From chutes to custom cattle working systems and pens, Arrowquip has been creating best-in-class livestock equipment since 1988. The company’s executive team come together to tell us more

Writer: Lily Sawyer | Project Manager: Michael Sommerfield

Guided by its mission to influence the global cattle handling industry through the practical application of animal science and welfare standards, and to increasing producer safety and profitability with innovative equipment, Arrowquip emerges as a cattle handling equipment company with a difference.

Deeply invested in its vast dealer network, Arrowquip provides ongoing support for each of its partners by

equipping them with the tools that they need to thrive.

Supported by a 160-strong base of dedicated employees, the company produces manual and hydraulic cattle chutes, alleys, tubs, feeders, and more for its global market.

“We manufacture equipment at our head office in Manitoba, Canada, then send it off to our various dealers across North America and Europe to sell to ranchers,” introduces CEO, Mark Firth.

Arrowquip’s core company values are rooted in fairness, togetherness, and industry agility, whilst the business strives to continue to help the cattle industry to succeed through its products.

As beef is a mainstay of the world’s current food ecosystem, Arrowquip is trying to improve this important industry.

As such, potential challenges that arise are tackled by the company with a sense of excitement and a growth mindset.

“Something can only be exciting if it is challenging! Maintaining the status quo only drives complacency, low energy, and a mood of losing,” outlines CIO, Jerry Langrell.

With herd cow inventories at an alltime low and the highest cattle prices the industry has ever seen, Arrowquip

Jerry Langrell, CIO: “Inspiration at Arrowquip is not just from one source. We get it from each other – we’re a group of people with similar passions that align around a few core values, and that creates inspiration!

“Our end users’ shared experiences, combined with interactions with clients during our after-sales service, have provided great insight and endless inspiration for our teams.

“But that’s not all we have. As we observe the global industry, we look into the future and that provides timely inspiration.

“Furthermore, there are a few world-renowned cattle handling experts that have committed their life to enhance and educate this industry. Their knowledge and insights have been a great inspiration, propelling us to design systems that are built for cattle, not just the operator. In other words, we create something where you get voluntary movement from the animal as opposed to using force or fear.

“Beyond that, it’s just plain hard work and our daily commitment to ensuring a better future for ranchers. It’s what gets us out of bed in the morning and provides that sense of worth when the day is done!”

recognizes that this makes for a challenging business environment, however, it is also a landscape with great opportunities for those that can see ahead.

“The introduction of beef production at small levels is gathering momentum, attracting newcomers to the industry,” Langrell points out.

Local production and supply is currently flourishing across the world, which gives producers more control over their product and drives forward their marketing efforts.

This, in turn, brings higher quality food into the hands of consumers and provides larger returns for local producers.

“Further to this, it is exciting to see the dairy industry partnering with the beef industry. This will grow our overall reach and ensure our voice in the world is heard,” he enthuses.

Arrowquip’s constant exploration of the market, coupled with its interactions with end users, brings the company real-life feedback in order to

30 Harvest Drive, CentrePort, Manitoba, R4B 0A6 204-296-8422 nji@shaw.ca njindustries.ca

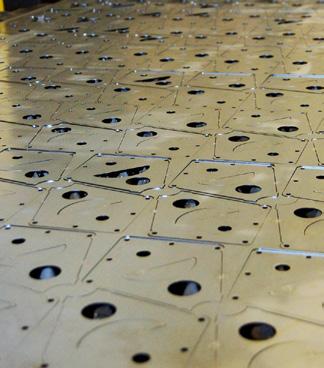

NJ Industries is a custom metal fabrication facility located in Winnipeg, Manitoba, Canada, servicing all North America for the past 16 years. We have years of experience in laser cutting, bending, welding, fabricating, and assembly. We also have the capability to quickly meet your production requirements and timelines.

NJ Industries currently provides services to many different areas such as the agriculture, automotive, railway and marine industries. In addition, we offer warehouse protection and storage solutions such as custom rack guards and custom storage cages. Finally, we offer research and development services to create a suitable product for your needs. At NJ Industries the possibilities are endless. Get in touch today, and we’ll work with you to ensure our manufacturing capability exceeds your requirements.

• At Arrowquip, a dedicated client care team works hard to ensure every customer is satisfied with the equipment they receive.

• The department is quick to get to the bottom of an issue and fix it promptly – for example, if a customer calls and they have an issue with their chute.

• Arrowquip recognizes that an issue can usually be resolved through a phone call, but it goes to great lengths to assist customers when this is not the case.

• For example, the company has seen recent instances of the client care team engaging in video calls with customers to help them resolve their issue.

stay relevant in today’s ever-changing industry environment.

“If it’s not broke, we fix it! We have global thinking and access to best practices, learnings, and new developments. Furthermore, our ability to network across the globe is a catalyst for change,” Langrell elaborates.

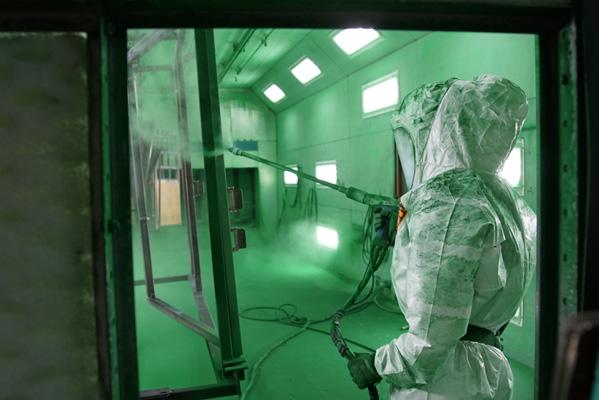

In addition, Arrowquip has taken an automotive approach to manufacturing of late, as it builds quality and repeatability into every product it manufactures. In this way, the company is able to provide an industry-leading warranty for every product.

Ensuring the safety of both the animal and the operator is of utmost importance to how Arrowquip develops and services its equipment. Therefore, the company leaves nothing to chance and creates immediate action when it receives feedback from customers.

In late October last year, Arrowquip launched a line-up of over 30 new products, a step change that had never before been achieved in the company’s history.

Impressively, Arrowquip was able to implement its new product portfolio in less than two weeks.

“Our ability to integrate our continuous product innovation is one of our key differentiators,” says Chief Manufacturing Officer (CMO), Dallas Cornell.

The company’s new line-up of Arrowlock cattle chutes is drastically different when compared to its previous line of Q-Catch chutes.

Firstly, the Arrowlock chutes are longer, taller, and wider. The head gate is also now designed using a ratchetlooking mechanism that gives users a more secure hold on their livestock

and requires less force.

“A manual cattle chute that can truly do it all is available for your ranch!” Cornell declares.

Arrowquip’s suppliers and valued dealer partners are considered the backbone of the company, and its chutes are all built at its headquarters in Canada with exclusively North American-made parts.

“We value our suppliers’ commitment to providing quality parts on time and their flexibility to our changing

demand,” he enthuses.

Primarily due to its dealers’ timely and reliable services, Arrowquip is able to maintain its noteworthy commitment of a four-week turnaround from order to delivery.

Product placement is also important to the company, whilst dealers across North America, the UK, and France allow Arrowquip to touch the lives of ranchers around the world.

“Our impact on this industry would not have been possible without our network of dealers. They not only make the equipment accessible, but are passionate advocates for ranchers,” Cornell imparts.

As a company deeply involved in all things cattle, over half of Arrowquip’s innovation team currently either have a family ranch or have been personally involved in the agricultural industry at some point in their careers. As such, its know-how in this sector is unparalleled.

“Two of our engineers actually test our products on their own ranch!” Langrell reveals.

With an engineering team that boasts both hard and soft skills, Arrowquip is able to relate to both its customers and internal departments on several levels.

“While many engineering teams isolate themselves and let their hard skills and personalities take precedence over communication and collaboration, our engineers are fully integrated and involved in every

department,” he prides.

The company believes that this integrated approach breaks down walls, builds trust, and leaves egos at the door, which has given Arrowquip the ability to build speed, creativity, and fun into its operations whilst solving its customers’ challenges on a daily basis.

Going forward, the company’s key priorities include continuing to innovate and improve its products, expanding its market reach, and maintaining its commitment to exceptional customer service in the agriculture industry.

“We aim to hit specific growth targets and goals, expanding our presence in both new and existing markets. We aim to reach 50,000 ranches and offer families a product they can be proud of for generations to come,” Firth summarises.

Diversification and expansion into new product lines or markets are also part of the company’s long-term growth strategy.

Of late, an upgraded manufacturing facility has provided Arrowquip with the capacity to meet growing demand and innovate its product offerings, and it is excited about the opportunities that lay ahead.

“We will continue to inspire tomorrow’s rancher by solving problems today,” he concludes.

Tel: 1-866-383-7827

marketing@arrowquip.com arrowquip.com