LOW CARBON 3D PRINTED CONCRETE FROM LOCAL WASTE

MADE

IN IOWA

Acknowledgments and Funding

The research and coursework exhibited during IGNITE 2024 were made possible by several grants and the work of many people over several years 2021-present.

This includes financial support from the ISU College of Design, ISU Department of Architecture, Stan G. Thurston Professorship, Iowa Economic Development Authority (Evans and Robison), American Restoration and Recovery Act (Evans, Doyle, Senske, Wu), The University of Iowa Center for Global & Regional Environmental Research “Made in Iowa: Agro-waste Concrete for Disaster Resilient 3D Printed Construction” (Doyle and Wu), BNIM Regenerative Design Challenge 2023 “Grown in Iowa: Low Carbon 3D Printed Concrete from Local Waste” (Doyle, Evans, Senske, Wu), and an ongoing industry partnership with OPN Architects Inc Digital Practice Group.

Thank you to Iowa BioCentury Research Farm for providing the corn stover ash and thank you to Vestas American Wind Technology for providing the group wind turbines used in this work. Thank you also to our lab manager Dayon Roster, the ISU Department of Architecture and College of Design staff, and ISU College of Design Institute of Research and Outreach staff for their support.

MATERIAL RESEARCH BRICK WALL CONCRETE 3D PRINTING CARNEGIE LIBRARIES OF IOWA FINAL EXHIBITION REIMAN GARDENS 8 26 56 68 74 92 CONTENTS

THE TEAM

With the help of Professor Shelby Doyle, the fifteen students in this studio curated and developed the work shown through this publication and exhibition. With multiple majors represented including Bachelors of Architecture, Masters of Architecture, Bachelor’s of Landscape Architecture, and Master’s of Landscape Architecture, we were able to use our different backgrounds to develop this semester long body of work.

4 | DSN S 546 MADE IN IOWA

Professor Shelby Doyle

Weston Fantz

Mahsa Keyhani

Gabriel Phillips

DSN S 546 MADE IN IOWA | 5

Priya Barot

Nick Cheung

Evan Corkery

Nicole Friedman

Thomas Hewitt

Mona Kazemian

Daniel Leira

Zachary Lin

Mircea Nastase

Jaren Pierce

Connor Shanahan Gabriel Yingst

RESEARCH BACKGROUND

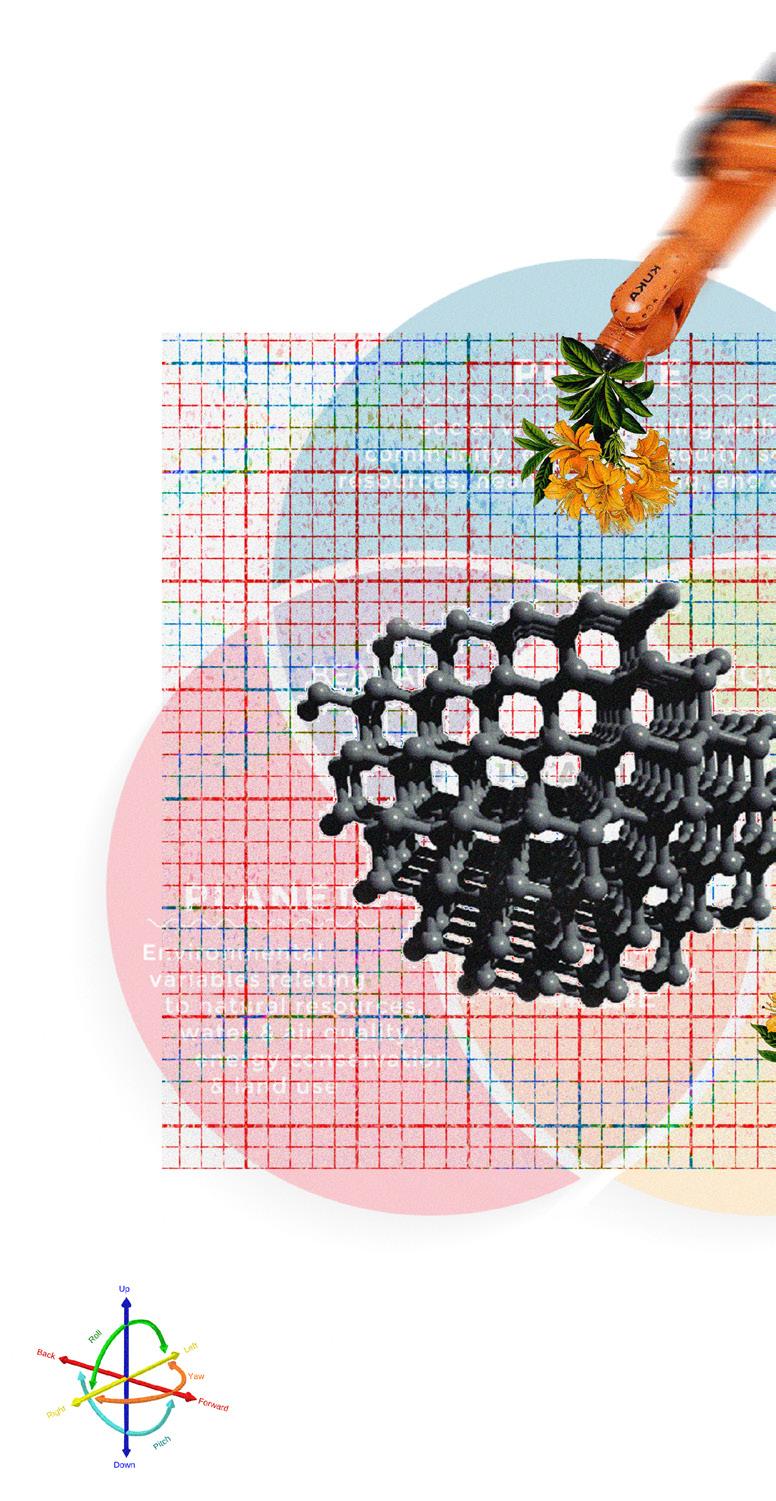

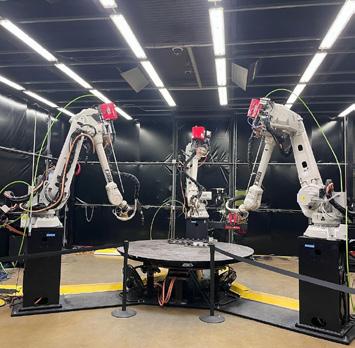

Following several climate disasters in Iowa, federal funding for recovery and reinvestment was released and administered by the Iowa Economic Development Authority. A portion of that funding was granted to the ISU College of Design to evaluate whether additive manufacturing (3D Printing) could be an effective method for sustainable, resilient, and affordable rural housing; specifically 3DCP or 3D Printed Concrete, or more accurately Cementitious Materials. A collaborative team co-developed several research tracks around these questions and the authors of this paper participated in: 1) testing of available 3DCP materials 2) development of local and low carbon 3DCP material alternatives 3) purchase and integration of hardware 4 development of software and integration with hardware 5) development 3DCP mixing and pumping protocols. This work occurred in the ISU Computation & Construction Lab, an initiative of the Department of Architecture and is home to $1 million in digital fabrication and robotics equipment that support cutting-edge teaching and research. The central hypothesis of Lab is that computation in architecture is a material, pedagogical, and social project; computation is both informed by and productive of architectural cultures. This hypothesis is explored through digital fabrication projects and engagement with non-profits and small towns in Iowa.

COURSE WORK

Iowa State University’s College of Design is one of the most comprehensive design colleges in the country. Home to seven departments, the college aims to foster unique interdisciplinary collaborations. This includes Design Studies 546, a capstone interdisciplinary studio in the last semester of the curriculum, which brings together students from across the College together around ongoing research projects. This studio engaged students in ongoing research to develop low carbon 3D printed concrete made from decommissioned wind turbines and corn stover ash.

Concrete is the most widely used construction material in the world and is responsible for 8% of annual greenhouse gas emissions. In 2017, the global market for ready-mix concrete was valued at $394.44 billion. This market is expected to double by 2024, and the 3D printing market is projected to grow exponentially by 2030. In this context, there is urgent demand for innovations that can reduce the costs and environmental impacts associated with concrete design and construction.

6 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 7

MATERIAL RESEARCH

The studio’s material research has been focused on finding alternative uses for bio-waste materials in Iowa. There are several sources of waste byproducts in Iowa infrastructure, including fly ash from coal plants, corn stover from corn harvests, and wind turbine powder from decommissioned wind turbines. The studio investigated several of these to identify viable opportunities to introduce them as aggregates in low-carbon concrete for construction. Methods of investigation included casting bricks using various waste products, exploring various additive manufacturing and material science facilities, and experimenting with 3D-printed concrete.

By studying and developing methodologies for implementing bio-waste materials into new uses, the studio aims to reduce the carbon footprint of concrete. Continued research will look to optimize mix formulations, test new materials, and scale up successful aggregates to promote their commercial application. This interdisciplinary research project can be impactful in reducing the environmental impact of concrete and promoting resource efficiency and reuse.

DSN S 546 MADE IN IOWA | 9

BioCentury Research Farm

BIOCENTURY FARM

The BioCentury Research Farm at Iowa State University stands as the nation’s pioneering integrated research and demonstration facility devoted to biomass production and processing. This facility has been a focal point for forwardthinking and sustainable

research and development, harnessing abundant raw materials in Iowa, such as corn, soybeans, crop residues, grasses, and algae.

Computation + Construction Lab

10 | DSN S 546 MADE IN IOWA

BIOMATERIALS

Between the BioCentury Research Farm and other local products, the studio was able to source sixteen different biomaterials and waste materials. These materials became a foundation for the explorations in finding alternative use values for

these waste materials. Each material was examined for its aggregate size, physical properties, and viability as a potential aggregate source in low-carbon concrete.

DSN S 546 MADE IN IOWA | 11

AGGREGATES

A variety of materials were tested as aggregates for lowcarbon concrete solutions. These aggregates explored varied in size, shape, color, consistency, and density. This allowed the studio to produce a diverse range of brick colors and strengths. The broad range of characteristics and properties were carefully evaluated in several ways.

Aggregates that were sourced from abundant waste materials, like corn stover and wind turbines, were privileged for their sustainable use. Particle size distribution was also an important factor, impacting the workability and strength of the bricks. Water absorption was a factor that varied drastically between the aggregates, with natural aggregates like biochar absorbing significantly more water than wind turbine powder. Finally, the compressive strength and durability of bricks made were compared based on aggregates. Aggregates that were successful did not significantly weaken the structural integrity of the brick while still reducing carbon

12 | DSN S 546 MADE IN IOWA

L to R: Bagasse, Hulled Barley, Red Oak, 1/4” White Pine

L to R: Raw Corn Stover, 1/8” Corn Stover, Corn Stover Pellets, Cracked Corn

L to R: Biochar, Fine Fiberglass, Shredded Fiberglass, Quikrete

L to R: Grey PLA Filament, White PLA Filament, Plastic Bags, Bike Tire Rubber

DSN S 546 MADE IN IOWA | 13

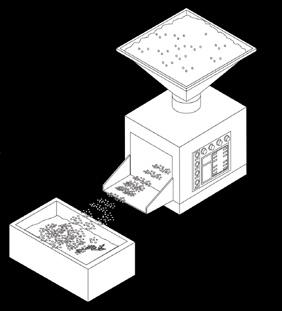

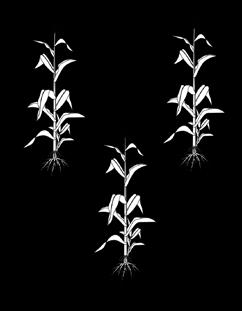

BIOCHAR

Corn stover is the stalks, leaves, and cobs that are left over in fields after the harvest. As an abundant material in Iowa, there is currently no continued recyclable utilization for it. Corn stover is put through pyrolysis, a process of thermal decomposition in a low-oxygen environment, to convert it into a liquid that can be further refined into hydrocarbon bio-fuels, fuel additives, and petrochemicals. The byproduct of pyrolysis is a dark black powder known as biochar, which is composed of carbon and ashes and currently has no use. Incorporating biochar into concrete mixtures created a very dark-colored and visually appealing brick.

14 | DSN S 546 MADE IN IOWA

1 - Wash + Dry Corn Stover

2 - Grind into Powder

3 - Heat

More Less

Corn Stover Biochar Crude Bio-Oil

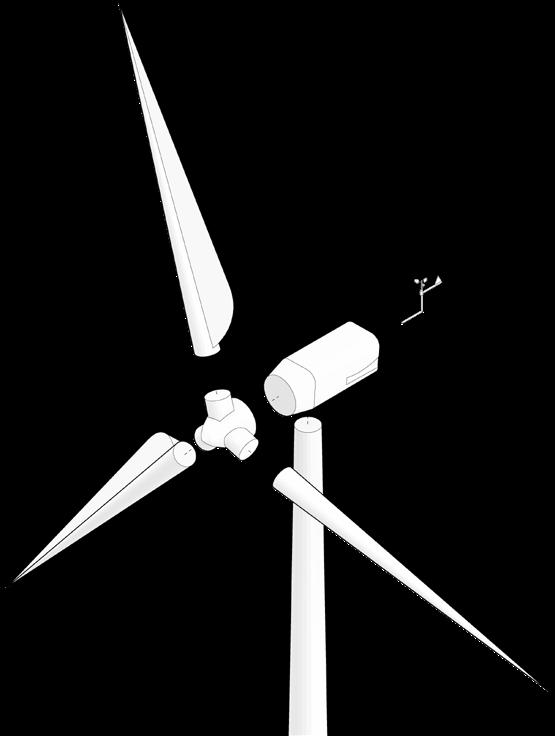

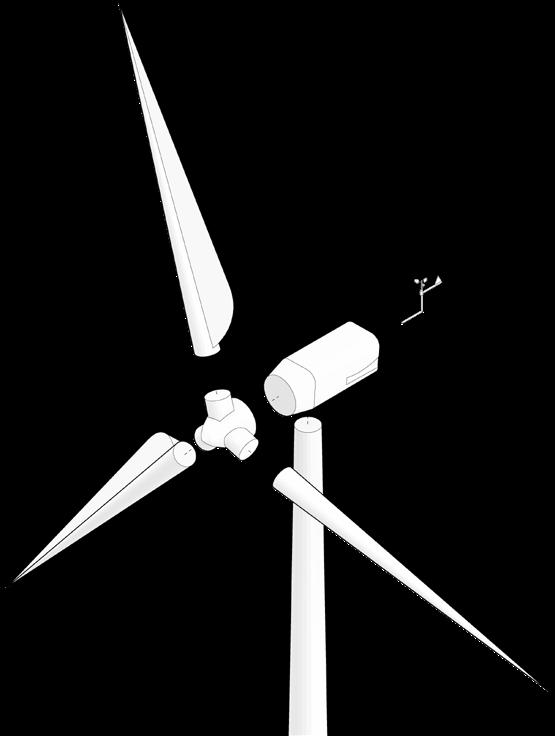

WIND TURBINE

With an abundance of wind turbines in Iowa, there is an opportunity to explore their viability as an aggregate substitute for bricks. Wind turbine blades are typically constructed from advanced composite materials chosen for their strength, flexibility, and lightweight qualities. The most common material used is fiberglass-reinforced epoxy resin, which balances durability and cost-effectiveness and offers tensile strength when used in concrete mixtures. Given the average lifetime of a wind turbine blade is roughly 25 years, and an estimated 7,000 blades are decommissioned each year, these waste materials offer a viable and abundant concrete aggregate.

DSN S 546 MADE IN IOWA | 15

Blade

Anemometer + Wind Vane Nacella

More Less

Tower

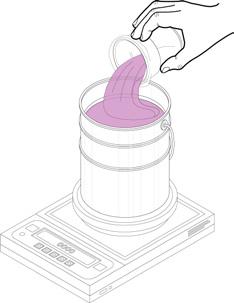

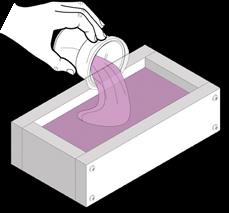

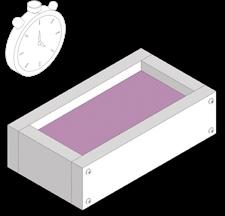

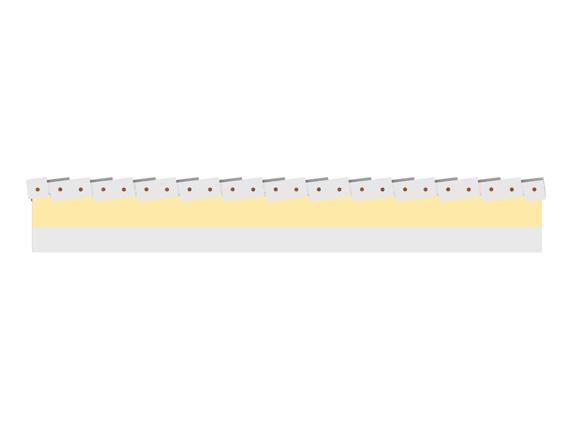

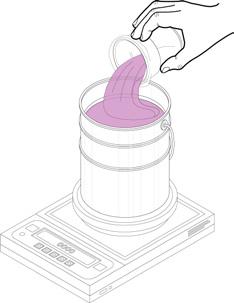

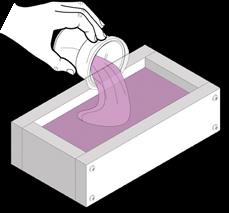

CASTING PROCESS

The bricks cast required four ingredients: concrete mix, sand, aggregate, and water. The ratio of the mixture started at one part concrete, two parts sand, three parts aggregate, and half part water. After obtaining the proper ratios, additional water may be added to the mix to allow even incorporation of the materials. Once the materials are all incorporated, you take the materials and pour or grab and put the mixture into a mold. The wood mold is filled, and the brick is flattened and left to set for 24 hours before being removed to examine its properties. Various ratios were tested to find a desirable strength and gradient of colors.

16 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 17 1

2

Dry

3

4 -

5 -

6- Demold Mixing Bucket Sand Water Cement Aggregate

- Measure

- Mix

Materials

- Mix Water

Pour Into Mold

Cure Brick

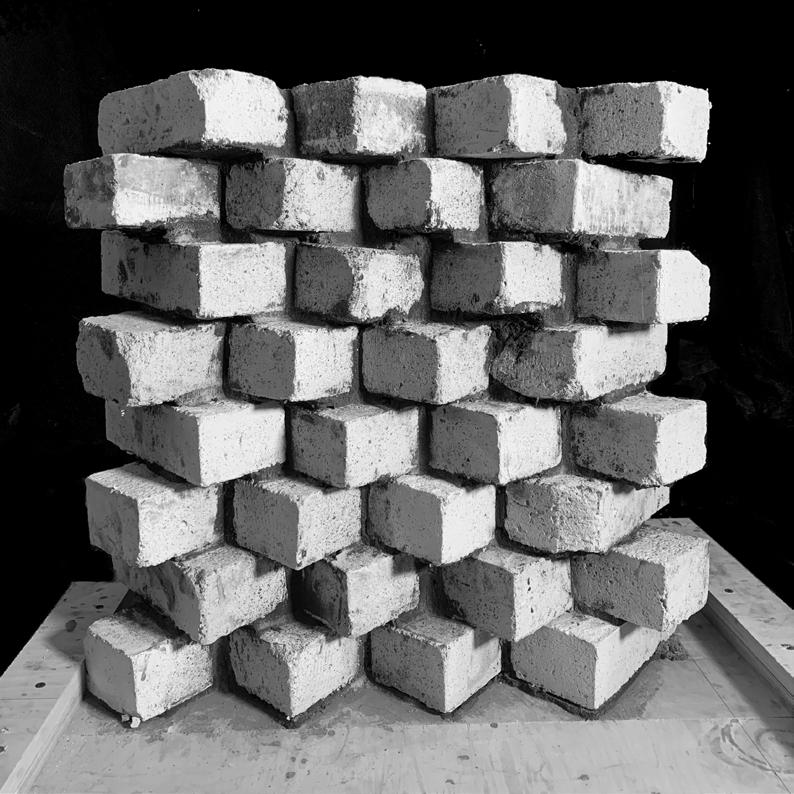

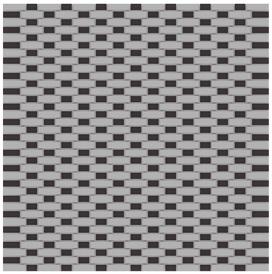

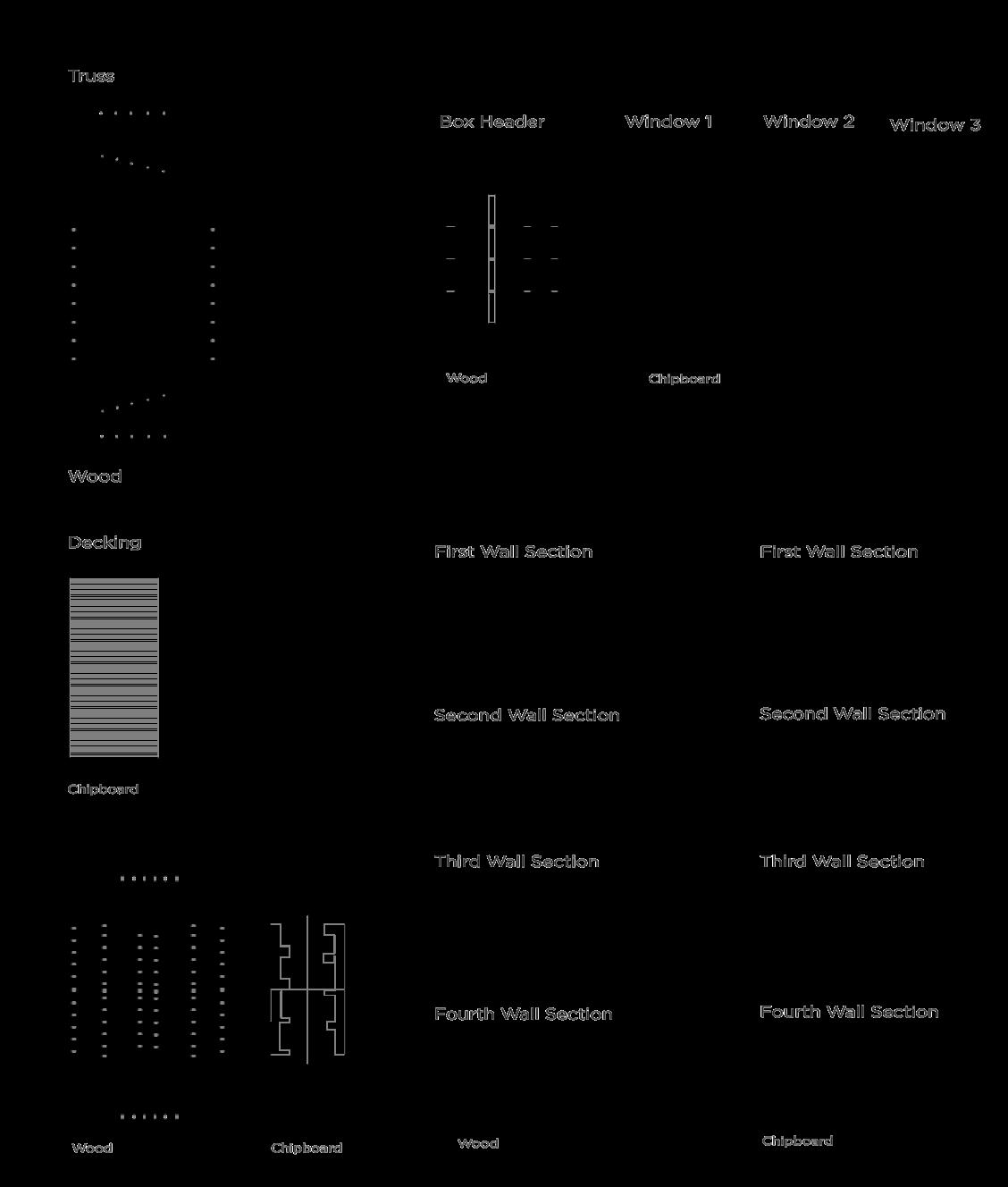

BRICKS

Bricks are a humble building block that have played a pivotal role in construction for generations. Being constructed from a variety of natural materials, that are a simple and versatile building module for a wide range of applications. Their strength, fire resistance, strength, modularity, and low maintenance, are a few advantages they have as a building material. In total, the studio cast over 200 bricks utilizing a variety of waste and biomaterial aggregates. This wide exploration allowed for experimentation with mix ratios to achieve desirable results that were aesthetically and structurally sound.

18 | DSN S 546 MADE IN IOWA

L to R: Bagasse, Hulled Barley, Red Oak, 1/4” White Pine

L to R: Raw Corn Stover, 1/8” Corn Stover, Corn Stover Pellets, Cracked Corn

L to R: Biochar, Fine Fiberglass, Shredded Fiberglass, Quikrete

L to R: Grey PLA Filament, White PLA Filament, Plastic Bags, Bike Tire Rubber

DSN S 546 MADE IN IOWA | 19

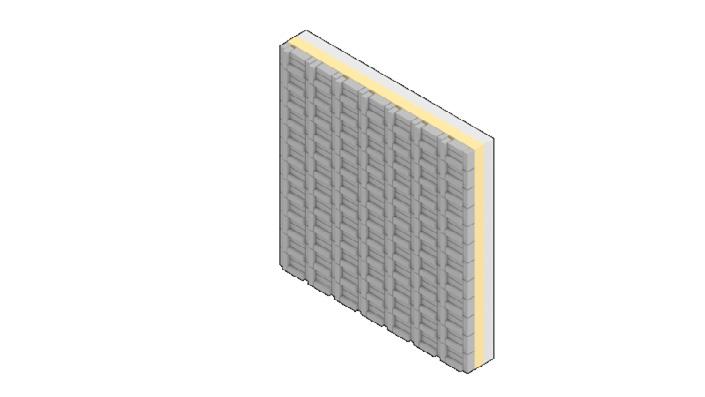

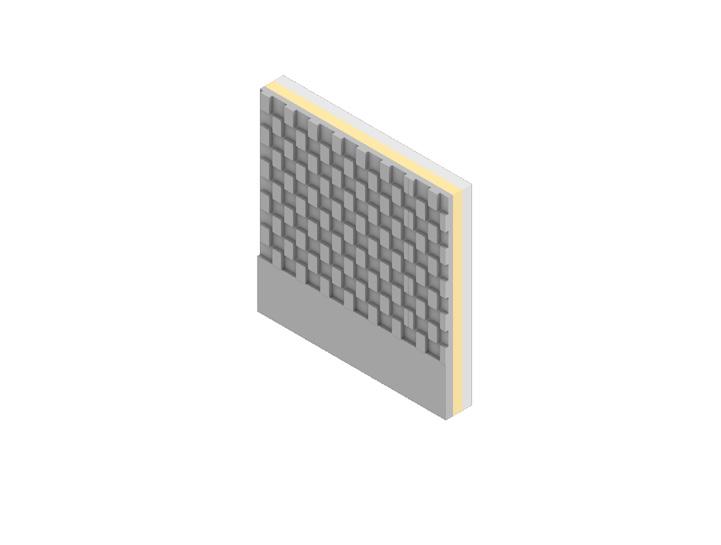

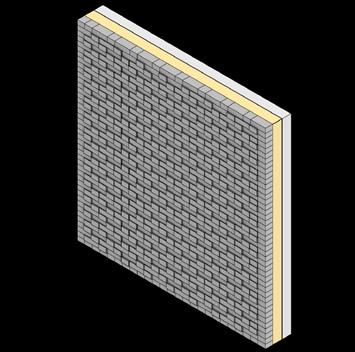

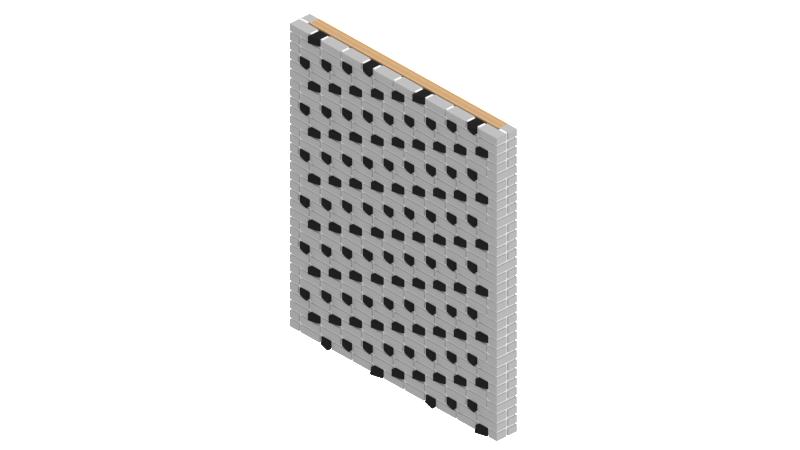

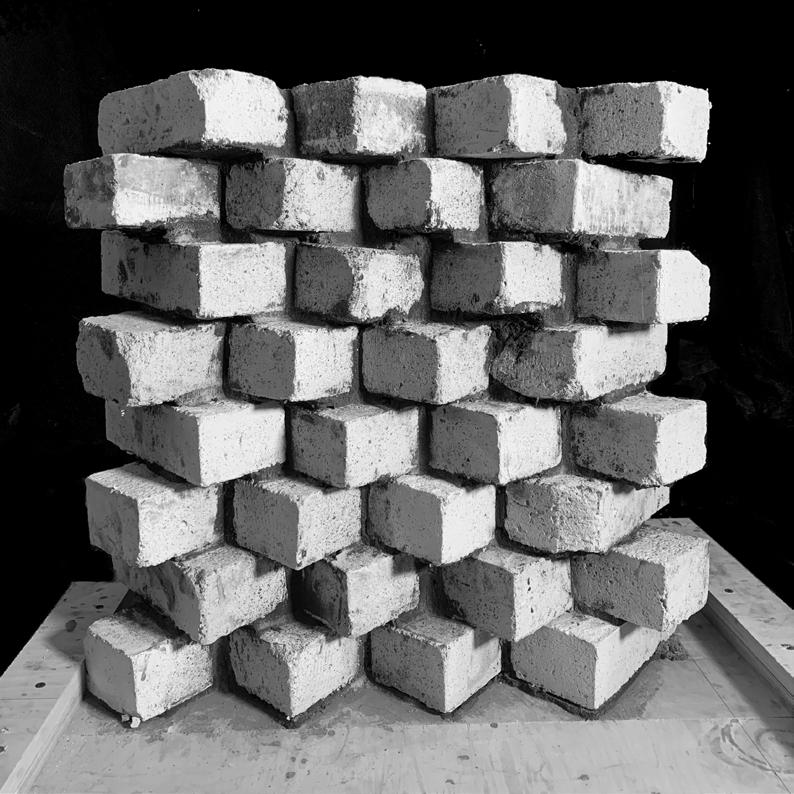

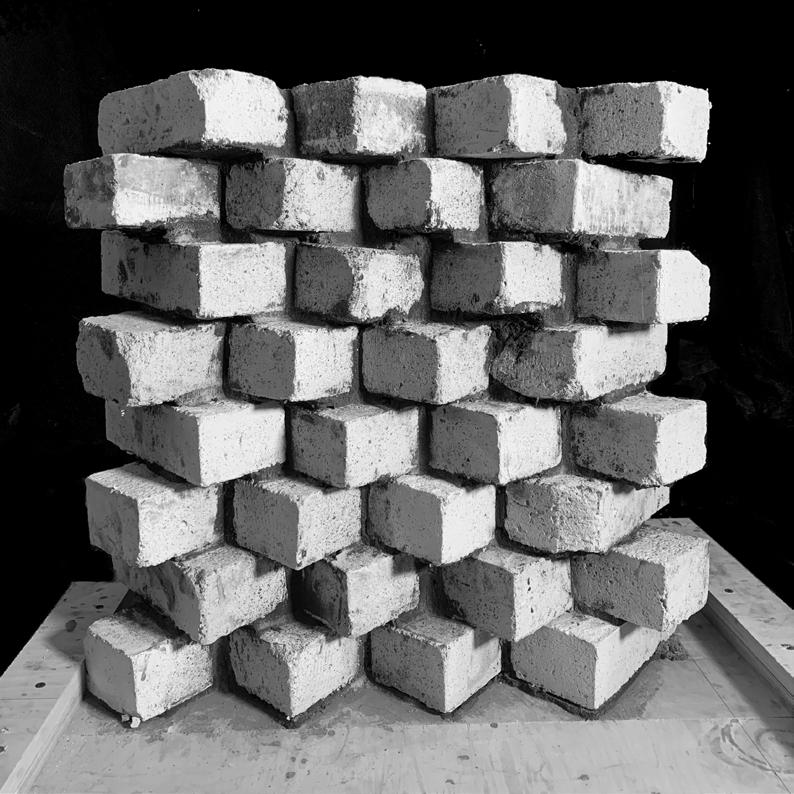

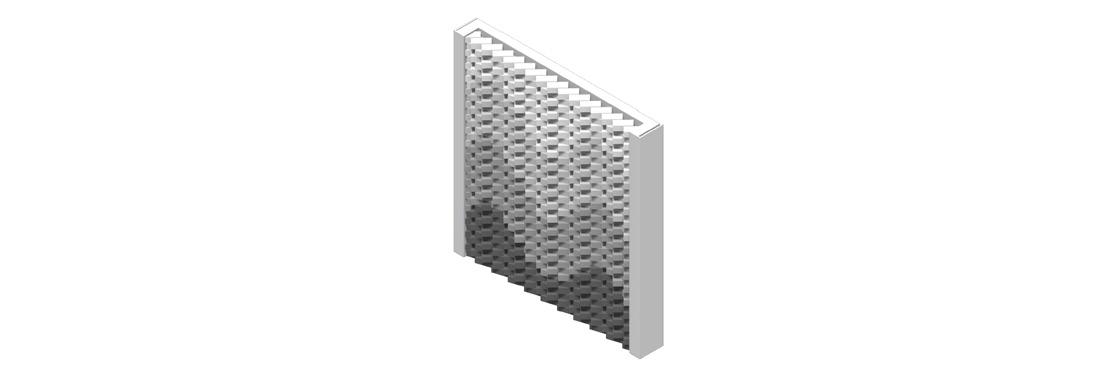

2’ x 2’ Mock Ups

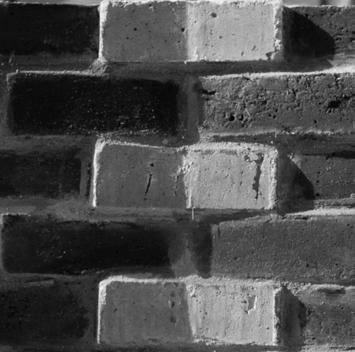

With a better understanding of concrete aggregates, the class divided into groups and were tasked with designing and fabricating 2’x2’ wall mock ups. Each group synthesized brick wall iterations to create a full 8’x8’ wall proposal. Using brick mixtures from individual research, each group selected mixtures and produced their own bricks. These bricks were then used to construct 2’x2’ wall samples. The class quickly understood the possibilities of brick fabrication and construction. We found that the bio-based bricks did not adhere well with standard mortar. Consequently, groups had to further develop brick mixtures to include more cement and create a more reliable brick when stacked.

20 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 21

ADDITIVE MANUFACTURING FIELD TRIP

As part of our research, this studio traveled to Knoxville,Tennessee to observe additive manufacturing methods and research in lowcarbon building materials. This field trip provided an opportunity to learn from professionals in the public and private sectors looking to leverage additive manufacturing to advance the building industry. The studio explored Oak Ridge National Laboratory, Branch Technologies, and the UTK Fabrication Lab.

The first day of the trip took place at Oak Ridge National Laboratory (ORNL), a multidisciplinary research facility known for investigating nuclear research, materials science, and supercomputing. ORNL is a leader in exploring, developing, and refining techniques in additive manufacturing. The research being conducted continues to push the boundaries of additive manufacturing to apply them in commercial industrial practices that enable faster production, reduced material waste, and enhanced design flexibility.

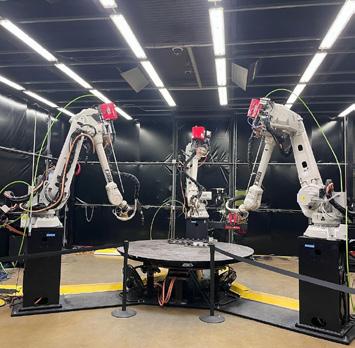

The studio also visited Branch Technology, a company based in Chattanooga, Tennessee, specializing in large-scale 3D printing using advanced robotic systems. Branch Technology’s Cellular Fabrication process, which utilizes large-scale 3D printing robots to create intricate structural elements.

22 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 23

FINAL BRICKS

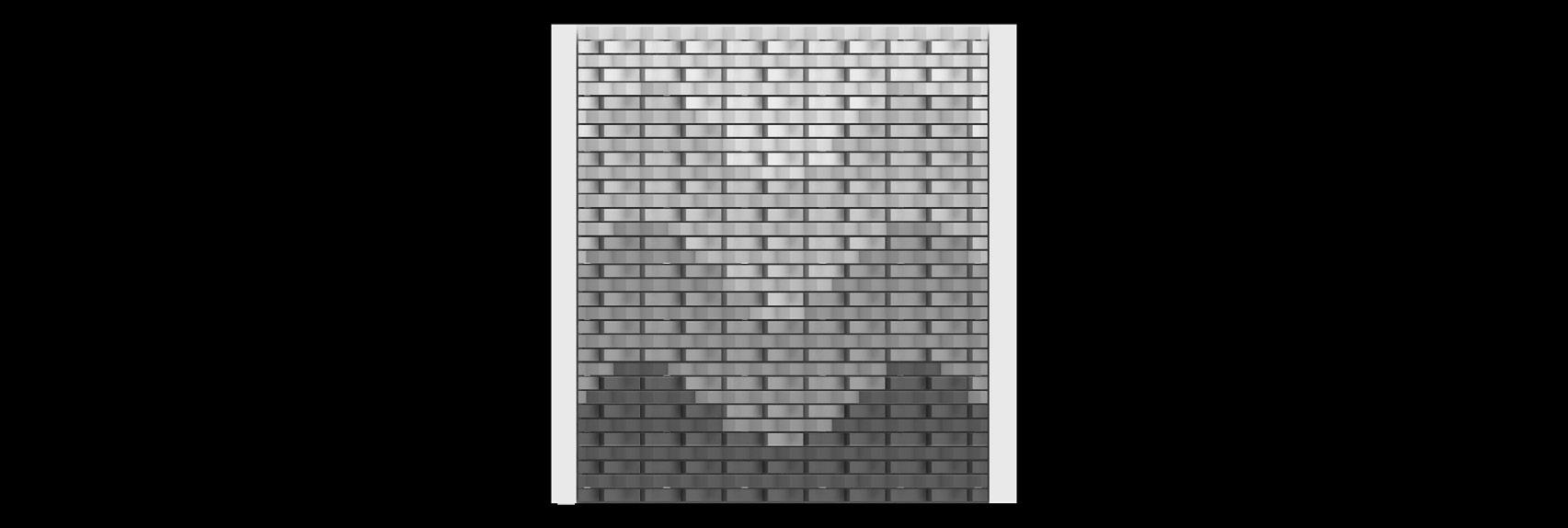

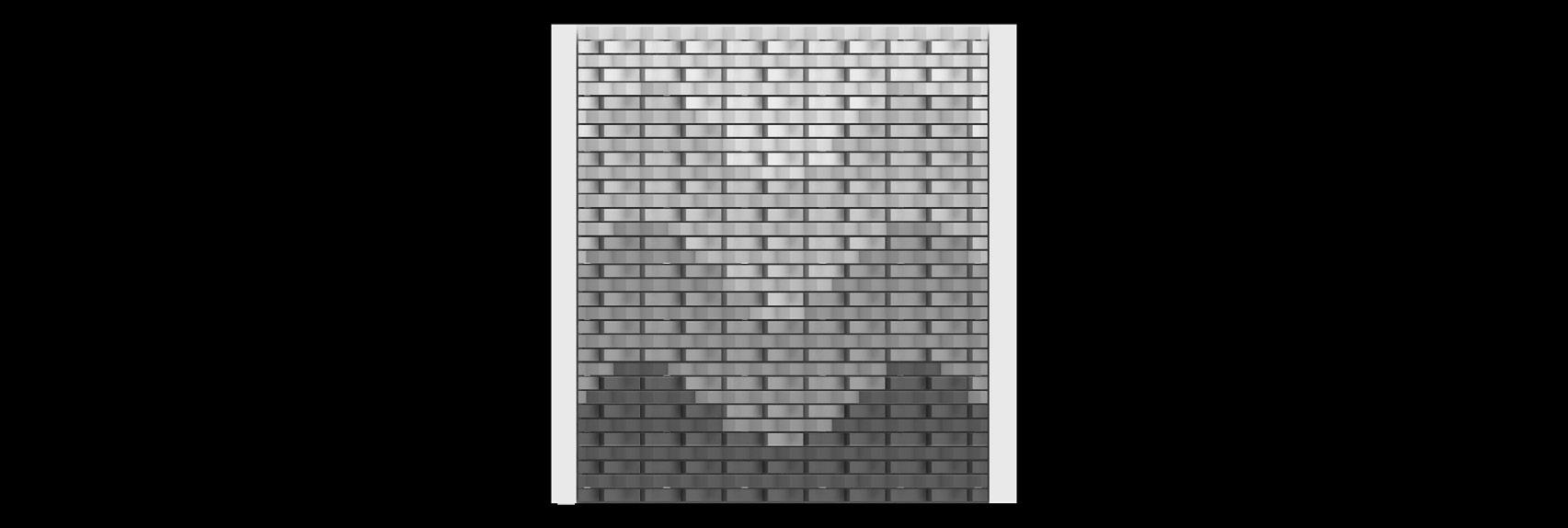

Through our collective material research, we eventually focused on producing bricks using corn stover biochar and wind turbine fiberglass as aggregates. These aggregates produced the most monolithic and strongest consistencies. Other biomaterials did not cure well once mixed with water and decreased the structural integrity of the bricks.

Biochar and fiberglass were also ideal for their aesthetic qualities. The biochar produced a very dark brick, whereas the wind turbine fiberglass produced a very light brick. Varying the amounts of both of these aggregates in the brick mixtures allowed us to customize a gradient that could integrate with our brick wall schemes and create more architectural interest.

24 | DSN S 546 MADE IN IOWA

Cement

Sand

Wind Turbine Fiberglass

Corn Stover Biochar

Brick 1 - Light

Cement: 400g

Sand: 400g

Water: 533g

W.T. Fiberglass: 366g

Biochar: 0g

Brick 2 - Med. Light

Cement: 200g

Sand: 300g

Water: 400g

W.T. Fiberglass: 300g

Biochar: 75g

Brick 3 - Med. Dark

Cement: 225g

Sand: 440g

Water: 580g

W.T. Fiberglass: 420g

Biochar: 250g

Brick 4 - Dark

Cement: 400g

Sand: 600g

Water: 350g

W.T. Fiberglass: 0g

Biochar: 600g

DSN S 546 MADE IN IOWA | 25

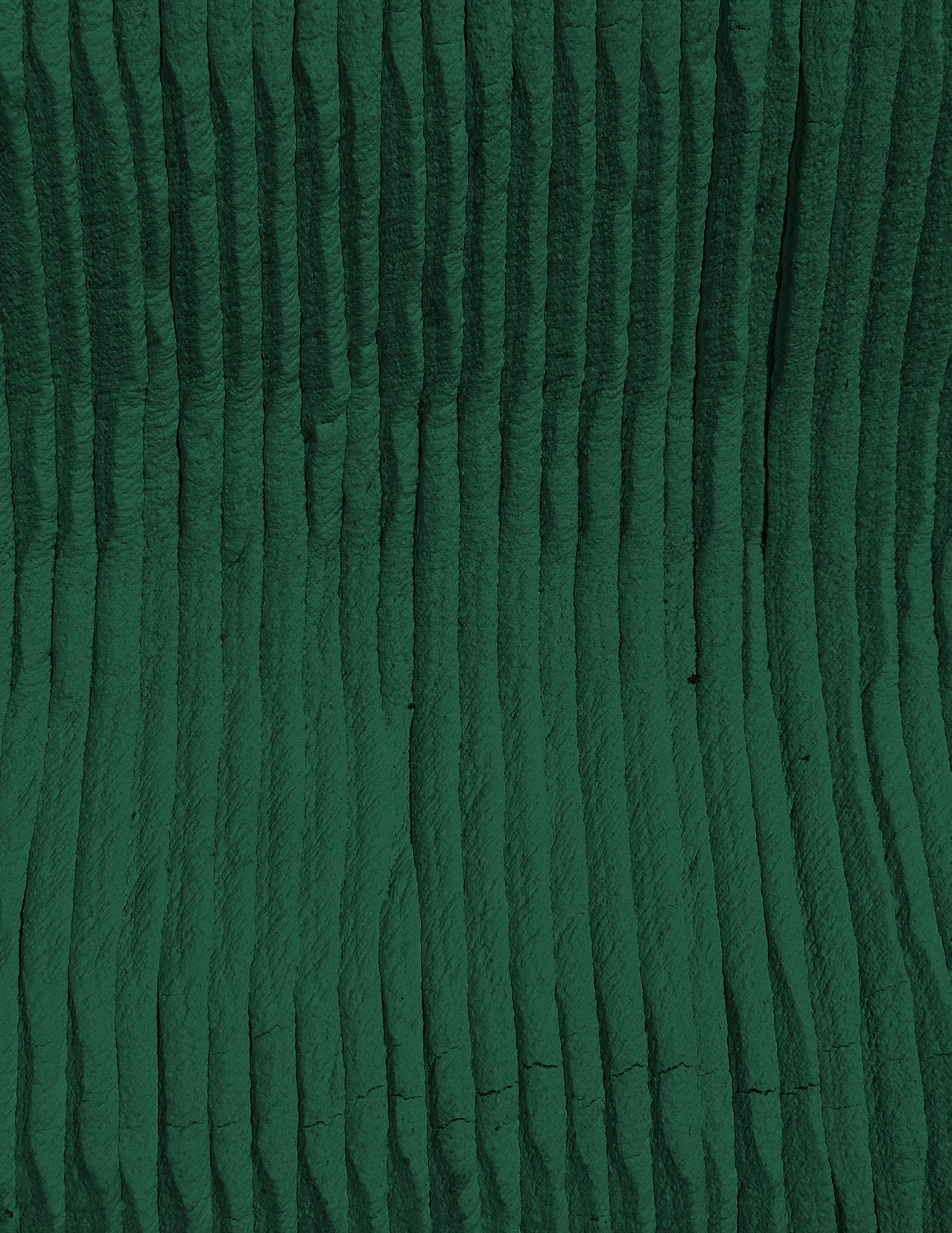

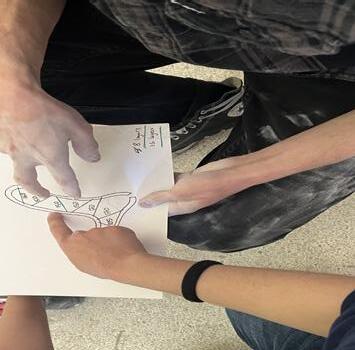

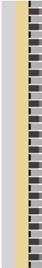

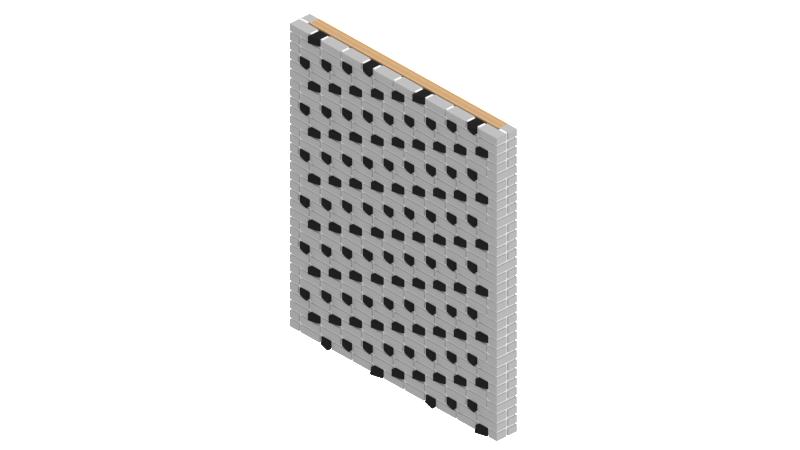

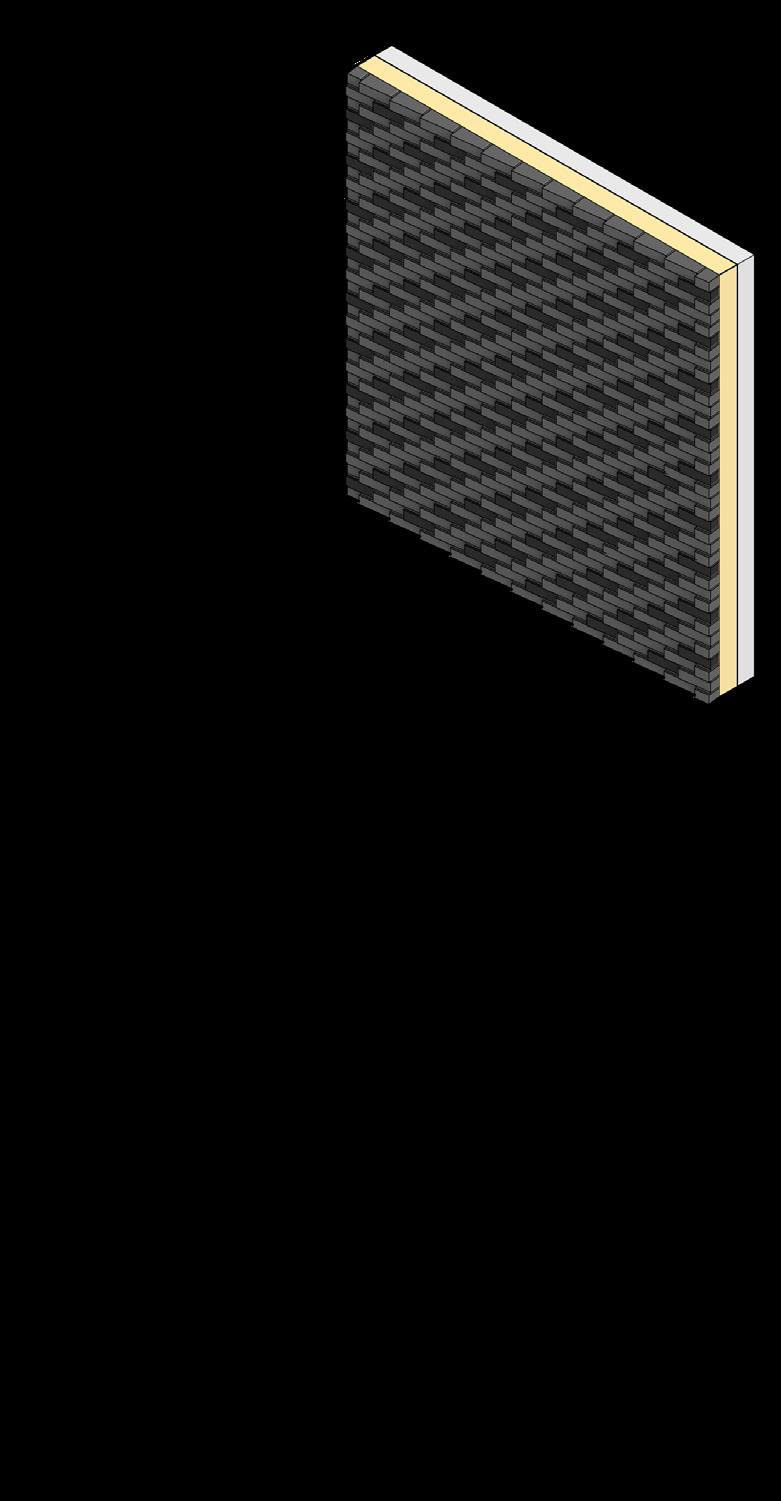

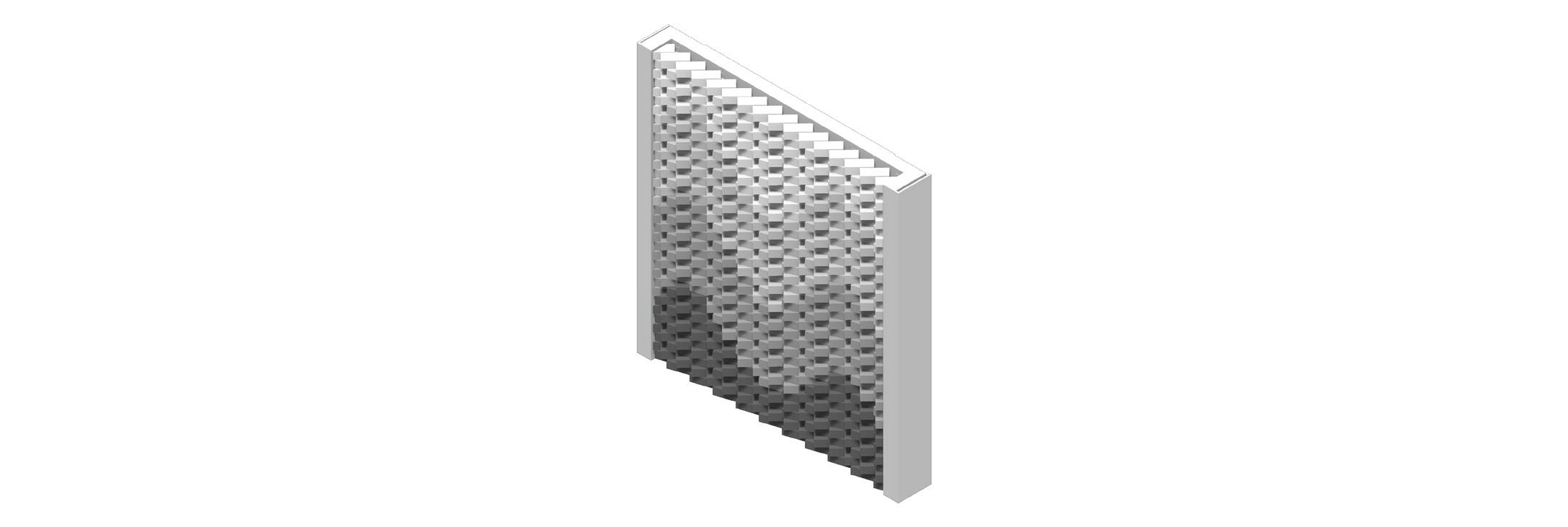

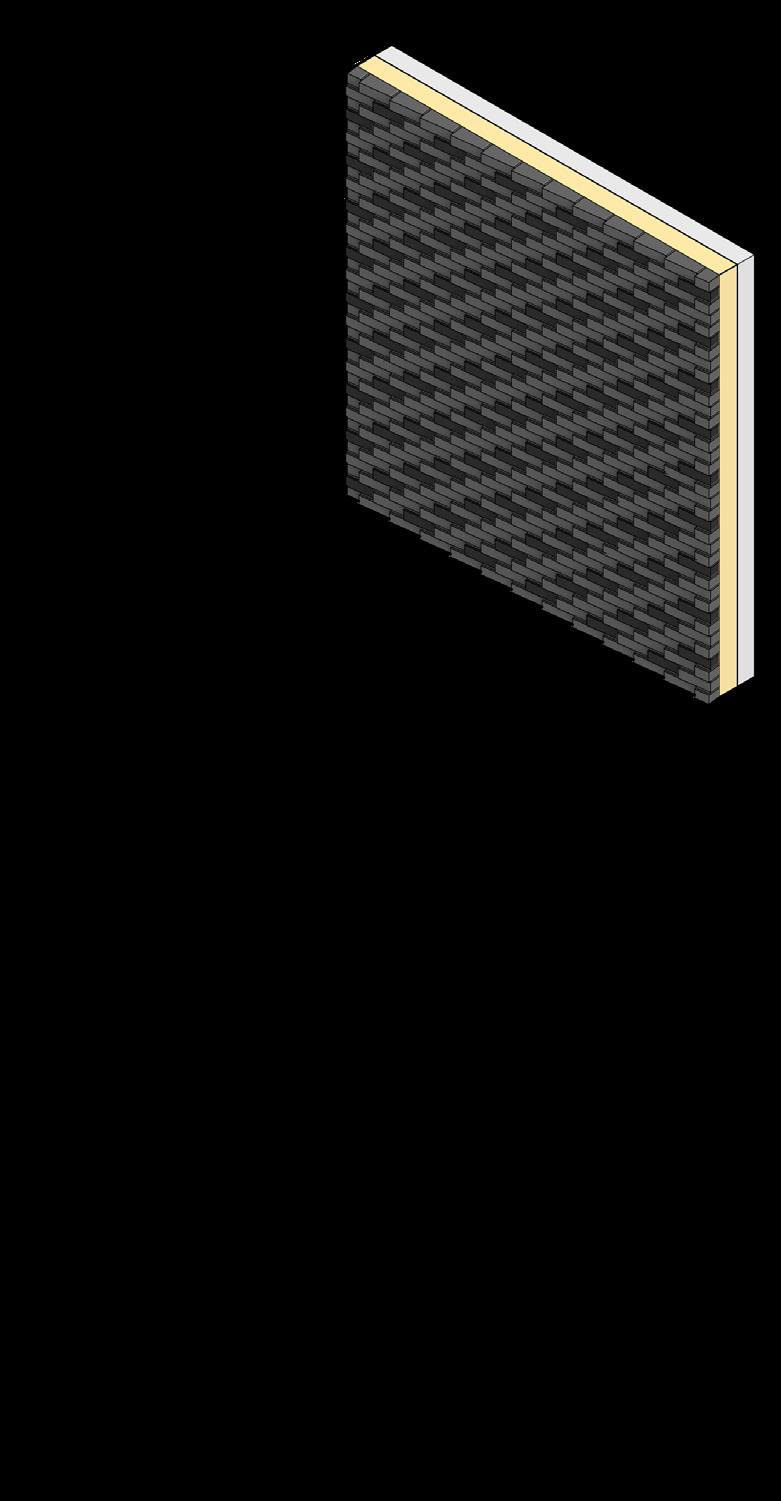

BRICK WALL

As a class, we used our material research and knowledge of masonry assemblies to design a brick wall to construct. Based on our collective knowledge from material research, wall designs primarily used corn stover biochar and wind turbine fiberglass as aggregates. This started our process of translating our original design concepts into a tangible wall. Through this process, we were divided into different teams, each focused on different aspects of the brick-making process, including brick casting, demolding, and laying. As we began to learn more about the brickmaking process, this lead to the challenge of laying bricks in a way that required precision and strength. This process of design to construction gave us a practical application of our knowledge from computer to hand. This way of experiential learning gave us the creativity and craftsmanship required to go from iteration to wall. Through the effort of the studio, we were able to iterate and develop a wall that utilized technical skills, both on the computer and as it stands today.

DSN S 546 MADE IN IOWA | 27

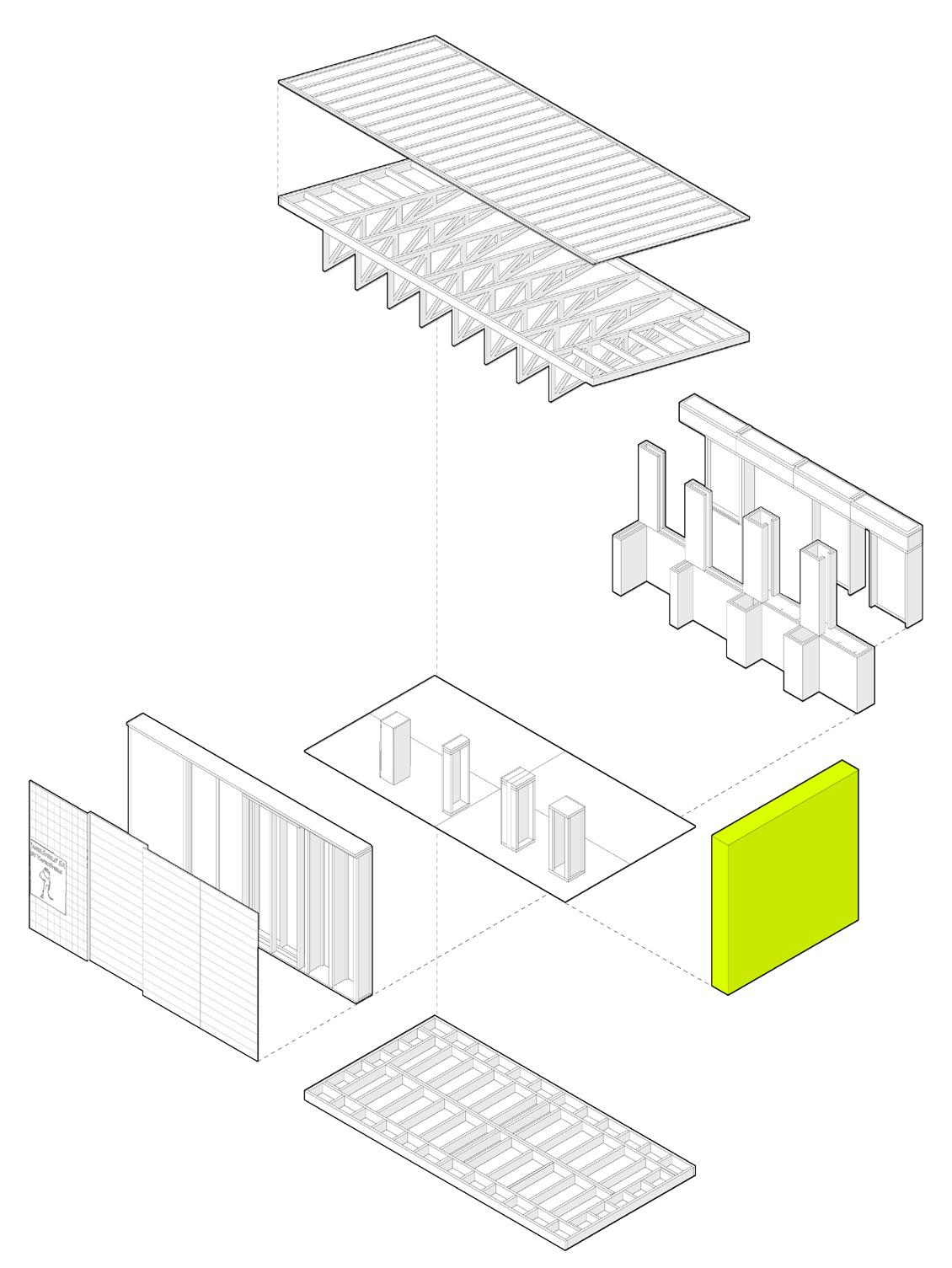

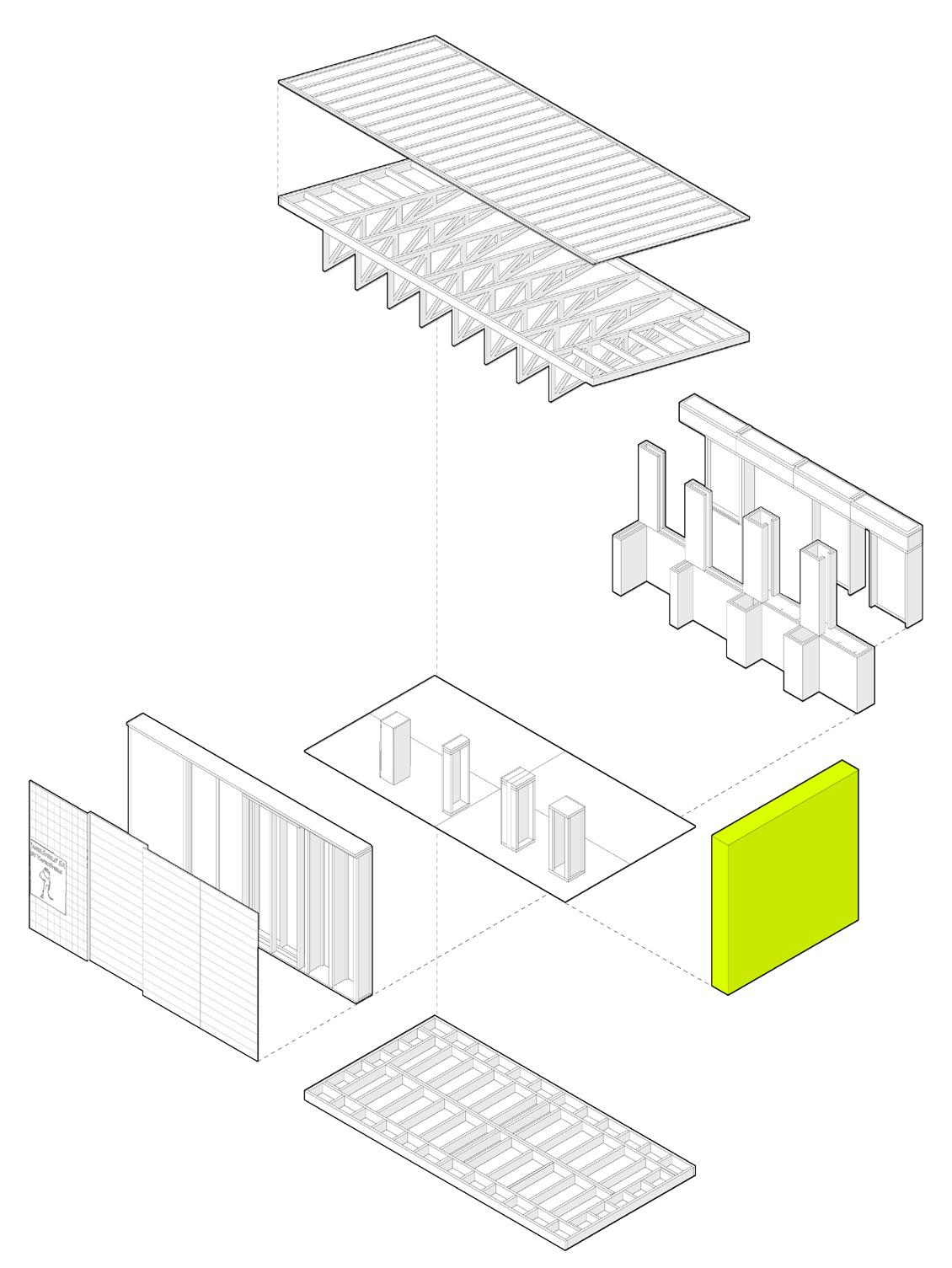

SHED AS INHERITED

In addition to ongoing research into 3D affordable innovative technologies, this studio was tasked with installing an approximately 8’ x 8’ wall using bio-materials and material research conducted in the first part of the semester. This wall was installed on an

existing shed outside of the Communications Building. The project served as an opportunity to experiment with masonry, material capabilities, and translating drawn ideas into reality.

28 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 29

NORTH WALL

SOUTH WALL ROOF

30 | DSN S 546 MADE IN IOWA

BRICK WALL

DSN S 546 MADE IN IOWA | 31

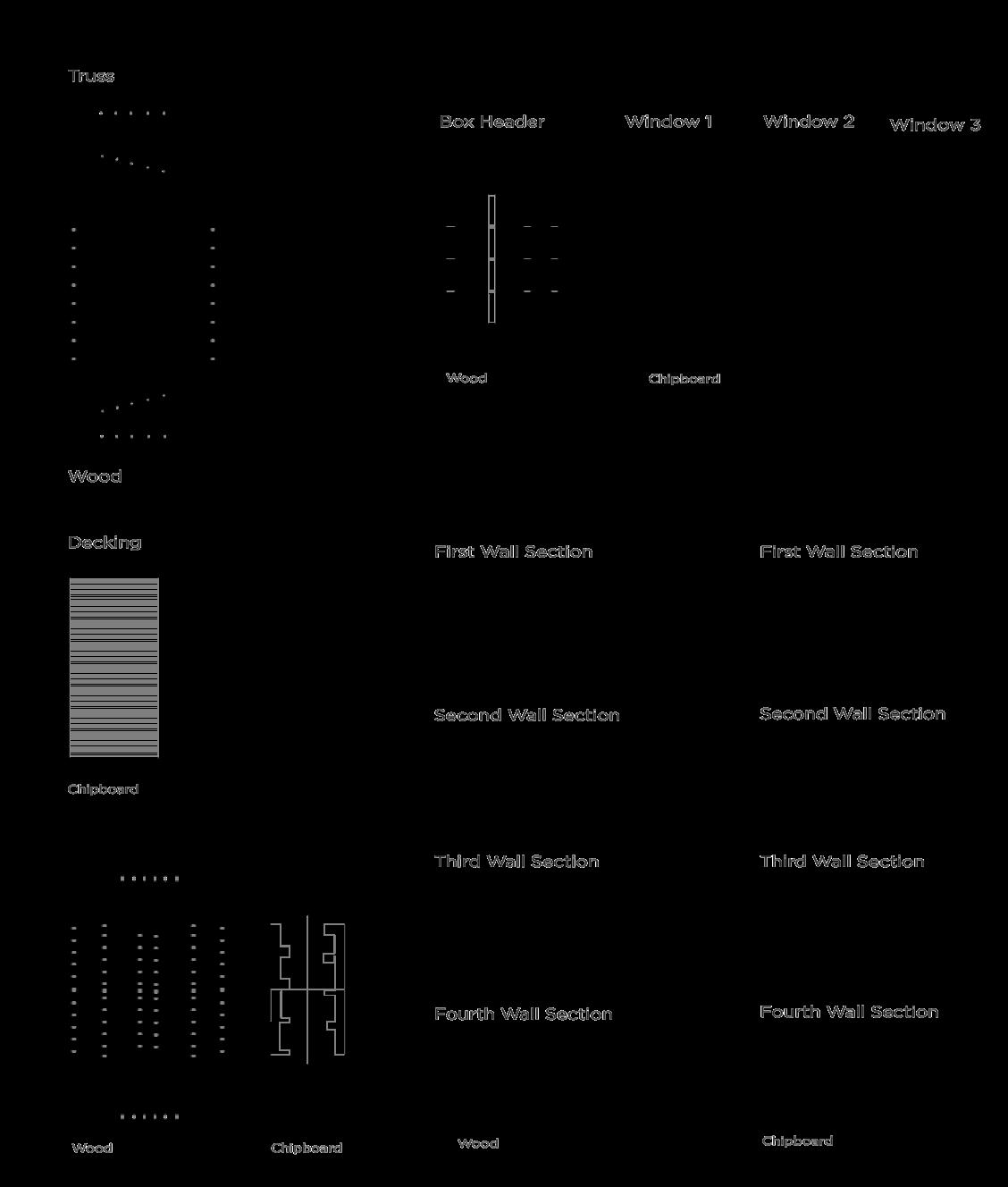

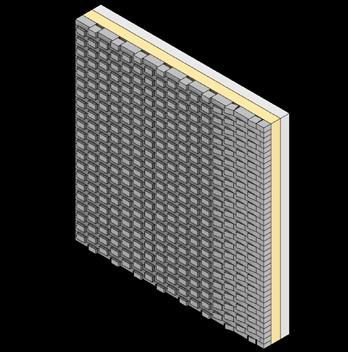

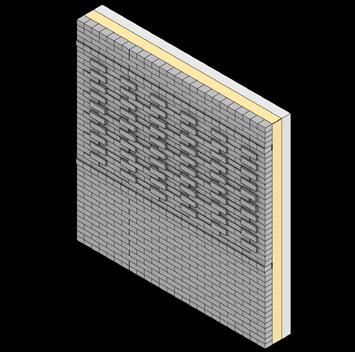

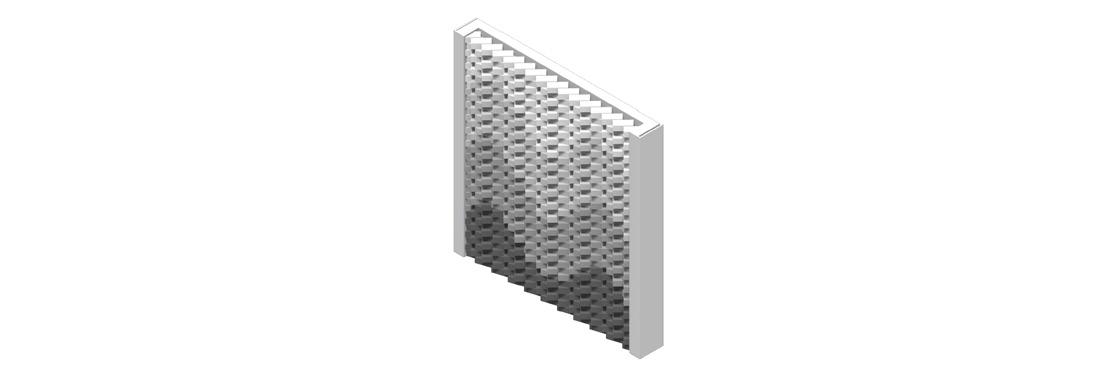

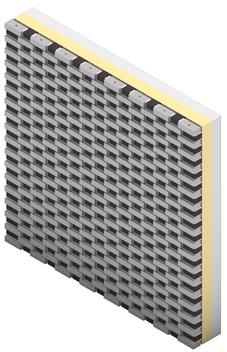

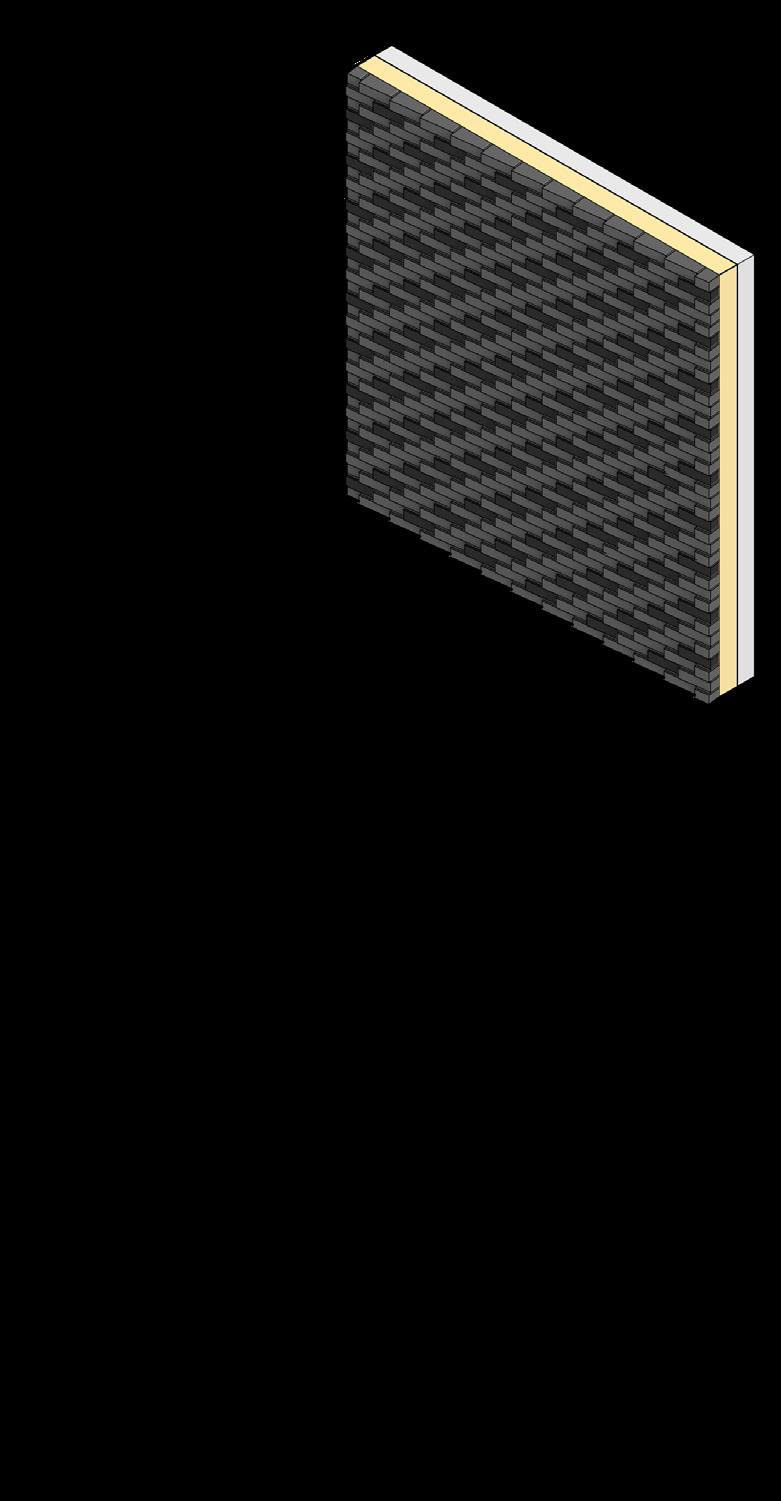

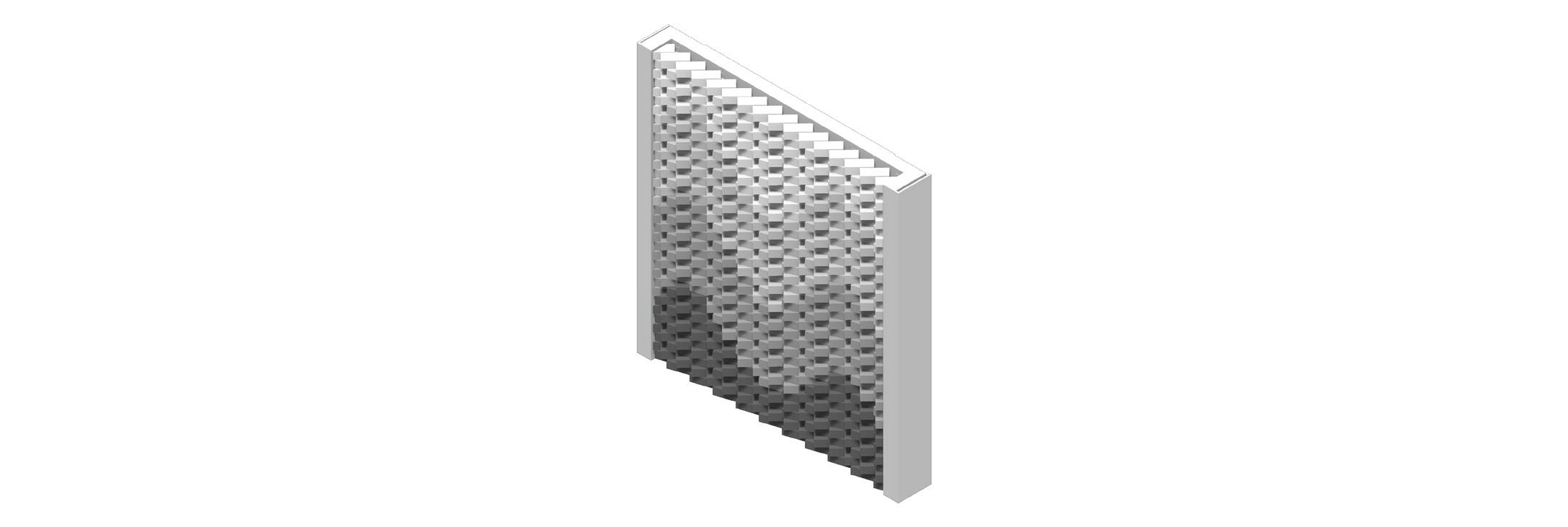

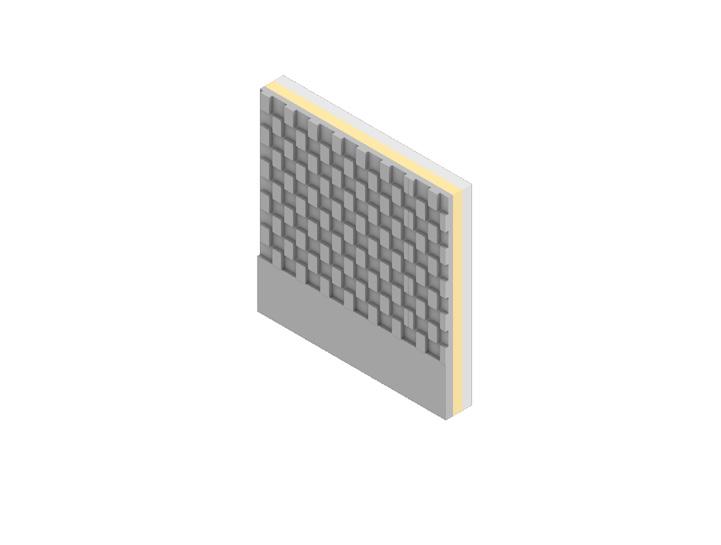

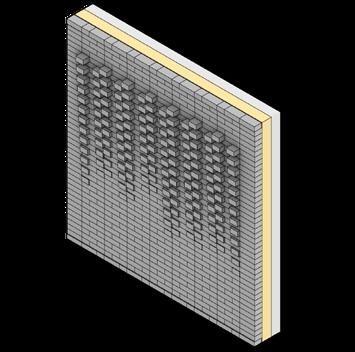

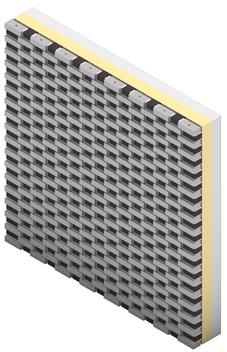

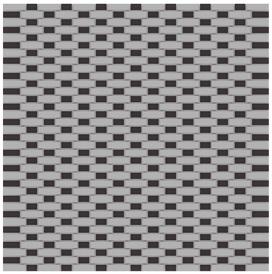

BRICK WALL ITERATIONS

For the shed wall, we were tasked as a studio to explore bricks and brick patterning. This process was two weeks long and each of us explored many options for what could go into the shed. As a studio, we explored patterns, different brick shapes, and different textures. The iterations included goals such as the least amount of bricks, using only standard-sized bricks, and other challenging iterations. As we developed these walls over the two weeks, we started to experiment with what we could do as a class through small wall mockups and tests to make sure we had structural stability with the different patterns. Through this iterative process, we narrowed down the walls to four and chose one of those to continue on with and build.

32 | DSN S 546 MADE IN IOWA

7'-111 2 1'-1" 8'-02

DSN S 546 MADE IN IOWA | 33 1'-2 1 2 7'-11 1 2 8'-1" 8'-0 1 2 1'-3 2 7'-11 2

34 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 35

36 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 37

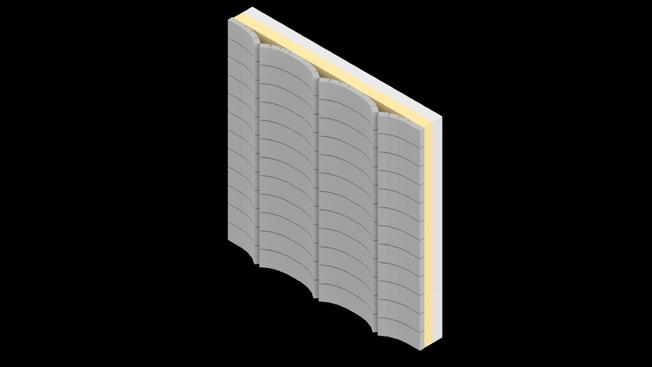

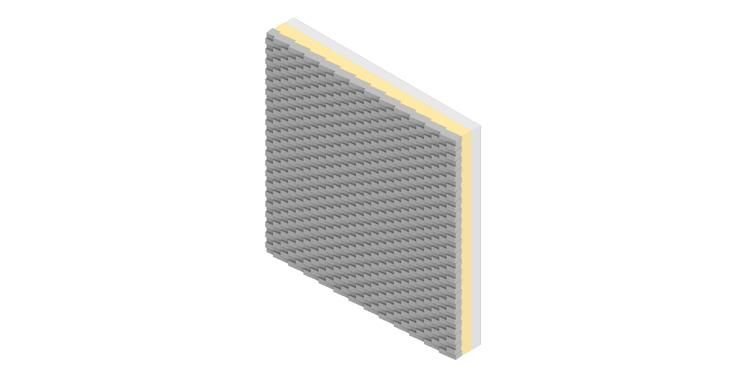

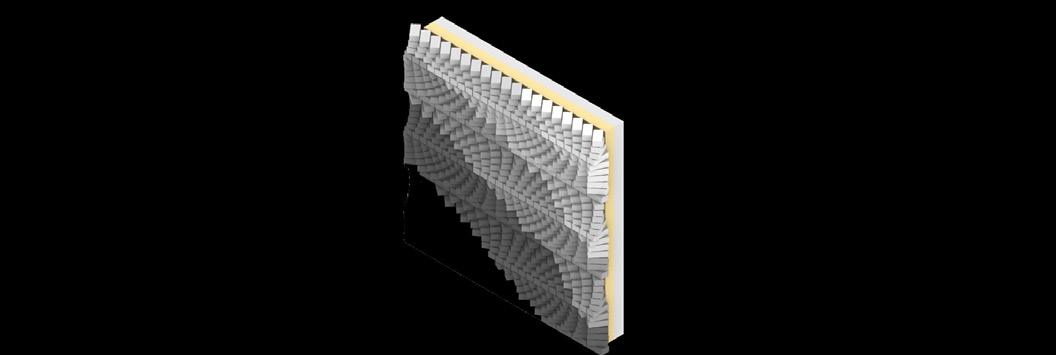

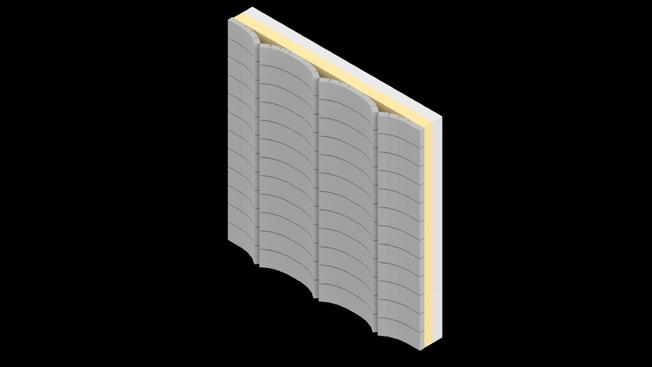

ITERATION 1

Number of Bricks: 421

Number of Half Bricks: 125

This wall contains a half brick that has a 15-degree angle that rotates every two bricks giving the wall dimension. These bricks alternate directions at every two bricks in the row. There are half and full standard bricks as well in this design.

38 | DSN S 546 MADE IN IOWA

6'-11 1 2 " 8'-2" 0'-8 1 2 " 6'-11 1 2 " 8'-2" 0'-8 1 2 6'-11 1 2 " 8'-2" 0'-8 1 2 " 6'-11 1 2 " 8'-2" 0'-8 1 2 "

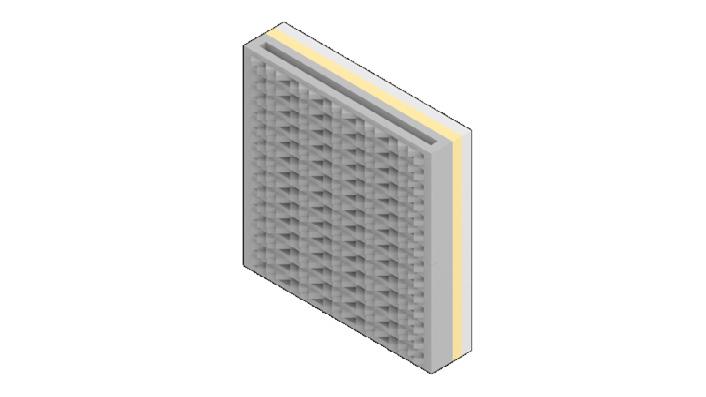

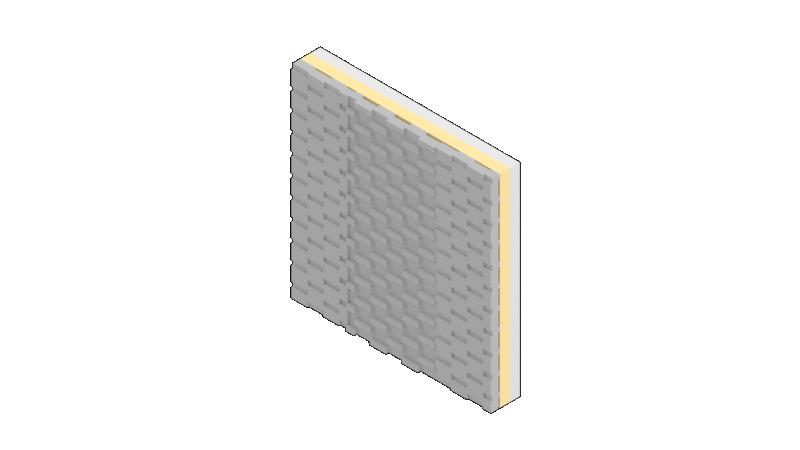

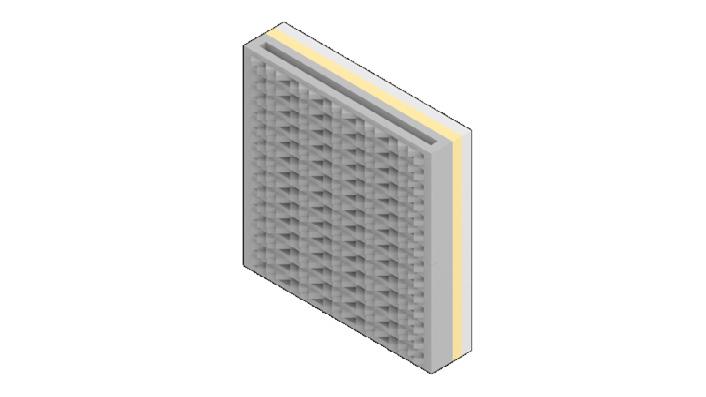

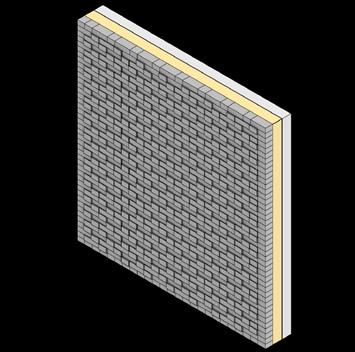

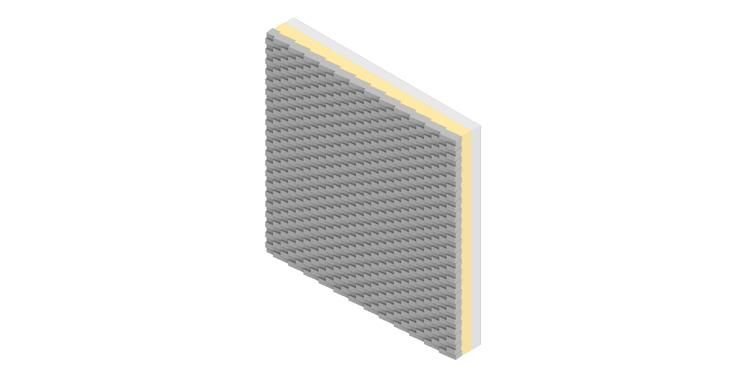

ITERATION 2

Number of Bricks: 425

Number of Half Bricks: 38

This wall design uses a sevendegree angle throughout the wall. The colors vary with an emphasis on the lighter bricks as we would have more material to create the wall. This design utilized half bricks to complete the corner condition of the wall, giving the bricks a seamless finish when connected to the shed.

DSN S 546 MADE IN IOWA | 39

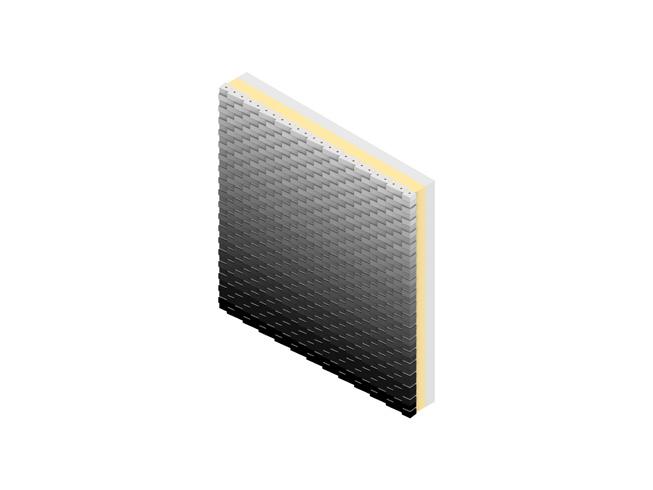

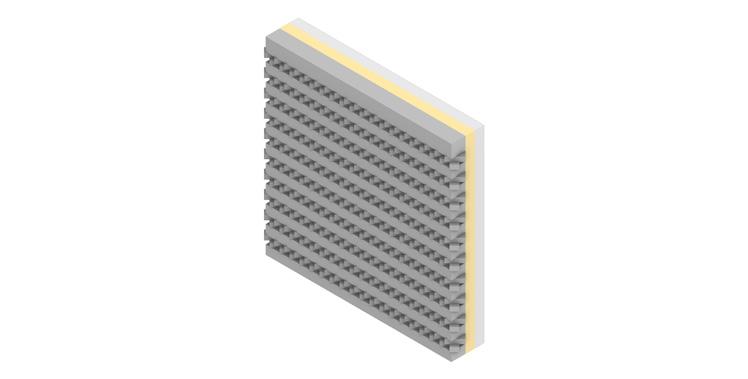

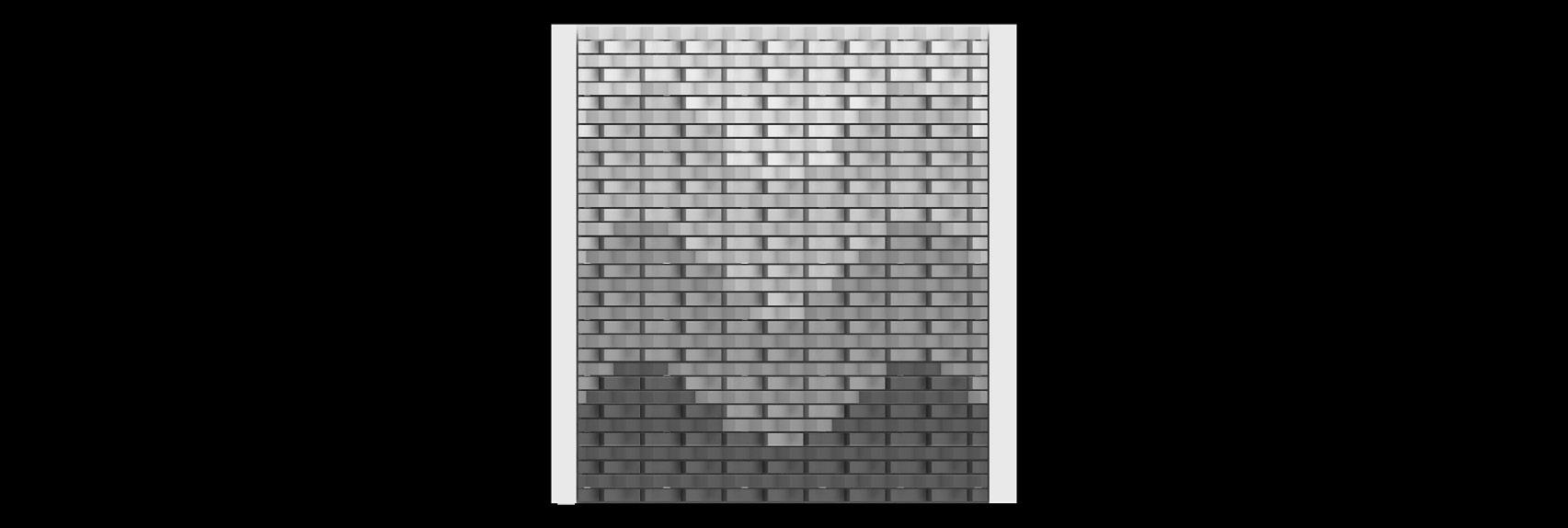

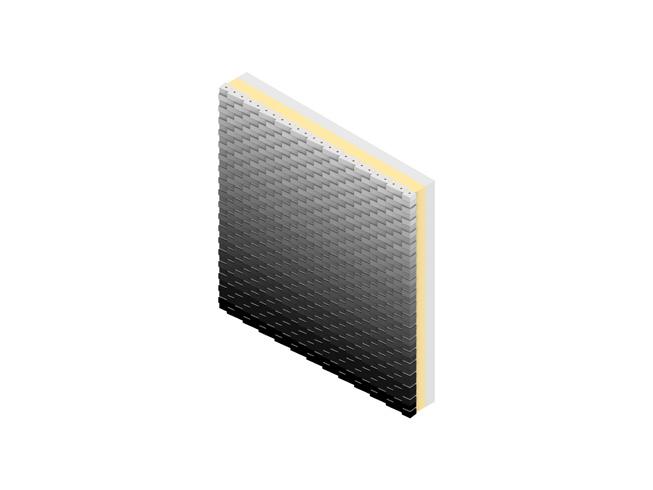

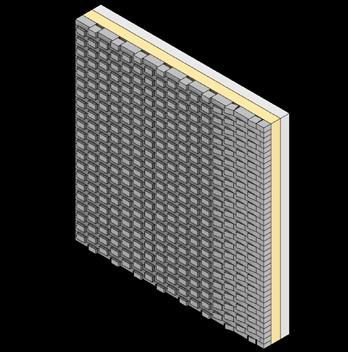

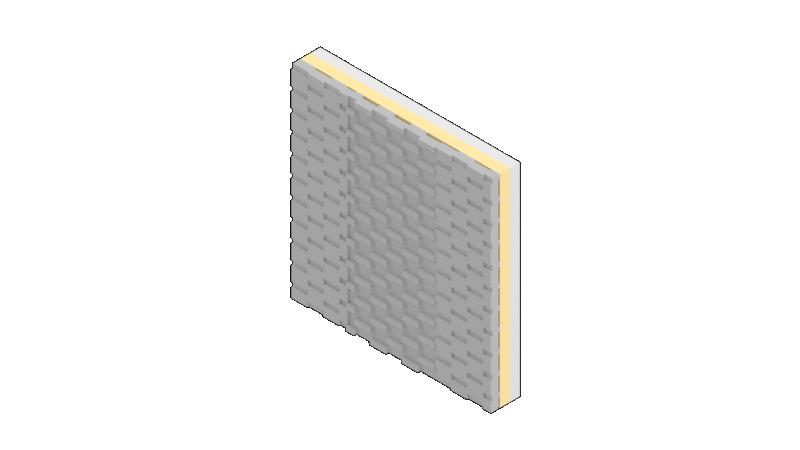

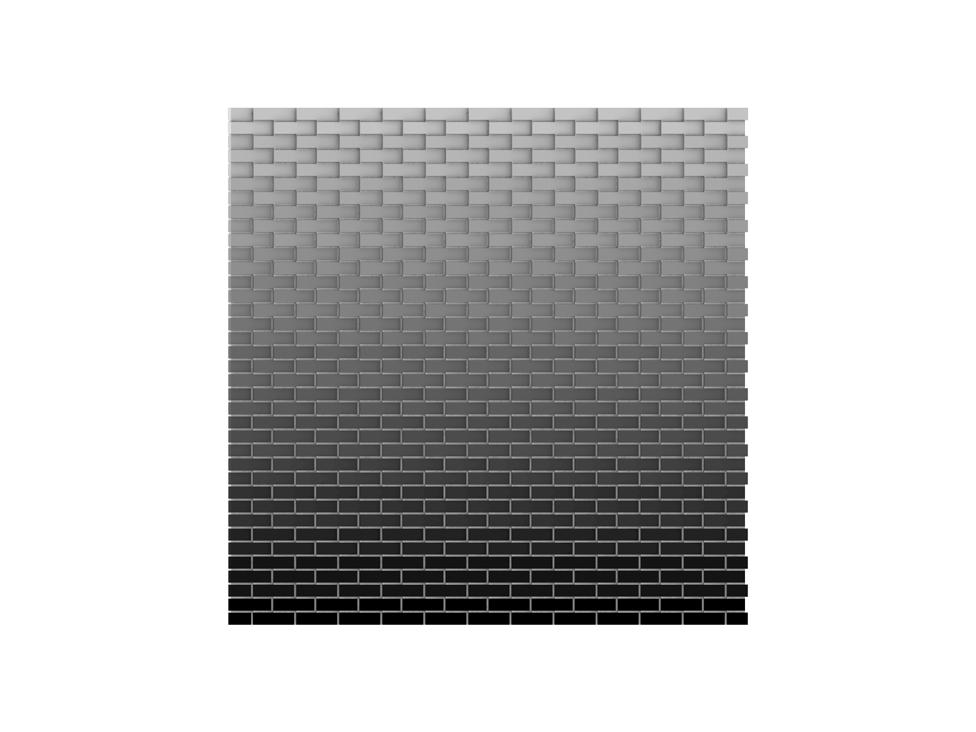

ITERATION 3

Number of Bricks: 391

Number of Half Bricks: 38

This wall design uses standard full bricks angled with two different layer rotations of eighteen and forty-five degrees. A wavy gradient pattern was designed and focuses darker bricks on the bottom of the wall as they tend to be more dense bricks compared to the lighter bricks. This wall has significant wood framing on the sides for extra support.

40 | DSN S 546 MADE IN IOWA 8'-2" 1'-1" 1'-0" 1'-1" 8'-2" 1'-0" 1'-1" 8'-2" 7'-11 1 2 " 1'-0" 1'-1" 8'-2" 7'-11 1 2 " 1'-0"

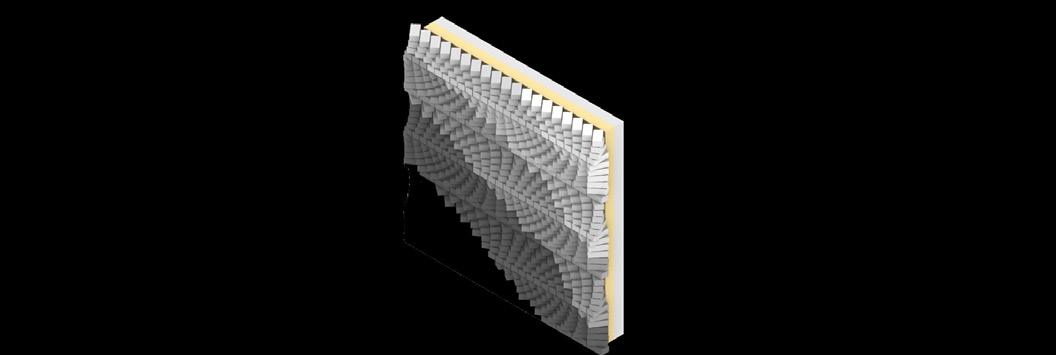

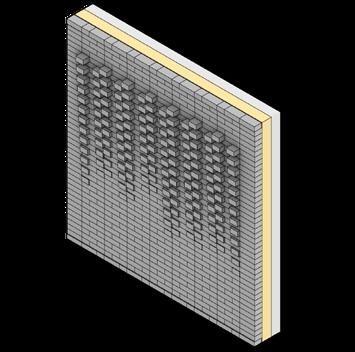

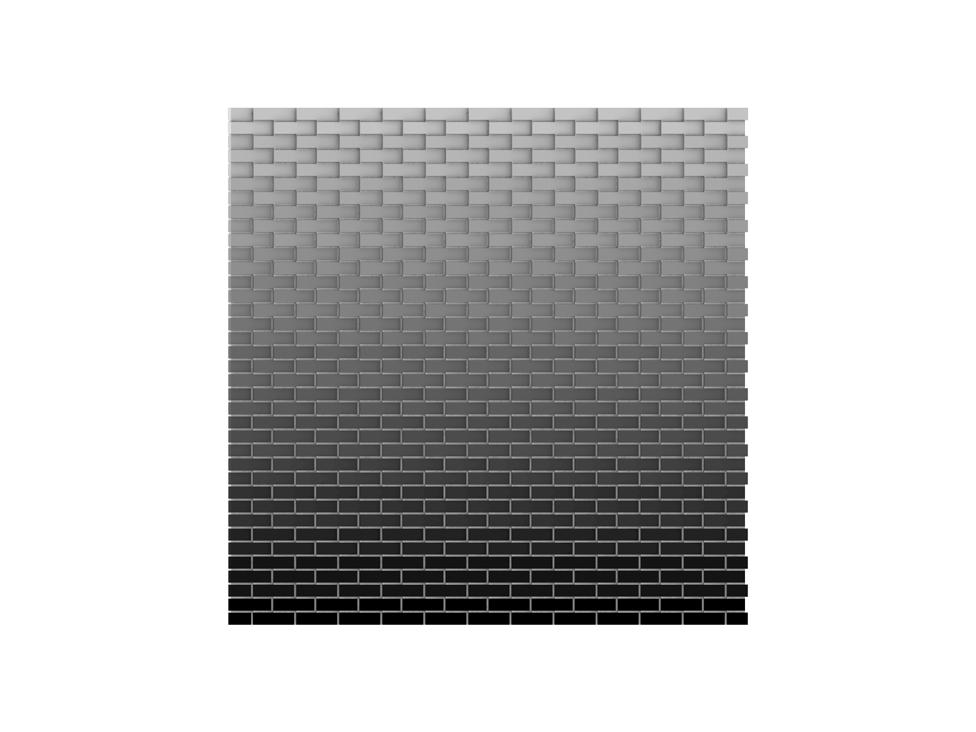

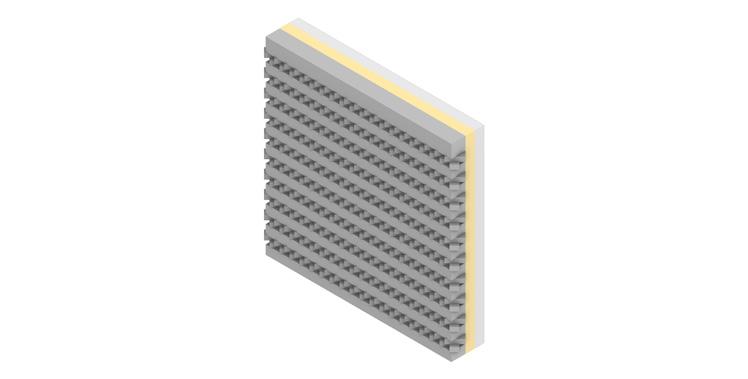

ITERATION 4

Number of Bricks: 426

Number of Half Bricks: 39

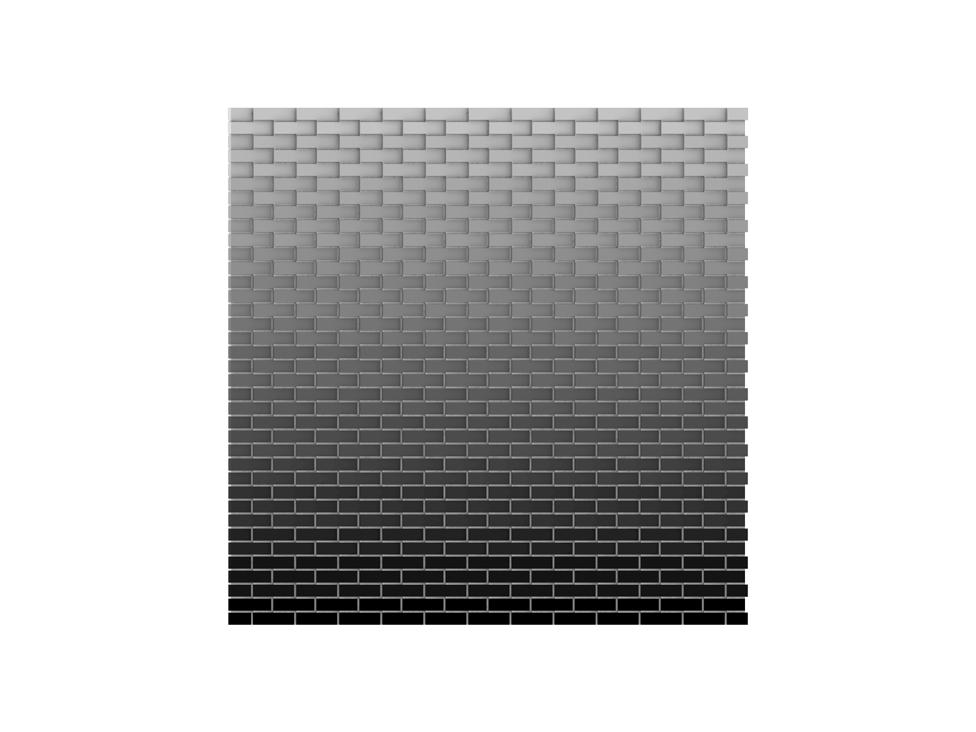

This wall design focuses on a simple angle emphasizing a strong gradient throughout the wall. The bricks on this wall are angled at seven degrees, giving the wall a textural quality while still remaining strong. The gradient pattern on this wall features fifteen different shades and gives a soft gradient starting from the bottom to the top.

1'-1 1 2 " Section Plan Elevation 8'-0 1 2 " 1'-1 1 2 " 8'-1" 1'-2"

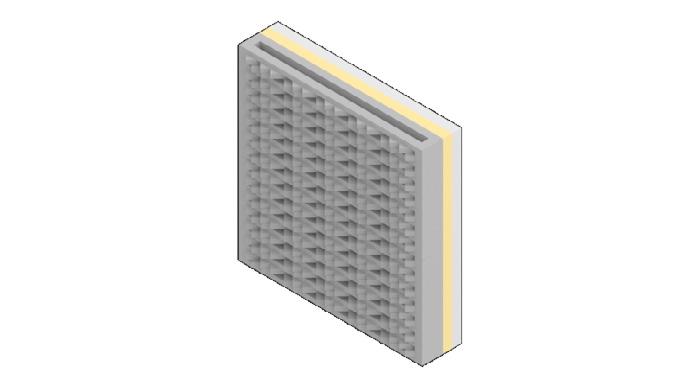

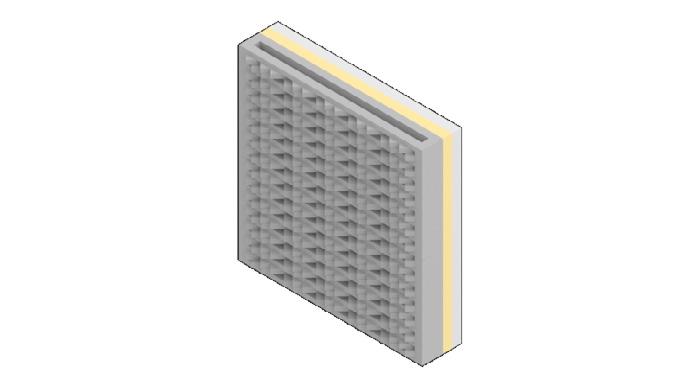

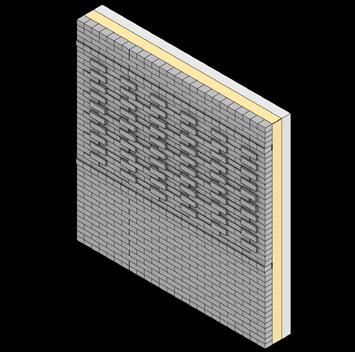

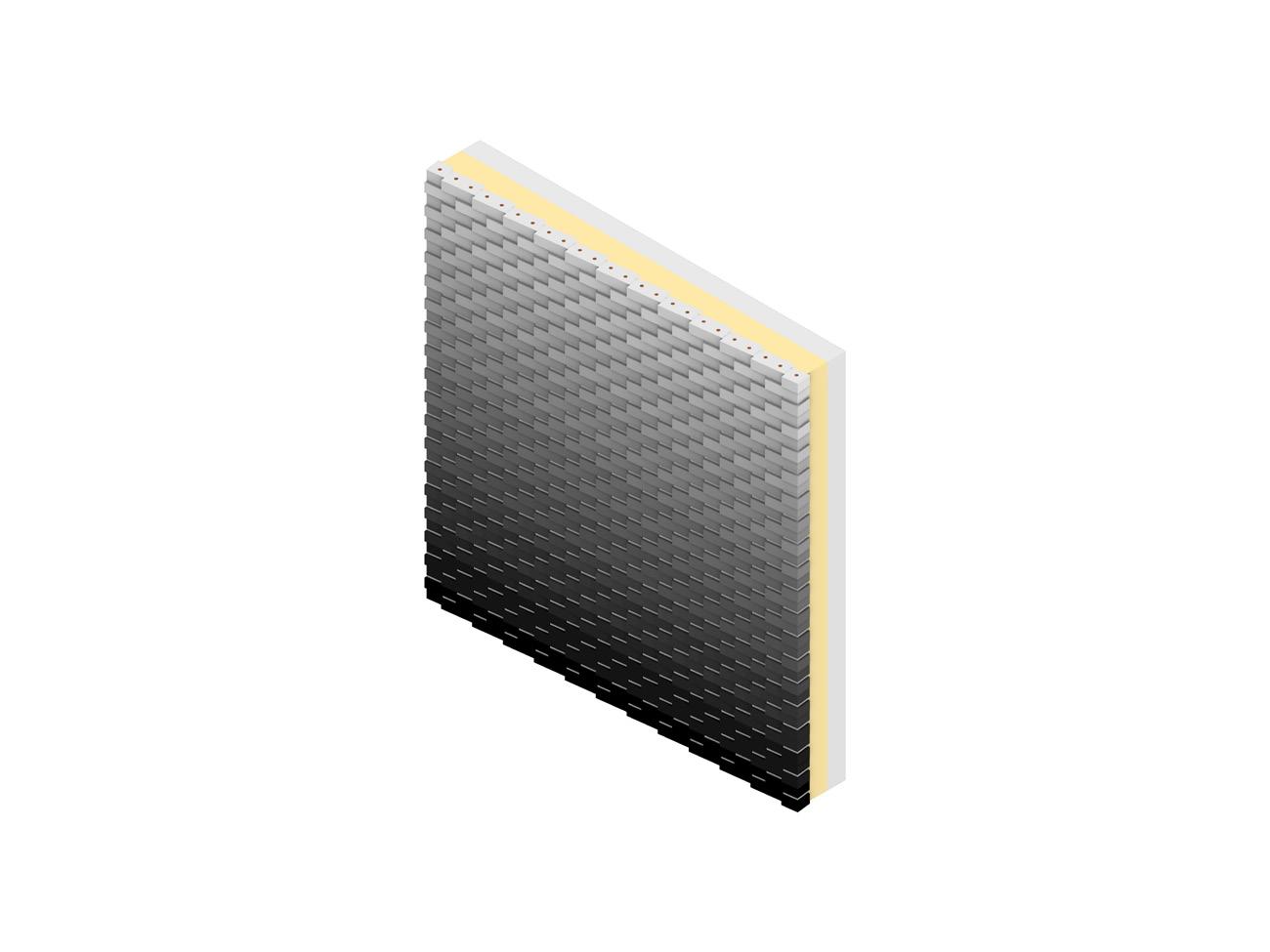

FINAL WALL DESIGN

Number of Bricks: 433

Number of Half Bricks: 36

Our final wall design featured a series of angled bricks at seven degrees stacked in a gradient. The studio determined that this design provided an elegant design while also being highly responsive to light conditions that would change its appearance throughout the day.

42 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 43

Brick Layer Dimensioned Plan 1 3 16 " 1 2 " 82 1 16 9 1 2 74" 2 5 16 " 2 1 8 " 65 15 16 1 3 8 1 7 8 57 7 8 1 7 16 " 1 15 16 1 4 94 1 8 " 4 15 16 " 49 13 16 " 1 7 8 41 3 4 " 17 9 16 90 1 8 33 11 16 " 25 5 8 3 8

Brick Wall Coursing

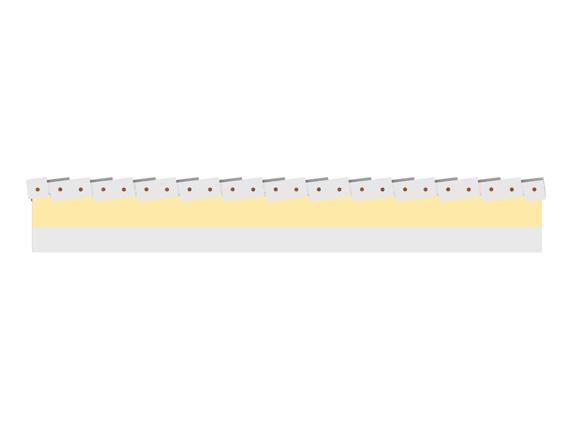

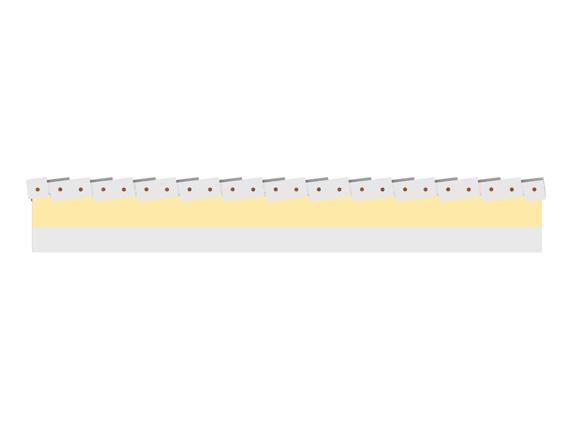

WALL CONSTRUCTION

A team of brick casters and brick layers were assembled to construct the wall over the course of three studio days weekly for a month. To begin the construction process of our 8’x8’ wall design onto the existing shed, a meticulous organization process of labeling bricks and referencing a draft elevation allowed for the seamless construction of our wall. The area for the wall to be constructed was then prepared and leveled to create a stable foundation. Mortar was then poured with the first layer of bricks applied. After ensuring the first layer was level, this process was then repeated, referencing the elevation to ensure the accuracy of our angled wall design.

44 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 45 3/183/22 3/253/29 4/14/5 4/84/12 4/154/19 Monday Tuesday Wednesday Thursday Friday Mixing Casting Group 1 Casting Curing Mixing Casting Group 1 Casting Curing Brick Curing in Mold Brick Curing in Mold Casting Group 1 Demold Casting Group 2 Mixing Demold Casting Curing Construction Group Wall Framing Construction Construction Group Wall Framing Construction Construction Group Brick Wall Construction (Lay 6 Rows) Construction Group Brick Wall Construction (Lay 6 Rows) Construction Group Brick Wall Construction (Lay 6 Rows) Construction Group Brick Wall Construction (Lay 6 Rows) Construction Group Brick Wall Construction (Lay 3 Rows) Construction Group Brick Wall Construction (Lay 6 Rows) Brick Curing in Mold Casting Group 3 Mixing Demold Casting Curing Mixing Casting Group 1 Casting Curing Casting Group 1 Demold Casting Group 2 Mixing Demold Casting Curing Casting Group 3 Mixing Demold Casting Curing Mixing Casting Group 1 Casting Curing Casting Group 1 Demold Casting Group 2 Mixing Demold Casting Curing Casting Group 1 Demold Casting Group 3 Mixing Demold Casting Curing March 22nd - April 17th

46 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 47

FOLOGRAM ELEVATION

The studio leveraged Fologram, a mixed-reality program, to aid with the visualization and construction of our 8’x8’ wall. Linking our Rhino model to the physical parameters of the shed allowed for the visualization of our wall design in real space.

48 | DSN S 546 MADE IN IOWA

CONSTRUCTED ELEVATION

The constructed elevation varied slightly from the Fologram elevation, given human error and a variety of other environmental factors that impacted the brick-laying process. Regardless, an overall gradient was still achieved, and the desired effect was visible.

DSN S 546 MADE IN IOWA | 49

50 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 51

52 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 53

54 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 55

CONCRETE

3D PRINTING

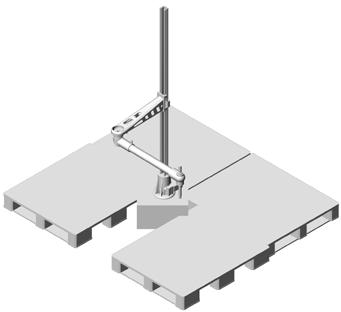

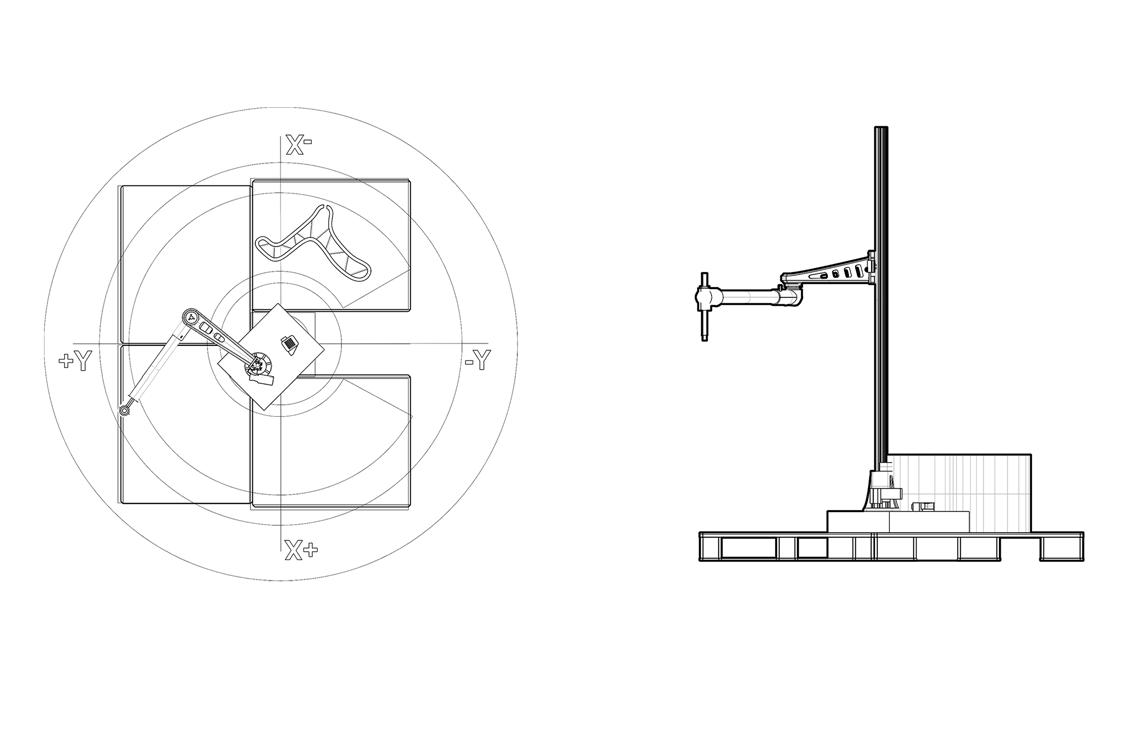

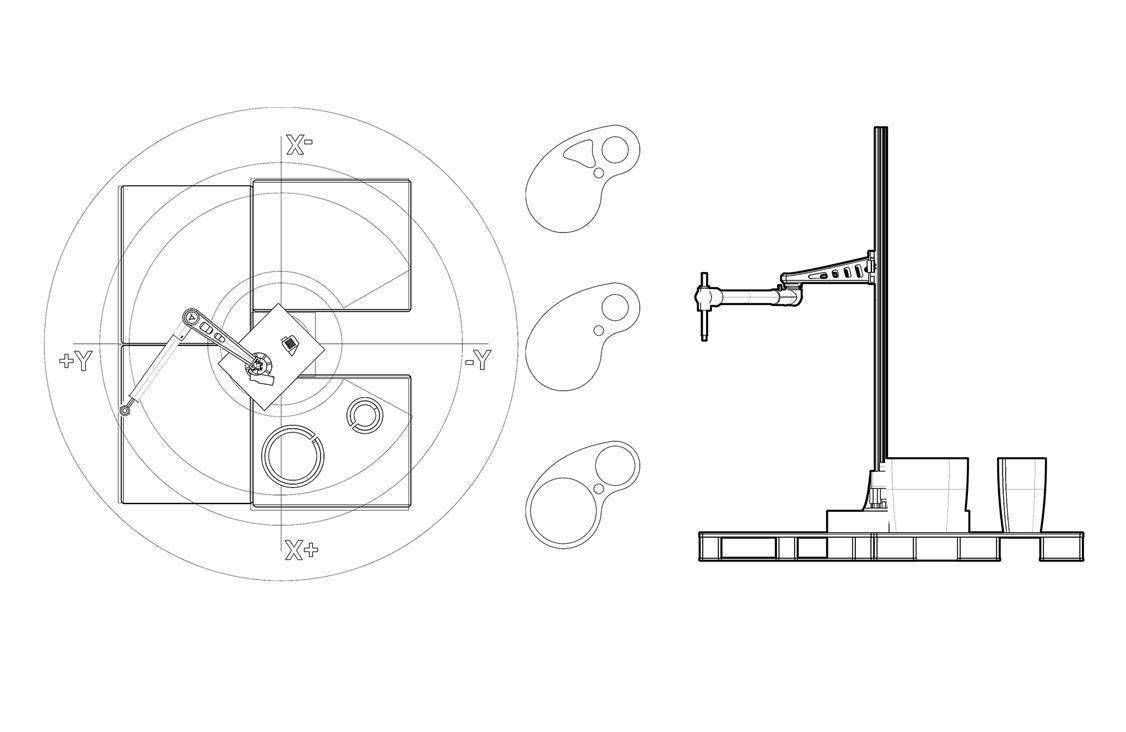

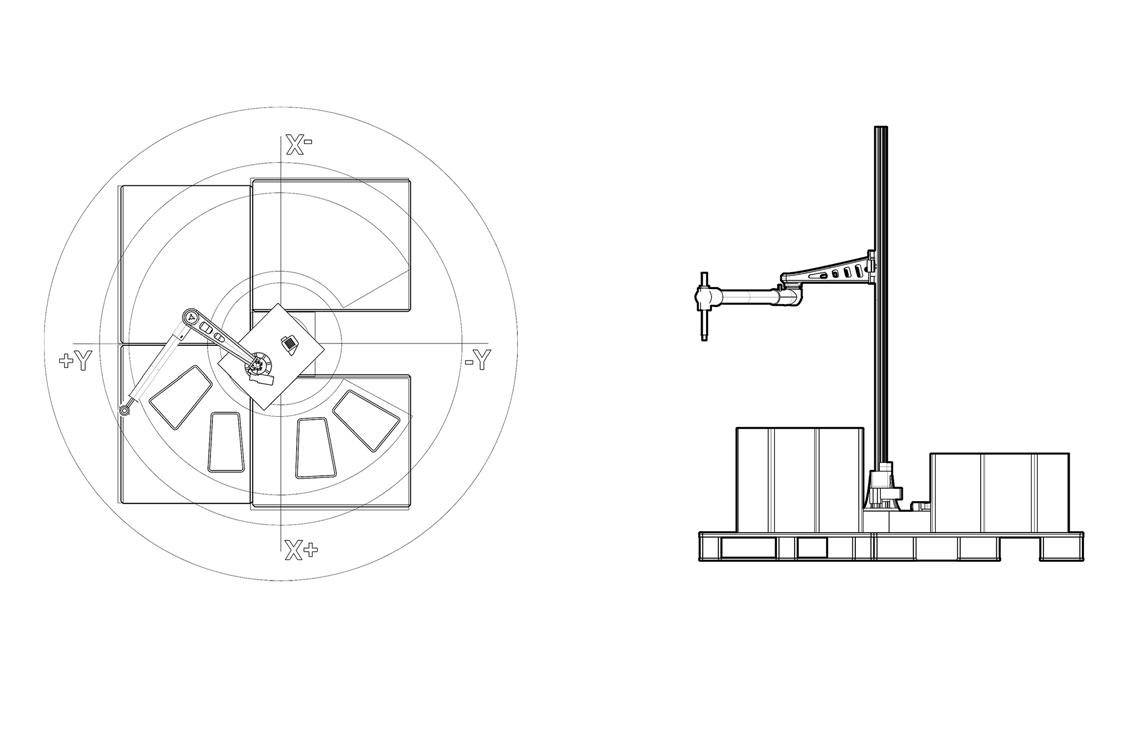

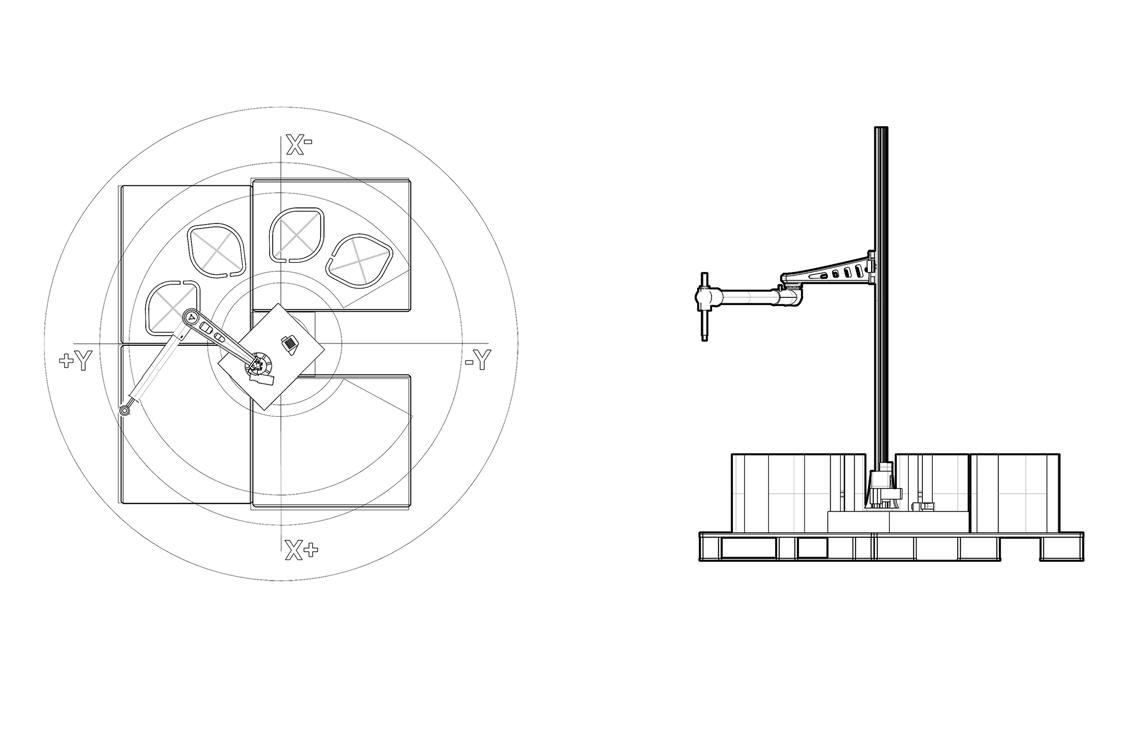

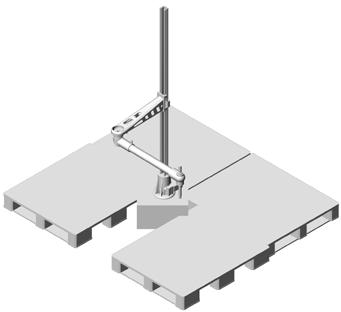

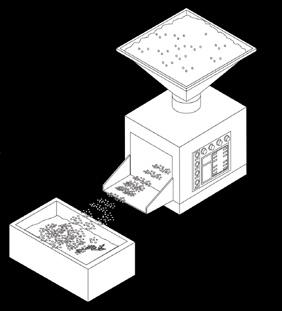

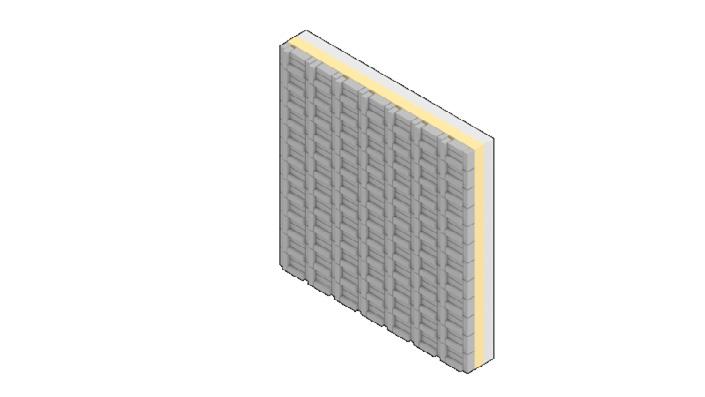

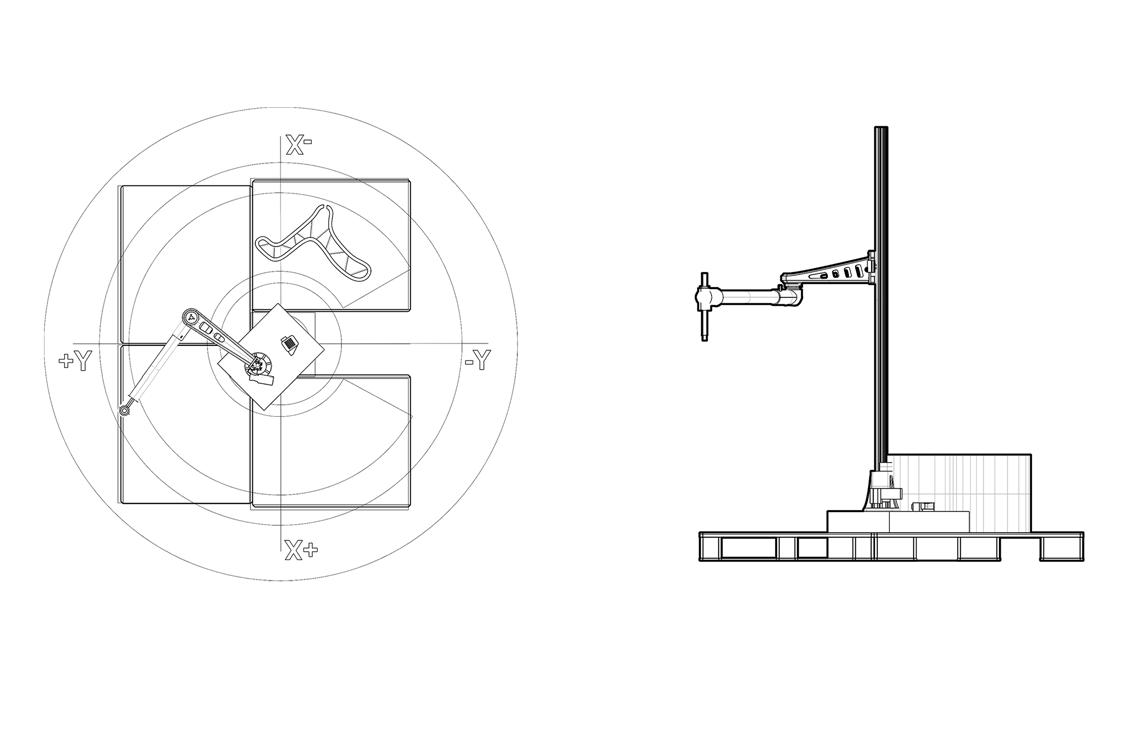

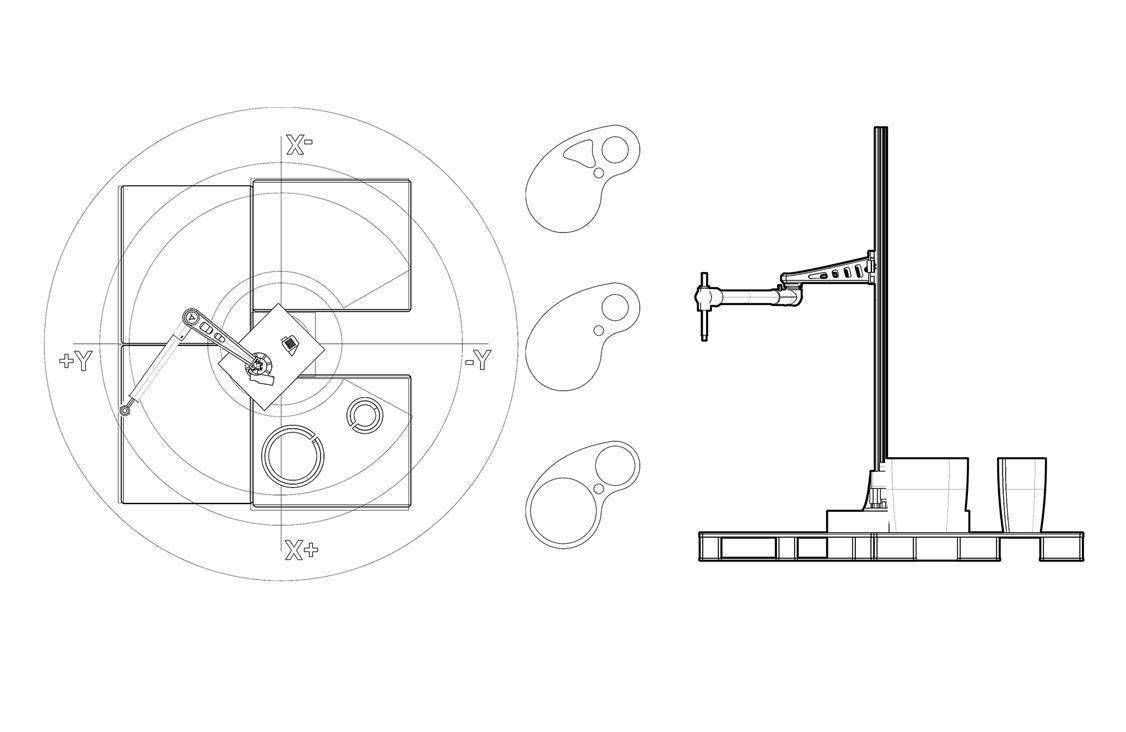

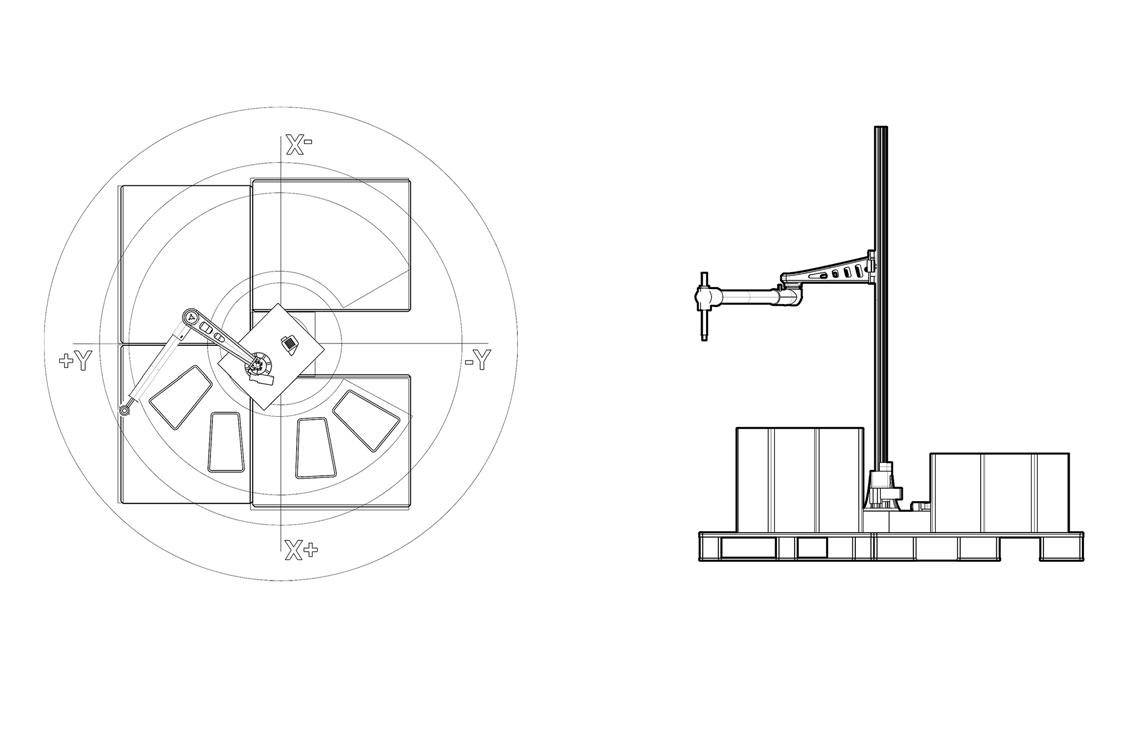

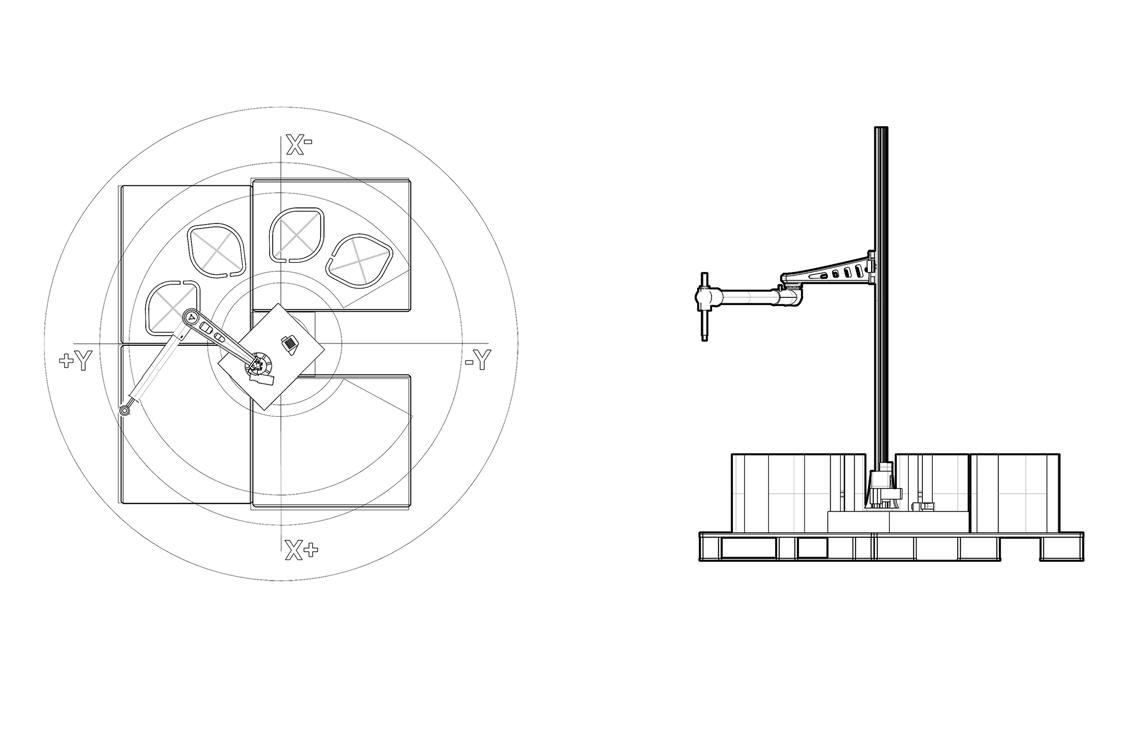

3D concrete printing presents an opportunity to transform the way buildings and infrastructure are designed and constructed. As additive manufacturing techniques continue to be developed and refined, a broader set of applications becomes feasible. On a smaller scale, our studio explored 3D concrete printing utilizing the material Sikacrete and a SCARA robot retrofitted with a concrete extrusion system. The process of 3D concrete printing began with digital modeling in Rhino to explore various seating and planter designs to be displayed during the Spring 2024 Ignite Symposium. Once digital designs were finalized and verified for viability, the labor-intensive process of setting up the 3D concrete printer was undertaken.

The set-up consisted of four plastic pallets arranged radially with the SCARA robot at the center. Various teams of students coordinated to achieve a consistent mix ratio, oversee the printing and extrusion process, document, and run the code. In the end, four planter and seat designs were successfully created. Experimenting with concrete additive manufacturing allowed the studio to explore complex geometries with precision and speed while also optimizing for material waste. This smallscale investigation, paired with the construction of the shed, gives optimism for additive manufacturing to be used in a variety of commercial applications, including housing and public infrastructure projects.

DSN S 546 MADE IN IOWA | 57

3D CONCRETE PRINTING

This studio gave us the opportunity to design and produce 3D concrete printed elements. This building technology allowed us throughout the semester to experiment and create pieces that push the limits of 3D printing. As the semester went on, we quickly realized how resource-intensive, delicate, and messy 3D concrete printing is. The hardships of 3-D printing concrete make this a key area of building technology to study, as the development of this concrete could lead to more carbon-neutral buildings and easier production of concrete structures.

58 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 59

THE CHAIR

This concrete 3D print took advantage of the simplicity of the single line used when 3D printing concrete, transforming it into a chair design. Through this continuous line, the chair achieves both structural integrity using the structural rebar and aesthetic appeal with the unique shape and form. Reinforced with rebar for enhanced strength and durability, the chair utilizes the single-line form to create both its bottom and backrest.

print isometric

60 | DSN S 546 MADE IN IOWA

print

plan/elevation

DSN S 546 MADE IN IOWA | 61 Images of print

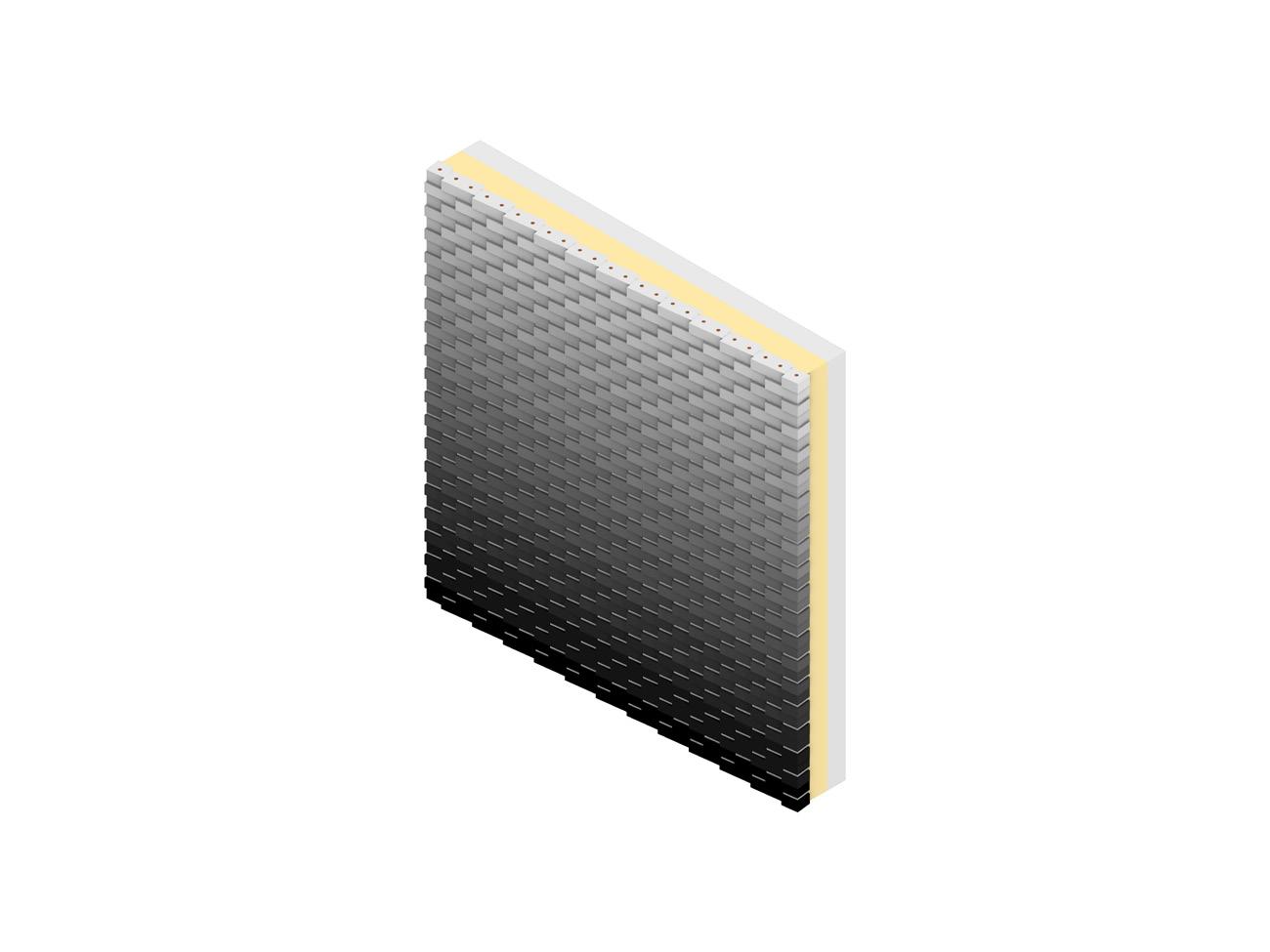

THE BENCH

This bench design integrates 3D printed concrete and CNCrouted plywood to create a functional and aesthetically pleasing bench. The structural integrity of the bench is ensured using 3D printed concrete pieces that are filled with spray foam. The larger bottom piece serves as the base that will support the weight of a person, while the smaller bottom piece is designed to accommodate a plant. The top piece of the bench is crafted from plywood that has been cut down using CNC routing, resulting in a unique and ergonomic shape. The plywood was then glued together, stained, and finished, providing a comfortable seat to users.

print isometric

print plan/elevation

62 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 63 Images of print

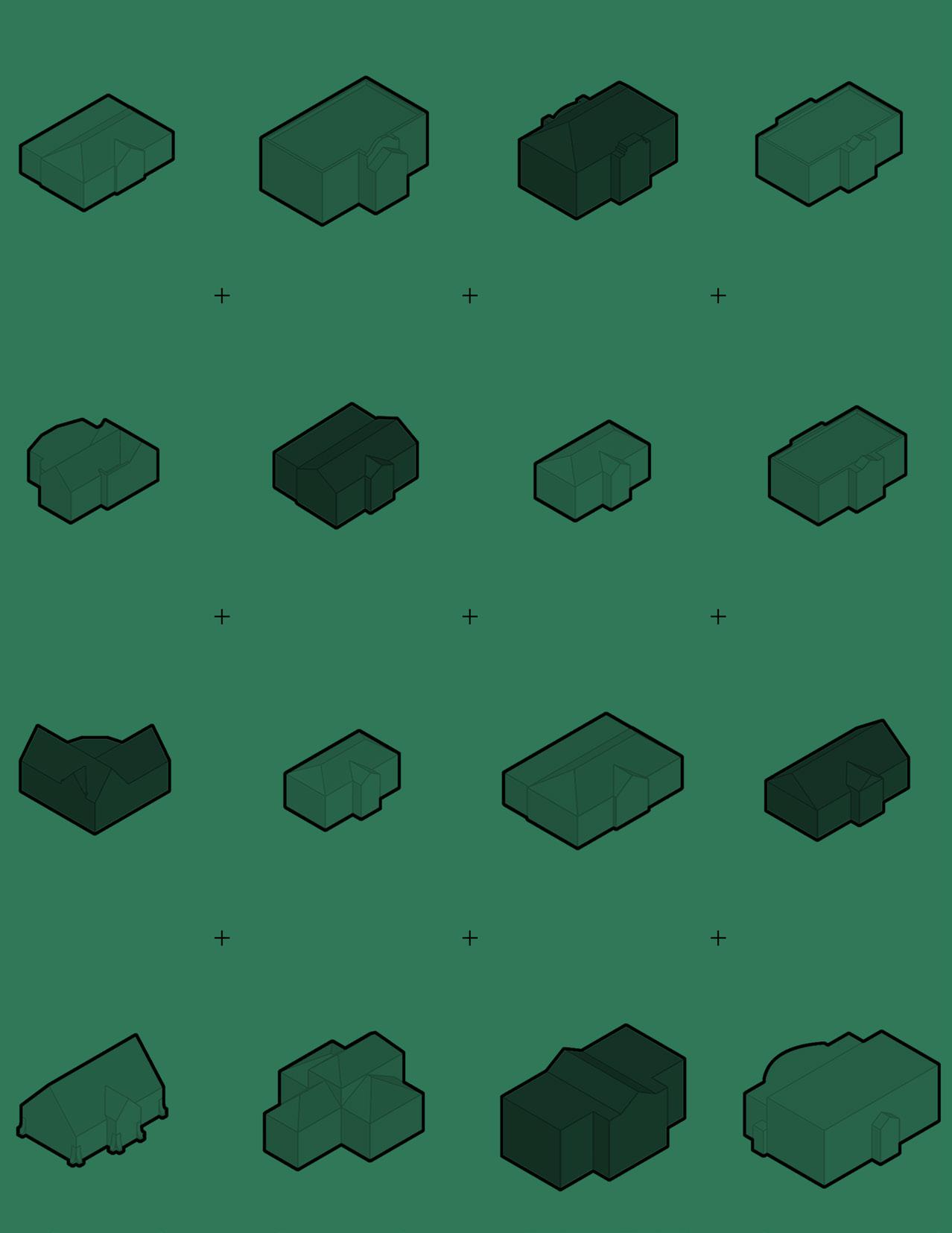

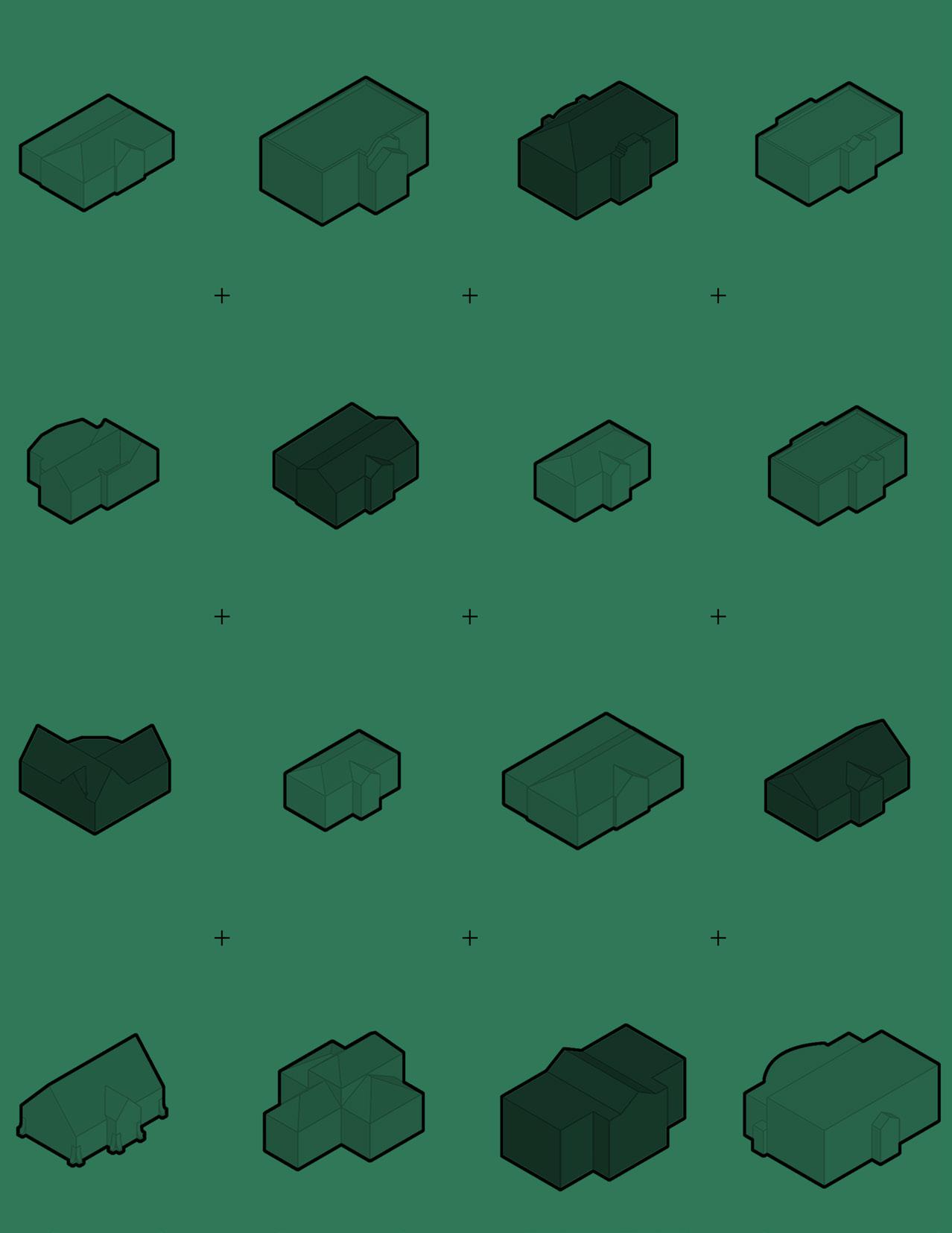

This concrete 3D print showcases parametric design, generating a series of distinct shapes that serve a variety of functions. Some pieces are crafted to function as seats, while others are designed to double as planters, all while maintaining a consistent and versatile shape. Each object is uniquely tailored to fulfill its purpose, whether providing a comfortable seating option or serving as a planter. Despite their different functions, all pieces share a common design language, enabling integration into a cohesive design.

print isometric

64 | DSN S 546 MADE IN IOWA

THE KERNEL

print plan/elevation

DSN S 546 MADE IN IOWA | 65 Images of print

THE PETAL

This concrete 3D print serves a dual purpose as both a planter and a bench, offering users a versatile seating solution with a floral design. Crafted with a unique shape, it provides a comfortable spot to sit, while its design allows it to transform into a petal/flower shape when turned flat. The individual pieces of this multifunctional piece were printed into petal-like forms, which, when assembled, create a flowerinspired shape. To ensure durability and strength, the concrete pieces are reinforced with rebar, providing stability and support for the seating arrangement.

print isometric

66 | DSN S 546 MADE IN IOWA

print plan/elevation

DSN S 546 MADE IN IOWA | 67 Images of print

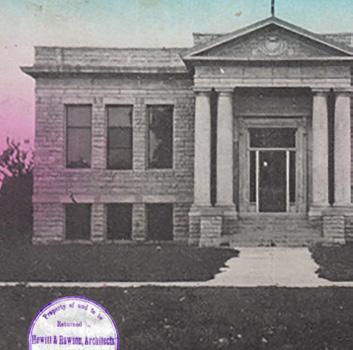

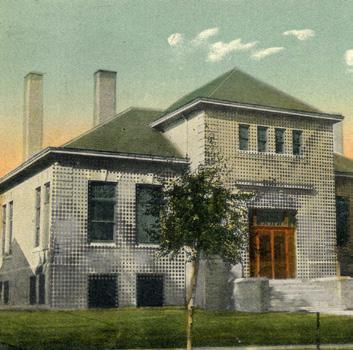

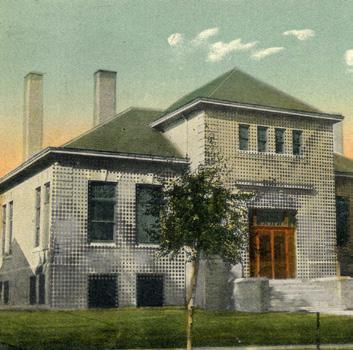

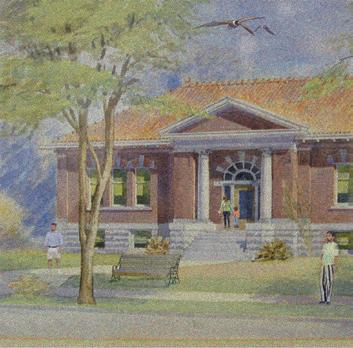

CARNEGIE LIBRARIES OF IOWA

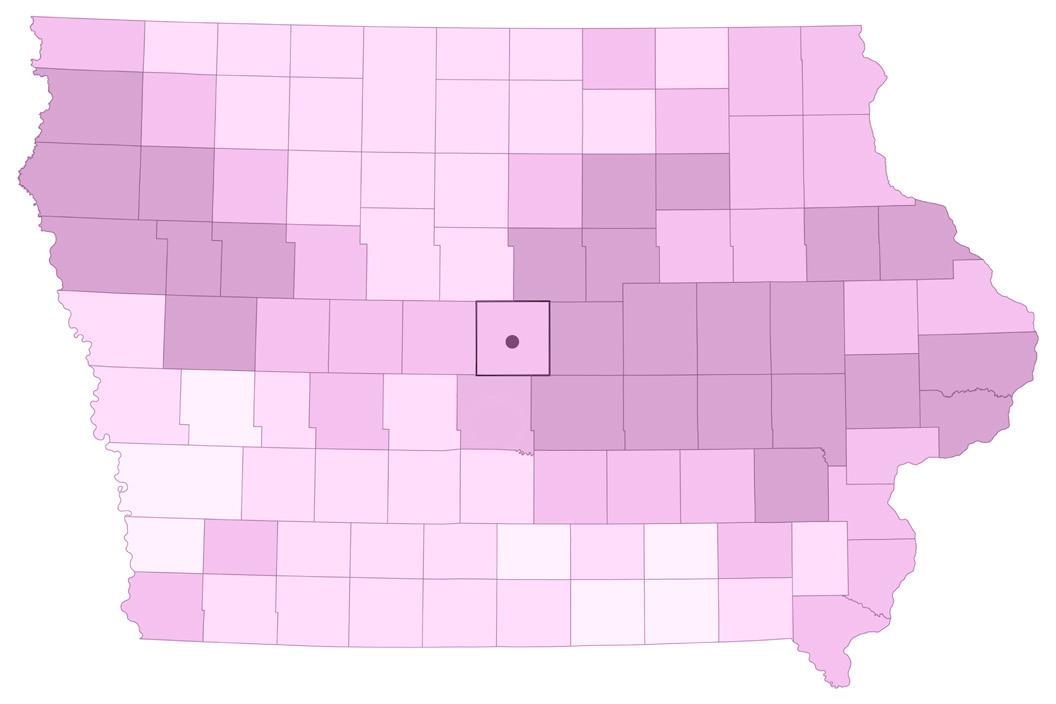

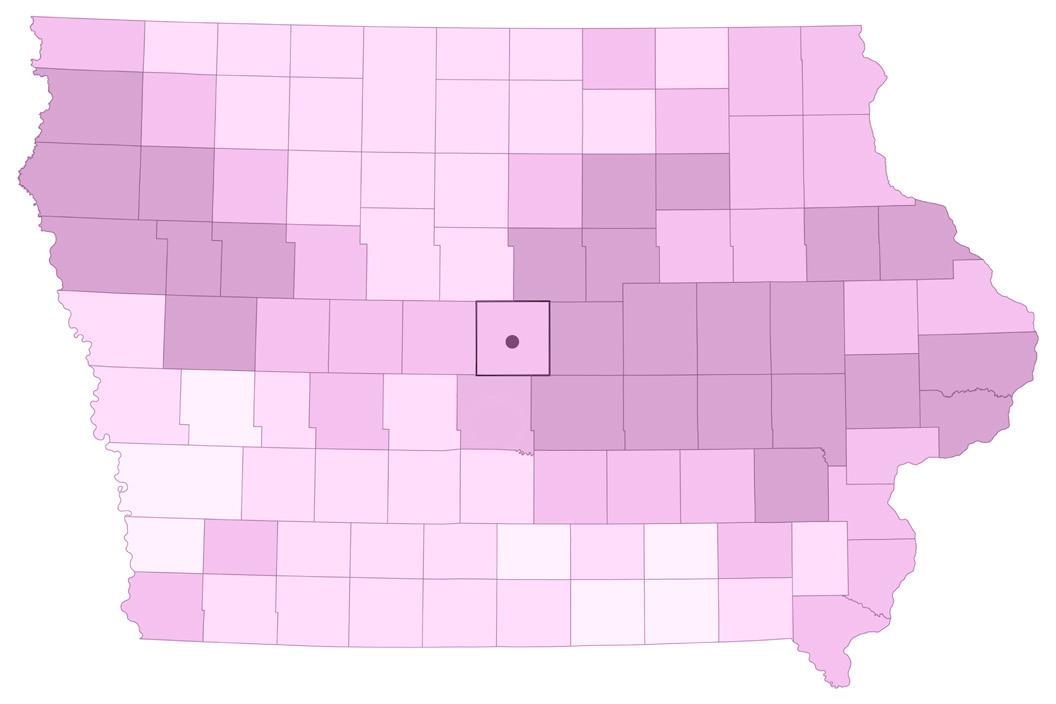

A Carnegie Library is a library built with money donated by Scottish-American businessman and philanthropist Andrew Carnegie. A total of 2,509 Carnegie libraries were built between 1883 and 1929, including some belonging to public and university library systems. 1,689 were built in the United States, 660 in the United Kingdom and Ireland, 125 in Canada, and 25 others in Australia, South Africa, New Zealand, Serbia, Belgium, France, the Caribbean, Mauritius, Malaysia, and Fiji. The first secretary of the Iowa Library Commission, Alice S. Taylor, criticized the use of Carnegie funding for extravagant buildings rather than providing quality library services. Carnegie’s funds covered only the library buildings themselves, and Carnegie gave library buildings to cities on the condition that the cities stocked and maintained them. As a result, small communities often struggled with maintenance costs associated with Carnegie libraries; towns were often happy to accept funding for new library buildings but often unwilling to allocate taxes for upkeep. In fact, this was the most frequent complaint about Carnegie libraries in hindsight: gifting libraries to towns too small to support them actually slowed the development of regional libraries that those communities now rely on.

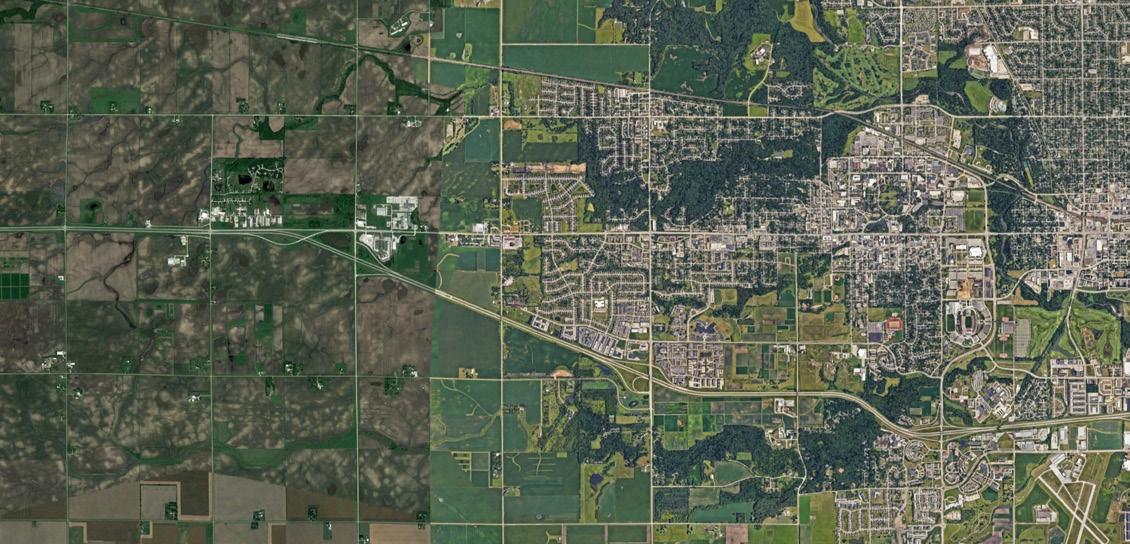

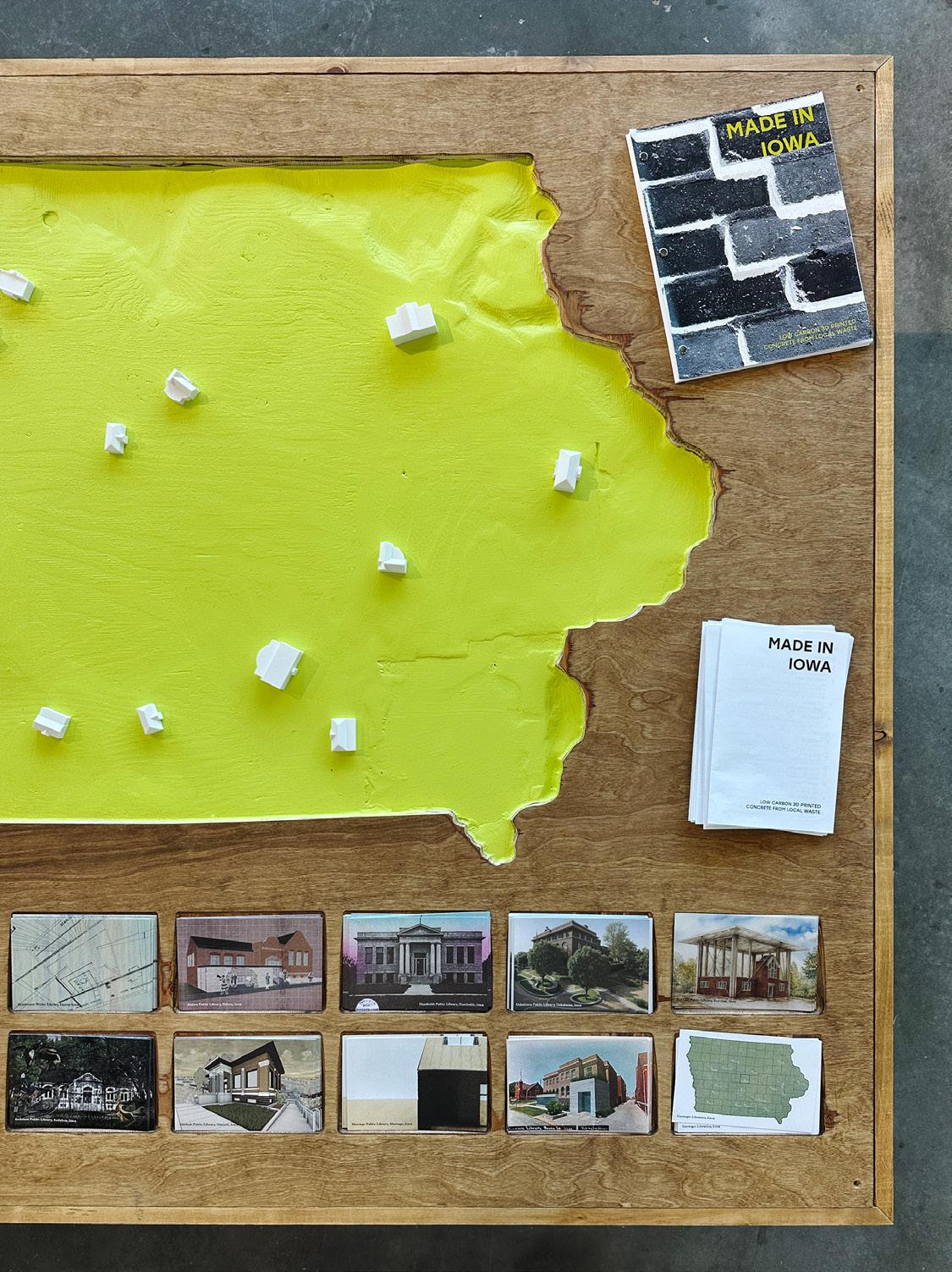

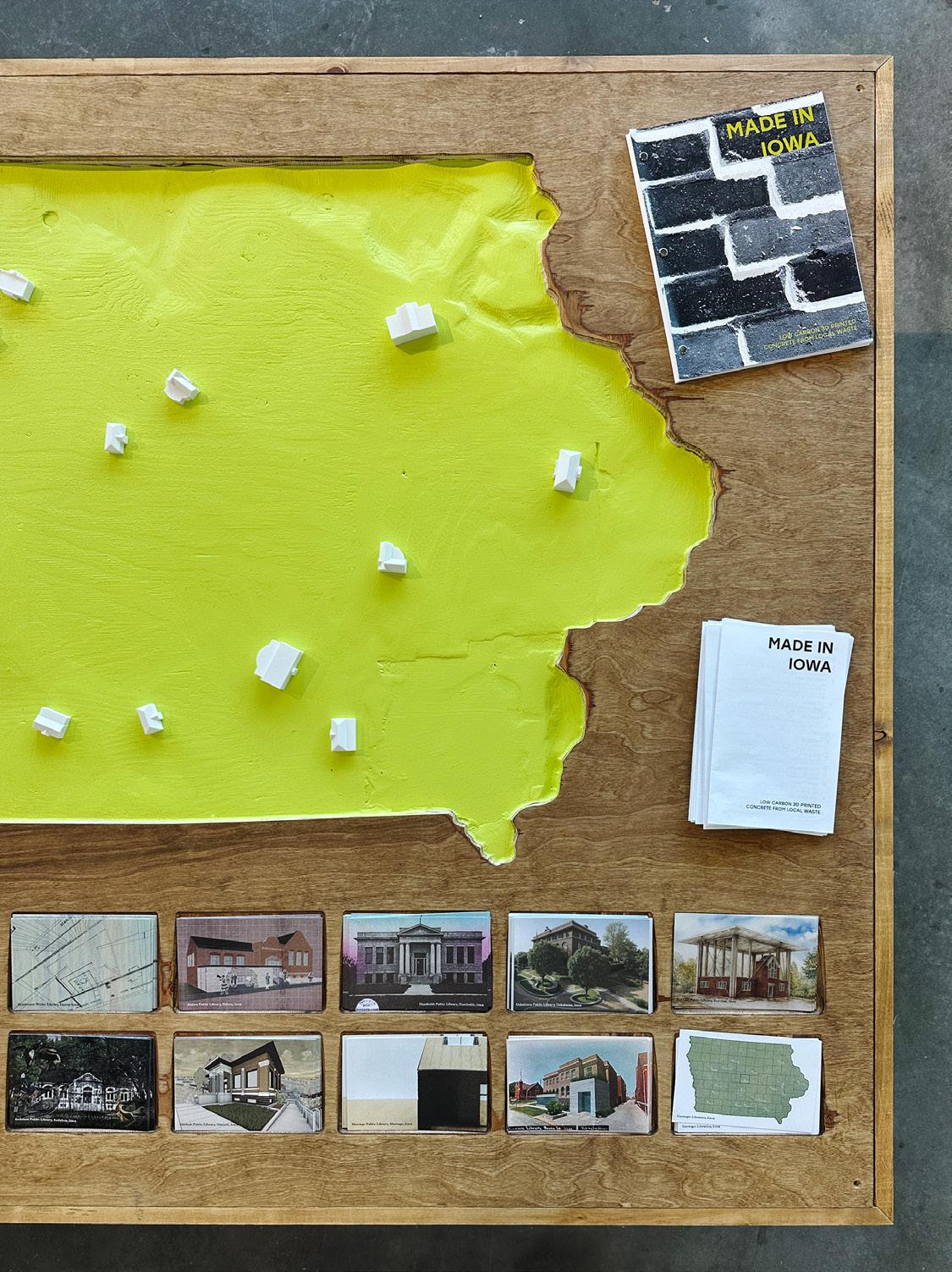

Iowa was home to 101 Carnegie libraries - many in small or shrinking towns that can no longer support maintaining and stocking the libraries due to declining populations and the transition to digital materials. Our task was to pick a Carnegie library around the state and use innovative building technologies and creative thinking to develop an artist residency.

DSN S 546 MADE IN IOWA | 69

SITES OF INQUIRY

This project imagines that the Iowa Arts Council has received a Mellon Foundation Grant to create a network of creative residencies housed in the remaining Carnegie Libraries. Each residency is 1-3 months long and residents are provided with the entire space of the library and space to cook, rest, and conduct creative work that ranges across creative practices from drawing and painting to weaving and sculpture to architecture and technology. Each residency will conclude with a public facing exhibition, workshop, or event located at the library - or public engagement may occur throughout the residency.

Using the materials and technologies we have explored this semester design a proposal to meet the above criteria: eating, sleeping, making, display / engagement. Consider the entire siteinterior / exterior - as your design area.

70 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 71

72 | DSN S 546 MADE IN IOWA

L to R: Mircea Nastase, Daniel Leira, Gabriel Yingst

L to R: Mahsa Keyhani, Nicole Friedman, Gabriel Phillips, Nick Cheung

L to R: Thomas Hewitt, Weston Fantz, Zachary Lin, Priya Barot

L to R: Evan Corkery, Jaren Pierce, Connor Shanahan, Mona Kazemian

DSN S 546 MADE IN IOWA | 73

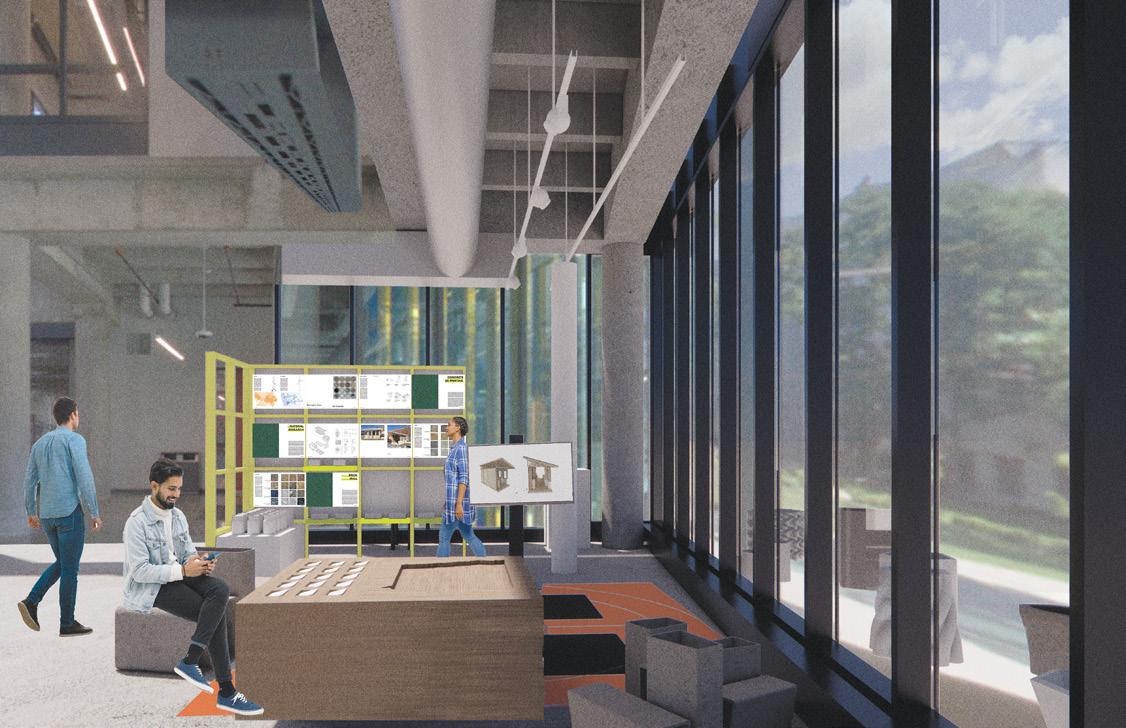

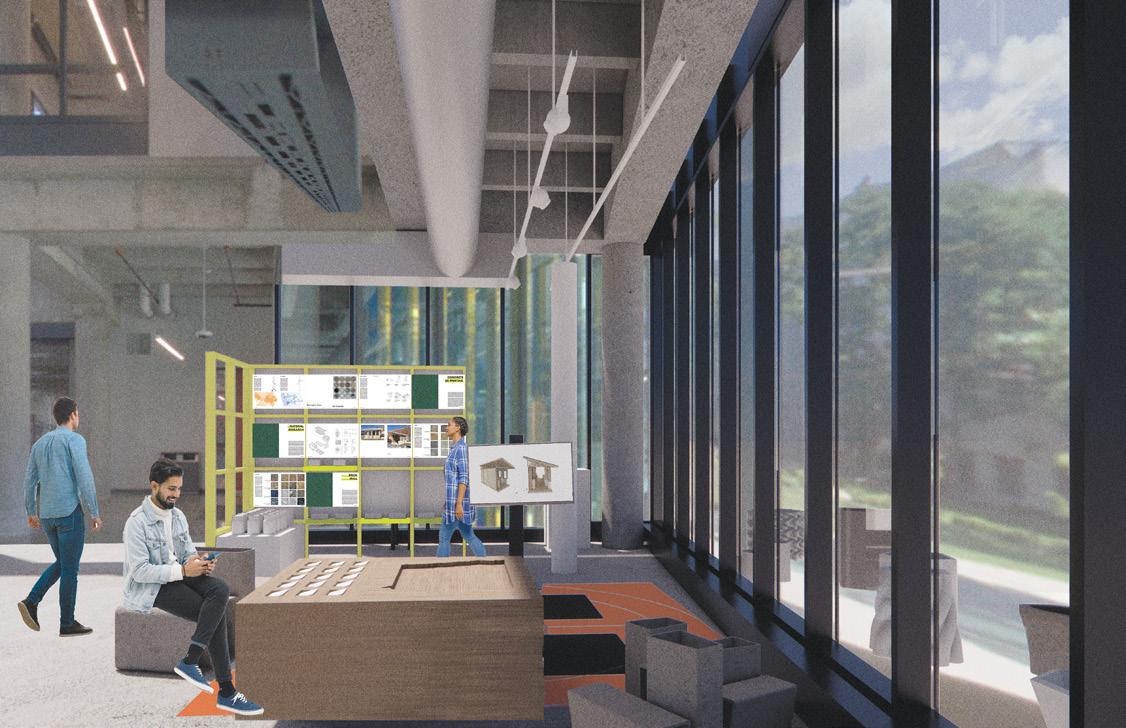

FINAL EXHIBITION

As part of this innovative studio, we were asked to participate in the IGNITE Exhibition at the Student Innovation Center. This exhibition is a semester long worth of work that demonstrates innovative building technologies. As the name of the studio suggests, Made in Iowa: Low Carbon 3D Printed Concrete from Local Waste, our focus was on concrete and 3-D printed concrete using local waste from Iowa. Heavily featured in our exhibition are the two local waste materials, biochar, and wind turbine fiberglass. This exhibition includes work from brick making, casting, and the process of production, 3-D printed concrete pieces, 3-D models, Carnegie libraries from the state of Iowa, and a brick wall that is demonstrated using AR, Augmented Reality. This exhibition is interactive and allows people to touch, explore, and learn about these new building technologies.

DSN S 546 MADE IN IOWA | 75

76 | DSN S 546 MADE IN IOWA

planters located outside were designed by fourth-year architecture students during the Fall 2023 and printed in Salt Lake City, Utah, in collaboration with PIKUS 3D, a commercial landscape element 3D printing company.

DSN S 546 Made in Iowa work done by Nicole Friedman, Daniel Liera, Zachary Lin, Jaren Pierce DSN S 546 Made in Iowa work done by Evan Corkery, Thomas Hewitt, Gabriel Yingst, Connor Shanahan

DSN S 546 Made in Iowa work done by Priya Barot, Nick Cheung, Mona Kazemian

DSN S 546 Made in Iowa work done by Weston Fantz, Mahsa Keyhani, Mircea Nastase, Gabriel Phillips

DSN S 546 Made in Iowa AR, Augmented Reality, brick wall composed of biomaterial bricks.

DSN S 546 Made in Iowa Carniege Libraries located around the state.

ARCH 490 Independent Study -The Decay of Architecture by Peter Jaynes and Pierre Mure-Ravaud

DSN S 546 Made in Iowa research into biomaterials that are local waste from Iowa.

DSN S 546 MADE IN IOWA | 77 MADE IN IOWA 1 2 3 4 5 6 7 8 OPN WORK ARCH 401 WORK THE BENCH THE KERNEL THE PETAL THE CHAIR FOLOGRAM WALL IOWA TABLE

planters located outside were designed by fourth-year architecture students during the Fall 2023 and printed in Salt Lake City, Utah, in collaboration with PIKUS 3D, a commercial landscape element 3D printing company. OPN Architects Inc Digital Practice Group: Jacob Gasper, Hugh Soward, Jamie Craine 1 2 3 7 8 9 6

S 546 Made in Iowa work done by

Friedman,

S 546 Made in Iowa work done by

S 546

in Iowa work done by Weston

S 546 Made in Iowa work done by

DSN S 546 Made in Iowa AR, Augmented Reality, brick wall composed of biomaterial bricks. OUTSIDE INSIDE 10 5 4 fourth-year in Gasper, 1 2 3 7 8 9 6 Mahsa wall around Architecture 10 are 5 4 MADE IN IOWA 1 2 3 4 5 6 7 8 9 10 OPN WORK ARCH 401 WORK THE BENCH THE KERNEL THE PETAL THE CHAIR FOLOGRAM WALL IOWA TABLE THE DECAY OF ARCHITECTURE MATERIAL RESEARCH

OPN

1 2 3 7 8 9 6

The

DSN

Nicole

Daniel Liera, Zachary Lin, Jaren Pierce DSN

Evan Corkery, Thomas Hewitt, Gabriel Yingst, Connor Shanahan DSN

Made

Fantz, Mahsa Keyhani, Mircea Nastase, Gabriel Phillips DSN

Priya

Barot, Nick Cheung, Mona Kazemian

The

Architects Inc Digital Practice Group: Jacob Gasper, Hugh Soward, Jamie Craine

OUTSIDE INSIDE 10

5 4

78 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 79

80 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 81

82 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 83

84 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 85

86 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 87

88 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 89

REIMAN GARDENS

Reiman Gardens is a 17-acre university-owned public garden located immediately south of Jack Trice Stadium on the Iowa State University campus in Ames, Iowa. Reiman Gardens is a yearround garden with events, programs, lectures, and tours that has consistently been one of the top visited attractions in Central Iowa. Reiman horticulturalists provided plants for the exhibition at the SICTR and then the plants, planters and seating were donated to Reiman Gardens.

_Tulipa ‘Design Impression’ (Darwin Hybrid)

_Narcissus ‘Standard Value’ (Trumpet Daffodil)

_Muscari americana ‘Valerie Finnis’ (Grape Hyacinth)

_Salvia rosmarinus (Rosemary)

DSN S 546 MADE IN IOWA | 93

94 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 95

96 | DSN S 546 MADE IN IOWA

DSN S 546 MADE IN IOWA | 97