INTRODUCTION

Following the introduction of the engineered stone ban around the country from 1st July this year, new rules when working with silica products have come into effect from 1 September 2024.

The new laws will impact the carrying out of general day-to-day tasks with working with crystalline silica substances (CSS) such as

• cutting floor and wall tiles,

• cutting or grinding concrete,

• cutting, trimming and drilling into bricks or roof tiles,

• cutting or drilling autoclaved aerated concrete (Hebel), etc.

This will include a requirement to control the processing of a CSS by specified means, for example, isolation, wet dust suppression, on-tool extraction or local exhaust ventilation.

Orbit are encouraging all our contractors who’s work involve the above listed tasks to become familiar with these new requirements in ensuring workers on site are across the new provisions.

What products do the new laws apply to?

A CSS is any material that contains at least 1% crystalline silica, determined by weight. It includes materials such as:

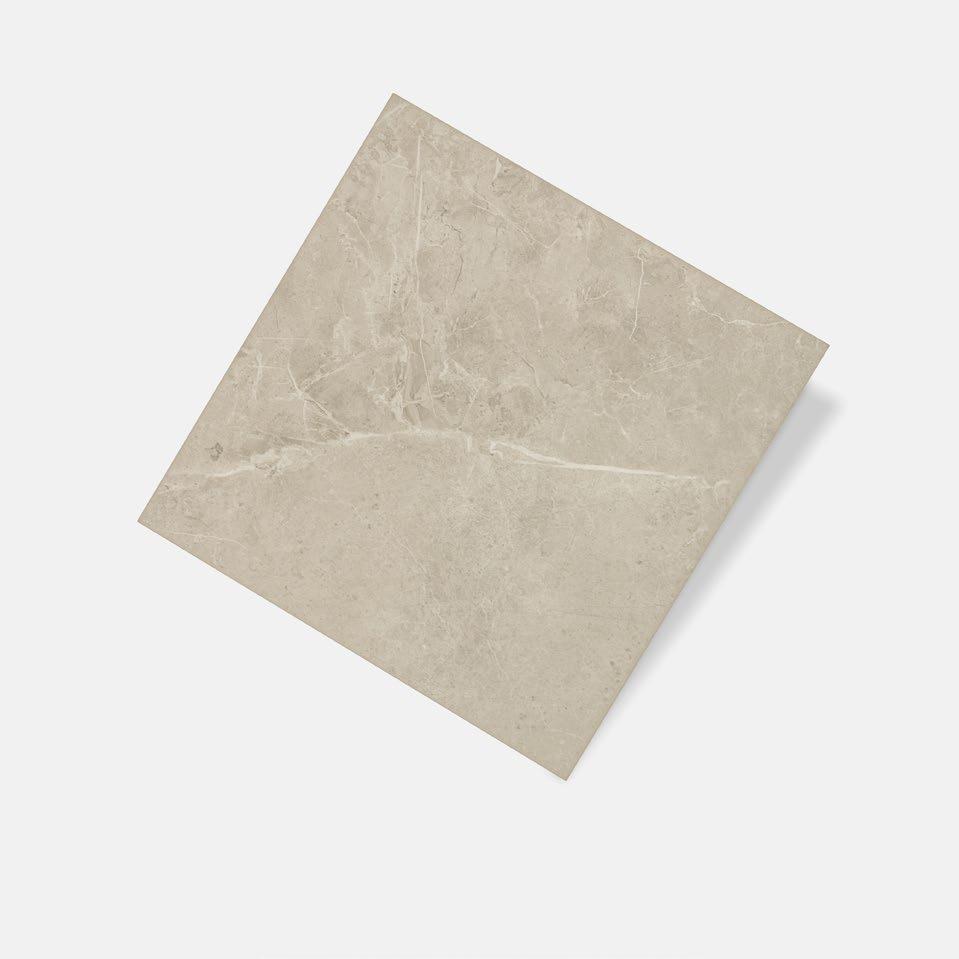

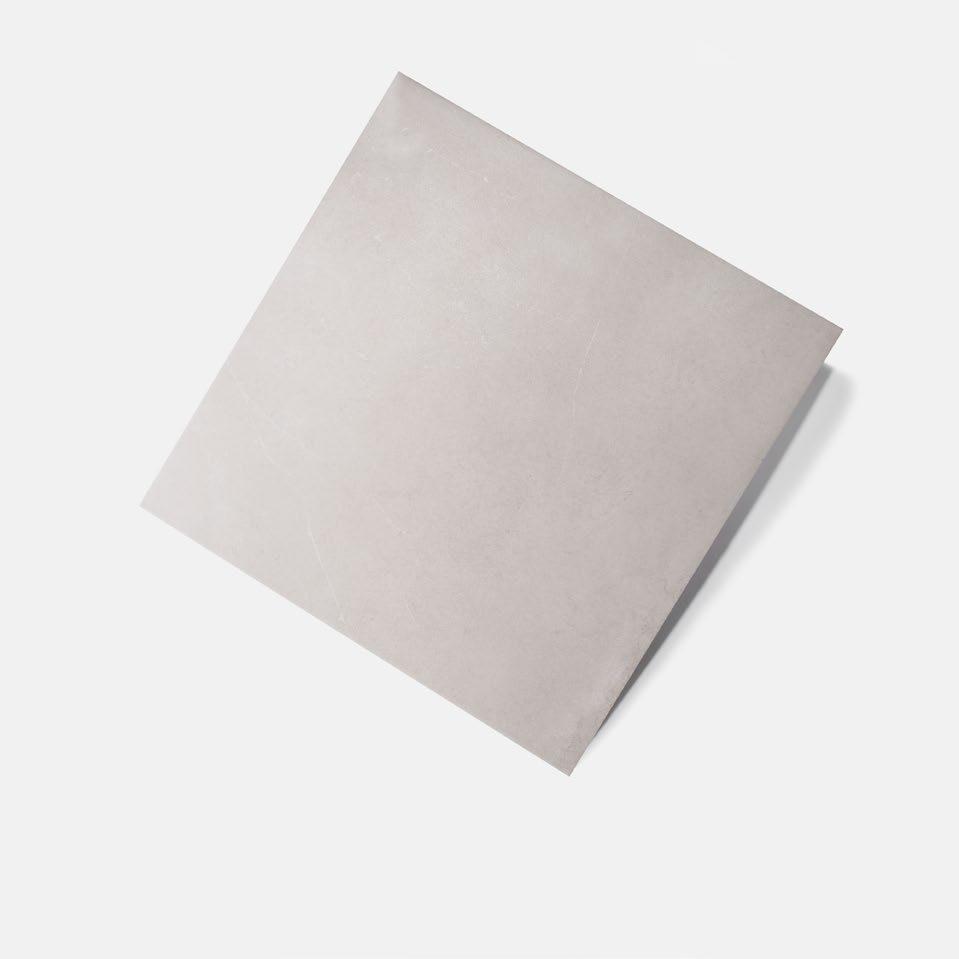

• natural stone products such as marble, granite, sandstone,

• sintered stone,

• porcelain products,

• asphalt,

• cement, mortar, render and grout,

• concrete, concrete blocks and fibre cement products,

• autoclaved aerated concrete (Hebel)

• bricks,

• pavers and tiles including roof tiles.

What should you do next?

When working with any of the products or materials listed above or any other material that contains at least 1% crystalline silica you must:

1. Control the processing of the product or material.

2. Assess if the processing of the product or material is classified as High Risk Crystaline Silica Work (HRCSW)

I have attached a document which is to be used when identifying whether the work or task is classified as HRCSW “High Risk Crystaline Silica Work Identification Management”

Also attached is a “Preparing Crystaline Silica Hazard Control Statement” which is to be used when you have identified the work or task is HRCSW.

As contractors for Orbit you must control the risks associated with exposure to crystalline silica by applying the hierarchy of control in Part 4.1 (Hazardous substances) of the OHS Regulations.

An employer must, so far as is reasonably practicable, eliminate the risks associated with exposure to crystalline silica dust in their workplace.

If it is not reasonably practicable to eliminate a risk associated with crystalline silica, the employer must reduce the risk so far as is reasonably practicable by:

• substitution, for example, instead of using engineered stone which can be up to 95% silica, use natural stone, which can have a much lower silica content

• isolation, for example using automated wet machines

• engineering controls, for example using on-tool water suppression, or

• a combination of any of these risk control measures

If the risks from exposure still remain after the listed risk control measures have been implemented, administrative controls must be used to reduce the risk so far as is reasonably practicable. Administrative controls include, for example, rotation during shifts between high and low-exposure tasks.

Worksafe have put together eight videos that have been developed (5 currently published), focusing on crystalline silica management in the workplace. The video series provides duty holders with practical information and guidance on hazard identification, risk control measures, atmospheric monitoring, and health monitoring. While the video series is primarily targeted to duty holders in the construction industry, the information and guidance can be applied across most industries who work with crystalline silica.

You can find the series of videos here: https://www.youtube.com/playlist?list=PL8jTfq7I4pElZbh3yCT1_Z0TZBp-Q3YU5

Worksafe have also published a very in depth guidance document which has all the information you need as well as the above videos in the document, so please click in the this link: Preventing exposure to crystalline silica dust | WorkSafe Victoria

Please ensure you read and understand the listed information as this affects you and your workers health.

Is my crystalline silica process high risk crystalline silica work? Find out more

• I believe/identified I am undertaking HRCSW; or • I am undertaking an engineered stone process (which is classed as HRCSW)

High risk crystalline silica work (HRCSW) is —

(a) an engineered stone process; or (b) work performed in connection with a crystalline silica process that is reasonably likely to result in— (i) an airborne concentration of respirable crystalline silica that exceeds half the exposure standard for respirable crystalline silica; or (ii) a risk to the health of a person at the workplace. YES:

Develop a crystalline silica hazard control statement (CSHCS)

Download CSHSC PDF or incorporate into a SWMS if the HRCSW is being undertaken as part of high risk construction work

Download SWMS PDF

A CSHCS must be prepared before HRCSW commences Risk assessment deems the

Perform a risk assessment Find out more

the risk assessment until the work is completed

e.g. Isolating persons from exposure to CS, for example excavator operators working in a pressurised cabin with a HEPA filtration system.

e.g. On-tool dust extraction with captor hood or shroud using Dust Class M or H vacuum, using on-tool water suppression that continuously supplies water and suppresses the dust generated.

e.g. Job rotation, implementing good housekeeping practices.

e.g. Provision and use of appropriate RPE, such as a P2 half face respirator (AS 1715 and AS 1716).

WORK SAFE - PREPARING CRYSTALLIND CONTROL STATEMENT

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

How and when to prepare and use a crystalline silica hazard control statement for high risk crystalline silica work.

July 2024

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

How and when to prepare and use

a crystalline silica hazard control statement for high risk crystalline silica work.

July 2024

Note: All engineered stone processes are considered to be high risk crystalline silica work and a crystalline silica hazard control statement is required.

Note: All engineered stone processes are considered to be high risk crystalline silica work and a crystalline silica hazard control statement is required.

From 1 July 2024, the manufacture, supply, processing or installation of engineered stone benchtops, panels or slabs is banned in Victoria. The engineered stone ban applies to engineered stone benchtops, panels and slabs. Engineered stone products not in these forms are not banned. There are limited exceptions to the ban where work can be performed on engineered stone benchtops, panels and slabs. This includes:

• removal, repair or modification of installed engineered stone benchtop and panels

• disposal of installed or uninstalled engineered stone benchtops, panels and slabs

From 1 July 2024, the manufacture, supply, processing or installation of engineered stone benchtops, panels or slabs is banned in Victoria. The engineered stone ban applies to engineered stone benchtops, panels and slabs. Engineered stone products not in these forms are not banned. There are limited exceptions to the ban where work can be performed on engineered stone benchtops, panels and slabs. This includes:

• research and analysis, and

What

is a crystalline silica hazard control statement?

A crystalline silica hazard control statement (hazard control statement) is a document. It is prepared for all high risk crystalline silica work (HRCSW) at a workplace. The hazard control statement sets out:

• the hazards and risks from the work

What is a crystalline silica hazard control statement?

• the measures to control those risks

• how the control measures will be implemented.

A crystalline silica hazard control statement (hazard control statement) is a document. It is prepared for all high risk crystalline silica work (HRCSW) at a workplace.

The hazard control statement sets out:

For quarrying or tunneling processes, the hazard control statement must include the results of sample analysis.

• the hazards and risks from the work

• the measures to control those risks

Find further guidance under the heading, Hazard control statement duties.

• how the control measures will be implemented.

For quarrying or tunneling processes, the hazard control statement must include the results of sample analysis.

What is high risk crystalline silica work?

High risk crystalline silica work is:

Find further guidance under the heading, Hazard control statement duties.

• to sample and identify engineered stone.

• removal, repair or modification of installed engineered stone benchtop and panels

• disposal of installed or uninstalled engineered stone benchtops, panels and slabs

• research and analysis, and

• to sample and identify engineered stone.

Specific controls are required when permitted engineered stone work involves an engineered stone process. An engineered stone process is also considered high risk crystalline silica work and you must comply with the high risk crystalline silica work obligations.

• an engineered stone process, or

• work performed in connection with a crystalline silica process that is reasonably likely to result in:

What is high risk crystalline silica work?

High risk crystalline silica work is:

• an engineered stone process, or

– an airborne concentration of respirable crystalline silica that exceeds half the exposure standard for respirable crystalline silica, or

For more information, see Working with engineered stone and Frequently asked questions - Engineered stone ban. The information is available from the Crystalline silica page on WorkSafe's website.

Crystalline silica

Specific controls are required when permitted engineered stone work involves an engineered stone process. An engineered stone process is also considered high risk crystalline silica work and you must comply with the high risk crystalline silica work obligations.

For more information, see Working with engineered stone and Frequently asked questions - Engineered stone ban. The information is available from the Crystalline silica page on WorkSafe's website.

Crystalline silica

• work performed in connection with a crystalline silica process that is reasonably likely to result in:

– a risk to the health of a person at the workplace.

– an airborne concentration of respirable crystalline silica that exceeds half the exposure standard for respirable crystalline silica, or

– a risk to the health of a person at the workplace.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Exposure standard

Exposure standard

Under the Occupational Health and Safety Regulations 2017 (OHS Regulations), employers must ensure employees are not exposed to respirable crystalline silica dust at the workplace at a level above the exposure standard.

Under the Occupational Health and Safety Regulations 2017 (OHS Regulations), employers must ensure employees are not exposed to respirable crystalline silica dust at the workplace at a level above the exposure standard.

Exposure standards are set out in the Workplace Exposure Standards for Airborne Contaminants, published by SafeWork Australia.

Exposure standards are set out in the Workplace Exposure Standards for Airborne Contaminants, published by SafeWork Australia.

Determining whether exposure exceeds half the exposure standard must be done without taking into account any controls in place that would reduce exposure.

Workplace Exposure Standards for Airborne Contaminants

Determining whether exposure exceeds half the exposure standard must be done without taking into account any controls in place that would reduce exposure.

• A tunnelling process involving material that contains crystalline silica.

• A process that WorkSafe has determined is a crystalline silica process.

• A tunnelling process involving material that contains crystalline silica.

• A process that WorkSafe has determined is a crystalline silica process.

Example of crystalline silica process

Dry sweeping of dust that contains crystalline silica at a workplace is an example of a process that exposes a person to crystalline silica dust.

Example of crystalline silica process

Dry sweeping of dust that contains crystalline silica at a workplace is an example of a process that exposes a person to crystalline silica dust.

What is an engineered stone process?

An engineered stone process is a process involving engineered stone at a workplace that generates crystalline silica dust, including cutting, grinding or abrasive polishing of engineered stone.

What is an engineered stone process?

For more information, see the guidance, Exposure standards and atmospheric monitoring.

Workplace Exposure Standards for Airborne Contaminants

Exposure standards and atmospheric monitoring

For more information, see the guidance, Exposure standards and atmospheric monitoring.

What is a crystalline silica process?

Exposure standards and atmospheric monitoring

A crystalline silica process is one or more of the following processes at a workplace:

What is a crystalline silica process?

A crystalline silica process is one or more of the following processes at a workplace:

• The use of a power tool or other mechanical plant to: – cut, grind, polish or crush material containing crystalline silica

• The use of a power tool or other mechanical plant to:

– cut, grind, polish or crush material containing crystalline silica

– carry out any other activity involving material containing crystalline silica that generates crystalline silica dust.

• The use of a roadheader on an excavated face, if the material in the face contains crystalline silica.

– carry out any other activity involving material containing crystalline silica that generates crystalline silica dust.

• The use of a roadheader on an excavated face, if the material in the face contains crystalline silica.

• A process that exposes a person to crystalline silica dust from the manufacture or handling of material that contains crystalline silica.

• The mechanical screening of crushed material that contains crystalline silica.

• A process that exposes a person to crystalline silica dust from the manufacture or handling of material that contains crystalline silica.

• A quarrying process involving material that contains crystalline silica.

• The mechanical screening of crushed material that contains crystalline silica.

• A quarrying process involving material that contains crystalline silica.

An engineered stone process is a process involving engineered stone at a workplace that generates crystalline silica dust, including cutting, grinding or abrasive polishing of engineered stone.

Specific duties and risk control measures must be complied with when working with engineered stone.

For this information, see Working with engineered stone. Working with engineered stone.

Specific duties and risk control measures must be complied with when working with engineered stone.

For this information, see Working with engineered stone.

When is a hazard control statement

Working with engineered stone.

required?

When is a hazard control statement required?

An employer or a self-employed person must prepare a hazard control statement before starting HRCSW. This includes when carrying out an engineered stone process.

An employer or a self-employed person must prepare a hazard control statement before starting HRCSW. This includes when carrying out an engineered stone process.

Identifying high risk crystalline silica work

Identifying high risk crystalline silica work

Before starting a crystalline silica process, an employer or self-employed person must identify whether the process is HRCSW. This must be done by:

• doing a risk assessment, or

Before starting a crystalline silica process, an employer or self-employed person must identify whether the process is HRCSW. This must be done by:

• choosing to treat the work as HRCSW without doing a risk assessment.

• doing a risk assessment, or

All engineered stone processes are considered to be HRCSW.

• choosing to treat the work as HRCSW without doing a risk assessment.

All engineered stone processes are considered to be HRCSW.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Work that is HRCSW cannot be done unless:

• a hazard control statement is prepared for the work before the work begins, and

Work that is HRCSW cannot be done unless:

• the work is performed in line with that hazard control statement.

• a hazard control statement is prepared for the work before the work begins, and

If a risk assessment is done, the employer or selfemployed person doing the assessment must make a written record that:

If a risk assessment is done, the employer or selfemployed person doing the assessment must make a written record that:

• describes how the listed factors have been taken into account, and

Find further information about hazard control statements under the heading, Hazard control statement duties.

• the work is performed in line with that hazard control statement.

• states whether the crystalline silica process is HRCSW.

• describes how the listed factors have been taken into account, and

• states whether the crystalline silica process is HRCSW.

High risk crystalline silica work assessment duties

Find further information about hazard control statements under the heading, Hazard control statement duties.

The employer or self-employed person must keep a copy of the written record. The copy must be kept for the entire time the crystalline silica process is happening at the workplace. Copies can be kept in electronic format.

High risk crystalline silica work assessment duties

If doing a risk assessment, the employer or selfemployed person must take into account the following factors:

If doing a risk assessment, the employer or selfemployed person must take into account the following factors:

• The specific tasks or processes being done with material that contains crystalline silica.

• The form of crystalline silica to be used, for example, brick, concrete, crushed rock.

• The specific tasks or processes being done with material that contains crystalline silica.

• The proportion of crystalline silica in the material.

• Previous atmospheric monitoring results.

• The form of crystalline silica to be used, for example, brick, concrete, crushed rock.

• The likely frequency and duration of exposure to crystalline silica dust.

• The proportion of crystalline silica in the material.

• Previous atmospheric monitoring results.

• The likely frequency and duration of exposure to crystalline silica dust.

• Any information about incidents, illnesses or diseases associated with exposure to crystalline silica dust at the workplace.

• Any information about incidents, illnesses or diseases associated with exposure to crystalline silica dust at the workplace.

Determining whether the exposure of an employee exceeds half the exposure standard must be done without taking into account any controls in place that would reduce exposure.

Determining whether the exposure of an employee exceeds half the exposure standard must be done without taking into account any controls in place that would reduce exposure.

Note: In conducting this risk assessment, it is not sufficient to rely on the effect of risk control measures that are implemented in accordance with the hierarchy of controls described in this guidance. This means that, for example, even if you are using on-tool dust extraction to control exposure to crystalline silica dust, you still need to undertake a risk assessment as described in this guidance or choose to identify that work as high risk crystalline silica work.

Note: In conducting this risk assessment, it is not sufficient to rely on the effect of risk control measures that are implemented in accordance with the hierarchy of controls described in this guidance. This means that, for example, even if you are using on-tool dust extraction to control exposure to crystalline silica dust, you still need to undertake a risk assessment as described in this guidance or choose to identify that work as high risk crystalline silica work.

An employer must also make the written record readily accessible during the same period to:

The employer or self-employed person must keep a copy of the written record. The copy must be kept for the entire time the crystalline silica process is happening at the workplace. Copies can be kept in electronic format.

• any employee who may be exposed to crystalline silica dust, and

An employer must also make the written record readily accessible during the same period to:

• relevant health and safety representatives (HSRs).

• any employee who may be exposed to crystalline silica dust, and

• relevant health and safety representatives (HSRs).

If an employer or a self-employed person cannot identify whether a crystalline silica process is HRCSW, the process must be treated as HRCSW. The process must be treated as HRCSW until the employer or selfemployed person can establish that it is not HRCSW.

Hazard control statement duties

If an employer or a self-employed person cannot identify whether a crystalline silica process is HRCSW, the process must be treated as HRCSW. The process must be treated as HRCSW until the employer or selfemployed person can establish that it is not HRCSW.

An employer or a self-employed person must not perform HRCSW unless:

Hazard control statement duties

• a hazard control statement is prepared for the work before the work begins, and

An employer or a self-employed person must not perform HRCSW unless:

• the work is performed in line with that hazard control statement.

• a hazard control statement is prepared for the work before the work begins, and

If the work is not done in line with the hazard control statement, the employer or self-employed person must stop that work immediately or as soon as it is safe to do so. Work must not resume until the hazard control statement is complied with or reviewed and, if necessary, revised in line with the OHS Regulations.

• the work is performed in line with that hazard control statement.

If the work is not done in line with the hazard control statement, the employer or self-employed person must stop that work immediately or as soon as it is safe to do so. Work must not resume until the hazard control statement is complied with or reviewed and, if necessary, revised in line with the OHS Regulations.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

An employer must review and revise the hazard control statement whenever:

• the HRCSW changes

An employer must review and revise the hazard control statement whenever:

• there is an indication that risk control measures are not adequately controlling the risk

• the HRCSW changes

• after any incident that occurs during the HRCSW.

• there is an indication that risk control measures are not adequately controlling the risk

• after any incident that occurs during the HRCSW.

A copy of the hazard control statement must be kept for the duration of the HRCSW. The hazard control statement should be available at the location of the HRCSW. It should be readily available to affected persons. Copies can be kept in electronic format.

A copy of the hazard control statement must be kept for the duration of the HRCSW. The hazard control statement should be available at the location of the HRCSW. It should be readily available to affected persons. Copies can be kept in electronic format.

Note: If the HRCSW is being done as part of high risk construction work, a separate hazard control statement is not required where:

What needs to be in a hazard control statement

A hazard control statement must do the following:

What needs to be in a hazard control statement

• State the hazards and risks to health associated with the HRCSW.

A hazard control statement must do the following:

• State the hazards and risks to health associated with the HRCSW.

• Clearly detail the measures selected to control those risks. Risks must be controlled in line with the hierarchy of controls set out in this guidance.

• Describe how the risk control measures will be carried out.

• Clearly detail the measures selected to control those risks. Risks must be controlled in line with the hierarchy of controls set out in this guidance.

• Describe how the risk control measures will be carried out.

• If an analysis is required of samples, contain the results of that analysis. See information under the heading, Quarrying and tunnelling processes.

• Be set out and presented in a way that is readily accessible and clear to the people who use it.

• a safe work method statement (SWMS) has been prepared, and

Note: If the HRCSW is being done as part of high risk construction work, a separate hazard control statement is not required where:

• the SWMS addresses the matters required for a hazard control statement.

• a safe work method statement (SWMS) has been prepared, and

• If an analysis is required of samples, contain the results of that analysis. See information under the heading, Quarrying and tunnelling processes.

The hazard control statement should also identify the:

• date and location the HRCSW is to take place

• Be set out and presented in a way that is readily accessible and clear to the people who use it.

The hazard control statement should also identify the:

• the SWMS addresses the matters required for a hazard control statement.

For more information about SWMS and high risk construction work, see WorkSafe's guidance, Safe work method statements (SWMS).

Safe Work Method Statements guidance

• people responsible for ensuring selected risk controls are put in place and maintained

• date and location the HRCSW is to take place

• names of employees consulted when preparing the document.

• people responsible for ensuring selected risk controls are put in place and maintained

Safe work method statement template

For more information about SWMS and high risk construction work, see WorkSafe's guidance, Safe work method statements (SWMS).

Safe Work Method Statements guidance

A sample hazard control statement template for HRCSW is provided at Appendix A.

Safe work method statement template

A sample hazard control statement template for HRCSW is provided at Appendix A.

Quarrying and tunnelling processes

• names of employees consulted when preparing the document.

If the HRCSW involves a quarrying or tunnelling process, the employer or self-employed person must, before the work begins:

Quarrying and tunnelling processes

• collect samples of materials to be used in the quarrying or tunnelling process, and

If the HRCSW involves a quarrying or tunnelling process, the employer or self-employed person must, before the work begins:

• collect samples of materials to be used in the quarrying or tunnelling process, and

• arrange for analysis of those samples by a suitably competent person to identify the proportion of crystalline silica contained in each sample.

The hazard control statement must contain the results of that analysis.

• arrange for analysis of those samples by a suitably competent person to identify the proportion of crystalline silica contained in each sample.

The hazard control statement must contain the results of that analysis.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Additional duties in relation to high risk crystalline silica work

An employer must ensure that an applicant who applies for work involving HRCSW is given information about:

Additional duties in relation to high risk crystalline silica work

• the health risks associated with exposure to crystalline silica dust

An employer must ensure that an applicant who applies for work involving HRCSW is given information about:

• the need for measures to control those risks, and

Hierarchy of controls

Hierarchy of controls

The hierarchy of controls is a step-by-step approach to eliminating or reducing risks. It ranks risk controls from the highest level of protection and reliability through to the lowest and least reliable.

Eliminate the risk

The hierarchy of controls is a step-by-step approach to eliminating or reducing risks. It ranks risk controls from the highest level of protection and reliability through to the lowest and least reliable.

• details of the control measures.

• the health risks associated with exposure to crystalline silica dust

• the need for measures to control those risks, and

Information, instruction and training

• details of the control measures.

Eliminate the risk

Where there is any risk associated with silica dust at the workplace, employers must first seek to eliminate that risk so far as is reasonably practicable. For example, by using materials that do not contain crystalline silica.

Reduce the risk

Information, instruction and training

An employer must ensure that employees who are likely to be exposed to risks associated with HRCSW are given information, instruction and training in:

• the health risks associated with exposure to crystalline silica dust, and

An employer must ensure that employees who are likely to be exposed to risks associated with HRCSW are given information, instruction and training in:

• the need for, and proper use of, any risk control measures and how they are to be implemented.

• the health risks associated with exposure to crystalline silica dust, and

Where there is any risk associated with silica dust at the workplace, employers must first seek to eliminate that risk so far as is reasonably practicable. For example, by using materials that do not contain crystalline silica.

Reduce the risk

If a risk cannot be eliminated, it must be reduced so far as is reasonably practicable. The risk can be reduced by doing one or a combination of the following:

If a risk cannot be eliminated, it must be reduced so far as is reasonably practicable. The risk can be reduced by doing one or a combination of the following:

• Substituting materials containing crystalline silica with a substance that is less hazardous, or a less hazardous form of crystalline silica. For example, materials with a lower crystalline silica content.

Is a pre-prepared hazard control statement acceptable?

• the need for, and proper use of, any risk control measures and how they are to be implemented.

Is a pre-prepared hazard control statement acceptable?

A pre-prepared hazard control statement is only acceptable if it has been adapted to the individual workplace and the specific HRCSW taking place at that workplace. Employers and self-employed persons will need to review the hazard control statement on-site. They will need to ensure it meets all the requirements set out in this guidance.

A pre-prepared hazard control statement is only acceptable if it has been adapted to the individual workplace and the specific HRCSW taking place at that workplace. Employers and self-employed persons will need to review the hazard control statement on-site. They will need to ensure it meets all the requirements set out in this guidance.

Selecting risk control measures for high risk crystalline silica work

• Substituting materials containing crystalline silica with a substance that is less hazardous, or a less hazardous form of crystalline silica. For example, materials with a lower crystalline silica content.

• Isolating people from the source of exposure to silica dust. For example, by restricting the work to an enclosed cabin.

• Isolating people from the source of exposure to silica dust. For example, by restricting the work to an enclosed cabin.

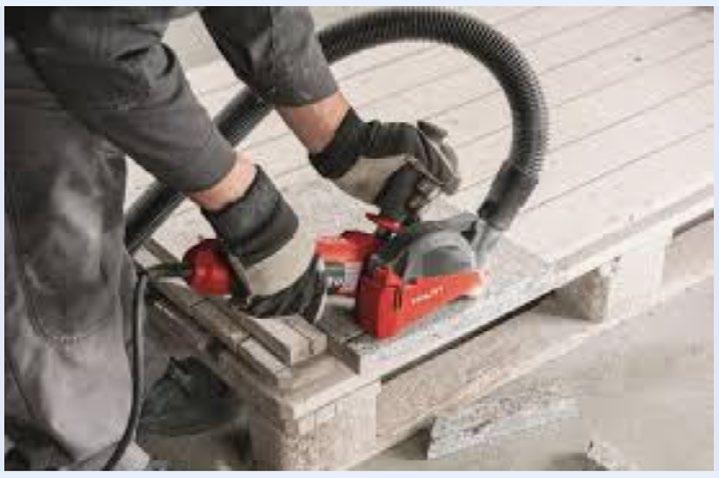

• Using engineering controls. For example, hand-held tools with on-tool water suppression or on-tool dust extraction.

Administrative controls

• Using engineering controls. For example, hand-held tools with on-tool water suppression or on-tool dust extraction.

Administrative controls are work methods or procedures designed to minimise exposure to a hazard.

Administrative controls

Administrative controls are work methods or procedures designed to minimise exposure to a hazard.

Selecting risk control measures for high risk crystalline silica work

When selecting measures to control the risks associated with HRCSW, an employer must apply the hierarchy of controls set out in the OHS Regulations.

When selecting measures to control the risks associated with HRCSW, an employer must apply the hierarchy of controls set out in the OHS Regulations.

Specific duties and risk control measures must be complied with when working with engineered stone. Find more information see under the heading, Required controls when carrying out an engineered stone process.

Specific duties and risk control measures must be complied with when working with engineered stone. Find more information see under the heading, Required controls when carrying out an engineered stone process.

If, after using the listed controls, a risk to health associated with silica dust remains, employers must reduce the risk with administrative controls. Again, they must reduce the risk so far as is reasonably practicable. Examples of administrative controls include:

• reducing the duration and frequency of exposure through job rotation

If, after using the listed controls, a risk to health associated with silica dust remains, employers must reduce the risk with administrative controls. Again, they must reduce the risk so far as is reasonably practicable. Examples of administrative controls include:

• reducing the duration and frequency of exposure through job rotation

• good housekeeping practices, including regular cleaning of work areas with H or M-class vacuums or water.

• good housekeeping practices, including regular cleaning of work areas with H or M-class vacuums or water.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Personal protective equipment

Personal protective equipment

If, after using administrative controls, a risk to health associated with silica dust remains, employers must reduce that risk. They must again reduce the risk so far as is reasonably practicable. This time they must reduce the risk by providing appropriate personal protective equipment (PPE) to employees at risk. For example, respiratory protective equipment such as a half-face negative respirator or powered air purifying respirator (PAPR).

Integrated water delivery system

Integrated water delivery system

An integrated water delivery system, also known as on-tool water suppression, is one of the most effective ways to reduce exposure to crystalline silica dust.

If, after using administrative controls, a risk to health associated with silica dust remains, employers must reduce that risk. They must again reduce the risk so far as is reasonably practicable. This time they must reduce the risk by providing appropriate personal protective equipment (PPE) to employees at risk. For example, respiratory protective equipment such as a half-face negative respirator or powered air purifying respirator (PAPR).

Effective control of risks to health will most likely require a combination of control measures.

Effective control of risks to health will most likely require a combination of control measures.

Note: Employers must, so far as is reasonably practicable, consult with affected employees and any HSRs when identifying hazards or making decisions about measures to control risk.

Note: Employers must, so far as is reasonably practicable, consult with affected employees and any HSRs when identifying hazards or making decisions about measures to control risk.

Required controls when carrying out an engineered stone process

When power tools are used

Required controls when carrying out an engineered stone process

The uncontrolled dry cutting, grinding and abrasive polishing of engineered stone is not permitted in Victoria.

When power tools are used

There are specific controls required when doing permitted work with engineered stone.

The uncontrolled dry cutting, grinding and abrasive polishing of engineered stone is not permitted in Victoria. There are specific controls required when doing permitted work with engineered stone.

When a power tool or other form of mechanical plant is used to undertake an engineered stone process, an employer or self-employed person must ensure plant is used with:

When a power tool or other form of mechanical plant is used to undertake an engineered stone process, an employer or self-employed person must ensure plant is used with:

• an integrated water delivery system that meets the requirements set out in this guidance, or

• an on-tool dust extraction system that meets the requirements set out in this guidance, or

• an integrated water delivery system that meets the requirements set out in this guidance, or

• if these controls are not reasonably practicable, another form of local exhaust ventilation (LEV).

• an on-tool dust extraction system that meets the requirements set out in this guidance, or

• if these controls are not reasonably practicable, another form of local exhaust ventilation (LEV).

An integrated water delivery system, also known as on-tool water suppression, is one of the most effective ways to reduce exposure to crystalline silica dust.

Water is used at the point of dust generation to dampen down or suppress dust before it is released into the air.

An integrated water delivery system must:

Water is used at the point of dust generation to dampen down or suppress dust before it is released into the air.

An integrated water delivery system must:

• deliver a continuous supply of water to the point of contact with the stone while the power tool or mechanical plant is in use, and

• if the system uses recycled or recirculated water, adequately treat that water.

• deliver a continuous supply of water to the point of contact with the stone while the power tool or mechanical plant is in use, and

On-tool dust extraction

• if the system uses recycled or recirculated water, adequately treat that water.

On-tool dust extraction

On-tool dust extraction removes the dust from the source as it is being produced. It is fitted directly onto the tool, with extraction attached to a high efficiency particulate air (HEPA) filtered Dust Class H vacuum cleaner.

An on-tool dust extraction system must:

• be commercially available, and

On-tool dust extraction removes the dust from the source as it is being produced. It is fitted directly onto the tool, with extraction attached to a high efficiency particulate air (HEPA) filtered Dust Class H vacuum cleaner.

An on-tool dust extraction system must:

• be commercially available, and

• be connected to a Dust Class H vacuum or another system that captures any dust generated by the power tool.

• be connected to a Dust Class H vacuum or another system that captures any dust generated by the power tool.

Dust Class H vacuum means a vacuum that complies with the Class H requirements in AZ/NZS 60335.2.69:2017 Household and similar electrical appliances—Safety— Part 2.69: Particular requirements for wet and dry vacuum cleaners, including power brush, for commercial use or its equivalent.

Local exhaust ventilation

Dust Class H vacuum means a vacuum that complies with the Class H requirements in AZ/NZS 60335.2.69:2017 Household and similar electrical appliances—Safety— Part 2.69: Particular requirements for wet and dry vacuum cleaners, including power brush, for commercial use or its equivalent.

Local exhaust ventilation

Local exhaust ventilation (LEV) is an engineering control that captures the emission of an airborne contaminant at its source and transports it to a safe emission point, filter or scrubber. On-tool dust extraction is one form of LEV.

Local exhaust ventilation (LEV) is an engineering control that captures the emission of an airborne contaminant at its source and transports it to a safe emission point, filter or scrubber. On-tool dust extraction is one form of LEV.

Another form of LEV should be used with power tools when integrated water delivery system, or on-tool dust extraction are not reasonably practicable.

Another form of LEV should be used with power tools when integrated water delivery system, or on-tool dust extraction are not reasonably practicable.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Local exhaust ventilation systems such as hoods, booths or extraction walls extract airborne dust from processing areas. While these controls may reduce background levels of silica dust, they are not as effective as water suppression or on-tool dust extraction in reducing the exposure of employees

Local exhaust ventilation systems such as hoods, booths or extraction walls extract airborne dust from processing areas. While these controls may reduce background levels of silica dust, they are not as effective as water suppression or on-tool dust extraction in reducing the exposure of employees

Where an integrated water delivery system, on-tool dust extraction system or another LEV system is required, employers and self-employed persons must ensure those systems are designed, installed, used and maintained, so far as is reasonably practicable, to eliminate or reduce the risk of exposure to crystalline silica dust.

Respiratory protective equipment

Where an integrated water delivery system, on-tool dust extraction system or another LEV system is required, employers and self-employed persons must ensure those systems are designed, installed, used and maintained, so far as is reasonably practicable, to eliminate or reduce the risk of exposure to crystalline silica dust.

Employers must provide an employee who undertakes an engineered stone process with respiratory protective equipment (RPE) that:

Respiratory protective equipment

• is designed to protect the wearer from the inhalation of airborne contaminants, and

Employers must provide an employee who undertakes an engineered stone process with respiratory protective equipment (RPE) that:

Information, instruction and training

Employers must provide their employees with any necessary information, instruction, training and supervision to enable them to do their work safely.

Information, instruction and training

Employers must provide their employees with any necessary information, instruction, training and supervision to enable them to do their work safely.

Employers must ensure employees who are likely to be exposed to risks associated with high risk crystalline silica work are given information, instruction and training in:

• the health risks associated with exposure to crystalline silica dust

Employers must ensure employees who are likely to be exposed to risks associated with high risk crystalline silica work are given information, instruction and training in:

• the need for, and proper use of, any risk control measures required under the OHS Regulations

• the health risks associated with exposure to crystalline silica dust

• how the risk control measures are to be implemented.

• the need for, and proper use of, any risk control measures required under the OHS Regulations

Employers must also provide information, instruction and training to employees who use power tools or other forms of mechanical plant to undertake permitted work on engineered stone.

• how the risk control measures are to be implemented.

Prohibition on cleaning with compressed air and gases

Employers must also provide information, instruction and training to employees who use power tools or other forms of mechanical plant to undertake permitted work on engineered stone.

• is designed to protect the wearer from the inhalation of airborne contaminants, and

• complies with AS/NZS 1716 – Respiratory protective devices, or requirements equivalent to those of the standard.

The employer must also ensure the employee uses the RPE.

• complies with AS/NZS 1716 – Respiratory protective devices, or requirements equivalent to those of the standard.

Prohibition on cleaning with compressed air and gases

An employer or a self-employed person must not use compressed air or other compressed gases to clean the following, unless the use of that air or gas does not result in a concentration of respirable crystalline silica that exceeds the exposure standard for crystalline silica:

• a work area where an engineered stone process has been undertaken, or

An employer or a self-employed person must not use compressed air or other compressed gases to clean the following, unless the use of that air or gas does not result in a concentration of respirable crystalline silica that exceeds the exposure standard for crystalline silica:

The employer must also ensure the employee uses the RPE.

Employers need to provide employees with information, instruction and training in the use, fit and maintenance of RPE, including the system for storage.

Employers need to provide employees with information, instruction and training in the use, fit and maintenance of RPE, including the system for storage.

• clothing a person wore in a work area where an engineered stone process was undertaken.

• a work area where an engineered stone process has been undertaken, or

It is not recommended to use compressed air in any situation where respirable crystalline silica dust may be produced.

• clothing a person wore in a work area where an engineered stone process was undertaken.

It is not recommended to use compressed air in any situation where respirable crystalline silica dust may be produced.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Examples of how to control risks

Example 1: Cutting concrete footpath

Example 2: Cutting a hole in an engineered stone kitchen splash back

Examples of how to control risks

Example 1: Cutting concrete footpath

An employee needs to use a concrete cutting saw to cut a section of footpath. A search of the internet for concrete lists washed sand as an ingredient. Sand contains over 95% crystalline silica (quartz). It is known that concrete may contain 25% to 40% of washed sand.

An employee needs to use a concrete cutting saw to cut a section of footpath. A search of the internet for concrete lists washed sand as an ingredient. Sand contains over 95% crystalline silica (quartz). It is known that concrete may contain 25% to 40% of washed sand.

The job will take one day to complete and it is known that dry cutting of concrete can produce high levels of dust. Cutting concrete is a crystalline silica process. It is unknown what the employee’s actual exposure to silica dust will be from the cutting, so the crystalline silica process is identified by the employer as HRCSW. The employer needs to ensure a hazard control statement is prepared, in consultation with employees, and implemented to minimise exposure to crystalline silica dust for employees and pedestrians.

The job will take one day to complete and it is known that dry cutting of concrete can produce high levels of dust. Cutting concrete is a crystalline silica process. It is unknown what the employee’s actual exposure to silica dust will be from the cutting, so the crystalline silica process is identified by the employer as HRCSW. The employer needs to ensure a hazard control statement is prepared, in consultation with employees, and implemented to minimise exposure to crystalline silica dust for employees and pedestrians.

Risk control measures identified in the hazard control statement and implemented by the employer include on-tool water suppression, preventing access to the work area, good housekeeping during the work and at the completion of the task, ensuring wet residue is not permitted to remain in the area to dry.

Risk control measures identified in the hazard control statement and implemented by the employer include on-tool water suppression, preventing access to the work area, good housekeeping during the work and at the completion of the task, ensuring wet residue is not permitted to remain in the area to dry.

Example 2: Cutting a hole in an engineered stone kitchen splash back

An employee needs to create a hole in a previously installed engineered stone splash back to install a new power point, as part of a kitchen renovation. The employee will need to use a power drill and grinder to create the hole. Cutting into engineered stone is an engineered stone process. The employer does not need to do a risk assessment as working on an engineered stone panel, slab or benchtop is automatically classed as HRCSW. This means that before starting work, the employer must ensure that a hazard control statement is prepared.

The employer must identify and capture the following risk control measures in the hazard control statement. Employers must ensure that:

An employee needs to create a hole in a previously installed engineered stone splash back to install a new power point, as part of a kitchen renovation. The employee will need to use a power drill and grinder to create the hole. Cutting into engineered stone is an engineered stone process. The employer does not need to do a risk assessment as working on an engineered stone panel, slab or benchtop is automatically classed as HRCSW. This means that before starting work, the employer must ensure that a hazard control statement is prepared.

• Power tools are fitted with:

The employer must identify and capture the following risk control measures in the hazard control statement. Employers must ensure that:

• Power tools are fitted with:

– an integrated water-delivery system with fresh or adequately treated recycled or recirculated water that provides a continuous supply of water to the point of contact with the stone while the power tool is in use, or

– an integrated water-delivery system with fresh or adequately treated recycled or recirculated water that provides a continuous supply of water to the point of contact with the stone while the power tool is in use, or

– a commercially available on tool dust extraction system fitted with Dust Class H vacuum.

• RPE such as half-face negative respirators (P2) or powered air purifying respirators (PAPR) are used.

• Access to the work area is prevented.

– a commercially available on tool dust extraction system fitted with Dust Class H vacuum.

• RPE such as half-face negative respirators (P2) or powered air purifying respirators (PAPR) are used.

• Work areas are cleaned to prevent a build-up of crystalline silica dust on plant, equipment, work surfaces and the floors/walls, by using:

• Access to the work area is prevented.

– low-pressure hosing, mopping, squeegeeing or wet wiping down of surfaces

• Work areas are cleaned to prevent a build-up of crystalline silica dust on plant, equipment, work surfaces and the floors/walls, by using:

– washing slabs after cutting

– Dust Class H vacuum.

– low-pressure hosing, mopping, squeegeeing or wet wiping down of surfaces

• Compressed air or other compressed gases must not be used to clean work areas.

– washing slabs after cutting

– Dust Class H vacuum.

• Compressed air or other compressed gases must not be used to clean work areas.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

• Waste contaminated by crystalline silica dust from wet processes and from dry extraction process is kept wet, where applicable, contained, sealed and identified as a silica dust hazard.

• Information, instruction, and training to employees is provided in:

• Waste contaminated by crystalline silica dust from wet processes and from dry extraction process is kept wet, where applicable, contained, sealed and identified as a silica dust hazard.

– the health risks associated with exposure to crystalline silica dust

• Information, instruction, and training to employees is provided in:

– the need for, and proper use of, any risk control measures required and how the risk control measures are to be implemented, and

– the health risks associated with exposure to crystalline silica dust

– the use, fit, maintenance and storage of RPE provided.

– the need for, and proper use of, any risk control measures required and how the risk control measures are to be implemented, and

– the use, fit, maintenance and storage of RPE provided.

Example 3: Demolition of large-scale structure

Example 3: Demolition of large-scale structure

A contractor wins a job to demolish a large structure consisting of bricks and cement-based products. The work will involve using a hammer attachment on an excavator to demolish the structure. There is an overhead electrical power line within 4 m of a perimeter wall to be demolished. Due to this, an electrical spotter is required to spot for the excavator operator while the excavator is within 3 m to 6.4 m of the powerline.

The contractor identifies the demolition task as a crystalline silica process because of the use of mechanical plant to crush the materials, which contain crystalline silica.

A contractor wins a job to demolish a large structure consisting of bricks and cement-based products. The work will involve using a hammer attachment on an excavator to demolish the structure. There is an overhead electrical power line within 4 m of a perimeter wall to be demolished. Due to this, an electrical spotter is required to spot for the excavator operator while the excavator is within 3 m to 6.4 m of the powerline.

The contractor identifies the demolition task as a crystalline silica process because of the use of mechanical plant to crush the materials, which contain crystalline silica.

The contractor conducts a risk assessment by doing the following things:

• Searches the internet to identify the likely silica content of the bricks and cement being demolished and finds a WorkSafe webpage that states that bricks and cement may contain 25% to 40% crystalline silica.

The contractor conducts a risk assessment by doing the following things:

• Searches the internet to identify the likely silica content of the bricks and cement being demolished and finds a WorkSafe webpage that states that bricks and cement may contain 25% to 40% crystalline silica.

• Consults with their employees and conducts a risk assessment. The risk assessment identifies that half of the respirable crystalline silica exposure standard may be exceeded, not taking into account any controls proposed to be used.

The contractor makes a written record describing the matters that were taken into account and identifies the work as HRCSW.

• Consults with their employees and conducts a risk assessment. The risk assessment identifies that half of the respirable crystalline silica exposure standard may be exceeded, not taking into account any controls proposed to be used.

The contractor develops a hazard control statement that lists and uses the following risk control measures:

The contractor makes a written record describing the matters that were taken into account and identifies the work as HRCSW.

• A water-spraying system will be attached to the hammer to produce a fine mist to suppress dust at the working area.

The contractor develops a hazard control statement that lists and uses the following risk control measures:

• A water-mist fan will be used to provide further fine water spray to the working area.

• A water-spraying system will be attached to the hammer to produce a fine mist to suppress dust at the working area.

• A water-mist fan will be used to provide further fine water spray to the working area.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

•The excavator cabin:

•The excavator cabin:

– is retrofitted with HEPA filters to reduce the risk of respirable crystalline silica being drawn into the cabin

– is retrofitted with HEPA filters to reduce the risk of respirable crystalline silica being drawn into the cabin

– will be enclosed and the doors and windows kept shut, air flow will be put on recirculation and the cabin will be cleaned every day using water or a H or M-class industrial vacuum.

– will be enclosed and the doors and windows kept shut, air flow will be put on recirculation and the cabin will be cleaned every day using water or a H or M-class industrial vacuum.

•Atmospheric monitoring of the excavator cabin is done to ensure the controls are managing the risk of exposure.

•Atmospheric monitoring of the excavator cabin is done to ensure the controls are managing the risk of exposure.

•An exclusion zone will be set up around the working area to prevent other people being exposed to the airborne dust.

•An exclusion zone will be set up around the working area to prevent other people being exposed to the airborne dust.

•The electrical spotter will wear a P2 reusable respirator, be clean shaven, trained in how to use, store and maintain the respirator and will perform a fit check after putting the respirator on.

•The electrical spotter will wear a P2 reusable respirator, be clean shaven, trained in how to use, store and maintain the respirator and will perform a fit check after putting the respirator on.

Example 4: Landscaping and high risk construction work

Example 4: Landscaping and high risk construction work

An employee is required to cut sandstone tiles with a brick saw as part of the landscaping works of a residential property under construction.

The supplier of the sandstone pavers has provided the employer with information that the sandstone pavers contain 80% crystalline silica. The task of cutting of the sandstone is a crystalline silica process.

The employer identifies the crystalline silica process as HRCSW.

An employee is required to cut sandstone tiles with a brick saw as part of the landscaping works of a residential property under construction. The supplier of the sandstone pavers has provided the employer with information that the sandstone pavers contain 80% crystalline silica. The task of cutting of the sandstone is a crystalline silica process.

The employer identifies the crystalline silica process as HRCSW.

The landscaping activities also involve movement of a small excavator backfilling trenches and moving soil on site at the same time. These activities are high risk construction work.

The landscaping activities also involve movement of a small excavator backfilling trenches and moving soil on site at the same time. These activities are high risk construction work.

The employer has documented a SWMS, in consultation with employees and the HSR, for the landscaping activities and has included the required elements of a hazard control statement into their SWMS.

The employer has documented a SWMS, in consultation with employees and the HSR, for the landscaping activities and has included the required elements of a hazard control statement into their SWMS.

The information provided by the supplier of the sandstone states that a brick saw should be used with on-tool extraction attached to either a class H or M vacuum to reduce the risk of exposure to respirable crystalline silica. The employer puts this control requirement into the SWMS and purchases the required on-tool extraction and industrial vacuum before starting the job.

The information provided by the supplier of the sandstone states that a brick saw should be used with on-tool extraction attached to either a class H or M vacuum to reduce the risk of exposure to respirable crystalline silica. The employer puts this control requirement into the SWMS and purchases the required on-tool extraction and industrial vacuum before starting the job.

The employee using the equipment is given information about the health risks associated with exposure to crystalline silica dust and trained on how to use the on-tool extraction and industrial vacuum before starting the job, as well as how to empty the industrial vacuum.

The employee using the equipment is given information about the health risks associated with exposure to crystalline silica dust and trained on how to use the on-tool extraction and industrial vacuum before starting the job, as well as how to empty the industrial vacuum.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Related information

•Crystalline silica

Related information

•Construction: Preventing exposure to crystalline silica dust

•Crystalline silica

•Working with engineered stone

•Construction: Preventing exposure to crystalline silica dust

•Dust containing crystalline silica in the extractive industry

•Working with engineered stone

•Safe work method statements (SWMS)

•Dust containing crystalline silica in the extractive industry

•Workplace exposure standards for airborne contaminants (Safe Work Australia)

•Safe work method statements (SWMS)

•Exposure standards and atmospheric monitoring

•Workplace exposure standards for airborne contaminants (Safe Work Australia)

•Exposure standards and atmospheric monitoring

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Appendix A – Sample crystalline silica hazard control statement for high risk crystalline silica work

Appendix A – Sample crystalline silica hazard control statement for high risk crystalline silica work

Employer/ selfemployed person's name:

Employer/ selfemployed person's name:

Workplace address:

Workplace address:

Hazard control statement prepared by:

Hazard control statement prepared by:

High risk crystalline silica work means work performed in connection with a crystalline silica process that is reasonably likely to result in:

High risk crystalline silica work means work performed in connection with a crystalline silica process that is reasonably likely to result in:

• an airborne concentration of respirable crystalline silica that exceeds half the exposure standard for respirable crystalline silica, or

• an airborne concentration of respirable crystalline silica that exceeds half the exposure standard for respirable crystalline silica, or

• a risk to the health of a person at the workplace.

• a risk to the health of a person at the workplace.

An engineered stone process is deemed high risk crystalline silica work.

An engineered stone process is deemed high risk crystalline silica work.

Crystalline silica process (tick all that apply)

Crystalline silica process (tick all that apply)

Trading name: If different from person's name

Trading name: If different from person's name

Hazard control statement date:

Hazard control statement date:

Affected employees and any HSRs have been consulted in the preparation of this hazard control statement:

Affected employees and any HSRs have been consulted in the preparation of this hazard control statement:

The use of a power tool or other form of mechanical plant to:

The use of a power tool or other form of mechanical plant to:

• cut, grind, polish or crush material containing crystalline silica, or

• cut, grind, polish or crush material containing crystalline silica, or

• carry out any other activity involving material containing crystalline silica that generates crystalline silica dust.

• carry out any other activity involving material containing crystalline silica that generates crystalline silica dust.

The mechanical screening of crushed material containing crystalline silica.

The mechanical screening of crushed material containing crystalline silica.

Yes No

Yes No

The use of a roadheader on an excavated face if the material in the face contains crystalline silica.

The use of a roadheader on an excavated face if the material in the face contains crystalline silica.

A quarrying process involving material containing crystalline silica.

A quarrying process involving material containing crystalline silica.

A process determined by WorkSafe to be a crystalline silica process.

A process determined by WorkSafe to be a crystalline silica process.

Person responsible for ensuring compliance with hazard control statement:

Person responsible for ensuring compliance with hazard control statement:

Is the hazard control statement accessible and comprehensible to persons who use it?

Is the hazard control statement accessible and comprehensible to persons who use it?

What measures are in place to ensure compliance with the hazard control statement:

What measures are in place to ensure compliance with the hazard control statement:

For example, direct supervision, regular spot checks.

For example, direct supervision, regular spot checks.

Date hazard control statement reviewed:

Date hazard control statement reviewed:

Reason for reviewing hazard control statement:

Reason for reviewing hazard control statement:

For example, post incident, ineffective risk controls.

For example, post incident, ineffective risk controls.

Who completed the review of the hazard control statement?

Who completed the review of the hazard control statement?

Name: Role:

Name: Role:

Yes No

Yes No

Name:

Name:

Role:

Role:

A process that exposes a person to crystalline silica dust arising from the manufacture or handling of material that contains crystalline silica.

A process that exposes a person to crystalline silica dust arising from the manufacture or handling of material that contains crystalline silica.

A tunnelling process involving material containing crystalline silica.

A tunnelling process involving material containing crystalline silica.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Risk controls specified by the Occupational Health and Safety Regulations 2017

Risk controls specified by the Occupational Health and Safety Regulations 2017

Selecting risk controls

Selecting risk controls

Any risk to health or safety must be eliminated. If it is not reasonably practicable to eliminate the risk, it must be reduced so far as is reasonably practicable.

Any risk to health or safety must be eliminated. If it is not reasonably practicable to eliminate the risk, it must be reduced so far as is reasonably practicable.

Eliminate the risk –most effective Use materials that do not contain crystalline silica. Do this so far as is reasonably practicable.

• Substituting the substance with a less hazardous substance, or a less hazardous form of the substance. For example, use materials that contain a lower crystalline silica content.

Eliminate the risk –most effective

Use materials that do not contain crystalline silica. Do this so far as is reasonably practicable.

Reduce the risk –less effective

Reduce the risk –less effective If it is not reasonably practicable to eliminate the risk, reduce the risk by:

If it is not reasonably practicable to eliminate the risk, reduce the risk by:

• Substituting the substance with a less hazardous substance, or a less hazardous form of the substance. For example, use materials that contain a lower crystalline silica content.

• Isolating people from the hazard. For example, using automated wet machines.

• Isolating people from the hazard. For example, using automated wet machines.

• Use engineering controls. For example, use power tools fitted with on-tool water suppression or on-tool dust extraction.

• Use engineering controls. For example, use power tools fitted with on-tool water suppression or on-tool dust extraction.

• A combination of any of the previously listed risk control measures.

• A combination of any of the previously listed risk control measures.

• If a risk to health and safety remains, use administrative controls to reduce the risk. For example, good housekeeping and waste management practices, task rotation and warning signs.

• If a risk to health and safety remains, use administrative controls to reduce the risk. For example, good housekeeping and waste management practices, task rotation and warning signs.

• If a risk remains after using substitution, isolation, engineering and administrative controls, the risk must be reduced with personal protective equipment (PPE). For example, respiratory protective equipment such as half-face negative respirators or powered air-purifying respirators, eye protection and protective clothing.

• If a risk remains after using substitution, isolation, engineering and administrative controls, the risk must be reduced with personal protective equipment (PPE). For example, respiratory protective equipment such as half-face negative respirators or powered air-purifying respirators, eye protection and protective clothing.

More effective

Less effective

Using administrative controls and PPE to reduce risks does not control the hazard at the source. Administrative controls and PPE rely on human behaviour and supervision. Used on their own, they tend to be least effective in minimising risks.

Using administrative controls and PPE to reduce risks does not control the hazard at the source. Administrative controls and PPE rely on human behaviour and supervision. Used on their own, they tend to be least effective in minimising risks.

What are the processes involved?

What are the processes involved?

List the work processes in logical order.

List the work processes in logical order.

What are the hazards and risks? What aspects of the work could harm workers or the public?

What are the hazards and risks? What aspects of the work could harm workers or the public?

For example: Inhalation of respirable crystalline silica dust from:

For example: Inhalation of respirable crystalline silica dust from:

• cutting a concrete footpath

• cutting a concrete footpath

• cutting a hole in an engineered stone kitchen splash back

• cutting a hole in an engineered stone kitchen splash back

• demolition of large scale structure

• demolition of large scale structure

What are the risk control measures and how will they be implemented?

What are the risk control measures and how will they be implemented?

Describe what will be done to make the process as safe as possible?

Describe what will be done to make the process as safe as possible?

• cutting sandstone tiles with a brick saw as part of the landscaping works, which may result in adverse health effects, such as silicosis.

• cutting sandstone tiles with a brick saw as part of the landscaping works, which may result in adverse health effects, such as silicosis.

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Preparing a crystalline silica hazard control statement for high risk crystalline silica work

Where high risk crystalline silica work involves a quarrying or tunnelling process: (tick all that have been undertaken)

Samples of materials to be used in the quarrying or tunnelling process have been collected.

Where high risk crystalline silica work involves a quarrying or tunnelling process: (tick all that have been undertaken)

Analysis of the sample has been arranged by suitably competent person to identify the proportion of crystalline silica contained in each sample.

Samples of materials to be used in the quarrying or tunnelling process have been collected.

Results of any analysis for quarrying or tunnelling process have been received and are attached to this hazard control statement.

Analysis of the sample has been arranged by suitably competent person to identify the proportion of crystalline silica contained in each sample.

Additional comments

Results of any analysis for quarrying or tunnelling process have been received and are attached to this hazard control statement.

Additional comments

HOW TO WORK SAFELY WITH PRODUCTS CONTAINING SILICA

How toworksafelywithbuilding products containingSilica/BenOutten Complete

SafetyAlertTopic

HowtoworksafelywithbuildingproductscontainingSilica

Date 25.10.202410:58AEDT

Preparedby BenOutten

ContextofSafetyAlert

Thissafetyalertistogiveabetterunderstandingtoourcontractorsaroundthebuildingproductsthat containcrystallinesilicaandthedifferentcontrolmeasuresthatshouldbeusedwhencutting,grinding, drillingoranyotherformofalterationstothematerial.Asthebuilderwewillbeensuringthatany noncompliancewiththeregulationswillresultinlossofcontractwithOrbitHomes.

SafetyAlert

SafetyAlert

TopicCovered

TopicCovered

TopicCovered1

Issue identified

Issueidentified

TopicCovered1

Alterations to a concrete slab once dried by any contractor

Alterationstoaconcreteslaboncedriedbyanycontractor

Issueidentified

Alterationstoaconcreteslaboncedriedbyanycontractor

Corrective actions

Correctiveactions

As a contractor you must, so far as is reasonably practicable, eliminate the risks associated with exposure to crystalline silica dust in your workplace.

Correctiveactions

Asacontractoryoumust,sofarasisreasonablypracticable,eliminatetherisksassociatedwithexposureto crystallinesilicadustinyourworkplace.

When any form of cutting, grinding, drilling or any other alterations to the concrete slab you MUST have a control measure in place such as on tool wet suppression or on tool dust extraction with a minimum of a P2 mask been worn for both measures.

Whenanyformofcutting,grinding,drillingoranyotheralterationstotheconcreteslabyouMUSThavea controlmeasureinplacesuchasontoolwetsuppressionorontooldustextractionwithaminimumofaP2 maskbeenwornforbothmeasures.

Asacontractoryoumust,sofarasisreasonablypracticable,eliminatetherisksassociatedwithexposureto crystallinesilicadustinyourworkplace.

AhazardcontrolstatementaswellasSWMSwiththeabovecontrolsmustbeimplementedasrequired.

A hazard control statement as well as SWMS with the above controls must be implemented as required.

Whenanyformofcutting,grinding,drillingoranyotheralterationstotheconcreteslabyouMUSThavea controlmeasureinplacesuchasontoolwetsuppressionorontooldustextractionwithaminimumofaP2 maskbeenwornforbothmeasures.

TopicCovered2

AhazardcontrolstatementaswellasSWMSwiththeabovecontrolsmustbeimplementedasrequired.

TopicCovered2

Issueidentified

Issue identified

AlterationstoScyonflooringmaterialinupperfloorwetareasbyanycontractor

Issueidentified

Alterations to Scyon flooring material in upper floor wet areas by any contractor

AlterationstoScyonflooringmaterialinupperfloorwetareasbyanycontractor

Correctiveactions

Corrective actions

Correctiveactions

As a contractor you must, so far as is reasonably practicable, eliminate the risks associated with exposure to crystalline silica dust in your workplace.

Asacontractoryoumust,sofarasisreasonablypracticable,eliminatetherisksassociatedwithexposureto crystallinesilicadustinyourworkplace.