Riding the heat wave

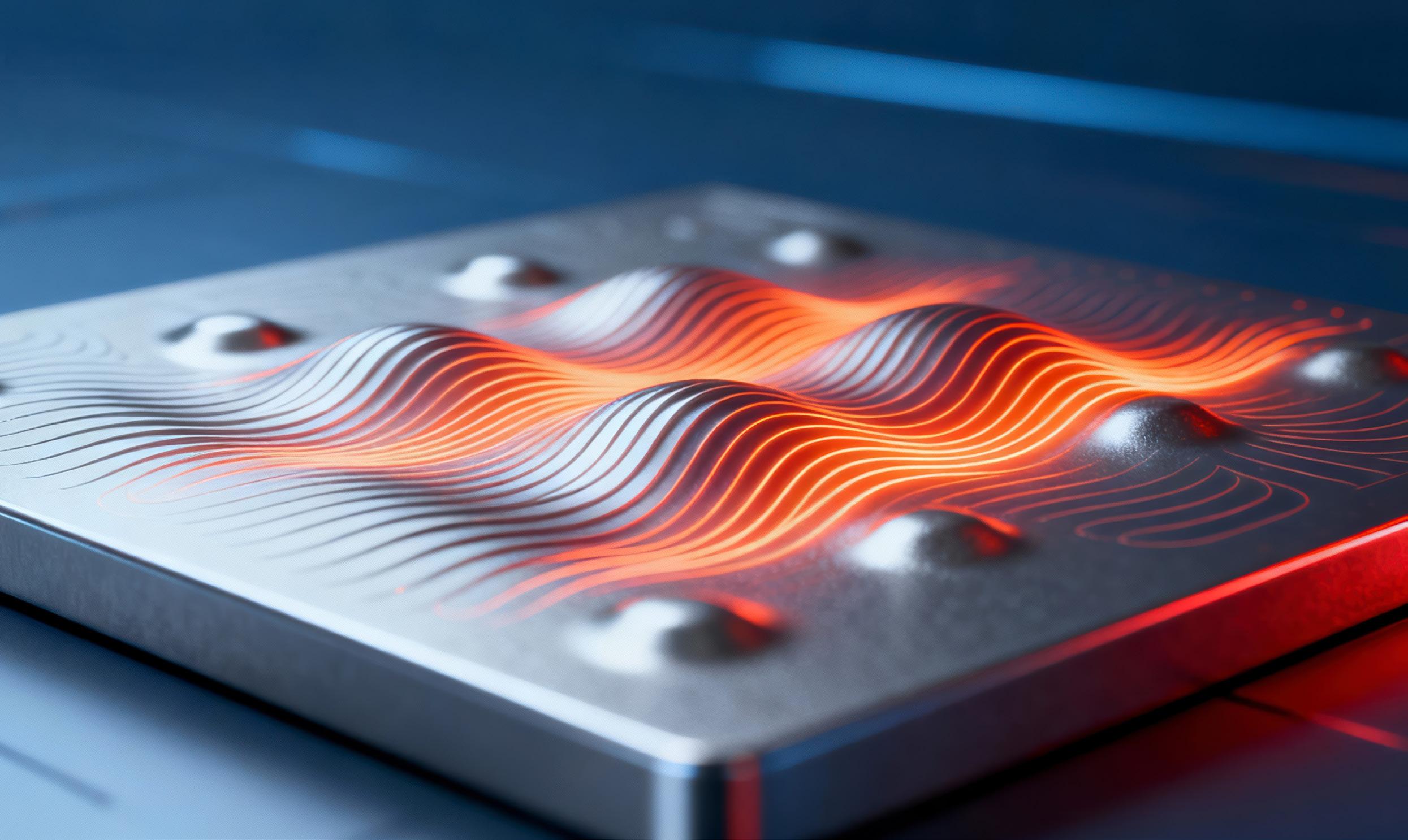

A new nanoscale design channels hybrid light–vibration waves to carry heat more efficiently, allowing better thermal management in compact, energy-hungry electronics.

Your phone warms up after a 20-minute Facetime call. Your laptop hums loudly while editing a large video file. Heat is a by-product of modern electronics — from everyday gadgets to the high-resolution screens and processors that power electric vehicles.

As components get smaller and more powerful, that heat becomes increasingly difficult to tame. In the cramped spaces of modern chips, the usual carriers of thermal energy — electrons and phonons (the tiny vibrations of atoms) — keep colliding

it travelled almost as though riding a guided wave of light. The team’s measurements also confirmed it. Even in structures a thousand times thinner than a human hair, heat moved nearly as efficiently as it does through bulk silicon dioxide. Devices with the patterned grating design showed a marked improvement too, carrying about 70% more of this light-driven heat than their flat-surfaced counterparts.

“It was surprising to see heat behaving almost independently of distance,” Asst Prof Shin notes. “That’s a clear signature that these surface waves can act as longrange energy carriers, even in structures this small.”

“It was surprising to see heat behaving almost independently of distance.”

The team’s design, detailed in their new paper published in ACS Nano, not only confirms that SPhPs can move heat efficiently, but also provides a way to tune how well they interact with solid structures — by adjusting the geometry rather than changing materials.

New ways to control heat

As data centres mushroom across the globe, driven by the boom in artificial intelligence, the world’s ever-growing appetite for computing power is also fuelling an “electronic heat wave.” A large share of the world’s energy bill today goes simply into preventing machines from overheating. Finding new ways to direct heat could make future electronics leaner, cooler and far more energy efficient.

The researchers’ solution is elegantly simple: instead of relying on bulky heat sinks or exotic materials, it reshapes surfaces at the nanoscale to influence how heat moves across. Shaping how light and matter interact at the nanoscale enabled the team to open a new route for managing thermal energy where traditional methods lack gusto.

In principle, devices that can guide heat in this way could help reduce dependence on fans and heavy thermal components, improve the stability and performance of compact chip designs and make electronics more resilient in high-temperature or demanding environments — from electric drivetrains to wearable sensors and photonic circuits. On a larger scale, with cooling already accounting for up to 40% of total power use in some data centres, even modest improvements in how heat moves through chips may translate into meaningful energy savings.

Looking ahead, the team plans to probe the theoretical upper limit of how much heat surface phonon polaritons can carry, and to demonstrate thermal routing, using these guided waves to steer heat intentionally across micron-scale paths. By integrating such wave-based heat channels into next-generation, chiplet-based microelectronics, the team aims to show that nanoscale surface design can serve as a practical cooling strategy for densely packed, high-power chips where conventional heat-spreading methods reach their limits.