6 Simple Steps to Build Your Own Pool

Let’s start off by thanking you for downloading our guide. Downloading this, shows us that you’re serious about creating a swimming pool of your own and that’s exactly what we want to help you to achieve.

Why build your own swimming pool?

A swimming pool is more than a luxury. It’s a place to entertain, have fun with your family and improve your health and wellbeing.

The team here at orbro POOLS have been established since 1999 and have over 25 years experience in pool building landscaping. Our team use the unique SolidPool system and our filtration systems to build our own award-winning pools. This is a build-yourself system that will give you a swimming pool you’ll be proud to share with friends and family.

Our mission is to help you build an award-winning standard pool, by using simple systems that anyone can build with. The system is endorsed by Chris Cook, two-time Great British Gold Medal Swimming champion. He understands first-hand the importance of a good quality swimming pool and the effect it has on a person. He has proven that keeping it simple leads to world class results. By simplifying the process, he was able to attain Gold, not once but twice!

This same simple process applies to our Pools and the way we build them, so partnering with Chris was the logical step for us. In order to help YOU with building your own dream pool, we have worked with Chris to simplify our own process, which we have been using for years, into the 6 simple, most important steps of a pool build. You can have any pool your heart desires, built by you, using only the best equipment.

Thanks,

Ben and Olly

Step 1 Plan your Pool

Step 2 Excavation

Step 3 Pool Walls

Step 4 Filtration & Heating

Step 5 Finishes

Step 6 Commissioning

This is the biggest part to getting your pool correct. It might seem really obvious to say you need to carefully plan your pool, but there’s considerations you might now know about that can change the look, feel and usability. That’s why we’re about to share some of our top tips for what to consider before deciding on your pool design:

First of all, you need to get a pool and garden ‘master plan design’ before you build anything. Now that’s pretty obvious, but it’s also always necessary. Because it helps you focus on the two most important factors of your pool and garden design.

A. What you want from your pool and garden (including the plants within it)

B. How you’ll use the pool and garden most when it’s finished.

Understanding what you are going to use the pool for is a big step? Is it a family pool, or needed for exercise or Entertaining or a mix of all of these.

Once you know the usage you can then determine a depth, you don't want to be the one hopping on tip toes whilst trying to return a volley ball serve.

Next consider, what's it going to be near?

Buildings: How close to the house is the pool going to be both neighbours or homeowners and how does this effect the sun light?

Trees: Large roots are an issue you may have with inground pool construction. You’ll need to cut them back a good 10 ft or so from your pool. Any organic material left in the pool will consume your chlorine and, when the chlorine gets too low, algae is next.

Plants: Think about what kind of plants you would like to have around your pool and choose the ones with the minimal leaf drop.

Sun: Where does the sun rise and fall. Design the pool area to maximise sun. If you get home late, you might like to make sure there is evening sun to relax in. Full sun is good but where could you put a shaded area.

Wind: The predominating wind direction will determine where the pool skimmers are positioned. Screens can be added to prevent wind chills. Air source Heat Pumps blow out ice cold air so you do not want this blowing onto a patio.

Evaporation: 70% of energy loss in swimming pools can be attributed to evaporation. The wind speed, and the lower the humidity, the greater the rate of evaporation.

Water: High water tables can be a problem when digging deep holes. Just because your on a hill does not mean you wont have water table issues. Look out for Rivers near by. Insist on some inspection holes before you start the main job.

Hard Standing: You will be using pumps, grabs, and concrete lorry's is this near the pool.

Access: What's the access like? Large machinery will speed the job up it can be cheaper to make good access than use a side gate and small machinery.

Elevation: What's the elevation of the site like, sloping sites will need extra retaining walls. Pools can be built into a slope and be made a feature of.

Spoil: Can you keep the spoil on site and design with it? An average pool will produce 18 grabs of waste. It will save thousands in waste.... but leads to extra landscaping.

A rectangle is a simple shape to draw, but its what goes on around and under this outline the less aesthetic parts but most important parts where the pool design is a must; drainage, covers, heating, pool safety, filtration, water quality and anything else that fits your pool type.

As you can see below the simple rectangle becomes a little more interesting...

Having a visual done like the one below, allows you to get the right pool in the right space and explore the pool surrounds and water colours easily to avoid unnecessary expenses.

There's more to digging out a pool than most people think, and we want you to read this carefully before rushing off and hiring a machine.

Every year people are killed or seriously injured by collapses and falling materials while working in excavations because of Material falling from the sides into an excavation; and people or plant falling into excavations. So please be careful.....

You only want to mark out the hole once. Line paint be easily removed and road pins knocked over. Spray out the pool with a suitable colour spray.

Setting up profile boards as far away from the dig avoids a digger and dumper knocking them and is a good datum for the entire build. Once in position the pool can be checked and marked out by one person.

Start at the deep end if you have one or furthest from the muck away pile. Check maintain safety fencing to protect others. Check the heights as you go you don't want be going back to try and excavate more.

A competent person who fully understands the dangers and necessary precautions should inspect the excavation at the start of each shift. Excavations should also be inspected after any event that may have affected their strength or stability, or after a fall of rock or earth. A record of the inspections will be required and any faults that are found should be corrected immediately. Ensure excavations are made safe, by trench supports, battering back fencing or other equally effective measures.

TOP TIP: Avoid getting the machines into the hole: When it rains and your in a hole in a heavy machine it can be hard to get in and out.

TOP TIP: Avoid getting the machines into the hole: When it rains and your in a hole in a heavy machine it can be hard to get in and out.

Sheeting the dig

You’ll need to sheet the sides of the dig, this protects the sides from rain and can prevent loose material falling into the hole.

An average 10m x 5m pool will generate 118 cubic meters of spoil. It can be a real challenge to get rid of; it’s heavy, bulky and messy, and becomes far more problematic once it’s wet.

TOP TIP: sheeting under the piles of spoil helps to keep it dry and makes it easier to move. You can recycle the spoil it if its good top soil. By keeping it dry, it means it can be worked with straight away.

You need to over dig a pool by 1.2m width and length from the internal pool size. This allows for the wall thickness and provides a safe working space. Making it too wide will cost you more money in back filling. If you dig the pool to deep it will cost you more in waste removal and concrete. Every 1cm you dig to deep on a 10m x 5m pool will equate to a ton of spoil or concrete.

TOP TIP: Always backfill with clean pea shingle to save any settlement around the pool.

Sheeting the dig

You’ll need to sheet the sides of the dig, this protects the sides from rain and can prevent loose material falling into the hole.

Keeping the dig dry

Keeping the dig out dry is so important. A sump Pump allows a dry working environment. It is essential if you have ground water issues.

Installing the pipework, filtration and heating. Poor equipment will ruin your experience of owning a pool, using energy efficient heating, pumps and water treatment will reduce overall running costs.

We stand by the old saying "you get what you pay for" and we are going to explain to you.... why we use the types of equipment in our own award winning pools.

If you have had a look at pool pumps you will see the industry is literally flooded with pumps. How do we choose which one is suitable for our pools? Simple, the shaft!!

Think of the pump as the heart of your pool, constantly running to circulate the water. That’s a lot of work.

Our pool pumps are highly efficient pumps and quiet running. Unlike other pool pumps our pumps impellers are enclosed and sits on its own axle, made with a high grade Stainless steel shaft and mechanical seal in graphite and alumina, it does not rust compared to other pumps with mild steel shafts.

This is why they come with a 5-year warranty.

Our pumps also have a government seal of approval for efficiency, as they use less power to achieve a highly efficient flow rate.

We only use sand because it has been tried and tested, not only in its simplicity but also the fact it is compatible with other additives if necessary.

Pool filters are normally made from fiberglass, smooth on the outside but rough on the inside, this rough surface collects bacteria in the one place you want to clean the water.

Our Filters with valves are made of chemical and weather-resistant modified polypropylene.Injection moulded, with the two halves thermally welded.

Highly versatile, with Top or Side-mounted, six-way valve. This gives a perfectly smooth finish on the inside and out, free from bacteria growth.

Working pressure: 2.5 bar; maximum pressure: 3.5 bar.Connection with 1 1⁄2” six-way valve for Ø520 and Ø620 mm models; 2” for Ø760 mm models.Fitted with a pressure gauge and air valve.

Double drainage in the lower section of the filter: 1 1⁄2” to totally empty the filter; 1⁄2” to drain water without loss of sand.Transparent lid on the Side-mounted version for easy inspection. Valve joint/lid (depending on Top- or Side-mounted version)to the filter via a 203 mm anti-blockage seal.

Water quality is a really important part of any swimming pool, the amount of chemicals added to the pool can cause irritations and be costly.

Over 2,000 years ago the Ancient Greeks found that algae did not grow in water stored in copper containers. They also discovered that it seemed to purify drinking water.

It was not until the nineteenth century that the reasons were understood, and the process was established commercially . . . we use charged ions to kill bacteria and algae.

A simple to use method of ensuring quality water with very little effort. As the pool water passes through the in-line cell unit, copper and silver ions are released, reducing bacteria and killing algae.

You still need to use a small amount of chlorine but by doing this Chlorine consumption is reduced by up up to 60% making it particularly ideal for those sensitive to chlorine.

That is the equivalent chlorine content tap water has, this method also reduces maintenance and running costs of the pool. We are that confident in our water quality we will drink from our pools to demonstrate how well our equipment is working on keeping the chlorine levels low.

Hiding the pool equipment can be costly. A plant room is often built in a wooden shed Or if you have a pool house an allocated area is used. We like to use a compact Filtration unit which means you don't have to clutter a pool house up with a plant room, or spoil uninterrupted views with ugly sheds.

All of the pool equipment can be housed in our filtration box. which can be buried partially or fully in the ground. Freeing up space and leaving sight lines around the pool completely untouched. Not only is the plant hidden, the filtration comes pre-plumbed.

This means is the most technical part of the plumbing is done for you by our team in the warehouse. A simple connection between the pool and filtration box and the plant room is done.

Anchored to the ground, with the lateral braces on the walls it's resistant to land movement. It has been specially designed to blend in discreetly with the land, with its cover.

Heavy-duty hinges and special safety lock keep the pool equipment safe. Its ease of transport and access for maintenance work. It comes in buried or partly buried versions, and with different equipment options to suit every pool’s needs.

There are two different types of pool pipes, PVC and ABS. We only use Grey PVC Pipe work in our pools

Compared to the standard white ABS pipework the PVC pipework is superior quality to and can be used for vaster temperature ranges and resists water with chemicals in it. It’s what's used on commercial installs.

Our Grey PVC Pipe is manufactured to BSEN1452 Rating 50mm pipe has an outer wall thickness of 2.4m, 63mm pipe has an outer wall thickness of 3m

We get asked all the time what is the most efficient way to heat a pool. There are many ways to heat a pool depending on location, size and what is available, Gas, Electric, Oil, Solar, Ground source or Air source. We recommend air source heat pumps. Think of an air-conditioning unit working backwards. We are using the hot air to heat the pool water.

Top Tip: Plan your pools use. Are you going to use the pool all year? The correct type of cover and heat pump will need to be specified to get the best performance.

It's not just a case of putting a massive heat pump on the pool.

Our Inverter Heat Pumps are 10 times quieter than standard heat pumps offering higher COP (The coefficient of performance) of over 15 and they can even work down to -7 degrees C and heat water up to 40°C.

Now you can have both quiet running and as near an all year heating as possible. Even if you do not need all year heating having the capability to run with an effective COP at low temperatures means our Heat Pump will allow you to heat an outdoor pool at the beginning and end of the season, normally the hardest times to keep the pool warm.

Our heat pumps can save energy by controlling the pool filtration pump, turning it on & Off intelligently, according to the heating requirement of the pool. With the pump running only when needed noise is reduced as well as running costs, whilst always maintaining the desired pool temperature.

Our Heat Pumps are powered by Twin-Rotary Mitsubishi DC Inverter Compressors. Based on the "Twin Mechanism" principle, two rotors operate together to balance the torque to stop most of the shaking created by normal compressors. This results in the highest efficiency, very low vibration and ultimately extremely quiet operation.

Our Heat Pumps come with Digital controls for easy operation and accurate pool temperature setting, a Titanium Heat Exchanger to protect against Chlorine in the pool water, a "Soft Start" on all Models which reduces the power required when turning the units on and a 7 Year Compressor & Heat Exchanger warranty, which is unmatched elsewhere. Our Heat Pumps cover just about every domestic swimming pool from 20m3 up to 120m3 pools.

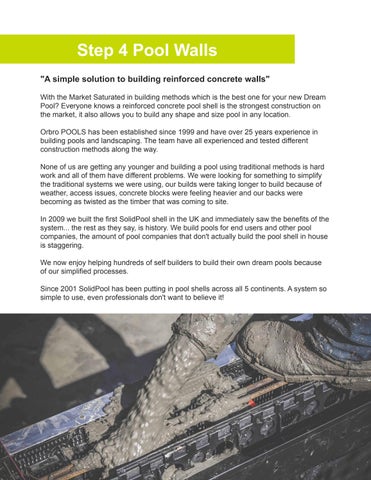

"A simple solution to building reinforced concrete walls"

With the Market Saturated in building methods which is the best one for your new Dream Pool? Everyone knows a reinforced concrete pool shell is the strongest construction on the market, it also allows you to build any shape and size pool in any location.

Orbro POOLS has been established since 1999 and have over 25 years experience in building pools and landscaping. The team have all experienced and tested different construction methods along the way.

None of us are getting any younger and building a pool using traditional methods is hard work and all of them have different problems. We were looking for something to simplify the traditional systems we were using, our builds were taking longer to build because of weather, access issues, concrete blocks were feeling heavier and our backs were becoming as twisted as the timber that was coming to site.

In 2009 we built the first SolidPool shell in the UK and immediately saw the benefits of the system... the rest as they say, is history. We build pools for end users and other pool companies, the amount of pool companies that don't actually build the pool shell in house is staggering.

We now enjoy helping hundreds of self builders to build their own dream pools because of our simplified processes.

Since 2001 SolidPool has been putting in pool shells across all 5 continents. A system so simple to use, even professionals don't want to believe it!

Simple Clip together construction. Just like Lego®

SolidPool won’t burst under the immense pressure of wet concrete, unlike traditional timber and metal shutters we have seen and been asked to repair

In 2020 alone, 897 pools were installed across the world using the SolidPool system which equates to 64,440 blocks with a 100% satisfaction rate. Which means you can choose to build your pool with absolute peace of mind.

SolidPool meets EuroCode 2 standard for swimming pool construction, which means our pools are built to the latest compliant codes.

The SolidPool system is universal so any fittings can be used on the pool shell. Or use our own range of fittings.

Pools built using the SolidPool system, result in the walls being reinforced concrete pool shell. Which we believe is the strongest option available.

Easily built by one person. With some guidance and some basic DIY skills you can build a pool shell, usually only built by professionals. Which means we can train anybody including new staff and even you, to use the system in one day.

SolidPool allows us to build pools and water features even in the hardest access areas. SolidPool can be built indoors, in the ground or out of the ground, meaning we can help our clients on any pool install.

One SolidPool block weighs just over 3kg which means it only takes approximately one hour for two people to move an average size pool’s worth of blocks from the front of a house to the pool site location. Compare this to a pool using concrete blocks which can take on average two days to move into the right location to start building the pool.

We can easily build from any sort of concrete base including a hopper, transverse, sloping or flat, meaning all types of pools are achievable.

It’s light weight construction means you or your workforce are not getting injured with heavy lifting, like you would from other methods. Or if you're like us years of heavy lifting has taken its toll.

SolidPool can be built in all weather conditions, which means it doesn’t matter if it’s pouring down with rain or even snowing, there is no need to walk off the pool job site. This ensures we can build our pools on time without any disruptions or additional labour costs.

Creates a reinforced concrete shell which does not not need rendering. It’s the only concrete shell for a tile or liner finish which requires no rendering thanks to our tile block’s unique design. Simply pump in wet concrete, even hand-fill the SolidPool blocks with concrete. It leaves a perfectly flat finish, ready for the liner or tiles. This saves between £1,960 to £4,000 each pool and avoids the need to hire a specialist to render the pool.

Our pools can be built to any shape thanks to our flex-block. It can be bent into shape with your bare hands. Curves will be precise, smooth and no need to render because there will be no sharp edges. Your pool can be built in any size shape or depth which means you have many design options available. Free form pools could not be any easier.

Easy to cut with a a simple pass through with a jigsaw or skill saw, no need for a diamond tip blade. Leaves no dust. Much cleaner workmanship and sites.

Tiled or Liner?

Installing the copings and internal finishes is what brings the pool to life. Choosing the Finish of the Pool is a really personal choice, and something to think about carefully.

An on-site Liner is a far superior product to a bag liner.

A bag liner is measured and made off site and then dropped in, if you measure it wrong you will need to have a new liner made.

With a lot of high-end companies opting for onsite lining it is becoming a go to solution for concrete pools. The quality of the liner and underlay is brilliant. A 4mm underlay is fitted to the walls first and then the 2mm liner cut and welded into position, no creases or lines in the corners or around the coping. The onsite liner comes in a range of colours and textures.

Our fitters chase a line out from under the coping and install a profile to weld the liner to. By doing this you do not have an unsightly bed of mortar between the coping and liner giving a seamless finish that also protects the mortar from frost damage. You know your swimming pool liner will be installed by qualified fitters and come with a 12 or 15-year warranty, compared to 7 years on a bag liner.

Tiled Pools: Tiled pools give a certain look to a pool, seen as the ultimate in luxury and come in a range of large format tiles down to mosaics.

Having a perfectly flat surface to tile to, is one of the biggest challenges to building a pool, and many people do not have the skills to achieve a high end finish without hiring skilled tradesmen

A paint on tanking Slurry or waterproof render is applied before tiling which gives a secondary system if the tile was to fail or blow in poor weather. With the SolidPool system we had a special tanking system tested on the blocks and can supply this if needed. Make sure the wall and floor junction are dealt with, by either using a sand and cement fillet or a joint tape.

TOP TIP: SolidPools do not need rendering so a perfectly flat and plumb wall is easily achieved without the need for skilled tradesmen.

Getting the pool colour right is so important and can totally effect the look of a pool area and surrounding buildings. Unfortunately we can't fill up a bowl and put some samples in to recreate the look of a pool. A pool will change colour because of the sunlight and also the depth of the pool.

TOP TIP: Remember the freeze is always visible and looks better if it blends in or compliments the pool coping.

Provides a Mediterranean feel to the pool, and has a more turquoise look great with limestone slabs.

Blue will give you that traditional pool colour, be careful this doesn't clash with surrounds or painted window colours.

Grey will give you a petrol blue colour, not so piercing and blends in with most surrounds.

Green or jade colours will give a much more green water, looks great at traditional properties and more natural settings.

Black.. believe it or not will still give you a blue pool on a sunny day, used on both more natural pools or if you want it to look like a reflective pool. Used a lot on traditional properties, or to make a statement in a contemporary garden.

Understanding a pool is important to make sure the pool is well looked after. There is nothing worse than being bamboozled by professional terminology when you don't understand the words.

Below we have simplified the maintenance for you and some of the terminology used. Note that covers and our water treatment system we use have a massive impact on maintenance.

When the Pool is built it will need to be commissioned. To do this you need to power and prime everything up and balance the chemicals in the water.

All the pipes will have been pressure tested, so anything with a Union joint in the equipment chamber can be checked and tightened if needed. The Heater can be programmed and the timer for the pump set.

A pool is very simple to maintain if you remember to do it. Once a week is all it takes to keep a pool crystal clear. If you forget to do it, you run the risk of it turning green especially in the summer months. It’s always best to have one person look after a pool or keep a log of what has been added week to week.

You have one basket in each skimmer which catches all of the surface debris in the pool. You’ll also have one in the pool pump housing which prevents and large debris from jamming the pump.

You will notice a series of valves near the pump, this is used to isolate the water from the pool whilst you work on the pump. You can also regulate the flow using these and isolate the skimmers and sumps to use a manual vac.

TOP TIP: Don't worry if you spill some water, it always looks like more than it is.

Multi Port Valve

The multi port valve is what you use to operate the pools cycles. Never use it when the pool pump is running. Push down on the lever and then turn it, don't lift the lever up as it will break.

TOP TIP: Be gentle when using it.

Back Wash

Is the term given when we are cleaning the sand filter. They are revising the pools cycle and removing the dirty water from the filter into a soakaway. The sand filter has a pressure gauge on it and when this is high its time to backwash. This will need to be done every week.

Top Tip: Don't put chemicals in the pool until you have backwashed, you will be throwing money down the drain.

Chemicals

Your new pool will require chlorine. We use liquid chlorine on brand new pools with fresh water in. Free chlorine is the amount of chlorine waiting to be used up, and its this the we are measuring. Chlorine is used up by a number of factors. Sun, Heat, People and organic matter. Don't over complicate the chemicals, keeping it simple is the best way. Follow a strict routine, and avoid the pool getting bad before treating it.

Test Kit

You don't need a degree in chemistry, to understand how to balance a pool. The two most important tests we need are the Ph levels and DPD Chlorine levels.

Ph Levels

Ph measures, acid and Alkalinity Optimum level is 7.4. Low Ph causes eye and skin irritation, erosion on pumps, ladders, even concrete. High Ph can cause cloudy water and deactivates the chlorine.

Chlorine Levels

The recommended range for chlorine in residential pools is 1 – 3 ppm (parts-per-million), one ppm is equivalent to 1 milligram of something per litre of water.

Once you know the volume of water you have in your pool you can calculate how many granules to add each week to maintain it and keep the pool crystal clear.

As the UK distributor of SolidPool, we build with the system on a daily basis, so you know we are the experts. SolidPool is an innovative, lightweight, permanent shuttering and construction block system for pools, walls and water features.

We believe it’s the future of pool building, because this unique system allows pool shells to be built quickly, whilst not compromising the build quality. It’s also better for the environment being a recycled system and uses less concrete than other building methods. Plus, the SolidPool system is kinder to pool builders (or you if you’re building the pool) as it is a lightweight system. This means you’re likely to get a faster and better build because the you aren’t breaking your back building with the system.

Kinder to the environment

Kinder to your builder

Faster pool installations

All year round pool build

Bespoke shape & finish

Strong & quality construction

The SolidPool system enables your pool to be easily customised to any shape and size, thanks to our three different blocks. It is a simple clip together system, which means it’s suitable for pool contractors and even those who want to build their own pool. The simplicity also leads to less room for errors which could compromise your pool quality. Because of the system design, it can be built all year round too, which means weather doesn’t tend to slow down a SolidPool build down. The different blocks in the system mean you can have any finish or liner you want and there is no need to waste time or money on rendering the pool either.

The liner block is available in two sizes 440mm and 530mm tall. The smooth front to the block gives you a perfectly flat face for the liner to sit on, so there’s no need to render the blocks smooth.

The tiled block is available in single or double sided. The perforated front allows the concrete to be buffed when poured, leaving a perfectly smooth face ready for tiling. No need for extra rendering costs.

The revolutionary flex block enables you to create seamless curves effortlessly. Available for both liner and tiled pools, walls and hot tubs. The block can be bent to create a minimum 2.4m diameter.

265.72

One ton of recycled plastic can save approx of plastic kept out of

SolidPool is made of recycled plastic. Here’s why recycled and re-used plastic products like ours are vital…

Making new products out of recycled plastic means we can reduce plastic space taken up in landfills, that can be used for biodegradable materials, to save the environment.

Recycling plastic reduces the strain on the finite resources of the earth like natural gas, petroleum, coal, wood, and water which are required to make plastic.

A reduction in the need for natural resources will help decrease the levels of carbon dioxide in the atmosphere and will prevent a surplus demand for petroleum products.

265.72 tons of landfills in 2022

imately seven cubic yards of space used in landfills. Overfilling landfills could spell disaster since space is limited, and waste is too high in quantity. Recycling plastic helps keep it out of landfills and also helps the environment.

Reusing plastics means there is less plastic in landfills, rivers, deserts, forests, and oceans across the earth. Plastic cannot be digested by living organisms and instead, harms animals and birds.

Plastic ends up destroying the natural habitats of the world with its non-biodegradable properties, and instead of helping to protect life, it ends up being the cause of many animal deaths. Every year, countless fish and marine animals die and face extinction due to excessive consumption of plastic.

Join the revolution and do your part, to not only save your wallet, but also save your world.

Whilst the system is so simple, we can do offer fully comprehensive training on using the system, along with support services. Whether you're looking to build your pools yourself, or have a builder you’d like to use, we can support you with a training day or support services.

You might also like to pop in to our HQ and have a chat about the SolidPool and see it in action. We welcome anyone who wants to see a little more to book in a visit to come chat to us.

After your training you’ll have telephone support, so if you come up against an issue or have a question, you know you can give our expert team a call. Plus if you feel you’d like a expert helping hand at some of the key stages of the build, you can purchase one of our support services. You’ll be able to book in our team to come along to your home and help you with whatever stage you want extra support with. Enquire to find out more about this.

Our team of experts are ready to chat to you today about your dream pool build.

Call us today and book a FREE consultation with one of our experts worth £497.00

scan for more info.

Office: 01903 944594

Mobile: 07976 850522

Email: info@orbro.co.uk

Instagram: @orbropro

Unit 5 Cottons Yard, Water Lane, Storrington, West Sussex,