Solutions for Sign and Display Applications

A dedication to quality is a source of pride for all of us at ORAFOL and it is a key factor in our continued growth & success.

Dr. Holger Loclair, MD

ORAFOL Europe GmbH

A dedication to quality is a source of pride for all of us at ORAFOL and it is a key factor in our continued growth & success.

Dr. Holger Loclair, MD

ORAFOL Europe GmbH

Located just outside of Berlin in the heart of Europe, the ORAFOL Europe GmbH headquarters is the hub of the organization’s culture of leadership and excellence.

Image courtesy of South Shore Sign Company, Matawan, NJ. Featuring ORAJET ® 3620 with ORAGUARD® 200. Typical application of ORABOND® 1819 Foam Tape.

Find the right solution for your needs

ORAFOL offers a truly comprehensive range of ORABOND® Industrial Tapes, ORACAL® Plotter Films, and ORAJET ® Digital Inkjet Print Media for the sign and display market.

Specially formulated air-egress technology that facilitates a quicker, easier bubble free application.

New advanced repositionable adhesive technology that enables a quick and easy application.

Very stable and won’t shrink!

Extreme Performance that won’t yellow or crack!

Most ORABOND® Tapes are UL and/or FDA-certified.

UL Approved Products: UL certified for UL 969 “Marketing and Labeling Systems” (USA) and CSA c22.2 NO. 0.15 “Adhesive Labels” (Canada)

ORAJET ® 3850 with ORAGUARD® 215SG. Typical application of ORABOND® 1375/1375S Transfer Tape.

Adhesive Performance Characteristics

Removable Adhesive /// Short-to-medium-term

• Removes cleanly within 2 – 3 years of application from most properly prepared, smooth, sealed surfaces.

• Beyond 3+ years, removal properties may diminish and the adhesive may become more permanent.

Permanent Adhesive /// Medium-to-long-term

• Stronger anchoring power when applied to smooth, properly prepared, sealed surfaces.

• May not remove cleanly from the surface

High-tack Permanent Adhesive /// Permanent

• Extremely high-initial-tack and final bond when applied to hard-to-stick low energy plastics and powder coatings.

• May not remove cleanly from the surface

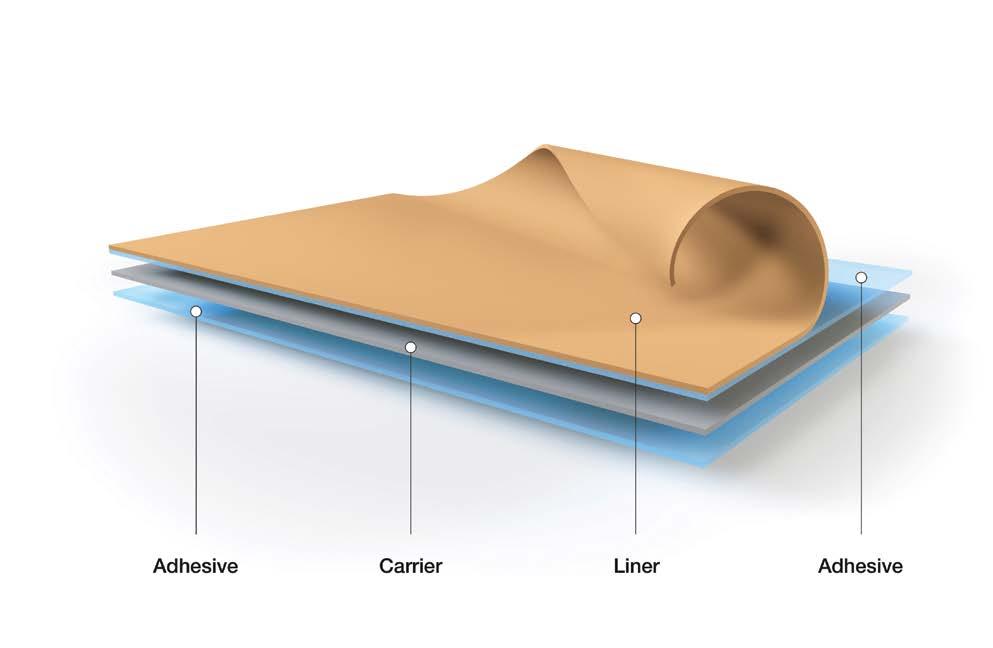

Learn more about ORABOND® adhesive, carrier, and liner properties

ORAJET ® Digital Medias are compatible with today’s Latex, Solvent, Eco-Solvent, and UV Curable inks. Exceptions are noted with an * throughout the guide.

Film Properties

Thicker

Flat surfaces only

When used incorrectly, material may tunnel, delaminate, or “shrink” from the application surface

Thin and flexible

Long-term applications

Premium film type

Perfect for both flat and heavily contoured, curved, recessed surfaces

Extremely durable

Eco-friendly film type

Self-healing properties

Will not yellow or crack

Best horizontal durability (hoods, roofs, trucks)

Most resistant to environmental contamination (fallout)

Transfer Tapes

Double-Sided Tapes

Foam Tapes

UHB (Ultra High-Bond) Tapes

1375 1375S (Sheet)

1377 1377S (Sheet)

/ -40℉ to

for the production of metal, polycarbonate, and other plastic fascias, nameplates and decals; used for lamination of membrane switch assemblies and other electronic component mounting in mobile telephones and for other applications that require an extremely high shear strength and temperature resistance; UL 969 listed

for the production of metal, polycarbonate and other plastic fascias, signs, nameplates and decals; used for lamination of membrane switch assemblies and other electronic component mounting in notebooks, mobile telephones and for other applications that require an extremely high shear strength and temperature resistance; UL 969 listed

for low energy surface lamination; for foams and materials that require an extremely high shear, adhesive strength and temperature resistance; excellent resistance to UV radiation, extreme temperatures, chemicals, solvents and humidity; UL 969 listed

the ideal bonding solution for low surface energy coatings and plastics; it offers a high initial adhesion, and works well also on rough structured or stamped surfaces; it is the product of choice when working with polypropylene sheets and filled polypropylene; UL 969 listed

/ -40℉ to +140℃ / +284℉

recommended for use where a permanent bond to the primary substrate is required, with a “post-note” low tack bond to the other substrate (open side permanent bonding); for window protection pads and removable splicing; easy and residueless removal from covered side

PVC extrusions, furniture trims, splicing for high temperature operations, splicing of difficult materials, intermediate thickness version of 1397PP Tesa 4967

sign making, digital graphics mounting, extrusion applications, lamination of automotive mirrors and white goods components; for rough surfaces 3M 9087

Tesa 4970

Lohmann 370

sign boards, general fixing, sail making tapes, electronic component mounting, special labels; thinner version of 1397 3M 9098 Nitto 5011

Lohmann 3720

PVC extrusions, furniture trims, splicing for high temperature operations, splicing of difficult materials, lamination of automotive mirrors

PP version also for production of sails for sailboards

high performance fixing, mounting of roller blinds, point of sale, foam lamination, splicing of difficult materials; for rough surfaces

3M 9088FL

Tesa 4965

Lohmann 376F/377F

for the secure attachment of truck and car mirrors in plastics housings; used as a self-adhesive medium for trims, covers and cable trunks and laminates to a variety of surfaces; for the fixing of covers and handles in the audio, household appliance industry as well as electrical industry

3M 9086

Tesa 4959

Lohmann 3702

3M 9087

Tesa 4970

ORABOND® Product

mounting of widow bars, signs, extrusion profiles and mirrors, for solar panel production; complies with FIRA requirements; UL 746C listed

certificate: mirror mounting according to TÜV/Rheinland/LGA guideline

point of sale, general fixing and mounting, e.g. cable trunking, displays, signs; for interior application

certificate: mirror mounting according to TÜV/Rheinland/LGA guideline

Alternative Product Information

3M 9539

Lohmann 918

furniture profiles, widow seals, window bars, displays; for even surfaces

general purpose fixing and high shear application, plastic hooks and hangers, mirror mounting; compiles with FIRA requirements, for rough surfaces

certificate: mirror mounting according to FIRA

3M 9546

Tesa 4952

Lohmann 5011

Scapa 5464

St. Gobain V1600

Lohmann 5021

Scapa 5469

St. Gobain V1600

3M 9536

Lohmann 5008

Scapa 5474

St. Gobain V1500

UHB04064G

Previously known as 3594 grey foamed acrylic, grey

UHB03064W

Previously known as 3595 white foamed acrylic, white

UHB03025T

Previously known as 3596 transparent foamed

UHB03050T

Previously known as 3597

UHB03080G

Previously known as 3598 grey foamed acrylic, grey

D1002

microns 20-mil

/ -40℉ to +90℃ / +194℉

D3330

800 microns 31-mil -40℃ / -40℉ to +100℃ / +212℉

high performance bonding and mounting; ideal for applications where thermal expansion differences are of concern ideally suited for structural and general bonding including automotive, solar, electronic, and the sign and display industry

UHB03100T

Previously known as 3599 transparent foamed acrylic, clear 1,000 microns 40-mil -40℃ / -40℉ to +90℃ / +194℉

UHB03110G

Previously known as 3600 grey foamed acrylic, grey 1,100 microns 44-mil

UHB03110W

Previously known as 3601 white foamed acrylic, white

UHB04200G

ASTM D1002

stainless steel

ASTM D3330

stainless steel

ASTM D1002

-40℃ / -40℉ to +100℃ / +212℉

high performance bonding and mounting; high shear holding power and temperature resistance; clear adhesive improves bondline aesthetics when joining transparent materials

high performance bonding and mounting; high shear holding power and temperature resistance ideally suited for structural and general bonding including body panels, emblems, illuminated displays, and signage

high performance bonding and mounting; high shear holding power and temperature resistance; elastomeric nature of the foamed adhesive makes it ideal for applications requiring conformability

high performance bonding and mounting; ideal for applications where thermal expansion differences are a concern; clear adhesive improves bondline aesthetics when joining transparent materials for mounting, bonding and sealing of illuminated displays, signage, and safety glass shower screens

Previously known as 3602 grey foamed acrylic, grey

2,000 microns 80-mil

UHB04150G

Previously known as 3603

stainless steel

ASTM D3330

stainless steel

ASTMD897 aluminium

high performance bonding and mounting; ideal for applications where thermal expansion differences are of concern ideally suited for structural and general bonding including body panels, emblems, illuminated displays, and signage

high performance bonding and mounting; high shear holding power and temperature resistance; ideal for applications where thermal expansion difference are of concern

Translucent Calendered

Translucent Premium Cast

Diffuser Premium Cast

Blockout Film

ORACAL® Product

ORACAL® 8500

ORACAL® 8800

Translucent Cal outdoor or indoor medium-term up to 7 years 3-mil calendered flat clear, solvent-based, permanent

ORACAL® 8830

Translucent Premium Cast outdoor or indoor long-term up to 10 years 2-mil cast formed or flat

ORACAL® 8860

Diffuser Premium Cast

ORACAL® 8870

Blockout Film 4-mil cast

24”, 48”

Diffuser Premium Cast outdoor or indoor long-term up to 10 years 48”

15” (punched), 24”, 30”, 48” 60” x 50 yd, in select colors only

150’ (50-yard) 30’ (10-yard)

illuminated signage and graphics, storefront channel letters, sign faces, retail, television set, and tradeshow displays

high-quality illuminated rigid or flexible signage and graphics,channel letters, sign faces, thermoformed illuminated dimensional signage

helps to hide and smoothly diffuse or evenly spread the internal light source in illuminated signage, great alternative to back-spraying with paint

block unwanted light transmission in illuminated sign faces, effective light control film for precise illumination management

Long-term

Medium-term

Short-term

Typical application of ORAJET ® 3551RA with ORAGAURD® 290 and ORABOND® UHB (Ultra High-Bond) 04200.

ORAJET ® Product

GOOD /// 3551

High Performance Calendered PVC with CommandForm® Technology with standard initial tack

GOOD /// 3551RA

High Performance Calendered PVC with RapidAir ® Technology with standard initial tack

BEST /// 3850

Translucent Calendered

BEST /// 3951

Professional Wrapping Film with CommandForm® Technology with standard initial tack

BEST /// 3951RA Premium Digital Printing Cast PVC with RapidAir ® Technology with

BEST /// 3951RA + ProSlide®

Premium Digital Printing Cast PVC Professional Wrapping Film with RapidAir ® + ProSlide® Technology with low initial tack

BEST /// 3971RA + ProSlide®

Premium Digital (Cast) Polyurethane (PU)

Wrapping Film with RapidAir

Technology with

ORAJET ® Product

GOOD /// 3165

Intermediate Calendered PVC

GOOD /// 3165RA

Intermediate Calendered PVC with RapidAir ® Technology

BETTER /// 3169RA

Intermediate Removable Calendered PVC with RapidAir ® Technology

BETTER /// 3651

Intermediate Calendered

BETTER /// 3651RA

Intermediate Calendered PVC with RapidAir ® Technology

BETTER /// 3691

Intermediate Removable Calendered PVC

BEST /// 3551

High Performance Calendered PVC with CommandForm® Technology with standard initial tack

BEST /// 3551RA

High Performance Calendered PVC with RapidAir ® Technology with standard initial tack

Product (Reflective)

GOOD /// 5600

Fleet Engineering Grade Reflective Film*

BETTER /// 5650RA

Fleet Engineering Grade Reflective Film with RapidAir ® Technology with standard initial tack*

Removable Outdoor Signage

GOOD /// 3621

BETTER /// 3169RA

Permanent Outdoor Signage

GOOD /// 3640

GOOD /// 3641

GOOD /// 3164

GOOD /// 3164RA

GOOD /// 3164XRA

BETTER /// 3165

BETTER /// 3165RA

/// 3651

///

P.O.P. Signage, typical application of ORAJET ® 3651RA with ORAGUARD® 210. Interior FCO Letters, typical application of ORABOND® UHB (Ultra High-Bond) 03025T (Transparent).

ORAJET

GOOD /// 3640

GOOD /// 3641

GOOD /// 3164

GOOD /// 3164RA

ORAJET ® Product

GOOD /// 3740*

Economical PVC-Free Polypropylene (PP) (3-mil)

BETTER /// 3258

BETTER /// 3165

BETTER /// 3165RA

Intermediate Calendered PVC with RapidAir

Technology

BETTER /// 3930

(glow-in-the-dark)

/// 3651

BEST /// 3651RA Intermediate

BEST /// 3850

ORAJET ® Product

GOOD /// 3268 Low-Tack Movable Wall Graphics

GOOD /// 3628

Low-Tack Wall and Window Graphics

GOOD /// 3720*

Economical

BETTER /// 3621 Soft Calendered

BETTER /// 3620 Transparent

BEST /// 3169RA

BEST /// 3691

Intermediate Removable Calendered

ORABOND® 1375/1375S

1377/1377S

1397TM

1399TM

1395TM ORABOND® 1397PP

1331TM

ORABOND® 1391PP

ORABOND® 3331TG

Foam Tapes

ORABOND® 1810

ORABOND® 1812TM

ORABOND® 1819/1819TM

ORABOND® 1831

UHB® Tapes

UHB04064G

Previously known as 3594

UHB03064W

Previously known as 3595

UHB03025T

Previously known as 3596

UHB03050T

Previously known as 3597

UHB03080G

Previously known as 3598

UHB03100T

Previously known as 3599

UHB03110G

Previously known as 3600

UHB03110W

Previously known as 3601

UHB04200G

Previously known as 3602

UHB04150G

Previously known as 3603

ORABOND® 1325 4, 27

ORABOND® 1328 4, 27

ORABOND® 1331TM 6, 27

ORABOND® 1375 4, 27

ORABOND® 1375S 4, 27

ORABOND® 1377 4, 27

ORABOND® 1377S 4, 27

ORABOND® 1391PP 6, 27

ORABOND® 1392TM 6, 27

ORABOND® 1395TM 6, 27

ORABOND® 1397PP 6, 27

ORABOND® 1397TM 6, 27

ORABOND® 1399TM 6, 27

ORABOND® 1810 8, 28

ORABOND® 1812TM 8, 28

ORABOND® 1819 8, 28

ORABOND® 1819TM 8, 28

ORABOND® 1831 8, 28

ORABOND® 3331TG 6, 27

ORABOND® UHB 03025T 10, 28

ORABOND® UHB 03050T 10, 28

ORABOND® UHB 03064W 10, 28

ORABOND® UHB 03080G 10, 28

ORABOND® UHB 03100T 10, 28

ORABOND® UHB 03110G 10, 28

ORABOND® UHB 03110W 10, 28

ORABOND® UHB 04064G 10, 28

ORABOND® UHB 04150G 10, 28

ORABOND® UHB 04200G 10, 28

Vertical & Horizontal Exposure In Years. Visit orafol.com to review the intended product’s technical data sheet listed in this guide to determine its Climate Zone 1 expected outdoor durability.

ORAFOL’s digital printing materials are manufactured in the industry’s most advanced computer-controlled facilities, assuring you of consistent, splice-free quality from roll-to-roll.

The self-adhesive products, ORACAL®, ORAJET ® , ORAGUARD®, ORABOND®, ORALITE®, and ORALUX® are supplied in rolls and should, at all times, be stored suspended or standing on end with provided roll blocks. NEVER store material lying on its side. Materials should be kept in a cool dry place. For optimal product performance, relative air humidity should be between 50% and 60% and temperature between 64°F and 72°F. Avoid storing material in direct sunlight, or near excessive heat (i.e. radiators). Please observe the shelf life instructions contained in the technical data sheet available for each film at www.orafol.com.

Digitally printed materials should be handled with the utmost care. To prevent surface damage use lint-free gloves. Before printing, check the surface quality of the film to remove obvious film damage, dirt, grime, lint, etc. For best results, use the correct ICC profile based on your specific combination of media, ink, printer and RIP software. For FREE color profiles, visit the Support section of the ORAFOL Americas website.

Don’t forget to match the digital media with the recommended laminate.

Lamination of inkjet prints is recommended to ensure longer lifespan at optimum quality (gloss, color, resistance to physical damage). ORAGUARD® laminate films enhance the desired appearance of the graphic (gloss, matte, semi-gloss). They also provide excellent protection against fading from exposure to UV rays. To avoid delamination, edge curling, and adhesive failure, allow solvent printed graphics to outgas for at least 24 hours at 70°F (48-72 hours), before trimming or applying a laminate.

Up to 8 Years of Protection for your Printed Graphics

The ORALIFE™ Component System (OCS) warranty from ORAFOL Americas includes specially matched media and laminates to fit almost any graphic application where a pressure-sensitive adhesive is needed. Combined with your approved wide-format inkjet printer and corresponding OEM ink sets, the OCS warranty can help you achieve an unrivaled level of performance and guaranteed reliability for your outdoor digital prints. For more information and enrollment forms, visit our website at www.orafol.com.

Our product experts are ready to help you. Call our knowledgeable Technical Support team for advice about product choice, color management, application techniques, care and maintenance and much, much more. For exceptional technical expertise call 888-672-2251.

ORAFOL products are German Engineered and proudly produced in the United States at our premier manufacturing facility in Ellabell, GA.

The facility is one of the most modern of its kind, in the Americas, and ensures both high quality product and rapid turn around time for delivery.

just outside of

ORAFOL

Americas Headquarters

1100 Oracal Parkway | Black Creek, GA 31308

Phone | 912-851-5000 • Toll Free | 888-672-2251

ORAFOL Canada

2831 Bristol Circle | Oakville, Ontario L6H 6X5

Phone | 905-829-2828 • Toll Free | 888-727-3374

• www.orafol.com