MUNICIPAL PAVING AWARD

Associated Paving & Materials wins ONTARIO

FIRST

diverging diamond interchange

SPRING OPS SEMINAR

preparing for the future

The official publication of the Ontario Asphalt Pavement Council,

Ontario Asphalt Pavement Council

365 Brunel Road, Mississauga, ON, L4Z 1Z5

Tel: (905) 507-1107 • Fax: (905) 890-8122

Email: info@onasphalt.org

Website: www.onasphalt.org

Publications Mail Agreement #40011181

ADVERTISING

Sharon Headley | 226.979.7315 | sharon.headley@orba.org

EDITOR Lara Henry | larahenry@sympatico.ca

DESIGN & EDITORIAL LAYOUT pdplante.com inc. | pdominiqueplante@gmail.com

CHAIR’s CORNER

Chris Campbell Chair

“ There is nothing permanent except change” - Heraclitus

Change is important. Without it, businesses and associations can become complacent and unable to adapt to the ever-evolving needs of customers and members. Even the largest organizations have fallen victim to the folly of not pivoting quickly enough in a dynamic marketplace.

But organizations are made up of people—and people tend to resist change. We are creatures of habit; we like consistency. It’s comfortable and easy. Yet change helps us stay fresh, identify new opportunities, shift our perspectives, and optimize how we operate.

This isn’t me trying to be ominous or negative—quite the opposite. I’m addressing a topic that’s often overlooked or misinterpreted. Within the pavement association, we’ve experienced significant change over the past few years. We’ve had staffing transitions that have led us in new directions and connected us with new partners. We’ve seen changes in our member offerings, including the types and locations of events we host. We’ve made changes within our committees, blending elements of both OAPC and ORBA to find common ground–all of which, I believe, have positively contributed to our growth.

However, change needs to be monitored and tailored to ensure it has a meaningful, lasting, and positive impact. Change should not happen simply for the sake of it. We must remain mindful of both the long-term benefits and the potential consequences. That’s why engaged membership is so critical to this process.

As the OAPC directors, it is our duty to represent our members and make decisions that ensure an effective and resilient association for years to come. With that responsibility comes key decisions: What strategies should we prioritize? Which engagements add real value? Where can we find cost savings? Which longstanding traditions have become outdated?

As both the OAPC and ORBA leadership continue to identify opportunities for improvement, we count on our members to provide feedback that guides us in new directions—while still holding us accountable to being the voice you deserve. It takes all of us to make this work.

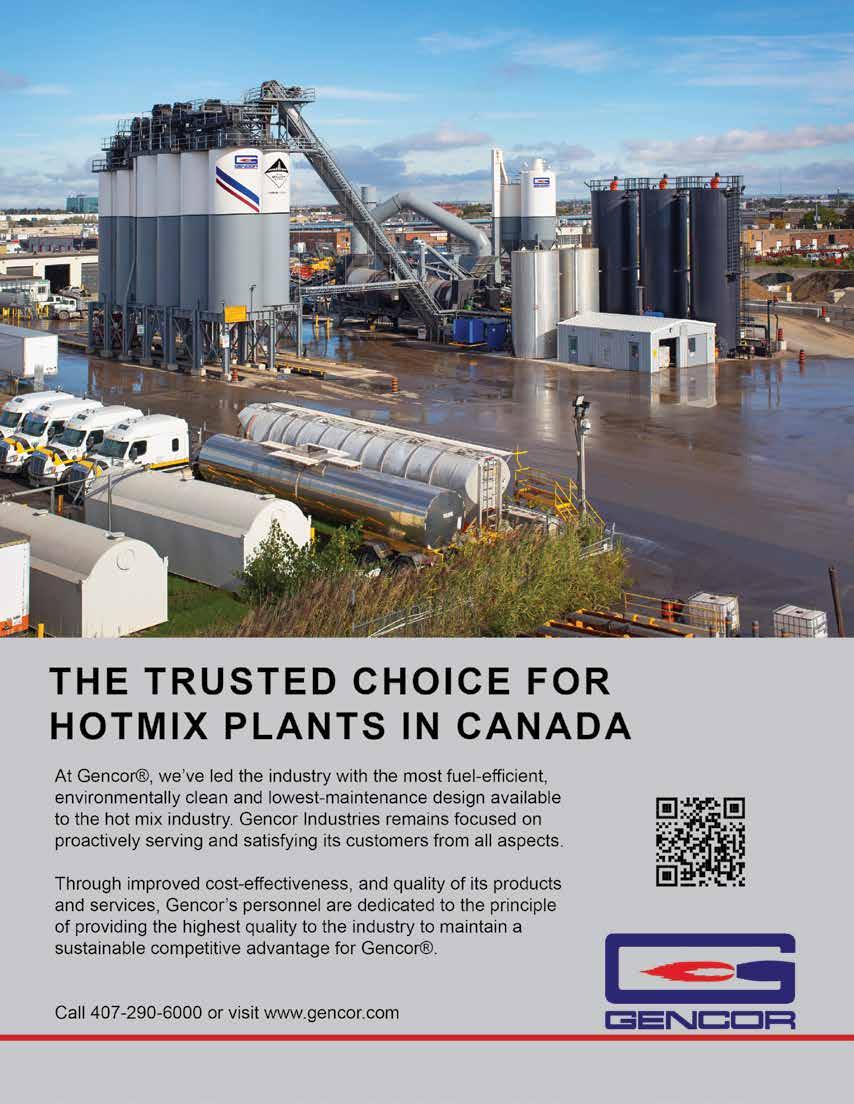

With that said, our association continues to focus on initiatives that benefit both our members and the industry as a whole. In April, we held our Spring Operations Seminar in Hamilton. This well-attended event, with over 120 participants, covered topics such as mentoring the next generation, managing moisture in RAP, and gaining insights into the asphalt binder manufacturing process. The agenda reinforced our commitment to educating members on preparing for the future—not only in attracting and retaining talent but also in deepening technical knowledge so we can confidently defend and promote our industry. The day concluded with being treated to an equipment show and a tour of the asphalt blending facility at Yellowline Asphalt Products Ltd.

Looking ahead, Toronto will host two prestigious events in 2025: the Asphalt Institute (AI) Summer Meeting in August and the Canadian Technical Asphalt Association (CTAA) Annual Conference in November. These opportunities don’t come around often, so OAPC is working closely with both organizations to support diverse content and meaningful engagement for our local industry. With this in mind, we’ve chosen to defer the Asphalt Technical Symposium for 2025.

As is tradition, we will still host our annual golf tournament in August and our Fall Asphalt Seminar later in the year. I look forward to seeing you at one of these fantastic events!

OPERATIONS CORNER

Donn Bernal Technical Advisor, Asphalt Industry

Collaborations are key to success!

I would first like to introduce myself for those who don’t know me. My name is Donn Bernal and I was recently appointed Technical Advisor, Asphalt Industry, for ORBA. I have been in the asphalt industry in Ontario for the past twenty-five plus years and involved in the various aspects of asphalt technology, production, and construction. I have also been a board/council member of OAPC as well as a member of various committees such as marketing and environment. I am excited to be part of a vibrant team of individuals with the singular focus of the betterment of the road building and infrastructure industry.

Secondly, I would like to thank Doubra Ambaiowei for his many years of contributions to OAPC and ORBA. Doubra has carried the baton of representing the asphalt members in Ontario with various stakeholder committees and participation in numerous seminars and conferences. It is now my responsibility to do the same as well as take two ORBA key initiatives that stem from our strategic priorities to the finish line — the development of asphalt Environmental Product Declarations for Ontario (EPDs), and the acceptance of an asphalt plant certification program with our membership and road owners.

You might have also heard that York Region has a high-RAP demonstration project that is happening in late summer/early fall. We want to make sure that everyone gets to see what this is all about. We talked about completing a pave-in, but the logistics and safety concerns for a project that is being paved at night no longer made it an option. However, we are doing one better with a mini-series on this project comprised of webinars and livestreams of the project. So keep an eye out for this. Details will be released shortly.

I want to thank York Region for taking on this initiative and working with our members to develop this demonstration project. Furthermore, the National

Research Council Canada (NRC) is participating in the project by installing various instrumentation in the pavement to help monitor this project for years to come.

The Asphalt Institute (AI) will be holding their summer meeting in August in Toronto this year. This is a perfect opportunity for the Asphalt Institute and ORBA to bring local stakeholders together for a “Conversation to Consensus” workshop and discuss and gain feedback on current challenges in the asphalt industry and how we can work together to resolve them.

Extending the OAPC golf tournament to an ORBA-wide event has allowed us to hold a larger tournament with more participants. With that comes a venue that allows us to really bring a lot of additional features to the golf tournament and the networking aspect of the event is bigger than ever. I hope you signed up early as registrations sold out quickly and a waitlist added. It’s the event of the summer!

Lastly, in the spirit of collaborations and finding synergies, the ORBA and OAPC environmental committees have combined into one committee. A couple of meetings have already occurred with terms of reference being established. Similarly, the marketing committees are also being combined and that should take effect shortly. By combining these committees, we can take advantage of the contributions of the subject matter experts from both committees and more effectively tackle the issues at hand.

Many projects are on the go this summer and we can’t make it all happen without the industry’s support. Thank you!

MARCOM MATTERS

Kourtney Adamson

Engaging and retaining youth in our industry

As we FINALLY see some warm weather, OAPC is very aware of the many hot topics that are having a major impact on the construction industry and has been actively working to bring these issues to the forefront.

One of the most persistent issues that affects all aspects of the construction industry is the shortage of skilled trades. This is something that OAPC, ORBA and the industry have had on our radar for some time, proactively hosting educational seminars and presentations which have featured how to encourage, engage and retain youth in our industry.

Our most recent presentation was at the OAPC Spring Operations Seminar held in April where we had a panel of wellrespected members of our industry focus on mentorship for youth. Each panelist had a different story of how they came to the construction industry, but all had one common reason as to why they stayed in the industry — they had amazing mentors.

Mentorship is something that we often talk about but still haven’t quite figured out how to do effectively and systematically. Mentorship is so critical to the growth and acceptance of employees and to the future growth of a company as well as an industry.

As an industry, we have not been well represented as an option for the younger generation in middle and high school or at home for that matter. We need to change this perception. We need to demonstrate how far this industry has come in so many ways through our safety initiatives, sustainability efficiency, technology, variety of career opportunities, and diversity. And we need to do better to educate, promote and encourage youth into the construction industry.

We have a clear and unified message to:

• Align training with real-world skill demands;

• Expand inclusion for women, Indigenous youth, and newcomers; and

• Scale up apprenticeships and upskilling programs in partnership with industry.

Stay tuned as OAPC and ORBA continue to educate and advocate to a wide range of groups including lobbying all levels of government to revisit how they promote skilled trades in schools.

Kourtney Adamson is Sales Manager for Yellowline Asphalt Products Ltd. and Chair of the OAPC Marketing Committee.

Excellence and innovation are hallmarks of the best paving projects in Ontario. Three of the best were recognized during the eighth annual Municipal Paving Project of the Year award ceremony held at the 2025 Good Roads Conference in April.

Tby James Careless

MUNICIPAL PAVING AWARDS HONOUR THE BEST IN ONTARIO

he 2024 Municipal Paving Project of the Year award winner was Associated Paving and Materials (APM) for their efficient, minimally disruptive work on the large-scale Town of Milton 2024 Overlay Program. The two finalists were G. Williams Paving for their reconstruction of Kingston’s Sand Hill Road, and Lisbon Paving for their resurfacing of County Road 9 in Simcoe County.

The Municipal Paving Project of the Year award recognizes successful municipal-private sector collaborations in hot mix asphalt road construction in Ontario. All municipal hot mix paving projects completed between January 1, 2024 and November 30, 2024 were eligible. Award applicants are judged based on a range of criteria including aesthetics, conformance to specifications based on testing, innovation, workmanship and considerations such as night paving, traffic, and work windows among others. ››

Town of Milton Overlay Program (APM)

ASSOCIATED PAVING & MATERIALS PAVES

SEVENTEEN ROADS FOR MILTON

The Town of Milton 2024 Overlay Program was an ambitious project, and Associated Paving & Materials (APM) was up for the job. As the successful bidder on the project, APM committed to executing various hard and soft surface repairs and full roadway resurfacing of 17 streets throughout the Town of Milton. This included approximately 95,000 square metres of roadway milling (90 mm/50 mm thicknesses), the laying down of approximately 7,500 tonnes (t) of fiber-reinforced HL1, 1,200 t HL1, 6,500 t HDBC, 3,200 t HL3 and 900 t HL8 asphalt; plus about 6,000 linear metres of crack repair, 3,000 linear metres curb repair, 1,000 square metres of sidewalk repair, and over 100 newly installed AODA corners.

To make matters more challenging, APM was required to complete the project between May 6 and August 9 while abiding with contract restraints such as separating binder asphalt paving and surface asphalt paving by five business days to ensure conformance of the binder asphalt prior to surface paving.

The use of advanced technology in this project exemplified best practices, innovative methods, and strong collaboration.

A maximum of five calendar days was allowed after the roadway was milled for the contractor to place the binder course. As well, a maximum of eight streets were allowed to be under construction simultaneously, while three streets (Croft, Laurier, and Savoline) had to be completed between July 2 and August 9 due to school zones.

Diana Betancour is the Town of Milton’s Project Manager, Infrastructure. “The asphalt overlay team was proud of the work completed as part of the resurfacing program, particularly on Savoline Boulevard,” she says. “The use of advanced technology in this project exemplified best practices, innovative methods, and strong collaboration.”

According to Betancour, the key aspects that made this project stand out included the use of echelon paving, which significantly improved the quality of the final product; night work that increased productivity and minimized disruption to the community; success in both technical execution and communications throughout the project that kept everything on track; and a strong commitment from the contractor, consultant and the town to deliver a high-quality result-on schedule and within the approved budget.

“Under a tight schedule and operational constraints, APM Paving worked closely with the Town of Milton and WSP (the consultant) to deliver the 2024 Milton Asphalt Overlay project on time, meeting or exceeding all quality and safety standards,” Betancour says. “Special attention was given to Savoline Boulevard, where nearly 3,300 tonnes of fiber-reinforced HL1 asphalt were placed in a single night. Using four pavers and two material transfer vehicles, the full 1.5 km stretch was

DIANA BETANCOUR

Town of Milton

paved in one 16-metre-wide pass in echelon, producing a virtually seamless surface. This result was achieved through careful planning and co-ordination among all project partners, with a shared goal of minimizing community impact. The project was completed on budget and received strong positive feedback from the community.”

Winning the 2024 Municipal Paving Award is a major accomplishment for APM, project consultant WSP, and the Town of Milton alike. “Recognition for this project is meaningful to all the team members — contractor, consultant and municipality,” says Betancour. “It validates the collaborative effort and provides a model that can be successfully applied to future projects.”

She adds that the team learned three lessons from this successful project – first, planning, collaboration, and commitment are key to a successful project; second, a contractor with the right capacity, equipment, expertise, and training is essential; and third, a knowledgeable and engaged consultant team adds significant value.

G. WILLIAMS PAVING LTD. COMPLETES KINGSTON’S FIRST RURAL ECHELON PAVING PROJECT

The reconstruction of Kingston’s Sand Hill Road [Phase 2] by G. Williams Paving was a standout in two ways. First, this project marked the first time that the city has used echelon paving for the entire pavement structure on a road project. Second, the reconstruction project was finished well ahead of schedule.

“The project highlights include the replacement of all cross-culverts, pulverizing the existing 150 mm to 240 mm thick asphalt, fine grading with 100 mm of additional granular A, new guiderail, slope protection, check dams, shoulder subdrains, asphalt millings shoulder, shoulder sealing, and two lifts of asphalt comprising 60 mm of SP19 and 50 mm of SP12.5,” says Melanie Knowles, Project Manager in Engineering Services at the City of Kingston. “We used 2800 tonnes of SP 19 (PGAC 64-28) and 2400 tonnes of SP 12.5 (PGAC 64-28).” ››

Sand Hill Road, Kingston (G. Williams Paving Ltd.)

Kingston chose echelon paving to construct a more robust centerline joint as well as shorten the overall traffic disruption.

MELANIE

KNOWLES

For Knowles, using echelon paving for the first time for the base and top lift was the biggest highlight of the Sand Hill Road project. The City of Kingston chose this method “in an effort to construct a more robust centerline joint as well as shorten the overall traffic disruption,” she says. “From a green perspective, we left existing RAP (Reclaimed Asphalt Pavement) in place to strengthen the road base and imported asphalt millings to prevent washout on shoulders. Thanks to G. Williams’ expertise, the project was completed successfully and 46 days ahead of schedule.”

The overall high quality and finish of the Sand Hill Road project makes it stand out. “The remarkable visual appearance and workmanship were reflected in compaction and asphalt test results, all within specification,” Knowles says. “The paving operation

occurred during full road closure with detour while the remaining work was completed under single lane closures to reduce the impact to local travelers.”

G. Williams Paving achieved these impressive results even though Sand Hill Road was not the easiest project to work on. “The road had a history of washing out, and small washouts constantly appeared until the road was repaved and ditches were revegetated and lined with riprap,” says Knowles. “The largest hurdle in this project was managing stormwater during active construction on this road with grades up to 7 per cent and super-elevated curves where the natural geology comprised sandy soils and granite cliffs.”

One year later, the reconstructed Sand Hill Road is handling traffic and the weather with ease. “The check dams and ditches are holding up well, a testament to the good design and workmanship,” Knowles says. “This project showcased innovative techniques and sustainable practices, setting a new standard for future projects within the City of Kingston.”

LISBON PAVING DELIVERS QUALITY WORK IN RECORD TIME

The second runner-up for the 2024 Municipal Paving Award was Lisbon Paving Company ‘s resurfacing of County Road 9 (from Centreline Road to Mary Street, approximately 5.3 km) in Ontario’s Simcoe County.

(Lisbon Paving/Simcoe)

City of Kingston

County Road 9 was last resurfaced in 1995 followed by a 2013 microsurfacing overlay to extend the pavement life.

Simcoe County decided to resurface County Road 9 in 2024 because its PCI (Pavement Condition Index) had declined significantly due to population growth in western Simcoe County. Increased traffic volumes, particularly truck traffic servicing the Village of Creemore, required the paved platform width to be increased to reduce edge breaks and increase ride quality.

“The County Road 9 project in the Township of Clearview included a full rehabilitation incorporating Cold-In-Place recycling to reuse and stabilize the existing asphalt surface followed by the placement of 90 mm of hot mix asphalt,” says Ryan Guthrie, Simcoe County Engineering Technician II. “The end result provides an asphalt composition of 190 mm of asphaltic material to provide an increased service life.”

The project included a full rehabilitation incorporating Cold-InPlace recycling to reuse and stabilize the existing asphalt surface.

RYAN GUTHRIE

Simcoe County

A separate contractor first recycled and stabilized 100 mm of existing County Road 9 asphalt while also incorporating the existing shoulder to obtain a wider paved roadway. Lisbon Paving then applied 5,010 tonnes of Superpave 19 PGAC 58-34 asphalt to a thickness of 50 mm, and then 4,400 tonnes of Superpave 12.5 PGAC 58-34 to a depth of 40 mm to the renovated roadbed. A further 260 tonnes of SP12.5 PGAC 58-34 was used for driveways, and 5,550 tonnes of Granular A gravel for road shoulders.

“The project overcame challenges such as weather delays and heavy traffic,” says Arlindo Araujo, Vice President of Lisbon Paving. “By applying best practices in asphalt production and paving, we achieved outstanding quality and efficiency.”

One benefit that the County Road 9 project delivered was speed. “We laid over 9,400 tonnes of asphalt in under 45 production hours for an average of 208 tonnes per hour and had a peak day of 3,100 tonnes laid at a site more than 70 kilometres from our asphalt production facility,” says Araujo. “The 5.3 km project was completed in less than one month for both the Cold-In-Place recycling and hot mix paving activities,” Guthrie adds.

The success of the County Road 9 project is an example of the positive client/ contractor relationship that the Municipal Paving Award celebrates. “The partnership between the County of Simcoe and Lisbon Paving was central to the project’s success, with all parties collaborating closely from the planning stages to final execution,” says the award submission. “Additionally, this collaboration has fostered stronger relationships between Lisbon Paving, Simcoe County, and other local municipalities, setting a positive precedent for future projects in Ontario.”

“One key lesson was the value of early and ongoing collaboration between the County of Simcoe and Lisbon Paving,” says Araujo. “Regular communication allowed us to quickly address challenges such as weather delays and high traffic volumes without compromising on quality.” His bottom line: “Lisbon Paving was able to demonstrate our ability to meet rigorous standards and tight timelines. From a community perspective, the project significantly improved road safety and quality.”

James Careless is an Ottawa-based freelance writer with credits in the National Post, Toronto Star, and AI’s Asphalt magazine.

MENTORING YOUTH, ASPHALT PROCESSING, AND TERMINAL TOUR HIGHLIGHTS

AT SPRING OPERATIONS SEMINAR

YOUTH, PROCESSING, TOUR

by Lara Henry

This year’s OAPC Spring Operations Seminar on April 10, 2025, featured a dynamic panel discussion on mentoring the next generation of road builders. The seminar opened with Chris Campbell highlighting OAPC’s objectives for 2025 and the Roads Scholarship Program. The morning’s agenda also included presentations on RAP moisture management; oil refining before the AC blending process; and asphalt binders and specifications.

Following the seminar, participants enjoyed lunch and a tour of the Yellowline asphalt blending terminal. ››

Panel Discussion

MENTORING THE NEXT GENERATION OF ROAD BUILDERS

MODERATOR:

Mike Deckert, Vice-President, Flo Components, and chair of the OAPC Plant & Paving Committee

PANELISTS:

• Adam Davies, Chair, School of Trades and Apprenticeship, Conestoga College, Brantford Airport & Guelph Campuses

• Steve Mate, Manager, Waterloo Construction, Steed and Evans Ltd.

• Melanie Winter, Executive Director, Support Ontario Youth

What are some common reasons employees who have been mentored and had a clear path forward in their career leave your company or the industry?

STEVE: One of the most common reasons that employees who have been mentored leave our company is growth. They want instant success; instant growth. They are not willing to put in the time to learn what the industry is about and what it has to offer.

Salary is another contributing factor for employees leaving. The area that we work in has a significant pay discrepancy versus those who work in the GTA for example.

We frequently hear that this next generation is seriously uncommitted to employers. Do you think this is true?

MELANIE: No, I don’t believe they are uncommitted. However, I do think they prioritize different values than previous generations did. And honestly, I don’t mind some of these values, especially considering the positive changes they’ve influenced in the market and legislation.

How many leaders find themselves glued to their smartphones after work hours, wishing they could truly disconnect and focus on their personal and family lives rather than always keeping one foot in work? These values have led to the right-to-disconnect policies and legislation.

Today’s generation wants to know that the work they do adds value to society — that it has meaning. They care about the impact their work has on the environment and strive for a work-life balance.

Additionally, many young people worry about whether they will ever be able to afford a home. Because many are living at home longer than those of us on this panel likely did, there are life lessons they haven’t yet experienced — ones that you may need to help them navigate.

3

Many of the most successful people in our industry were/are not necessarily academics. What are your thoughts on young employees who show the right aptitude? What is required to mentor these employees?

L-R: Steve Mate, Melanie Winter, Mike Deckert, Adam Davies.

ADAM: It’s not uncommon for colleges to have learners with many different styles of learning. In the trades, some students pick up things better with hands-on work and may struggle with the theory. It’s important to build training programs that reinforce the theory with a practical aspect. Students can see that the theoretical side has a technical application to grasp concepts better.

MELANIE: I believe that aptitude, initiative, and a strong desire to learn are the key ingredients in developing highperforming employees. While formal education can provide valuable knowledge, success in our industry often comes down to practical experience, problem-solving skills, and a willingness to adapt.

Mentoring these employees requires a structured approach that includes guidance, support, and opportunities for growth. First and foremost, it’s important to foster a culture where curiosity and continuous learning are encouraged. Providing challenging but manageable tasks allows young employees to develop their skills while building confidence in their abilities.

At what level of your career did you begin to benefit from being mentored?

ADAM: I was mentored right out of university as I was entering the workforce. I was very lucky to encounter someone in the trade that I was going into even before I entered the field. Having a mentor and that influence was so helpful. Since then, I have had many mentors throughout my career. I think mentorship should be occurring from day one on the job.

MELANIE: I grew up professionally in a manufacturing organization that strongly valued mentorship and had a well-structured succession planning system. We hired new graduates in HR and finance and paired them with senior HR or finance professionals, providing them with a safe space to learn, make mistakes, and receive mentorship over a two-year period.

Early in my career, I was fortunate to be mentored by a senior leader who understood that his legacy would be built on the individuals he helped grow and develop. His mentorship profoundly shaped my career within that organization over an 18-year commitment, and even now, I continue to give him credit for recognizing my potential back then. I still carry his lessons with me and often find myself quoting his wisdom in my work today.

STEVE: Mentoring began on day one for me. As a labourer, I watched and learned, always aspiring to work like the experienced crew members around me. My goal was simple: to perform and give my best every day.

As I advanced, I had the privilege of learning from a variety of mentors—skilled inspectors, project managers, and seasoned professionals who had spent years immersed in this industry. Each one shaped my understanding and growth in unique ways.

5

What have you learned about yourself as you have progressed through your career?

STEVE: One of the first things I learned was the importance of asking questions. I entered the workforce as a 21-year-old college graduate, thinking I had all the answers, but I quickly realized that there was much more to the job than what I had learned in the classroom. The real-world experience of the older, more seasoned staff proved invaluable

Patience was another key lesson. When I first joined Steed and Evans as a labourer, I knew that starting at an entrylevel position was just the beginning. I worked hard, stayed patient, and trusted that if I remained dedicated and focused, opportunities would come my way. The journey from labourer to owner has been challenging but deeply rewarding, and it serves as a reminder that growth in any career takes time, perseverance, and a willingness to learn from others.

6

What are the expectations of students coming from the college programs? Where do they expect to start?

ADAM: Many students expect to start at top of company! As a college, we work to temper expectations and make them realistic. We explain that in their field, graduates will start at various levels of responsibility with their employers. We tell students that while we’ve prepared them for where their career will take them, they have to earn their employer’s trust and demonstrate competencies to move up in the company.

7

MELANIE: I believe there is a disconnect between the expectations of the new generation and the needs of employers when it comes to workforce development. As employers, it is our responsibility to set realistic expectations regarding career goals and advancement while clearly outlining how we will support employees in their growth. ›› 4

Would developing and having a “career roadmap” be advantageous when speaking with today’s youth? What are their expectations?

MELANIE: My organization is a not-for-profit charity, so I’m never going to be able to compete with for-profit companies when it comes to salary. That’s why it’s crucial for me to have open conversations with my staff about the areas of the organization they would like to explore and grow in.

In many ways, if I can’t be the highest-paying employer in the market, then providing opportunities for development, promotion, and overall job satisfaction becomes even more important. These aspects align with what this generation values—having the ability to give back, contribute to society, and see their work as meaningful and impactful.

8

What are the main points you would like to make sure everyone starting in this industry understands about advancing?

Employers play a critical role in shaping the next generation of workers by providing structured guidance, fostering skill development, and creating opportunities for growth within the industry.

Providing guidance on skill development, career progression, and workplace expectations ensures that young professionals understand the opportunities available to them while aligning their aspirations with the realities of the industry. When organizations invest in mentorship, training, and transparent communication, employees can build meaningful careers with a clear understanding of how to advance within the field.

STEVE: The key to success in this field is to start from the bottom and climb your way up. Companies recognize and value people who show promise, and they’re always looking for individuals who provide value. If you show that you’re dedicated, hard-working, and willing to learn, a company will find a position for you.

A business doesn’t want to lose good people, and the more value you bring to the table, the more likely you are to advance. So, if you’re starting in an entry-level position, keep in mind that it’s just the beginning. Show your potential, work hard, and opportunities for growth and advancement will follow. In construction, the path to success is there for those who are willing to put in the effort.

9

10

How much impact do high school guidance counsellors have on students pursuing postsecondary options?

ADAM: Guidance counsellors have a lot of impact on students, as do other family influencers. However, not all high school guidance counsellors understand the pathways into the trades and the apprenticeship process, or polytechnic

MELANIE WINTER

education as a whole. At the college, we host events for guidance councillors on pathways through apprenticeship and educate on the right courses for students such as math and sciences. We educate guidance counsellors and other influencers so that they have the right information to provide prospective students

MELANIE: Over the past three years, the Ministry of Education has actively supported the upskilling of guidance counsellors, particularly in skilled trades. We’ve had the privilege of contributing to this effort, assisting with their professional development across various school boards throughout the province.

Guidance counsellors play a crucial role in helping students navigate their post-secondary options by providing information, support, and direction tailored to their strengths and aspirations. With enhanced training, they can offer deeper insights into emerging career opportunities, ensuring students make well-informed decisions about their futures.

What are your expectations of employers continuing the mentoring/learning process for today’s youth?

MELANIE: My expertise lies in apprenticeship, and 85 per cent of learning in the apprenticeship pathway is achieved through on-the-job training and mentorship. Because of this, my expectations for employers to actively mentor young workers are quite high - it’s essential if we want to build the skilled labor force that our industry requires.

Investing in mentorship ensures that young professionals develop the hands-on experience and practical knowledge needed to succeed. Employers play a critical role in shaping the next generation of workers by providing structured guidance, fostering skill development, and creating opportunities for growth within the industry.

From your experience, how are other industries approaching the workforce, especially at young ages, to attract them to a career in their industry?

ADAM: What I see in other trade sectors is that they participate in awareness events such as job fairs, work experiences, coops, and so on. They try to involve students at an early stage by getting involved with elementary schools, so they are exposed to that particular industry or trade. It’s also important to reach family members so that they understand the trades and industry as they have a lot of influence.

How do we make our industry more appealing to the younger workforce?

STEVE: One of the initiatives we’ve implemented is our Counselor Day which I’m involved with as a member of the CHCA board. The idea behind this day is that we invite high school counselors and students who have decided that postsecondary schooling isn’t the path they wish to take. We give them a hands-on, real-world experience by putting them

through various road-building disciplines. They get the chance to see, feel, and understand what it’s really like to work in construction and build roads from the ground up. What’s often overlooked is the tremendous opportunity that road building can provide. While the work can be tough, it offers a great standard of living for those who are willing to put in the effort and dedication.

How do we lose the mindset that construction cannot balance a good work-to-home relationship and is only for those with low education levels?

ADAM: Education is key – guidance counsellors and family influencers need to understand that technology has advanced rapidly and many positions in trades need high levels of math, science and computer skills. For work-life balance, industry needs to promote that balance and support it by building that balance into company policies and procedures.

MELANIE: The perception that construction is only for individuals with low education levels is false. While some trades allow entry without completing high school - requiring only Grade 10, in some cases - those apprentices often need additional support, tutoring during in-class training, and more preparation before taking their Certificate of Qualification (licensing exam). Additionally, many unions and college programs have their own prerequisites, reinforcing the need for skill development and formal training.

Regarding work-life balance, as the industry continues to evolve, forward-thinking employers who explore new and innovative ways to address labor needs will be able to attract talent from previously untapped markets. Companies that prioritize flexibility, employee well-being, and sustainable work practices will help reshape the narrative that construction demands an unbalanced lifestyle.

Technology impacts our business daily. The need for these systems to meet job specifications is evergrowing. How can we convey to the next generation that their skill sets are highly in demand in our industry?

ADAM: We convey it when we build technology into the curriculum and programs, and when we have industry advising those programs and incorporating their trade or industry into various events. We host high school students at events where they can see what’s involved in a particular industry. They learn how skills and technology are incorporated and try out equipment.

MELANIE: One of Support Ontario Youth’s on-staff mentors who work in the HVAC sector often speaks about how technology has made her job easier and safer. However, despite these advancements, the need for skilled professionals remains just as strong. Technology isn’t replacing workers - it’s enhancing efficiency and reducing the risks associated with hazardous tasks.

Attendees toured and learned about the asphalt cement terminal operations at the afternoon program at Yellowline’s terminal.

YELLOWLINE ASPHALT CEMENT TERMINAL TOUR

by Donn Bernal

The Spring Operations Seminar included a tour of the Yellowline asphalt cement terminal in Hamilton, the first time the seminar has featured an asphalt cement terminal. While the weather didn’t co-operate and if felt like a snow storm was coming with the high winds and wet air, there was a lot of excitement and intrigue about how an asphalt terminal operates.

Most attendees had been to a hot mix asphalt plant before where storage tanks hold two to three loads of asphalt cement at approximately 40 metric tonnes each. The terminal has four massive asphalt storage tanks that hold 8,000 tonnes and five-day storage tanks that hold 800 tonnes for a total of 36,000 tonnes. It would take 200 asphalt cement tanker truck loads or 100 rail cars or one large barge to fill just one of these large storage tanks!

Another feature of interest was the rail cars and the steam emanating from them. These railcars are loaded from a refinery and come in from various points across Canada, mostly from the west. Steam lines are connected to the bottom of the railcar to allow steam to circulate around coils to soften the asphalt cement to a pumpable or flowable temperature (usually 125 to 150˚C). Once it reaches the desired temperature, another hose is connected to the bottom of the railcar to pump the asphalt cement to one of the large storage tanks.

Yellowline has two polymer modification plants to handle the increased demand for polymer modified asphalt cement. Attendees learned about the whole process from the milling of the polymers to the shear mill, mixing tank, addition of the cross-linker, and the letdown tank where the final product is made.

Yellowline also has an on-site quality control performance graded asphalt cement (PGAC) laboratory where attendees saw the extent of testing required to ensure quality asphalt cement in delivered to the hot mix asphalt plants.

A good day of learning on all counts.

SPRING OPERATIONS SEMINAR PRESENTATIONS ARE AVAILABLE ON THE OAPC WEBSITE AND INCLUDE THE FOLLOWING:

OAPC Plant Safety Awards – Daulta O’Hanlon

OAPC Trillium Award Program — Barry McFadyen

RAP Moisture Management: A Review of Infrared Heating Technologies — Barry McFadyen

Smart Roadway Management — Ray Atrvash

Asphalt Cement (AC) 101: Oil Refining Process Before Sending to AC Suppliers — Chris Campbell

Asphalt Binders 101: Towards Better Specifications — Tony Kucharek

By emphasizing how technological advancements improve workplace safety and productivity rather than eliminating the need for skilled trades, we can help the next generation see the value of their expertise in the industry. Encouraging hands-on learning alongside technical knowledge will reinforce that their role is indispensable, no matter how advanced the tools become.

Can you provide any guidance as to how to promote our Industry opportunities to middle and high school?

ADAM: We recommend to industry to get in touch with the local workforce planning boards and local chamber of commerce committees, many of whom have education advisory committees. In Brantford, we ran events for middle schools where industry participates and runs events. This also applies to high school. Everyone benefits when there’s a strong partnership between colleges and industry. If industry tells us what they need, then we can help run the events.

MELANIE: Getting into schools is keystudents start talking about what they want to be when they grow up as early as grade one. I’ve personally offered to speak in my children’s classrooms multiple times and have always been welcomed with enthusiasm.

Teachers and school boards are constantly looking for ways to engage with industry professionals and bring real-life examples into their classrooms. Offering presentations, hands-on activities, and mentorship opportunities provides students with practical insights into career paths while keeping costs low for schools. By making industry outreach interactive and accessible, we can spark interest and inspire the next generation to explore the opportunities available to them.

Lara Henry is a communication specialist and editor of ASPHALTopics.

AWARD-WINNING DIVERGING

(Brennan)

by James Careless

MAKING PAVING HISTORY IN ONTARIO

The interchange at St. Catharines’ Glendale Avenue and the Queen Elizabeth Way (QEW) has always been a very busy traffic zone and one that has been the site of many vehicular accidents. To reduce accidents and improve traffic flow, the Ontario Ministry of Transportation (MTO) initiated the province’s first Diverging Diamond Interchange (DDI) at this location which opened to traffic in November 2022. ››

The Glendale Diverging Diamond Interchange (Glendale DDI) project was the first of its kind in Ontario and an award-winner for general contractor Brennan Paving and Construction Ltd., a key business within The Miller Group. Brennan won the MTO contract in August 2020 in partnership with Morrison Hershfield who provided the detailed design, engineering, and environmental services with assistance from Thurber Engineering and Engtec.

Two years later, Brennan’s work on the Glendale DDI was recognized with the company winning the Outstanding Achievement Award in the Enduring Design Category at the Niagara Biennial Design Awards. Hosted by the Niagara Region government, the Niagara Biennial Design Awards are a biannual awards program that celebrates design excellence in Niagara.

WHAT IS A DIVERGING DIAMOND?

According to the MTO’s RoadTalk newsletter (summer 2023 edition) that headlined the Glendale DDI project, “A diverging diamond interchange (DDI) is an innovative breakthrough in road engineering. On this type of interchange, traffic on a minor street, in this case Glendale Avenue, diverges to the left-hand side of the road through two cross-over intersections. This enables left-turning traffic to access the major road or highway, in this case the QEW, without waiting for signals or crossing oncoming traffic.”

The DDI design eliminates the need for left-turning drivers to cross lanes of opposing traffic when entering or exiting the QEW. Instead, the motorists use interconnected crossover lanes controlled by traffic lights and signs with no risk of being hit by oncoming vehicles going in the opposite direction.

“The crossover intersections are what make DDIs different from other interchange designs,” says RoadTalk . “The crossovers smoothly transition traffic from the right side of the road to the left side of the road and then back again. Because traffic is on the left-hand side between the crossovers, all left turns occur without having to cross opposing traffic. The road geometry, signs, and pavement markings all work together to make this very intuitive.”

The benefits associated with the DDI model are numerous. With left-hand turns across opposing traffic eliminated, studies have found fewer accidents, less injury to drivers, less vehicle damage, better traffic flows, and reduced traffic congestion.

“Reducing vehicle conflicts and allowing unrestricted left turning movements improves the overall performance of the interchange,” RoadTalk says. “Typically, where two, two-lane roadways intersect, there are 32 possible conflict points between all vehicle paths. Diverging diamonds reduce the number of conflict points to 14.”

The results speak for themselves. According to this MTO publication, the first DDIs that were implemented in Missouri have delivered a 60 per cent drop in collisions since being opened in 2011. Meanwhile DDIs in Calgary have led to a 40 per cent reduction in overall collisions and a 75 per cent reduction in turning movement collisions.

DDIs can also be built to be pedestrian and cyclist friendly. For instance, the Glendale DDI’s multi-use path directs cyclists and pedestrians to the interior of the interchange’s traffic island where they are protected from traffic as they cross from one side to another.

BRENNAN’S ROLE IN THE GLENDALE DDI PROJECT

The Glendale DDI contract was valued at $54 million. “The project took three years,” says Jim Whitehead, Brennan’s General Manager of Central Region, Paving Operations. “The design was done in 2020; we started work in 2021 and finished it in 2023.”

Tom Saxton is General Manager of Brennan Paving Niagara, a division of Brennan Paving and Construction. “Our civil group handled all aspects of the general contractor role,” he says. “The main focus was the bridge and bridge earthworks of the divergent diamond interchange. It replaced the existing Glendale bridge structure over the QEW which was old and due for replacement.”

Brennan Paving Niagara provided all of the granular placing for the project as well as all of the asphalt paving with some help from Miller Paving. All told, 50,000 tonnes of asphalt were laid down along with 4,500 cubic metres of concrete and 150,000 tonnes of granular.

“There were three main kinds of hot mix asphalt used,” says Saxton. “There was some SP25 — not a lot of that — say about a couple thousand tonnes. There was close to 30,000 tonnes of SP19 and then around 20,000 tonnes of SP 12.5 FC2.”

Brennan Paving Niagara started the Glendale DDI project in April 2021 with the staging work to accommodate revised traffic flows and prep work for the new bridge structure’s approaches and granular courses. The detour construction, median sewers, airport structure shoring, and Airport Road connection were also addressed at this time.

The work really accelerated in 2022. “The main focus that year was on the divergent diamond approaches and reworking the north and south sides of the Glendale Bridge superstructure,” says Saxton. There was a turning circle constructed on the north side of the structure plus a commuter carpool lot built on the northwest quadrant of the project which connects to Airport Road. A new connection from Glendale Avenue to Airport Road was built as well along with a single-lane roundabout at the intersection of Glendale and York Road. All the tie-ins for both sides of the divergent diamond interchange

To minimize the project’s impact on traffic, paving on the QEW was done at night.

(Brennan)

were completed as well as the milling and resurfacing of the QEW in the vicinity of the structure.

PLANNING AND CO-ORDINATION KEY

A project as big and potentially disruptive as the Glendale DDI involved a great degree of preplanning and co-ordination. According to RoadTalk , “The project required consultation with several stakeholders including local businesses, Niagara College, the Town of Niagara-on-the-Lake and internal MTO offices. Other provincial ministries and federal agencies were also indirectly involved to ensure the project complied with the Species at Risk Act (MNR), Ontario Water Resources Act (MECP), and Fisheries Act (DFO) legislation. The Region of Niagara partnered with the Ontario Ministry of Transportation (MTO) by entering into a cost sharing agreement for work within the Region’s authority.”

“There was preloading that was required to consolidate the earth at the abutments, so we had to get material in and preload right away,” says Whitehead. “It took time to get the soil to consolidate and it was being monitored. Once it hit a level of settlement that was acceptable to the designers, we were able to remove the material and start building first with temporary shoring. There were box culverts, new drainage patterns, extensive electrical work, plus a lot of staging back and forth because not only was there a bridge replacement

being built across the QEW, but there was another bridge that had to be constructed to access Airport Road which runs beside of the QEW.

We also had to deal with the fact that the new structure was being built while the existing structure remained. The original structure was demolished after the new interchange was complete. We found the shoulders needed to be strengthened after we did some shoulder widening work to facilitate traffic flow. They were not performing as anticipated, so they needed to be repaired. Fortunately, that was resolved very quickly.”

To minimize the project’s impact on traffic, paving on the QEW was done at night. Still, the large scope of the construction meant that the ramps on and off the QEW to Glendale Avenue had to be closed for 60 days. “There were also lots of limitations early in the contract with regard to environmental concerns with species at risk and bird nesting,” says Whitehead. “So they all had to be mitigated early.”

AN AWARD-WINNING PERFORMANCE

Despite being the first Diverging Diamond Interchange to be built in Ontario, the Glendale DDI project went quite smoothly. “The project turned out great as far as the paving work went,” says Saxton. “We’re very happy with it. We did a good job and it’s standing up well.” ››

This sentiment was evidently shared by Niagara Region, the chief beneficiary of the Glendale DDI project. Its organization presented the Niagara Biennial Design Award to Brennan Paving and Construction.

“Obviously we’re quite pleased winning this award,” Saxton says. “Everyone at the company is quite proud of it and our involvement with the Glendale DDI Project.”

Even though paving the Glendale DDI was similar to other road projects, Saxton says this job was “a very interesting project for us and our crews because it was so

different. Even though the operations themselves were very similar, it was a different type of design that they found interesting to work on.”

This fact helped offset the stresses associated with working in a high traffic area like the QEW. “It is a heavy use area,” says Saxton. “There’s an outlet mall there. Niagara College is adjacent to it and there are many vehicles going to Niagara-on-the-Lake. So there were periods of very heavy traffic which did impact schedules and planning, but nothing out of the ordinary for us to handle with our type of work.”

What really helped was the teamwork, Whitehead noted. “There was a good relationship between the contractor, the Ministry, and the consultants,” he says. This opinion is shared by Stephanie Huppunen, Niagara Region’s Manager of Capital Projects –Transportation Engineering in RoadTalk “The partnership and communication with the MTO and other key team members on this project throughout all stages has been excellent overall.

“With our residents and visitors as the end users, it is an exciting time in the Niagara Region to be part of this monumental and innovative form of transportation engineering.”

“The locals were very nervous about using a diverging diamond interchange,” says Whitehead. “This is why an information session was held before it opened. It helped to inform and calm locals and those who attended because they were very concerned about manoeuvring their vehicles through. Afterwards, when we opened the Glendale DDI and people drove through it, they found it to be straightforward and efficient.”

The success of the Glendale DDI project in reducing accidents while improving traffic flows on the QEW suggests that more such projects may be in Ontario’s future.

OAPC Plant Safety Excellence Awards at Spring Ops

The Plant Safety Excellence Award recognizes asphalt plants for their outstanding achievement in plant safety that have gone one year without an accident and those that have reached the milestone of being accident-free for 5, 10, 25 and 30-plus years.

Consecutive thirty-five-year threshold with zero lost time

L-R: Chris Campbell, Will Van Vliet, Mike Deckert

OXFORD SAND AND GRAVEL LIMITED

Woodstock Asphalt Plant

Consecutive ten-year threshold with zero lost time

L-R: Chris Campbell, Jake Dekker, Mike Deckert

STEED AND EVANS LIMITED

Halton Asphalt Supply Plant

L-R: Chris Campbell, Daniel Mayo, Mike Chapman, Mike Deckert

STEED AND EVANS LIMITED

Heidelberg Asphalt Plant & Cambridge Asphalt Supply Plant

L-R: Chris Campbell, Gerald Sullivan, Kate Lyons-Davies, Mike Deckert

DUFFERIN CONSTRUCTION COMPANY

Simcoe Asphalt Plant & Hamilton Asphalt Plant

Consecutive five-year threshold with zero lost time

L-R: Chris Campbell, Mitch Knapton, Mike Deckert

G. TACKABERRY & SONS

CONSTRUCTION COMPANY

Athens Asphalt Plant

Congratulations to all the 2024 OAPC plant safety excellence award winners.

One year accidentfree mentions

• Aecon Construction and Materials Ltd.

• Associated Paving & Materials Ltd. • Brantco Asphalt and Materials Ltd.

• Bruno’s Contracting

• Cornwall Gravel Company Limited • Cox Construction Limited • D. Crupi & Sons Ltd.

• Dufferin COnstruction Company

• Fermar Asphalt Limited

• Forest Paving Ltd.

• Four Seasons Site Development Ltd.

• Fowler Construction Company Limited

• GIP Interpaving Ltd.

• GIP Paving

• Greenwood Asphalt Products Limited

• J-AAR Paving

• J Provost Contracting

• King Paving & Construction Ltd.

• Lisbon Asphalt Products Limited

• Miller Group

• Pave-Al Limited • Pioneer Construction Inc.

• R.W. Tomlinson Ltd.

Steed and Evans Limited • Taranis Contracting Group

• Thomas Cavanagh Construction

• Villeneuve Construction Co. Ltd. • Walker Aggregates Inc.

MIXBUSTERS

by Dr. Buzz Powell and Dave Johnson

Most of you are probably familiar with the Discovery Channel program, “Myth Busters.” For 15 years they would address various myths or urban legends to try to determine if they were true or not. We enjoyed the application of science and engineering to determine whether a commonly held strong belief was actually false.

Typically, a strong true or false was established for a particular subject; however, that was not always the case. Sometimes, they found that circumstances and conditions would influence the outcome. In such cases, the answer would begin with, “it depends on…”

Similarly, within the asphalt world, there are many long and often strongly held beliefs that may need to be examined objectively to establish if they are true or not. Together, we have over 70 years of experience designing, constructing, maintaining and experimenting with asphalt pavements and will tackle some myths.

We have a willingness to question and challenge various “truths” we “know” about the design, construction and maintenance of asphalt pavements.

“ TACK COAT CAN BE SKIPPED WHEN PAVING MULTIPLE LIFTS IN SHORT ORDER AS THE FRESH MATERIALS WILL STILL BOND TOGETHER.”

Most asphalt roads are constructed by building in successive layers to reach an overall design thickness. Inherent in the determination of that overall design thickness is an assumption by the designer that all ››

THE TRUTH ABOUT ASPHALT

MYTHS

the layers will be bonded together so that they act as a single unit and not independently. This is why we call it “structurally adequate” bonding. Much like a glulam that might be used in the building of your house, asphalt construction includes the use of a gluing layer known as a tack coat. Most commonly this glue will be a light application of an asphalt emulsion, which admittedly, can be a pain for the contractor to deal with.

Because it can be a pain, it’s not uncommon for field personnel to believe there is no need for interlayer tack when paving multiple lifts. The root of this belief goes back to pre-Superpave mixes almost exclusively produced with neat asphalts and all virgin aggregates.

Typically, these mixes were also produced with higher asphalt content. Modern mixes are often produced with lower total binder content, virgin binder can contain polymer(s) and significant recycled binder can come from RAP and/or RAS. The notion that tack can be skipped was completely disproven on the 2012 NCAT Pavement Test Track when debonding between the new base and binder layers resulted in the premature failure of a structural test section

The objective of the section was to use higher percentages of RAP to improve sustainability, improve performance, and reduce costs. Total pavement thickness was only six inches thick to produce significant deflections that would result in failure within the 10 million equivalent single axle loading (ESAL) three-year research cycle. The base layer was produced with a highly modified binder and 35 percent RAP. The binder (middle) layer was produced with neat asphalt and 50 percent RAP. Emulsion was shot at a rate of 0.06 gallons per square yard between the adjacent layers. Materials testing and modeling indicated this section would be the best performer in the experiment (that also included sections built with recycled asphalt shingles and recycled tire rubber); however, transverse fatigue cracking was observed in both wheel paths throughout the section after only approximately 2.5 million ESALs.

A forensic study at NCAT determined the pavement had debonded between the base and binder layers. The unbonded top portion of the pavement then responded as if it were a thinner pavement, which quickly failed in fatigue from “middle-up” cracking.

A laboratory study further revealed the need for a much higher tack rate, and the section was rebuilt using a rate of 0.10 gallons per square yard of the same emulsion. As a result of this corrective action, the test section supported over 15 percent more traffic than the next best performer. Additionally, the rate of progression after the onset of cracking was less than any other section. The worst-performing section became the best-performing section, demonstrating the importance of interlayer tack in modern mixes with higher RAP contents and stiffer modified binder.

Still having doubts? A simple common demonstration of the lack of bonding between existing asphalt layers occurs routinely when a road is cored. Many times, the core that is produced exhibits a separation of its layers during the coring. The only reason this happened was that structurally adequate bonding was not present. Skipping the tack coat is certainly suspected in these cases. If it wasn’t skipped, then poor tack practices likely came into play, compromising the bond

For more information on the importance of tack coats, how to best apply them in the field, and relative cost information, read FHWA’s Tech Brief on the subject.

“ MIXES WITH HIGHER RAP AND/OR RAS COOL FASTER THAN VIRGIN OR LOWER RAP MIXES.”

The same thermodynamic relationships apply to all mixes, regardless of RAP and/or RAS content. Namely, as most mixes consist of about 94-96 percent aggregates, and it is the aggregates that are the thermally dominant component of a mix, under the same external conditions all mixes will cool at about the same rate.

Mixes with higher RAP and/or RAS contents do not cool faster than any other mixes; however, the relationship between mix stiffness and temperature can be very different. Although they are not cooling faster, it is true that recycled mixes are stiffer at the same temperature. In other words, at equal production temperatures, it takes the same amount of time for a conventional mix and higher RAP and/or RAS content mixes to cool to a certain temperature, but the conventional mix will be more workable and more compactable at that temperature. If a field crew thinks the mix is cooling faster because they perceive higher RAP and/or RAS mix to be stiffer, that may be an indication the mix either needs more virgin binder, a recycling agent, or some other change to reduce the mix stiffening as a function of cooling mat temperature.

Two free proven tools (PaveCool and MultiCool) are available which model asphalt cooling characteristics. Please use your favorite search engine to locate them for use within your browser. Mobile apps for them also exist, but not across all platforms.

“

LAYING AN ASPHALT LAYER GREATER THAN FOUR TIMES NMAS WILL RESULT IN POOR COMPACTION.”

Most practitioners agree the minimum compacted thickness of asphalt pavement ranges from three times the nominal maximum aggregate size (NMAS) for fine mixes to four times NMAS for coarse mixes. These minimum thicknesses are necessary for mix compaction purposes. It may not be possible to comply with density specifications in thinner layers as aggregates will fight each other, resisting compaction. For example, a 37.5 mm NMAS fine mix should have a compacted thickness of at least 12.5 mm thick.

These same practitioners commonly believe it is impossible to meet density targets when the thickness exceeds four times NMAS. The logic behind this limitation assumes that the effective depth of compaction is approximately five times NMAS, beyond which density will be reduced. Research on the 2018 NCAT Pavement Test Track disproved this belief when they successfully compacted a 12.5 mm NMAS surface mix at up to 16 times NMAS. Additionally, the states of South Carolina and Utah have both achieved excellent compaction on projects with 12 times NMAS and more.

At the NCAT test track, sections were built with both neat and highly modified binder. In all cases, cut cores were sliced into thirds to develop a density profile. These data demonstrated that density is effectively a “sandwich” where the greatest density is in the middle third of the “ThickLay” core and the upper and lower thirds were more or less a mirror image of each other. In subsequent track rebuilds at the test track, ThickLay paving has become a standard practice to expedite construction, avoid the use of interlayer tack and completely eliminate the possibility of interlayer shear failures.

In Utah, a 12.5 mm NMAS mixture with low design air voids easily exceeded the target density of 96 percent without an alteration of the contractor’s typical compaction process. This mixture has handled over four million commercial vehicles at the port of entry along Interstate 80 at Wendover, Utah without any rutting, bleeding or other noted distress in a very challenging location.

For more information on either the NCAT 2018 cycle or the Utah Wendover installation, please visit NCAT Report 21-03 or Thick and rich in Utah.

Dr. Buzz Powell, P.E., is Technical Director at the Asphalt Pavement Alliance and Dave Johnson, P.E., is Senior Regional Engineer at the Asphalt Institute. This article appeared in the fall 2024 issue of Asphalt magazine and is reprinted here with permission from the author and publication.

Mixes with higher RAP and/or RAS contents do not cool faster than any other mixes; however, the relationship between mix stiffness and temperature can be very different.

by Ryan Link

GLOBAL TRENDS IN ASPHALT & PAVING TECHNOLOGY

What’s the rest of the world doing?

As an industry, it’s important that we stay informed about global trends in asphalt and paving technology, and what the rest of the world is doing.

Achieving required density remains one of the most important aspects of producing long life pavements. Studies and demonstration projects carried out by the FHWA have shown as little as a one per cent increase in in-place density can improve the fatigue performance of asphalt pavements between eight and 44 per cent and rutting resistance by seven to 66 per cent. In addition, a one per cent increase in in-place density between 91.0 per cent and 96.0 per cent of the theoretical maximum density (Gmm) would extend the service life of asphalt overlays by 10 percent. (FWWA report1)

What we are seeing around the world now is the increased use of technology to hit targets including a new breakthrough in compaction technology from Hamm called Smart Compact Pro. Smart Compact Pro is an automated compaction system with real time density measurement on the fly. This product was launched at a global release at the Bauma 2025 show this year.

AUTOMATIC COMPACTION

Smart Compact Pro simplifies compaction in asphalt construction. After selecting the course to be compactedbase course, binder course, or surface course – Smart Compact Pro automatically controls both the compaction mode and the compaction force in both drums. This is based on various physical properties of the asphalt, such as the

temperature or rigidity values. It also takes into account the cooling behaviour of the asphalt. There is also the option of incorporating local weather data via a weather station.

The new ‘Realtime Density Scan’ sensor, integrated into the automated compaction, establishes the real-time asphalt density by calculating the dielectrical conductivity of the asphalt mix being compacted. Smart Compact Pro uses all this information to determine the most suitable compaction settings for each of the two drums resulting in homogeneous compaction results and a significant increase in process reliability.

INCREASE IN QUALITY, HIGH COST-SAVING POTENTIAL

Reaching target density is no easy game, and over and under compaction plays a critical role in quality, production time and job efficiency. Will having the technology to automatically adjust frequency and amplitude until the target density is achieved and then shut off so as to not over compact be a game changer? We are excited to see this technology arrive to North America later this year giving customers another important tool in their tool box.

Ryan Link is Wirtgen Territory Manager – Central & Northern Ontario for Brandt Tractor Ltd.

Keeping busy is key to success of Nal Nallaratnam UNSUNG HEROES

by Steve Pecar

atnam (Nal) Nallaratnam just keeps on going. And that is a very good thing as far as his colleagues at Green Infrastructure Partners (GIP) are concerned.

The long-time estimator has been a steadying and reliable influence in the paving industry for a number of years, a person that his employers have come to depend on and whom his fellow workers have learned to trust.

“He’s about as professional as you can get,” says Rick Logozzo, Regional Vice President, Central, GIP, who has known Nallaratnam for about 25 years as the company transitioned from Warren Bitulithic Ltd. to Lafarge to Coco Paving and now GIP. “He’s got a lot of respect in the workplace and the industry. And he’s a great guy, too.”

Educated as a civil engineer, Nallaratnam has enjoyed a career that has seen him take on many different roles. Starting in the business back in 1988, Nallaratnam began at Peto McCallum Consulting Engineers Ltd., later moving to Warren Bitulithic in 2000. Now he is the chief estimator for Greater Toronto Area projects for GIP, overseeing a large staff and tackling major projects daily.

“I always enjoyed the challenges of taking on different roles,” Nallaratnam explains. “I like all aspects of this industry and seeing how things come together and how I can contribute and take part in that.”

As an estimator, he analyzes the project details, gathers material, equipment and labour costs, develops budgets, determines the cost of a project, prepares bids and follows them through to make adjustments as needed. It’s that versatility that Nallaratnam brings to the job that makes him such a valuable contributor according to Logozzo.

“He’s the type of guy that can fly under the radar but carries a lot of weight,” Logozzo explains. “He works hard and does what he has to do, and at the end of the day, people notice his contributions.”

For example, Logozzo says when managing bids, an estimator is at the mercy of someone else’s timeline, so there is always a need to be flexible, be able to change direction, and make quick decisions, something that Nallaratnam excels at.

These abilities have translated to a strong leadership role for Nallaratnam, both as a mentor and a supervisor, as he has shown dozens of newcomers over the years how to go about their business in the correct way. A lot of people who are in the business now have learned under him, Logozzo says, which has been good for the industry as Nallaratnam constantly creates a good work culture.

“The work culture is very important in creating the team environment,” Logozzo continues. “You have to lead from the top to create that culture, and that is what Nal does. If you don’t walk the walk, you can’t create that culture, and Nal creates that culture by what he does. You can see it. The hard work, the dedication, the team player, it’s all there. He leads by example, and everyone can see that.”

Nallaratnam appreciates the accolades and says he just does what comes naturally to him, which is to keep busy and try to do a good job. He says he enjoys the day-to-day challenges – it keeps him motivated – in a business where a particular job can change quickly and how you react can determine the outcome of a project.

“Every job is unique; there are always challenges, especially with the MTO where the timeframe is everything,” says Nallaratnam. “There are only so many hours in a day, and in a short period time, you have to do multiple tasks, so you have to optimize your operations and find efficiencies.”

Steve Pecar is a Mississauga-based writer, editor and designer.

TECHNICALLY SPEAKING

Donn Bernal Technical Advisor, Asphalt Industry

Specification harmonization

Earlier this spring, the Ontario government introduced a series of harmonization initiatives to reduce costs, improve efficiencies, and streamline processes across various sectors. This includes aligning Ontario specifications with national standards such as the Building Code. It will fall under Bill 17: Protect Ontario by Building Faster and Smarter Act, 2025. ORBA has been using its lobbying efforts to lay out a platform to include the harmonization of municipal specifications using the current Ontario Provincial Standards (OPS) as the basis of these specifications.

The benefits of having a harmonized set of specifications include consistency, efficiency, cost-effectiveness and clarity. However, not all these sets of specifications are being utilized as they should be and this has led to the loss of the benefits. In particular, asphalt specifications over 25 years ago involved only four or five mixes based on the type of application and penetration graded asphalt cement that could be different based on geography (ie. southern Ontario vs. northern Ontario).

For the highways, there were two to three heavy-duty mixes and one grade of asphalt cement which could differ based on the larger geography and climate differential of Ontario. This was fairly straightforward for the asphalt producer to organize within their asphalt operations. In parts of northern Ontario and south-west Ontario, there were areas that utilized an HL4 mix only. As asphalt technology evolved and traffic in mostly urban areas increased, there was a need to introduce a more performancebased asphalt mix which included the birth of the Superpave mixes. With performance graded asphalt cement (PGAC) and Superpave mixes, typical pavement distresses such as rutting and transverse cracking were all but eliminated when designed properly.

The MTO led the way with this initiative with the transition beginning in 1997 with full implementation of Superpave in 2005 and the complete elimination of the Marshall mix design method (the old mix design method dating from the beginning of World War II). During this transition period, the asphalt OPS was crafted with Superpave

specifications for MTO projects and a separate set for municipal projects (MUNI version). The purpose of the two versions was that municipal pavement design requirements did not always need the same rigour of a highway but the framework was the same.

One difference during this process, however, was that the municipal version of asphalt specifications did not remove the Marshall mix design method. Municipalities were free to choose the Marshall or Superpave mix design method. The adage of “if it ain’t broke, don’t fix it” was commonly held by many municipalities. Most didn’t see a need to change if the municipality didn’t see issues with the asphalt mixes they were using and, in some cases, they were concerned that it would not allow the use of locally sourced aggregate that was working well for them currently. This left two versions available for the municipalities, and that framework still stands today. Marshall versus Superpave has long been debated and will continue to be debated, but I believe there has to be a way to unify them under Superpave with the OPS Specification Review Committee leading that transition.

The municipalities always looked to the MTO for specification advancements, but as the downloading of responsibilities continued between the province and municipalities, a greater disconnect occurred. This left the municipalities potentially having a gap in their knowledge of asphalt specifications and turning to consultants and academia for advice, leading to the proliferation of asphalt specifications. As an example, in the GTA, a plant could have 100+ different mixes. Not only are there variations in the asphalt mix volumetric design specifications and tolerances, but there are also variations in the actual asphalt cement whether it be the grade or the properties within a grade.

This has led to asphalt plants requiring more asphalt cement storage tanks and/or asphalt storage silos. It has also led asphalt cement terminals requiring additional smaller storage or day tanks

for all these variations. All in all, significant capital investments have to be made for asphalt mixes and asphalt cement grades and tolerances that can be simplified to just a few and still produce the same level of performance.

A contractor in eastern Ontario has said that they require seven asphalt cement tanks to accommodate the different grade and specifications utilized in their area. Each region or municipality in the area has a different philosophy on what is needed to make the asphalt pavement perform. Each of these asphalt cement tanks can cost 200 to 300 thousand dollars or more depending on the capacity – a significant capital investment for a contractor. This could limit where and how contractors bid projects and increase the estimated price of their bid due to logistical issues in the timing to complete their construction projects.

Recently, a road owner in Ontario specified Alberta-sourced crude oil as the basis of the asphalt cement that is required for their project. This was a further proliferation of specialty asphalt cement specifications that are already difficult to follow, source and store between municipalities and regions. It is just another example of why specification harmonization needs to happen.

A question will be asked about how new technologies and innovation get implemented. The structure is already there within OPS for upgrading the specifications. It just needs to become more robust. Creating an organizational structure that includes MTO, MEA, and ORBA will provide for equal responsibilities amongst the stakeholders to ensure that Ontario uses leading-edge technology to build Ontario. These will be outlined in the framework that ORBA is presenting to the Ontario government.

As part of its strategic initiatives within the council, ORBA has also initiated a plant certification program framework. With the support and acceptance by the municipalities, asphalt producers, and paving member companies, the program requires an asphalt plant to be certified to bid on municipal contracts. This will not only raise the bar on asphalt quality and sustainability, but on plant safety and operations as well. The goal is to have the plant certification program eventually integrated into OPS and will fit in well into the harmonization initiative of ORBA and the Ontario government. Harmonization of specifications by legislating the use of OPS will provide the following examples of benefits to the stakeholders:

• At the asphalt plant, the logistical production nightmares will be eliminated.

• Production of asphalt mixes will be more consistent and efficient as there will be less switching between mixes to serve the multiple paving crews that run out of that asphalt plant. This will indirectly improve quality as well and reduce the chance of mix-ups with asphalt cement grades or asphalt mix types.

• Municipalities will reduce costs associated with developing their own specifications.

• MTO will once again be the go-to level of government to lean on for the technological advances and design specifications which they do already on their MTO projects.

And this goes back to the Operations column about collaboration. When all parties work together as one, quality improves, trust improves, efficiency improves, and tax dollars can be stretched further to build even more asphalt roads!

ENVIRONMENTAL ESSENTIALS

Donn Bernal Technical Advisor, Asphalt Industry

Launch of the Ontario Asphalt Environmental Impact Benchmarking Project