Wake Up with Cotton & Coffee! Season six of The Cotton Board’s Cotton & Coffee Zoom series is here! In just the time it takes to enjoy your morning coffee, get the latest updates from the Cotton Research and Promotion Program. Join us for a quick 30-minute session, followed by Q&A, to see how assessment dollars are working to boost cotton’s demand and profitability. Visit cottonboard.org/cotton-coffee for upcoming dates and to sign up!

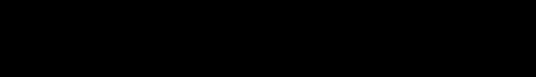

Sam Spruell, who has been characterized by many in the cotton industry as “larger than life,” passed away in 2021, but his legacy lives on through present-day partners at Spruell Farms. They include his wife, Lynn Spruell; son Jonathan Spruell (left); daughter Elizabeth “Liz” Spruell (right); and granddaughter Madilyn Rhodes. This storied family’s agricultural beginnings date back to 1947 in Mount Hope, Alabama.

In tight times, can starter or pop-up fertilizer be cut out of the budget? Here are some considerations to mull over while making your decision.

Where nematode-resistant varieties are not planted, growers are encouraged to use a nematicide to protect the seed and root zone and increase yield.

No one wants to mess up anything related to planting and stand establishment. Ensure your planters are dialed in for peak performance in the eld.

the official publication of the ginning industry

CCGGA’s 2025 Annual Meeting registration opens, NCGA 2025 o cers named and the warehouseman’s responsibilities for re control and prevention listed.

Each year, the Texas Chapter of the American Society of Farm Managers and Rural Appraisers publishes a Rural Land Value Trends report. It also provides information on the value of hunting leases. “This is one of the best documents available for those interested in the sales value and lease value of rural lands in Texas,” said Ti any Lashmet, Extension specialist in ag law. Go to www.cottonfarming.com for this Web Exclusive report.

ON THE COVER: Brother and sister team, Jonathan and Liz Spruell, strive for success at Spruell Farms in Mount Hope, Alabama. Cover photo by Drew Harris.

Carroll Smith

Many sources attribute the origin of the phrase “in my mind’s eye” to Chaucer who used it in The Man of Law’s Tale in the 14th century. Shakespeare picked up the phrase in “Hamlet,” and today it’s a common idiom.

Having grown up in Concordia Parish in east-central Louisiana, I have a lot of memories involving cotton in my mind’s eye. When I sift through the files stored away in my head, the first one that pops up is getting lost in a cotton field as a young child while my parents were visiting some friends one afternoon. My mom rescued me although I wasn’t frightened. I was just having fun exploring the maze of brilliant white bolls.

Another clear image is of the grounds at my elementary school where my friends and I sat cross-legged in a grassy ditch near an adjacent cotton field during recess. From that vantage point, we watched a crop duster make slow turns in the sky, followed by quick, low passes across the top of the crop.

I can look back on myself standing in a field of tall, rank cotton on a hot and humid summer day before plant growth regulators were used. I remember the earthy smell of dark, gumbo clay following a pop-up shower that rolled through in the middle of the afternoon.

Another scene depicts driving through the thick canopy of pecan trees that lined each side of the lake road on the way to one of Dad’s fields where he was picking cotton. I can still smell the strong, chemical odor of defoliant in the air.

I can see the bright, lime green cone-shaped boll weevil traps placed around the perimeter of a cotton field to catch the pest that almost wiped out our industry.

In my mind’s eye, I have a view of folks standing at the counter at the John Deere store waiting on picker parts and can hear the sound of clacking keys coming from the Smith Corona manual typewriter in the secretary’s office.

While driving past a huge field of skip-row cotton on the brink of harvest near Yazoo City, Mississippi, I can see streaks of color coming from the sunset there on the horizon. I can call up a clear picture of traveling to a large cotton operation in North Louisiana to interview a farmer and being spooked out by the image of a huge bat painted on the water tower in Transylvania.

All these sights and sounds and smells are clear as a bell in my mind’s eye, and, for the love of cotton, I hope it will always be this way.

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

Publisher/Vice President Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief Carroll Smith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

ONE GROWER PUBLISHING, LLC

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2025 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

Gary Adams

e National Cotton Council’s leaders champion the cotton industry’s interests in Washington, D.C., advocating for crucial economic and legislative support.

What was the purpose of the recent visit to Washington, D.C. by leaders of the NCC?

■ NCC Chairman Patrick Johnson and I traveled to Washington, D.C. for a series of important meetings with the Administration and members of Congress. Our visit was part of a broader effort to address the pressing issues facing the cotton industry and to ensure that the voices of cotton producers are heard at the highest levels of government.

What were the main topics discussed during your visit?

■ Patrick and I met with Secretary of Agriculture Brooke Rollins, officials from the Department of Treasury, and senior staff from both the House and Senate Agriculture Committees. Our discussions were comprehensive and covered several critical topics. One of our primary concerns was the dire economic conditions currently affecting the cotton industry. We highlighted the increased competition from Brazilian cotton and synthetic fibers, which has put significant pressure on U.S. cotton producers. Additionally, we discussed the impact of textile imports under the de minimis exemption, which allows certain goods to enter the U.S. duty-free, further challenging domestic producers.

Another major topic was the necessity of a new Farm Bill that would be effective for the 2025 crop. We emphasized the importance of an enhanced safety net within this legislation to protect cotton producers from market volatility and other economic

challenges. We also explored opportunities to spur cotton demand through innovative measures such as tax credits for brands and retailers who can fully document the use of U.S. cotton in their textiles and apparel. This initiative aims to incentivize the use of domestically produced cotton and boost demand.

Our discussions included the federal government’s role in addressing the health impacts of microplastics and microfibers from synthetic garments. This issue is becoming increasingly important as awareness grows about the environmental and health risks associated with synthetic fibers.

What other advocacy e orts did the NCC undertake?

■ In addition to our meetings, Patrick wrote a letter to President Trump urging the continuation of dutyfree trade on USMCA qualified textile and apparel products. Preserving duty-free trade is crucial for the economic viability of the U.S. cotton and textile industry.

The NCC also joined over 300 organizations in a letter to USTR Jamieson Greer, urging his office to refrain from imposing Section 301 remedies against the Chinese shipping industry. The letter argued that USTR’s proposed fees on Chinese shipping operators could increase container shipping costs by at least 25 percent and potentially lead ocean carriers to divert cargo to Canada or Mexico. It also pointed out that the U.S. does not have the capacity to achieve the goal of revitalizing U.S. shipbuilding within the seven-year timeframe envisioned by the USTR, urging avoidance of actions that would significantly impact stakeholders relying on efficient maritime services.

Finally, the NCC advocated for a permanent extension of Section 199a deductions. This tax provision allows owners of pass-through businesses to deduct up to 20 percent of business income from their ordinary income. Making it permanent will provide much-needed certainty for producers planning future investments.

BY DR. GUY COLLINS EXTENSION COTTON SPECIALIST NORTH CAROLINA STATE UNIVERSITY

Farmers have been asking if starter or pop-up fertilizer is essential for cotton, or if it can be cut out of the budget. This is a relatively common question, especially when times are tight. During flush times, we see starters commonly used in cotton, and we usually don’t argue with it as long as two conditions are met:

1. We don’t argue with it, if it is not applied in-furrow, but is rather applied in a true 2×2 manner, and in acceptable volumes (10-15 gal/A) so that starter does not migrate or splash into the furrow. Starters applied in-furrow are always a risk.

There are many cases where there is no impact on seed or seedlings. Loosely speaking, in the large majority of situations, a grower can get away with it and observe no adverse effects from starter applied in-furrow. However, in some cases, the impact is substantial, and stands are drastically reduced as seedlings can be killed when environmental conditions align to cause ammoniafication or salt injury.

In lean times, “Is starter one of those line items I can cut out?”

There is no recourse when this happens, and it is usually aggravating to replant. Replanting costs can be substantial; therefore, growers are encouraged to ask themselves if it is really worth the risk of applying starters in-furrow given that the benefits are seldom to none. There are several formulations that claim to be low ammonia or low salt, which brings us to our next point.

2. We don’t argue with it as long as the starter formulation is an affordable way of applying a small fraction of nutrients. In other words, we don’t argue with it as long as the cost per pound of actual nutrient applied is comparable to other common fertilizer sources. Growers are encouraged to closely consider the cost per actual pound of nutrient in starter sources.

In lean times, such as what we are experiencing now, the questions often turn to “Is starter essential for cotton? Do I need to apply starter? or, Is starter one of those line items I can cut out?” The primary advantages to applying starter include:

■ If phosphorous is needed as indicated by soil test results. In many cases, starters can be an affordable way to meet P needs. But also, most of our soils have adequate P levels. Therefore, this decision should be based on soil test results.

■ Starter fertilizer can be an affordable way to apply a small fraction of nutrients to the crop when there is essentially little to no residual nitrogen in the soil. In these cases, theoretically, starters can potentially buy you a little time if you are late when side-dressing or top dressing, but not much. As mentioned earlier, the cost per actual pound of nutrient needs to be comparable to other common fertilizer sources.

■ If cotton is following soybean or peanut, or if we haven’t had substantial rainfall since the last crop season, chances are that there is some residual N remaining in the soil, at least

enough to get cotton up and growing. It is important to remember that cotton utilizes very little N between planting and first square; therefore, the response to fertilizers during this period is low to none. Nitrogen uptake drastically increases once squaring begins, therefore you would want some fertilizer in soil solution once squaring begins. If starter is not used, we need to be applying top-dress or side-dress fertilizer in a timely manner when squaring begins.

■ Starter fertilizer can occasionally result in a small boost in seedling vigor. In theory, this could help us in some regards. However, we are unaware of any replicated data anywhere (in NC or any other cotton state) that suggests there is a yield response to starter fertilizers.

In most cases, temperatures are either ideal, or too cool during planting, and no difference is observed in seedling vigor when starter is used or not. In rare cases, we do see a small boost in vigor associated with starters, but it does not seem to translate into any benefit beyond that, such as higher yields.

Given that the benefits of using starters in cotton are seldom, or small at best, this could easily be something that could be cut from the budget.

Growers are encouraged to consider all the points made in this article when making this decision. If starter is to be cut from the budget, be timely with side-dress or top-dress fertilizer as soon as squaring begins (6-7 leaf cotton) or maybe slightly earlier than normal.

Dr. Keith Edmisten, Extension cotton specialist North Carolina State University, contributed to this article.

Bu alo Island Crop Services Lake City, Arkansas

Both sides of my family always farmed cotton. It’s all I have ever known. Last year, the cotton crop got o to a good start although we did have a lot of thrips pressure. Because of the resistance we are seeing with organophosphate insecticides, research has shown that the best control you are going to get with those products is 40%.

When you get 40% control of a bunch of thrips, that is not enough, so we go directly to Intrepid Edge® insecticide. It’s as close to a home run with an insecticide as I have seen in a long time. I don’t know what we are going to run into this year, but with the economics the way they are, we can’t let an insect hold us back or cost us yield. We will be pretty aggressive on our threshold for thrips.

Our No. 1 insect pest is tarnished plant bug. We base our treatment thresholds on the number of plant bugs per sweep and do a percent small square set to monitor retention in each field. We want to keep the square set at 80% or above throughout the squaring period. Once the crop moves into flowering, we switch to a drop cloth or shake sheet and continue to do square sets until a square no longer has enough time to turn into a profitable boll.

For us, Transform® WG insecticide has been one of the most e ective products we’ve seen on tarnished plant bugs. With each application you make, it provides some level of residual activity. During the flowering period, we make two applications of Transform back-to-back. This strategy has been the backbone of our plant bug program for several years, and it still works extremely well. Transform WG insecticide always gives us the best and longest-lasting control of anything we use. It’s been the centerpiece of what we do to control plant bugs. After the second application, we switch chemistries for good insect resistance management.

I believe yield potential is established in the first 40 days of the cotton crop’s life. Here in the northern tier of where cotton is grown in the Mid-South, earliness means profit for us. We want to get a healthy crop out of the ground and moving quickly before it’s time to shut it down. Then we want to defoliate and harvest the cotton before the November and December rains set in.

One of my most successful farmers once told me that to be successful in this business, you survive the bad years and take advantage of the good ones. We’ve been in a tough spot before, and we are still here. The good Lord willing, we will continue to be here.

• B.S. degree in plant science, Arkansas State University.

• Master’s degree in general agriculture, University of Arkansas, Fayetteville.

• Started Bu alo Island Crop Services in 1996 after working for the Arkansas Cooperative Extension Service for three years.

• Consults on cotton, corn, soybeans and peanuts.

• Member, Arkansas Agricultural Consultants Association and the Arkansas Crop Protection Association.

• Member, First Baptist Church in Lake City.

• Married to Angie for almost 30 years. Daughter, Lauren, 26, and son, Grant, 22.

• Enjoys duck and turkey hunting, spending time with family and friends at Norfork Lake.

1. We go directly to Intrepid Edge® insecticide for thrips control. It’s as close to a home run with an insecticide as I have seen in a long time.

2. For us, Transform® WG insecticide has been one of the most e ective products we’ve seen on tarnished plant bugs. Transform WG insecticide always gives us the best and longest-lasting control of anything we use.

3. Earliness means profit for us. We want to get a healthy crop out of the ground and moving quickly before it’s time to shut it down. Then we want to defoliate and harvest the cotton before the November and December rains set in.

crop out of the ground and moving quickly before it’s time to shut it down. Then we want to defoliate and harvest the cotton before the November and December rains set in.

BY CARROLL SMITH EDITOR

When a young, north Alabama girl wakes up to see ice forming in the glass on the bedside table, she knows they are living in hard times. Despite those early childhood circumstances, fourth-generation cotton farmer Elizabeth “Liz” Spruell recognizes there’s something special about the crop that drives them to make it work from day to day.

The storied family’s agricultural beginnings date back to 1947 when Liz’s great grandfather started Spruell Farms in Mount Hope, Alabama. His son eventually joined the operation, but when times got tough in the late ’70s and early ’80s, her grandfather went on the road as a truck driver for a while and owned one of the local gas stations in Mount Hope.

“He wasn’t involved in the day-to-day farm operation but was always around to help out,” Liz said. “When my father, Sam Spruell, took over the farm in the early ’80s, it was in a deficit. We were very poor, but Dad worked the farm out of bankruptcy and restored it to the vision his grandfather would have had.

“I grew up going to work with my dad and riding in the fields. As I got older, I drove a tractor hooked to a grain cart or operated a bush hog or some other type of implement. I always knew I would come back to the farm, but I wouldn’t start out there.”

Sure enough, after her senior year, Liz went away to school in Birmingham, got involved in treasury management and built an executive career in banking for the next 22 years. Then, as she had envisioned before leaving Lawrence County, the Alabama native had the opportunity to return to Spruell Farms, work alongside her father and run the operation in two of the five counties where Spruell Farms is located.

and sister team,

Sam Spruell, who has been characterized by many in the cotton industry as “larger than life,” is described by his daughter, Liz, as “very funny, very loyal and extremely intelligent. He always fought for the underdog and was active in a policy setting. He did it all from making decisions at the farm to advocating for the betterment of the entire industry. Dad always saw the big picture even if it didn’t necessarily benefit his own operation.”

Sam passed away in 2021, but his legacy lives on through the present-day partners: His wife, Lynn Spruell; son Jonathan Spruell; daughter Elizabeth “Liz” Spruell; and granddaughter Madilyn Rhodes. Spruell Farms typically plants a crop mix of cotton, corn, soybeans and wheat. With double cropping, that would amount to about 9,000 acres. This year, however, they decided not to double crop but to plant 4,000 acres of cotton and 2,500 acres of corn.

“For us, the price wasn’t there for soy and wheat, so I didn’t want to plant a loss,” Liz said. “My banking career made me very risk-averse, but it also helped me develop the mindset of providing a career for our employees. We provide things like health care, uniforms, insurance, a 401k and investment opportunities. We make this investment because we depend on our employees heavily and want them to enjoy working here.”

Jonathan, Sam’s son, describes his day-to-day role on the farm as making the decisions and implementing the production practices on the “dirt side.” Once these pieces are in place, Chase Wilson, the farm manager, organizes the labor to keep the operation running smoothly, and their crop consultant, Clay Cook, scouts the fields and keeps Jonathan informed about what he sees out there.

After his father passed and Liz had come back home, Jonathan went out and worked in the corporate world for a

Jonathan Spruell, who also is a partner at Spruell Farms, is the one who gets it done on the “dirt side.”

couple years to expand his perspective.

“He came back with a set of eyes similar to what I had for those 20-something years,” Liz said. “It has made us a much stronger pair. We communicate well, but he is the one getting it done out in the field.”

Liz said from a management standpoint, one of the best decisions she ever made was hiring Will Gotcher as the farm’s chief financial officer.

“Will is a huge asset to this operation,” Liz said. “He was my dad’s John Deere precision ag specialist for our fleet and had a very special relationship with my father. He was like another son

to him. After working for John Deere for a while, Will worked for Alabama Farm Credit as a lender. After three years, I was able to hire him from the bank. Will has a passion for this business just like my brother, myself and my daughter.”

Although Gotcher typically works from the office, he is available to bring his technical expertise to the field to troubleshoot any precision ag issues that may arise with the equipment.

“We do a good bit of variable-rate seeding and fertilizer applications, so Will and my brother work together to load the prescriptions into the machines,” Liz said.

At Spruell Farms, variety selection is very important because their cotton is sourced by retail brands, such as Vanity Fair, Vann’s tennis shoes, North Face and Victoria’s Secret. Although Peter Bunce, the cotton marketing specialist at Indigo Ag, works with The Fashion Pact to connect Spruell Farms with the first three brands, Liz said Victoria’s Secret has a completely separate, independent relationship with Spruell Farms.

To produce a crop for a quality market, Liz said they need a “Pima-like, Upland cotton.” For example, they have a very defined contractual relationship with Victoria’s Secret. In the contract, the company states how many bales they will commit to purchase with specific quality guidelines that Spruell Farms must meet.

The lingerie, clothing and beauty company said it initiated its Cotton Journey a few years ago to source cotton “from U.S. family-owned farms” to provide transparency in its product line. This is how the Victoria’s Secret website explained the strategy to its customers: “The direct-source partnership allows us to ensure our cotton is grown responsibly — from the fields of Alabama to your top drawer.”

Today, the Victoria’s Secret growers include Martin Farm in Courtland, Alabama; Spruell Farms in Mount Hope, Alabama; Blythe Cotton Co. in northwest Alabama and Bridgeforth Farms, which also is in Alabama.

“This year, we are growing PhytoGen varieties because we believe they can deliver the quality we are looking for,” Liz said. To help determine which varieties they will choose to grow

in an upcoming season, Jonathan said he is a strong believer in trial data.

“I look at the trial data from all the seed companies for the different crops we grow, and we do our own test plots and trials, too,” he said. “I take that information coupled with trial data from other locations and heavily weight my decisions based on those numbers.”

From an agronomic standpoint, Jonathan said he is comfortable with the decisions he has to make when “known” factors are involved. It’s the uncontrollables — labor, weather, markets — that are tough on everyone.

“I have worked on the farm all of my life,” Jonathan said. “My father was a big influence on my way of thinking. He always challenged us to look further than what is right before us and to think outside the box.”

This career farmer is also a pilot who is looking beyond the turnrow to develop an airpark where residents own and store their private aircraft in hangars that are often adjacent to their homes.

“Somehow, I always seem to turn my hobbies into a job, so that is what I am doing,” he said. “Building an airpark seems like a good way to share with others who want to live the same type of lifestyle.”

Today, Sam Spruell’s legacy remains strong. His boots sit in a place of honor in the farm office, perhaps as inspiration for “walking in high cotton” or maybe as a symbol of what Liz calls her tagline — “What got us here won’t get us there.”

One thing is for certain. On all fronts, Spruell Farms appears to be on the right track for continued success in achieving their ever-evolving goals.

BY CARROLL SMITH EDITOR

In cotton, nematodes have been called the invisible enemy, the threat beneath the soil and other ominous names. They tend to attack the plant’s roots — which increases susceptibility to disease — hinder water and nutrient uptake and ultimately result in economic loss from decreased yield.

Dr. Bob Kemerait, University of Georgia Extension plant pathologist, noted, “Where a nematode-resistant variety is not planted into a field infested with plant-parasitic nematodes, growers are advised to consider using a nematicide to protect the crop.”

Last year, Averland FC nematicide stepped out on the cotton production stage via a soft launch before being officially released in 2025. This true, broad-spectrum liquid nematicide, manufactured by Vive Crop Protection, might be described as “having the whole package” in terms of ease of handling, low-use rate, broad-spectrum activity, safety and economical cost per acre.

Averland is designed to go out in-furrow at planting at 3.5 fluid ounces per acre, and no special system is required to apply it. At this rate, the cost is about $10 per acre compared to other products that fall in the $30 to $35-per-acre range.

George Huckabay, Vive’s Southern technical sales agronomist, said Averland has good activity against all nematodes and

While nematodes are trying to invade the roots of the cotton plant, thrips — another troublesome early season cotton pest — is feeding on the leaves and terminal tissues, especially during cool, wet periods.

To help take them out of the picture, Averland FC nematicide can be applied with Viloprid 4, a new imidacloprid insecticide used for thrips control. According to Huckabay, before Viloprid came on the market, the biggest issue with imidacloprid was storability.

“When imidacloprid sits in the jug, it clabbers and forms a chalky base on the bottom to where it won’t pour well,” he said. “Viloprid can be stored longer, and it pours better. Sometimes a jug will sit for two or three years. We want to make sure that when the farmer is ready to use it, Viloprid will have the same pourability as when it was brand new.”

is not species-specific. It’s also compatible with pretty much all liquid fertilizers, he said.

Protecting the seed and root zone of the cotton plant can result in a yield increase at the end of the season.

“We do a lot of university testing and agricultural contract research trials,” Huckabay said. “We’ve got five years’ worth of trial data not only showing nematode control but also showing a yield increase.

“We then plug in the product cost per acre to see to see what the return on investment is. We’ve found that Averland FC is a viable ROI product to help the grower make more money per acre.”

BY WES PORTER UNIVERSITY OF GEORGIA

Cotton planting season has arrived, so be sure that your equipment is ready to go. This season is going to be tough on cotton with input prices on the continued rise and cotton prices very low. We cannot afford to mess up with anything during the season and especially not with planting and stand establishment.

Some planters have already been used to plant corn, so it’s important to note that significant changes in planter settings are required to ensure accurate metering and seed placement for cotton when moving from another crop.

Planter malfunctions in the field or mistakes at planting are common and can become costly, especially with the high seed prices. Therefore, it is important to ensure that the planters are dialed in for peak performance in the field.

I encourage Extension agents and growers to use the following checklist and thoroughly go over different planter components to check if any parts need replacement or adjustment to get it field ready. Once out in the field, it’s important that the operator gets out of the tractor during the first few passes and carefully checks seed depth and spacing across all rows behind the planter.

This is also the best time to check if the planter is set up and functioning properly for the given field conditions such as soil moisture, residue, etc.

Here are a few other key points to consider related to planter set up and performing in-field checks when planting cotton:

The recommended seed depth for planting cotton is 0.5 to 1.0 inches and if the same planter has been used for planting corn, it is most likely set closer to 1.5 to 2 inches deep. Verify seed depth before planting both on a hard surface and in the field. Mechanical seed depth settings (T-bar handle adjustments) can vary among the row-units on the same planter so take the time to check planted seed depth for each row-unit and make necessary adjustments accordingly.

This is very important, especially when planting cotton at shallower depths (≤0.5 inch) as even a small deviation from target depth setting on some row-units can result in seeds being placed on top of the ground instead of in the soil and with proper seed-to-soil contact.

Proper planter downforce is important to achieve target seeding depth so make sure the downforce system (whether using mechanical, pneumatic or an active hydraulic system) is set to apply adequate downforce on each row-unit. For planting cotton, the required downforce could range anywhere from none (just the weight of the row-unit itself) up to 200 lbf depending on the soil type, moisture and field conditions at planting.

Lighter, sandy soils and conventional tillage systems will require considerably less downforce than heavy loamy soils and conservation systems (strip-till or no-till). Higher moisture content will require lower downforce to prevent compaction. Remember, it is common to have variable conditions within the same field, so make sure to adjust settings accordingly as field conditions change within the same field or when moving from one field to another.

The recommended seeding rate for cotton is at least two seeds per row-foot to attain a plant population of 1.5 to 1.75 plants per row-foot (again, here the seed plate and plant population for corn are drastically different so adjust the population accordingly for cotton). As dumb as this sounds, check the seed plate and ensure you have switched the plate and any other internal components to cotton.

For growers planting less than two seeds per row-foot, it is critical to avoid any seed-metering and placement issues as it may result in inadequate stand establishment with a potential

for yield loss. For growers who are not using a seed monitor during planting, it is highly recommended to check all seed meters on a test stand with their nearest dealership as most equipment dealers have these available today and offer seed meter testing as a service.

Seed meter testing is important as any unnecessary skips or multiples during planting will result in poor or uneven stand establishment that can further impact yield if the stand is reduced significantly. Cotton seed being smaller that corn and peanut seed is also very sensitive to vacuum pressure, so make sure to adjust the vacuum appropriately to avoid skips and multiples.

First, check seed tubes to ensure they are free of debris and the seed has a clear path.

Proper setup and functioning of row-cleaners (when planting in conservation systems), double-disc openers, gauge-wheels and closing wheels for prevalent field conditions is critical for attaining adequate seed placement and proper seed-to-soil contact.

Make sure that the double-disc openers are creating a true V-shape furrow, gauge-wheels are running tightly (but not rubbing excessively) against the opening-discs, and closing wheels are aligned perfectly behind the planter and set to apply adequate pressure to properly close the furrow.

Check for any signs of improper furrow formation when doing field checks behind the planter and make necessary adjustments. It is important to have both good seed placement and seed-to-soil contact for timely and uniform emergence.

Several planting technologies are available today on modern planters to improve seeding performance.

Ensure to perform a thorough and timely inspection (at least

a week or more) before planting to check status and functioning of all technology components including GPS, seed monitor, wiring harnesses, seed tube sensors, rate control module, electric seed meters and active downforce system (if available) as well as for any subscription or latest firmware updates for the GPS and the in-cab display.

Back up your planting data from the previous year before you begin planting and make sure the seeding prescriptions are ready to go if using any variable-rate seeding in your operation. Issues with planting technology in the middle of the planting season can cost significant time and money so make sure to address any issues before heading out to the field.

As mentioned previously, variable field and environmental conditions are unavoidable during planting. It is critical that growers evaluate their planting conditions day to day, field to field, and especially if there are significant weather events (such as temperature changes or rainfall) during the planting window. These are common and will require adjustments to planter settings based on the existing in-field conditions, with special consideration to variability in soil texture, moisture and crop residue.

Most growers usually plant two to three varieties on their farm so any change in cotton varieties, specifically in seed size, would also require adjustments to seed meter settings and vacuum to ensure good seed singulation with minimal skips or doubles.

Remember, you only get one chance to place the seed and close that furrow properly so consistent and regular checks are important to ensure that the planter is operating at peak performance in each field and throughout the whole planting window.

Dr. Wes Porter is the irrigation/precision ag specialist at the University of Georgia. He also is a member of the UGA Cotton Team.

The past five to 10 years have brought many innovations in technology that we see in our daily lives and the devices we use. Even on the farm, equipment, GPS and applications are changing constantly. Five years ago, we all knew there were satellites taking images to use for things like mapping systems.

What you might not realize is that today there are more and more satellites going overhead — maybe even multiple times per day — gathering a database of images of farms and fields. These images can have so many uses if we just know how to use them.

Cotton Incorporated Agricultural and Environmental Research Director Dr. Ed Barnes, said these satellite images have increased not only in the frequency captured, but also in the resolution of images. This allows us to use them clearly and effectively in different field applications.

“The scale and quality of the satellite images in the last three to five years has really changed the game of being able to use remote imaging for farm data and research analysis,” Barnes said. “We are also able to access these images mostly free, or at a very low cost, which is a great advantage to growers to see how they could readily incorporate remote imaging into their management practices.”

Cotton Incorporated has partnered with researchers in Arizona to utilize remote imaging databases to analyze heat stress and canopy temperature. The information assists in developing irrigation schedules, capturing drought tolerance in specific varieties and predicting boll retention and development characteristics.

Dr. Randy Norton, director and Extension agronomist at the University of Arizona, has been working on the effects of canopy temperature and boll retention for a couple of decades. He said this research has provided a great understanding of what elevated canopy temperatures are doing to boll retention and viability of pollen, mainly from growth chamber work

BY CHRISTI SHORT O’BRIEN, TEXAS

and reading sensors in the field. Now they can take this knowledge and apply it to a large field by using satellite images.

Dr. Varaprasad Bandaru, a research plant physiologist with the USDA-ARS, is also working on these projects alongside Norton and other Arizona scientists. Bandaru’s expertise in modeling systems and analyzing satellite images has brought together the knowledge of heat stress and reading of satellite images, allowing this information to be understood and applied at the farm level.

“Essentially, we can acquire satellite images, analyze them and estimate the canopy temperatures for these fields on specific days. That information can be used by growers in a variety of ways— determining irrigation schedules, monitoring the balance between vegetative and reproductive growth conditions during these heat stress periods, developing heat stress maps, and more,” Bandaru said.

Irrigation scheduling is a perfect example of how this imagery has benefited the crop. According to Norton, a weather shift has happened in Arizona over the past several years resulting in less of a monsoon season pattern to more days with lower humidity and more extreme high daytime temperatures, creating more heat stress.

Even though Norton is continuing to see level two heat stress in cotton crops across the state, analyzing canopy temperature trends will allow growers to

maximize an irrigation schedule to use the water most effectively during those heat events and still harvest a good crop.

Farmers can also record heat events and correlate fruit loss or stress during flowering to make management decisions utilizing the remote imaging galleries.

“Through years of research, we have a good grasp on what heat stress does to boll retention and pollen dehiscence through our smaller scale research plots,” Norton said. “But now, using these satellite images, we can apply what is happening in a large field to help manage the crop in heat stress.”

Not only is this information useful to growers for managing crops mid-season, but seed companies are also using Norton and Bandaru’s expertise and research during their variety trails. Companies participating in variety trials in Arizona are using this information to develop more heat and drought tolerance in their lines.

While not all states experience the high temperatures of Arizona, all states do experience some type of heat stress and elevated crop canopy temperatures in their specific area for a variety of reasons.

“It’s very exciting for us at Cotton Incorporated when we can invest in research that not only benefits growers in that state but will also have a great impact beltwide,” Barnes said.

For more information on Cotton Incorporated funded projects in remote imaging, you can contact Barnes at ebarnes@cottoninc.com.

Funded by America’s cotton producers and importers through check-off dollars collected by The Cotton Board, the Cotton Research and Promotion Program’s research and promotion activities are conducted by its contractor Cotton Incorporated, with the purpose to increase the demand for and improve the market position of cotton.

Christi Short is The Cotton Board’s regional communications manager for the Southwest. Email her at cshort@cottonboard.org.

The U.S. Department of Agriculture’s Commodity Credit Corporation has announced the 2025 crop loan rate differentials for upland and extra-long staple cotton.

The differentials, also referred to as loan rate premiums and discounts, were calculated based on market valuations of various cotton quality factors for the prior three years. The Commodity Credit Corporation adjusts cotton loan rates by these differentials so that cotton loan values reflect the differences in market prices for color, staple length, leaf, extraneous matter, micronaire, length uniformity and strength. This calculation procedure is identical to that used in past years.

The 2025 crop differential schedules are applied to 2025 crop loan rates of 52 cents per pound for the base grade of upland cotton and 95 cents per pound for extra-long staple cotton. The 2018 Farm Bill stipulates that the loan rate for the base quality of upland cotton ranges between 45 and 52 cents per pound based on the simple average of the adjusted world price for the two marketing years immediately preceding the next crop planting.

However, the established loan rate cannot be less than 98% of the preceding year’s established loan rate. Along with USDA’s Agricultural Marketing Service classing (quality) measurements, these differentials are used to determine the loan rate for each individual cotton bale.

Visit https://www.fsa.usda.gov/resources/price-support/commodity-loan-rates to see the loan rates.

Cotton farmers and their families gathered in Lubbock, Texas, April 3 to celebrate FiberMax cotton yield achievements as part of BASF’s FiberMax One Ton Club, a long-standing tradition now in its 20th year. The club recognizes cotton farmers who produce FiberMax yields of one ton or more in a given year. Fifty-six members made this year’s club following the 2024 growing season and were recognized at the annual banquet.

All three new FiberMax cotton varieties that were introduced for the 2024 growing season (FM 765AX, FM 868AXTP and FM

823AXTP1) were used by farmers who achieved this year’s One Ton Club status.

The banquet culminates with a sweepstakes drawing for a two-year lease on a Ford Super Duty F-350 Lariat truck. This year’s winners were Cooper and Rene Ellison of Petersburg, Texas.

“The FiberMax One Ton Club is an important and meaningful tradition at BASF, and we are proud to have honored cotton farmers’ achievements now for 20 years,” said Mark Kelling, area manager at BASF Agricultural Solutions.

Many cotton farmers have qualified for the One Ton Club over its 20-year history, and a growing number have become multi-year winners. Of the 56 growers who made the club this year, 42 were repeat winners. One Ton Club standouts who received special awards for their 2024 performance include:

■ Highest yield: Scott and Jodi Meeks of Dalhart, Texas, harvested an average of 3,012 pounds per acre with FM 1621GL.

■ Highest gross value: Scott and Jodi Meeks of Dalhart, Texas, achieved the highest gross value of $1,551.78 with FM 1621GL.

■ Most acres: H Bar H Farms of Dalhart, Texas, planted 3,239 acres to FM 1621GL and FM 765AX.

■ Most varieties: H Bar H Farms of Dalhart, Texas, planted 3,239 acres to FM 1621GL and FM 765AX. Kornelious and Susana Enns of Enns Farm in Ackerly, Texas, planted 134 acres to FM 823AX and FM 868AX.

■ Highest loan value: Cooper and Rene Ellison of Petersburg, Texas, achieved the highest loan value of $0.5769 with FM 1830GLT.

To qualify for the FiberMax One Ton Club, growers must produce a minimum of 2,000 pounds of ginned cotton per acre on a minimum of 20 acres planted with 100% FiberMax cotton from Jan. 1 to Dec. 31, 2024.

The FiberMax One Ton Club is open to farmers in Alabama, Arizona, Arkansas, California, Georgia, Kansas, Louisiana, Mississippi, Missouri, New Mexico, North Carolina, Oklahoma, South Carolina, Tennessee, Texas and Virginia. Growers must provide an accurate and complete qualification form and gin recap sheets to verify 2,000 pounds per acre yields. Go to rb.gy/3fqyxk to see full details for qualification.

To view the complete list of 2024 winners, visit FiberMax.com/OTC.

Cotton Consultant of the Year established 1981

The Cotton Consultant of the Year Award is sponsored by Syngenta and Cotton Farming magazine. This prestigious award honors a consultant for dedication, innovation and hard work. Their footprints in the field and eyes on the crop help cotton farmers succeed and maintain a healthy bottom line.

Go to cottonfarming.com/ ccoy to access the 2025 nomination form and a list of past recipients. Nominees are voted on by the former CCOY winners.

The 2025 CCOY will be honored Feb. 27, 2026, at the Peabody Hotel in Memphis and featured in a four-page salute in the February 2026 issue of Cotton Farming.

Nominate a consultant today who has enriched your cotton farming operation!

Cotton Consultant of the Year sponsored by

As I write this in late March, the North Carolina Department of Agriculture is in full swing with the cotton seed quality testing program as seed is moving into North Carolina more and more rapidly. By the time this article is read, planting should be largely underway in the state. With acreage being down, this will hopefully allow for more strategic planting into ideal conditions. Hopefully temperatures during May will bring ideal conditions and replanting won’t be a big issue.

It is important to evaluate stands in a timely manner (seven to 10 days a er planting) so that action can be promptly taken, if needed, before the late May crop insurance deadlines or at least in time to replant and reasonably achieve ideal stands without substantially delaying maturity. We don’t normally expect cotton to emerge to completion before seven days unless nearly perfect conditions prevail and cotton is planted shallow (less than a half inch) as it should be. By 14 days a er planting into good moisture, a full stand should be present, so if it isn’t, replanting may be needed. e most common exception to this may be planting into very dry soils and waiting on a rain. Regardless, shallow planting is nearly always advantageous over deep planting, even when dusting cotton in.

Some of our research a few years ago suggested that replanting may be justi ed when 30% or more of the planted area is occupied by 3-foot skips. Fields that are noticeably worse than this threshold obviously need replanting if cotton was planted shallow and into good moisture and 14 days or more have elapsed. Fields that are very near this threshold o en appear to be debatable so they should be evaluated thoroughly. erefore, growers should focus their time and e orts on these “debatable” elds while avoiding wasting time making decisions on elds that clearly have either very good or very poor stands. guy_collins@ncsu.edu

ere is still not much excitement surrounding cotton, so I imagine there will not be too much excitement surrounding the input costs and management of early season pests. However, if you have read my Specialists Speaking comments for the past few months, you have read what I have been telling growers: “If you decide to plant cotton in 2025, you have to make it!” Management of early season pests is crucial to making a crop in 2025.

At-plant decisions have to be made for thrips and nematodes. Utilizing resistant varieties or other at-plant treatments (seed treatment, in-furrow liquid or granular) are the main ways to handle these two pests, and the decision needs to be based on risk of yield loss and species in your eld (with respect to nematodes). If you are planting in a heavy thrips window or in a nematode eld, these are two things that cannot be neglected.

Most people are concerned about the situation surrounding weed management in 2025, with a major tool not available for growers to utilize. e emphasis in a weed management program should be heavy on residuals — two e ective mechanisms of action at planting, overlapping residuals over the top and a layby application. We are very fortunate in Georgia in that we still have tools that work when implemented in a timely manner.

Timeliness is key. e worst pest management application a grower can make is the one they have to make twice — and in a year like 2025, we do not need to be making unnecessary trips over the eld. Get out

there, make the right decision on your place and implement that pest management decision in a timely manner.

As always, if you have any questions or need anything, please don’t hesitate to reach out to your local University of Georgia county Extension agent. We’re here to help! camphand@uga.edu

For many early season pests, management decisions are made when seed is ordered. Varieties (herbicide technologies, ryvOn for thrips or nematode resistance) and seed treatments (thrips, seedling diseases) play a big role in mitigating many issues.

Planting date can also play a role in early season pests. Cool, wet conditions can exacerbate thrips injury and increase the incidence of seedling diseases. In some situations, dry periods can make other insects, like three-cornered alfalfa hoppers, worse as dying hosts on ditch banks and eld borders aren’t suitable for the insects. Unfortunately, we can’t sit around and wait until things are “perfect” to plant (and we can’t get everything in on the three “perfect” days we get a year either).

e best way to address early season pests is to have a plan. at plan should include eld history, such as grasshoppers or nematodes. Prepare to make decisions based on the risk you are willing to take (grasshoppers) or certainties (nematodes).

e next thing the plan should involve is a consultant or trained scout. ere is no substitute for having someone walk elds weekly to provide reports and recommendations for insects, weeds and diseases. Finally, the plan should involve reaction. If the recommendation calls for treatment, react as soon as possible. is year, we shouldn’t think about crop protection as a “cost” but as an “investment” in the crop. When following economic thresholds, crop protection materials consistently provide a return on investment greater than or equal to the cost of controls.

Let’s get the crop o to a good start and react as needed throughout the year! Reach out to your local Extension agent or specialist if you ever need any help! scottg@auburn.edu

It appears to be an early spring this year. As I write this on April 2, birds are chirping, trees are green, burndown is out, and cotton planting is right around the corner. Early season pests are always concerning, and a few tips can help avoid delays in maturity.

Most importantly, burndown and PRE applications will set the stage for weed pressure in acres that normally would be in a dicamba system. Starting clean will make it easier to stay clean without in-season dicamba applications.

For thrips, acephate will likely be used to some degree, but it’s worth noting that it is under evaluation with EPA and some thrips populations show resistance in Mississippi. ryvOn and Intrepid Edge are still effective management tools against thrips damage during the early season. Hopefully the weather will hold up and we can get this growing season underway during the rst couple weeks of May! bkp4@msstate.edu

As I write this on the morning of March 27, the sun is shining and I’ve already shed my jacket. I hope, by the time you read this in early May, we have seen a window favorable for cotton planting. For acres that have been planted, we are likely moving quickly toward a period of time critical for thrips control.

Keep in mind that our entomologists ARE NOT recommending thrips sprays on ryvOn cotton. For acres that are not ryvOn, the best approach is to protect the plant from the emergence of the rst true leaf until the emergence of the fourth true leaf. Physiologically, above-ground growth through this time period is very slow, but root growth is quite rapid. Because of this, we occasionally are tempted to make “revenge sprays” — a er addressing the thrips population with an initial foliar spray, the slow growth rate allows injury to remain visible for quite a while and tricks us into thinking we need to re-spray. Make sure thrips are again present at a treatable level before triggering a re-spray. Favorable growing conditions occasionally allow us to move through this window with a single spray. I’m hoping we nd that to be the case for 2025. traper@utk.edu

As you read this in May, a good portion of our acres are likely being planted. Addressing early season pests is crucial for cotton producers in Southeast Missouri, as a minimal delay in maturity can impact cotton lint yields in this short-season environment.

e goal is to start with a clean eld. Planting into elds with moderate-to-heavy weed pressure can harbor insect pests and reduce cotton plant stand.

e No. 1 insect pest during early development is thrips. rips control options include in-furrow insecticide at planting and foliar insecticide applications at the two-to-three-leaf growth stage. Limited options are available for thrips control, and reduced e cacy rates with acephate have been documented in 2023 and 2024. New-traited cottonseed technology has provided good control of thrips in Missouri. brwilson@missouri.edu

e most notable early season pest we observe in Oklahoma cotton production is thrips. Although thrips may not necessarily be considered a major pest in cotton, poor growing conditions a er emergence can lead to damage impacting a producer’s bottom dollar. Poor growing conditions include a period of cool, cloudy days that slow the growth of the plant. Weekly scouting is encouraged to ensure seed treatments (if utilized) are still e ective. Forages like wheat and alfalfa are prime hosts for thrips that migrate into cotton elds looking for a fresh source of nutrients. It is important to be extra vigilant if you have wheat elds adjacent to your cotton.

When scouting, check the underside of the cotyledons and true leaves, as well as the terminal bud of the plant for the insect. rips like to “hang out” and feed in the terminal so carefully opening those leaves and observing inside is key. However, keeping track of thrips numbers through visual inspection of the plants can be challenging, especially in the delicate terminal tissue and with our Oklahoma winds. One method you could try is pulling up plants from di erent parts of the eld (how many plants depends on your eld size) and beating them into a plastic cup. Keeping track of the number of plants you sampled, count the number of thrips you observe inside the cup and calculate how many thrips per plant you observed. e threshold is based on cotton stage and increases with the number of true leaves the plant has. e general rule of thumb

Check the underside of the cotyledons and true leaves, as well as the terminal bud of the plant for thrips.

is the number of true leaves is equal to thrips per plant threshold. For example, if the plant has two true leaves, the threshold is two thrips per plant. If the average plant in your eld has two true leaves and you calculated three thrips per plant, it is likely time to spray. Once the plants reach the ve to six true leaf stage, scouting and spraying for thrips is rarely justi ed economically.

rips color can di er by species but are usually yellow, light brown or a similar color to wheat straw. ey are very small and cylindrical in shape. ey also have rasping-sucking mouthparts and feed on the outer layer of tissue on the plant; this causes plant cells to burst then they suck up the released uids for nutrients. is feeding causes dark brown spots that eventually turn a silver color on the underside of the leaf. Damaged leaves are cupped, crinkled and can have a leathery texture. If they damage the terminal bud by feeding, new growth and overall plant development can be delayed.

Other pests we are identifying in more cotton acres across the state are nematodes, both root-knot and reniform. Chemical control is an option, with aldicarb making its way back as trade name AgLogic and products like Velum. However, resistant cotton varieties on the market are very promising, especially when dealing with a reniform nematode infestation. If you suspect you have nematodes, please reach out to myself or Dr. Maira Du eck, Oklahoma State Extension plant pathologist, for assistance in sampling and identi cation.

As we are pulling out and dusting o our planters, I want to wish our cotton producers a smooth and safe 2025 planting season. As always, I will continue to pray for rain and a prosperous year. jdudak@okstate.edu

When visiting with growers about the many options of traits available in current commercial cotton varieties, I encourage them to select and utilize trait packages that will best alleviate pressure from common pests in their area. One example is early season thrips pressure, which can vary from year to year and from location to location. If thrips are typically troublesome for producers early in the season, selecting varieties with the ryvOn trait can greatly assist in the management of these pests. My colleagues and I have evaluated many varieties with this trait over the past few years and the results speak for themselves in a year with heavy, early season thrips pressure.

Nematodes are another common pest in some Texas production regions. While nematodes are more of a season-long pest, the commercialization of cotton varieties with nematode resistance traits over the past few years has put another tool in our toolbox when it comes to nematode management. Trials conducted over the past few years evaluating these varieties in multiple locations with o en heavy nematode pressure have demonstrated the value these traits can bring to your operation if nematodes are one of your top yield-reducing pests. bmcknight@tamu.edu

As I write this in early April, recent rainfall in South Texas has brought some relief to very dry soil moisture conditions in the area. Despite some areas in the southern cotton production regions of Texas receiving several inches of precipitation, the drought monitor map still has these areas in drought conditions as more rainfall will be needed to replenish depleted soil moisture as the 2025 growing season progresses.

As with most things related to West Texas cotton production, early season pest pressure greatly depends on rainfall and moisture. While we’re still celebrating the moisture we received across the region from the early November 2024 rains, which is safely stored deep in the pro le, our top 6-inch to 12-inch soil layers are extremely dry. is scenario dramatically a ects how our growers are attacking weed control and preparing for any insect pests.

Yellows are still an important part of the weed control strategy in West Texas, and normally those applications will have already been made, either broadcast and incorporated or through pivot or drip systems. Some growers have made the chemigation application, but many growers are reluctant to apply yellows when it is this dry at the surface, especially with no significant rain in sight. Adequate incorporation can be a challenge under these dry conditions. at said, yellows should still be on the list of necessary tools to use to battle weeds, as they are about 75% to 85% e ective on pig-

weed when properly incorporated, which is the same level of control this herbicide group has always been…when properly incorporated.

Burndown applications typically use chemistries that need activation with water, which is a tremendous challenge this year in West Texas. Light water pivots sometimes only partially activate herbicides, and of course, we are le to Mother Nature to activate drip and dryland elds. Additionally, due to our dry conditions, many weeds have yet to emerge. We will receive rain at some point, and growers need to be poised to handle the weed ush that will, no doubt, follow the next signi cant rain event.

Of great concern is that this di cult pre-season drought will make in-season weed control even more crucial. Residuals are the key, but we still heavily rely on over-the-top chemistries like glufosinate, glyphosate and auxins. It has now become clear that in-season labeled dicamba will not be an option, and that has presented some growers with di cult choices to make. Some have opted to adapt to the 2,4-D tolerant Enlist system from Corteva/PhytoGen to enable in-season, over-the-top auxin applications. Many others are planning to use only glyphosate and glufosinate and their only over-the-top non-residuals and not deviate their variety choices. Proper timing, rates and carrier volumes will help make that system work better.

Because of the ongoing drought and heat in West Texas, we have been nearly an insect desert for the past few years. at’s not to say that we don’t have insect pests that exceed threshold, but rather, it is easy to get complacent about insects because they tend to be sporadic. e top insect pests for the Texas High Plains are thrips, cotton eahopper and plant bugs. And even those pests can be inconsistent as to having levels above economic thresholds, which makes scouting even more critical. Occasionally, we will see aphids, grasshoppers and stink bugs make an appearance that warrants control, but those tend to be very spotty in distribution. One of the newest pests for West Texas is wireworms, which is generally associated with planting into a cover crop.

While most West Texas growers would like to have cover crops on most, if not all, their acres, many have di culty balancing the use of water to sustain those cover crops versus the cotton crop. Where we do have cover crops, wireworm pressure awaits quite o en. Insecticide seed treatments and some in-furrow insecticide applications have shown good ecacy for wireworms, but treatments once the crop is planted have proven

not e ective. Be prepared for those elds in which you will be planting into a cover crop.

See https://lubbock.tamu.edu/ for more information on all the early season pests we face in West Texas. ken.lege@ag.tamu.edu

Winter precipitation across Arizona during the 2024/2025 season was historically low. If it had not been for some late winter/early spring weather events, snowpack across the northern parts of Arizona would have been extremely low. is will obviously impact water availability for the coming growing season. Producers will need to make some tough decisions on acreage planted based upon water availability.

e other consequence of little to no winter precipitation in the lower deserts is the absence of vegetation (weeds) in uncultivated areas this winter and early spring. O entimes, these weedy areas will harbor insect pests. As the temperatures rise and the winter vegetation begins to dry down, these insects may migrate into nearby cotton elds. Management of early season insect pests is critical to help ensure vigorous early season growth and early fruit set.

A recent technology that has proven e ective against early season insect pressure is the ryvOn trait contained in several commercially available cotton varieties. e ryvOn trait is available from a few different seed companies in locally adapted varieties. e primary and most extensive o erings are from Bayer as Deltapine varieties. ere is still considerable work being done to determine the overall economic benet of utilizing this relatively new technology in our Arizona production systems.

Our University of Arizona Extension specialists continue to develop locally adapted recommendations for use of this technology. Yield and ber quality is still the driving in uence in variety selection, but each year we are seeing additional ryvOn varieties that perform well in our environment. For more information on this topic and others go to our website at https://extension.arizona.edu/topics/ eld-crops. rnorton@cals.arizona.edu

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

Originally established in 1937 with its charter of incorporation in Mississippi, the National Cotton Ginners Association is the umbrella organization for eight state and regional ginner associations. NCGA also represents approximately 500 individual cotton ginning operations in 17 cotton producing states. During its annual meeting, the association elected its 2025 o icers.

Serving as president is Larry Black, Roscoe, Texas. First vice president is Brad Williams, Burlison, Tennessee, and second vice president is Tom Pires, Riverdale, California.

Ben Evans, Douglas, Georgia, will serve as third vice president, and Richard Lindsey, Centre, Alabama, will become chairman of the board.

Harrison Ashley, Cordova, Tennessee, is NCGA’s executive vice president.

It’s time for the California Cotton Ginners and Growers Association’s 2025 Annual Meeting. This year, Supima will join forces with CCGGA to showcase valuable industry updates. The meeting will be held on Wednesday, May 21, at the International Agri-Center in Tulare, California. Please visit rb.gy/elrs7d to access the registration form, then complete and submit it. You can email the form to Michelle Franco at michelle@ccgga. org or fax it to the CCGGA o ices at 559-252-0551.

There is also an opportunity to sponsor the event. All sponsorships go toward o setting the costs, which helps us deliver our message to the industry. If you’d like to sponsor, please call the CCGGA o ices at 559-252-0551.

The cost of the event is free, but we encourage you to consider making a donation of at least $25 to the CCGGA Federal PAC or CCGGA State PAC to help protect California cotton at the state and federal levels. The CCGGA Federal PAC can only accept personal checks. Any corporate contributions must be made to the CCGGA State PAC.

Cotton Farming magazine, co-sponsor of the Texas Cotton Ginners’ Association Gin Show, recently contributed $3,571 to the TCGA/Texas Tech Scholarship Fund.

Each year, the magazine donates a portion of revenue from ad sales in the TCGA printed show program.

“TCGA is proud of our partnership with Cotton Farming magazine on the TCGA Scholarship program,” said TCGA Executive

Vice President J. Kelley Green. “This program is an investment in the future of Texas Tech students and the cotton industry. We believe these scholarships are crucial to our e orts in developing the next generation of agricultural leadership in agriculture.”

On the upcoming schedule, TCGA’s Summer Membership Meeting will be held at Hilton Palacio Del Rio, 200 South Alamo, San Antonio, Texas, June 22-24.

Warehousemen work in facilities that store and handle cotton bales. They are responsible for the storage, handling and movement of cotton, ensuring its proper condition and security. Their duties include inspecting equipment, maintaining safety and managing the flow of cotton bales within the warehouse.

According to the Agriculture Guaranty Warehousemen Best Practices, “Warehousemen, you play a crucial role in fire control and prevention. Your vigilance and actions are integral to maintaining a safe warehouse environment.” The warehouseman’s responsibilities for fire control and prevention include:

• Fire Hazard Awareness: Warehousemen are responsible for remaining vigilant and actively identifying potential fire hazards within the warehouse premises. This includes promptly identifying conditions or materials that may increase the fire risk.

Larry Black, gin manager of Central Rolling Plains Co-op in Roscoe, Texas, was recognized recently as the Texas Ginner of the Year at the awards dinner during the TCGA Gin Show. He was joined by friends and family to celebrate this honor. Front left to right: August Ickert, Samuel Ickert, Kameron Betts, Brayson Betts, Brenda Stirl, (behind Brayson) Cynthia Black, Carolyn Boyd, Renee Moore, Armida Saenz and Kelly Shelton. Back left to right: Alyssa Betts, Kade Betts, Mathew Ickert, Madison Ickert, Larry Black, Richard Osborne, Ralph Stirl, Steve Moore, Marcial Saenz, Cason Hull and Todd Shelton.

• Firefighting Equipment Inspection: Regularly inspect and assess the firefighting equipment to ensure it is in proper working condition. This regular inspection ensures that we are always prepared to combat any fire emergencies, providing a sense of security for all personnel.

• Maintenance Of Warehouse Facilities: Monitor and report any deterioration or damage to the warehouse facilities or drainage system that may pose a risk to fire safety. Prompt repairs should be conducted to maintain a safe environment.

• Enhanced Security Precautions: Ensure all security precautions are in place to safeguard the facility. This involves securing the warehouse, closing and securing all walk-through and loadout doors and implementing adequate security measures to prevent unauthorized access.

• Compliance With Fire Protocols: Ensure all fire protocols and other risk mitigation measures are up to date and practiced by all personnel. This includes regular training sessions and drills to familiarize everyone with emergency procedures.

David Guthrie

My love of cotton began first as a subject of study for its fascinating mysteries. In the 40+ years I have studied this botanical immigrant, I have met many students of the plant from different backgrounds and disciplines who are equally fascinated with the unique quirks that make the plant endlessly challenging and, ultimately, rewarding.

My journey began not on a farm but in the suburban backyard watching my father argue with uncooperative plants that followed their own internal compass rather than my dad’s planned vectors. Among the many gifts he gave me was a curiosity about the natural world.

My own path led me to study botany and ecology at university when I wasn’t pursuing other subjects commonly sought by youthful explorers. Upon graduation, I learned the difference between joyful, albeit unpaid, immersion in the inner workings of plants and economic botany that paid money.

The total cotton acreage in the state had fallen to about 50,000 acres due primarily to the destruction caused by the cotton boll weevil and growers’ response to the pest. But the remaining growers witnessed the success of the Boll Weevil Eradication Program in the state and knew they could produce cotton profitably with the support of the university and Extension service.

I remember my first meeting with some of the leading growers, including Marshall Grant, David Burns and Billy Carter, at a state support meeting where funds are distributed to various cotton projects conducted by university researchers.

Their advice and cooperative spirit provided a sort of ground truthing mentorship to complement my academic preparation. They welcomed me with financial support for agronomic programs that addressed their production needs to help drive the revival of the crop after the long period of decline and stagnation.

“Most cotton growers in the state operated their farms from the tractor seat rather than the o ce chair.”

Enter course correction, California State University, Chico. Without any background in agriculture, it made sense that some practical instruction in crops was appropriate. The professors at Chico laid a groundwork that I appreciate to this day.

Equally valuable was my employment at the university farm as a student worker and later as an equipment operator. That was enjoyable work that might have become my professional destiny had not the farm manager recognized my calling lay elsewhere.

Enter cotton and Dr. Tom Cothren at the University of Arkansas. My interest was in stress physiology and the adaptations that plants make to cope with it. He offered me his first Ph.D. assistantship in his cotton physiology program at the Altheimer Lab. I owe the late Dr. Cothren a great debt for his patient mentorship. Even after he accepted a position at Texas A&M, he along with the late Dr. Stutte, pushed me intellectually to raise my game.

Upon concluding my Ph.D., I accepted a position at North Carolina State University. Today, North Carolina cotton production has regained its rightful position as the producer of quality fiber under a primarily rainfed production system. It wasn’t like that back in 1983 when I arrived in the state as the Extension cotton specialist.

I came to realize over time that most cotton growers in the state operated their farms from the tractor seat rather than the office chair. They didn’t just produce cotton, which averaged less than 500 acres per farm, but also corn, soy and the money crops peanuts and/or tobacco. They had to multitask and, admittedly, cotton was frequently not their mainstay.

They were also challenged to produce their crops without widely available irrigation due in large part to small field sizes. One vivid reminder of cotton’s place in the production pecking order was revealed in my answer to a researcher’s question at the Beltwide Conferences on how we determined when to irrigate the cotton: “When they finished irrigating the tobacco,” I replied.

The indeterminant flowering habit of cotton and its relative tolerance to drought became a point of leverage to encourage farmers to supplement or replace corn acreage. With time, acreage in North Carolina increased to almost 500,000 acres by the time I left the state in 1992. I cannot adequately express my appreciation to the cotton farmers of North Carolina for their encouragement and support during my tenure as their cotton specialist.

It brings a smile to my face to recall an interaction I had with the late Billy Carter. In looking at my failed research cotton stand, he remarked, “It’s a good thing you’re in research because you would make a p--- poor farmer.” Billy was right!

— David Guthrie, Ph.D. Redwood

Valley, California dsguthrie@pacific.net

Cotton Farming’s back page is devoted to telling unusual “farm tales” or timely stories from across the Cotton Belt. Now it’s your turn. If you’ve got an interesting story to tell, send a short summary to csmith@onegrower.com. We look forward to hearing from you.