Australians and supports a broad supply chain of businesses.

The state is additionally home to the Fosterville Gold Mine, the largest gold mine in Victoria. Exploration also proceeds elsewhere, such as in Glen Wills, an isolated mountain area near Mitta Mitta in north-east Victoria.

Recently, a spotlight has been placed on the growing demand for

green energy alternatives and battery technologies. Therefore, mineral exploration is widely underway with a particular focus on vanadium and lithium.

AN EXPLOSIVE START FOR BUMA

BUMA was established in 2021, to acquire the Open Cut Mining Business of Downer. This acquisition included the transition of all people, mining services contracts, assets, systems, and IP from a business that successfully provided mining services in diverse locations across many commodities since 1922.

In only two years of operating as BUMA, 750 new employees have joined the business, the number of operations has increased by 57 percent, and the size of the business has doubled. BUMA has exploded onto the Australian market and further strategic growth is planned.

BUMA’s rapid growth has been based on the quality of services that it provides its clients and its strict adherence to the company’s core values. BUMA pursues a relationship-based long-term approach and willingness to work with clients to ensure the mutual success of all projects.

“Ensuring we provide value to our clients through all stages of mining, including rehabilitation, is a mainstay of our business,” Taylor informs us.

With a strong focus on delivering optimal outcomes for our clients and a strong commitment to safety, innovation, and technology BUMA Australia has quickly become one of Australia’s leading mining contractors.

BUMA AUSTRALIA: DELIVERY AND COMMITMENT

BUMA is an established mining services provider currently operating several long-term contracts within Queensland. The company has been providing mining services for 75 years and has established, numerous longterm relationships within the industry.

Mining Outlook Issue 6 | 15 BUMA AUSTRALIA ASIA PACIFIC

“THE KEY TO OUR CONTINUED CONTRACT SUCCESS COMES FROM OUR FOCUS ON DELIVERING SERVICES TO MEET EVOLVING CLIENT NEEDS USING A FLEXIBLE AND ADAPTABLE APPROACH”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

BUMA’s current contracts are diverse, tailored to suit client requirements, encompassing a range of services from full mine operation, pre-strip, coal mining, processing plant maintenance and operation, and statutory management, as well as incorporating activities from greenfield development to closure and rehabilitation services.

With a strong commitment to safety, systems and technology, BUMA pursues a relationship-based, long-term approach to ensure the mutual success of all its projects.

“The key to our continued contract success comes from our focus on delivering services to meet evolving client needs, using a flexible and adaptable approach,” Taylor remarks.

“Our strength lies in our people,

with an experienced and diverse workforce of over 1,500 individuals, who conduct new-to-industry training programmes.”

Further to this, BUMA’s operational capabilities and technical services include mine planning, dozer push, dragline operation, load and haul operations, wash plants, and drill and blast across seven different sites.

BUMA also provides full mining services, including statutory roles, at both the Broadmeadow East and Burton mines. In addition to the Bowen Basin, the company has also provided full mining services, which include statutory roles and coal delivery to power stations at the Meandu mine for the last 10 years, as well as the Commodore mine for over two decades.

Underpinning every facet of the business, BUMA has established a set of core values that are applied daily throughout the business, and with a well-established history of successfully completing rehabilitation and environmental projects, BUMA now offers a full suite of services from mine development through to closure, including progressive rehabilitation as the mine advances.

“We have key operational sites that are actively working under Progressive Rehabilitation and Closure Plan (PRCP), which provides us with first-hand knowledge of rehabilitation delivery requirements under this new regime.”

BLACKWATER MINING PROJECT

One of the operations that BUMA is most proud of is the Blackwater Mine, which is situated in the Central Highlands of Queensland, known for its mining heritage and substantial coal deposits.

Blackwater is one of BUMA’s most established and successful projects, showcasing efficient operational practices, along with a steadfast commitment to safety, community, and our team.

As such, BUMA has been conducting truck and excavator pre-strip operations at Blackwater since 2012. Each year, the company’s fleets mine over 44 million banked cubic meters of material. To facilitate the efficient movement of this material, BUMA operates and maintains a substantial equipment fleet, which includes a Hitachi EX8000 excavator, three Caterpillar 6060 excavators, and a Hitachi EX3600 excavator. These are further supported by 28 Komatsu 930E and CAT 789 haul trucks.

Led by Project Manager, Freya Perrins, Blackwater’s success is a testament to the collective strength and expertise of its diverse and

16 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

seasoned workforce. The Blackwater project’s established training department oversees the site’s newto-industry programmes such as the First Nations work readiness initiative that has been operating since 2016.

The purpose of the work readiness initiative is to provide an introduction to mining life and offer helpful advice on potential career pathways in the industry. The programme covers topics that employees will face on a day-to-day basis to help assist those who are new to the mining sector or even the BUMA workforce.

Overall, this has had great success in preparing new-to-industry operators to be successful in securing full-time positions in the company.

“Diversity is a valued part of BUMA’s

employment approach, and we are committed to fostering a diverse and inclusive workplace that facilitates opportunity and respect,” Perrins tells us.

“Our focus on cultural inclusiveness is active and ongoing, and we are continually working to build our organisational culture with a focus on enhancing workforce diversity,” he establishes.

BUMA’s relationship with the community is a significant component of its business and the company’s reputation as a valued corporate citizen and community-conscious organisation has been achieved by consistently working closely with its neighbours. Subsequently, BUMA is committed to continuously

implementing this across all its projects.

The future of the company will depend on its ability to maintain its social license to develop, operate, and close mines consistently alongside its stakeholders’ expectations.

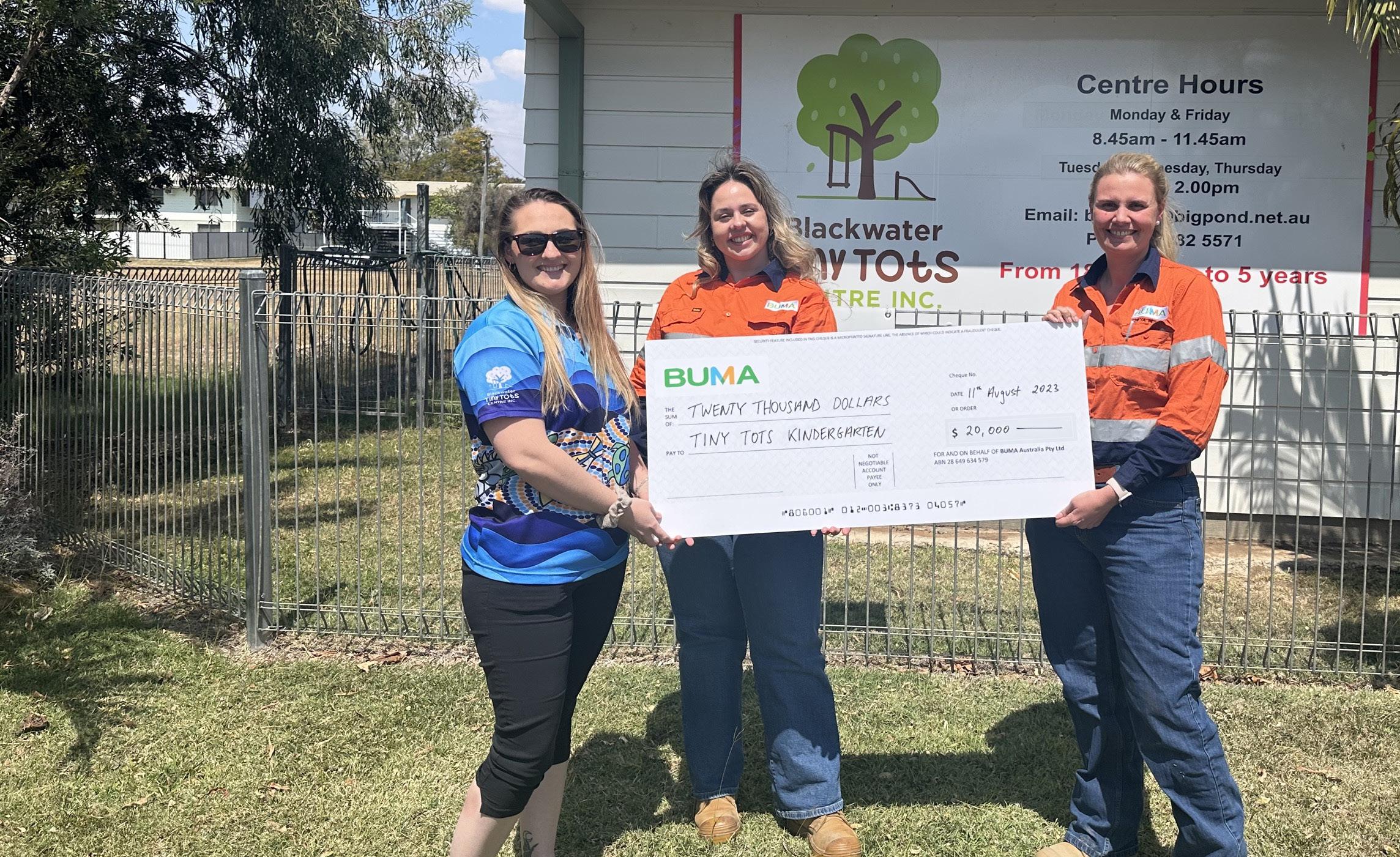

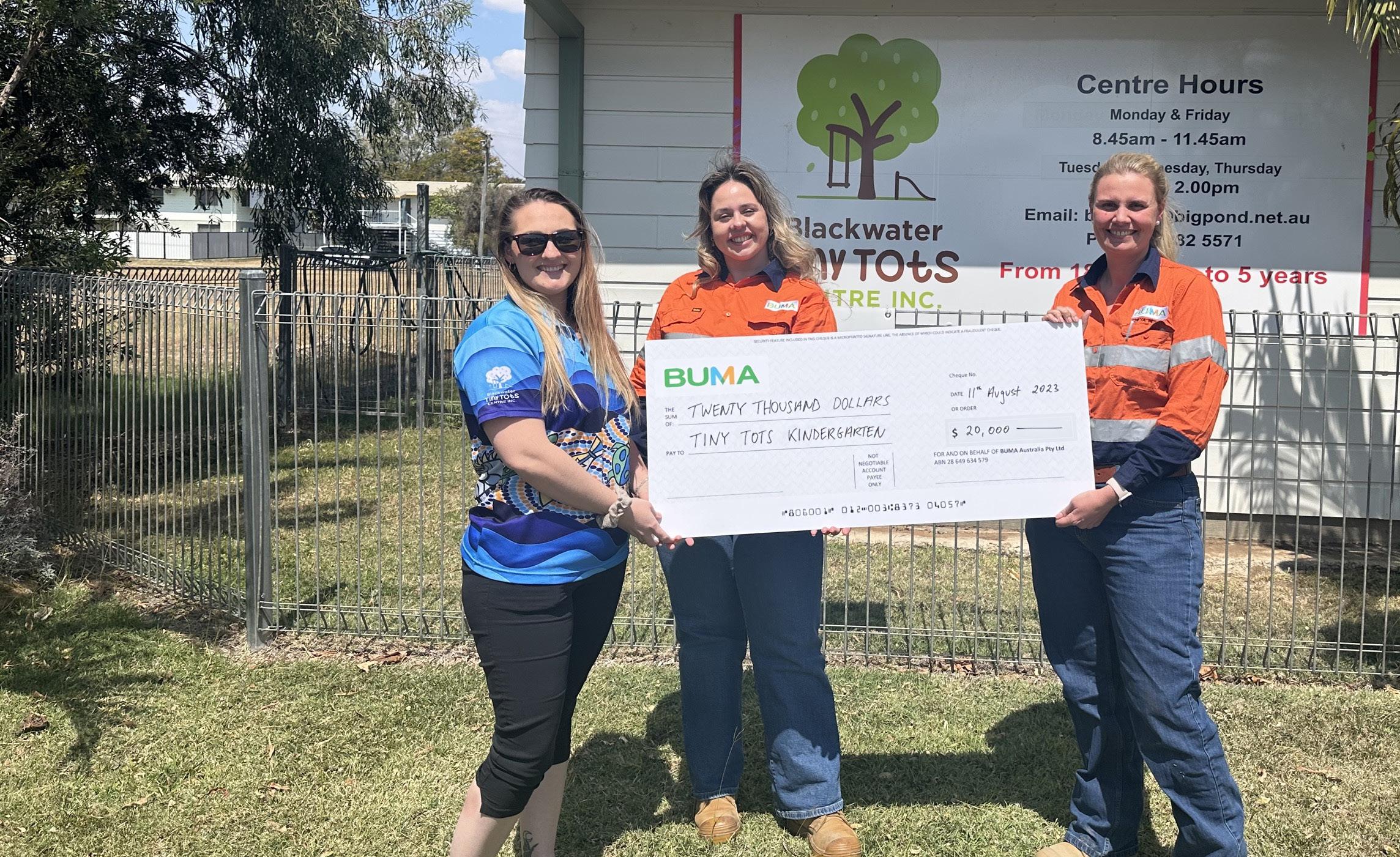

“At Blackwater, we highly value our community and continuously seek opportunities to assist both individuals and local businesses. This support extends to local goods and services procurement, as well as offering ongoing financial assistance to various local initiatives, including the Tiny Tots Kindergarten Centre, local youth football teams, and the Blackwater Police Citizens Youth Club (PCYC) Braking the Cycle (BTC) programme,” she adds.

BUMA AUSTRALIA ASIA PACIFIC

DRILLING INTO THE FUTURE

A trusted, family-owned company for over 45 years, built on honesty, integrity, and safety. Led by Gayle Coldwell and her son Brendan, our experienced team operates in Australia and the Asia Pacific region, delivering top-quality drilling services tailored to your needs. Safety, expertise, and commitment are our priorities.

Ph - 0456 961 485 enquiries@coldwelldrilling.com.au www.coldwelldrilling.com.au

Coldwell Brendan Coldwell

Gayle

Conclusively, the Blackwater Mine has consistently maintained a high level of operational efficiency and a strong commitment to safety standards. This achievement has been made possible through BUMA’s people, technology, and thorough safety measures.

BUMA OBJECTIVES

REHABILITATION PROJECTS

It has become a significant focus for BUMA to carry on delivering exceptional service in collaboration with its clients, BUMA recognises that there has been a significant investment into technical resources to develop rehabilitation and closure

To achieve the company’s vision, BUMA’s senior leadership and management:

• Take accountability for the effectiveness of quality management.

• Guarantee that all quality objectives have been set and are maintained adjacent to internal auditing and monitoring in order to enhance customer satisfaction.

• Promote the use of a process approach and risk-based thinking.

• Engage, direct, and support people to contribute to the effectiveness of the quality management system, encourage improvement and professionalism, and motivate employees

This list of policies is communicated to all employees, subcontractors, and organisations working for BUMA.

plans across the Australian mining industry. As such, the delivery of works in accordance with these requirements is paramount.

“We aim for long-term stable and sustainable landforms, with our focus firmly set upon efficiency in earth movements right from bulk earthworks through to the ongoing management and maintenance of completed areas,” Taylor comments.

“This, supported by our quality control and evidence-based monitoring processes, ensures that we support our clients in equally meeting their scheduled physical delivery and statutory reporting outcomes,” he furthers.

Today, rehabilitation activities at Stanwell’s Meandu Mine commence as soon as areas become available,

20 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

with over 930 hectares (ha) of native vegetation rehabilitation already completed across the site.

This year, the Meandu site is aiming to achieve an additional 41.5 ha of native vegetation rehabilitation. Significant work has already occurred, with the land profiled, topsoiled, and seeded earlier this year. Previously, during 2022, BUMA successfully completed 28.7 ha of native vegetation rehabilitation across the Meandu Mine.

“Our native vegetation rehabilitation areas, designed to meet the final post-mining landform, exemplify our commitment to safety, stability, sustainability, and adherence to environmental regulations,” Tranter shares.

“To ensure the project’s success, we thoroughly follow government

“OUR STRENGTH LIES IN OUR PEOPLE, WITH AN EXPERIENCED AND DIVERSE WORKFORCE OF OVER 1,500 INDIVIDUALS”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

regulations, incorporating specific design elements such as gradients, cover materials, and drainage systems.”

Similarly, BUMA also designed and constructed a network of rock-lined drains, utilising basalt rock sourced from the mine, to manage the overland flow and mitigate the risk of erosion.

“We place topsoil across the entire rehabilitation surface, drawing from on-site topsoil stockpiles that are assessed for quality, ensuring optimal performance for native vegetation

rehabilitation. To reduce the compaction of the cover material, we employ a single-pass method, which included the processes of fertilisation, ripping, and seeding,” he continues.

BUMA is committed to restoring the environment to its natural state, a promise that extends to its choice of seeds. Over 600 kilograms (kg) of seeds, comprising a diverse mix of species of trees, shrubs and grasses mirroring the local regional ecosystem, are spread across the rehabilitation site.

Mining Outlook Issue 6 | 21 BUMA AUSTRALIA ASIA PACIFIC

Culleton Contracting Pty Ltd (Culleton Contracting) is an all-encompassing and comprehensive bulk excavation and earthworks company, permeating many industries across Queensland and Western Australia.

With over three decades of experience, the company has progressed to become highly respected as a reliable source of excavation operations, regardless of the size and complexity of the project in hand.

Mining Outlook (MO): Please could you briefly introduce us to Culleton Contracting and tell us more about the company?

Kristy Presnell, Office Manager (KP): Culleton Contracting is a privately-owned, proprietary limited, Australian company based in South-East and Central Queensland. Established in 2020, we provide services for clients operating in mining, local and state government infrastructure, and land development sectors throughout the state.

Our continued and steady growth has been revolved around developing close, long-term working relationships with our clients. This is achieved by providing experienced people a variety of modern equipment using our internal expertise and knowledge, to deliver a wide range of contracts in a timely and cost-effective manner, whilst upholding the highest safety standards.

Culleton Contracting’s staff – consisting of approximately 40 employees - have extensive experience in projects, operations, and maintenance activities in a variety of heavy industries. These include coal and metalliferous mining, upstream and downstream gas transmission and facilities, marine services utilities including water and sewer lines, bridge and

dam construction, windfarms, solar plants, and the farming industry, including organic farms.

MO: What differentiates Culleton Contracting from the competition?

KP: Culleton Contracting is large enough to respond to our clients’ needs while being small enough to develop and maintain personal business relationships.

The company’s reputation is built on the commitment and dedication of all its employees, delivering outcomes that meet our clients’ specific requirements.

Our business supports the community and local groups by way of donations, attendance at community events, and supply of Culleton Contracting merchandise.

MO: Please could you elaborate on the company’s partnership with BUMA Australia? How long have you worked together and what is the nature of your interaction?

KP: Culleton Contracting, known as ‘Downer’ previously, has had a strong relationship with BUMA Australia for the past four years. We believe to be key partners to its operations, providing services and equipment for the client as requested. We have current agreements in place which are regularly reviewed by both parties for ongoing works on multiple BUMA Australia sites. We have also recently been given the opportunity to be a part of the company’s major editorial and marketing project.

MO: How do Culleton Contracting and BUMA Australia mutually benefit each other and what complementary strengths do you bring?

KP:

- Establishing clear goals and expectations: Building trust and communication through regular interactions, whilst seeking mutually beneficial opportunities for growth and innovation, whilst ensuring minimal impact on the environment.

- Prioritising open communication: Developing and maintaining the relationship with regular check-ins, sharing feedback, and establishing clear goals and expectations.

- Effective communication: Fostering transparency and nurturing mutual understanding by continuously exchanging knowledge, challenges, solutions, success stories, and needs.

- Identifying how Culleton’s strengths complement BUMA and how their strengths complement us: Working together as much as possible to bolster each other’s complementary strengths.

- Sharing media opportunities: Creating a mutually beneficial relationship where both companies will gain advantages from the exposure given by the press hit.

- Schedule regular meetings: Discuss new initiatives, products and services, promotional campaigns, and other growth activities.

MO: Could you tell us more about the company’s current projects?

KP:

- Supply of provision and open-cut mining equipment and services in accordance with good industry practice for BUMA Australia at Burton and Commodore Mines.

- Supply of material and rehabilitation works for the local power station.

- Works at Coolmunda Dam consisting of trenching, diversion, and pipe laying.

- Multiple civil jobs including farm works, road works, and fire protection methods for local properties.

- Windfarm project consisting of the construction of new pads, roadways, and drainage.

MO: Similarly, are there any projects in the pipeline Culleton Contracting is excited about?

KP: We have multiple tender applications in the pipeline for next year. The company is also excited to continue our strong relationship with BUMA Australia in the mining space, as well as focusing on civil works around our local area and beyond.

MO: How does the company try to empower its staff and recognise the contributions that they make?

KP: Culleton Contracting strives to foster an environment of trust and safety. We build employees confidence with recognition and incentives, offering flexibility in work arrangements, and asking employees for feedback and actioning it.

The company supports professional growth with coaching and delegation, showing appreciation and recognition, and supporting a balanced family/work lifestyle.

Furthermore, we have an excellent safety and industrial relations track record, being five years lost-time injury (LTI) free at our operations, and have enjoyed a harmonious, collaborative, and co-operative relationship with our workforce.

MO: Looking ahead, what are Culleton Contracting’s key priorities?

KP: Core Values

- Safety is our core focus and an integral part of all activities.

- Quality is an essential element of our business. Do it once, do it right.

- Minimising the environmental impacts from our activities. Our Commitment

- Continuous improvement, innovation, and repeat business development.

- The utilisation and implementation of safe and responsible work practices.

- A can-do approach whilst also working hard to understand our clients’ business needs and provide them with excellent service. This is demonstrated by our return client business.

- Conducting our business ethically, honestly, and with diligence always.

- Providing a work environment where our people are motivated and satisfied.

- Working under a self-performing model and delivering on our commitments.

Culleton Contracting Pty Ltd 11-13 Lomax Street, Millmerran QLD 4357 M: 0455 932 057 ABN: 6814 2244 522

BUMA CORPORATE GOVERNANCE

Strong corporate governance is an essential driver of BUMA’s operations and performance, and underpins the culture of its workforce.

The company’s governance framework is overseen by the BUMA’s board and executive leadership team. This framework enables BUMA to make sustainably responsible decisions and maintain strong relationships with employees, clients, and other stakeholders.

BUMA operates under a robust and transparent governance framework that applies across all operations and functions of the company. This framework provides a structure that ensures:

• Transparency

• Accountability

• Responsibility

• Independence

• Fairness

Each of BUMA’s employees has committed to a code of conduct that instils the high importance of compliance in everything the company does. The code also includes commitments in relation to:

• Individual behaviour

• Use of communication platforms

• Conflicts of interest

• Confidentiality of information

As such, BUMA source 25 different native seeds from a local supplier, further enhancing the project’s authenticity. In addition, the seed mix incorporated grasses, serving as a cover crop to facilitate the establishment of native vegetation.

“Among the species we have reintroduced to the Meandu Mine area is the Yarraman Ironbark (Eucalyptus crebra), a native variety indigenous to the region, as well as the Native Apricot (Pittosporum angustifolium), and the Brisbane Golden Wattle (Acacia fimbriata).”

BUMA’s unwavering commitment to conducting high-quality and progressive rehabilitation projects remains at the core of its central values.

“We are dedicated to ensuring the sustainable and responsible transformation of mining areas back to their natural state, embodying our commitment to the environment and community,” finishes Taylor.

COMMODORE BACK CREEK DIVERSION

BUMA’s Commodore Mine is located in a sensitive agricultural region close to the farms and township of Millmerran.

At this site, BUMA works closely with the local community to operate a safe and environmentally-responsible mining operation. Dust, excessive noise, and blasting restrictions are managed to ensure minimal impact, while special attention is also placed on the rehabilitation of the post-mine landform.

The post mine landform must be capable of supporting long-term primary industries, such as grazing. Furthermore, the site’s water management is achieved through the use of contour banks, sediment traps, and dams, separating mine run-off water from clean water in accordance with the Site Water Management Plan.

“Environmental sustainability solutions have been applied to all

24 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

Drill-Bourn Pty Ltd provides mechanical repairs and reliability consultation. Located in the Hunter Valley NSW supporting customers globally, as required

Drill-Bourn can carry out all machine upgrades and improvements. We’re not your run of the mill technicians, we believe in going above and beyond. That’s why we can also work with you to help evaluate and optimise your machine design, and collaborate with you to achieve low maintenance solutions that are better for your business.

OUR SERVICES

All machine upgrades/improvements consider machine design and target low maintenance solutions.

• Drill automation consultation

• Increased machine reliability

• Maintenance improvements and modifications

• Operator and maintenance training

• Parts support and supply

Successful Projects:

• Patented drill specific stands

• High density poly sheaves to reduce manual handling hazards

drillbourn.com.au Making Drills Great Again

aspects of the mine’s operations, including water recycling, waste management, and rehabilitation. The project is self-sufficient in its water use and prioritises best practice rehabilitation practices that minimise disturbance and protect rare grass species,” Taylor shares.

Additionally, the Commodore Back Creek Diversion Project is an earthworks civil construction operation designed as a meandering creek bed, comprising floodplains, terraces, and a clay-lined, low-flow channel. It has been constructed within the overburden and backfilled for rehabilitation of previously minedout coal seams.

The work involved the excavation and the localised placement of 30 ha of floodplain and terraces. The primary activity for BUMA was

NORTH END BOX CUT WASTE DUMP REHABILITATION

BUMA has completed the rehabilitation of the North End Box Cut waste dump rehabilitation in the Pilbara region of WA for Rio Tinto in 2022.

The project involved reshaping waste material and encapsulating it with waste cover. The slopes were then sheeted with rock armour before the final surfaces were topsoiled. In total, 80 ha were then reseeded using a dozer and the process of cross-ripping.

The project involved two load and haul fleets using excavators and articulated dump trucks. Larger off-road dump trucks were unsuitable due to the required gradients for the operations and because of the limited workspace. Additionally, a significant amount of dozer push was also required to assist in the reshaping and spreading of the encapsulated cover and subsequent topsoiling.

The client was satisfied that the work was finished to a high standard and exceeded their expectations in regard to First Nations engagement. The project was operated on-site with technical and management services provided by BUMA’s Brisbane office.

26 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

• Hydraulic service

• Metal fabrication, both light and heavy

• Sheet metal work

• Machining

• Line boring

• Sand blasting and painting

• Labour hire

• Retail outlet

• Plant and equipment hire Kingaroy Hydraulic Sales and Service (KHSS) has been in operation for 32 years. We are more than our name suggests. We provide the following services to our wide range of clients:

07 4162 1551 accounts@kingaroyhydraulics.com.au

the excavation and placement of a thick liner to form the low-flow channel. This was required to be placed, compacted, and tested to a highly intricate level of accuracy. The project scope also required topsoiling, vegetation, installation of timber habitat, and embankment construction for interim flood levees.

The project required a complete quality assurance programme to ensure all statutory regulations and environmental requirements were achieved to the highest standard.

The Commodore Back Creek Diversion Project attracted attention from a range of stakeholders, including heritage considerations, local community members, and multiple government departments.

Finally, the project was selfsufficient in its water use and

“OUR WELL-ESTABLISHED SYSTEMS AND PROCESSES COVER EACH PHASE OF A MINING OPERATION, FROM START-UP THROUGH TO OPERATIONS, AND EVENTUALLY CLOSURE”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

innovative rehabilitation practices were prioritised throughout to restore disturbed areas, recreate the original landform, and ensure strict adherence to reinstating original tree and grass species for the area.

SECURING A POSITIVE LEGACY

BUMA is resolutely focused on leaving a positive legacy through delivering high-quality rehabilitation and closure outcomes.

“We aim to contribute towards the establishment of thriving local communities during and after mining, through initiatives such as our Rural Seed Collective programme, which is focused upon delivering high quality, localised seed stock to mine rehabilitation and broader land regeneration projects within the regions we operate,” Tranter sets out. This initiative sees qualified environmental practitioners work

28 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

with landholders and community participants to harvest, and in some instances propagate, native plants via a certified programme that provides them with income, qualifications, and access to support for broader natural resource management initiatives.

“We believe that investing in this type of programme is mutually beneficial for the industry and regional communities, in that it reduces the risk of limited native seed supply, which is a common issue during intensive periods of rehabilitation on a region wide scale and provides additional income streams for landholders,” he affirms.

This programme also facilitates

access to new vocational pathways for a diverse range of individuals across BUMA’s communities.

Looking ahead, BUMA is now focusing on growing its rehabilitation services from bulk earthworks right through to ongoing maintenance and monitoring requirements. The company is also committed to contributing to adding long-term value for regional communities through the restoration of previously mined terrain, which allows for beneficial land uses well into the future.

“We know that here in Queensland, PRCP requirements are a primary focus along with the connection to

miner’s surety obligations under the Financial Provisioning Scheme,” Taylor sets out.

“We’re focused on ensuring that mining organisations can confidently plan on achieving compliant outcomes in accordance with their PRCP and internal rehabilitation delivery schedules in a way that makes commercial sense,” he culminates.

In summary, BUMA also understands how progressive rehabilitation feeds into broader closure planning considerations, and in this way, the company will continue to support its clients with rehabilitation trials which will contribute to positive closure outcomes.

30 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

KEEP YOUR WHEELS TURNING

In today’s ever-changing business environment, optimising your tyre and wheel assets is crucial, whether you have a large fleet or just a few vehicles.

Take control of your fleet

• Track tyre usage: Gain insights into performance and usage.

• Rim certification: Ensure the safety and reliability of your rims to prevent accidents and downtime.

• Prevent premature tyre failures: Identify and address issues early to avoid costly problems.

• Operator training and on-site feedback: Empower your team with the right skills and provide real-time insights to management.

Track performance and actual cost per hour

• Tread utilisation: Ensure efficient usage.

• Customised reports: Get the data that matters most.

• Supply security forecasting: Stay ahead to keep operations running smoothly.

Save through effective tyre management

Enhance performance and profits through customised reports:

• Interactive graphical analysis: Visualise data for quick insights.

• Evaluation of tyre-related issues: Identify potential problems and take corrective action.

• Productivity and cost efficiency recommendations: Benefit from expert advice to optimise operations.

• Initiative implementation: Use findings to maximise operational value.

SERVICES

• Tyre repairs

• Tyre bay tooling

• Rim testing and repair

• Valving & components

• Tyre fitting

• Tyre & wheel management

• Inspections & reporting

• Tyre bay equipment hire

Talk to the experts today about transforming your tyre and wheel management. 1800 897 336 | tyredoctor.com.au BRISBANE • BLACKWATER • KALGOORLIE • LEETON • MACKAY • SINGLETON

CONTRIBUTING TO COMMUNITY

Since 2016, BUMA’s Blackwater Mine has proudly supported local community organisations, including organisations such as the PCYC with financial assistance to help run youth programmes in the local community. These initiatives focus on various community needs, aiming to make a positive impact on the lives of young people and promote social cohesion through inclusive programmes. The mine is located adjacent to the town of Blackwater, where BUMA’s workforce is accommodated and integrated. The company endeavours to exist as a proud supporter of local community groups in the area.

The Blackwater site is also proud of its First Nations work readiness initiative that has also been operating

“AT BUMA, OUR COMMITMENT TO HEALTH, SAFETY, AND THE ENVIRONMENT MEANS PROVIDING A WORKPLACE THAT SUPPORTS THE WELL-BEING OF OUR PEOPLE AND CONDUCTING OUR OPERATIONS IN A MANNER THAT IS ENVIRONMENTALLY RESPONSIBLE AND SUSTAINABLE”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

since 2016. The programme has been triumphant in preparing new-toindustry operators to be successful team members of the broader BUMA team at Blackwater.

Elsewhere this year, BUMA Blackwater has proudly sponsored the BTC programme.

“The BTC programme gives our

local young people the ability to drive legally and safely on the road and accumulate their 100 log-book hours alongside a dedicated volunteer to help mentor good driving habits,” Perrins explains.

“Additionally, this programme improves employability and opportunities for young people as

32 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

MINE DEWATERING EXPERTS

Western Australia PERTH KARRATHA ALBANY KALGOORLIE Victoria MELBOURNE GEELONG New South Wales SYDNE Y South Australia ADELAIDE Queensland BRISBANE MACKAY Tasmania HOBART BURNIE Northern Territory DARWIN

lack of transport is a major barrier to attaining employment in Central Queensland.”

BUMA Blackwater’s investment in BTC is also an investment in each young participant and their future as they are empowered through road education to be safe and responsible drivers.

Meanwhile, BUMA also presently possesses a dedicated team of sustainability professionals as well as a broader corporate ESG framework which allows the company to develop initiatives that meaningfully empower its employees and present them with exciting opportunities, as well as facilitating the opportunity to contribute to the communities in which BUMA operates.

“We believe in transparency across the entire business, so

BUMA currently undertakes annual sustainability reporting on its own ESG impacts in accordance with the United Nations Sustainable Development Goals (SDGs) and the Global Reporting Index (GRI),” Taylor elaborates.

HEALTH, SAFETY, AND THE ENVIRONMENT

The health and safety of BUMA’s

people and the protection of the environment for future generations are of paramount importance to the ongoing success of the company.

“At BUMA, our commitment to health, safety, and the environment means providing a workplace that supports the well-being of our people and conducting our operations in a manner that is environmentally responsible and sustainable.

34 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

NITRO CRUSHING

As one of Australia’s largest and most reputable contract crushing companies, Nitro Crushing is a leading provider of contract crushing services and solutions. We are dedicated to meeting our clients needs through a determined focus on delivering outcomes with efficiencies while not compromising on safety, environment and personnel. We pride ourselves on being first adopters of innovative and technology advanced solutions to build efficiency for us and our clients. We have an extensive low hour, fully maintained fleet of crushing equipment.

BUMA Broad Meadow East Case Study

Nitro is proud to be a working partner with BUMA mining solutions, in Australia. BUMA approached Nitro to crush at the Broad Meadow East Coal Mine while the wash plant was under construction. Nitro slipped in effortlessly meeting the highest of standards with their machinery, systems and staff and hit the ground running to produce to target from the first instance. “We really enjoy working with a company like BUMA who has the same focus on outcomes and safety as we do” said managing director Trent Marino. “The staff at BUMA head office were great at letting us know what was required, the SSE and her team set the standards early and let us get on with our job without incident, hitting 100kt target per month in production.”

More than just crushing

Nitro Crushing owns and supplies fully equipped service vehicles with capabilities of oxy cutting, welding, conveyor belt repair, manganese replacement, breakdown repair and general servicing, thereby reducing any downtime which could impact the supply chain. We constantly keep a full range of parts in stock. Nitro Crushing has qualified diesel fitters trained in this industry, specialising in looking after quarrying and mining machinery. We also have a highly skilled team of boilermakers to assist in major repairs and maintenance.

The Go to in Crushing

Trent Marino – Managing Director of Nitro Crushing has over 15 years’ experience in the mining and quarrying industry, with a dedication and understanding to supply quality cost effective solutions to our clients.

In 2004 Trent started his Diesel Fitting apprenticeship in Cairns with the reputable Hastings Deering Pty Ltd QLD, working on all aspects of mining plant equipment and operations, completing his apprenticeship in 2008. In 2007 Trent expanded his career in the industry, starting works with local Quarries. Trent purchased crushers leading to the creation of Nitro Crushing.

Over the past 15 years Trent has devoted himself to creating an honest and reliable service with a high quality of workmanship, easy to work with, friendly, loyal, and approachable staff. Trent has the philosophy of buying new machines and keeping them in great conditions so he can be proud of his fleet.

We pride ourselves on our crushing and screening expertise. Our crews are led by experienced crushing professionals who have multiple years experience, and formal qualifications. Employees of Nitro Crushing have detailed knowledge and understanding of quarry material, specifications, and making big rocks into small rocks allowing us to crush anything anywhere in almost any conditions. Experience that ensures we achieve compliance. We operate under a fully integrated management system, delivering a quality and consistent finished product every time.

Managing Director - Trent Marino: 0439 712 867

General Manager - Hamish Jenkins: 0412 575 373 | manager@nitrocrushing.com.au

Therefore, all projects strive to exceed our client, stakeholder, and industry expectations,” shares Taylor.

Safety requires strong leadership and commitment. To ensure this, BUMA’s leadership teams set clear, positive expectations, actively involving its people to identify improvements, be accountable, and uphold industry-leading safety standards.

“We believe that everyone at the company has a responsibility for improving and maintaining health, safety, and environmental performance. Therefore, BUMA has an organisational structure to support the achievement of its targets and strategy in this area,” he adds. Underpinning this safety

“THE BTC PROGRAMME GIVES OUR YOUNG PEOPLE THE ABILITY TO DRIVE LEGALLY AND SAFELY ON THE ROAD AND ACCUMULATE THEIR 100

LOG-BOOK

HOURS ALONGSIDE A DEDICATED VOLUNTEER TO HELP MENTOR GOOD DRIVING HABITS”

–

FREYA PERRINS, PROJECT MANAGER, BUMA AUSTRALIA

commitment is a carefully constructed framework structured around leadership, risk, controls, planning, improvement, monitoring and enables BUMA to meet the correct legislative certifications.

The company uses various reporting and performance systems and controls to support its ongoing

commitment to the safety of its people and the environment, ensuring that it remains proactive in its approach to the mitigation of risks on each of BUMA’s sites.

Furthermore, BUMA recognises that a stable, educated, and focused workforce is essential for delivering a safe and productive project.

36 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

Transforming Tyre Management

Otraco International is the leading provider of off the road tyre management solutions in Australia.

Our team of highly skilled and qualified tyre technicians have been assisting clients lower their total cost of ownership in the tyre space for over 50 years.

From our humble beginnings at Mt Newman in 1972, we have grown into a 1000 strong workforce operating in six countries, and we continue to grow, performing over 50,000 EM tyre changes per annum across 55 separate mining operations.

Through the creation of our bespoke and industry-unique, dedicated training facility, we have the capacity to meet the resource sectors’ never-ending demand for tyre management expertise.

Otraco, keeping the big wheels turning since 1972

www.otraco.com

“Across BUMA, our training system is designed to ensure that our employees and contractors are suitably trained and competent enough to conduct their activities in a safe, productive, and environmentally sustainable manner,” Taylor elaborates.

Through a process of continuous improvement, the company has implemented formalised practical skills training that utilise alternative forms of education, including e-learning through video and interactive programmes.

MODERN SLAVERY STATEMENT

Earlier this year, BUMA proudly announced the publication of its Modern Slavery Statement, confirming its commitment to addressing modern slavery and supporting ethical practices in its business operations. The statement outlines BUMA’s approach to mitigating modern slavery risks, which includes implementing relevant policies and procedures, and conducting regular due diligence, aligning with the company’s core values

Modern slavery is a significant human rights issue impacting many individuals worldwide, and BUMA acknowledges the important part it has in tackling this problem. The company is focused on making sure its operations and supply chains do not involve any forced labour, human trafficking, or exploitation.

BUMA’s strategy to addressing modern slavery ensures its employees, contractors, and suppliers maintain high ethical standards, including awareness of the importance of identifying and reporting potential modern slavery incidents.

As part of its risk assessment and due diligence processes, BUMA identifies high-risk areas within its supply chain to enable focused interventions and ongoing improvement.

38 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

Frontline Equipment Maintenancekeep your wheels turning

Frontline Equipment Maintenance has a reputation for supplying highquality, skilled tradespeople to any sized business for any sized job.

We specialise in supplying a quality workforce with experience in all facets of hydraulic excavators, off-highway trucks, blast hole drills, and all other earthmoving and ancillary equipment repairs and maintenance. This includes fault diagnosis and repair, servicing, midlife overhauls, machine relocations, as well as major and minor shutdowns.

Our tradespeople have high levels of experience with all original equipment manufacturer (OEM) brands of earthmoving and ancillary equipment, used in both the mining, civil, and construction industries.

Frontline’s mackay-based maintenance workshop has the capability to work on a wide range of light to heavy vehicles and machinery, air conditioning service and repairs, roadworthy inspections, and able to cater to any fabrication requirements.

Contact Steve Green on: +61 417 600964

sgreen@horizonrental.com.au

Horizon Rental is proud to be a preferred supplier of off- highway service trucks to BUMA Australia. All trucks are fully mine compliant and include high pressure cabin filtration and monitoring. Our dry hire agreements include three monthly module servicing, carried out by qualified BARD Technicians, irrespective of location.

www.frontlineequipment.com.au

Mining Outlook Issue 6 | 39 BUMA AUSTRALIA ASIA PACIFIC

In terms of training and awareness, BUMA understands the crucial role of education in tackling modern slavery risks. The company provides training to its employees, educating them to identify, prevent, and report any potential exploitation.

“By publishing our Modern Slavery Statement, we aim to uphold transparency and accountability within our business. We are dedicated to continuously improving our practices and we welcome feedback and suggestions from all stakeholders,” he adds.

Beyond the Modern Slavery Statement, BUMA’s commitment to ethical practices is an integral

part of its broader corporate social responsibility strategy, underscoring its dedication to making a positive societal impact.

SPECIALISTS IN SUSTAINABILITY

The ensured sustainability of the Australian resources sector relies on the efficient planning, management and operation of mining activities.

As specialist operators of mines, contract mining service providers have an important role to play in the future sustainable development of the Australian mining industry. As one of Australia’s leading contract mining service

providers, BUMA’s environmental strategy is progressive, adaptive, and responsive, with a strong focus on continually improving its management systems and performance.

“Our well-established systems and processes cover each phase of a mining operation, from start-up through to operations and eventually closure. Central to upholding our systems and processes is our ISO 14001 certified Environmental Management System (EMS),” Taylor informs us.

Alongside this, BUMA has developed a sustainable procurement framework which it strives to

40 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

Supporting Mining Companies since 1974! Specialists in: • Thermal Solutions • Exhaust Solutions • Emission Technologies • Fire Mitigation • Sound Attenuation 1300 310 340 SALES@MAMMOTHEQUIP.COM.AU MAMMOTHEQUIP.COM.AU ADELAIDE BRISBANE DARWIN MACKAY PERTH PORT HEDLAND RUTHERFORD MOUNT ISA MELBOURNE STRONGER WITH www.heq.net.au HEQ, Make it happen! PH: 1800 955 854 www.comiskeyminingservices.com.au Comiskey Mining Services is an innovative mining and earthmoving equipment rental business, with office locations in Rockhampton, Mackay, Brisbane, and Mount Thorley (NSW) servicing the Australian resources sectors. CMS supply a range of prime production, loading, hauling, and heavy ancillary equipment. Setting the standard for MACHINE HIRE Mining Outlook Issue 6 | 41 BUMA AUSTRALIA ASIA PACIFIC

continuously improve upon via regular communication with its suppliers, allowing the company to ensure that it is supporting these businesses in meeting the sustainability objectives of mining organisations wherever possible.

“Suppliers are integral to our business, because without them, we can’t deliver for our clients or continue to grow our market share. We look to partner with quality suppliers who we know can deliver and, just as importantly, expand as we expand,” Taylor shares.

“We also rely upon their expertise in terms of supply and logistics, and technical matters in relation to their relevant areas of our business.”

All BUMA’s sites have detailed and specific environmental management plans in place to ensure that the company meets compliance requirements and hits its environmental targets and objectives.

“The environmental processes

“OUR FOCUS ON CULTURAL INCLUSIVENESS IS ACTIVE AND ONGOING AND WE ARE CONTINUALLY WORKING TO BUILD OUR ORGANISATIONAL CULTURE, WITH A FOCUS ON ENHANCING WORKFORCE DIVERSITY”

– RUSSELL TAYLOR, COO, BUMA AUSTRALIA

and systems focus on the areas in which we have the greatest potential to make a difference, such as reducing GHG and energy emissions, minimising water use and waste, and responsibly managing the land on which we conduct our activities,” she continues.

“We also work to minimise disruptions to the surrounding communities, neighbours, and other stakeholders.”

Similarly, BUMA has implemented continuous improvement measures to reduce fuel usage across its numerous

sites and support its sustainability goals. The company remains resolutely committed to setting and reporting targets for CO2 intensity.

With these plans in place, the mining industry in Australia has a rich history and an exciting future ahead of it, a future within which BUMA is firmly entrenched and thriving.

BUMA AUSTRALIA info@buma.com.au www.buma.com.au

42 | Mining Outlook Issue 6 BUMA AUSTRALIA ASIA PACIFIC

www.emeoutlookmag.com/work-with-us we’ll tell the world www.mining-outlook.com/subscribe Roadworthy Inspections Motorbikes and Cars, Prime Movers and Trailer Combinations Sales & Hire View our plant & equipment range available for sales or hire. Design & Manufacture Front end loader attachments and excavator attachments. Conversions Soil compactor, fuel & water truck and service truck conversions. www.turnerseng.com.au • Plant Hire, wet or dry Plant & Equipment Sales • Bukets & attachments • Heavy Haulage • Roadworthy and compliance services for all vehicles • Insurance repair work Labour hire of Trade Qualified Staff • Fuel, Service and Water Trucks CONSTRUCTION, EARTHMOVING & MINING EQUIPMENT FOR SALE OR HIRE IN QUEENSLAND Looking for a change? Employment and training opportuni�es at BUMA buma.com.au Looking for a change? Employment and training opportuni�es at BUMA buma.com.au Mining Outlook Issue 6 | 43 BUMA AUSTRALIA ASIA PACIFIC

BUMA Level 11, 199 Grey Street South Brisbane QLD 4101 PO Box 3027 South Brisbane QLD 4101 info@buma.com.au www.buma.com.au INNOVATION IN EXCAVATION PRODUCED BY MINING OUTLOOK MAGAZINE