2021 E1

Since 1911

Corporate Headquarters

830 Phillips Road Victor, NY 14564 585.924.2176

Albany

2360 Maxon Road Ext. Schenectady, NY 12308 518.346.0077

Buffalo

20 Lancaster Parkway Lancaster, NY 14086 716.675.9010

Rochester

Power Group 390 Systems Road Rochester, NY 14623 585.424.3472

Construction Services 400 Systems Road Rochester, NY 14623 585.869.4630

Syracuse

Hancock Airpark 7001 Performance Drive N. Syracuse, NY 13212 315.437.1453

Construction Services

- Building Information Modeling - Prefabrication - Design Build

Service and Maintenance

Security Integration

Victor/Rochester brian.rittenhouse@oconnellelectric.com Buffalo brad.keatley@oconnellelectric.com Syracuse donald.coon@oconnellelectric.com Albany tom.sauer@oconnellelectric.com

Victor/Rochester andrew.dohse@oconnellelectric.com Syracuse david.coon@oconnellelectric.com

Victor/Albany/Buffalo/Rochester rob.unger@oconnellelectric.com Syracuse joseph.duh@oconnellelectric.com

Power Group michael.parkes@oconnellelectric.com

Commercial Solar lane.young@oconnellelectric.com

Large Wind Projects tim.ehmann@oconnellelectric.com

Communications -

Albany tom.sauer@oconnellelectric.com Victor/Buffalo rob.unger@oconnellelectric.com Syracuse joseph.duh@oconnellelectric.com

Victor/Albany/Buffalo/Syracuse joe.leggo@oconnellelectric.com

Victor/Rochester craig.ramsdell@oconnellelectric.com Syracuse donald.coon@oconnellelectric.com Natural

Temperature Control

joel.clester@oconnellelectric.com

2

BuALBANY, NY BuSYRACUSE, NY BuROCHESTER, NY BuBUFFALO, NY BuVICTOR, NY Bu

Our strength as a full service electrical contractor is rooted in the diversity of our services

Solar

Renewable Energy -

- Wind

Preventative Maintenance - Testing and Commissioning

Tele Data - Fiber Optic - Data Centers

Technical Services -

Gas

Transportation - Airport - Bridge - Highway richard.maher@oconnellelectric.com www.oconnellelectric.com

A LU1249 crew transferring distribution underbuild on a large sub-transmission project in Plattsburgh, NY. We are nearing completion of the four-circuit, 42-mile re-build that has taken over 24 months and 70,000 manhours.

This newsletter is a publication of O’Connell Electric Company, Inc. For comments, inquiries, or to be added to our mailing list, email john.miller@oconnellelectric.com

What a year 2020 has been.... Unlike any year we have seen in our lifetime. It was a year of resiliency - full of new rules, a tremendous amount of obstacles and hurdles, and plenty of fears and concerns that we all saw and continue to experience. We know we are not out of the woods yet, but hopefully there is an end in sight as we all learn to navigate the new normal together.

Despite all that 2020 threw at us, O’Connell has remained strong thanks to all of our employees and all of the efforts that each of you put into keeping this company moving forward.

I’m very proud and hopefully you will be to as you look through this newsletter at some of the work we are currently and have recently been involved in that is going to help bring an end to this pandemic. I cannot express enough the importance of the work that each and every one of you does every day. When you sit back and look, you realize that every job we do does make a difference. Often it can be small but sometimes it’s life changing.

We have our fiscal year ending in a few weeks, where total sales are expected to be somewhere around 325 million and with north of 800 employees on the payroll. We also wrapped up 2020 with some great safety statistics. Thank you all for your commitment to safety, please make sure it is always your top priority.

We especially take pride in all of our customer relationships and just want to take this opportunity to thank them all. This year our customers have worked with us, and we in turn have worked to keep their projects safe, on schedule and productive.

Looking ahead to 2021 we are hopeful for a quieter but exciting year filled with many opportunities. We know there is a lot of uncertainty out there, but we promise to remain committed in keeping our employees working, delivering safe and quality work to our customers. We are hopeful that, in the not to distant future, we will have time to celebrate the growth of the company and all of the hard work put forth by the entire O’Connell Electric Team.

Thank you again for all you do for us. Be your brother’s keeper and please work safely at work and at home.

Stay healthy,

3

COO A MESSAGE FROM 4 Company Rankings 5 Safety Moment and Shoutouts 6 OCE Field Safety Committee Erie County DOH Headquarters 7 MVHS Regional Medical Center Amazon Distribution Updates 8 Thermo Fisher 9 Tessy Plastics 10 OGS State Campus Substation Substation 418 11 Construction Services - PreFab OCE Holiday Recap 12 Golf Tournament Thank You 13 OCE Succession Announcement 14 Employee News Submit your photos & news to be shared on our social media sites.

Tom Parkes President and

ON THE COVER

This Issue

Follow us online

REGIONAL AND NATIONAL RANKINGS

It is an honor to be recognized as the 29th largest Electrical Contractor in the United States.

It's obvious that hard work and dedication pay off, especially for our customers.

markets in memindustry like a confusion. During design fi rms, contractors to manage subcontractors problem was supervisors were protected while be seen in Specialty Congenerated rev11.9% over Top 600 had for the past had risen began in 2011. growth to a wonder how already in O’Connell February, understanding of and dusted

“In February, we dug out and dusted off our uniform Pandemic Response Plan, and began to update it with current names, locations and actions we would take in the event that there became a need.”

Victor E. Salerno, CEO, O’Connell Electric Co.

off our uniform Pandemic Response Plan, and began to update it with current names, locations and actions we would take in the event that there became a need,” says Victor E. Salerno, CEO. He notes that the initial eight-page plan now has grown into a 69-page document that has become all-inclusive and dynamic.

Another fi rm that was quick off the mark was Menard Group USA. Owned by French contractor Vinci, it was receiving intelligence on the impact of the virus ahead of the directives in the U.S. “In midMarch we took an immediate stop on all of our active sites across the country for about two weeks to retool our fi eld activities, procure PPE [personal protective equipment], train our site crews, write and issue new standard operating procedures and fully reinforce the behaviors necessary to protect field staff and their families,” says Seth Pearlman, Menard’s CEO. “This was a difficult and costly decision, and it was ultimately respected by the bulk of our staff and clients.”

ENR's Top 600 Specialty Contractors is a comprehensive package of data and analysis. It contains the rankings by revenue of the 600 largest specialty contractors in the U.S. For 2020, O'Connell made a significant jump in the rankings for top electrical contractors, landing at 29, up eleven spots from 2019.

C3M Power Systems LLC also reacted quickly, taking multiple key team members out of operations to focus on COVID-19. “Although it was a sacrifice, we felt it was a necessity and their central effort benefited our entire team. They developed new processes, procedures, PPE and roles to keep our jobsites, of-

2020

Pretty impressive! We're currently ranked 24 among Rochester's fastest growing, privately held companies.

Congratulations! We're ranked #2 in Central New York for Commercial Builders.

SAFETY SHOUTOUTS

On January 11, 2021 an employee of a glass installation contractor suffered serious injuries from a fall that occurred at a job site in Syracuse. O’Connell Electric has been working at the Schine Student Center to upgrade the facility at Syracuse University for the past 14 months. The project has seen many changes over time and is approaching completion. Up to this date, there had been no major incidents or injuries on the project. The injured employee was ascending a fixed ladder to access a roof hatch. As our crews were working in the stairwell, they heard the crashing sound of the worker falling. He fell past our Foreman, Jason Jones, who was standing on a stairwell landing, after striking a handrail and a stack of drywall. The employee fell another 15 feet before becoming entangled in the stairwell handrail, unconscious and hanging upside down by his leg. He landed several feet from Ed Rowe, a LU 43 Apprentice.

O’Connell employee Eric Evans was first to respond to the injured employee. He and Ed Rowe, along with the help of another contractor, safely pulled the employee from the handrail and carried him to a landing to begin care. Jason Jones called 911, provided directions to the site and critical details of the victim's condition to the dispatcher. Ed Rowe quickly went to the entrance of the building to escort emergency responders to the scene while several OCE employees cleared a path for the reponse team to access the victim. The worker is recovering from significant injuries, but is lucky to have survived a 28 foot fall.

We are honored to recognize the quick response of our employees, Jason Jones, Ed Rowe, and Eric Evans who immediately put their training to use and assisted in offering care to an injured worker.

The crew gave credit to the Tailboard process, which reminds employees daily of the site address and emergency response procedures in place to offer immediate assistance in the event it is needed.

Thank you again to Jason, Ed, and Eric, as well as the entire crew at Schine Student Center for making a true difference and assisting in saving a life that day.

Submitted by Matt Yonts, Senior Safety Supervisor

4

The Top 600 Specialty Contractors’ New Contracts 2019 2020 (Measured in $ millions) $100,847.8 $111,757.1 Loss in profits Gain in profits (Measured in firms reporting) 19,357.04 Glazing & Curtain Wall $2,329.34 1.5% Roofing $2,522.89 1.7% Demolition 2,020.23 1.3% Concrete $10,041.81 6.6% Wall & Ceiling $5,700.97 3.8% Fire Protection $2,396.69 1.6%

10/13/20

5:17 PM

OCE SAFETY MOMENT

FROM DAN OBERLIES - DIRECTOR OF SAFETY & RISK MANAGEMENT

2020 was a year to remember for many reasons. We're proud of the work our safety team puts into ensuring the health and wellness for all of our employees, especially as we ride out this COVID-19 pandemic. Listed below are some highlights from the previous year that reflect our strong and ever-growing safety culture. Great work, team!

AWARENESS TRAINING AND STAND

High Voltage Safety Awareness Training

Electrical Hazard Awareness Training Active Shooter Office Training Fall Protection Stand Down

COVID-19 RESPONSE

DOWNS

Emergency Response Bag use Training

Developed Power Group Line Skills Awareness Training Program Subcontractor On-Site Safety Orientation

Developed the COVID-19 Uniform Response Plan

SAFETY TEAM ADDITIONS AND ACCOMPLISHMENTS

Restructured Safety Team

Hired Andrew Giordonello and Todd Forman

Revised & Recommitted Corporate Safety Committee Charter Weekly Coordination Calls for Safety Team

PROCESS AND PROCEDURE UPDATES

Improved toolbox talks with fleet material

Updated Switching, Rigging and Lifting Plan

Developed Standard Operating Procedures for the Power Group Enhanced vehicle reflective markings and strobe light packages

Procurement/distribution of all necessary COVID-19 PPE and cleaning supplies

Credentials earned by Safety Team members

Low Voltage Safety Subcommittee Safety Awards & Recognition

Conducted Safety Perception Survey

Updated the 2021 Health and Safety Manual Safety Audit on DoForms with major revisions Technical Services – Squirt Bucket Use Policy

"Mike and Gary did a fantastic job on the work while performing the job safely. In the two years I have been working with contractors, they were hands down the safest and best contractors I have had. I know people normally only ever email you when things are bad, but I believe positive reinforcement of these guys doing a great job goes a long way as well. Please thank them for me for being great contractors on our site at USG."

Maci Gauthreaux, Project Engineer – United States Gypsum Company

This is exactly the kind of culture we are trying to build and it was so refreshing with everything else going on to see this.

Submitted by Brad Keatley, GM – Buffalo Office, Steve LaJoie, Project Manager, and Brian Chamberlain, Safety Coordinator

Roy Schumacher, General Foreman, LU 86, and his team have faced many challenges while working on the Erie Canal lift bridge renovations across Western NY. The challenges have ranged from aerial lift work over the canal and at times on barges in the canal; intricate pipe runs due to the moving components of the bridges; very small job sites with many other trades present performing high risk work such as sandblasting, crane picks, and extensive rigging. Imagine all of this occurring while working over water. The projects' long duration has spanned all four seasons, exposing the crews to many different weather conditions. Roy continues to keep safety at the forefront by planning ahead for fall protection, hearing protection, electrical safety, and the safety of other trades.

Submitted by Brian Chamberlain, Safety Coordinator

5

2021 Field Safety Committee

O'Connell's Field Safety Committee was chartered in 2014 after it was determined that leadership and input directly from our employees in the field could have a significant impact on developing our safety culture.

The committee is comprised of representation from every field division as well as at least one person from each office or geographic location.

Members meet every month to discuss a range of topics relating to tools and equipment, safety procedures, industry "hot topics", and provide valuable input from the field that helps shape O'Connell's safety culture.

Interested in learning more or have any comments and/ or suggestions? Reach out to one of our Field Safety Committee Members at anytime.

OCE FIELD Safety Committee members

Jeff Harter, TEGG/Chairman - 585.350.8165

Jason Stanley, Power Group/Co-Chairman - 585.474.9984

Mark Valerio, Power Group/Secretary - 585.613.2354

Pat Arnold, Albany Office - 518.265.7754

Jon Olszowy, Albany Office - 518.708.7927

Nick Garnier, Victor Construction - 585.301.5722

Doug Carpino, Victor Service - 585.943.1483

Scott Rohr, Power Group - 585.208.9179

Will Sandvik, Victor Communications - 585.415.3090

Tom Stewart, Power Group - 585.236.0980

Scott Guerra, Buffalo Office - 716.985.0031

Scott Moran, 390 Systems Rd. Warehouse - 585.313.3247

Gary Means, 400 Systems Rd. Warehouse - 585.303.1795

Jason Jones, Syracuse Construction - 315.263.2313

Paul Vaughan, TEGG - 585.236.7986

James VanCamp, Syracuse Warehouse - 315.400.7659

Zach Presley, Albany Safety - 518.312.5481

Brian Chamberlain, Buffalo and Victor Safety - 716.364.6789

Matt Yonts, Syracuse Safety - 315.350.1716

Jeff Freund, TEGG Safety - 315.374.2530

Todd Forman, Syracuse Safety - 315.632.2817

Andrew Giordonello, Power Group Safety - 315.657.8354

Erie County Health Department's New Headquarters

One of the oldest structures in downtown Buffalo, the TICOR building is being re-purposed as a new headquarters and COVID call center for the Erie County Department of Health.

The building was originally a church and dates back to 1833, making it the oldest office building in the city of Buffalo. It will be renamed the Lincoln Building in honor of Abraham Lincoln, who once attended a service in it.

O’Connell was called to support renovations by upgrading the building's electrical infrastructure and installing equipment to provide state-of-the-art technology including high speed Internet.

When it is complete, the Health Department’s contact tracers, epidemiologists and COVID-19 hot line personnel will each have their own floors in the fourstory building.

DIVISION: Buffalo Construction, Temperature Controls, Communications

PROJECT MANAGERS: Steve LaJoie, Craig Ramsdell, Dave D'Ettorre

FOREMEN: David Gottler, LU 41, Peter Campanello, LU 41, Guenther Mundorff, LU 86

6

Our mission is to bring all employees together to achieve and maintain a safe, healthy workplace as we continue to shape the safety culture within our organization, families, and homes.

AMAZON UPDATE

In case you missed the incredible project OCE has been involved with since last year, the Amazon Fulfillment Center is a 4.2-million-square-foot structure on a portion of the 110acre Liverpool Public Golf and Country Club in Clay, NY.

This $350 million project is on schedule for being operational by the 2021 holiday season. When the fulfillment center is open, it will be one of the largest warehouses, by floor space, in the world.

To please the surrounding residents and town, the developer offered to improve several intersections around the property and agreed to the town's request to reconstruct one more.

As of January 2021, the five-story building is totally enclosed. Single story bump-outs for offices still needs to be decked-out while the roof is nearing complete closure. Total electrician count has reached 90 workers putting in a lot of effort with an extended first shift and Saturdays.

UTICA REGIONAL MEDICAL CENTER

The Mohawk Valley Health System is taking huge steps to improve the healthcare of Utica and its surrounding areas. A brand new regional medical center is being constructed in a downtown location in much need of change. The new medical center is expected to be 702,000-square-feet and ten stories high.

The hospital will be complete with 373 beds, an advanced emergency department with 47 treatment centers, imaging/ cardiology, fully integrative surgical suits, a birthing center and conference/meeting spaces.

The campus is designed as an urban park with enhanced lighting, gardens and sitting areas. The Mohawk Valley Health System believes that this new hospital will help revitalize the downtown area to become a vibrant destination point in the community.

DIVISION: Syracuse Construction PROJECT MANAGERS: Jeff Pratt, Sam Obermayer

FOREMAN: Tom Reap, LU 43

DIVISION: Syracuse Construction

Don Coon, Vice President, Syracuse Operations

SENIOR PROJECT MANAGER: Steven Briem

JUNIOR PROJECT MANAGER: Andrew Spring

FOREMEN: Andy Schaffner, LU 43, Jake Kelly, LU 43, Mike Halko, LU 43

SUPPORTING TEAMS: Construction Services Group, Technical Services Group

7

THERMO FISHER CLEAN ROOM COVID SUPPORT

Thermo Fisher Scientific, a leading global provider of scientific instrumentation, reagents and consumables as well as software and services to healthcare, life science, and other laboratories, is wrapping up a clean room expansion at its Rochester facility to support COVID-19 efforts.

The rapid increase in research and production related to COVID-19 testing, treatment, and vaccines has created historic demand for laboratory plastics including pipette tips, storage tubes and plates, transfer pipets and packaging vials and bottles, which is expected to continue for the next 18-24 months.

The expansion will be used to supply a variety of essential laboratory plastic components for not only the research and development of the vaccine, but also the manufacturing of those vaccines various components. The facility is also manufacturing the components for diagnostic testing kits.

O’Connell has been installing all of the necessary electrical infrastructure and upgrades to support the expansion. Crews have been working multiple shifts to help get the clean room running at full production as soon as possible.

DIVISION: Victor Service

PROJECT MANAGER: Andy Dohse, Bruce Vassallo

FOREMAN: John Schuster, LU 86

SUPPORTING TEAMS: Construction Services Tom Zielke, Rob Sampson

8

TESSY PLASTICS COVID SUPPORT

Tessy Plastics purchased its Auburn, NY facility in 2016 for warehousing with hopes to use the space for manufacturing in the future. COVID-19 increased the need for PPE which offered Tessy a crucial role in being part of the solution.

The pandemic gave the company an opportunity to create prototypes for various products relating to the testing and treatment of COVID-19; specifically face shields and test kits. In fifteen weeks, the facility was converted into two class-eight cleanrooms encompassing 135,000-square-feet of manufacturing space.

Turning the building into a corona virus test kit manufacturing facility so quickly seemed like an impossible task to most, but for Tessy, they were prepared and asked their suppliers to help pull off this project.

Tessy partnered with a global healthcare company to manufacture parts for a portable testing kit. The kit consists

of 20 components, requiring 50 molding machines along with several automation and assembly lines. These tests can deliver positive results in as quickly as five minutes and negative results in about thirteen minutes. One-sizefits-all shields are manufactured in a three-piece assembly consisting of a headband, visor and shield.

O'Connell's involvement started early, and very quickly. We provided all of the electrical infrastructure to support renovating the warehouse space. Three divisions collaborated with, at times, an electrician count over 70. We worked 24-hour days, seven days a week to help Tessy reach production goals.

9

DIVISION: Syracuse Construction, Technical Services Group, Power Group, Syracuse Communications PROJECT MANAGERS: Jeff Pratt, Tom Spicer, Doug Marolf, Jeff Merrell ENGINEERING: Jaime Rowley FOREMEN: Craig Schmidt, LU 43, Josh Shoff, LU 43, Dan Brooks, LU 1249

OGS State Campus Substation

The W. Averell Harriman State Office Building Campus is an office park in Albany that houses sixteen State Government office buildings. The land totals roughly 330 acres and over 3-million-square-feet of office space with about 7,000 state employees. The campus was built during the 1950s and 1960s, and with its own steam generation power plant for cooling and heating it is mostly self-sufficient.

Harnessing all of the power for the Campus, and nearby SUNY Albany, is a bulk transmission substation owned by the State consisting of four - 20MVA transformers. It is fed by two - 115,000 volt feeders that both service and feed through the substation. The substation’s primary purpose is to transform the 115 kV down to 13.2 kV and subsequently distribute power to all of the loads in the SUNY college campus as well as all of the buildings of the Harriman State Office Campus. As one can imagine there are many critical customers fed from this source including state police, a 911 center, the Department of Homeland Security, the Office of Taxation and Finance, and more.

O’Connell replaced three of the four transformers and made modifications to the fourth. We furnished and installed new switchgear, battery banks for the DC distribution, and SCADA equipment as well as all the additional items and equipment needed for a new switchgear building.

DIVISION: Victor Construction, Albany Construction, Power Group, Technical Services Group

PROJECT MANAGERS: Phil Yandow, Paul Galarneau, Chris Oberman, Rich Franco

COMMISSIONING/TESTING: John Sargent P.E.

FOREMAN: Nick Zeboris, LU 363

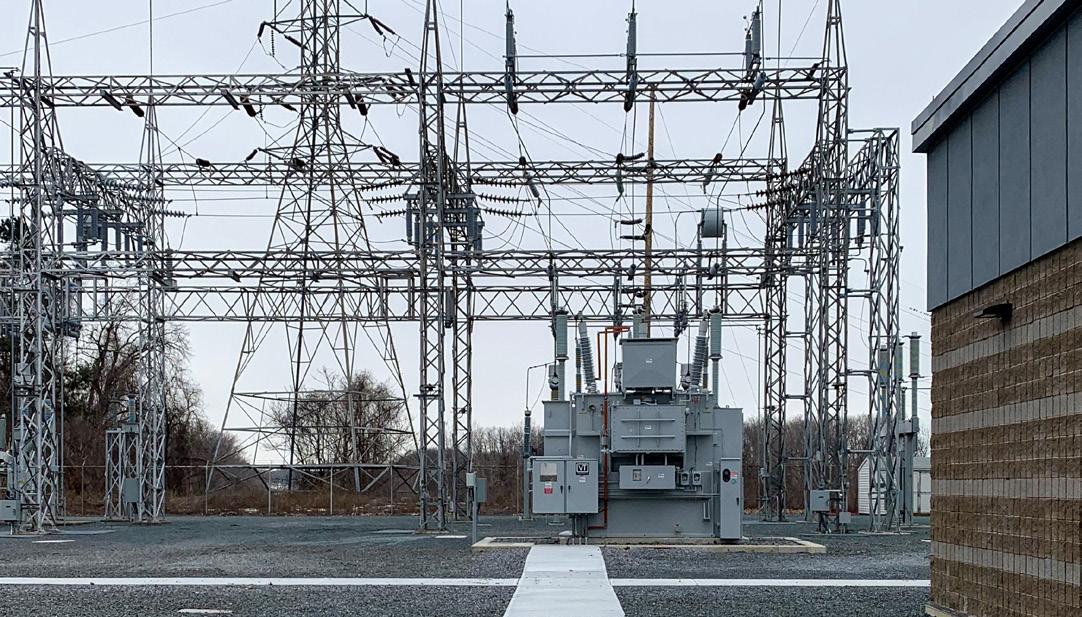

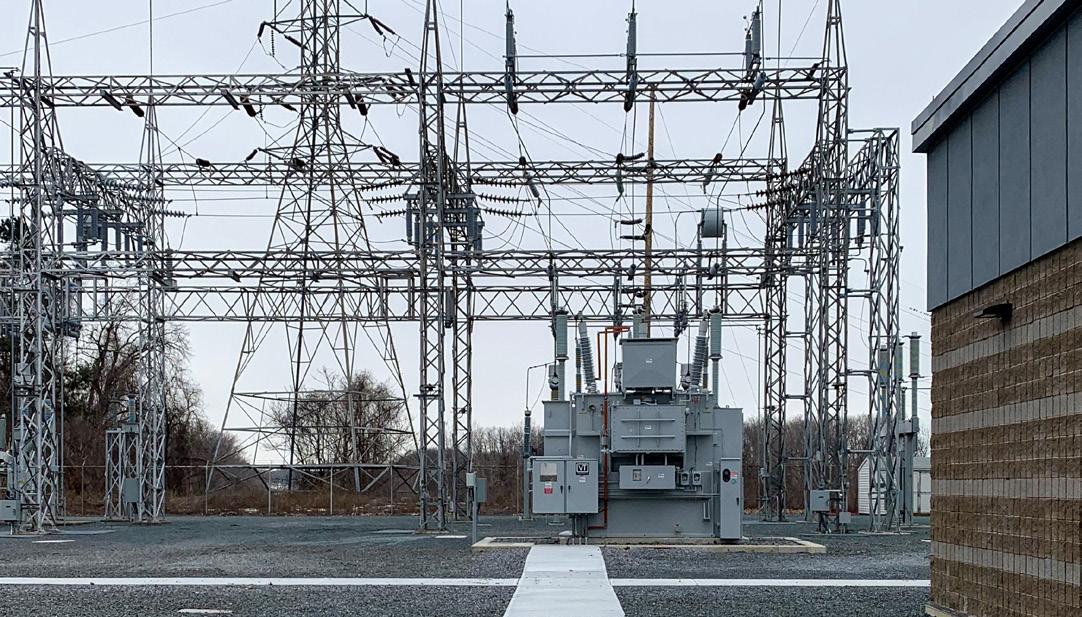

Station 418

RG&E, in conjunction with its parent company AVANGRID, is making a significant investment to upgrade the electricity transmission system in the Rochester region. This project, known as the Rochester Area Reliability Project (RARP), is located in the towns of Chili, Gates and Henrietta, and in the City of Rochester, and was developed to provide additional power to support growing demand, increase reliability, and accommodate economic development in the region.

Part of the scope of this larger project includes building a new 115 kV transmission line between station 255 in Rochester and station 418, which sits adjacent to the Rochester Technology Park in the Town of Gates. O’Connell was brought in to upgrade station 418 to accommodate the additional power demands.

The Project involves construction and improvements across several different types of terrain, from agricultural fields to cleared and maintained rural residential areas to urban land. Our crews installed two new 115 kV bays and upgraded two existing bays. We also handled installation of the new 115 kV circuit that was brought in from station 255, and installed a new control building with associated equipment.

DIVISION: Power Group

PROJECT MANAGER: Tom Sweeney

FOREMAN: Tim German, LU 86

10

From Prefab to the Field

Updates from our Construction Services Team

The Construction Services Team was asked to support the design and coordination for a conduit feeder installation for a 5,000-amp main switchgear along with all power distribution loads for the Thermal Fisher Clean Room project. Our Construction Services team started by modeling everything that had already been installed. Instead of waiting for measurements from the field, the design team visited the site and performed 3D scans for the project. Within a couple of hours, over 25 scans were taken containing over two million points of measurement each, that were reassembled into a working cloud model.

A total of 71 Spool Drawings were designed and fabricated for the installation of the complete power distribution system for this project. Twenty-seven conduits assembled into 71 different conduit racks resulting in close to 5,000 feet of conduit and 700 feet of channel.

Every section of the conduit system was fitted together prior to shipping to ensure a fast connection on site. The Construction Services team utilized EMT S.S. slip couplings, allowing the installer to match the ends of each rack section and avoid the sliding back and forth while trying to fit the conduits into each coupling. The use of this coupling allowed for a very cost-effective installation of the fabricated conduit racks.

All of us at O'Connell strongly feel that we have been blessed and are fortunate for the relationships we have with our vendors, customers, and communities we live and work in. Over the holiday season, we decided to share our good fortune in everyone's honor by making charitable donations to local organizations in the communities each of our offices are located.

School of the Holy Childhood Victor Farmington Food Cupboard

Rochester Area Buffalo Area Syracuse Area Albany Area

Central New York Food Bank McMahon-Ryan Child Advocacy Center

Family Promise of Western New York Habitat for Humanity

City Mission of Schenectady Regional Food Bank of Northeastern NY

11

Employees from our Rochester and Syracuse offices volunteered time and equipment to bring holiday cheer to local organizations.

CNY Hospice

Boys & Girls Club of Rochester

A heartfelt thank you!

For donating to the 25th Annual Charity Golf Tournament

Covid-19 and 2020 presented the world with unseen challenges and the inability of having our annual golf tournament. However, the care offered at the Mary Parkes Center for Asthma, Allergy and Pulmonary Care became even more essential to thousands of patients and their families. The heart of what makes The Mary Parkes Center for Asthma, Allergy and Pulmonary Care so inspiring is simple, yet profound. We have continued to be committed to one another, our patients and their families supporting the important priority of caring, protecting and advancing their health and well-being and community overall.

Despite the continued uncertainty and unpredictability today, here’s one thing we have shown “Alone we can do so little, together we can do so much” as Helen Keller said. “THANK YOU” cannot possibly express the level of our deep heartfelt gratitude to everyone for your support and generosity! Because of you, the Mary Parkes Center is stronger and we will continue to expand and offer the greatest chance, hope and promise for care to all of the patients and their families who enter our doors. We hope this note also finds you and your families, staying safe and healthy! We look forward to the time when we can all be together again. In the meantime, let’s take care of ourselves and each other.

AAC Contracting, Inc.

Admar Supply Company, Inc.

Altec Industries/Global Rental

A-Verdi LLC

BJ and Jodi Revill

Blue Collar Workwear

Brown & Brown of New York, Inc.

Burke Group, LLC

Colin Garwood

Congistics Corporation

Crosby-Brownlie, Inc.

Dale and Tracey Peters

Dale Carnegie

Dan and Denise Burns

Dominick Crisalli

Emerging Tel Corporation

Gottogo Electric

Graybar Electric

Green Mountain Electric Supply

H.C. Zang Agency, Inc.

Harmco Fastener

Harris Beach, PLLC

HasGo Power Equipment Sales, Inc.

IBEW Local Union 1249

Irby Utilities/Sonepar

JAGG Electrical & Control

Jeffrey and Susan Gould Joe Muscolino

John and Therese White Johnson Controls

Since 1911

- The Parkes Families

Joseph and Florence Pellerite

Kolvasky-Carr Electric Supply, Inc.

LeChase Construction and Affiliated Companies

Lee and Kristen Sampson/UBS Financial Servicess

M & T Charitable Foundation

Manning Squires Hennig Company, Inc.

Matthew Galphin and Ben Blaudschun/Connection, Inc.

Maureen Prince

Northeratern Line Contractors Chapter, Inc.

Pluta Family Foundation Power Sales Group

'

Raymond and Theresa Ross/ Horizon Solutions, Inc.

Robert and Deborah Gringeri

Robert and Phyllis Anderson

Robert and Carolyn Acquilano Ruth Wakeman

Sam & Son Company

Skyworks

The Bonadio Group

The Duke Company

The Parkes Families

Turtle & Hughes United Rentals

Upstate Roofing & Painting

Mary Parkes Center for Asthma, Allergy, and Pulmonary Care

A multi-disciplinary center serving adults and children

Mary Parkes is far more than the namesake of our Center; she is our daily inspiration. Though Mary suffered for many years with severe asthma, she was first and foremost, a nurse. As a critical care nurse at a local Rochester hospital, Mary was known for her unfailing optimism and perseverance. Mary understood the challenges of being a patient as she was hospitalized more than 50 times for her severe asthma. As a result, she carried a special understanding with her to every patient’s bedside. After a long struggle with the disease, Mary died at age 32 on April 2, 1991.

Soon after Mary’s passing, her parents, Walter and Carmina Parkes, siblings, family, friends, and physicians who cared for her, started a support group for individuals and their families struggling with asthma. This led to the building of the first Asthma Center in the area in Mary’s memory, which was a huge step toward eliminating the isolation many asthma patients felt as well as providing a Center of Excellence to those who need specialized asthma care.

The Center was a long time component of The Genesee Hospital, which closed in May of 2001. Today, the Mary Parkes Center is affiliated with UR Medicine and recently completed its third expansion in 2012, which continues to offer the greatest promise in preserving and building upon excellence in patient care, high technology, and enhancing research efforts.

12

Mary M. Parkes, RN

1958 - 1991

To our valued employees and customers,

As you know, we have been working toward a long-term company succession plan. In spring 2022, I will officially retire from my position as CEO, but will continue in the role as Co-Chairman of the Board of Directors thereafter. After a half-century serving O’Connell Electric Company, and the past 14 years as CEO and working closely with my mentor, Walter Parkes, it is with great pleasure, confidence and respect that the board of directors hand the reins to current President & COO Tom Parkes, my long-time colleague, friend and business partner, and soon-to-be successor.

A recently established team of vice presidents will assist Tom and the current executive team which includes our other longest-serving officer, Executive Vice President, Treasurer and HR Director Susan Parkes-McNally, as well as Executive Vice President of Operations Joe Pellerite and Chief Financial Officer Jeff Gould, to round out the company’s leadership. This team will position our 110-year-old company for continued success as one of the largest, highest-ranked and most successful electrical contractors in the country. These new Vice Presidents are (1) VP of Syracuse Operations Don Coon, (2) VP of Technical Services Group Joe Leggo, (3) VP of Power Group Michael Parkes, and (4) VP of Construction & Construction Services Brian Rittenhouse.

Tom is looking forward to leading the company that Walter, his family, key management members, and I have worked so hard to build over the past 53 years when Walter and his late wife Carmina purchased the company in 1968. He is eager to put his mark on the company and our plans for continued, sustainable growth. With your continued hard work and dedication in your respective roles, I am confident that our leadership team will continue finding ways to differentiate the company from the competition and will continue with plans to expand our services throughout the Mid-Atlantic region.

Tom will ensure we remain fiscally responsible, make wise investments to keep the company in a strong market position, remain competitive, invest in capital improvements, and recruit and train top talent. He is also committed to carry on O’Connell’s vital community philanthropy by working closely with his sister, Susan, founding family member and board member of the Mary M. Parkes Center for Asthma, Allergy & Pulmonary Care and the Walter & Carmina Parkes Family Foundation.

This is a significant milestone for our company, and I trust you will support each other, myself and the fellow officers to welcome Tom and the fellow vice presidents to carry on the legacy another 110 years (or more)! We are poised for great success and I can’t begin to express what an honor it’s been to serve you, the community, and our treasured customers and long-time partners.

I look forward to remaining loyally committed to O’Connell Electric, actively involved in my volunteer work in the community, and the biggest fan and supporter to all of you. We are successful because of each and every one of you, and for that I thank you for the opportunity to celebrate this significant milestone, together

To our continued success,

Vic Salerno CEO, Co-Chairman, Board of Directors

13

Employee News

New Employees and Position Changes

Chad Anderson Project Manager/Estimator, Buffalo

James Gould Intern, Victor

Wilbur Hebing Jr. Fabrication Shop Welder, 400 Systems Rd.

Bryan Jensen Truck Driver/Warehouse, 400 Systems Rd.

Margaret Matteliano Estimator, 400 Systems Rd.

John Nelson Jr. Project Manager/Estimator Albany

Zacharias Peters CO-OP Intern, Buffalo

James Planeta Truck Driver, Syracuse

Michael Schreiner TEGG Intern, Victor

In December, our Victor Service division volunteered their time and expertise to install a new generator that was donated to the organization to support a new building that will house and care for reptiles.

Wild Wings Inc. is a not-for-profit educational organization that operates a birds of prey facility at the Mendon Ponds Park Nature Center. The organization cares for permanently injured and nonreleasable animals which are unable to survive on their own in the wild.

Visit their facility 10am-2pm, Friday through Tuesday!

27 Pond Road Honeyoye Falls, NY 14472.

ABOUT

CERTIFIED SAFETY PROFESSIONAL

®

Congratulations Todd Forman, Syracuse Safety Coordinator, for passing his Certified Safety Professional (CSP) exam!

Certificants who hold the CSP mostly work in private industry, which could include being a government contractor. A CSP who works in the government sector may work in the military, federal, state, or local agencies. Safety at this level is virtually in every industry including petroleum exploration, production and refining, manufacturing, construction, healthcare, and insurance. A CSP’s professional time is spent on safety management systems, occupational health and ergonomics, emergency response and preparedness, fire prevention and protection, and security responsibilities. A CSP may also have environmental management system responsibilities, including managing safety, health, and environmental programs that can cover up to 1,000 or more employees.

and certificants cannot use unaccredited degrees, and the use is a violation of the BCSP Code of Ethics

Non-US degree holders who wish to apply for BCSP certifications which have an education requirement, may upload their academic record directly to BCSP, where they will be evaluated under the same rigorous standards for U.S. equivalency.

EXPERIENCE REQUIREMENT

say hello

ACADEMIC AND/OR TRAINING REQUIREMENT

CSP candidates must have four (4) years of professional safety experience to sit for the CSP exam. Professional safety experience must meet the following criteria to qualify:

* Professional safety must be the primary function of the position. Collateral duties in safety are not counted.

Recent Addition to our O’Connell Family

All individuals applying for the CSP must have a bachelor’s degree or higher in any field from an accredited institution.

There is no waiver of the academic requirement and proof of a minimum qualifying degree must be provided. For U.S. degrees, BCSP requires the school to hold institutional accreditation recognized by the Council for Higher Education Accreditation (CHEA) (chea.org) and/or the U.S. Department of Education (ed.gov).

Continuing education courses, seminars, and certificate programs are not a substitute for, and do not receive credit toward, the academic requirement.

Unaccredited degrees are a growing concern and some states have laws making it illegal to use unaccredited degrees. Applicants

* The position’s primary responsibility must be the prevention of harm to people, property, or the environment, rather than responsibility for responding to harmful events.

* Professional safety functions must be at least 50% of the position duties. BCSP defines full-time as at least 35 hours per week. Part-time safety experience is allowed if the applicant has the equivalent of at least 900 hours of professional safety work during any year (75 hours per month or 18 hours per week) for which experience credit is sought.

* The position must be at a professional level. This is determined by evaluating the degree of professional charge by which there is a reliance of employees, employers, or clients on the person’s ability to identify, evaluate, and control hazards through engineering and/or administrative approaches.

14

Alaina Marie Hurley

First granddaughter of David and Desiree Coon, Syracuse PM

20

Congratulations Recent Awards and Achievements

Michael Parkes appointed to serve as Council Chair for ELECTRI International

ELECTRI International was established in 1989 by the National Electrical Contractors Association (NECA). The non-profit organization works to help electrical contractors meet today’s demands and tomorrow’s challenges by funding, conducting, coordinating and transforming research results into meaningful, useful educational and consulting programs and practical publications.

Mike's grandfather and Co-Chairman of our Board, Walt Parkes, was a founding member of ELECTRI'21 COUNCIL.

Vic Salerno, CEO and Co

2020 ICON Honors award from the Rochester Business Journal.

To be eligible for ICON Honors, honorees (over the age of 60) must have a long-standing commitment to the Rochester business community and significant professional accomplishments through innovation and leadership. Honorees must also be champions of their industries and demonstrate a sustained commitment to community service.

Walt Parkes, Chairman, received the ICON Honors award in 2019.

"Certain

"Communication is key with every member of your team across all offices and divisions."

"I learned several effective strategies to manage customer expectations for both internal and external stakeholders."

Amie Gorog, Amy Porter, Andrew Spring, Angel Andrews, Brent Bodine, Brian Shaffer, Chris Oberman, David Curtis, David Horosko, David Adams, David D'Ettorre, DeAnna Darling, Deborah Moore, Georgianna Kimball, James VanCamp, Jeff Freund, Jim Chase, Jennie Morrow, Jennifer Myers, John May, Joe Clement, Karen MacDonald, Karl Turner, Kelley Nudd, Ken Boyer, Mary Kate McCarthy, Matthew McDonald, Michael Jankowski, Paul Galarneau, Paul Iorio, Robyn Cull, Ryan Osswald, Scot Gerould, Scott Moran, Sharon Avila, Stacy Foster, Steve LaJoie, Susan Ames, Todd Forman, Tom Sauer, Tyler Bulluck, Valerie Clark, Zach Presley.

50-75% Complete

Andy Perry, Brad Keatley, Brad Sargent, Brian Chamberlain, Brooke Tegas, Dana Miceli, Dan Oberlies, Darrell Strong, David Emmi, David Rath, Diane Pepe, Faye Gillette, Jason Shaffner, Jeff Merrell, Joe Leggo, Joel Clester, John Miller, Lexie Poudrier, Lisa Prentice, Matthew Hickman, Matthew Yonts, Phil Matthews, Rob Unger, Ruth Wakeman, Sean Callaghan, Steve Briem, Theresa Lewis, Therese White, Zach Zielke.

15

Chairman of the Board, received the

In September 2020, O'Connell kicked off an employee development initiative in partnership with

of Western, NY. The program includes up to twenty hours of live virtual training courses, scheduled to be completed in 12 months. 960 Core Course Enrollments 76% In Progress Participation 935 Hours Completed OCE'S EMPLOYEE DEVELOPMENT PROGRAM

75% Complete

Dale Carnegie

HITS THE HALFWAY MARK Over

courses have taught me to organize and prioritize in order to increase my productivity."

WATCH YOUR LINE OF FIRE.

Being in harm's way, Line of Fire injuries occur when the path of a moving object and an individual's body intersect.

Three Major Categories

Caught-in

or between Struck-by Released energy

The best way to avoid these incident types is to eliminate the related hazards whenever possible. By totally eliminating the hazards there is no chance that you or anyone else in the work area can be injured by that hazard.

In the path of moving equipment.

Underneath lifted load or static objects that could fall.

Working next to unstable materials and objects that could shift.

Working next to objects under tension.

Placing hands or body in equipment that can rotate.

Since 1911 830 Phillips Road | Victor, NY 14564