Your comfort, our roof.

Roofing systems

We are an Italian company that has been designing and manufacturing roofing systems since 1953. Technology, experience and know-how are what make us stand out. Expertise and enthusiasm have always guided our team in meeting our customers’ needs.

Mission Vision

We work every day to ensure the comfort of those living inside the buildings, offering roofing solutions that provide long-lasting insulation and protection over time, maximizing the value of your investment.

Our values

Integrity

We manage our business in an ethical and professional way. We foster long-term partnerships and collaborations.

We want to apply our systems to as many buildings around the world as possible because we believe that solid and durable roofing improves the quality of life and has a positive impact on the environment.

Commitment

Our references and reviews speak about the quality of our services. We work hard to keep our standards high.

Sharing

Through teamwork, we enhance the value of individual skills. “We” is more important to us than “I”.

Sustainability

We are committed to fair and appropriate conduct, taking into account the economic, social and environmental impact of our work.

Our roofing solutions, which we have been designing and manufacturing since 1953, in Italy and all over the world, ensure comfort and savings over time.

2

ONDULIT

Over 65 years of experience in the roofing sector in Italy and abroad

Over 40 destination countries

Over 100 million square meters installed all over the world

Over 20 product certifications

Multilayer technology

Multilayer technology protects the roofing from atmospheric agents, such as changing thermal cycles and corrosive substances that would otherwise lead to rapid degradation. Furthermore, our roofs provide optimal thermal and acoustic insulation, saving you money and time in the long run.

Multilayer technology combines different materials in a single five-layered metal sheet that is light and resistant.

Steel

Due to its high mechanical strength, it is structurally sound and can be applied to any supporting structure.

Aluminium

It protects itself from corrosion. On the upper surface, it reflects the sun’s rays and emits solar radiation. On the inner surface, it transmits only a minute fraction of the heat absorbed.

Our plastic compound

It soundproofs the metal from even the heaviest rain and hail. It also has high thermal inertia.

The synergy between these materials ensures excellent performance and durability.

4

ONDULIT

5 1700 100 0 0

COMPOUND STEEL DETAILS ON TECHNICAL SHEET PRIMER ALUMINIUM ALUMINIUM TECHNOLOGY

PLASTIC

Durability

Ondulit products are long-lasting even in corrosive atmospheres. Our solutions are suitable for use in marine, industrial and urban environments (> RC5 EN10169). This has been demonstrated by several corrosion resistance tests.

Acoustic comfort

Multilayer technology makes it possible to absorb the impact of precipitation, thus avoiding the rumble effect, typical of other metal roofs.

Thanks to this technology, our sheets and panels are silent.

Ondulit produces the only CE marked roofing sheet that guarantees:

Salt spray corrosion resistance: 4000 hours (ISO 9227)

Resistance to humidity: 3000 hours (EN ISO 6270-1)

Resistance to sulphur dioxide: 45 cycles (EN ISO 6988)

Resistance to accelerated ageing: 2000 hours (ASTM G155)

Soundproofing power: 28 dB (UNI EN ISO 10140-2:2010)

The power to lessen sound generated by the pouring rain:

ISTEDIL Certificate 1302-3: Up to 8.41 times greater than a 0.7 mm thick aluminium sheet and up to 4.17 times greater than a sandwich panel with 40 mm insulation 52.3 dB (UNI EN ISO 140-18)

6

ONDULIT

TEST OF RESISTANCE TO CORROSION IN SALINE FOG (ISO 9227) MINIMUM TIME BEFORE THE ONSET OF WHITE RUST

Salt spray fog test

COMPARATIVE TEST OF SOUND ATTENUATION BETWEEN DIFFERENT ROOF MATERIALS

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 SHEETS PANELS Coverpiù Panel Aluminum+ Felt Aluminum Fiber Cement Noise index

the

Coverib = 1 Steel inside external Sandwich Panel Ondulit Coverib PERFORMANCE

assuming

value

STATE OF THE SAMPLES AFTER 4000 HOURS INITIAL STATUS OF SAMPLES CORROSION CORROSION LEVEL OF DEGRADATION NO CORROSION Polyester HD 25 PUR/PA 50/55 Multilayer Protection Ondulit

4000 3000 2000 1000 0 RC2 RC3 RC4 RC4 RC5 RC5 RC4 > RCM-I Hours

CORROSION CATEGORY EN 10169 SAMPLE Standard polyester HD 25 polyester Plasticized Multilayer Protection Ondulit Plastisol 100/200 PVDF 25 PVDF 35 PUR-PA 50/55 4000 h 1000 h 700 h 500 h 360 h 360 h 500 h 500 h

Thermal comfort

Multilayer technology gives the roof superior thermal performance. The Ondulit multilayer system considerably reduces the inconvenience of the roof overheating thanks to:

• The high solar reflectance and thermal emittance of the external natural aluminium layer (over 90% of the thermal load);

• The thermal inertia of the extraordinarily thick protective layer;

• The low emissivity of the natural aluminium lower layer,that emits only 5% of the residual thermal load.

Thanks to the special composition of the paint used, our roofs have excellent Cool Roof performance, ensured even for the darker aluminium surface coating finishes. Due to its ability to dissipate solar radiation, the multilayer sheet ensures thermal performance equivalent to that of an insulated panel with a thickness of 4 cm. In hot environments with strong sunlight, especially for buildings with natural ventilation, it is often unnecessary to use any other insulating materials.

Solar Reflectance Index (SRI): (ASTM E1980-11)

LIGHT COLOURS > 65%

Natural Aluminium (N) 107%

Off White RAL 9002 (W) 73,0%

Silver (L) 75,7%

DARK COLOURS > 30%

Aluminium Slate Grey colour RAL 7012 (D) 34,3%;

Aluminium Grey colour RAL 7023 (GR) 42,6%;

Aluminium Blue colour (B) 37,3 %;

Aluminium Medium Green colour (VM) 35,6%;

Aluminium Red (R) 35,2%,

Aluminium Oxide Red RAL 3009 (S) 33,4%;

Aluminium Terracotta (T) 37,6%

Electrolytic Copper (C) 54,9%.

Summer Thermal Transmittance: 1,07 W/m2K (ISO 6946)

The colour range of Ondulit sheets has a solar reflectance R > 30%

Energy Performance of Building Directive (EPBD) 2010/31/ EU, EN ISO 52017-1:2017, Energy performance of buildingsSensible and latent heat loads and internal temperatures, U.S. Environmental Protection Agency,ENERGY STAR Program Requirements for Roof Products.

U.S. Green Building Council, LEED v4 for Building Design and Construction (2017).

8

ONDULIT

THERMAL BEHAVIOR

R GR D B N W T S VM C L PERFORMANCE SOLAR RADIATION FRACTION SOLAR ENERGY REFLECTED FRACTION RADIATED SOLAR ENERGY HEAT ABSORBED TRANSMITTED

STEEL

MADE

WHITE

SHEET

OF PRE-PAINTED STEEL

N - Natural Aluminium L - Silver C - Electrolytic Copper D - Slate Gray RAL 7012 B - Blue GR - Gray RAL 7023 R - Red S - Oxide Red - RAL 3009 T - Terracotta - Ral 8004 VM - Medium Green W - Off White RAL 9002

WHITE SHEET WITH MULTILAYER PROTECTION WHITE SANDWICH PANEL 40 mm PUR

COMPARISON

Mechanical resistance and thermal expansion

The mechanical strength and thermal expansion of a roof are properties that must be carefully evaluated during its design. Thanks to the special manufacturing process used, multilayer technology maintains compatibility between the differential thermal expansion of the various materials, both with each other and with respect to the loadbearing structures of the building on which the roof is installed.

Sustainability

Multilayer technology is at the forefront of energy-saving and combats the phenomenon of heat islands.

Our products have a long service life, with a positive eco-balance and a low life cycle cost. At the end of their life, they can be subjected to a selective treatment, allowing the recovery of recyclable raw materials.

The entire Ondulit production has been ISO 14001 certified for over 10 years.

Multilayer insulated sheets ensure the mechanical strength and thermal expansion of S250 structural steel (EN 10346).

The Ondulit Coverib sheet consists of low environmental impact components in terms of natural resources and:

• It is certified Remade in Italy®, for:

- the recycled material content

- disassembly at the end of its life cycle

• It is certified with the Solar Reflectance Index (ASTM E1980-11) > 30% for dark colours and > 65% for light colours

• It is certified for the absence of dangerous substances such as cadmium, lead, hexavalent chromium and mercury (Cert. AQC 18/494 B 20/12/2018).

COM(2008) 397 Sustainable production and consumption action plan

EN 15804:2019 Sustainability of buildings - Environment products declaration

ISO 14040:2006 Environmental management - Life cycle assessment

10

ONDULIT

COOL ROOF PERFORMANCE 250 0,017 95-180 330 0,024 0,011 Rm=N/mm 2 min. mm/m°C Breaking unit load Thermal expansion coefficient Copper Copper Aluminuim 3103 Aluminuim 3103 Steel Fe E 250 Steel Fe E 250 MECHANICAL RESISTANCE AND THERMAL EXPANSION VALUES

ONDULIT

14 28 32 Our range Multilayer Sheets - Panels Integrated Solutions Translucent elements and accessories

PRODUCT DESCRIPTION

Ondulit multilayer metal sheet with corrugated profile, CE marked according to UNI EN 14782 Appendix A; compliant with UNI EN 508-1 Appendix B, Remade in Italy certified for the content of recycled raw material, disassembly and absence of hazardous substances, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.60 mm (ie 0.50 or 0.80 mm) protected on the upper surface by an anticorrosive and soundproofing thermoplastic coating (about 1.5 mm thick) and by a natural aluminium foil (or pre-painted aluminium, or electrolytic copper), and on the lower surface by a primer and a natural aluminium foil (or prepainted aluminium). The external layers wrap the side edges of the sheets along the entire length to guarantee their full protection. To ensure the stability of the characteristics’ performances over time, the protection with an anticorrosive and soundproofing function has a thickness of about 1.5 mm and it is positioned on the extrados of the sheet.

The cover element ensures the following performance requirements: Concentrated loads resistance ON5

(EN 14782 Appendice B)

Reaction to fire: Class B-s1, d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

Performance in the event of external fire: Class B Roof T3 (UNI EN 13501-5; UNI CEN/TS 1187)

Durability - Salt spray resistance: 4000 hours (UNI EN 14782 - ISO 9227)

Durability - Humidity resistance: 3000 hours (UNI EN 14782 - EN ISO 6270-1)

Durability - SO2 resistance: 45 cycles (UNI EN 14782 - EN ISO 6988)

Sustainability: Remade in Italy certification for content of recycled raw material, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

Sound insulation: 28 dB (UNI EN ISO 10140-2:2010)

Sound deadening of noise generated by

ISTEDIL cert. N°1302/202-G 1302/202-C

8.41 times higher than a mm 0.7 mm thick aluminium sheet, 4.17 times higher than a sandwich panel with 40 mm insulation - 52.3 dB UNI EN ISO 140-18

Summer thermal transmittance: 1.07 W/m2K (ISO 6946) with natural aluminium lower surfacing

14 ON-EN - VER 220722 Ondulit

1.2 kN

1.35 m

ON6 1.2 kN span 1.80 m

1.2 kN

span

-

- ON8

span 2.00 m

heavy

rain:

LENGTH (Lp) custom tailored,

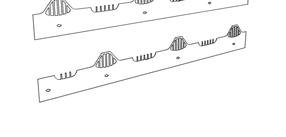

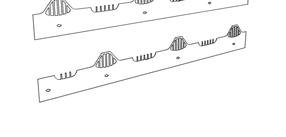

0.70 m NOMINAL LENGTH (Ln) 900 mm COVER WIDTH (Lu) 785 mm PROFILE (H) 20.5 mm PITCH (P) 87 mm AVERAGE TOTAL THICKNESS 2.4 mm STEEL THICKNESS 0.50 - 0.60 - 0.80 mm MASS 7.600 kg/ m2 steel thickness 0.50 8.200 kg/ m2 steel thickness 0.60 9.400 kg/ m2 steel thickness 0.80 TOLERANCES on length

20

P= 87 H = 20,5 P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 Ln = 900 Lu = 785 Ln = 850 Lu = 773 Ln = 1000 Lu = 900 Ln = 900 Lu = 785 Multilayer protected sheet with corrugated profile SRI % (ASTM E1980-11) 37,3 % 34,3% 42,6% 35,6% 73% 107% 35,2% 33,4% 37,6% 75,7%AVAILABLE FINISHING Upper surface L Blue Slate Grey Grey Medium Green Off White Natural Aluminium Red Oxide Red Terracotta Silver Copper Electrolytic RAL / PANTONE 540C 7012 7023 378C 9002 - 8016 3009 8004 9006Lower surface Natural Aluminium PERFORMANCE AND QUALITY GUARANTEED BROOF

TECHNICAL CHARACTERISTICS PRODUCT

minimum

+

- 5 mm; cover width (Lu) +/- 5 mm., average total thickness and mass +/- 10%

Ondulit

Multilayer protected sheet with corrugated profile

MECHANICAL STRENGTH TO DISTRIBUTED LOADS

Allowable spans L in function of distributed loads P and of the static scheme.

J = Moment of inertia

W + min. = Flexural strength module for positive moments

W - min. = Flexural strength module for negative moments

δ max ≤ 1/200 L (total load) δ2 max ≤ 1/250 L (incidental load only) f y ≥ 2.500 daN/cm2 (yield strength)) Mc,Rd = Mel,Rd = Wel fyb / γM0 Geometric and static properties of the profiles have been calculated according to EN 1993-1-3, EN 1993-1-5, Italian Min. Decree of 14.01.2008

AVAILABLE PROCESSES CURVED

15 PRODUCT

MECHANICAL

STATIC SCHEME: ONE SPAN STATIC SCHEME: TWO SPAN STATIC SCHEME: THREE SPAN STEEL THICKNESS J cm4/m W + min. W - min cm3/m 0.50 mm 2.66 2.53 0.60 mm 3.23 3.07 0.80 mm 4.39 4.12 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.29 1.24 1.20 1.13 1.07 1.02 0.98 0.95 0.92 0.89 0.87 0.85 0.83 0.81 0.80 0.78 0.60 mm L = m 1.38 1.32 1.28 1.20 1.14 1.09 1.05 1.01 0.98 0.95 0.93 0.91 0.89 0.87 0.85 0.83 0.80 mm L = m 1.52 1.47 1.41 1.33 1.26 1.21 1.16 1.12 1.09 1.06 1.03 1.00 0.98 0.96 0.94 0.92 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0,50 mm L = m 1,73 1,66 1,61 1,51 1,44 1,37 1,31 1,25 1,19 1,14 1,10 1,06 1,02 0,99 096 0,94 0,60 mm L = m 1,85 1,78 1,71 1,61 1,53 1,47 1,41 1,36 1,31 1,26 1,21 1,16 1,13 1,09 1,06 1,03 0,80 mm L = m 2,04 1,97 1,90 1,79 1,70 1,62 1,56 1,51 1,46 1,42 1,38 1,35 1,30 1,26 1,23 1,19 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.62 1.56 1.50 1.41 1.34 1.28 1.23 1.19 1.15 1.12 1.09 1.07 1.04 1.02 1.00 0.98 0.60 mm L = m 1.73 1.66 1.60 1.51 1.43 1.37 1.32 1.27 1.23 1.20 1.17 1.14 1.11 1.09 1.07 1.05 0.80 mm L = m 1.91 1.84 1.78 1.67 1.59 1.52 1.46 1.41 1.36 1.33 1.29 1.26 1.23 1.20 1.18 1.16 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.42 1.29 1.20 1.13 1.07 1.02 0.98 0.95 0.92 0.89 0.87 0.85 0.83 0.81 0.80 0.78 0.60 mm L = m 1.51 1.38 1.28 1.20 1.14 1.09 1.05 1.01 0.98 0.95 0.93 0.91 0.89 0.87 0.85 0.83 0.80 mm L = m 1.68 1.52 1.41 1.33 1.26 1.21 1.16 1.12 1.09 1.06 1.03 1.00 0.98 0.96 0.94 0.92 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.90 1.73 1.61 1.51 1.44 1.37 1.32 1.27 1.22 1.17 1.12 1.08 1.04 1.01 0.98 0.9 0.60 mm L = m 2.03 1.85 1.71 1.61 1.53 1.47 1.41 1.36 1.32 1.28 1.24 1.19 1.15 1.11 1.08 1.05 0.80 mm L = m 2.25 2.04 1.90 1.79 1.70 1.62 1.56 1.51 1.46 1.42 1.38 1.35 1.32 1.29 1.25 1.22 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.78 1.62 1.50 1.41 1.34 1.28 1.23 1.19 1.15 1.12 1.09 1.07 1.04 1.02 1.00 0.98 0.60 mm L = m 1.90 1.73 1.60 1.51 1.43 1.37 1.32 1.27 1.23 1.20 1.17 1.14 1.11 1.09 1.07 1.05 0.80 mm L = m 2.10 1.91 1.78 1.67 1.59 1.52 1.46 1.41 1.36 1.33 1.29 1.26 1.23 1.20 1.18 1.16 M max + (p+q) l2 M min - = f max (q) 5/384 q l4/EI f max (p+q) 5/384 (p+q) l4/EI M max + 1/14 (p+q) l2 M min - 1/8 (p+q) l2 f max (q) 2.07/384 q l4/EI f max (p+q) 2.07/384 (p+q) l4/EI M max

1/12.5 (p+q) l2

min

1/10 (p+q) l2

max (q) 2.53/384 q l4/EI

max (p+q) 2.53/384 (p+q) l4/EI

RESISTANCE

+

M

-

f

f

L p p L L p L L L

PRODUCT DESCRIPTION

Coverib 850 multilayer metal sheet with corrugated profile, CE marked according to UNI EN 14782 Appendix A; compliant with UNI EN 508-1 Appendix B, Remade in Italy certified for the content of recycled raw material, disassembly and absence of hazardous substances, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.60 mm (ie 0.50 or 0.80 mm) protected on the upper surface by an anticorrosive and soundproofing thermoplastic coating (about 1.5 mm thick) and by a natural aluminium foil (or pre-painted aluminium, or electrolytic copper), and on the lower surface by a primer and a natural aluminium foil (or prepainted aluminium). The external layers wrap the side edges of the sheets along the entire length to guarantee their full protection. To ensure the characteristics stability performances over time, the protection with an anticorrosive and soundproofing function has a thickness of about 1.5 mm and it is positioned on the extrados of the sheet.

The cover element ensures the following performance requirements:

Concentrated loads resistance: Steel thickness 0.5: 1.2 kN span 1.80 m; Steel thickness 0.6: 1.2 kN span 2.30 m; Steel thickness 0.8: 1.2 kN span 2.60 m (EN 14782 Appendix B)

Reaction to fire: Class B-s1, d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

Performances in the event of external fire: Class B Roof T3 (UNI EN 13501-5; UNI CEN/TS 1187)

Durability - Salt spray resistance: 4000 hours (UNI EN 14782 – Appendix A; ISO 9227)

Durability - Humidity resistance: 3000 hours (UNI EN 14782 – Appendix A; EN ISO 6270-1)

Durability - SO2 resistance: 45 cycles (UNI EN 14782 – Appendix A; EN ISO 6988)

Environmental sustainability: Remade in Italy certification for content of recycled raw material, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

Sound deadening - noise generated by

Summer

ISTEDIL cert. N°1302/202-G 1302/202-C

8.41 times higher than a 0.7 mm thick aluminium sheet. 4.17 times higher than a sandwich panel with 40 mm insulation. 52.3 dB UNI EN ISO 140-18

natural aluminium lower surfacing

16 CO-EN - VER 220720

www.ondulit.com

Coverib 850

heavy rain:

W/m

CHARACTERISTICS PRODUCT LENGTH (Lp) custom tailored, min. 0.70 m NOMINAL LENGTH (Ln) 850 mm COVER WIDTH (Lu) 773 mm PROFILE (H) 32 mm PITCH (P) 192 mm AVERAGE TOTAL THICKNESS 2.4 mm STEEL THICKNESS 0.50 - 0.60 - 0.80 mm MASS 8.000 kg/ m2 steel thickness 0.50 8.600 kg/ m2 steel thickness 0.60 10.000 kg/ m2 steel thickness 0.80 TOLERANCES on length + 20 - 5 mm; cover width (Lu) +/- 5 mm - average total thickness and mass +/- 10% P= 87 H = 20,5 P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 Ln = 900 Lu = 785 Ln = 850 Lu = 773 Ln = 1000 Lu = 900 Ln = 900 Lu = 785

SRI % (ASTM E1980-11) 37,3 % 34,3% 42,6% 35,6% 73% 107% 35,2% 33,4% 37,6% 75,7%AVAILABLE FINISHING Upper Surface L Blue Slate Grey Grey Medium Green Off White Natural Aluminium Red Oxide Red Terracotta Silver Copper Electrolytic RAL / PANTONE 540C 7012 7023 378C 9002 - 8016 3009 8004 9006Lower Surface Natural Aluminium PERFORMANCE AND QUALITY GUARANTEED BROOF

thermal transmittance: 1.07

2K (ISO 6946) with

TECHNICAL

Multilayer protected sheet with trapezoidal profile

MECHANICAL STRENGTH TO DISTRIBUTED LOADS

Allowable spans L in function of distributed loads P and of the static scheme.

STEEL THICKNESS J cm4/m W + min. cm3/m W - min cm3/m

J = Moment of inertia

W + min. = Flexural strength module for positive moments

W - min. = Flexural strength module for negative moments

MECHANICAL STRENGTH

STATIC SCHEME: ONE SPAN STATIC SCHEME: TWO SPAN

δ max ≤ 1/200 L (total load) δ2 max ≤ 1/250 L (accidental only) f y ≥ 2.500 daN/cm2 (yield stres) Mc,Rd = Mel,Rd = Wel fyb / γM0

The geometric characteristics of the profiles have been calculated according to the DM of 14.01.2008. EN 1993-1-3 and EN 1993-1-5

SCHEME: THREE SPAN

The suggestion and data reported in this catalogue are based on information we believe to be reliable, being the result of long experience and considerable knowledge as well as of field and lab test. They are offered in good faith, but with no guarantee, as conditions and methods of use of our products are beyond our control. They do not involve any responsibility whatsoever for Ondulit Italiana S.p.A. Ondulit Italiana S.p.A. is fully entitled to modify or improve its products at any time without notice.

17 PRODUCT

STATIC

0.50 mm 8.78 2.93 3.39 0.60 mm 10.61 3.79 4.38 0.80 mm 14.48 6.59 5.92 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.83 1.76 1.70 1.60 1.52 1.45 1.40 1.35 1.31 1.27 1.24 1.21 1.18 1.15 1.11 1.08 0.60 mm L = m 1.99 1.91 1.84 1.73 1.65 1.58 1.52 1.46 1.42 1.38 1.34 1.31 1.28 1.25 1.23 1.20 0.80 mm L = m 2.26 2.217 2.10 1.97 1.87 1.79 1.72 1.66 1.61 1.57 1.52 1.49 1.45 1.42 1.39 1.37 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.07 1.9 1.86 1.71 1.59 1.49 1.41 1.34 1.28 1.23 1.18 1.14 1.10 1.07 1.03 1.01 0.60 mm L = m 2.35 2.22 2.12 1.94 1.81 1.70 1.60 1.52 1.46 1.40 1.34 1.29 1.25 1.21 1.18 1.15 0.80 mm L = m 2.91 2.76 2.63 2.42 2.25 2.11 2.00 1.90 1.81 1.74 1.67 1.61 1.56 1.51 1.47 1.43 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.30 2.19 2.08 1.91 1.78 1.67 1.58 1.50 1.43 1.37 1.32 1.27 1.23 1.19 1.16 1.12 0.60 mm L = m 2.49 2.40 2.31 2.17 2.02 1.90 1.79 1.70 1.63 1.56 1.50 1.45 1.40 1.36 1.32 1.28 0.80 mm L = m 2.83 2.73 2.63 2.48 2.35 2.25 2.16 2.09 2.02 1.94 1.87 1.80 1.75 1.69 1.64 1.60 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.76 1.60 1.49 1.40 1.33 1.27 1.22 1.18 1.14 1.11 1.08 1.06 1.03 1.01 0.99 0.97 0.60 mm L = m 1.91 1.73 1.61 1.52 1.44 1.38 1.32 1.28 1.24 1.20 1.17 1.14 1.12 1.09 1.07 1.05 0.80 mm L = m 2.20 1.99 1.85 1.74 1.65 1.58 1.52 1.47 1.42 1.38 1.35 1.31 1.28 1.26 1.23 1.21 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.37 2.15 2.00 1.88 1.78 1.67 1.57 1.49 1.42 1.35 1.30 1.25 1.21 1.17 1.13 1.02 0.60 mm L = m 2.56 2.33 2.16 2.03 1.93 1.85 1.78 1.69 1.61 1.54 1.48 1.42 1.38 1.33 1.29 1.17 0.80 mm L = m 2.95 2.68 2.48 2.34 2.22 2.12 2.04 1.97 1.91 1.86 1.81 1.75 1.69 1.63 1.58 1.46 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.21 2.01 1.87 1.76 1.67 1.60 1.54 1.48 1.44 1.39 1.36 1.33 1.29 1.27 1.24 1.22 0.60 mm L = m 2.40 2.18 2.02 1.90 1.81 1.73 1.66 1.60 1.55 1.51 1.47 1.43 1.40 1.37 1.34 1.32 0.80 mm L = m 2.75 2.50 2.32 2.19 2.08 1.99 1.91 1.84 1.79 1.74 1.69 1.65 1.61 1.58 1.55 1.52 M max + (p+q) l2 M min - = f max (q) 5/384 q l4/EI f max (p+q) 5/384 (p+q) l4/EI M max + 1/14 (p+q) l2 M min - 1/8 (p+q) l2 f max (q) 2.07/384 q l4/EI f max (p+q) 2.07/384 (p+q) l4/EI M max

1/12.5 (p+q) l2 M min - 1/10 (p+q) l2

max (q) 2.53/384 q l4/EI

max (p+q) 2.53/384 (p+q)

/EI

+

f

f

l4

L p p L L p L L L

AVAILABLE PROCESSES BENT CURVED DOUBLE CURVED

Coverib 1000

TECHNICAL

PRODUCT DESCRIPTION

Coverib 1000 multilayer metal sheet with corrugated profile, CE marked according to UNI EN 14782 Appendix A; compliant with UNI EN 508-1 Appendix B, compliant with UNI EN 508-1 Appendix B, certified by Remade in Italy for the content of recycled raw material, disassembly and absence of hazardous substances, consisting of a structural galvanized steel sheet (EN 10346) of thickness 0.60 mm (or 0.50 mm) protected on the upper face by an anticorrosive and soundproofing thermoplastic coating (about 1.5 mm thick) and by a natural aluminum sheet (or pre-painted aluminum), and on the face lower by a primer and a natural aluminum foil (i.e. prepainted aluminum). The external coatings wrap the side edges of the sheets along their entire length to ensure their protection. To ensure the stability of the performance characteristics over time, the protection with anti-corrosion and soundproofing function, with a thickness of about 1.5 mm, is positioned on the extrados of the sheet.

The cover element ensures the following performance requirements:

Concentrated loads resistance:

Reaction to fire:

Steel thickness 0.5: 1.2 kN span 1.50 m

Steel thickness 0.6: 1.2 kN span 1.70 m (EN 14782 Appendix B)

Class B-s1, d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

Performance in the event of external fire: Class B Roof T3 (UNI EN 13501-5; UNI CEN/TS 1187)

Durability - Salt spray resistance: 4000 hours (UNI EN 14782 – Appendix A; ISO 9227)

Durability - Humidity resistance: 3000 hours (UNI EN 14782 – Appendix A; EN ISO 6270-1)

Durability - SO2 resistance: 45 cycles (UNI EN 14782 – Appendix A; EN ISO 6988)

Environmental sustainability: Remade in Italy certification for content of recycled raw material, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

Sound insulation: 28 dB (UNI EN ISO 10140-2:2010)

Sound deadening of noise generated by heavy rain: ISTEDIL cert. N°1302/202-G 1302/202-C

W/m2K (ISO 6946) with natural aluminium lower surfacing Multilayer protected sheet with trapezoidal profile SRI % (ASTM E1980-11) 42,6% 35,6% 73% 107% 37,6% AVAILABLE FINISHING Upper surface Grey Medium Green Off White Natural Aluminium Terracotta RAL / PANTONE 7023 378C 9002 8004 Lower surface Natural Aluminium PERFORMANCE AND QUALITY GUARANTEED BROOF

8.41 times higher than a mm 0.7 mm thick aluminium sheet - 4.17 times higher than a sandwich panel with 40 mm insulation. 52.3 dB UNI EN ISO 140-18

1.07 H = 37

18 CM-EN - VER 220720

www.ondulit.com

Summer thermal transmittance: PRODUCT LENGTH (Lp) custom tailored min. 0.70 m NOMINAL LENGTH (Ln) 1000 mm COVER WIDTH (Lu) 900 mm PROFILE (H) 38 mm PITCH (P) 300 mm AVERAGE TOTAL THICKNESS 2,4 mm STEEL THICKNESS 0.50 mm - 0.60 mm MASS 7.700 kg/ m2 steel thickness 0.50 8.500 kg/ m2 steel thickness 0.60 TOLERANCES on length + 20 - 5 mm; cover width (Lu) +/- 5 mm - average total thickness and mass +/- 10% P= 300 Ln = 1000 Lu = 900

CHARACTERISTICS

MECHANICAL STRENGTH TO DISTRIBUTED LOADS

Allowable spans L in function of distributed loads P and of the static scheme.

STEEL THICKNESS

J

MECHANICAL RESISTANCE

STATIC SCHEME: ONE SPAN

W + min. = Flexural strength module for positive moments

L p p L L p L L L δ max ≤ 1/200 L (total load) δ2 max ≤ 1/250 L (incidental load only) f y ≥ 2.500 daN/cm2 (yield strength)) Mc,Rd = Mel,Rd = Wel fyb / γM0 Geometric

and static properties of the

The suggestion and data reported in this catalogue are based on information we believe to be reliable, being the result of long experience and considerable knowledge as well as of field and lab test. They are offered in good faith, but with no guarantee, as conditions and methods of use of our products are beyond our control. They do not involve any responsibility whatsoever for Ondulit Italiana S.p.A. Ondulit Italiana S.p.A. is fully entitled to modify or improve its products at any time without notice.

19 PRODUCT www.ondulit.com

cm4/m

min. cm3/m W - min cm3/m 0.50 mm 10.67 2.59 3.18 0.60 mm 12.95 3.40 4.13 M max + (p+q) l2 M min - = f max (q) 5/384 q l4/EI f max (p+q) 5/384 (p+q) l4/EI M max + 1/14 (p+q) l2 M min - 1/8 (p+q) l2 f max (q) 2.07/384 q l4

max

1/12.5

min

1/10

max (q) 2.53/384

STATIC SCHEME: TWO SPAN STATIC SCHEME: THREE SPAN max

W +

/EI f max (p+q) 2.07/384 (p+q) l4/EI M

+

(p+q) l2 M

-

(p+q) l2 f

q l4/EI f

(p+q) 2.53/384 (p+q) l4/EI

J = Moment of inertia

profiles

EN 1993-1-3, EN 1993-1-5, Italian Min. Decree of 14.01.2008

W - min. = Flexural strength module for negative moments

have been calculated according to

SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.93 1.85 1.79 1.68 1.60 1.53 1.47 1.40 1.33 1.28 1.23 1.19 1.15 1.11 1.08 1.05 0.60 mm L = m 2.09 2.01 1.94 1.83 1.74 1.66 1.60 1.54 1.49 1.45 1.40 1.35 1.31 1.27 1.23 1.19 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.95 1.84 1.75 1.61 1.50 1.40 1.33 1.26 1.20 1.15 1.11 1.07 1.04 1.00 0.97 0.95 0.60 mm L = m 2.22 2.10 1.00 1.84 1.71 1.61 1.52 1.44 1.38 1.32 1.27 1.23 1.19 1.15 1.11 1.08 SNOW OVERLOAD - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.18 2.06 1.96 1.80 1.67 1.57 1.48 1.41 1.35 1.29 1.24 1.20 1.16 1.12 1.09 1.06 0.60 mm L = m 2.48 2.35 2.24 2.06 1.91 1.80 1.70 1.61 1.54 1.48 1.42 1.37 1.32 1.28 1.25 1.21 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 1.79 1.63 1.51 1.42 1.35 1.29 1.24 1.20 1.16 1.13 1.10 1.07 1.05 1.02 0.99 0.96 0.60 mm L = m 1.94 1.77 1.64 1.54 1.47 1.40 1.35 1.30 1.26 1.22 1.19 1.16 1.14 1.11 1.09 1.07 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.40 2.18 2.03 1.88 1.73 1.62 1.52 1.44 1.37 1.31 1.26 1.21 1.17 1.13 1.10 0.96 0.60 mm L = m 2.61 2.37 2.20 2.07 1.97 1.84 1.73 1.64 1.56 1.50 1.44 1.38 1.34 1.29 1.25 1.10 UPLIFT WIND - P (daN/m2) steel thickness 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 0.50 mm L = m 2.25 2.04 1.90 1.78 1.69 1.62 1.56 1.50 1.46 1.42 1.38 1.34 1.31 1.27 1.23 1.19 0.60 mm L = m 2.44 2.22 2.06 1.94 1.84 1.76 1.69 1.63 1.58 1.54 1.50 1.46 1.43 1.40 1.37 1.34

AVAILABLE PROCESSES CURVED

Tile-shaped multilayer protected steel roofing

CoverTile

TECHNICAL CHARACTERISTICS

PRODUCT LENGTH (Lp) see chart

DISTANCE BETWEEN TILES 325 mm

NOMINAL LENGTH (Ln) 900 mm

COVER WIDTH (Lu) 785 mm

PROFILE (H) 20.5 mm

PITCH (P) 87 mm

AVERAGE TOTAL THICKNESS 2.4 mm

STEEL THICKNESS 0.50 mm

MASS 7.600 kg/ m2

TOLERANCES on LENGTH + 20 - 5 mm; cover widht (Lu) +/- 5 mm average total thickness and mass +/- 10%

MINIMUM SLOPE 15%

PRODUCT DESCRIPTION

Multi-layer metal sheet with tile shape, CE marked according to UNI EN 14782 - Appendix A - compliant with UNI EN 508-1- Appendix B, Remade in Italy certified for content of recycled raw material, disassembly and absence of dangerous substances. CoverTile sheets are made of a structural galvanized steel sheet (EN 10346) with a thickness of 0.50 mm protected on the upper face by an anticorrosive and soundproofing thermoplastic coating (about 1.5 mm thick) and by an aluminum sheet natural (i.e. pre-painted aluminum), and in the lower face by a primer and a natural aluminum sheet (i.e. pre-painted aluminum). The external layers wrap the side edges of the sheets along the entire length to guarantee their protection. To ensure the stability over time of the performance characteristics, the protection with an anticorrosive and soundproofing function, has a thickness of about 1.5 mm and it is positioned on the extrados of the sheet.

The cover element ensures the following performance requirements:

Reaction to fire:

Class B-s1, d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

Durability - Salt spray resistance: 4000 hours (UNI EN 14782 – Appendix A; ISO 9227)

Durability - Humidity resistance: 3000 hours (UNI EN 14782 – Appendix A; EN ISO 6270-1)

Durability - SO2 resistance: 45 cycles (UNI EN 14782 – Appendix A; EN ISO 6988)

Sustainability: Remade in Italy certification for recycled raw material content, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

Sound insulation: 28 dB (UNI EN ISO 10140-2:2010)

Sound deadening of noise generated by heavy rain:

ISTEDIL cert. N°1302/202-G 1302/202-C

8.41 times higher than a mm 0.7 mm thick aluminium sheet. 4.17 times higher than a sandwich panel with 40 mm insulation. 51.3 dB UNI EN ISO 140-18

Summer thermal transmittance: 1.07 W/m2K (ISO 6946) with natural aluminium lower surfacing

AND QUALITY

The suggestion and data reported in this catalogue are based on information we believe to be reliable, being the result of long experience and considerable knowledge as well as of field and lab test. They are offered in good faith, but with no guarantee, as conditions and methods of use of our products are beyond our control. They do not involve any responsibility whatsoever for Ondulit Italiana S.p.A. Ondulit Italiana S.p.A. is fully entitled to modify or improve its products at any time without notice.

CVT5-EN - VER 220902

ondulit.com

20

P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 Ln = 850 Lu = 773 Ln = 1000 Lu = 900 Ln = 900 Lu = 785 SRI % (ASTM E1980-11) 37,3 % 34,3% 42,6% 35,6% 73% 35,2% 33,4% 37,6% 75,7% AVAILABLE FINISHING L Blue Slate Grey Grey Medium Green Off White Red Oxide Red Terracotta Silver RAL / PANTONE 540C 7012 7023 378C 9002 8016 3009 8004 9006 PERFORMANCE

GUARANTEED LENGTH OF STANDARD COVERTILE SHEETS PITCH NR. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 PRODUCT LENGTH (m) (LP) 1.25 1.58 1.90 2.23 2.55 2.88 3.20 3.53 3.85 4.18 4.50 4.83 5.15 5.48 5.80 6.13 6.45 6.78

21

Insulated and ventilated panel with multilayer protection

Insulated and ventilated panel with multilayer protection

Insulated and ventilated panel with multilayer protection

PRODUCT DESCRIPTION

Insulated and ventilated panel with multilayer protection, CE marked according to the EN 14509 standard, Remade in Italy certified for the content of recycled raw material, disassembly and absence of hazardous substances, consisting of:

(1) Covering element in metal sheets with a total thickness of 2.4 mm, CE marked according to UNI EN 14782, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.50 mm (or 0.40 mm or 0.60 mm) protected in the upper face by a thermoplastic cover (about 1.5 mm thick) anticorrosive and soundproofing and a natural aluminum foil (or pre-painted aluminum), and in the lower face by a bituminous primer and a natural aluminum foil. To ensure the stability of the performance characteristics over time, the protection with an anticorrosive and soundproofing function, of a thickness of about 1.5 mm, must be positioned on the extrados of the sheet.

(2) Shaped insulating element in sintered expanded polystyrene with improved lambda closed cells containing graphite (reaction to fire Euroclass E, EPS 100);

(3) Micro-ribbed lower sheet in structural steel (EN 10169), galvanized and pre-painted, RAL 9002 color, thickness 0.40 mm (or 0.50). The covering element (1) must project at least 5 cm into the eaves in order to protect the head of the insulating panel (2); Between the covering element (1) and the insulating layer (2) there are ventilation channels that allow free air circulation. The micro-ventilation of the panel reduces the thermal load on the extrados of the insulation, improving internal environmental comfort, and also avoids excessive overheating of the roof, resulting in the most favorable operating conditions for the insulation and for the upper sheet in time.

Insulated and ventilated panel with multilayer protection, CE marked according to the EN 14509 standard, Remade in Italy certified for the content of recycled raw material, disassembly and absence of hazardous substances, consisting of:

The roofing system ensures the following performances:

Reaction to fire:

(1) Covering element in metal sheets with a total thickness of 2.4 mm, CE marked according to UNI EN 14782, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.50 mm (or 0.40 mm or 0.60 mm) protected in the upper face by a thermoplastic cover (about 1.5 mm thick) anticorrosive and soundproofing and a natural aluminum foil (or pre-painted aluminum), and in the lower face by a bituminous primer and a natural aluminum foil. To ensure the stability of the performance characteristics over time, the protection with an anticorrosive and soundproofing function, of a thickness of about 1.5 mm, must be positioned on the extrados of the sheet.

B. s2-d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

(2) Shaped insulating element in sintered expanded polystyrene with improved lambda closed cells containing graphite (reaction to fire Euroclass E, EPS 100);

Performances in the event of external fire:

B-Roof T3 (UNI EN 13501-5; UNI CEN/TS 1187).

(3) Micro-ribbed lower sheet in structural steel (EN 10169), galvanized and pre-painted, RAL 9002 color, thickness 0.40 mm (or 0.50). The covering element (1) must project at least 5 cm into the eaves in order to protect the head of the insulating panel (2); Between the covering element (1) and the insulating layer (2) there are ventilation channels that allow free air circulation. The micro-ventilation of the panel reduces the thermal load on the extrados of the insulation, improving internal environmental comfort, and also avoids excessive overheating of the roof, resulting in the most favorable operating conditions for the insulation and for the upper sheet in time.

Environmental sustainability:

Remade in Italy certification for recycled raw material content, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

Thermal transmittance: 0,31 W/m2K for 100 mm thickness; 0,26 W/m2K for 120 mm thickness; 0,22 W/m2K for 140 mm thickness; 0,19 W/m2K for 160 mm thickness.

The roofing system ensures the following performances:

Reaction to fire: B. s2-d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2)

Performances in the event of external fire:

Environmental sustainability:

B-Roof T3 (UNI EN 13501-5; UNI CEN/TS 1187).

Remade in Italy certification for recycled raw material content, disassembly and absence of hazardous substances (Italian Ministerial Decree 11/10/2017 Minimum Environmental Criteria)

22

P = 900 5 cm 20 cm 30 cm 915 dc CPU - VER 221019 EN ondulit.com

CROSS

SECTION

(1) Steel cover sheet with multilayer protection

(2) Shaped insulation in expanded polystyrene sintered

Compressible

(4)

(4)

SHEET STANDARD PROJECTION L > 2m LONGITUDINAL JOINT SRI % (ASTM E1980-11) 42,6% 35,6% 73% 107% 37,6% AVAILABLE FINISHING Upper Layer Grey Medium Green Off White Natural Aluminium Terracotta RAL / PANTONE 7023 378C 9002 - 8004 GUARANTEED PERFORMANCES AND QUALITY BROOF P = 900 5 cm 20 cm 30 cm 915 dc

(3) Natural aluminum foil

gasket

Ventilation channels

Ventilation channels

PRODUCT DESCRIPTION

Thermal transmittance: 0,31 W/m2K for 100 mm thickness; 0,26 W/m2K for 120 mm thickness; 0,22 W/m2K for 140 mm thickness; 0,19 W/m2K for 160 mm thickness.

CROSS SECTION

(1) Steel cover sheet with multilayer protection

(2) Shaped insulation in expanded polystyrene sintered

(3) Natural aluminum foil

Compressible gasket

SHEET STANDARD PROJECTION L > 2m LONGITUDINAL JOINT SRI % (ASTM E1980-11) 42,6% 35,6% 73% 107% 37,6% AVAILABLE FINISHING Upper Layer Grey Medium Green Off White Natural Aluminium Terracotta

(4) Ventilation channels (4) Ventilation channels

CoverPiù

Insulated and ventilated panel with multilayer protection TECHNICAL

standard / 20 and 30 cm for overlapping Standard processing only on panels with L > 2 meters. Insulation pre-cut and bottom lining: maximum height 90 mm.

5

* Values calculated according to UNI 14509: 2013 - appendix A - valid for both descending load (snow) and ascending load (wind); Arrow with light 1/200.

*Values calculated according to UNI 13786

Values calculated according to UNI 14509: 2013 - appendix A - valid for both descending load (snow) and ascending load (wind); Sagitta 1/200 span.

23 PANELS L p

TRANSMITTANCE dc Insultation thickness [mm] Thermal transmittance Winter [W/m2K] * Periodic thermal transmittance Summer [W/m2K] ** fd** Attenuation decrease factor [-] φ** Decrement factor delay, Phase displacement [h] 40 0,94 0,83 0,990 0,62 60 0,61 0,57 0,990 0,70 100 0,31 0,289 0,990 1,08 120 0,26 0,241 0,982 1,26 140 0,22 0,204 0,980 1,56 160 0,19 0,174 0,970 1,83

MECHANICAL STRENGTH

PROPERTY SYMBOL QUANTITY DEFINITION TOLERANCE PRODUCT LENGTH Lp on demand, max 14.00 m Covering element lenght +/- 10 mm PROJECTION Ag

Distance between

+/- 10 mm USEFUL WIDTH Lu 900 mm Panel mounting distance +/- 5 mm SHEET PROFILE H 37 mm Height of the covering element profiles +/- 0.2 mm NOMINAL THICKNESS dc 40-60-100-120-140-160 mm Distance between internal facing and external facing (part between the two profiles) +/-2 mm (dc ≤ 100 mm) +/-2 % (dc > 100 mm) Lower sheet 0.4 mm Cover sheet thickness 0,4 mm 0,5 mm 0,6 mm Panel insulation thickness (mm) 40 60 100 120 140 160 40 60 100 120 140 160 40 60 100 120 140 160 Interaxis Maximum load p [kg/m2) 1,5 m 378 483 700 810 922 1034 433 539 757 868 979 1091 488 595 813 924 1036 1148 2,0 m 202 276 434 515 597 679 227 302 460 542 624 707 251 327 486 568 651 734 2,5 m 126 182 302 365 429 494 140 197 318 382 446 511 153 211 333 397 462 527 3,0 m 128 223 274 325 378 95 138 235 286 338 391 103 147 245 296 349 402 3,5 m 103 171 212 255 298 102 180 222 265 309 109 188 230 274 318 4,0 m 134 168 204 240 142 176 213 250 148 183 220 257

PHYSICAL CHARACTERISTICS

cm

the outer edge of the covering element - insulation

STATIC SCHEME: ONE SPAN WEIGHTS dc Insultation thickness Steel Thickness Upper Element [mm] 0,4 mm kg/m2 0,5 mm kg/m2 0,6 mm kg/m2 40 11,15 12,02 12,89 60 11,55 12,42 13,29 100 12,35 13,22 14,09 120 12,75 13,62 14,49 140 13,25 14,12 14,99 160 13,65 14,52 15,39 M max + (p+q) l2 M min - = f max (q) 5/384 q l4/EI f max (p+q) 5/384 (p+q) l4/EI

MULTILAYER METAL PANEL

In order to respond to the different types of application and the needs of discontinuous structures, the Coverpiù family consists of four variants.

Isolated and ventilated single-sheet panel with multilayer protection

Isolated and ventilated single-sheet panel with multilayer protection

Compressible gasket

PRODUCT DESCRIPTION

CoverPiù MONO CoverPiù AGRI

FIBERGLASS

Insulated and ventilated multi-layered Deck Panel consisting of:

Insulated and ventilated panel with multilayer protection, in Fiberglass for Zootechnics

(1) Covering element in metal sheets, CE marked according to UNI EN 14782, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.50 mm (or 0.40 mm or 0.60 mm) protected in the upper face by a thermoplastic cover (about 1.5 mm thick) anticorrosive and soundproofing and a natural aluminum foil (or pre-painted aluminum), and in the lower face by a bituminous primer and a natural aluminum foil. To ensure the stability of the performance characteristics over time, the protection with an anticorrosive and soundproofing function, of a thickness of about 1.5 mm, must be positioned on the extrados of the sheet.

(2) Shaped insulating element in sintered expanded polystyrene with improved lambda closed cells (reaction to fire Euroclass E, EPS 100).

(3)

The covering element (1) must project at least 5 cm into the eaves in order to protect the head of the insulating panel (2); Between the covering element (1) and the insulating layer (2) there are ventilation channels that allow no free circulation of air. The micro-ventilation of the panel reduces the thermal load to the extrados of the insulator, improving the internal environmental comfort, moreover it avoids the excessive overheating of the covering, determining for the insulation and for the upper slab operating conditions more favorable to their reliability in time.

The roofing system ensures the following performances:

Reaction to fire:

Performances in the event of external fire:

Thermal transmittance:

- Class 1 - 2 - EPS 40 - 50 mm

- Class 1 - 1 - EPS 60 - 100 - 130 - 160 mm

B Roof T3 class (UNI EN 13501-5; UNI CEN / TS 1187)

0.32 W/m2K for 100 mm thickness; 0.25 W/m2K for 130 mm thickness; 0.20 W/m2K for 160 mm thickness.

Compressible gasket

24

MONO 900 900 5 cm 20 cm 30 cm d C

Natural aluminum foil.

(1) Steel cover sheet with multilayer protection

(2) Shaped insulation in expanded polystyrene sintered

(3) Natural aluminum foil

SHEET STANDARD PROJECTION L > 2m LONGITUDINAL JOINT CROSS SECTION SRI % (ASTM E1980-11) 42,6% 35,6% 73% 107% 37,6% AVAILABLE FINISHING Grey Medium Green Off White Natural Aluminium Terracotta AGRI 910 P = 900 5 cm 20 cm 30 cm d C Insulated and ventilated panel with multilayer protection, in Fiberglass for Zootechnics

(4) Ventilation channels (4) Ventilation channels

(1) Steel cover sheet with multilayer protection (4) Ventilation channels (4) Ventilation channels

LONGITUDINAL JOINT SHEET STANDARD PROJECTION

CROSS SECTION

(2) Shaped insulation in expanded polystyrene sintered with graphite (3) Fiberglass laminate

The only panel for curved roofs with variable radius

CURVABILE CURVABLE

Isolated and ventilated single-sheet panel with multilayer protection

(4)

Compressible gasket

PRODUCT DESCRIPTION

CoverPiù CoverPiù

Insulated and ventilated multi-layered Deck Panel consisting of:

FONO

Insulated and ventilated sound-absorbing panel with multilayer protection

Insulated and ventilated sound-absorbing panel with multilayer protection

(1) Covering element in metal sheets, CE marked according to UNI EN 14782, consisting of a structural galvanized steel sheet (EN 10346) with a thickness of 0.50 mm (or 0.40 mm or 0.60 mm) protected in the upper face by a thermoplastic cover (about 1.5 mm thick) anticorrosive and soundproofing and a natural aluminum foil (or pre-painted aluminum), and in the lower face by a bituminous primer and a natural aluminum foil. To ensure the stability of the performance characteristics over time, the protection with an anticorrosive and soundproofing function, of a thickness of about 1.5 mm, must be positioned on the extrados of the sheet.

(5)

(2) Shaped insulating element in sintered expanded polystyrene with improved lambda closed cells (reaction to fire Euroclass E, EPS 100).

(3) Natural aluminum foil.

The covering element (1) must project at least 5 cm into the eaves in order to protect the head of the insulating panel (2); Between the covering element (1) and the insulating layer (2) there are ventilation channels that allow no free circulation of air. The micro-ventilation of the panel reduces the thermal load to the extrados of the insulator, improving the internal environmental comfort, moreover it avoids the excessive overheating of the covering, determining for the insulation and for the upper slab operating conditions more favorable to their reliability in time.

The roofing system ensures the following performances:

Reaction to fire:

Performances in the event of external fire:

Thermal transmittance:

- Class 1 - 2 - EPS 40 mm

- Class 1 - 1 - EPS 60 - 100 -120-140-160 mm

B Roof T3 class (UNI EN 13501-5; UNI CEN / TS 1187)

0,31 W/m2K for 100 mm thickness; 0,26 W/m2K for 120 mm thickness; 0,22 W/m2K for 140 mm thickness; 0,19 W/m2K for 160 mm thickness

25

PANELS

900 900 5 cm 20 cm 30 cm d C

(1) Steel cover sheet with multilayer protection

(2) Shaped insulation in expanded polystyrene sintered

(3) Natural aluminum foil

2m LONGITUDINAL JOINT

SECTION SRI % (ASTM E1980-11) 42,6% 35,6% 73% 107% 37,6% AVAILABLE FINISHING Grey Medium Green Off White Natural Aluminium Terracotta FONO d c P= 900 235 235 235 25 35 45 45 85 915 5 cm 20 cm 30 cm

Ventilation channels (4) Ventilation channels

SHEET STANDARD PROJECTION L >

CROSS

(1) Steel cover sheet with multilayer protection (5) Ventilation channels

(4) Panel in rock wool with non-oriented fibers

(3) Micronervated bottom sheet in microperforated prepainted steel

LONGITUDINAL JOINT SHEET STANDARD PROJECTION

Ventilation channels

CROSS SECTION

(2) Shaped insulation in expanded polystyrene sintered with graphite

PRODUCT DESCRIPTION CURVABLE

From a flat roof to a sloping, insulated and ventilated one

5

Ventilcover

Insulated and ventilated roofing system for flat slabs

DESIGN

The Ventilcover system is available in different versions, depending on:

1. type of roof (Coverib 850 sheets / Coverpiù sandwich panels)

Insulated and ventilated roofing system for flat slabs Ventilcover

2. maximum height of the telescopic support (135/200 cm)

3. type of attachment to the slab (Standard = with telescopic support directly on the existing floor; with Divider = with telescopic support on omega profile which distributes the actions on the existing slab.

The Ventilcover system is sized to withstand the overloads required by law (Ministerial Decree 18.01.2018 Technical Standards for Construction., NTC); for this purpose, a General Calculation Report is available, signed by a structural engineer, complete with overload verification as required by law according to the following parameters:

(3) Vertical supports made of galvanized structural steel, CE marked according to EN 1090 - 1: 2009 + A1: 2011, telescopically adjustable and placed at progressive heights, to obtain the formation of the necessary pitch gradients.

• verification of the stress and deformation states of the omega-profiled purlin

• compression check with control of the instability of the telescopic supports

• verification of the bearing strength of the tightening of the telescopic supports

The insulated and ventilated pitched roof system is equipped with a General Calculation Report in accordance with the following standards: UNI EN 1993 -1-3-5: 2007; UNI EN 14782: 2006; Ministerial Decree 17 January 2018 “Technical Standards for Construction”.

• verification of the tension states on the tightening screws

• verification of the stress and deformation states of the roof

Special aerated accessories at the ridge cap and gutter ensure the ventilation of the system.

• verification of pedestrian traffic and concentrated loads

• contact pressure at the foot of the telescopic supports

• overall average load on the existing structure

• depression due to the action of the wind.

COMPONENTS

1. ROOFING ELEMENT

2. PURLINS STRUCTURE

3. TELESCOPIC SUPPORTS

SUPPORT

4. RIDGE BARS

5. THERMAL INSULATION

6. LOAD DIVIDER

In order to facilitate the design of a roof with the Ventilcover system, diagrams and tables have been prepared within the General Calculation Report from which it is possible to obtain the data necessary for the specific design of the system.

Ondulit Coverib multilayer insulated steel sheet

Galvanized steel section bar with omega profile, h. 60 or 80 mm

Telescopic supports in galvanized steel, adjustable in height from 17 to 200 cm

Crossbars for main and secondary ridge construction

Panels in sintered expanded polystyrene or glass-wool or rock-wool rolls

The Ondulit Technical Office is available to assist the designer in every phase of the design Ondulit provides designers and installers “On The Roof” a plug-in for Revit that makes easier and immediate the design of the roof, from the geometry to the bill of components.

Register and download for free on ontheroof.it

Galvanized steel profile with telescopic support compartment* * only for “divider” version.

Coverib multilayer insulated steel sheet

26 Ventilcover 1 2 3

4

PERFORMANCE AND QUALITY GUARANTEED BROOF

INTEGRATED SOLUTIONS

ELEMENT Ondulit

TECHNICAL CHARACTERISTICS LENGTH custom tailored NOMINAL LENGTH(Ln) 850 mm COVER WIDTH (Lu) 773 mm PROFILE (H) 32 mm PITCH (P) 192 mm AVERAGE TOTAL THICKNESS 2,4 mm STEEL THICKNESS 0,50 - 0,60 - 0,80 mm MASS 8,000 kg/ m2 steel thickness 0,50 8,600 kg/ m2 steel thickness 0,60 10,000 kg/ m2 steel thickness 0,80 82 150 15 0 4 0 35 35 3 0 2 0 3 0 160 60 / 8 0 VTC D IS EGNI PE R S CHEDA TECNICA ± 5 ± 1 ± 5 ± 1 ± 1 ± 1 ± 1 150 15 0 4 0 35 35 3 0 2 0 3 0 160 60 / 8 0 VTC D IS EGNI PE R S CHEDA TECNICA ± 5 ± 1 ± 5 ± 1 ± 1 ± 1 ± 1

1. ROOFING

EasyFix

Support and fastening system for photovoltaic modules

If the fastening systems are not well-designed, the impermeability of the roof may risk being punctured or an impediment to the disposal of water may arise.

ADVANTAGES

Easyfix is a system that takes critical issues into account and ensures numerous advantages:

• It promotes architectural integration;

• It does not cause any perforations except for those required for the installation of the roof;

• It remains solid and durable, since it is anchored to the support structure;

• It improves ventilation of the modules as the cavities are free from obtructions;

• It does not require any electrical installation work on the other components of the roof.

28 INTEGRATED SOLUTIONS FOR PV SYSTEMS

CROSS SECTION

EasyFix

ELEMENTS DESCRIPTIONS

Cover element *

(1) Coverib 850 sheet in steel with multilayer protection with steel thickness 0.5 mm. Upper cover in pre-painted Natural Aluminum. Manufactured according to UNI EN 14782 - CE mark.

Photovoltaic modules

(2) Paneles fotovoltaicos de silicio cristalino

Fastening anchoring system

(3) Aluminum profile, thickness 2 mm, of photovoltaic fastening system (PCR)

(4) Special washer for PCR Coverib 850

(5) Bracket for photovoltaic modules.

* In addition to Coverib 850 profile sheet, as in the graphic schemes and descriptions above, the Easyfix solution is also available for Coverib 1000, Ondulit and CoverTile profiles.

Fixing system for rigid photovoltaic panels on a corrugated roof consisting of extruded aluminum U-bolts, spacer profiles in extruded aluminum, aluminum brackets for anchoring the module to the profile and anchoring system (M8 screw and steel guided slider).

Photovoltaic crystalline modules system for multilayer Ondulit/Coverib sheets

The extruded aluminum U-bolts are at the same time an element for fixing the cover to the supporting structure and housing the spacer.

BRACKET

The spacer, placed parallel to the slope of the roof, in correspondence with a rib of the sheet, consists of an extruded aluminum profile characterized by two lateral grooves for fixing the profile to the jumper, by means of a guided steel slider with an M8 threaded bolt and by an upper groove for fixing photovoltaic modules by means of a steel slider with an M8 threaded bolt. The system allows the fixing of the photovoltaic modules to the supporting structure through the corrugated sheet, without holes in the roof with the exception of holes for structural fixing. The system creates a layer of ventilation beyond the corrugated profile of about 6 cm.

ANCHORING WASHER PROFILE PV - PCR

SFFCR SFFCRF35 SFFCRF40 SFFCRF50

29

45.95 54.50 49.9 11.8 10.5 18 15.6 10 46 54 3 3 46 3 3 58 32 32 36 2 1 1 2 4 4 5 3 5 3 35 35 35 35 CA1FV 21 11,4 17 10 85° 35 8 70 14 45.95 54.50 49.9 11.8 10.5 18 15.6 10 46 54 3 3 46 3 3 58 32 32 36 2 1 1 2 4 4 5 3 5 3 35 35 35 35 21 11,4 17 10 85° 35 8 14 45.95 54.50 49.9 11.8 10.5 18 15.6 10 46 54 3 3 46 3 3 58 32 32 36 2 1 1 2 4 4 5 3 5 3 35 21 11,4 17 10 85° 35 8 14 45.95 54.50 49.9 11.8 10.5 18 15.6 10 54 46 3 3 46 3 3 58 32 32 36 2 1 1 2 4 4 5 3 5 3 35 35 standard 54 46 3 3 C EFX

- EN ondulit.it/en

INTEGRATED SOLUTIONS

- VER 220914

DESCRIPTION

CHARACTERISTIC QUANTITY WEIGHT 1.517 Kg/ml PROFILE LENGTH PCR 600 cm PROFILE LENGTH PCRFS Max 750 cm MAXIMUM INTERAXIS 200 cm C B A

LONGITUDINAL SECTION

46 54 3 3 32 36 2 4 4 3 3 2 1 1 2 4 4 5 3 5 3 46 54 3 3 46 3 3 58 32 32 36 45.95 42.9 49.9 11.8 10.5 18 4 10 35 35 35 35 light 12 17 2,5 17 18 20 35 12 17 2,5 17 23 20 40 12 17 2,5 17 20 12 17 2,5 17 20 40 20 2,5 19 2 4 4 3 3 46 54 3 3 46 3 3 32 32 36 2 1 1 2 4 4 3 5 2 1 1 2 4 4 5 3 5 46 54 3 3 46 3 3 58 32 32 36 45.95 42.9 49.9 11.8 10.5 18 4 10 35 35 35 35 standard light 12 17 2,5 17 18 20 35 12 17 2,5 17 23 20 40 12 17 2,5 17 20 12 17 2,5 17 20 40 20 2,5 19 11,4 17 10 85° 2,5 22 12.5 35 36 12.5 18 39 12.5 49 2,5 2,5 2,5

FOR PV MODULE - SFFCR ANCHORING WASHER PROFILE PCR - ONDULIT/COVERIB CA2FV Special Anchoring Washer profile PCR-Coverib 850 Long. 70 mm. Extruded aluminum: weight 0,105 Kg/cad CA1FV Special Anchoring Washer profile PCR – Ondulit Length 70 mm Extruded aluminum: weight 0.160 kg/cad CA3FV Special Anchoring Washer profile PCR-Coverib 1000 Long. 70 mm. Extruded aluminum: weight 0,105 Kg/cad CA1FVC Special washer for PCR Ondulit Length 400 mm. Extruded aluminum: weight 0.700 Kg/cad CA3FVC Special washer for PCR Coverib 1000 Length 400 mm. Extruded aluminum: weight 0.542 Kg/cad SFFCR Intermediate bracket SFFCR 35 Ending bracket for PV module l.35 mm. SFFCR 40 Ending bracket for PV module l.40 mm. SFFCR 50 Ending bracket for PV module l.50 mm.

Translucent elements

For areas with natural light, three versions of translucent sheets with the same profiles as the Ondulit-Coverib roofing sheets are available.

POLILUX

Translucent elements consisting of a corrugated compact polycarbonate sheet with a constant thickness of 1.2 mm. and an outer surface protected by a coextruded external layer “Absorver”. The elements can be overlapped transversely and longitudinally with Coverib sheets.

POLILUX HP

Translucent elements consisting of a corrugated extruded polycarbonate slab with a constant thickness of 2.5 mm and a satin finish. The elements can be overlapped transversely and longitudinally with Ondulit and Coverib sheets. The ends are heat-sealed.

PROFILES

Ondulit profile

Coverib Profile 850

Coverib Profile 1000

30 P= 87 H = 20,5 P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 An = 900 Aú = 785 An = 850 Aú = 773 An = 1000 Aú = 900 Aú = 785 P= 87 H = 20,5 P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 An = 900 Aú = 785 An = 850 Aú = 773 An = 1000 Aú = 900 An = 900 Aú = 785 P= 87 H = 20,5 P= 192 H = 32 P= 300 H = 38 P= 87 H = 20,5 An = 900 Aú = 785 An = 850 Aú = 773 An = 1000 Aú = 900 An = 900 Aú = 785

ONDULIT

RAW MATERIALS

Natural Aluminium mm 1 - 1,5 mm* thicknesses

Pre-painted Aluminium 1 mm thicknesses

Micro-perforated aluminium 1 mm thicknesses

Electrolytic Copper 0,6 - 0,8 mm thicknesses

Accessories

Pre-painted steel - RAL 9002 0,6 mm thicknesses

Pre-painted steel - RAL 3009 0,6 mm thicknesses

*printed accessories

Ondulit makes every type of tailor-made flashings for roofs and walls, whatever the shape and complexity.

Based on the need to adapt to every shape and type of building, Ondulit designs - on a case-by-case basis - specific and “ad hoc” fittings to satisfy every requirement. By way of example, these pages include a selection of some of the most frequently used accessories. These elements can be manufactured in different shapes and sizes as well as those presented.

Accessories such as ridges, borders, flashings and fittings are made from different metals, depending on the needs of the structure. They can be made of embossed aluminium, either natural or pre-painted aluminium. The colours are the same as the range of colours for the sheets and roof panels, ensuring perfect integration between the accessories and the roof.

Additional materials available for accessories are copper and pre-painted steel. The standard connecting elements are available in various sizes , up to a maximum of 1250 mm. The most used sizes are 415 mm, 500 and 625 mm. Edgings, flashings and fittings are available and are made using a press-bending process or they can be created according to the same trapezoidal profile of the sheets on which they are to be installed.

31 www.ondulit.it ▲ PRONTUARIO REV 8.0 VER 160706 - PAG. O5-3

www.ondulit.it ▲ PRONTUARIO REV 8.0 VER 160706 - PAG. O5-3 MATERIE

PRONTUARIO REV

www.ondulit.it ▲ PRONTUARIO REV 8.0 VER 160706 - PAG. O5-3 MATERIE

FLASHINGS, FITTINGS

FITTINGS FOR

MATERIE PRIME

PRIME

MATERIE PRIME

PRIME

AND BORDERS TRANSLUCENT ELEMENTS METEORIC WATER COLLECTOR SYSTEMS

EMERGING ELEMENTS

RIDGE CAPS

ONDULIT

RIDGE CAPS

MAIN FLAT RIDGE CAP [CP0*]

SECONDARY FLAT RIDGE CAP [CS0*]

VENTILATED RIDGE CAP [CLAR*]

BORDERS

END FLASHING [BL0*]

END FLASHING WITH DRIP TRAY [BLG0*]

CURVED END FLASHING [BLC0*]

32

FLASHINGS, FITTINGS AND BORDERS

SIDE WALL FLASHING [SL0*]

PRESSED ROOF-TO-ROOF FLASHING [SF0*]

REVERSE ROOF-TO-ROOF FLASHING [RFF*]

PRESSED ROOF-TO-ROOF FLASHING [RRF*]

ACCESSORIES

SPECIAL FITTINGS, SNOW STOPS

RAISING ELEMENT PPRESSED FLASHING [RES*W]

RAISING ELEMENT PPRESSED FLASHING SQUARE HOLE [RES**40Q]

RACCORDO PER CORPI EMERGENTI

SNOW STOP [FN0*]

Elemento che garantisce la tenuta all'acqua in corrispondenza dell'intersezione tra una falda ed un corpo emergente

RACCORDO STAMPATO COMPONIBILE PER CORPI EMERGENTI

INSIEME ELEMENTI COMPONENTI

CLOUSURE STRIPS

ELEMENTI SAGOMATI CHIUDI GRECA*

PERFORATED VERSION [LSF*]

FULL VERSION [LS*]

LOWER STRIP COVERPIÙ

LEFT VERSION [LICPU**S]

VITI

CAPPELLOTTI

VITE AUTOFILETTANTE LEGNO - FERRO

RIGHT VERSION [LICPU**D]

VITE AUTOFORANTE

CAPPELLOTTI CON ONDULIT

34 25 165 25 1.5

EMERGENTI LASTRA RETTA

RACCORDO STAMPATO PER CORPI

40 x 40 22 150 25 8 8 25 15 22 25 37.5 a 25 37.5

LISTELLI COVERIB 850 3 7 3 7 5 3 2 3 5.5 1.5 5 3 2 3 5.5 1.5 3 3 1

E

ø 12.5 8 ø 10 8

ONDULIT

METEORIC WATER COLLECTOR SYSTEMS

The rainwater drainage system using gutters, eaves and drainpipes makes it possible to collect rainwater as it falls on a building and carries it to the ground. Gutters, the main function of which is to protect basements, walls and pedestrians from splashes and drips, are no longer just a functional element but have become real decorative elements that give personality to the roofing system.

Rainwater collection systems are composed of:

• Gutter channel

la tenuta all'acqua in corrispondenza dell'intersezione tra una falda ed un corpo emergente

• Gutter channel support brackets (upper and lower)

• Accessories for gutter channels (Plugs, gutter caps, nozzles, overflow pipes)

Ondulit gutter channels are designed according to the European standard UNI EN 612: 2005 “Gutters with frontal irrigation rib and cold-joined downpipes made of metal sheet”. Each roof needs a specific project in order to size the rainwater collection system. Ondulit designs the rainwater collection system according to the European standard UNI EN12056-3.

Ondulit’s range of rainwater collection systems includes eight types, diversified according to:

• Whether the gutter channel is inside or outside the building

• Gutter systems for Ventilcover and Sheet

• Gutter systems for panels

EXTERNAL COLLECTION SYSTEM, WITHOUT LOWER BRACKET [G*1]

EXTERNAL COLLECTION SYSTEM, WITH LOWER BRACKET [G*3 - SI3*]

INTERNAL COLLECTION SYSTEM [G*6]

FASTENING

KITS

SELF-DRILLING SCREW FOR IRON [VZAPFTX*]

WASHERS WITH GASKET

SELF-TAPPING SCREW FOR WOOD - IRON [VXAFLF*] [CA1*] [CA2/3*]

35 VAR VAR 1.5 25 25 165 1.5 EMERGENTI RACCORDO PIANO ROVESCIO

ELEMENTI COMPONENTI VITE AUTOFILETTANTE PER LEGNO - FERRO VITI E CAPPELLOTTI VITE AUTOFORANTE PER FERRO ø 12.5 8 8 ø 12,5 ø 6.5 8 VAR VAR 1.5 25 25 165 165 25 25 1.5 STAMPATO COMPONIBILE PER CORPI EMERGENTI diversa ma non opposta 37.5 STAMPATO RACCORDO PIANO ROVESCIO RACCORDO PIANO corrispondenza dell'intersezione tra una falda ed un corpo emergente 3 1 3 3 3 1 3 2.5 ELEMENTI COMPONENTI VITE AUTOFILETTANTE PER LEGNO - FERRO CAPPELLOTTI CON GUARNIZIONE VITI E CAPPELLOTTI VITE AUTOFORANTE PER FERRO ø 12.5 8 8 ø 12,5 ø 6.5 ø 10 8 8 ø 10 ø 5.5 VAR VAR 1.5 25 25 165 165 25 1.5 CORPI RACCORDO STAMPATO COMPONIBILE PER CORPI EMERGENTI 22 8 25 15 37.5 25 37.5 a CORPI EMERGENTI

corpo emergente

SAGOMATI CHIUDI GRECA* 3 7 5 3 2 3 5.5 1.5 3 1 3 3 3 1 3 1 3 2.5 INSIEME ELEMENTI COMPONENTI VITE AUTOFILETTANTE PER LEGNO - FERRO CAPPELLOTTI

GUARNIZIONE ONDULIT COVERIB VITI E CAPPELLOTTI VITE AUTOFORANTE PER FERRO ø 12.5 8 8 ø 12,5 ø 6.5 ø 10 8 8 ø 10 ø 5.5

CON

ACCESSORIES

36 NAUTICAL STORAGE SUD CANTIERIITALY ONDULIT

39 STELLA MATUTINA MUSEUMRÉUNION ISLAND

40 FREE ZONE WAREHOUSESEL SALVADOR ONDULIT

Specialized technical support

We work every day to identify the best solutions for every architectural and environmental context.

Ondulit is able to provide

Tailor-made solutions

We develop a personalized proposal to meet the needs of each customer.

Full support

We handle all the technical and regulatory aspects linked to the creation of a roof.

Immediate and free advice

We are always present with a team of specialized technicians.

42

EXTERNAL ENCLOSURE | DETAIL

ONDULIT

43

Customized solutions for every context

SLOVENIA

MEDITERRANEAN - MARINE

ITALY

MEDITERRANEAN - INDUSTRIAL

CUBA

TROPICAL - MARINE

KENYA

TROPICAL - RURAL

ARIDO EQUATORIALE TROPICALE MONSONICO

ARID EQUATORIAL TROPICAL MONSOON

ARIDO EQUATORIALE TROPICALE MONSONICO

ARID EQUATORIAL TROPICAL MONSOON

ONDULIT

MOROCCO

MEDITERRANEAN - RURAL

CHINA

CONTINENTAL - URBAN

INDIA

MONSOON - URBAN

RÉUNION ISLAND

TROPICAL - MARINE

MEDITERRANEO OCEANICO CONTINENTALE POLARE

MEDITERRANEAN OCEANIC CONTINENTAL POLAR

Paradisus Varadero Resort & Spa

46 CLIMATE Tropical ENVIRONMENT Marine PLACE Cuba, Varadero TYPE Hospitality DATE 2019

CUBA

47

SURFACE sqm 16,500

PRODUCT Coverib 850 mm 0.5

FINISHING Aluminum Off White RAL 9002

Apartments Coeur de Ville RÉUNION ISLAND

48

CLIMATE Tropical ENVIRONMENT Marine PLACE Réunion, La Possession TYPE Residential DATE 2017 - 2019

FINISHING

Natural Aluminum Copper

49 SURFACE sqm 1,800 PRODUCT Ondulit Z mm 0,6

Jiqing High Speed Train Station

50

CHINA

CLIMATE Continental ENVIRONMENT Urban PLACE China, Jiqing TYPE Infrastructure DATE 2020

51 SURFACE sqm 60,000

Coverib 850 mm 0.8

Grey RAL7040

White RAL 9002

PRODUCT

FINISHING Aluminum

Off

52

ITALY CLIMATE Mediterranean ENVIRONMENT Industrial PLACE Italy, L’Aquila TYPE Industrial DATE 2018

Accord Phoenix Electrical Equipment Plant

53

SURFACE sqm 1,000

PRODUCT Ventilcover System Coverib 850 mm 0.5

FINISHING Natural Aluminum

54 CLIMATE Mediterranean ENVIRONMENT Rural PLACE Morocco, Temara TYPE Industrial DATE 2013

MOROCCO

AR Factory Warehouses

55 SURFACE sqm 27,000 PRODUCT Coverib 850 mm 0.6 Ondulit mm 0.5

Aluminum

FINISHING Natural

The Bengal Rowing Club

56

INDIA CLIMATE Monsoon ENVIRONMENT Urban PLACE India, Kolkata TYPE Sport and leisure DATE 2017

57

SURFACE sqm 1,000

PRODUCT Coverib 850 mm 0.5

FINISHING Aluminum Patina Green Off White RAL 9002

Koper Port Warehouses

58

CLIMATE Mediterranean ENVIRONMENT Marine PLACE Slovenia, Koper TYPE Infrastructure DATE 1980 -2020 SLOVENIA

59 SURFACE

250,000

0.5

0.8

sqm

PRODUCT Coverib 850 mm

/

FINISHING Natural Aluminum

60 CLIMATE Tropical ENVIRONMENT Rural PLACE Kenya, Kakamega TYPE Office DATE 2017 KENYA

Headquarters

One Acre Fund

61

SURFACE sqm 2,500

PRODUCT Ondulit mm 0.5

FINISHING Aluminum Grey RAL 7023

ONDULIT

MULTILAYER PROTECTED SHEETS CERTIFICATIONS:

Multilayer steel sheets compliant with European standard UNI EN 14782 - Appendix A

SYSTEM TECHNICAL SUITABILITY CERTIFICATES:

FRENCH C.S.T.B. Cert. No. 5/16 – 2537

ITALIAN I.T.C. Cert. No. 645/07

MIAMI DADE COUNTY BUILDING NOA NO. 13-1010.10

CHINA MAC Cert. n° 201500856E

UEB LABET.CTEC CUBA I.U.:19-C-318

201500856E

201500856E

DURABILITY

Salt spray corrosion resistance: 4000 hours (ISO 9227)

Resistance to humidity: 3000 hours (EN ISO 6270-1)

Resistance to sulphur dioxide: 45 cycles (EN ISO 6988)

Resistance to accelerated ageing: 2000 hours (ASTM G155)

FIRE PERFORMANCE

Reaction to fire: Class B-s1, d0 (UNI EN 13501-1; EN 13823; EN ISO 11925-2) Class B (ASTM E84)

Fire performance in the event of external fire: BRoof T3 Class (UNI EN 13501-5; UNI CEN/TS 1187) Class B (ASTM E108)

ACOUSTIC COMFORT

Soundproofing power: 28 dB (UNI EN ISO 10140-2:2010)

Sound attenuation power generated by heavy rain:

ISTEDIL Certificate 1302-3: Up to 8.41 times greater than a 0.7 mm. thick aluminium sheet and up to 4.17 times greater than a sandwich panel with 40 mm. insulation 52.3 dB (UNI EN ISO 140-18)

THERMAL COMFORT

Solar Reflectance Index (SRI): (ASTM E1980-11)

LIGHT COLOURS > 65%

Natural Aluminium (N) 107% Off White RAL 9002 (W)73.0% Silver (L) 75,7%

DARK COLOURS > 30%

Aluminium Slate Gray color RAL 7012 (D) 34.3%;

Aluminium Grey color RAL 7023 (GR) 42.6%; Aluminium Blue color (B) 37.3 %;

Aluminium Medium Green color (VM) 35.6%;

Aluminium Oxide Red RAL 3009 (S) 33.4%;

Aluminium Terracotta RAL 8004 (T) 37,6%; Aluminium Red (R) 35.2%.

Summer Thermal Transmittance: 1.07 W/m2K (ISO 6946)

MANAGEMENT SYSTEM PRODUCTION CERTIFIED

QUALITY MANAGEMENT SYSTEM QUALITY - ISO 9001

BUREAU VERITAS CERTIFICATE N° IT 244368

OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT SYSTEM - ISO 45001

BUREAU VERITAS CERTIFICATE N° IT293075

ENVIRONMENTAL MANAGEMENT SYSTEM - ISO 14001

BUREAU VERITAS CERTIFICATE N° IT269494/UK

LEGEND OF SYMBOLS

ONDULIT MULTILAYER PROTECTION

RESISTANT TO CORROSION

SILENT UNDER RAIN OR HAIL

THERMICALLY COMFORTABLE

LOW THERMAL EXPANSION

HIGH MECHANICAL RESISTANCE

REDUCED SPECIFIC WEIGHT

SUITABLE FOR ROOFING WITH LOW SLOPES CERTIFIED STATIC BEHAVIOR

VERSATILE AND CUSTOMIZABLE

REDUCED THERMAL TRANSMITTANCE

HIGH SOLAR REFLECTANCE

FIRE CLASS BROOF T3 CLASS

REACTION TO FIRE

CE MARKING EN 14782: 2006

SUPPORTS WITH ADJUSTABLE HEIGHT

HIGH INSTALLATION SPEED

HIGH WATERPROOFNESS

BROOF

The information contained in this documentation must be considered as simple guidelines: therefore, it does not entail responsibility for Ondulit Italiana spa, which reserves the right to make its own technical modifications or improvements to its products at any time and without notice.

ONDULIT.COM MAIN OFFICE I - 00153 Roma 95/E Via Portuense Tel. +39 0658330880 info@ondulit.it USA SALES DEPARTMENT Ondulit USA Inc. 14400 SW 96 AVE Miami - Florida - 33176 Tel. +1 7863347984 usa@ondulit.com

EXPORTVER 221027EN

ARIDO EQUATORIALE TROPICALE MONSONICO

ARID EQUATORIAL TROPICAL MONSOON

ARIDO EQUATORIALE TROPICALE MONSONICO

ARID EQUATORIAL TROPICAL MONSOON