HAOMENG CHENG

8 Kendrick Drive, Barnet, London, EN4 0FD, The United Kingdom

TEL +44 7341 047699

EMAIL oliverkingarcher@gmail.com

EDUCATION: SKILLS - Software:

2020-2023 Central Saint Martins

- BA [Hons] Architecture (pending)

2019-2020 University of Strathclyde - BSc [Hons] Architectural Studies

2018-2019 Aspire Private British School Paphos

- Business Studies A-level & Greek Apolyerio

- Fine arts A-level & Greek Apolyerio

- Mathematics A-level & Greek Apolyerio

- Citizenship Studies Greek Apolyerio

- Physical Education Greek Apolyerio

2017-2018 Aspire Private British School Paphos

- Mathematics International GCSE

Adobe Photoshop

Adobe Illustrator

Adobe InDesign

Adobe Lightroom

AutoCAD

Archicad

Rhinoceros

Sketchup

Twinmotion

Microsoft

Vectorworks

Encape

Vray

SKILLS - Other:

- Precision model making

- Moulding and Casting (Concrete, Plaster, Jesmonite, Alginate and Resin)

- Clay

- 3D Printing

- Lasercut

- Photography

LANGUAGES:

• English - Fluent

• Chinese Mandarin - Fluent

• Part 1 Architectural Assistant - Rundell Associates, 2024 - 2025

During my gap year after my BA, I joined Rundell Associates as their Section 1 Architectural Assistant. was introduced to several historic restoration projects, which is what initially drew me to architecture.

• RIBA Mentoring Scheme - Mace Limited, London, UK, January 2023

Introducing to the different RIBA stages of residential projects, following along one ongoing project particularly, with site visits in the Mace office in London.

• NIGERIA: Home After Crisis Competition

In the summer of 2023 after my graduation of Part 1, me and my other 4 friends attended the Young Architects Competitions as a group of five. It was a challenge of group working and creative thinking as well as communication skills among teammates.

• Final Year Work

My final year work encourages recycing and plastic waste reduction through Bioplastic. The key programme is to create an intergenerational community through reviving the local theatrical culture.

• Dissertation

My final year dissertation topic is ‘towards a vernacular urbanism in the contemporary era of China’, it aims to study the modern transformation of China architecutre. Including the impacts of the Communist Party’s ideology on China’s architecure, and the lost of Chineseness in globalisation.

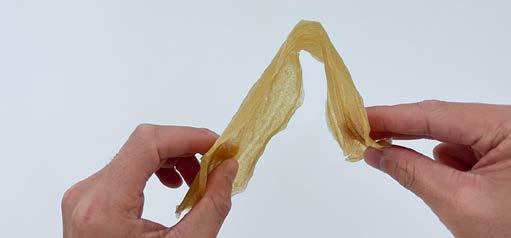

• Bioplastics and Future of construction thesis

My technical thesis was an investigation of cornstarch based bioplastic. Questioning whether “bioplarch” can be used in the future construction industry as part of building’s envelope.

• Oscar Brito Gonzalez

BA Architecture Stage 3 Leader and Year 2 Tutor

Central Saint Martins o.brito@csm.arts.ac.uk

• Inigo Cornago Bonal

BA Architecture Stage 2 Leader and Year 3 Tutor

Central Saint Martins i.cornagobonal@csm.arts.ac.uk

• Alex Warnock-Smith

Programme Director Spatial Practices Central Saint Martins a.warnocksmith@csm.arts.ac.uk

The boundary between architecture and the urban environment has been blurred throughout years. The city that we understand as an ecosystem, a complex interaction network between the built environment and the set of actors that inhabit it. Integrating with research and design, architecture can act as a tool to make the built environment more inclusive and resilient for humans and nonhumans alike.

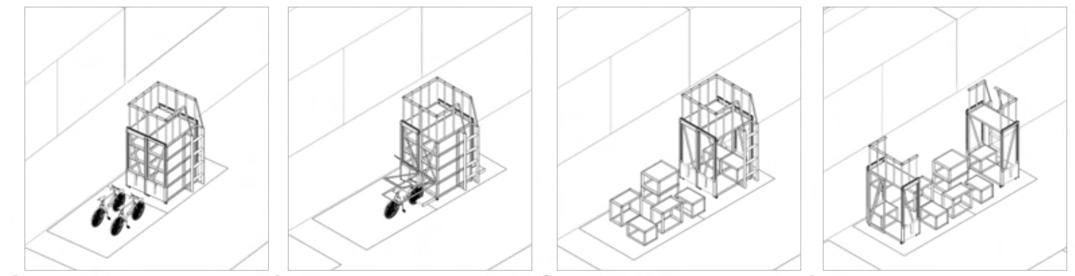

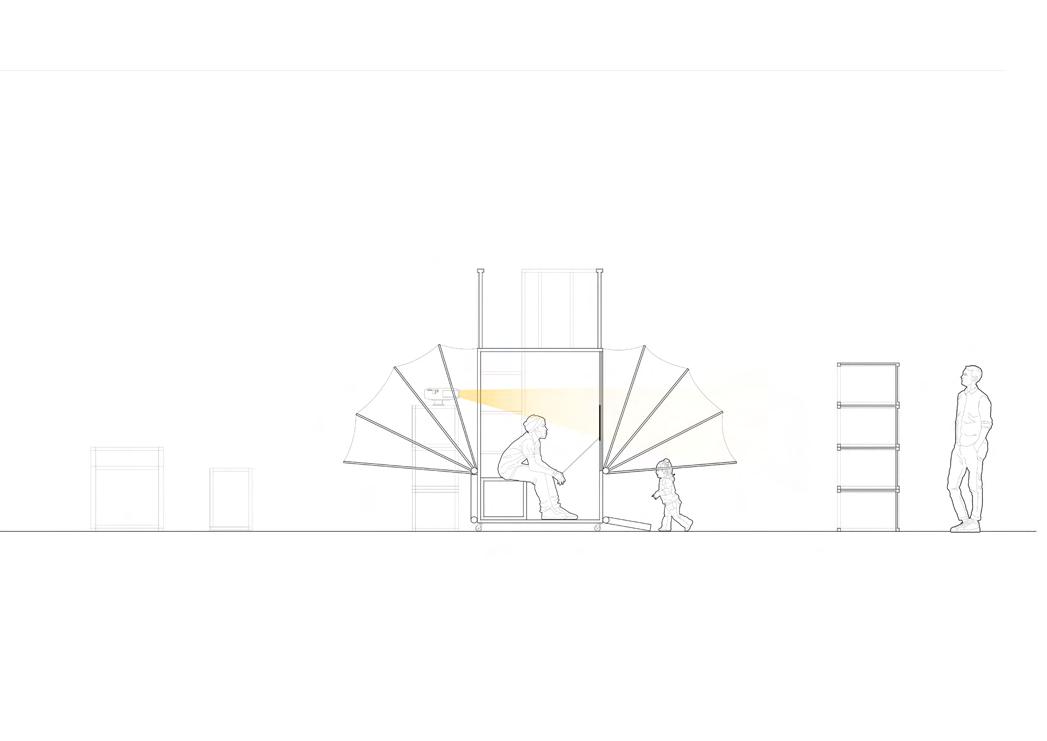

My final year warmup project is to create a civic stall for the Chapel Market, islington. The project aim is to address social interaction with the aim of making the street more inclusive. According to my research, Chapel Market acts as a community space for the local people to gather during the day. However, the market has no public seating area for the market users and visitors.

Moreover, Islington is one of the top 10 most dangerous boroughs in London. More importantly, most of the crime is related to youth crime and anti-social behaviours. On the Chapel Market, the crime rate is gradually higher on the East end compare to the West end. This this because the West end is closer to the local police station, but the East end is close to all the trasportations such as Bus stops and Underground station.

Therefore, I designed a Roaming Kiosk for the users. During the day, it is an Urban Furniture for the street and at night it is a roaming theatre with a pop-up stage on the top of the structure. This aims to reduce the crime rate at night, and at the same time to activate the street for night activities after the markets are left.

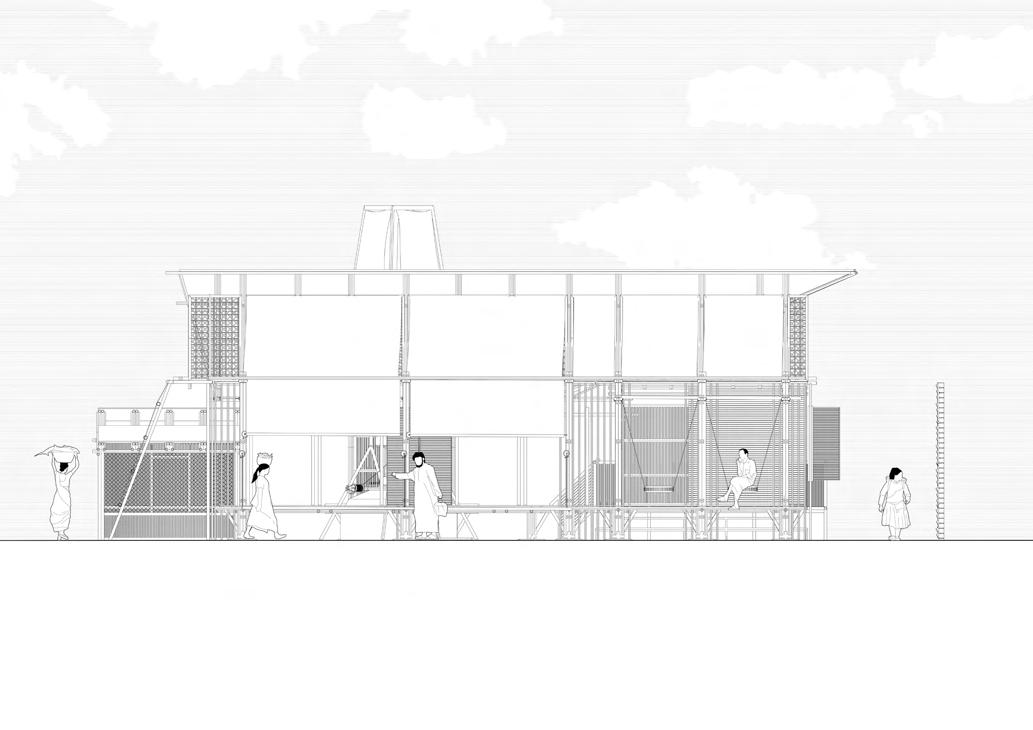

Chapel Market North Street Elevation

Chapel Market North Street Elevation

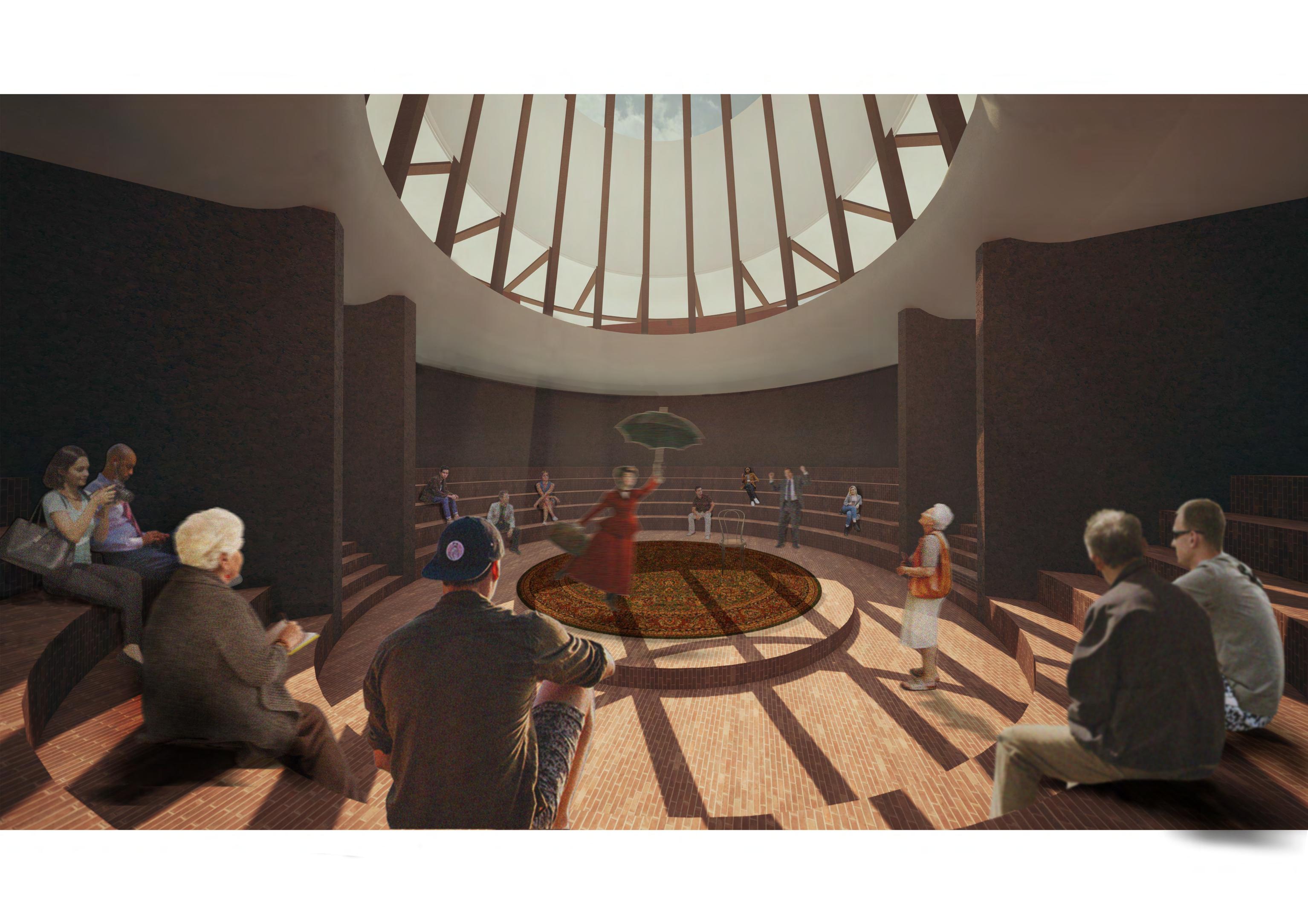

My final year project is located in ANGEL, ISLINGTON. It was a home for many creative theatrical performers, which has been a big part of the local heritage for such a period of time. Moreover, it also became a type of local identity in recent years, However, along with the city developments and local economy development, this magnificiant part of local identity seems lost by new generations. Also, due to the fire, most of the historical theatres are demolished.

The site is right next to the Chapel Market, which is the local traditional street market. However, the mobility of the area is quite unfriendly to older people, however, the old people do make up 9.4% of the local population, therefore, this makes them isolated from the existing society.

Over the past few decades, the increasing number of older people suffering from mental illness, the incidence of dementia and the large number of young people suffering from depression have been a major concern for society.

The proposal aims to generate a mobility hub for the society, it contains intergenerational programs, during the daytime, it is a civic centre providing youth care facilities and elderly care. It aims to bring both generations together to make one inclusive community. it also focuses on boosting the local heritage by creating performance programs including recreational theatre, rehearsal studio and puppetry theatre shows to engage the interaction between elderly and youth.

- Section CC cuts through the civic cafe and the recreational theatre.

- Experience with different casting materials such as

- The space encourages interaction through its structural design, it gathers the most amount of daylight during the day, while other parts of the building plays with shadow and patterns, this space is meant for people to take a breathe and release their mental str ess.

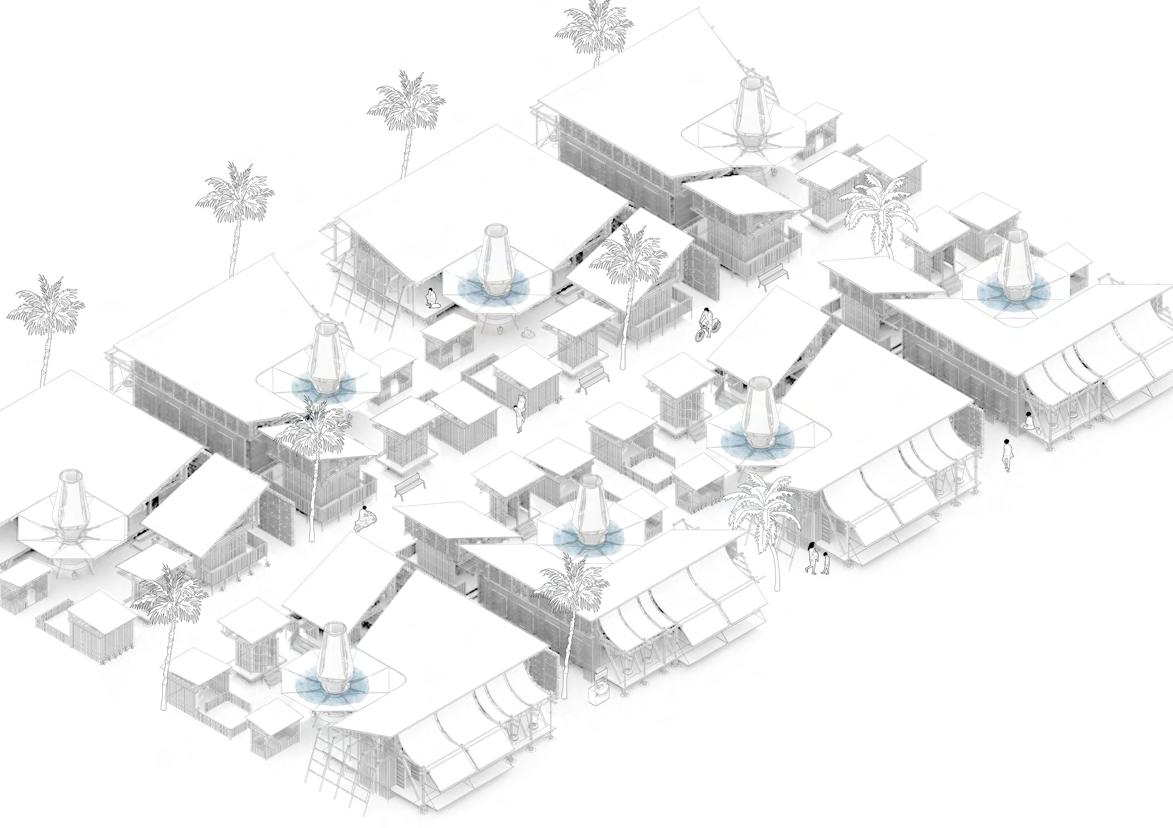

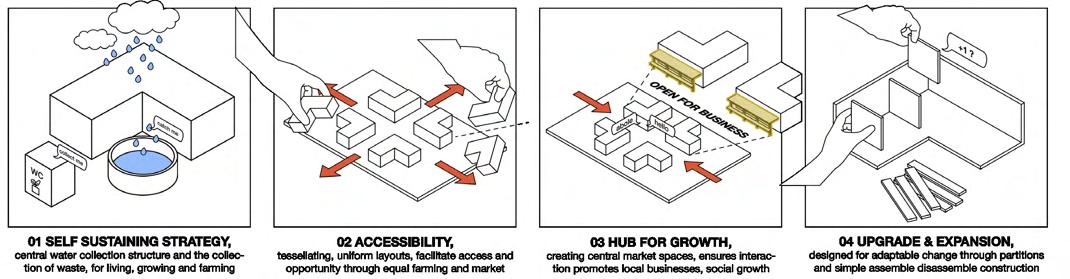

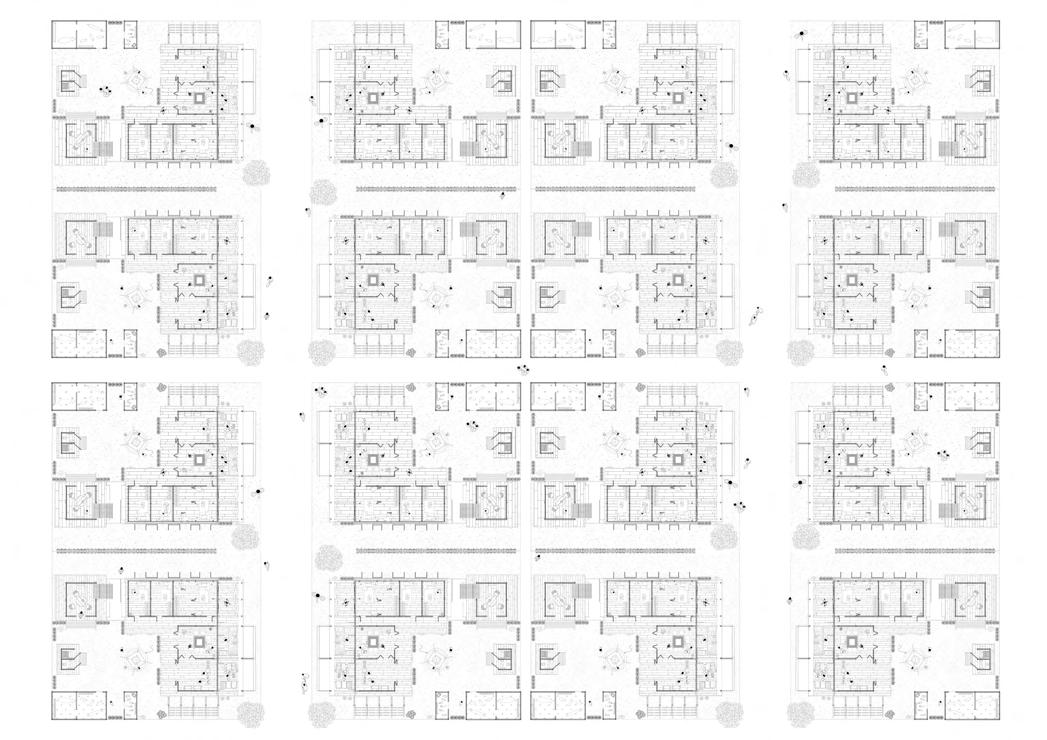

In an ever-changing world where emergencies and crises frequently displace communities, the importance of providing rapid accommodation that not only provides shelter but also feels like home must be highlighted.

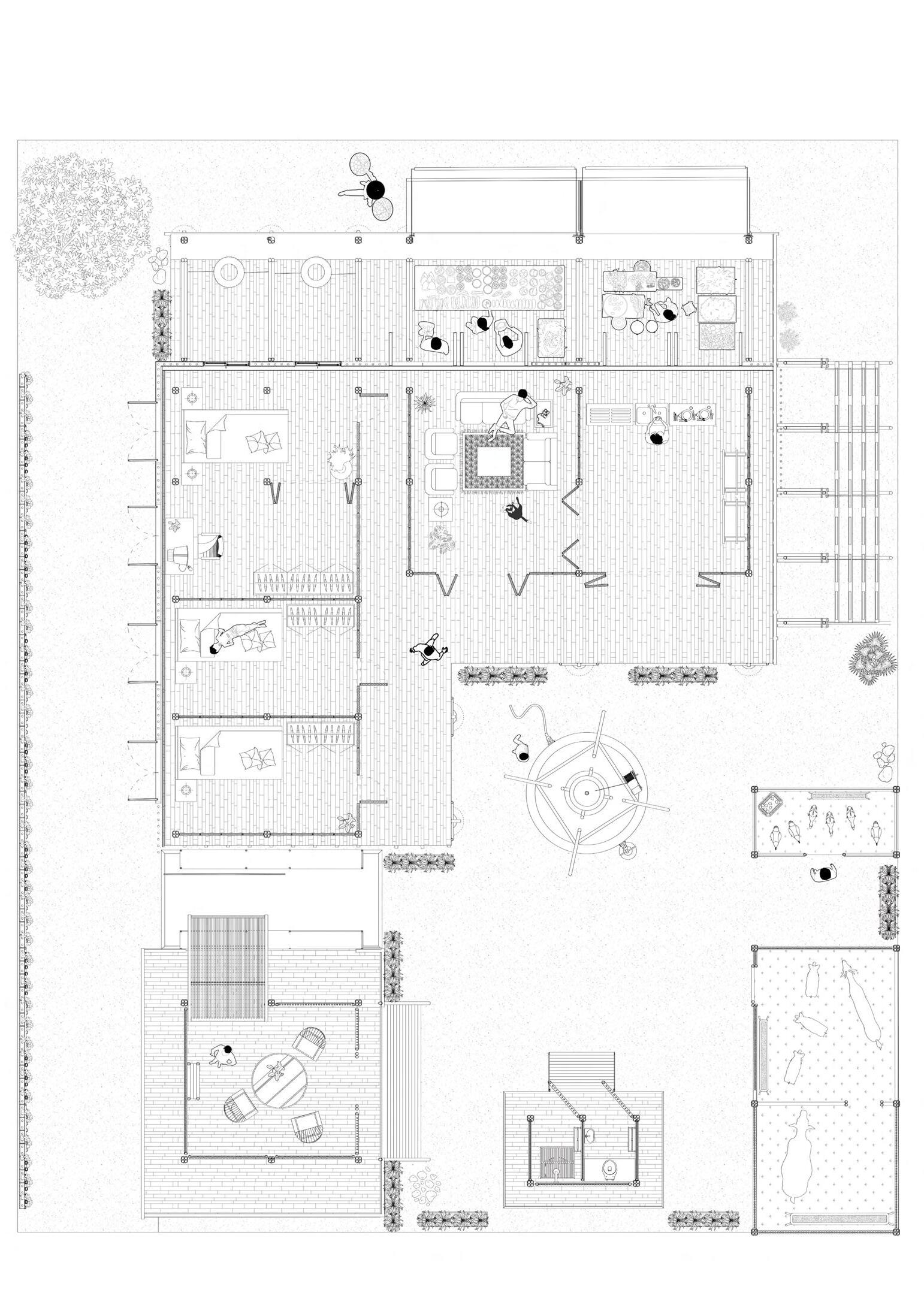

This fuelled our project to become one that goes beyond temporary relief, instead laying the foundation for enduring new families and communities. We recognise the potential for these emergency shelters to evolve into thriving villages and dynamic developing areas filled with opportunities.Central to our approach is the utilisation of locally accessible materials such as bamboo, and adobe, fostering efficiency and reducing environmental impact.

The design weaves together public spaces such as markets, communal areas for water collection and cooking, and private spaces for living. The aim is to create a community that can grow and adapt over time.

To achieve this, flexibility and adaptability are integrated into the very fabric of the structures. Easily changeable divisions and joinery enable simple assembly and disassembly, ensuring that structures can expand, or contract as needed. Our common gathering spaces, stimulate connection and a sense of belonging. The central water collection area and Majalisa space may be connected to the core module to create a shaded open space that encourages community involvement. Ultimately, this project not only offers immediate relief but also nurtures the potential for lasting transformation.

-The front elevation of each household is a convertible structure that allows the family members to have a little market stall area facing the main street. With all the households together, the market stalls slowly form a market street for the locals. This could form a local identity as well as bringing health and wealth to the society.

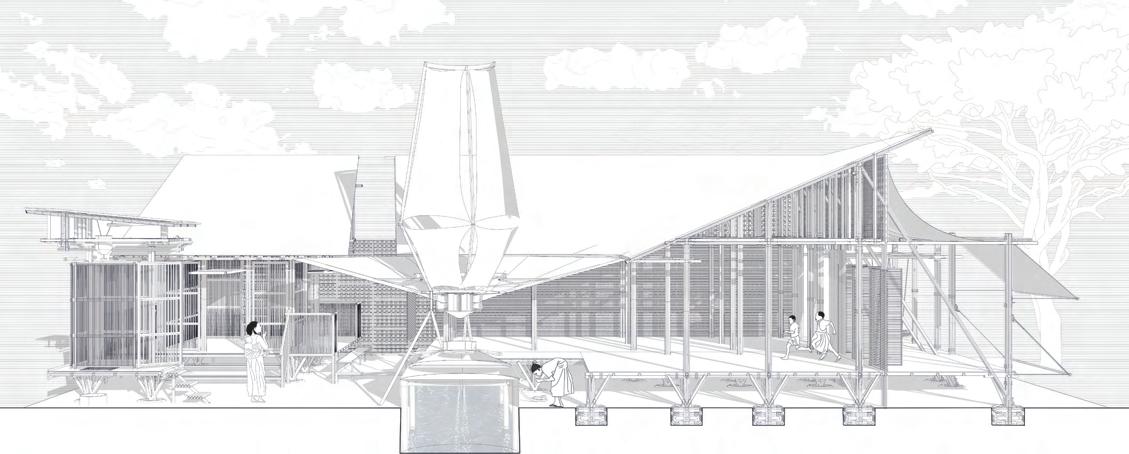

- Elevation through the villagers living area including livestock and water collection.

-Elevation through the individual household’s front, it is used as a market space for common growth.

-Section cuts through the water collection system and the waste collection from the toilets.

-Section cuts through people’s living space showing the relationship between cooking area and the growing spaces.

-The central water collection structure collects rain wawter also filters water through fog meshers. Each household has its own waster collecting toilet systems underneath the structure that combines with the waste from the livestocks can be then used as fertilis ers to farming and growing.

Guryong Village in Seoul, South Korea, symbolises resilience amid land ownership disputes and government challenges. This project explores the community’s spatial dynamics, focusing on care architectures and the waste economy. Recognising residents’ self-sufficiency and amid ongoing debates, we highlight the proactive role of the elderly in leading the waste transformation economy.

Our goal is to propose an infrastructural framework supporting and normalising collections, and improving accessibility. This project aims to deepen understanding of selfcreated spaces and communities. Embracing sustainability, our proposed infrastructures use locally sourced materials, aligning with the green belt policy to prevent urban sprawl. Ultimately, we strive to empower Guryong Village, contributing to a sustainable, locally rooted model that harmonises with broader city planning goals.

To uplift Guryong Village, we implemented various elements to enrich community life. Local markets were introduced to stimulate economic activity and foster local interdependence, providing a platform for residents to exchange goods and services. Emphasising sustainability, community farming initiatives were also integrated, encouraging residents to participate in shared agricultural practices that not only promoted self-sufficiency but also strengthened communal bonds. Additionally, outdoor exercise spots were placed to cultivate an active lifestyle and create communal hubs for spontaneous interactions among residents. The introduction of restaurants also serve as a communal gathering space, contributing to the social fabric of the village. A recycling station reinforces a collective commitment to responsible waste management. These integrated elements aimed to create a vibrant, holistic living environment, empowering Guryong Village residents and fostering resilience, interconnectedness, and a deep sense of community belonging.

The Guryoung Village redevelopment aims to combine detached housing and apartment typologies, creating a hybridization that actively combats loneliness. Upon assessing the existing housing conditions on the site, it became evident that most structures were in a state reminiscent of slums, posing safety concerns for residents.

Whilst designing, a distinctive feature was introduced: a wooden deck, enveloping each building. The design opens the living room in all directions onto the deck, thereby creating an interstitial gathering space within each unit. This layout fosters meaningful interactions between residents. Furthermore, the incorporation of two diagonal cores within each unit, both balances internal life and addresses safety concern. This approach promotes a dynamic and engaging living environment for the residents of Guryoung Village.

On the aspect of environmental benefit, growing sweet corn could reduce the nitrate nitrogen content in soil profiles efficiently,especially could decrease shallow nitrate nitrogen content,especially for the nitrate nitrogen content in the soil surface(0-20 cm) were declined the most obviously.

It is a versatile food, as the entire plant can be used. The husks can be used to make tamales, silk to create medicinal tea, kernels for food, and stalks for livestock feed. Corn is used to make tortillas, tortilla chips, polenta, cornmeal, corn oil and more.

Generally, it takes two to three months from sowing seeds to picking ripe sweet corn. The exact amount of time depends on the variety. Usually, the number of days from sowing to harvest will be noted on the seed packet.

Corn is rich in vitamin C, an antioxidant that helps protect your cells from damage and wards off diseases like cancer and heart disease.

Corn is a carbon sink, says South Dakota scientists. Per acre, every acre of corn absorbs 8 tons of carbon dioxide.

Corn has relatively low water footprint as well. It takes 1,222 liters of water to produce 1 kilogram or 2.2 pounds of corn / 146 gallons of water to produce 1 kilogram or 2.2 pounds of corn.

and called corn packaging

alginate, the plasticizer to could wasts, too. material complicated, performance ingredients, methods ( different find according to too if heat, while into this the more final on a paper finish Hair expose the soild. of it

BIOPLASTIC COMPOSITION

BIOPOLYMER(S)

(Natural and Synthetic)

Polymers are used to increase the stiffness an strength of plastic products, and Biopolymers are used in the creation of bioplastics, which unlike their purely synthetic counterparts, biodegrade in a short amount of time. Traditional plastics can take thousands of years to break down.

Plasticizers are generally nonvolatile, high boiling, low molecular weight compounds added to a polymer to improve its processability, flexibility, and stretchability by modifying the mechanical properties making the films more ductile, lowering the melt viscosity and the Tg of the product without altering the fundamental chemical character of the plasticized material.

ADDITIVE(S)

Bioplastic with additives has better tensile strength and long biodegradability than that with silica solution.

EXAMPLES EXAMPLES EXAMPLES

( Starch, Agar Agar, Chitin, Cellulose, Gelatin, Alginate, Algae, Protein )

( Sorbitol, Xylitol, Glycerol, Vegetable oil )

( Spirulina, Vinegar, Fibers, Kelp Power )

Biopolymer: - Corn Starch

Mixer: -Water

Plasticizer: - Vegetable glycerine

-Vinegar

-Chitin Power

Additives: -Hemp Fibres

-Egg Shells (Powder)

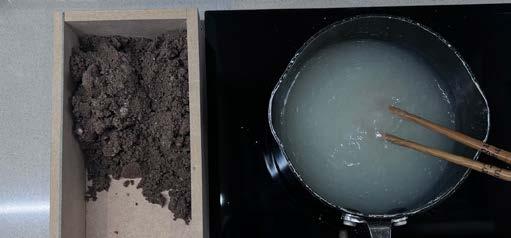

1. Measure biopolymer powders and water seperatly according to the water to biopolymer ratio (Additives could be added too if required).

2. Put the measured water to boil in a hot pan under medium heat, and then add biopolymers (and additives if there is any) while stiring constantly until the material is completely dissolved into a homogeneous solution.

3. Add plasticizer to the hot pan with the mixed material, in this research, will be using vegetable based glycerine for the plasticizer. Keep mixing and stiring, the more cooking the more water is evaporated which helps the shrinkage of the final outcome.

4. Roughly 6 minutes of cooking, pour the mixure out on a unsticking surface In this research silicone mold, foil paper and baking paper).

5. There are several drying methods to use to create the final finish of your bioplastic: Oven dry at 50 degrees for 2 hours/ Hair dryer drying until the mixure become soild/ air dry by expose the mixure under the sun for approximately 8 days for it to get soild.

6. Document the final outcome and seer the performance of it (Shrinkage, waterpooring, compression and tension tests).

Main Ingredients:

-Water

-Cornstarch

-Glycerine

Additional; ingredients:

-Dehydrated black tea leaves, and also tea bags leaves

-Vinegar

-Food colouring: freshly made black tea

Characteristics of substance:

Generally the colour of the outcome tends to be transparent, however, the longer it is cooked in the oven, the more yellowish the outcome will be. The material tends to shrink, and it is easy to cut just by cutting knifes. It depends on the ratio of the ingredients, that can change the characteristics of the material easily. The tea leaves both from the tea bags and fresh tea can relatively reduce the amount of shrinkage on the material.

Main Ingredients:

-Water

-Cornstarch -Glycerine

Additional; ingredients:

-Chitin powder

-Vinegar

-Food colouring

-CMC (Carboxymethyl cellulose or cellulose gum)

Characteristics of substance:

The material that has CMC powder involved will be shown has transparent, and it tends to be more flexible and elastic, the ones that has the ingredient of chitin powder involved will be shown as in yellow. It tends to be less elastic but stiffer and more brittle.

Main Ingredients:

-Water

-Cornstarch -Glycerine

Additional; ingredients:

-Dehydrated Food wasts such as: grounded coffee, egg shells, and orange peels

-Vinegar

-Food colourings and coffee drops

Characteristics of substance:

Generally speaking, the ones that are made from food wastes are the prettiest. The samples that contain grounded coffee will look darker and with the grounded coffee on the surface of the material, it tends to be less elastic and less brittle, it feels like card paper. The ones with egg shells will also end up with shells on the surface of the material, it is more flexible and also stiffer. Orange peels make the material very brittle.

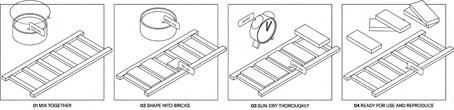

In this section, I will be testing out my last experiment and to answer my last question, which is whether bioplastic can be a replacement for cement in the process of concreting.

After all the samples of biopalstic that I made, I have realized and understood much more about the property and characteristics about the material, in this case, I want to try to mix aggregates with boiled bioplastic instead of water and cement. In order to start the test, I had to order a large bag of 25kg mixed aggregates online, and then I boiled my biopalstic with the ingredient of water (200ml), cornstarch (5tsp), Vinegar (20ml), and glycerine (20ml). Then I mixed it with aggregate mix and set in a mold to cook in the oven for 5 hours at 60 degrees celsius. Eventually it ended up like a jelly, and with big chunks of bioplastic in it. I assumed this was the reason of not mixing the bioplastic and aggregates properly, but also perhaps I have used too much glycerine which made the biopalstic too jelly-ish with crackings all through the material. This is the other word will reduce the stiffness and strength of the concrete brick. In this case, have learned to change the ingredient of bioplastic a little bit, so that it can probably have the opportunity to mix the aggregates and join with the rest of the material better.

In my second experiment, have tried to add 3 tsp of pure cornstarch to mix with the aggregates mix first. The mixture will start to turn much thicker and stiff ( Like clay). After this step I gradually added my bioplastic with water (200ml), cornstarch (5tsp), vinegar (!0ml), and glycerine (5ml). With this ingredient the bioplastic turned out less sticky and jelly-ish, but more liquid. This means that I can properly mix it with the aggregatex mix and without it being too sponge like.

Eventually, I added the biopalstic into the aggregate mixa and mixed it really well for 20 minutes. Then I put it into the oven to bake for 5 hours at 60 degrees celsius, and the outcome was surprisingly good. As I predicted, the brick is much more solid than the task 1, there is not jelly chunks or either crackings throughout the brick, It would be picked up just like the normal brick and it has the look and the property of the normal bricks too.

Eventually, moved on to conpression test, in this case, the test was done at home so used my own body wieight on it by standing on top of it. and it did not brick surprisingly. It still needs further texting, but as an initial approach, the coRncrete brick has turned out quite nicely, and I believe with further texting of different ingredient of biopalstic, that could affect the property of the coRncrete brick as well. With further experiement, the coRncrete brick could be used in the future construction induestry.

In conclusion, after all the tests and experiments that have done with bioplastic, believe it has the possibility of being used in the future construction industry. Of course the property of bioplastic depends on many things especially the ratio between the Biopolymer, Plasticizer, and Additives. After my experiment, I realized that to make the material change in its property also depends on the cooking time, with more glycerine based ingredients, the longer the cooking time, the less sitcky the material is going to be. However, with more vinegar based ingredients, the longer the cooking time, the more brittle the outcome will be. This means that the material is hard and sharp, also easy to break. The coRncrete brick is possible to be used in the future industry as well, however, instead of facading material, it might still needs futher testing for it to be proved for structural elements.