Our Timber Engineering Division designs & manufactures roof truss, i-beam joist & posi-joist solutions using specialist modelling software & precision cutting equipment. These bespoke products are value-engineered & produced off-site to deliver time & cost-savings for commercial & domestic projects.

We stock an extensive range of premium structural timber & panels for floors, walls & roofs, supported by expert advice for specific applications. In addition, we offer cut-to-size & fire treatment services.

Engineering: 01633 414 414

& Midlands: 0121 265 4822

& South West: 01633 254 422

& South East: 01895 253 491

07

Welcome: Foreword

Cover image:

Rhodes House Garden Pavilion

Winner of the Small Project category at the Wood Awards 2024.

Architect: Stanton Williams

Photo: Hufton+Crow

Welcome from the publishers

Welcome to the 26th edition of the Timber Industry Yearbook.

09

Welcome: From the editor A collaborative approach

We connect the key partners and organisations that are driving a more collaborative, informed, and united timber sector.

10

Events: Award winners

Celebrating structural timber

Dr Liz Walder presents a selection of buildings recognised by key industry award panels. Each winner exemplifies the technical and aesthetic capabilities of timber as a primary construction material.

16

Forest & Land APF Demo

The APF Demo is the flagship event for the industry and the must visit show for anyone working in the forestry, woodland, arboriculture, fencing, estate and ground maintenance sectors.

18 Forest & Land: Ecosystem services

Timber building and forest biodiversity

Are timber buildings helping or harming forest biodiversity? asks Asselia Katenbayeva. An ASBP project explores the impacts of timber sourcing and the challenge of measuring biodiversity.

22 Forest & Land: Supply chain Landscapes of change

Kate Palmer explores how policy, natural capital, and market innovation reshape the landscape for a resilient future.

26

Forest & Land: Timber supply

Maximising the climate benefits of timber

John Healey discusses the case for domestic wood production, as outlined in a Nature Communications paper co-authored with Eilidh Forster, Research Associate at Bangor University, and David Styles, Associate Professor at the University of Galway.

30

Forest & Land: Productive forestry

Reimagining materials for circular construction

Tom Henderson believes a strategic circular timber economy can unlock climate, housing and economic benefits for Wales – but only if we align forest policy, processing, and procurement.

32

Forest & Land: Productive forestry

Seeing the wood in the trees

Heddwyn Bye explains how terrestrial LiDAR scanning offers a breakthrough in assessing timber quality and carbon stocks in complex UK woodlands.

34

Forest & Land: Policy

Timber construction as climate infrastructure

Gary Newman explains why wood in construction must be treated as a greenhouse gas removal mechanism.

36 Materials

UK Construction Week

UK Construction Week is the UK’s largest built environment event..

38

Materials: Timber supply

Future-proofing timber merchants

David Hopkins looks at why embracing sustainability and circular economy principles is smart business for timber merchants.

42

Materials: Timber specification

It’s time to champion timber in the home

Helen Hewitt discusses the urgent need to challenge outdated myths in both housebuilding and homeownership.

51

Materials: Timber specification

Challenges of strength grading reclaimed timber

Phil O’Leary explores strength grading reclaimed timber.

57

Materials: Circular economy

Reimagining materials for circular construction

Dr Diana Waldron explores structural timber reuse.

60

Materials: Circular economy

The reclaimed wood market in the UK: an overview

Sara Morel explores how the sector can overcome challenges to play a crucial role in building a circular, low-carbon future.

68

Timber structures

UK Timber Design Conference

UK Timber Design Conference explored how timber can accelerate low-carbon transformation through innovation, policy and practice.

70 Timber structures: Policy

Unlocking timber’s role in construction

Timber has long played a critical role in sustainable construction.

73

Timber structures: Moisture

Moisture measurement importance in construction

Andy Pitman explains why measuring and controlling wood moisture content is essential to avoid decay, delays and design failure.

76

Timber structures: Offsite construction

Timber frame and offsite construction

David Himmons explains why factory-built timber systems are vital to meeting regulatory, environmental and housing challenges.

85 Timber structures: Sustainability

Reducing embodied carbon from the outset

Clara Koehler explores how early-stage thinking can unlock the greatest opportunities for embodied carbon reduction.

91 Timber structures: Engineered timber

Towards performance-led timber

Anna Lisa McSweeney highlights why a new national centre, new metrics, and new partnerships are driving mass timber forward.

96

Timber structures: Architecture

Timber innovation from Baden-Württemberg

Sabine Groeneveld uses Baden-Württemberg, a south-western federal state in Germany, as a case study to illustrate how to help promote the local timber industry whilst reaching out internationally.

104

Timber structures: Roofs

Raising standards with metal web beams

Nick Boulton explains why metal web beams structural use is on the rise in both new build and retrofit.

111

Timber structures: Exteriors

Timber cladding battens

Janet Sycamore clarifies why using the wrong battens for timber cladding can compromise durability, ventilation and performance.

117

Timber structures: Infrastructure

The rise of timber bridges in modern Britain

Timber bridges are making a comeback across the UK, blending engineering reliability with environmental sensibility.

120 Fire safety & protection

The Fire Safety Event

The UK’s No. 1 fire safety event explores the next-generation solutions, live product demos, and expert-led CPD sessions.

123

Fire safety & protection: Timber treatments

Flame-retardant treated wood

Jennie Ward outlines the legal obligations for businesses supplying flame-retardant treated timber.

129

Fire safety & protection: Safe buildings

Safe schools for the future

Seb Laan Lomas explains how new fire research shows how a low-impact design approach can deliver safe, healthy buildings.

132

Fire safety & protection: Certified doorsets

The importance of certified doorsets

Ainsley Evershed explains why certified doorsets offer a reliable, efficient route to safer, regulation-ready buildings.

137 Fire safety & protection: Fire doors

The Golden Thread: digital data conduits vs data silos

Philip Duckworth explains why moving from data silos to integrated digital conduits is essential for managing critical fire safety data.

142

Fire safety & protection: Fire doors

The changes to timber fire doors

Tomos Jones reflects on what the upcoming changes to Approved Document B may mean for timber door manufacturers.

147

Fire safety & protection: Fire doors

Advancing panelled fire door performance

Mike Rooney presents a case study demonstrating that EN 1634-1 testing shows panelled fire doors can achieve certified fire performance without compromising architectural design.

150 Wood knowledge WoodBUILD

A gathering for change-makers, WoodBUILD 2025 fused systems thinking with practical action across forestry and construction.

152

Wood knowledge: About WKW

Working together for a low carbon timber future

A gathering for change-makers, WoodBUILD 2025 fused systems thinking with practical action across forestry and construction.

156 Wood knowledge: Technical tools

TDUK’s Tech Toolbox

David Hopkins explores the most influential and technically robust outputs from Timber Development UK’s knowledge base.

158 Wood knowledge: Wellbeing

Woodland wellbeing

Woodlands are becoming spaces for healing, not just recreation. Ian Baker explores why woodland settings work.

162 Wood knowledge: Training

A training roadmap for UK low carbon buildings

Trish Andrews and her team have developed e-learning courses on retrofit and low energy buildings to upskill the construction sector.

166 Wood knowledge: Growing skills

Growing skills, growing futures

Caroline Harrison announces new initiatives to open doors across the UK and inspire a new generation of professionals.

170 Association partners Directory

The Timber Industry Yearbook 2025 brings together expert voices from across the supply chain.

Welcome to the 26th edition of the Timber Industry Yearbook. As publishers, we are proud to present this expanded edition reflecting a wider reach across more associations within the forestry and wood sector. Our mission remains clear: to connect people, policies, and practices across the full wood value chain.

This year, we’ve worked more closely than ever with partner associations, highlighting a shared ambition to bring together knowledge, innovation, and purpose across the industry. Collaboration lies at the heart of this edition driven by a growing momentum to align expertise from every corner of the timber world.

A key contributor to this effort is Woodknowledge Wales (WKW), whose deep commitment to building a sustainable, low-carbon future has shaped both the content and direction of this Yearbook. Led by Sarah Lawton, Editor-in-Chief and an outspoken advocate for timber innovation, the WKW team has played a central role in curating the insights, case studies, and technical contributions you’ll find in these pages.

Thanks to their efforts, this Yearbook brings together voices from across the wood value chain—from foresters and sawmillers to fabricators, architects, specifiers, contractors and clients—each sharing forward-looking perspectives.

This publication continues to champion timber’s dual role: reducing emissions while storing carbon for the long term. At the same time, it provides trusted, up-to-date technical information from experts across the sector.

To stay connected with the latest developments, thought leadership, and project updates across the timber industry, we invite you to visit our website www.timberindustryservices.co.uk and sign up for our monthly e-newsletter. It’s a simple way to stay informed, inspired, and involved with the growing timber community.

Yet this Yearbook is more than a compendium—it is an active connector. Whether you’re building forest capacity, designing with timber, responding to procurement opportunities, or shaping policy across the UK, we hope these pages inspire insight, collaboration, and ambition.

© Open Box Media & Communications Ltd

Advertising sales & production, and Timber Industry Yearbook published by:

Open Box Media & Communications, Premier House, 13 St Pauls Square, Birmingham B3 1RB

Telephone: +44 (0)121 200 7820

Email: inside@ob-mc.co.uk

Website: www.ob-mc.co.uk

Whilst every effort is made to ensure the accuracy of the advice given, we cannot accept liability for loss or damage arising from the information supplied. All information and photographs/drawings are the responsibility of the contributor.

The publisher gratefully acknowledges the support of the firms whose advertisements appear in this publication. Whilst every care has been taken in compiling this publication, the publisher cannot accept responsibility for any inaccuracies, or for the products or services advertised.

The inclusion of adverts and information herein does not in any way imply endorsement. All commercial contributors are encouraged to meet the highest ethical and environmental standards in their operations and supply chains.

As we are committed to sustainable forest management, Open Box specifies paper that meets chain of custody certification requirements. This publication is printed by Buxton Press. Further environmental information is available here: www.buxtonpress.com/environment

Let’s continue to grow a timber sector and a built environment that is rooted, responsible, regenerative, and ready for the future. We hope you enjoy the Timber Industry Yearbook 2025.

With an editorial career that includes technical publishing at BM TRADA and my current role leading communications at Woodknowledge Wales, I’ve had the privilege of working closely with experts across the forestry, timber and construction sectors. That experience has given me both an appreciation for the depth of knowledge within our industry and a commitment to making it more widely accessible.

As editor of the 2025 Timber Industry Yearbook, my role has been to connect the key partners and organisations that are driving a more collaborative, informed, and united timber sector. This edition brings together a diverse range of expert voices from across the entire value chain. Our contributors have shared their knowledge generously, helping to shape important industry conversations, amplify insights, and strengthen the connections between professionals across forestry, timber, construction and policy.

We extend sincere thanks to all our partners for their expert contributions and for sharing this digital edition with their members and networks. You are helping to ensure that it reaches a broad and engaged readership.

In addition to the Yearbook, we are launching a dedicated website www.timberindustryservices.co.uk and a monthly e-newsletter with the latest thinking and developments from across the sector, designed to keep you informed, inspired and connected all year round. n

Sarah M Lawton Timber Industry Yearbook Editor Woodknowledge Wales

Email: sarah.lawton@woodknowledgewales.co.uk www.woodknowledge.wales

The Timber Industry Yearbook 2025 brings together expert voices from across the supply chain. Our publication partners help amplify these insights—sharing knowledge, shaping the conversation, and connecting professionals across forestry, timber, construction and policy.

In this section, Dr Liz Walder presents a selection of buildings recognised by key industry award panels. Each winner exemplifies the technical and aesthetic capabilities of timber as a primary construction material.

From the expressive timber cladding of the affordable housing development at Hazelmead for Bridport Cohousing CLT, to the precise structural framing of Hastings House by Hugh Strange Architects, and the refined internal interventions at the Brighton Dome Corn Exchange & Studio Theatre by Feilden Clegg Bradley Studios—each project demonstrates a deliberate and skilful integration of timber within the architectural fabric.

These buildings reflect high levels of design ambition and execution. The architects and engineers involved have leveraged timber’s inherent versatility, working with its structural, environmental and tactile properties to shape spaces that are both functional and characterful. The detailing and articulation across each scheme reveal a clear understanding of timber as a material that demands precision and rewards craftsmanship.

Timber is not only renewable and carbon-sequestering, but also offers practical advantages in construction, including reduced build times and improved site performance. It contributes to a built environment that is warm, natural and resilient.

This showcase highlights the best of contemporary timber architecture—celebrating the innovation, performance, and enduring appeal of timber in the hands of expert practitioners.

About the author

Dr Liz Walder

Events, Woodknowledge Wales

Email: liz.walder@woodknowledgewales.co.uk www.woodknowledge.wales

Brighton Dome Corn Exchange & Studio Theatre by Feilden Clegg Bradley Studios

Gold Award winner at the Wood Awards 2024, Brighton Dome Corn Exchange & Studio Theatre by Feilden Clegg Bradley Studios also won the Restoration & Reuse category. Celebrating its rich cultural past, this cherished piece of Brighton’s history adjoining the famous Royal Pavilion, the Grade-I listed Corn Exchange and Grade-II listed Studio Theatre buildings have been transformed and reimagined for today’s audience.

A new foyer and café have been introduced creating more welcoming and accessible spaces, whilst behind the scenes, master craftspeople carefully repaired dormer roof arches and restored the iconic decorative window details, bringing the beauty of the UK’s longest single-span timber frame back into view. Innovation and tradition sit alongside each other in a detailed marriage of craftsmanship. >>

Brighton Dome Corn Exchange & Studio Theatre

Architect: Feilden Clegg Bradley Studios

Structural Engineer: Arup

Wood Supplier: Neil Burke Joinery (NBJ) / Weitzer Parkett

Contractor: R. Durtnell & Sons / Westridge Construction Ltd

Landscape Services: LT Studio

Quantity surveyor & project manager: Jackson Coles

Building services & sustainability consultant: Max Fordham

Species: European Oak (Croatia). FSC certified

Architect: Koto Design and Hiraeth Architecture

Structural Engineer: Paramount Structures

Wood Supplier: Unnos Systems

Contractor: Unnos Systems

Joinery: Kenton Jones Collection

Cladding & Decking: IRO/BSW Timber

Species: Douglas Fir (Wales), Sitka Spruce (UK), Larch (UK), Oak. FSC certified

Situated on the Isle of North Uist in the Outer Hebrides of Scotland, Uist House by Koto Design and Hiraeth Architecture uses home-grown Welsh timber to withstand the uncompromising Scottish weather. Winner of the Research & Innovation category at the Wood Awards 2024, Uist House merges natural, local materials with cutting-edge design, delivering superior performance that respects its natural setting.

Building to meet passivhaus standards can bring challenges in durability and sustainability. This approach tackles both head-on: combining ultra-airtight insulation with timber box beams filled with cellulose for strength and low carbon impact. Engineered to handle extreme wind loads, Uist House delivers performance without compromising the environment.

Rhodes House Garden Pavilion by Stanton Williams

Winner of the Small Project category at the Wood Awards 2024, Rhodes House Garden Pavilion by Stanton Williams crafted an inviting glass and timber meeting space for scholars and the public to connect.

Architect: Stanton Williams

Structural Engineer: Webb Yates Engineers

Wood Supplier: Braden Timber Structures

Contractor: Beard Construction

Mechanical & Electrical Engineer: Skelly & Couch

Joinery: Braden Timber Structures

Internal Joinery: Paragon Joinery

Species: Spruce LVL (Scandinavia), Ash (Europe). PEFC certified

The Rhodes House Garden Pavilion seamlessly combines craftsmanship and innovation through its organic design. Traditional woodworking blends with advanced engineering, creating a timber lattice that elegantly extends over protected tree roots. Above, the green roof, resting gracefully on frameless glass walls, offers users the chance to experience beauty, sustainability, and harmony with nature.

Hazelmead, Bridport Cohousing, Bridport

Masterplan & Housing Architect: Barefoot Architects

Common House Architect: Common Practice

Structural Engineer: JDL Consultants

Landscape architect: LT Studio, Land Products, Aileen Shackel Landscape Design

Contractor: C G Fry

Species: Timber frame with MMC-insulated panels

Cladding in brick and larch

Winner of the RIBA South West & Wessex Sustainability Award and a RIBA National Award 2025, Hazelmead, Bridport Cohousing by Barefoot Architects is the culmination of 10-plus years of collaboration between the architect and client Bridport Cohousing CLT.

Against a backdrop of urgent affordable housing need, Hazelmead delivers 53 safe, accessible, and eco-friendly timber-framed homes designed to foster community living and sustainability. This development offers homes built with low-carbon materials, functional design and energy efficiency, with sustainability at its core.

These homes offer streamlined designs, airy interiors with abundant natural light, and traffic-free spaces rich in greenery—delivering peace, safety, and stunning countryside views.

Architect: MawsonKerr Architects

Client: English Heritage

Structural Engineer: Ramboll UK Limited

Contractor: Hutton Group

Species: Douglas Fir

Winning the Retail & Leisure Project of the Year at the 2024 Structural Timber Awards is the new Visitors Centre and Exhibition space at Grimes Graves, Norfolk by MawsonKerr. This delightful timber structure hovers above the entrance to Pit 1 of the UK’s largest known Neolithic flint mine.

Delivering a sympathetic building on a sensitive site is always a challenge but this scheme bonds the constraints of a Scheduled Ancient Monument and a Site of Special Scientific Interest (SSSI) with a modern building that floats above the protected landscape.

The circular timber pavilion acts as an interpretive guide to Grimes Graves as dates from the site’s history are inscribed on the structure as visitors wind their way beneath the ground. The structure has minimal impact on the landscape and has become part of the fabric of one of Britain’s most remarkable prehistoric sites. >>

Winner of the Interiors category at the 2024 Wood Awards, Bough Terrace by Tuckey Design Studio set out to celebrate the natural timber structure through its interior finishings.

By uncovering the natural textures and imperfections of the floor joists and roof trusses, the project turned preservation into a highlight of the design. Gnarled and old timber sits side-by-side with the precise craftsmanship of new timber, opening a conversation about old and new, past and present.

The new joinery flows upwards from a single post in the basement, branching and rising to the upper floor like a tree, whilst handcrafted by skilled shipbuilders, the curved staircase is made from hand-folded plywood and appears to levitate in its dedicated space. This enchanting structure is a true celebration of the form, function and colour of timber.

Four single storey timber clad “huts” form Angles House which won the 2024 Structural Timber Awards Timber Frame Project of the Year. This scheme, by Beech Architects, was inspired by the single storey Anglo-Saxon settlements at West Stow Country Park, thus Angles House is also single storey.

Blending seamlessly into the wildflower landscape, the building is constructed entirely in wood, for its frame, walls and cladding, sourcing materials and craftspeople locally. A series of glazed boxes will break up the timber forms,

Architect: Tuckey Design Studio

Structural Engineer: BC Structural Design

Contractor: Imperial Building

Joinery: Cube and Design & Making

Species: Redwood Pine (Sweden, Finland), Douglas Fir, reclaimed timber. FSC certified

interlinked and inserted as connected areas between the Siberian larch panels. In time, its timber cladded form will weather naturally into the colours of the Waveney Valley.

This dramatic but quiet, environmentally friendly building reflects the landscape in which it sits, yet offers a full domestic structure of sustainability and functionality.

Architect: Beech Architects

Structural Engineer: Frith Blake

Contractor: Amplis Ltd

Species: Siberian Larch FSC® certified

Factory coated with OrganoWood® surface treatment

St Mary’s Catholic Voluntary Academy in Derby by Hawkins\Brown

The Education Project of the Year for the Structural Timber Awards 2024 is St Mary’s Catholic Voluntary Academy by Hawkins\Brown, and was the first school in the UK to meet the Department of Education’s GenZero specification. Known as the UK’s “greenest primary school”, the commitment to sustainability led the project design team to select natural materials wherever possible, including a rooftop meadow and timber cladding.

Along a connecting, covered central canopy sit five buildings designed for five age groups, each offering light and airy learning environments with easy access to the outdoors. Students are linked both physically and visually with the changing seasons of their landscape.

The innovative design of the school is part of a research programme with the University of Derby, to understand and quantify the health benefits of the GenZero specification through reporting health and wellbeing of the students.

Dovehouse Court Passivhaus Almshouses

Architect: Mole Architects

Timber Frame: Lowfield Timber Frames

Structural Engineer: Conisbee

Contractor: Barnes Construction

Species: Spruce softwood

Architect: Hawkins\Brown

Landscape Architects:

Ares Landscape Architects

Structural Engineer: Adept Engineering

Contractor: Tilbury Douglas Construction

Species: Red cedar

The new almshouses of Dovehouse Court in Cambridge have redefined accessible elder-living housing, combining independent living with draught-free electric homes. Designed by Mole Architects, the three timber-frame Passivhaus certified blocks was named as the Social Housing Project of the Year for the Structural Timber Awards 2024

Dovehouse Court seamlessly blends independent living with improved air quality, better insulation and low energy costs, achieved through passive solar principles, optimal orientation, and deep overhangs for shading. Each apartment has triple-glazed windows, air source heat pumps and mechanical ventilation systems.

Spruce softwood was used for the timber framed panels, sourced from Scandinavia and manufactured in Welshpool by Lowfield Timber. n

The APF Demo is the flagship event for the industry and the must visit show for anyone working in the forestry, woodland, arboriculture, fencing, estate and ground maintenance sectors. It is the place to network with all the industry’s stakeholders, catch up with old friends, and see the latest state of the art machinery and equipment.

APF 2026 will celebrate 50 years of the APF Demo since the very first show in 1976 at Longleat Estate. It will take place on the 24–26 September 2026 at Ragley Estate, Warwickshire.

APF 2024 was a huge critical success, and we are working hard to ensure that APF 2026 is a fitting event for our 50th birthday. 300 exhibitors and 20,000 visitors are expected to attend with over £90m of working machinery on show.

One of the standout features of APF 2024 was the number of events and competitions we had on display. There were two world championships, one European championship and five UK championships. We are looking to build on that for APF 2026. The favourites will be there including the World 25m poleclimbing championships, the European chainsaw carving championships, the UK Forwarder driving championships, the UK tree climbing competition and the British fencing championships.

Look out for new events such as the UK Loggers and the UK Lumberjack championships and a new category event for students in the Forwarder driving, with a chance to take part in a state-of-the-art forwarder. There will be plenty of have-a-go events such as tree climbing, axe throwing and a 4 x 4 course.

Our Arb worker zone will return and be based around the UK tree climbing arena so you can watch the climbers go against the clock and then browse all the latest arb kit on offer. The Forest Worker Zone will, as ever, be a fantastic source of help, advice and practical demos on a huge array of subjects.

The woodland craft area will have the largest display of rare and traditional woodland crafts on show anywhere in the UK. The seminar tent will have all the latest topical news on grants, safety, training, pests and diseases.

We have now opened for bookings for both exhibitors and visitors. Exhibitor booking forms are available on our website. Demand is expected to be high and we sold out our Demo circuit last time. Advance visitor tickets are just £25 and represent a £5 saving on the gate price.

We still have some fantastic sponsorship opportunities to promote your company to a very targeted audience including the chainsaw carving, UK Loggers, UK Lumberjacks and tree climbing competitions as well as axe throwing, tree climbing, gates and car parks, our schools and education programme, woodland crafts area and seminar tent.

We look forward to welcoming you to APF 2026. n

When the first exhibition took place at Longleat in 1976 it was run by The Association of Professional Foresters (The APF).

Around the year 2000 the APF merged with other member organisations to form Confor and the full name of the Association disappeared, however, most people in the industry referred to the Exhibition as The APF so we kept the initials as our trading name and, at the same time, formed a separate limited company, The APF International Forest Machinery Exhibition Ltd, whose sole shareholder is Confor. This was to keep the trading nature of the exhibition separate to the representative role of Confor.

For more information on APF 2026 then please visit our website at www.apfexhibition.co.uk, or email info@apfexhibition.co.uk or call us on 01428 723545.

Are timber buildings helping or harming forest biodiversity? asks Asselia Katenbayeva. An ASBP project explores the impacts of timber sourcing and the challenge of measuring biodiversity. Why biodiversity matters—now more than ever.

One million species are edging toward extinction, the global science body IPBES warns.1 Forests remain their main refuge: four-fifths of all land plants and animals live under a canopy. Woodlands stabilise soils, regulate water, and sequester carbon; their biological richness is therefore a silent buttress for every climate-mitigation plan.

rules—and a blind spot

The topic of biodiversity has never been as high as it is today. In England, Biodiversity Net Gain regulations now oblige most developments to deliver a 10% ecological uplift on site. Some companies also disclose nature-related risks in supply chains under voluntary TNFD framework.2 But how many consider whether a glulam beam CLT panel they specify helped or harmed the biodiversity of the forest it came from? Supply chain impacts remain a blind spot.

To gauge sentiment, the Alliance for Sustainable Building Products (ASBP) surveyed architects, engineers, developers, and other construction stakeholders; 46% thought that harvesting timber for construction has a negative impact on forest biodiversity and 26% were unsure. Barely one in five believed that timber harvesting could go hand-in-hand with thriving ecosystems.

Bridging that gap was the goal of IMPACTT, an 18-month ASBP-led initiative funded by Built by Nature and partnered with PEFC UK, Stora Enso, DoubleHelix, Woodknowledge Wales, Agrodome, Eurban, and other partners. The team traced the supply chains of 11 timber buildings—from forest to frame—and published the journeys as interactive maps (see ASBP Impactt3). The project also addressed common misconceptions around sourcing timber.

Myth — “Commercial forests are ecological deserts”

This view is outdated. While early commercial forests focused on monocultures and timber production only, modern sustainable forestry aims to integrate a balanced approach. The truth is, in the Anthropocene, we are beyond the idea of “just leave the forest alone”. Faced with rapid climate change, forests must be actively managed to curb pests and diseases, lessen fire risk, and buffer escalating climate impacts.

Two large-scale surveys assessed biodiversity in commercial forests of Great Britain:

• 2003 Forestry Commission study4 recorded 2,000+ species in commercial forests, with vascular plants and lichens sometimes richer than in native woods.

• 2024 survey5 confirmed that commercial forests can support specialist woodland mammals, birds, amphibians, and reptiles.

A key finding is that forest age and structure significantly affect biodiversity levels. Younger plantations tend to have lower species diversity, but as they mature – developing varied tree heights, understory growth, and deadwood accumulation – they become increasingly valuable wildlife habitats. In many respects, habitat development in planted forests in Great Britain has occurred by accident rather than design, as a result of ‘normal’ (not sustainable) commercial forestry practice during the 20th century. With deliberate, well-managed practices, the potential is far greater.

Let’s refer to real examples of biodiversity in commercial forests. Kielder Forest, England’s largest planted estate, shelters roughly half of Britain’s endangered red squirrel population. Thetford Forest, on the border of Norfolk and Suffolk, is a Site of Special Scientific Interest supporting nightjar, goshawk, woodlark and other birds. Under deliberate management, a working forest can be a thriving living landscape.

“The truth is, in the Anthropocene, we are beyond the idea of ‘just leave the forest alone’.”

“Measure it, manage it” sounds simple until you enter the woods. A review of 149 studies6 found 83 different sets of indicators used by academics for biodiversity in European forests, which fall into two groups:

1. Species-based metrics – presence, richness or abundance of birds, beetles, fungi, microbes.

2. Structural metrics – habitat proxies such as deadwood volume, canopy layering, soil moisture.

No single, universally accepted forest biodiversity metrics exist. To capture varied perspectives, we convened a workshop with forest specialists, forest owners, leading academics, and eDNA analysis company.

UK-based NatureMetrics analyses forest soil and water, sequencing genetic fragments left by organisms. This method can reveal hundreds of taxa, including cryptic fungi and invertebrates, offering a rapid biodiversity snapshot. It cannot, however, establish a population size or confirm breeding success, but it widens the lens beyond what field observers can spot.

CLT producer and one of the world’s largest forest owners, Stora Enso, apply a range of methods for monitoring and managing biodiversity. They build digital twin simulations of its forests to test management options and use predictive modelling to pinpoint where certain species are likely to thrive. Where the company buys from third-party forests, it offers financial incentives for owners who exceed sustainable forestry certification targets. >>

Counting species alone does not tell the whole story. Chris Jones, silviculture specialist at Woodknowledge Wales, notes that each species should play a functional role—a “service” in the woodland ecosystem. For example, certain conifers, like spruce, are valuable for harvesting timber, while deep-rooted pine species offer wind resistance. Using an ecosystem services approach, different functions of the forest—timber, recreation, biodiversity, clean air—can be assigned value. In multifunctional forests, resilience to environmental change underpins the forest’s ability to support biodiversity.

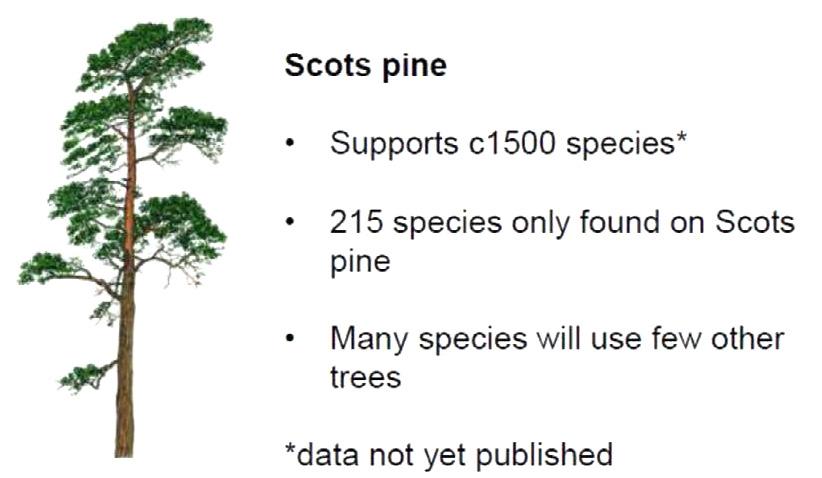

Different trees also host very different lives. Dr Ruth Mitchell from James Hutton Institute referred to research comparing four UK staples: Scots pine, oak, ash, and Sitka spruce.7,8 Scots pine, a native tree, supports far richer biodiversity than Sitka. However, simply counting the species is not enough; it is crucial to understand the roles these species play within the forest ecosystem. Likewise, tree species diversity alone is not sufficient for promoting biodiversity; forest managers must also consider how forests are structured and managed.

“If we want to determine the impact,” noted Prof. John Healey of Bangor University, “how do we decide what to compare it against?” Should a production forest be compared with an unharvested reserve, an area managed exclusively for biodiversity, or another production forest managed differently? The choice of counterfactual can reverse conclusions. Biodiversity in forests is also influenced by complex variables such as management practices, geographic location, and the forest growth cycle. Furthermore, the metrics must consider not only species numbers but also conservation values. For example, a forest with fewer species might actually host a higher proportion of endangered animals.

Borrowing concepts from carbon accounting helps:

• Additionality – gains must be above business-as-usual.

• Leakage – protection in one area must not shift damage elsewhere.

• Permanence – benefits should last in the long term.

Switching the narrative from ‘do no harm’ to ‘achieve net benefit’ is crucial.

• Measuring forest biodiversity is complex; no standard system yet exists.

• Biodiversity and sustainable forest management are intertwined—timber, recreation, clean air, carbon sequestration and habitat are co-produced services.

• Biodiversity is not a league table; what matters is ecosystem function and the resilience of forests in the face of rapid climate change.

• Choosing the right baseline, considering complex variables (e.g. geographic location, and the forest growth cycle), as well as additionality, leakage and permanence, can help to turn metrics into meaningful management.

• “Do no harm” is too low a bar; the real goal is net-positive biodiversity—forests that leave nature richer than they found it.

Every joist, beam and panel that rises inside a building begins life in a living forest. If we want architecture to serve the planet, the ledger must capture the full impact of sourcing materials. Specifying timber is not merely a procurement decision; it is a vote for the forest’s future. We should raise the bar and ask not only about cost and thermal performance—or even how many tonnes of CO2 were sequestered and locked into the building— but also: What did the forest of origin gain? n

Dr Asselia Katenbayeva

Sustainability Research Lead

Alliance for Sustainable Building Products

LinkedIn: www.linkedin.com/in/asselia-katen

1. IPBES (n.d.) A million species threatened: thirteen questions and answers. Intergovernmental Science-Policy Platform on Biodiversity and Ecosystem Services. Available at: www.ipbes.net/news/million-threatened-speciesthirteenquestions-answers

2. Taskforce on Nature-related Financial Disclosures (n.d.) Available at: www.tnfd.global

3. Alliance for Sustainable Building Products (n.d.) IMPACTT Project: Assessing and improving the performance of construction materials. Available at: www.asbp.org.uk/project/ impactt

4. Humphrey JW, Ferris R, Quine C. (2003) Biodiversity in Britain’s planted forests. Forestry Commission, Edinburgh, p. 118. Available at: www.cdn.forestresearch.gov.uk/2003/01/ fcrp004.pdf

5. Barsoum N, Field E, Broome A, Cottrell J. (2024) Rapid review of evidence on biodiversity in Great Britain’s commercial forests. Forest Research, Edinburgh, pp. i–iv + 1–44. Available at: www.forestresearch.gov.uk/publications/biodiversitycommercial-forests

6. Gao T, Nielsen AB, Hedblom M. (2015) Reviewing the strength of evidence of biodiversity indicators for forest ecosystems in Europe. Ecological Indicators. 57:420–434. www.doi.org/10.1016/j.ecolind.2015.05.028

7. Mitchell RJ, Beaton JK, Bellamy PE, Broome A, Chetcuti J, Eaton S, et al. (2014) Ash dieback in the UK: a review of the ecological and conservation implications and potential management options. Biological Conservation. 175:95–109. www.doi.org/10.1016/j.biocon.2014.04.019

8. Mitchell RJ, Bellamy PE, Ellis CJ, Hewison RL, Hodgetts NG, Iason GR, et al. (2019) Collapsing foundations: The ecology of the British oak, implications of its decline and mitigation options. Biological Conservation. 233:316–327. www.doi.org/10.1016/j.biocon.2019.03.040

For further information visit: www.asbp.org.uk

Woodland creation is central to UK land use, balancing climate goals, biodiversity, and rural livelihoods. Kate Palmer explores how policy, natural capital, and market innovation reshape the landscape for a resilient future.

As 2025 unfolds, the UK faces a pivotal juncture in land use and natural capital policy. Competing demands—securing future timber supply, meeting net zero targets, halting biodiversity loss, ensuring food security, and sustaining rural economies— are reshaping how we value and manage land.

Woodland creation sits at the heart of this transformation, recognised not only as a vital carbon sink but also as a reservoir of biodiversity and a long-term economic asset. With major policy shifts underway - such as England’s ELMs, Wales’s Sustainable Farming Scheme, and Scotland’s AgriEnvironment Scheme - the role of multifunctional woodlands in a resilient green economy has never been clearer.

The UK’s policy framework for woodland creation is increasingly ambitious, with each devolved nation setting its own strategic direction. England’s Environmental Improvement Plan 1, Scotland’s Forestry Strategy 2019–2029 2, Wales’s Woodlands for Wales 3 initiative, and Northern Ireland’s Forests for the Future 4 program all aim to expand tree cover and enhance ecosystem services. Despite a shared UK-wide target of 30,000 hectares of new woodland per year 5, progress is mixed. Scotland consistently leads on planting rates, while England and Wales face delivery challenges linked to land availability, planning and approval processes, and capacity within the sector.

Funding and incentives remain a key area of uncertainty. England’s Environmental Land Management (ELM) schemes have experienced delays and shifting eligibility criteria, affecting landowner confidence. Wales is transitioning to its Sustainable Farming Scheme, aiming to integrate woodland creation into broader land stewardship, though details remain in flux. Scotland’s Forestry Grant Scheme is struggling to keep pace with rising costs and pressure on public funding. Divergent policy approaches

across the UK highlight the need for greater coherence and long-term certainty to scale woodland creation and realise natural capital ambitions.

Woodlands are no longer valued solely for the timber they produce. A new era of land management is emerging, driven by natural capital accounting - where ecosystems that historically had limited economic value are assessed for the full range of services they provide, from carbon sequestration and water regulation to biodiversity, recreation, and air quality. This shift is reshaping investment priorities and landowner strategies across the UK.

Carbon and biodiversity markets are creating new revenue streams, but they also introduce complexities. Ensuring permanence, avoiding double-counting, and achieving credible verification are ongoing challenges. As these frameworks mature, they are influencing woodland creation at scale, guiding where and how new planting occurs.

For landowners, understanding these evolving metrics is crucial - not only to unlock new funding mechanisms but to ensure their land-use decisions support long-term environmental and economic resilience. The landscape is changing - both in how land is managed and how we value it.

Land use across the devolved nations is increasingly shaped by a complex interplay of priorities - from timber and food production to housing, biodiversity, and renewable energy. Woodland creation, while vital for growing timber for houses, fencing, biomass, as well as sequestering carbon and enhancing ecosystem resilience, must navigate these competing demands. The principle of “the right tree in the right place for the right reason” has never been more relevant.

Thoughtful spatial planning is essential to resolve these tensions and maximise synergies. Tools like Local Nature Recovery Strategies and the emerging Land Use Framework in England can offer structured approaches to align national ambitions with local needs. These mechanisms can integrate woodland creation with wider land use goals, however, these tools have highlighted that at a local level there is still limited understanding of the value of productive woodlands in supporting both environmental and socio-economic outcomes.

Agroforestry and integrated land management practices are also gaining traction, presenting promising pathways to reconcile woodland expansion with agricultural productivity and biodiversity goals. By embedding woodland creation within a multifunctional landscape vision, the devolved nations can unlock natural capital benefits while supporting resilient rural economies.

Woodland creation remains a cornerstone of the UK’s strategy for enhancing natural capital and securing future timber supply. In Wales and beyond, demand for softwood continues to grow, driven by a tightening global timber market and increased focus on sustainable construction. The Welsh Industrial Timber Strategy reinforces this demand by setting out a clear ambition to increase the supply of high-quality,

“Woodland creation remains a cornerstone of the UK’s strategy for enhancing natural capital and securing future timber supply. In Wales and beyond, demand for softwood continues to grow, driven by a tightening global timber market and increased focus on sustainable construction.”

domestically grown softwood for use in modern construction and manufacturing. It emphasises the economic potential of productive forestry and the role of homegrown timber in decarbonising the built environment. Yet, afforestation rates lag well behind government targets. Across the UK, approximately 16,000 hectares of new woodland were created in 2024–25, falling far short of the 30,000-hectare annual UK goal set in the England Tree Action Plan.6

Across the UK, woodland creation projects continue to be planted, but regulatory challenges, economic viability, and land availability, continue to pose serious challenges. Added to this are labour shortages and a pressing need for upskilling across the forestry sector. Success depends heavily on early and meaningful engagement with local communities and landowners to build trust and long-term support. >>

Situated on the edge of the Tywi Valley Forest Complex, the Llwyn Derw project is a 250-hectare mixed species woodland creation scheme that exemplifies large-scale integrated land stewardship. Delivered under the Welsh Government’s Woodland Creation Grant Scheme, the project is being implemented in two phases on previously degraded land dominated by steep, bracken-covered banks.

The scheme features 80% native broadleaves, alongside a carefully selected mix of Scots pine and Norway spruce to support the adjacent red squirrel buffer zone. Designed to support the red squirrel population with additional carbon sequestration benefits, Llwyn Derw also contributes significantly to flood prevention, watercourse protection, and landscape resilience.

Crucially, the estate has prioritised positive stakeholder engagement, hosting farm open days to inform and involve the local community. This early and transparent approach has helped build trust and foster support for the project’s long-term goals.

Located in a heavily wooded area with strong biodiversity value, Llwyn Derw enhances ecological connectivity while offering potential for recreational access and local economic benefit. The project stands as a compelling example of how strategic woodland creation can meet climate, nature, and community objectives in tandem.7

Across Wales and the wider UK, over 40% of existing woodlands remain unmanaged8. Bringing more woodlands into active management is essential - not only to enhance biodiversity and timber yield, but also to improve long-term carbon sequestration, which is consistently higher in well-managed forests. Certification schemes such as FSC and PEFC provide frameworks to assure sustainable practices, yet uptake and monitoring require further support.

Emerging technologies, including drone surveillance, remote sensing, and digital inventory platforms, offer powerful tools to monitor forest condition, assess risks, and inform timely interventions. By embracing innovation and integrated stewardship, we can secure resilient, productive woodland landscapes for future generations.

The private sector is increasingly pivotal in driving woodland creation through innovative market mechanisms and green finance. A surge in private investment - driven by carbon offsetting commitments and ESG-aligned forestry funds - is reshaping land use strategies across the UK.

Frameworks like the Woodland Carbon Code provide critical assurance, enabling credible, measurable climate benefits that attract institutional investors. These verification schemes are essential in translating natural capital into investable assets, aligning carbon sequestration with financial returns.

However, the long-term success of these schemes hinges on transparent governance and robust verification standards. Market confidence depends on integrity: without it, the risk of greenwashing could undermine both ecological outcomes and investor trust.

Looking ahead: integration, collaboration, and landscape resilience

Over the next decade, the future of woodland creation will depend on a more integrated and collaborative approach to land use. Developing a clear, cross-sectoral land use framework is essential to align public policy with private sector action, providing clarity and confidence for long-term investment.

Bridging the gap between policy and practice will require new mechanisms that incentivise multifunctional landscapes - those that deliver for nature, climate, and rural economies.

Crucially, forestry, farming, and conservation communities must work together to navigate competing demands on land. By fostering collaboration, we can co-create resilient landscapes that support timber and food production, carbon sequestration, and biodiversity within a shared natural capital strategy. n

About the author Dr Kate Palmer

Technical and Industry Support Manager

Confor: Confederation of Forest Industries (UK) www.confor.org.uk

1. Department for Environment, Food & Rural Affairs (2023) Environmental improvement plan 2023: Delivering a green future. UK Government. Available at: www.gov.uk/ government/publications/environmental-improvement-plan

2. Scottish Government (2019) Scotland’s forestry strategy 2019–2029. Available at: www.gov.scot/publications/ scotlands-forestrystrategy-20192029

3. Welsh Government (2018) Woodlands for Wales: The Welsh Government’s strategy for woodlands and trees. Available at: https://www.gov.wales/woodlands-wales-strategy

4. Department of Agriculture, Environment and Rural Affairs (2023) Forest for Our Future – Forest Expansion Scheme reopens. Northern Ireland. Available at: www.daera-ni.gov.uk/news/ forest-our-future-forest-expansion-scheme-reopens

5. UK Parliament (2024) Seeing the wood for the trees: The contribution of the forestry and timber sectors to biodiversity and net zero goals. House of Commons Environmental Audit Committee. Available at: www.committees.parliament. uk/work/7989/forestry-and-biodiversity

6. Forest Research (2025) Forestry statistics 2025. Forestry Commission. Available at: www.forestresearch.gov.uk/ tools-and-resources/statistics/publications/forestrystatistics/ forestry-statistics-2025

7. Llwyn Derw (n.d.) Llwyn Derw Broadleaved Woodland Creation Project. Available at: www.llwynderwwoodlandcreation.com

8. Forestry Commission (n.d.) Woodland management: Missed opportunities. [PDF file].

John Healey discusses the case for domestic wood production, as outlined in a Nature Communications paper co-authored with Eilidh Forster, Research Associate at Bangor University, and David Styles, Associate Professor at the University of Galway.

“Only a strategy that combines large-scale expansion of productive forest area and a substantial increase in tree growth rates will enable higher rates of wood use to make a positive contribution to reducing global warming over the coming century.”

Wood is a low-carbon alternative to materials like steel, concrete, and plastic, and plays an increasingly prominent role in strategies to decarbonise the built environment. But while the UK government has highlighted increased wood use as a key element in meeting climate goals, there is a critical issue often overlooked: the supply chain behind that wood.

Despite its ambitions, the UK currently imports more wood than almost any other country and has one of the lowest levels of forest cover in Europe, with just 14% of its land area under woodland. Only a fifth of UK demand is met by domestic timber production. This reliance on imported wood not only increases vulnerability to global market shocks—it also risks undermining the environmental benefits of choosing wood in the first place.

New research published in Nature Communications (www.doi.org/10.1038/s41467-025-58463-5) explores how national net zero strategies could be affected by these supply dynamics. In particular, it examines the carbon implications of sourcing wood from domestic sources or importing it from different types of overseas forest.

The findings highlight a crucial point: using more wood in construction and manufacturing can indeed contribute to lowering emissions—but only if the wood comes from forests managed in a way that enables rapid regrowth and sustained carbon sequestration. It takes far longer for the stocks of carbon in slow-growing boreal forests, such as those in Scandinavia and the Baltic States, to recover after harvesting than is the case for faster-growing temperate conifer forests, such as those in the UK.

To investigate this further, researchers at Bangor University developed an advanced consequential life cycle assessment (LCA) modelling methodology. We used “prospective dynamic LCA” to project global warming impacts over the next century. Our approach combined modelling forest carbon stock dynamics (using the Canadian CBM-CFS3 model) >>

with our new model for wood harvesting, transport, processing and use to generate an integrated analysis of future net greenhouse gas emissions for the whole wood value chain system. We included the emissions resulting from greater use of alternative materials—such as concrete and fossil fuel derivatives—if timber was not available in sufficient quantities, using “expanded system boundary LCA”.

Our results show that it is possible to increase wood use and still achieve substantial benefits of reduced global warming—provided there is a sufficient uplift in temperate

“The findings highlight a crucial point: using more wood in construction and manufacturing can indeed contribute to lowering emissions—but only if the wood comes from forests managed in a way that enables rapid regrowth and sustained carbon sequestration.”

forest production in countries like the UK. Under modest growth in wood demand (1.1% annually), this would require at least a 50% increase in the area of productive conifer forest over the next 50 years. A more ambitious approach, involving both a doubling of productive forest area and an increase in forest productivity by 33% (e.g. from a yield class of 18 to 24), would amplify climate benefits of reducing global warming further—by as much as 175%.

To illustrate this specifically: starting with 100,000 hectares of temperate conifer forest at yield class 18, expanding this to 200,000 hectares while improving productivity to yield class 24 could deliver cumulative greenhouse gas emissions reduction of around 277 million tonnes of carbon dioxide equivalent over a 100-year period. However, this scenario depends on maintaining forest health and growth rates, which are threatened by tree pests, diseases and drought, all of which are predicted to increase due to climate change.

The challenge becomes even more pressing under higher rates of increase in wood demand. If annual demand rises by 2.3%, individual measures—whether increasing temperate forest productivity, expanding forest area, or adjusting rotation cycles—will not be sufficient on their own. Only a combined strategy including a doubling of productive conifer forest area and a 33% increase in forest growth rates will sustain a net reduction in global warming over the coming century.

The study outlines four core priorities for the UK:

1. Reassess sourcing strategies: The timber industry needs to examine more closely its future sources of wood in terms of their potential impacts on net carbon emissions. There is a significant risk that increasing supply from the main current source forests will have harmful global warming impacts.

2. Reverse the stagnation in afforestation: The UK has seen virtually no increase in productive conifer forest over the past three decades. Harvestable volumes are expected to decline after 2039, while rise in demand is forecast to continue. Strategic land use planning is urgently needed to address the priority of wood security alongside those of food security and biodiversity conservation.

3. Improve forest resilience and productivity: Research and investment should focus on enhancing the productivity of UK forests while building resilience to threats from pests, pathogens and drought.

4. Use timber more efficiently: We need to moderate future increases in demand by reducing waste, extending the life of wood products and promoting reuse, in line with circular economy principles.

Ultimately, our study provides strong evidence of the need for better alignment between net zero strategies and land use policy. The full potential of timber as a contributor to greenhouse gas removal lies not just in its use, but in how and where it is grown, harvested and reused. As such, policy assessments must integrate forest and wood product carbon accounting, including material substitution, using the kind of forward-looking analysis developed in our study.

By ensuring that more of the UK’s wood demand is met domestically—through well-managed, productive forestry—the nation can reduce pressure on overseas forests, lowering the risk of ‘offshoring’ carbon and biodiversity impacts of our wood consumption. Just as food security is advocated as a priority for national resilience, so too must wood security become a strategic priority in the transition to a low-carbon future. n

John Healey Professor of Forest Sciences Bangor University

Download the paper at www.nature.com/articles/ s41467-025-58463-5

Tom Henderson believes a strategic circular timber economy can unlock climate, housing and economic benefits for Wales—but only if we align forest policy, processing, and procurement.

As global efforts to decarbonise accelerate, timber is back in the spotlight—not just as a renewable material, but as a strategic climate solution. And yet, in Wales, despite world-class growing conditions and deep cultural connections to land, our timber resource remains underutilised.

We import most of the wood we use. Our forests are not expanding fast enough to meet national afforestation targets. And of the timber we do harvest, the vast majority is directed to short-lived uses—pallets, fencing, biomass— while only 6% is structurally graded for housing.

alternatives to steel and concrete. Yet the UK currently has no large-scale engineered timber production—and imports dominate.

Meanwhile, demand for timber in construction is booming. If Wales is serious about climate leadership, rural regeneration, and affordable housing, we must ask: what would it take to turn our timber value chain into an engine of low-carbon prosperity?

Timber and Decarbonising Wales1, an evidence-based report written as part of the Timber Industrial Strategy for Wales is an attempt to answer that question. It sets out a joined-up vision: expanding forest cover, managing it well, using timber wisely, and recovering its value through reuse, remanufacturing and recycling.

Timber is uniquely suited to circularity. Though it degrades over time, each piece can serve multiple lives. A beam can become joinery; offcuts become panel board; fibres can be recycled into insulation; and only at the very end should timber become fuel. When wood is kept in circulation – in buildings, products and fibres – it stores carbon, displaces more harmful materials, and generates greater economic value from every tree harvested.

A key piece of the puzzle is engineered timber. Products like crosslaminated timber and glulam offer high-performance, low-carbon

Wales has the softwood resource (notably Sitka spruce), the workforce potential, and the market need to change that. A modest-scale CLT facility using 60,000 m³ of Welsh timber could produce 30,000 m³ of panels a year – storing over 22,000 tonnes of CO2 annually, creating skilled rural jobs, and keeping value in the domestic economy.

The same logic applies to wood fibre insulation—ideal for retrofitting homes, yet less than 0.1% of the UK insulation market. As new fibre recovery techniologies and systems come on line, Wales could lead the way in recycling and manufacturing biobased materials for net-zero construction.

But manufacturing is only one part of the story. It begins—and depends—on what we grow. Forest creation and management are crucial to the long-term carbon story.

Afforestation alone, if scaled to 5,000 hectares per year, could deliver around 15 million tonnes of CO2e removals by 2050. Add to that the carbon stored in timber products, and the avoided emissions from substitution, and forestry becomes a major contributor to national climate targets.

Timber alone is not a silver bullet. But used wisely, it can help us meet our goals for climate action, housing supply, rural jobs, and resource resilience.

To get there, we need to act on several fronts:

• Scale up afforestation on suitable land— with multifunctional, productive forests that serve both climate and biodiversity.

• Invest in domestic manufacturing— especially engineered timber and wood fibre insulation, to retain value and reduce imports.

• Upgrade circular infrastructure—from advanced sorting to fibre recovery, ensuring wood stays in the system longer.

Forest management matters too. Adaptive forest management silviculture suited to site and climate can enhance both forest resilience and the provision of ecosystem services. As climate pressures mount across all European temperate forests, shifts in what we grow will be unavoidable—and there is an opportunity to align this with demand. We therefore need to bring markets and processing into step with adaptive management, while also considering the long-term markets for the alternative species we establish. At the same time, Wales has a comparative advantage in being able to grow trees exceptionally quickly. In the context of European forestry, where traditional systems are increasingly threatened by climate pressures and institutional inertia, Wales’ more fluid land use and timber sector creates scope for dynamism. Without this, we risk degradation or worse, offshoring our climate impacts by relying on slowgrowing boreal forests elsewhere, as Elidh Forster warns.2

Housing is where many of these threads come together. Timberframe construction offers one of the clearest climate wins—each home locking in 15 –18 tonnes of CO2 from the wood alone, and avoiding another 15 – 20 tonnes by replacing concrete and steel.

Redirecting just 15% of Wales’s current timber harvest into housing could support over 8,000 homes per year and save around 0.56 MtCO2e annually. That’s equivalent to the emissions from over 120,000 cars.

Most Welsh softwood primarily Sitka spruce can meet C16 construction standards, but specifier confidence remains low. This is where public procurement and programmes like Tai ar y Cyd come in creating stable demand for Welsh-grown timber and supporting a homegrown industrial base.

• Reform procurement and design standards— so low-carbon, circular materials like Welsh C16 become the default, not the exception.

• Support rural enterprise and workforce development— particularly the small mills and nurseries that add value locally.

This is not a prescriptive roadmap, but a shared evidence base to guide future investment, policy and practice. It offers a practical foundation for decision-makers across forestry, housing, manufacturing and public procurement to coordinate action— helping Wales transition from extractive to regenerative systems, and from imported dependency to homegrown opportunity. n

Tom Henderson

Forestry & Timber at Woodknowledge Wales

Email: tom.henderson@woodknowledgewales.co.uk www.woodknowledge.wales

Further information

www.woodknowledge.wales/timber-anddecarbonising-wales/

References

1. Henderson T Timber and Decarbonising Wales Woodknowledge Wales 2025 www.woodknowledge.wales/ timber-and-decarbonising-wales

2. Forster EJ, Styles D, Healey JR Temperate forests can deliver future wood demand and climate-change mitigation dependent on afforestation and circularity Nat Commun 2025;16:3145 www.nature.com/articles/s41467-025-58463-5

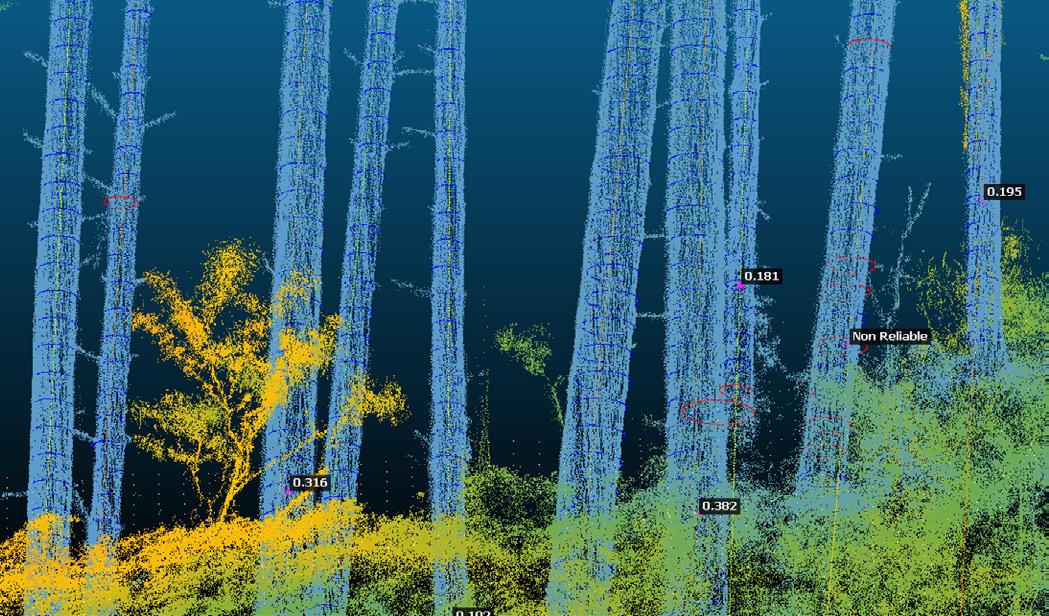

Heddwyn Bye explains how terrestrial LiDAR scanning offers a breakthrough in assessing timber quality and carbon stocks in complex UK woodlands—unlocking economic potential and supporting climate-smart, precision forestry.

Across the UK, hundreds of thousands of hectares of small, irregular and underutilised woodlands are overlooked by traditional forest management systems. Their complex structure and non-uniform species mix make it difficult to assess timber value or carbon potential using standard inventory tools. But what if there were a way to peer inside the tangled canopy and see, with precision, what each tree could really offer?

A growing body of research suggests there is. At Bangor University, I’ve been exploring how terrestrial laser scanning (TLS)—a tripod-mounted form of LiDAR (Light Detection and Ranging)—can measure the structure of standing trees with millimetre accuracy. Our findings show that TLS doesn’t just replicate conventional forest inventory metrics like DBH (diameter at breast height) or tree height—it is able to provide deeper insights into timber quality and carbon storage potential.

This technology could be transformational for complex woodlands: the unmanaged alder and hazel groves, the overstood coppice, the farm woodlands that dot the Welsh landscape. These are the forests that rarely see a forester’s tape measure, let alone a management plan. TLS gives us a way to measure their value—accurately, efficiently, and, crucially, before a single tree is felled.

Traditional forest surveys rely on manual tools and a great deal of subjective visual assessments by a professional. Measuring the structural quality of a tree—its sweep, lean, taper, or stem defects—is a slow and imprecise process. For small-scale or inaccessible sites, it’s often simply not done.

TLS changes this. It works by firing hundreds of thousands of laser pulses per second, creating a dense 3D ‘point cloud’ of the forest. From this cloud, we can extract not just DBH and height, but also detailed shape parameters: how straight or curved a tree is, how much it leans, how its trunk narrows towards the top.

In our study, we surveyed 55 trees across eight Welsh woodland plots of varying complexity—from well-managed Douglas fir plantations to dense, naturally regenerated broadleaf stands. Using a Leica BLK360 scanner, we

captured highly detailed scans of each plot, later segmented and analysed using open-source tools like CloudCompare and RStudio. A custom-built algorithm then applied UK-specific sawlog grading rules to the measurements, estimating what proportion of each tree’s stem could be classed as green or red sawlog—and calculating the associated market value.

The results were promising. TLS-derived measurements of DBH and taper showed high correlation with manual methods, while also offering a level of detail—and consistency— that manual surveys struggle to match. For each tree, we could estimate not only total timber volume, but the likely grade, length, and commercial value of future sawlogs.

What’s needed next is automation: software that can process TLS data in the field, classify trees, assess their form, and generate usable inventory outputs with minimal human input.

Better timber data is only half the story. When it comes to forestry’s role in climate mitigation, accurate carbon accounting is essential. Current approaches rely heavily on allometric equations—broad statistical estimates based on simple measurements like DBH and height. These are useful at scale but often fail to capture the structural quirks of broadleaf trees or small branches, leading to underestimates of biomass and stored carbon.

TLS allows us to move beyond estimation. By directly measuring the tree’s volume in 3D—including its taper, sweep, and branching structure—we can derive more accurate calculations of aboveground biomass. In one comparison, TLS-derived volumes were found to be nearly double those predicted by standard equations. This has profound implications for landowners participating in woodland carbon schemes or aiming to quantify the climate benefit of restoration efforts.

For example, a neglected farm woodland that’s too complex for traditional inventory may still hold significant carbon value. TLS provides a method to evidence that, bringing these woodlands into scope for management, funding, and long-term stewardship.

Despite its promise, TLS is not yet widely used in UK forestry. There are several reasons. First, the scanners themselves are expensive and sensitive to weather—rain or strong wind can distort point clouds. Second, the data they generate is complex and unwieldy. Processing a single plot’s scan requires specialised software and expertise.

In our study, we developed a multi-step data processing pipeline using open tools and custom R scripts. This approach worked—but it’s not realistic for routine operational use.

Some progress is being made on this front. Researchers have demonstrated helmet-mounted laser scanners with real-time processing capability. But these tools are not yet widely available, and full automation remains a work in progress.

TLS will not replace conventional forest inventory overnight. But it could expand what’s possible—especially in the UK’s mosaic of small, complex woodlands. These are the areas where conventional approaches struggle but where the need for better management is acute. Better data leads to better decisions. And with the right tools, we can see beyond the trees to understand the full value of our woodlands— economically, ecologically, and climatically.

By embracing TLS, we can bring overlooked forests into active management, increase the proportion of timber going into high-value, long-lived products, and deliver more robust carbon outcomes. In a world racing toward net-zero, that’s a shift worth scanning for. n

Heddwyn Bye

A researcher with Woodknowledge Wales and an MScRes candidate at Bangor University, co-supervised by Dr Marielle Smith, Professor John Healey (Bangor University) and Matthew Drummond (University of Wales Trinity Saint David), specialising in forestry measurement and sustainable land use.

Email: heddwynb@hotmail.co.uk www.woodknowledge.wales

www.woodknowledge.wales/estimating-timbervalue-and-carbon-in-complex-woodlands-usinglaser-scanning

Gary Newman explains why wood in construction must be treated as a greenhouse gas removal (GGR) mechanism, and what this means for policy, carbon accounting, and the future of our industry.

As the UK Government ramps up its investment in carbon capture and storage (CCS) pledging over £21bn to remove 8.5 MtCO₂e a year by 2050 it remains bafflingly slow to recognise an arguably simpler, cheaper, and already-scalable solution: using more wood in construction.

Our new research, Using Wood in Construction as a Significant Greenhouse Gas Removal Mechanism 1, sets out the case for treating timber-based buildings not merely as low-carbon alternatives to concrete and steel, but as legitimate carbon removal infrastructure. Done well, and at scale, this could remove atmospheric carbon faster, more affordably and with greater co-benefits than many engineered solutions currently in the spotlight.

This is not fringe science. The Intergovernmental Panel on Climate Change (IPCC), the Climate Change Committee (CCC), and even the UK Government’s own consultants have acknowledged the role of biogenic materials in construction in engineered carbon removal2-4

The principle is simple. Trees capture carbon through photosynthesis. If the resulting biomass is harvested from a sustainably managed forest and used to construct a home, that carbon stays locked away—potentially for decades or centuries. This transfer from the forest carbon pool to the ‘harvested wood products’ (HWP) pool is already recognised in national greenhouse gas inventories. The building becomes a carbon store.

In 2018, it was estimated that 1.14 MtCO2e were added to the UK’s HWP pool through timber construction—mostly in housing5. With the right demand signals, we could rapidly increase that annual inflow. Critically, even modest interventions—such as favouring timber frame over masonry— can double the carbon stored per unit of floorspace.

Yet, life cycle assessment (LCA) rules used in net-zero building frameworks assume that all biogenic carbon stored in construction products and materials is released. In GWP100 terms, this means no net climate benefit is recorded—regardless of whether the building lasts 30 years or 130. Our report challenges this logic, aligning instead with emerging international carbon removal frameworks1,6

What makes this issue urgent is that timber buildings do more than reduce emissions (by replacing concrete and steel). They actively remove atmospheric CO2—just like direct air carbon capture and storage (DACCS) or Bioenergy with carbon capture and storage (BECCS).

This makes them part of the UK’s GGR arsenal. The CCC’s Sixth Carbon Budget and the Royal Society’s landmark 2018 report both state clearly: to hit net zero by 2050, we must remove 75–130 MtCO2e per year through GGR3,2. Yet wood in construction was inexplicably excluded from the UK Government’s GGR demonstration programme4

This omission matters. Not because wood is better than every other method—but because it is shovel-ready. Unlike DACCS or BECCS, it needs no new infrastructure, no long-term liabilities, and no billion-pound subsidy regimes. We already know how to build with timber. What we lack is a market and regulatory framework that rewards the carbon value of doing so.

For this to change, we must do three things:

1. Push for recognition in policy. Timber buildings must be included in national GGR portfolios and treated equivalently to other carbon storage technologies. That includes eligibility for incentives under future carbon certification schemes.

2. Improve measurement and reporting. New standards under development—such as ISO’s draft for quantifying carbon in harvested wood products—should be adopted and operationalised by manufacturers and building clients alike.

3. Design for longevity and reuse. If buildings are to be recognised as carbon stores, they must be built to last. That means paying attention to service life, circularity, and deconstruction pathways. Reuse and cascading use can extend carbon residence times well beyond 100 years7

It’s time the timber industry claimed its rightful place in the climate solution portfolio. We are not just low-carbon. We are carbon negative. But unless we frame our product as a GGR mechanism—not just as a ‘greener material’—we risk being sidelined in favour of flashier tech with bigger lobbyists.

The timber sector needs to speak the language of climate policy: quantification, degree of permanence, additionality, verifiability, and cost-effectiveness. If we do, we will not only grow our market, but ensure that the buildings of the future actively help to cool the planet.

Wood in construction is not a silver bullet. But it is an overlooked workhorse. Let’s put it to work. n

Download

Gary Newman CEO of Woodknowledge Wales and MAKAR board member

Email: gary.newman@woodknowledgewales.co.uk

Using Wood in Construction as a Significant Greenhouse Gas Removal Mechanism:

References

1. Newman, G. et al. (2025). Using Wood in Construction as a Significant Greenhouse Gas Removal Mechanism. Woodknowledge Wales.

2. The Royal Society (2018). Greenhouse Gas Removal.

3. Climate Change Committee (2020). Sixth Carbon Budget: The UK’s path to Net Zero.

4. Element Energy & Centre for Ecology and Hydrology (2021). Greenhouse gas removal methods and their potential UK deployment.

5. Ricardo Energy & Environment (2024). UK Greenhouse Gas Inventory: 1990–2022. Prepared for DESNZ.

6. Matthews, R. et al. (2023). “Temporary carbon storage in wood products and the climate change mitigation challenge.” Nature Communications.

7. Spear, M. (2024). How long is long enough? Carbon storage and wood products. Bangor University.

8. HM Government (2022). UK NDC ICTU Report.

9. UNECE/FAO (2021). The carbon sink potential of harvested wood products. Policy Brief.

UK Construction Week (UKCW) is the UK’s largest built environment event— bringing the supply chain together to showcase innovation, share knowledge, and accelerate the transition to low-carbon construction.

UKCW is the UK’s leading showcase of structural timber, offsite solutions, and engineered innovations such as CLT and glulam.

Alongside, the Roofing, Cladding, Insulation Expo demonstrated cuttingedge systems that define the building envelope—delivering energy efficiency, safety, and design flexibility. The London event also features the Offsite Show, giving visitors insight into how modern methods of construction and prefabricated timber systems are reshaping project delivery.

“From timber to roofing, insulation and cladding— UKCW is where the future of construction comes together.”