GENERATIONS OF INNOVATION

Renowned throughout the transportation industry for its advanced tarp system manufacturing, Aero Industries boasts a rich legacy and illustrious history. John Rodgers, Vice President of Operations, provides insight into the legendary company

Writer: Rachel Carr | Project Manager: Michael Sommerfield

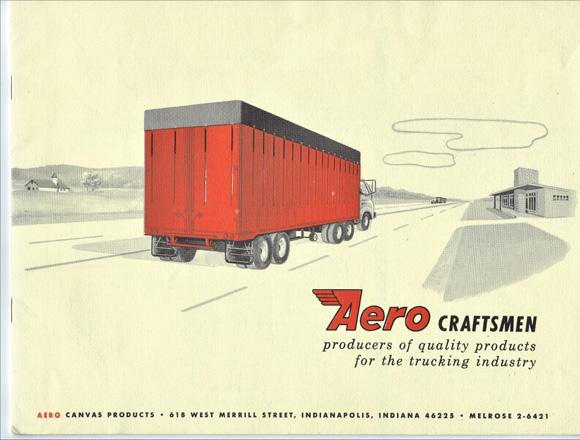

In 1944, innovative tarp systems and trucking accessory manufacturer Aero Industries opened its doors, originally as Aero Canvas Products.

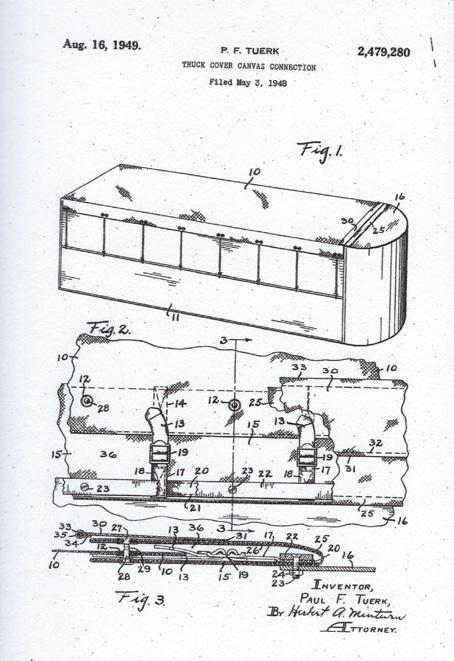

Founded by Paul Tuerk after a brush with death, ingenuity and persistence in the face of adversity have come to define the company.

Indeed, the tarp industry would have been a very different space if Paul had boarded the RMS Titanic in 1912, which was initially planned as part of his voyage to emigrate from Germany to the US.

Fortunately, a late train interrupted the journey, allowing Paul to form Aero Industries, which has been granted over 100 patents to date.

“Many of our design ideas come from customer requests and their

The DataCo vision is to improve and expand the availability of affordable internet access to all people of PNG, by partnering with the government and surrounding communities. It ensures the company is a responsible entity championing safe and sustainable development.

Connect my District Initiativeparamount to its core values is connecting PNG to the digital world and driving development and growth.

Environment Safety - ensuring that local communities benefit from services in a way that the environment is safe.

New Triplex Units - were handed over by DataCo as part of its community social responsibility initiative.

confidence in our ability to solve engineering problems,” introduces John Rodgers, Vice President of Operations.

To establish itself as an innovative industry leader in the competitive manufacturing market, Aero Industries has demonstrated a remarkable ability to think creatively with new materials, design breakthroughs, and cutting-edge patents.

Beginning in the lingerie business during the Great Depression, Paul was determined to provide for his family. This drive led him to Indiana, where he bootstrapped his business while working at Hoosier Tarpaulin, manufacturing army tents.

His experience in fitting lingerie

proved valuable for his next venture, selling customized tarps. The early logic was simple – “if Paul could fit a woman, he could fit a truck.”

Today, Aero Industries employs 215 people across Indiana, Ohio, Nebraska, and Oklahoma, operating in the dump, flatbed, agriculture, refuse, and work truck sectors.

After overcoming many obstacles, the company is now in its third generation of ownership by the Tuerk family.

Last year, Aero Industries celebrated its 80th anniversary, a testament to the company’s resilience which is rooted in family values.

Built on a foundation of community,

Aero Industries has made a lasting impact on generations of employees and customers.

Fortunately, an entrepreneurial spirit is embedded in the Tuerk family’s DNA, allowing the company to continue innovating to this day.

“We celebrated the anniversary at all our locations, hosting cookouts, games, and team activities. We also marked our packaging and labelling with ‘80’ and ‘1944-2024’ logos to communicate the event with our customers,” Rodgers enthuses.

The company has introduced significant innovations throughout its history. As an industry leader, it developed the Neoprene-Hypalon Tarp in the 1950s, replacing traditional canvas and vinyl tarps.

“OUR REPUTATION IN THE INDUSTRY IS FOR PRODUCTS THAT OUTLAST THE COMPETITION AND QUALITY THAT IS SUPERIOR”

– JOHN RODGERS, VICE PRESIDENT OF OPERATIONS, AERO INDUSTRIES

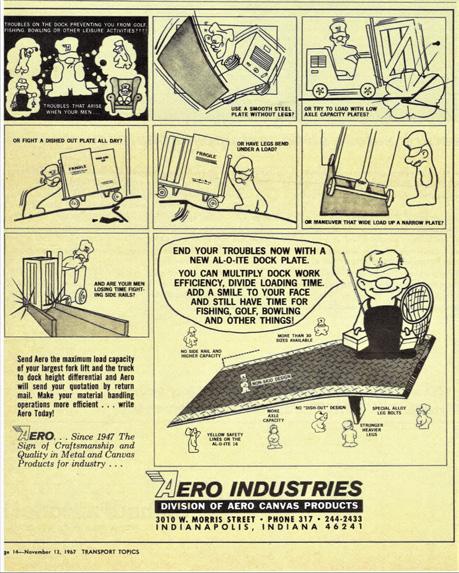

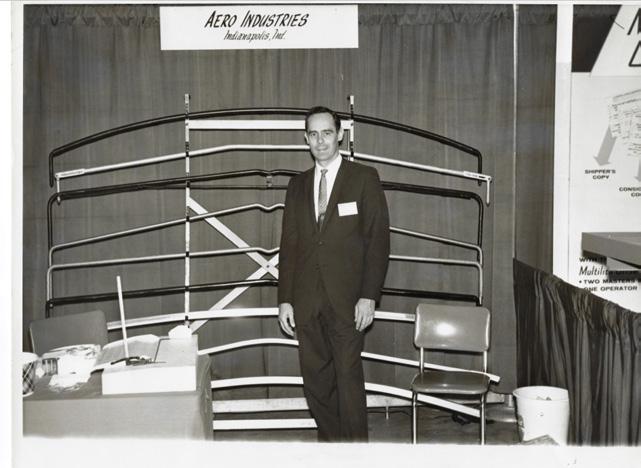

In the 1960s, other major innovations were introduced, starting with the One-Minute Roll-Away Tarp, followed by the Shortie Roll Tarp.

“Of special note is Aero Industries’ pioneering rolling tarp system, the Conestoga,” he acknowledges.

The Conestoga has long been one of the company’s top products. However, in the late 1990s, it faced challenges related to the width of the tarping systems.

After a demanding four-year effort by the Aero Industries team, led by Paul’s grandson, Jim Tuerk, the issue was resolved in conjunction with new regulations that benefited the entire US trucking industry.

Looking ahead to the next 80 years, Aero Industries has a guiding mission and an ambitious vision that will further solidify its position at the forefront of the industry.

Crown Screw & Bolt (Crown) has evolved over the last 50 years to diligently meet the needs of a vast range of industries, including construction, automotive, aerospace, manufacturing, and many more.

In fact, the North American fastener industry has experienced substantial levels of growth, driven by the upward trajectory of key end-user industries and is expected to be worth over $25 billion by 2030.

In this context, the company understands its customers’ diverse requirements in an evolving sector, having come from humble beginnings and adhering to a simple philosophy ever since: ‘Work hard for your customers and offer the best services available’.

Moreover, thanks to a steadfast dedication to industry requirements, Crown has garnered an outstanding reputation for its second-to-none products, best-in-class technical assistance, and most competitive pricing in the market.

Its expert ability to serve customers stems from a worldwide network of supply partnerships, highly comprehensive inventory, professional sales team, and an all-encompassing commitment to excellence, which each help the company stand out in a saturated field.

Crown boasts a diverse fastener inventory and unsurpassed product availability for its customers, providing them with everything they need to get the job done.

Namely, it is the go-to supplier for all types of nuts, bolts, washers, screws, pins, and specialty fasteners, available in both metric and imperial measurements.

Additionally, Crown also supplies standard and custom brackets, clamps, fittings, metal stampings, and extruded products, offering personal attention to customers’ fastener needs.

The company promotes both quantity and quality, stocking world-class brands in its inventory to guarantee the best solutions for businesses across the US.

Delivering an unmatched repertoire of products across the country, Crown’s central distribution facility in Indiana – situated at the crossroads of the US – offers fast and easy shipping to every corner of the nation. The company is committed to maintaining a dynamic and world-class delivery fleet, which guarantees the efficient and reliable delivery of products.

Crown also offers custom packaging and bin stocking services to ensure orders arrive safely in the hands of customers, further guaranteed by the highly accurate packaging and labelling of all products according to strict customer specifications.

The company’s delivery services also extend to end user assembly assortment and the option to have items sent bagged or boxed, thus optimizing the entire delivery process. Crown’s customers can also rest assured that purchased items are of the highest quality, as the entirety of the company’s product list ardently meets industry standards and is ISO 9001:2000 certified.

Top-of-the-range companies that Crown has in its inventory include but are not limited to:

• Rotor Clip/Clamp

• Tinnerman

• Oetiker

• Allen

• Universal Metal Products

• E-Z LOK

• Engineered Components Company (ECC)

• Avdel Cherry Textron

• Huck® Fastening

• DimcoGray

• RAF Electronic Hardware

• Holo-Krome

The company also offers the Fastener Locator – an easy-to-use online tool that lets businesses find the best product to fit their needs.

After customers complete a short form to describe what they are looking for, Crown’s experienced team conduct a thorough search of their nationwide supply chain to find the most suitable product, before getting in touch with the customer with the best price and availability.

As such, this unique tool grants customers access the best of what the US fastener industry has to offer, all at the click of a button!

Evidently, customers can rely on Crown to provide the best solution as quick as possible.

Crown additionally provides guidance and support with its turnkey Crown System Buying option, which offers each client endto-end and highly personalized services. Through the system, the company is able to make a note of customers’ buying patterns,

which are then closely analysed by professional sales personnel.

As a result, Crown can compile a list of products that it thinks would be useful for meeting future challenges. Such items are subsequently stocked in the company’s warehouse, ready to deliver to customers at a moment’s notice.

This unparalleled service alleviates many logistics and warehouse obstacles for customers. For instance, it greatly reduces the burdens of limited inventory space whilst maintaining areas for working capital, therefore allowing businesses to focus more on what matters.

On top of this, Crown System Buying eliminates waiting times for specialist products and large-scale orders, further reducing stress for customers and fostering a more pleasant buying experience.

Most significantly, the service helps facilitate future planning opportunities by preempting challenges and providing advanced solutions.

Businesses can make the most of this allencompassing service by selecting Crown System Buying at the website checkout, creating an easy shopping experience.

Crown’s success is built on an encouraging family culture, as its employees strive every day to promote the quality nature of its products through a close-knit workforce. Indeed, the company’s experienced team work for their customers, offering an

• Acorn nuts

• Cap nuts

• Flexloc nuts

• Hex nuts

• Heavy hex nuts

• Jam nuts

• Anchor bolts –concrete and foundation

• Askew head bolts

– Grades 1 and 2

• Castle nuts

• Coupling nuts

• KEP nuts

• Left-handed nuts

• Machine-screw nuts

• Locking nuts

• Pal nuts

• Security locknuts

• Serrated flange nuts

• Structural nuts

• Square nuts

• T-slot nuts

• Tinnerman nuts

• Weld nuts

• Wing nuts

• Plow bolts

• Eye bolts

• Cap screws

• Hexagonal flange bolts

attentive and personal service to ensure that every obstacle is overcome.

Its highly vigilant team of professionals are on call around the clock to provide each customer with a complete service, regardless of its complexity.

By liaising directly with each customer, businesses across the US have easy access to the company’s extensive inventory. In addition, Crown can provide guidance and pricing quickly and efficiently without timewasting follow-up calls.

Furthermore, the sales team can be trusted to provide the best and most up-to-date advice on the latest developments in the

• Hex machine bolts

• Lag bolts

• Structural bolts

• Square head bolts

• T-slot bolts

• Tap bolts

• Spring toggle bolts

fastener industry thanks to a diversified pool of experience and the full range of merchandise at their disposal.

This specialist know-how permits them to inform customers of fluctuating product prices and advise customers on any potential changes that may affect their business.

As such, the Crown team works hard to exceed customer expectations, meeting the fastener needs of the nation.

“Our mission is to provide innovative and quality solutions that enhance the lives of customers and employees; our vision is that Aero Industries’ transportation accessories and tarp systems are the solution above anything else; and finally, our values are that we innovate and persevere as we create and grow relationships while continuing to build our legacy.

“What differentiates us from our competitors is our people and the relationships we have both internally and externally,” expresses Rodgers.

Aero Industries boasts state-ofthe-art facilities and a top-tier team that contributes to the innovative products it has developed over the years.

“Our reputation in the industry is for products that outlast the competition and quality that is superior,” Rodgers prides.

The recent projects undertaken by the company provide clear evidence of its innovation. In 2021, the design of the Crank-N-Go system was updated

and rebranded as the Aero TopGlide. This new version combines advanced drive cable and bow-end technology with a pleat system that has been reimagined and re-engineered to meet industry demands, ensuring reliable movement of the bow and tarp.

The AeroForce ROC 700 series, meanwhile, addresses the need for a lightweight roll-off container cover system suitable for Class 4 and 5 chassis. Additionally, the enhanced slide design improves serviceability and maintenance.

1900S – 30S – Paul journeyed from Germany to New York and later Illinois. While living in Chicago, he married Viols Mueller and started a family. In 1939, he went to work for Hoosier Tarpaulin & Canvas Goods Co., which changed the course of his life.

1940S – 50S – Aero Canvas Products opened and, with successful sales leading to continuous growth, introduced rubberized tarps.

1960S – 70S – The company introduced the aluminum stake side kit and the use of vinyl tarps. It also opened a manufacturing and installation facility in Omaha, Nebraska, and the first Side-to-Side Roll Tarp was developed.

1980S – 90S – Aero Industries launches the first cable tarp system in the US – the Crank-N-Go – along with launching the Easy Cover, which is the industry’s leading front-to-rear flip tarp system and introducing the first rolling tarp system – the legendary Conestoga.

2000S – 10S – The SideKick 2 is developed, and the Conestoga 2, the industry’s most advanced rolling tarp system, is launched. The company also introduced StorMor storage boxes.

TODAY – Aero Industries is still growing and innovating, instilling a deep sense of pride in those committed to its future.

“We are very fortunate to have excellent relations with our customers, and we have found a few key opportunities to provide some significant product improvements for 2025 to our flatbed accessories products.

“In addition to product improvements, we have seen a consistent increase in demand for our AeroForce F2B and S2S products, so much so that we are now expanding production into a second facility to support growing customer demand,” shares Rodgers.

Aero Industries has built a strong reputation over the past eight

“MANY OF OUR DESIGN IDEAS COME FROM CUSTOMER REQUESTS AND THEIR CONFIDENCE IN OUR ABILITY TO SOLVE ENGINEERING PROBLEMS”

– JOHN RODGERS, VICE PRESIDENT OF OPERATIONS, AERO

INDUSTRIES

decades, recognizing that its employees, customers, and suppliers contribute significantly to its success.

“The culture here is special; we genuinely care about and look after each

other. I like to say – “we get to do this!” – which means that we are blessed to be able to come to work at a place like Aero Industries alongside fantastic team members,” Rodgers prides.

Supplier relationships are also vital for smaller companies such as Aero Industries, whose supply chain has a mix of centralized and decentralized elements.

“With Indianapolis being our primary production location, components and assemblies are distributed to our Nebraska, Ohio, and Oklahoma sites for installation, where we have some of their own established product-specific supply chains.

“We are reliant on a handful of international suppliers for fabrics, motors, castings, and extrusions to support us. We also have several

local supplier partners for polishing, printing, painting, and more, with whom we have had long-standing relationships.”

As Aero Industries continues to innovate and introduce new products to the market, the company seeks new opportunities while overcoming challenges – a mindset it was built on and will sustain for decades to come.

“The flatbed industry is currently in a recession, while dump products remain stable. Our focus during this time is to grow our market share by expanding into adjacent regional markets, playing offense against our competitors, and improving service

and delivery,” finishes Rodgers. Despite the challenges the market may present, Aero Industries will boldly forge ahead as a leader in innovation and excellence, poised to embrace the next chapter in its story.

Tel: 800 535 9545

info@aeroindustries.com www.aeroindustries.com