www.grecopublishing.com Collision & Maintenance Alignments: NOT the Same Q&A with New WMABA President Kris Burton April 2024 Volume 17, No. 4 $5.95 www.wmaba.com More to Learn at the 2024 MAY 16-18 SOUTHEAST COLLISION CONFERENCE

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen

107 West Glebe Rd.

Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Ourisman Volkswagen of Bethesda 5415 Butler Road Bethesda,MD 20816 301-652-2452

Fax: 301-652-2589

e-mail: vwwholesale@ourisman.com

Fitzgerald Volkswagen 114 Baughmans Lane

Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com

www.fitzparts.com

Fitzgerald Volkswagen of Annapolis 34 Hudson Street Annapolis, MD 21401

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157

www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville

801 Rockville Pike Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com

Wholesale Parts

2 April 2024

“Volkswagen“ and the Volkswagen logo are registered trademarks of Volkswagen AG. ©2024 Volkswagen of America, Inc.

by Chasidy Rae Sisk

by Chasidy Rae Sisk

WMABA NEWS by Chasidy Rae Sisk

8 COLLISION AND MAINTENANCE ALIGNMENTS ARE NOT THE SAME: WMABA’S ANNUAL MEETING RECAP

In-house alignments can improve efficiency.

WMABA FEATURE by Chasidy Rae Sisk

10 CONTINUING THE LEGACY: A Q&A WITH NEW WMABA PRESIDENT KRIS BURTON Standing together, succeeding together.

NATIONAL FEATURE by Chasidy Rae Sisk

14 PROFILE “FLEXIBILITY” BUT NO GUIDANCE CHANGE: MITCHELL RESPONDS TO SCRS BLEND STUDY

Beneficial to shops…or not?

SOUTHEAST

27

CONFERENCE 2024 CLASS

INDUSTRY

32 WHAT ARE YOUR MAIN EDUCATIONAL GOALS AND OFFERINGS FOR 2024?

A sneak peek into Mike’s new classes.

3 April 2024

COLLISION

CONFERENCE

SOUTHEAST COLLISION

SCHEDULE

ADVICE: ASK MIKE

DEPARTMENTS 4 Editor’s Message 6 Executive Director’s Message 7 WMABA Member Application 11 WMABA Sponsors 31 WMABA Board of Directors 34 Advertisers’ Index April 2024 CONTENTS 24 COVER STORY

MORE TO LEARN AT THE 2024 SOUTHEAST COLLISION CONFERENCE

the whole shop.

Education for

EDITOR’S MESSAGE WEIRD BOOK GIRL

It’s easy to focus on an employee’s perceived shortcomings in one area without understanding why they may not meet those expectations.

When I was 18 years old, I began working at a real estate appraisal management company while attending college. I planned to work there until I graduated – when I would immediately land a high-profile writing/editing job with a $100,000 starting salary, of course (hahaha, the naivety of youth)! Well, I was wrong, so I hung onto that reliable paycheck for the next 17 years, transitioning from one position to another in an attempt to make myself valuable enough to survive the layoffs that came every couple years. And I excelled in every role, becoming the top performer on my team more often than not. But when I expressed interest in an opening as a team lead (the lowest of management positions), I was discouraged from pursuing it. In fact, one of my managers outright laughed at me, while another told me it wouldn’t be a good fit.

See, I was a hard worker, but I didn’t socialize much with my co-workers. I always saw that as a distraction from what I was being paid to do. In fact, I spent my daily breaks walking around or sitting on a bench with a book in my hand. Little did I know, I’d earned myself the moniker “Weird Book Girl.” As time passed, I grew increasingly bored with my position – and along with boredom came discontent; I was miserable because I wasn’t reaching my full potential.

I began searching for a new job, and after only one interview, I received an offer; however, my supervisor (Molly) learned of my plans and came up with an idea: what if I helped write some standard operating procedures (SOPs) for the team? It wasn’t her strong suit, but it would be helpful since we had pretty high turnover at the time. From that endeavor, she recognized that I had an untapped skillset, so she began asking for my help with reports to track the team’s productivity and quality, and when Molly’s team lead left the company, I finally received that promotion. The funny thing was my new role required a lot more interaction with my co-workers…and no one was more surprised than me to find that I had no problem meeting that requirement. And when a supervisor position opened up a couple years later, our manager (Jeanette) offered it to me right away.

WMABA OFFICERS

PRESIDENT Kris Burton kris@rosslynautobody.com - 703-820-1800

VICE PRESIDENT Phil Rice phil@ricewoods.com - 540-846-6617

TREASURER John Shoemaker john.a.shoemaker@basf.com - 248-763-4375

SECRETARY Barry Dorn bdorn@dornsbodyandpaint.com - 804-746-3928

IMMEDIATE PAST PRESIDENT Steven Krieps steve@gregclineauto.com 304-755-1146

BOARD OF DIRECTORS

ADMINISTRATION

EXECUTIVE DIRECTOR

Jordan Hendler (jordanhendler@wmaba.com) 804-789-9649

WMABA CORPORATE OFFICE

P.O. Box 3157 • Mechanicsville, VA 23116

By then, I had begun my side hustle as a freelance writer, so I still spent the majority of my breaks being the weird book girl, though it was more likely to find me with a notebook and pencil in hand. But instead of seeing that as a quirk and detriment like past managers did, both Molly and Jeanette viewed it as a strength that also benefited our business since I was constantly learning new things and even applied some of the business, leadership and training knowledge I acquired to what I was doing in our appraisal world.

Because of my experiences early in my career, I went into my supervisory role with a different perspective than my peers had. I viewed each member of my team as an individual, not as cogs in a wheel that were supposed to fit a certain mold. I adapted training as necessary to meet their needs, I delegated tasks to the people who were interested in and equipped to take them on, and I got to know them all and engaged in conversations both professionally and personally…and our previously distressing retention rate soared. In my six years as a supervisor, I only had to fire one associate, and our team saw very little turnover. Every month, we met or exceeded our team goals, even after they were made more stringent.

Playing to my team’s strengths made their jobs more enjoyable, and it made mine easier. When the opportunity arose in 2021 to join the team at Thomas Greco Publishing, my boss and my team expressed sorrow at seeing me leave, but they were also overwhelmingly happy for me to pursue my writing dreams. After all, I’ve always been – and will always be – that weird book girl, but that’s never been the weakness that people used to believe it was. It’s one of my greatest strengths!

So, take a look at your team. Embrace their quirks, focus on their strengths, and reevaluate what you see as their weaknesses. They could have skills you’re not capitalizing on…and that type of shortsightedness might be a weakness worth overcoming!

Multiple studies have shown that helping employees develop their strengths, instead of focusing on what you might see as shortcomings, is a much more effective method of improving overall performance. It also enhances engagement and makes companies more likely to retain those employees. And those are great ways to boost profit! H&D

HAMMER & DOLLY STAFF

PUBLISHER Thomas Greco thomas@grecopublishing.com

SALES DIRECTOR Alicia Figurelli alicia@grecopublishing.com

EDITORIAL/CREATIVE Alana Quartuccio COORDINATOR alana@grecopublishing.com

MANAGING EDITOR Chasidy Rae Sisk chasidy@grecopublishing.com

PUBLISHED BY TGP, Inc.

973-235-1963

571-458-0648

Bill Hawkins (hawkinswilliamjr@gmail.com) 510-915-2283

OFFICE MANAGER Donna Greco donna@grecopublishing.com

PRODUCTION Joe Greco COORDINATOR joe@grecopublishing.com www.grecopublishing.com @grecopublishing

4 April 2024

Rodney Bolton (boltonconsulting61@gmail.com) 443-386-0086 Tom Brown (thbrown@ppg.com) 703-624-5819 Torchy Chandler (torchy.chandler@gmail.com) 410-309-2242 Tracy Dombrowski (tracy@collisionadvice.com)

244

Nutley,

FAX

Reproduction of any portions of this publication is specifically prohibited without written permission from the publisher. The opinions and ideas appearing in this magazine are not necessarily representations of TGP Inc. or of the Washington Metropolitan Auto Body Association (WMABA). Copyright © 2024 Thomas Greco Publishing, Inc. Stock Images courtesy of istockphoto.com.

Chestnut St., Suite 202

NJ 07110 973-667-6922

Chasidy Rae Sisk 302.593.7002 chasidy@grecopublishing.com

Co-celebrating decades of creating chemistry between two industry leaders

Here’s to 241 years of combined service excellence

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

5 April 2024

626 E. Elizabeth Ave., Linden, NJ 07036 Phone: (908) 925-6133 Fax: (908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524 Phone: (973) 279-8300 Fax: (973) 279-9030 631 Clifton Ave., Toms River, NJ 08753 Phone: (732) 797-3942 Fax: (732) 797-0774 100 Melrich Road, Cranbury, NJ 08512 Phone: (609) 860-2800 Fax: (609) 860-2801 4 Emery Ave., Randolph, NJ 07869 Phone: (862) 244-4818 Fax: (862) 244-4822 www.kemperle.com

EXECUTIVE DIRECTOR’S MESSAGE

FORWARD CHANGE: One Weekend Effort, One Giant Download, Only One Month Away!

You’ve picked up this issue, and you’re right on time! We’re one month and a straight-shot drive away from the Collision P.R.E.P (Professional Repairer Education Program) series coming May 16-18 at the Southeast Collision Conference (SCC) in Greensboro, North Carolina – see page 27 for classes and more information.

I’m sure you’ve heard about the SCC, now coming soon, and my hope is that you’ve already gotten your tickets, hotel room, education selections, show shopping list, and – if you’re that kind of person –your ’fits selected for each day! (Uniform or business casual works, too.)

All joking aside, our associations work very hard to bring you the best. We care about your experience, because we know how hard it is to peel away from shop and family to attend a conference. But once you do… Well, we know you’ll be forward changed

“Forward Changed”

I just made that up, because I want to have a way to convey to you what it means to be forever changed, and for the future of yourself AND your business. To me, it means the doors of your mind are opened, maybe even for the first time. Those who’ve been can attest to it, even if they cannot put words to all they feel.

The most successful shops get educated. They train – many for numerous weeks of the year – so they understand more about

business management, OEM procedures, advanced repair techniques and any way they can improve the outcome. The other thing they have in common is their community. Every success story is tied to a support system. These accomplishments came after years of asking questions, talking to the most knowledgeable people and implementing strategies. Strategies that need to be watched, tweaked and even re-imagined. Then, bounced off others.

These are the same people who help others find their way. They dedicate themselves to the connections they make.

So, “Choose your hard.”

I know it’s difficult to get away for these special events. I look at the effort it takes for repairers to get to the Southeast Collision Conference like the latest pop culture “choose your hard” examples. My adaptations are pretty simple…

• Creating engaged culture is hard. Replacing employees who quit because of your culture is hard. Choose your hard.

• Having to work around technician training weeks is hard. Talking to customers about why their car wasn’t fixed right the first time is hard. Choose your hard.

• Performing full teardown to create complete repair plans is hard. Frantically ordering parts throughout the repair process while increasing cycle time and stress is hard. Choose your hard.

• Making arrangements to attend SCC, Collision P.R.E.P. classes and getting away from the shop is hard. Not having community, education and a view into the future is hard.

Choose your own hard.

Come for the tradeshow and education, but stay for the people and even some fun. You’ll never regret giving yourself the opportunity to be found Forward Changed!

6 April 2024

Choose your hard. BY JORDAN HENDLER Check the WMABA website and newsletters for regular updates and reportsfrom the Executive Director’s perspective.

Jordan Hendler (804) 789-9649 jordanhendler@wmaba.com

Conquest your Mitsubishi parts needs!

Mitsubishi now offers Genuine OEM parts through our new “Opt-OE” parts program at discounted prices. See Mitsubishi’s Ultra-Conquest parts and prices in the Optional OEM Suppliers category of popular collision estimating systems.

Ultra-Conquest Collision Parts Program Highlights:

• Discounted prices on quality new and unblemished OEM parts

• Automated price and part selection in collision estimating systems

• High parts availability

• Delivery to most major U.S. cities within 24 hours

To find out more about Ultra-Conquest pricing contact your local Mitsubishi dealer.

For Genuine Mitsubishi parts, contact these authorized Mitsubishi Dealers.

Fitzgerald Mitsubishi

1930 West Street Annapolis, MD 21401

Direct: 410-224-4636

Fax: 410-224-4264

E-mail: adamsf@fitzmall.com

Younger Mitsubishi 1945 Dual Highway Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465

www.youngermitsubishi.com

Buy Genuine Mitsubishi Parts and get the perfect fit at the perfect price. 10% off on all parts orders when you mention this ad.

• Available through all participating Northeastern area Mitsubishi dealers

• Includes the majority of key collision components for select popular models

• We can meet or beat aftermarket prices!

7 April 2024

2024 DUES OPTIONS:

NEWS COLLISION AND MAINTENANCE

ALIGNMENTS ARE NOT THE SAME:

WMABA’S ANNUAL MEETING RECAP

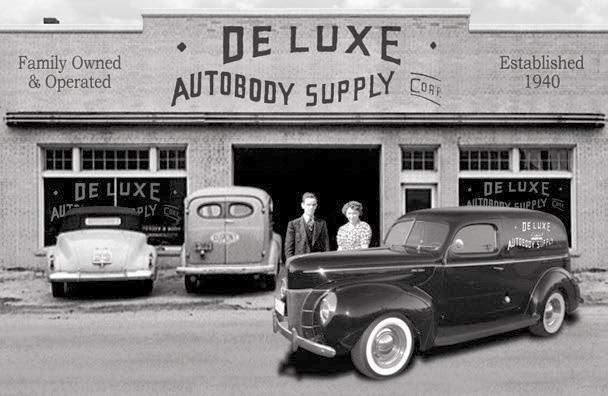

“Collision alignments are NOT maintenance.” That was the message shared by Steve Dawson (Hunter Engineering) as he discussed “Collision Alignments: Don’t Guess at What’s Bent, KNOW IT Before Teardown” during WMABA’s Annual Membership Dinner at Hunter Engineering Regional Training Center in Frederick, MD. He went on to explain “alignments can make a shop more effective.”

Every vehicle brought to an auto body shop should be placed on the alignment rack at least once during the repair process, according to Dawson, who acknowledged that, for many facilities, the biggest challenge lies in collecting payment. “When you have a car with many components, you feel like you can’t document everything you did. You think something is bent, but the insurance company is pushing back a little bit. There are ways to get that information, and we want to make sure

everyone understands that, as well as some of the benefits that come from looking at an alignment as a collision repair shop as opposed to a general repair shop [that] performs a maintenance alignment.

“But after a collision, there’s a significant amount of additional items that the OEM manufacturers are asking you to do to make that car similar to what it was when it came off the assembly line, so you’re bringing it back to its original condition,” Dawson pointed out. “But the insurance companies don’t necessarily look at it the same way; they think, ‘I can go down the street up here and grab an alignment for $89.99. That should be good.’ But that’s not bringing our car back to that OEM standard.”

In addition to insurers being more willing to pay a sublet bill for an alignment, a common reason Dawson hears for why collision shops don’t perform alignments in-house boils down to a lack of space; however, most shops have a frame machine, and “alignments can potentially

be done in the same space as a frame machine,” he insisted, noting that subletting the procedure often leads to delays which shops “can control by performing their alignments in-house…you can even reduce cycle time by a couple days!”

Dawson identified the typical types of alignment: preventative (after new tires or worn part replacement), symptom (used when the steering wheel is off-center or the car pulls), performance (for lowering, raising and customizing) and collision, which is performed for a variety of reasons, including to identify bent and damaged components, position of new parts, structural changes, calibrations, electronic alignment, returning the vehicle to its pre-accident condition, ride heights, wheel run out, tire condition, etc.

“Collision alignments have a whole lot more involved,” Dawson emphasized, sharing that Hunter Engineering has created several reference guides to help shops understand the possible alignment needs of a car post-collision. Documentation is the key means of convincing bill payers to

8 April 2024

Steve Dawson (Hunter Engineering)

Dozens of repairers gathered to learn more about collision alignments at WMABA’s 2024 Annual Meeting.

pay for these procedures, he reiterated, yet subletting alignments often yields a printout that leaves auto body shops uncertain about which component is bent.

“You receive a report that ‘something is bent,’ so you get your measuring device out and start measuring. They basically tell you, ‘Something is wrong, but here’s no information to figure out what is bent,’ so you might replace 15 parts to figure out what’s wrong. It makes sense to know what’s wrong before getting started. A pre-alignment assessment is a critical piece in getting repairs done more efficiently.”

Performing a pre-alignment assessment at the beginning of the repair process allows shops to collect a lot of information. From there, it’s easier to “identify bent components, complete the repair process and then perform another alignment if needed,” Dawson said.

“Almost every OEM requires an alignment be done on every vehicle that’s been in a collision,” he added, examining several manufacturers’ specific requirements. “We want to do things the way the OEM says they need to be done.”

Offering a glimpse at the feedback received from his company’s alignment equipment, he first demonstrated the amount of information acquired from the primary alignment angles report. “It’s not so obscure that you need to find a tech that knows it well. We have tools to teach anyone to use it well and read it as well as explain to adjusters exactly why something is needed,” Dawson advised, noting that more details are provided via the secondary measurements report which gives shops the ability to “provide insurance companies with the documentation to show unequivocally why we need to do the repair.

Dawson stressed the importance of documentation further, and as the most important basis for procedural justification with the bill payer. He shared his experiences with working with insurance professionals, and how shops could improve discussions of needed repairs with alignment readings and charts which clearly show where the problem lies. It even prevents repair delays with increased diagnostic accuracy, rather than guessing.

Dawson’s presentation took a technical bend as he explored the circumstances in

which diagnostic measurements become necessary, explaining that the amount of ADAS in today’s vehicles creates additional alignment needs to prevent calibration issues. He again referred to the importance of documentation.

He outlined how readings of internal damage can prove necessary replacements, and with documentation in which an adjuster would be looking for. The ability to outline all necessary procedures related to alignments would then improve the shop processes and efficiencies. Shops who have good processes and higher efficiency tend to be more profitable as a by-product.

State of the Industry

Prior to Dawson’s presentation, WMABA Executive Director Jordan Hendler updated attendees on some of the association’s key initiatives, such as representing its membership at national meetings including the Collision Industry Conference (CIC) and SEMA, and stressed the value of WMABA’s affiliation with national organizations like the Society of Collision Repair Specialists (SCRS). She lauded the benefits of SCRS’s 401(k) plan and health insurance which is “saving money for everyone who participates.” More information is available at scrs.com.

WMABA also sponsors the Database Enhancement Gateway (DEG), where collision repairers can submit inquiries to the database providers about inaccurate times and missing operations, parts, numbers,

procedures and more. Hendler encouraged repairers who notice discrepancies in the systems to file an inquiry with the DEG at degweb.org

She also urged attendees to participate in WMABA’s 2024 Shop Rate Insurers Survey, describing the results as a “helpful way to see how insurers are behaving in our market which offers valuable insights to use during conversations with customers.”

Hendler explained how WMABA is seeking to alleviate the workforce shortage the industry is facing by working with schools like Northern Virginia Community College (NVCC) and Center of Applied Technology North (CAT North). (See our feature on NVCC online at bit.ly/HD-0123 and the profile on CAT North at bit.ly/HD-0523). WMABA’s Education Committee is currently actively involved with these two schools and hoping to broaden its outreach in the near future.

All collision repair professionals should add the Southeast Collision Conference (SCC) to their calendar, according to Hendler. Taking place May 16-18 in Greensboro, NC and featuring WMABA’s Collision P.R.E.P. educational experience, the show promises “a great experience, so make plans to attend.” (Flip to page 24 to get more details on the upcoming SCC 2024).

WMABA’s Annual Membership Dinner also included an opportunity for attendees to network while enjoying a meal provided by the association.

Make sure to sign up for membership in WMABA, to take advantage of being in the local - and national - repair community. H&D

Executive Director’s Thoughts

The WMABA meetings are one of my favorite things we do in the association, because it’s a great way for shops to have and find their connection to the community. It’s great education, and while I appreciate everything Hunter did to bring fantastic info and technology to the night, it was the members talking to one another that really makes it special. Every colleague they can know improves the overall engagement they can have and resources they can use. We are simply better together!

-

Jordan Hendler

9 April 2024 Documentation is vital to collecting compensation. BY CHASIDY RAE SISK

WMABA Executive Director Jordan Hendler

FEATURE

CONTINUING THE LEGACY: A Q&A WITH NEW WMABA PRESIDENT KRIS BURTON

After three years under the leadership of Past President Steve Krieps (Greg Cline Auto Body; Winfield, WV), who bid adieu to his role in last month’s Hammer & Dolly (available at bit.ly/HD-0324), WMABA has a new head honcho, current President Kris Burton (Rosslyn Auto Body; Alexandria, VA), a dedicated collision industry professional whose affiliation with the association spans more than two decades.

What can members expect as WMABA moves into this new era? Burton sat down with Hammer & Dolly to help readers get to know him a little better as he shares his thoughts on what he hopes to accomplish as he takes the reins.

Hammer & Dolly: How did you get your start in the collision repair industry?

Kris Burton: I started working in my father’s shop after school while I was still in high school, but after I graduated, I was a typical rebellious 18-year-old who decided this was not the career path I wanted to follow. I moved out and waited tables while attending community college. In the middle of the semester during my third year of college, my dad called me and told me that he needed me to come work in the shop on Monday. I objected, but he had no one to answer the phones because the rest of my family is deaf. I dropped out of school that Friday, went to work for Dad on Monday and have been here ever since, for a little over 20 years. When my dad retired in 2019, I took over running the shop, and I’ve never looked back.

H&D: When and how did you get involved with WMABA?

KB: Since I started working in collision repair in my early 20s, I’ve always read Hammer & Dolly cover to cover; I still do. I realized I didn’t know much, but I believed there had to be a better way to do certain things. One day, I was flipping through the magazine and stopped on the Board of Directors page. At the time, Mike Anderson (Collision Advice) was the president of WMABA, so I picked up the phone and called his shop, Wagonwork Collision. I asked to meet with him, and he agreed to meet me after work one evening. He told me to write down my questions, so I showed up with a yellow legal pad with all kinds of questions – everything from basic car questions and business questions to how to pay people, what types of parts went where and what to paint first. I was so nervous, but Mike took his time answering my questions for a couple hours. It was a really cool experience, and after that, I started attending WMABA’s meetings to learn as much as I possibly could.

“This association has always had my heart; I wouldn’t be where I am today without WMABA.”

H&D: When you first joined the association, did you have any ambitions of serving on the Board or becoming president?

KB: Not at all. I was happy being part of an organization filled with so many successful shop owners. When you’re young and impressionable, you’re really just trying to navigate the industry and figure it all out, so I was excited to surround myself with so many active, engaged shops and just absorb all the knowledge and experience they had to offer and were willing to share.

H&D: So, what convinced you to join the Board and eventually agree to your new role as president?

KB: A year or two after I joined WMABA, Mark Boudreau called me and told me I needed to be at Wagonwork Collision that Saturday morning. I had no idea what was going on, and when I showed up, Mark told me I was the new secretary of WMABA. That’s also when Aaron Schulenburg (Society of Collision Repairs Specialists) was named treasurer, Barry Dorn (Dorn’s Body & Paint; Mechanicsville, VA) became vice president, and Torchy Chandler (Chandler’s Collision Center; Columbia, MD) was chosen as president. I was really honored and appreciative of the faith they put in me. I didn’t know it yet, but it actually was something I really wanted to do.

This was around 2007, when WMABA made the transition from Sheila Loftus to Jordan Hendler as executive director. I served on the Board for a couple years, but in 2009, my father bought a second shop, and I was so busy and overwhelmed that I decided

10 April 2024

Making time for what matters. BY

RAE SISK

CHASIDY

Kris Burton

continued

20

on pg.

THANKS YOU WMABA WMABA thanks their generous supporters of the Corporate Sponsor Program for 2024! We encourage YOUR SUPPORT of those who SUPPORT US! For more information about the sponsorship program, please contact Executive Director Jordan Hendler at (804) 789-9649 or email jordanhendler@wmaba.com www.wmaba.com BAPS Auto Paints & Supply Certified Automotive Parts Association FinishMaster National Coatings and Supplies LEVEL 1 LEVEL 2 11 April 2024

Your business is our business.

Audi Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Mercedes-Benz Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm

S 8:00am - 3:00pm

Porsche Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Sprinter Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

12 April 2024

Free delivery on our fleet of 15 GPS-equipped delivery trucks - delivering all Silver Spring brands on the same truck throughout Maryland, D.C. and Virginia

We use IRF automotive systems including CCC, CollisionLink, OPSTrax, PartsTrader and RepairLink

Highly knowledgeable, experienced and dedicated wholesale specialist team

Large inventory of OEM parts and tires

Contact our dealers for all your Genuine Parts needs!

BMW of Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Herb Gordon Subaru

Direct: 301-890-3065

Fax: 301-847-2239

Email: herbgordonsubaruwholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Volvo Cars Silver Spring

Direct: 301-890-5456

Fax: 301-847-2239

Email: herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

13 April 2024 Service. Trust. Genuine Parts. It’s what we do.

NATIONAL FEATURE

PROFILE “FLEXIBILITY” BUT NO GUIDANCE CHANGE: MITCHELL RESPONDS TO SCRS BLEND STUDY

Since the Society of Collision Repair Specialists (SCRS) released the results of their blend study in late 2022, collision repairers have been waiting for updates from the three major information providers (IPs). While CCC/MOTOR and Audatex both addressed the concerns raised by making changes to their systems last year, Mitchell remained reticent…until earlier this year when Repair Sales Senior Vice President Jack Rozint casually announced an imminent enhancement to Mitchell Cloud Estimating during open mic at the Collision Industry Conference, held in Palm Springs in January.

“There have been a lot of questions, apparently, about what Mitchell is doing in the area of refinish calculations,” Rozint acknowledged, explaining that an upcoming release to Mitchell Cloud Estimating would offer “the opportunity for users to set up, at the profile level, seven different areas of refinish calculations,” allowing users to “set up their own default settings for clear coat, three-stage and two-tone blend refinishing adjustments as well as different blends for each insurer, giving a ton of flexibility to our customers.”

In response to Rozint’s announcement, SCRS Executive Director Aaron Schulenburg asked, “Will the guidance in the Mitchell Guide also change relative to any of the formulas, or is it just the flexibility in the actual profile setup?” to which Rozint responded, “Our defaults will not change at this time.” So, Mitchell’s guide still indicates blends as 50 percent of the full refinish time, unlike the other two IPs that updated their solutions to provide profile flexibility and updated their guidance to recognize the variables associated with blending and changes in modern automotive refinish products. The updated guidance in CCC and Audatex addresses the difficulty of blending by recommending deference to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.

While Mitchell communicated these changes as an improvement, their insistence on adhering to the 50 percent formula that has been utilized in their Collision Estimating Guide for more than three decades will likely continue to make it challenging for shops to take advantage of the system’s newfound “flexibility.”

Although Rozint claimed that the enhancements are designed to provide users with greater flexibility and control over labor time calculations and will enable repair planners to adjust all seven common refinish calculations in the estimate profile (clear coat, refinish, blend, three stage, two tone, finish sand and buff and de-nib and finesse), Mitchell’s insistence on maintaining its previous guidance is curious in light of evidence that has been repeatedly presented.

The SCRS blend study, conducted in collaboration with AkzoNobel, Axalta, BASF, PPG and Sherwin-Williams, evaluated blending in comparison to full refinish values when considering solid, metallic and tri-stage refinish options across all the paint manufacturers and concluded that blend times are 31.59 percent greater than full refinished value on average, a significant difference than the 50 percent formula utilized by the IPs at the time.

After conducting its own observational studies of the blend process, MOTOR/CCC released guidance in April 2023, changing its Estimated Worktime Development Methodology related to color blend of adjacent panels to account for variations in modern vehicle paint refinishing. Since their October system enhancement, users are able to click a blend button in CCC ONE which automatically calculates a two-stage blend at 50 percent of the refinish time and a three-stage blend at 70 percent of the full refinish time. An on-the-spot evaluation allows users to either input a default value for two-stage and threestage blends or opt to have the system prompt them for the blend time specific to that repair.

CCC also updated its Guide to Estimating to remove the prior formula and add verbiage clarifying that “estimated refinish times for color blending should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.”

MOTOR specifically identifies judgment time as “the outcome reached when an estimator or appraiser considers the specifics of the vehicle and repair or refinish operation being evaluated to determine the estimated work time,” according to their response to an inquiry submitted by the Database Enhancement Gateway (DEG).

DEG’s inquiry questioning MOTOR’s removal of blend formulas elicited the following clarification: “MOTOR removed the previously published color blend formulas after determining they may not reflect the many variations encountered with modern vehicle finishes and designs. Citing these variations, MOTOR does not intend to publish a list of included or excluded items specific to color blend.”

Audatex followed suit with a July update, ultimately providing users with the ability to adjust refinish labor time to specify a value between 50 and 150 percent in October, and by the end of 2023, the IP had updated its Database Reference Manual to remove its previous 50 percent blend formula guidance which was replaced with the following:

“Audatex refinish labor is based on the use of new and undamaged panels. Audatex Estimating does not provide a standard labor allowance for blended panels as this requires the estimate preparer’s judgment, expertise and consideration of the unique

14 April 2024

requirements for each repair. Determination and assessment of labor and materials necessary in the blending process is best provided by the estimate preparer during the estimate preparation process. To assist the user, profile settings allow for customization to enter a specified blend percentage, as necessary.”

“They didn’t just update their system based on our research; they conducted their own research and based their system updates on their findings,” Schulenburg notes an important factor related to the IPs’ updates. “These changes are based on their decisions and are NOT the result of the SCRS blend study; that study was merely the catalyst that prompted them to re-evaluate their own information.

“This is an important fact for shops to understand and use as a talking point because an insurance company doesn’t need to believe what SCRS found during our blend study…those well-documented findings were persuasive enough that the IP re-evaluated its own studies and came to its own conclusion.”

Acknowledging that some shops have reported challenges in conversations with bill payers around blend times, Schulenburg suggested that repairers might find it valuable to present insurance carriers with documentation related to the IPs’ responses, including trade press articles on the topic, as a means of furthering the conversation. “When we have representatives from the estimating providers who share that they are aware and have been aware of this being an issue long before the SCRS blend study ever occurred, that’s probably useful in your dialogue.”

In fact, Solera Product Management Senior Director David Davoodi

told industry news outlet Repairer Driven News in November 2023 that Solera was already aware of the concerns SCRS and other repairers had for months – if not years! – prior to the release of the results of the association’s blend study results.

Schulenburg encouraged repairers to be conscientious that they spend time understanding the variables within their own process at their facility and use that to present data in a meaningful way.

“It’s easy to state that you’re doing something because of what the blend study says, but it fails to really express how the research relates to what is happening in your repair process and tasks that your technicians are already performing in your repair facility. Some carriers may push back because they don’t recognize SCRS as an entity that does time studies, and that’s fine; we’re not. But the IPs didn’t make those changes just because SCRS did the blend study. The study opened a conversation that led them to do their own research and come to their own conclusions, and noting that could lead to a very different conversation.” H&D

Executive Director’s Thoughts

Understanding the issue with the “blend vs full panel” process, and how the guides have been updated, is crucial to the improvement of your ability to communicate with a bill payer as well as see how it affects your cost and charges structures. Just like any hurdle you face in your shop, this is a big one to make sure you get over, because it’s been PROVEN it is costing you money every day you haven’t. This is a perfect example as to how the industry can help itself with larger issues with the estimating guides; they are not as accurate as they could be with everyone working together. -

Jordan Hendler

15 April 2024

BY CHASIDY RAE SISK

The power is in your hands to collect on blends.

Superior service starts with superior parts.

Contact

Safford Brown Mazda Fairfax

10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Designed

Get the right part the first time

We're

Fitzgerald Mazda

114 Baughmans Lane

Frederick, MD 21702

Toll Free: 800-545-4745

Fax 877-696-1841

E-mail: parts@fitzmall.com

www.fitzparts.com

Ourisman Mazda of Rockville 801 Rockville Pike

Rockville, MD 20852

Parts Direct: 301-340-7668

Fitzgerald Mazda of Annapolis

1930 West Street Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

Phone: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com

www.ourismanmazdaofrockville.com

16 April 2024

vehicles

specifically for Mazda

you

an accurate, trusted resource as close as your phone Give us the opportunity to serve

these Mazda dealers for all your parts needs:

on what Mazda drivers already know-Genuine Mazda parts extend a car's life.

Rely

EV REPAIR: FIRE SAFETY CONSIDERATIONS

When it comes to repairing electric vehicles, safety should always be the number one priority. One of the primary risks in EV repair is the high voltage present in batteries and powertrain components. Even a small mistake could lead to a deadly situation.

Lithium-ion batteries, while efficient and powerful, can be prone to thermal runaway if damaged or improperly handled. This could result in a fire that is difficult to extinguish, posing significant danger to the entire repair area.

In addition to always wearing personal protective equipment when working on hybrid and e-vehicles, technicians must be trained using manufacturer procedures on how to safely handle lithium-ion batteries and how to respond in the event of a fire. Properly outfitting the repair area with preventative safety equipment and accessories is a necessary measure to not only ensure efficient and effective repairs, but also minimize the risk

of accidents or injuries.

If a fire does occur, products like the RAE containment blanket are essential to prevent building damage in the repair area. When used properly, the fire blanket will prevent flames from spreading to surrounding areas, isolating the fire and lowering the oxygen content at the scene of the fire. All this helps give professional emergency services time to respond to the incident.

The WS 1100 fire protection ceiling is nonflammable (A1) according to EN 13501-1, with innovative, mineral-coated high-temperature fabric on both sides with continuous thermal load up to 2012 °F. The blanket can withstand a short-term thermal load of up to 2462 °F, with a melting point above 2912 °F. It is extremely lightweight and easy to deploy in an emergency.

For more information on the WS fire containment blanket or critical safety measures that should be considered when repairing EVs

If a fire does occur, products like the RAE containment blanket are essential to prevent building damage in the repair area.

or conventional vehicles, Reliable Automotive Equipment is your source for products, training and support. Visit them at raeservice.com or call (800) 328-7855 to learn more.

17 April 2024 INDUSTRY UPDATE

www.raeservice.com

(800)328-7855

For over 30 years, Reliable Automotive Equipment has been the premier OEM Collision Repair equipment supplier. Please continue reading for details on our range of OEM certified riveting sets, tailored for diverse automotive needs. Discover the ideal choice for your workshop today!

WHICH XPRESS 800 RIVETING SET IS BEST FOR YOUR SHOP?

BASIC SET

Modular Riveting System to place self-piercing rivets (SPR) on flanges and to remove SPR’s.

INCLUDES: Xpress 800 Power Pack, Cylinder SSC35/25, C-arm GC 80/40, Tool Box RS-03, Transport case & Manual

STANDARD SET

Self-Piercing Rivets, Flow Form Rivets, and Solid Rivets.

INCLUDES: Xpress 800 Power Pack, Cylinder SSC35/25, C-arm GC 80/40, C-arm GC 80/120, C-arm GC 140/240, Tool Box RS-03, Transport case & Manual

SCAN TO LEARN MORE

April 2024 18

VISIT US AT THE SOUTHEAST COLLISION CONFERENCE!

FULL SET

Self-Piercing Rivets, Flow Form Rivets, Solid Rivets, Blind Rivets, Blind Rivet Nuts, and Rivbolt Threaded Studs.

INCLUDES: Xpress 800 Power Pack, Cylinder SSC35/25, C-arm GC 80/40, C-arm GC 80/120, C-arm GC 140/240, Tool Box RS-03, Tool Box RS-04, BR 20, BR50, BRN 50, Transport case & Manual

XPAC STARTER SET

Mechanically driven Hydraulic actuator to place and remove self-piercing rivets.

INCLUDES: XPac (including torque support), C-arm GC 80/40, Tool Box RS-03, Red Handle & Manual

OEM APPROVALS

PERFECT

FIND YOUR

SET.

19 April 2024

WMABA FEATURE

continued from pg. 10

to relinquish my position. Not long after, someone told me, ‘Everybody is too busy; you have to make time for what’s important.’ That really resonated with me, and luckily, WMABA let me return to my position on the Board.

It’s an even bigger honor to be named president. This association has always had my heart; I wouldn’t be where I am today without WMABA. Being part of this organization has allowed me to develop lasting relationships and make friends that have become like family, and I wouldn’t have them if I hadn’t joined this group. It’s surreal to be named president – I’m just a single shop owner, not a guy with 12 shops, but I believe you get what you put in. Serving on any association’s leadership team is a volunteer position, but it brings me joy and happiness, and I’m excited to see how we grow as we continue passing on WMABA’s legacy to other shops.

H&D: You also serve on the Board of Directors for the Society of Collision Repair Specialists (SCRS). How does your involvement with SCRS and other national organizations benefit WMABA and its members?

KB: It definitely gives me a different perspective of everything happening in the collision repair industry. Unless you’re involved with SCRS, most people don’t really understand the full scope of what they do or the amount of work that has happened, is ongoing and is planned. The amount of change SCRS strives to accomplish for this industry is vast and really impressive, even though it’s not all recognized. It’s amazing what these gentlemen and ladies have been able to achieve along the way. I believe my involvement with SCRS builds another bridge for WMABA and provides another opportunity to help educate other shop owners if they so desire.

H&D: As WMABA President, what are your top three priorities for the association moving forward?

KB: First and foremost, education – not only from the angle of providing educational opportunities for our members but also by helping to foster strong relationships between the industry and our local vo-tech schools and community colleges. I’m passionate about trying to help open the door for the younger people who want to get into this field. I believe lots of kids want to do what we do. In fact, I know it’s not true when people claim this generation is not interested in auto body work. A lot of them are interested, but they want to feel safe and protected, and they want to work in an environment where it’s okay to fail because that allows them to learn and grow.

Secondly, I’ve always wanted to improve WMABA’s member engagement. Every association has the same questions: Why don’t the shops show up? How do we get more shops to participate? I hope we can figure out how to get more people in the room and encourage greater involvement from the shops. At the same time, I want to continue focusing on making our events the best they can be for the people who are involved. I never want anyone to feel too intimidated to show up; I want them to call, text or email me or other Board members when they have questions or are facing challenges they’d like advice on. Showing up is the first step to building these relationships. At our meetings, I try to talk to everyone who attends, but if you’re new, please make sure to say hi! We want you to get involved and are looking forward to learning more about what you need to make that happen.

Lastly, I just want to help the association continue. It’s been around

for over 60 years at this point, so I plan to continue that legacy as we grow new relationships and hopefully set us on a path to continue being successful in the future. I’m truly looking forward to it.

H&D: What do you think are some of the industry’s biggest challenges, and how do you hope to help address them in your new role?

KB: I think some of our biggest challenges come back to education, primarily with educating insurance companies and consumers. As we transition into the complex types of cars that are now finding their way to our shops, we need to recognize all the training and equipment that’s required, and we need to better explain these factors to our customers and the insurance adjusters. The billing practices of yesteryear no longer work; changes are necessary, and better dialogue is needed to bridge that gap. I’m still figuring all these things out myself, but the more people involved in these conversations, the better.

H&D: What advice or encouragement would you offer a fellow shop owner who may be struggling?

KB: Get involved! The first thing to do is reach out and participate in the discussions that are happening. If you’re struggling and need help, staying to yourself is only going to make it worse. Joining an association or just coming to a meeting and staying afterward to talk to other shop owners, introduce yourself, build a relationship...it’ll make a world of difference. WMABA is really fortunate to have Jordan and her team, and they’re very supportive of our members as well; we wouldn’t be where we are today without them. I’d also invite anyone who needs advice or encouragement to reach out to me. I want to help because when one of us succeeds, we all succeed. H&D

Executive Director’s Thoughts

I’ve known Kris since my first WMABA meeting, which, I believe, was 2005. He’s always been a sponge for the education and engaged with his fellow repairers. He’s the one who will be the first to show up, first to lend a hand, and first to jump in when a committee or team needs help. It’s truly been a long time coming for his leadership within WMABA to take the “top seat”, but I assure you it’s not for his own glory but for what he always hopes for the rest of the WMABA members and the association’s future!

- Jordan Hendler

20 April 2024

• Audi Parts Professionals are your subject matter experts on collision parts, replacement components and mechanical items.

• Many Audi dealers offer technical service support hotline access that can reduce your repair times and help you meet an on-time promised delivery.

• Installing Audi Genuine Parts contributes towards improved cycle time that makes both your customer and their insurance company happier.

• Regardless of the age of your customer’s Audi, Audi dealers have access to over 200,000 part numbers. No other supplier comes close.

Audi Bethesda

5206 River Road

Bethesda, MD 20816

Parts Direct: 240.762.5636

Parts Fax: 301.718.1847

www.audibethesda.com

Audi Chantilly

14839 Stonecroft Center Ct.

Chantilly, VA 20151

703.956.2100

Fax: 703.956.2139

www.audichantilly.com

Rockville Audi

1125 Rockville Pike

Rockville, MD 20852

Parts Direct: 301.296.2870

Parts Fax: 301.762.5055

www.rockville-audi.com

Audi Silver Spring

3151 Automobile Boulevard

Silver Spring, MD 20904

844.413.6929

Parts Direct: 301.890.3015

Fax: 301.890.3748

Email: wholesaless@mileone.com

www.audisilverspringparts.com

21 April 2024

Audi dealers strive to make you an Audi Genuine Parts fan

business is

business.

from

Helping you do

our

Order Audi Genuine Parts

these select dealers.

THERE HAS NEVER BEEN A BETTER WAY TO BUY THE WORLD’S BEST ENGINEERED PARTS.

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING BMW.

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring

3211 Automobile Blvd

Silver Spring, MD 20904

866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com

bmwofsilverspring.com

Passport BMW

5000 Auth Way

Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717

passportbmw.com

Richmond BMW

8710 West Broad Street

Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com

richmond-bmw.com

BMW of Catonsville

6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600

bmwofcatonsville.com

22 April 2024

©️2024 BMW of North America, LLC. The BMW name, model names and logo are registered trademarks.

PROGRAM PROFESSIONAL REPAIRER EDUCATION Presented by

COVER STORY MORE TO LEARN AT THE 2024

Ongoing education is a vital part of life and success for collision repair professionals hoping to keep pace with the constant changes pervading this complex industry, and the Southeast Collision Conference (SCC) provides an optimal opportunity for the entire shop – owners, managers, repair planners and body techs – to update their knowledge by training with some of the industry’s best educators and presenters.

Hosted by WMABA and the Carolinas Collision Association (CCA), SCC 2024 takes place May 16-18 at the Greensboro Coliseum Complex in Greensboro, NC, and the third iteration of this regional event promises to deliver more than ever before…more training, more exhibitors, more hands-on experiences and more excitement! This year’s agenda features a full slate of educational offerings through Collision P.R.E.P. (Professional Repairer Education Program) that will engage repairers at every level in the shop.

“Having two full days of classes gives repairers multiple facets from top experts, including calibration, repair planning, shop trends nationwide and so much more,” emphasizes WMABA Executive Director Jordan Hendler. “The classes offered, in addition to the tradeshow, ensure you will leave informed, have purchase options, and elevated your community. Being around many of the best repairers in the country is the intrinsic benefit of being where our industry shows up. We pride ourselves on national level community with personal connection. It will be the highlight of your entire year.”

The educational extravaganza kicks off on Friday morning with none other than industry icon Mike Anderson (Collision Advice) as he shares insights on how to “Future-proof Your Shop: Tomorrow’s Success Starts with Today.” Brand new in 2024, this class covers a variety of topics that today’s top shops need to know to stay ahead of the curve; attendees will acquire valuable information on industry trends related to employee retention, OEM certification, DRP and non-DRP models, AI and building customer relationships.

Anderson returns the next morning with his “100 Percent Disassembly” course. “One of the most common things I see while traveling over 300 days a year and visiting so many shops is that most people believe they’re doing 100 percent disassembly, but they’re actually doing more like 80 or 90 percent disassembly,” Anderson points out. “Repairers need to realize 100 percent disassembly is the foundation for so much. It’s necessary and required to write an accurate repair plan; it’s critical for capturing all the items that can be removed and installed, improving the quality of your repair plan and minimizing supplements. It’s also critical to the parts mirror-matching process. If we don’t remove everything, it’s much more difficult for the parts person to mirror-match the parts.”

Disassembly is actually vital for all stakeholders, according to Anderson. “The customer service person can set more accurate delivery expectations for the customer, and it’s critical when we order parts from our vendor. Really, it’s critical to everything we do and to all stakeholders. One of the most important things I want to impart to everyone who attends this class: When I had my shops, a big mistake I made would be to tell people what to remove instead of telling them WHY it needs to be removed. If we can help our team understand WHY something needs to be removed during 100 percent disassembly, it’s more sustainable, so I’m very excited to share some insights on this subject with SCC attendees.”

Complete disassembly puts estimators in position to write an accurate, detailed repair plan…but perfecting the process often leaves repair planners feeling stuck. As Danny Gredinberg (Database Enhancement Gateway) and Kyle Motzkus (Hunter Auto Body and Missouri Auto Body Association) engage in an honest conversation

about “Self-Confidence: An Advanced Repair Plan You Can Expand On,” they encourage attendees to weigh in.

“Repairers are challenged with limited time to perform repair planning being able to capture all the required operations to complete safe and proper repairs. Locating the information can be a timeconsuming process, but it’s an absolute necessity with today’s complex vehicle designs,” offers Gredinberg, who recommends, “Focus on a factbased conversation sticking to the information provider’s p-pages and required OEM procedures prescribed by the OEM. We will share where to find your supporting proof to your evidence package.”

“When shops transition from writing ‘estimates’ to effective repair planning, it’s important to have those tough conversations with customers upfront,” Motzkus stresses. “All the customer knows is they need to get an estimate for the damages from the shop, but in reality, as a repair facility, we cannot write an upfront estimate because we don’t really know what needs to be done until we do our research, reference procedures and put a detailed repair plan together. Repair planners often fail to effectively communicate why we need to perform those steps; they talk too much, too little or get too technical in their explanation, and as a result, they alienate the customer before they’ve even had a chance to do anything with the vehicle.

“This industry is full of ego, yet repairers who insist they do everything correctly often have issues with customers leaving poor reviews,” he adds. “Would they have bashed you online if you treated them like a person during your interactions? Remember: this is a stressful situation, so if you spend five minutes with them and five minutes with the car before writing a (likely inaccurate) estimate and expect them to schedule, how can they be confident in you as an expert? We need to look at repair planning from a customer’s perspective and help establish their faith in us by presenting ourselves as the repair experts we actually are. There’s no one turnkey answer for these issues, so Danny and I will cover multiple scenarios as we discuss how repair planners can boost their confidence to tackle these conversations with customers. Be prepared for an engaging, hands-on conversation – we look forward to questions from the audience, and if you’re confident enough to challenge our ideas, you might just be confident enough to have these difficult conversations with customers too!”

Panel discussions provide a great chance for attendees to interact with presenters and ask clarifying questions, and SCC 2024’s two Lunch-and-Learn segments are expected to arm repairers with valuable real-world tips they can apply in their shops. Friday’s “Efficiency Unleashed: Rethinking Roles in Collision Repair” features Michael Bradshaw (K&M Collision; Hickory, NC), Barry Dorn (Dorn’s Body & Paint; Mechanicsville, VA) and WMABA President Kris Burton (Rosslyn Auto Body; Alexandria, VA), who will take participants on a transformative journey into strategic role segmentation as they explore its impact on maximizing shop efficiency.

“Everyone can’t do everything anymore,” Burton simplifies the concept. “With all the technology on modern vehicles, it’s virtually impossible to be thoroughly trained on every make and model, so today’s technicians need to specialize by focusing on just two to three manufacturers and becoming the expert on those. Segmentation offers an interesting approach to how shop owners can best utilize employees’ talents to maximize their potential and promote greater efficiency in the shop immediately. This approach also benefits facilities from a retention standpoint as it keeps younger technicians engaged by allowing them to focus on learning and mastering specific tasks, rather than being overwhelmed by trying to tackle everything all at once.”

Sign up today for a successful tomorrow. BY CHASIDY RAE SISK 25 April 2024

continued from pg. 25

Seeing the industry’s future and moving into it gracefully is one of the panel’s goals. “Most shops still operate in a very traditional way as far as how roles in the facility – from the front office to the back of the shop – are defined and how work is assigned,” Bradshaw observes. “It’s been the same for 25 to 30 years; there typically is not a lot of innovation in the way the majority of shops approach this, but we want to show them that segmentation offers a lot of power. This panel provides a really unique opportunity to learn more about this new-school approach from three shop owners who have used it to revolutionize our businesses.”

“Collision repairers tend to believe that our industry is unlike any other industry,” Dorn adds. “In some cases, we have differences, but we have common issues and shortfalls just like any other industry, and we can look to other industries for solutions. This program will discuss ways to make your facility and culture more defined with efficiencies, technology and effective implementation. Repairers can expect to have a better understanding of preparing themselves and their teams on OEM future trends and why the OEMs are going in the directions that they have been. This will enable them to set themselves apart as the employer of choice and create a culture that doesn’t repeat or continue the legacy traditions of how collision repair facilities have operated in the past.”

On Saturday, lunch-and-learners will tackle the topic of “Repairer to Repairer: RTAs and PRIs, The Process & the Shop’s Role” with Adrian Mora (Collision Consumer Advocates), Billy Walkowiak (Collision Safety Consultants) and moderator Steve Krieps (Collision Safety Consultants of WV).

“With regard to Right to Appraisal (RTA), a lot of people see it as a way for shops to ‘get paid more’ for the repair, but the shop actually has no dog in that fight; it’s a mechanism for the consumer to handle loss disagreements with their insurer,” Krieps continues. “It’s useful for shops to understand what the RTA is, so they can educate the consumer about that option, but the Appraisal Clause really just allows the shop to put the indemnification process back in the consumer’s hands so they don’t feel powerless. The shop’s job is to generate the repair plan, properly execute the repairs with the customer’s approval and get paid for what they do. Whether the insurer fully indemnifies the consumer is between them and their insurer, and RTA puts that ball back in the customer’s court. From a shop perspective, it’s not your monkey, not your circus.”

Presented by

the world, but if one customer destroys your reputation on social media, you wind up with a giant question mark over your head, which could lead to customers asking for a PRI to make sure things were done correctly, not just from a repair standpoint but also in regard to documentation. Attendees will learn more about PRIs from people who actually perform them, and we’ll provide a little insight into some of the factors that might trigger somebody to go digging around. We’ll share some estimating tips and identify some commonly missed items that shops may or may not be performing. As a shop owner or manager, it’s impossible to look over your technicians’ shoulders 24/7, so you need to implement a system of checks and balances because even an honest mistake could open up a whole can of worms that lands you in a buy-back situation or worse.

Following OEM repair procedures to perform a proper repair, of course, is firmly located within a shop’s purview, but the wide variety of ADAS available on today’s vehicles often presents challenges. Greg Peeters (Car ADAS Solutions) will explore this subject during “The Critical

PROGRAM PROFESSIONAL REPAIRER EDUCATION

“Shop owners will benefit from our discussion on post-repair inspections (PRIs),” explains Walkowiak. “Implementing a strong quality control system protects shops from potential liability issues if a technician neglects to perform procedures according to the OEM guidelines. It’s also very important for shops to understand the Appraisal Clause in order to educate customers about the need for proper repair procedures as well as how to make sure their vehicle is being valued appropriately. Attendees will walk away with more knowledge of the insurer’s legal duties according to the policy, and shops that are better educated about consumer rights tend to be empowered to assist customers when they receive pushback from their insurance carriers.”

“When it comes to PRIs, shops never want to get caught up in a situation where they did something horribly wrong and wind up owning a car they didn’t want to purchase, not to mention the potential for consumer fraud issues,” Krieps adds. “As a collision repair facility, you want to be very familiar with the repair requirements, proper documentation and also your state’s consumer protection regulations. Consumers have become less trusting; you can have the best shop in

Steps Involved to Achieve an OEM-Centric Calibration.”

“Vehicle safety systems protect people by helping to prevent or minimize accidents and injuries,” Peeters expresses. “These safety systems are often compromised after an accident and the subsequent repair process. Calibrating these safety systems to OEM specifications is critical not only to the future safety of this vehicle, but also every vehicle and pedestrian they encounter. Repairers who attend this class will learn more about when a repaired vehicle requires a calibration and how to integrate this into the repair plan, OEM calibration procedures and how they affect the performance of vehicle safety systems, how to get a calibration center ready for OEM-compliant calibrations, the importance of following OEM procedures for successful and accurate calibration and why an inaccurate calibration can be worse than no calibration.”

On the non-technical side of the business, the biggest challenge many shops encounter is “Navigating the Challenges of Recruiting and Retaining Technicians,” which is the topic being presented by WrenchWay’s Jay Goninen, who notes, “Shops often say that people are their number one priority, yet they spend very little time on their recruiting and retention plans. With the challenges in today’s market to find quality help, this needs to change. In this session, we’ll talk through ways to recruit and retain top level talent, and attendees can expect to walk away with ideas to take back and implement in their shop immediately. They will also understand what it is that quality technicians are looking for to ensure their business is a destination for good technicians.”

Goninen will share insights into what technicians are looking for in an employer, based on data from WrenchWay’s 2023 Voice of Technician Survey, plus he’ll offer strategies for recruiting technicians via job boards, career pages, social media, partnerships with schools, etc. as well as tips for retaining technicians by focusing on training, career development, communication and more.

Shop owners pour their heart and soul into their businesses, but ensuring life after the shop looks the way one hopes, it will require strategizing and building value in advance. During “Building Value in Your Shop,” High Lift Financial’s Matt DiFrancesco, CExP™ will share insights that allow owners to focus on growth and prepare to exit the business on their own terms.

“Building value is about increasing cash flow, which obviously offers an immediate benefit but is also important for a long-term transition,” DiFrancesco says. “The shop is typically one’s biggest asset, so we want to grow it to benefit the business in terms of cash flow, employee retention, attracting top talent and also from a risk management

26 April 2024

COVER STORY

1 6 - 1 8 GREENSBORO NORTH CAROLINA

F R I D A Y , M a y 1 7

8:30am – 10:00am |

Future-proof Your Shop: Tomorrow’s Success Starts with Today Mike Anderson, Collision Advice

11:30am – 1:00pm | LUNCH & LEARN

Efficiency Unleashed: Rethinking Roles in Collision Repair Michael Bradshaw of K&M Collision, Barry Dorn of Dorn's Body & Paint, and Kris Burton of Rosslyn Auto Body

2:00pm – 3:00pm | Option 1

The Critical Steps Involved to Achieve an OEM-Centric Calibration Greg Peeters, CEO, Car ADAS Solutions

2:00pm – 3:00pm | Option 2

Building Value in Your Shop

Matt DiFrancesco, CExP™, Principal/Certified Exit Planner, High Lift Financial

4:30pm – 5:30pm | Option 1

Self Confidence: An advanced repair plan you can expand on Danny Gredinberg, the DEG, and Kyle Motzkus, General Manager of Hunter Autobody and Missouri Autobody Association

4:30pm – 5:30pm | Option 2

Navigating the Challenges of Recruiting & Retaining Technicians Jay Goninen, Co-Founder & President, WrenchWay

and even more happening on the tradeshow stage!

8:30am – 9:30am | Option 1 100% Disassembly

Mike Anderson

8:30am – 9:30am | Option 2

Do You Have Leaky Profit? Find Out Where Profit Leaks from Your Collision Center and How to Fill the Holes!

Taylor Moss, OEConnection

11:00am – 12:30pm | LUNCH & LEARN

FEATURING

Repairer to Repairer: RTA’s and PRI’s, The Process & the Shop’s Role Panelists: Adrian Mora, Collision Consumer Advocates, Billy Walkowiak, Collision Safety Consultants; Moderated by: Steve Krieps, WMABA Imm Past President / Collision Safety Consultants of WV

2:00pm – 3:30pm | Option 1

Nurturing the Goose That Laid the Golden Egg

Bruce Schronce, StrongLead’s Executive Partner and Leadership & Business Consultant

2:00pm – 3:30pm | Option 2

Increased Profitability through Proper Documentation: How communication, documentation and collision shop positioning must change in 2024 and beyond

Keith Manich, AMAM - Director of Collision Services, Automotive Training Institute

S

T U R D A Y , M a y 1 8

A

T

O L L I S I O N

S O U

H E A S T C

A PARTNERSHIP OF:

F r i d a y 5 / 1 7 F r i d a y 5 / 1 7 T r a d e s h o w 1 0 a m – 5 p m T r a d e s h o w 1 0 a m – 5 p m E d u c a t i o n 8 : 3 0 a – 5 : 3 0 p E d u c a t i o n 8 : 3 0 a – 5 : 3 0 p S a t u r d a y 5 / 1 8 S a t u r d a y 5 / 1 8 T r a d e s h o w 9 a m – 3 p m T r a d e s h o w 9 a m – 3 p m E d u c a t i o n 8 : 3 0 a – 3 : 3 0 p E d u c a t i o n 8 : 3 0 a – 3 : 3 0 p Greensboro Coliseum C O N F E R E N C E t H U R S D A Y 5 / 1 6 t H U R S D A Y 5 / 1 6 k i c k o f f & a w a r d s d i n n e r 6 : 3 0 p k i c k o f f & a w a r d s d i n n e r 6 : 3 0 p

QUESTIONS OR INFORMATION: QUESTIONS OR INFORMATION: Conference Admin | Chris Cage Conference Admin | Chris Cage chris@ chris@ SoutheastCollisionConference com SoutheastCollisionConference com Phone Phone || 804.789.9649 804 789 9649

M A Y

T r a d e s h o w > > E d u c a t i o n > > N e t w o r k i n g > > R a f f l e s S I G N - U P T O D A Y | S O U T H E A S T C O L L I S I O N C O N F E R E N C E . C O M

COVER STORY

standpoint by putting vehicles in place to ensure business continuity in case disaster strikes. Most shop owners neglect to maximize the value of the business by establishing proper vehicles to increase that value, yet 100 percent of shop owners will exit the business at some point in time – whether that’s through sale, transition, death, disability or divorce – and building that value in advance ensures they have the means available to live the lifestyle they want and are able to create a multigenerational legacy for their family and their community.”

Growing one’s business can often feel overwhelming, and for many, it’s certainly not a fun task. Bruce Schronce (StrongLead) will guide shops on ways to grow and sustain their business, while enjoying the journey, as he presents “Nurturing the Goose that Laid the Golden Egg.”

Subaru and Volvo fax:

Fax# is wrong..

“We work with every type of business – from industry to the education system to government and even non-profits – and one thing that most of them have in common is that people start their businesses because they have skills, passion and opportunity, but they have a hard time sustaining or growing that business the way they’d like to,” Schronce states. “Their business often ends up controlling them, instead of them controlling their business, and it’s vital to help owners learn to develop and grow their organizations in every aspect AND enjoy the process.”

we actually help businesses through the process by sharing five critical aspects to help them develop a sustainable, growing business, and we’ll teach them how to do it in such a way that they enjoy the journey. To present our method, I’ll be partnering with an organization in the collision repair industry that we have helped successfully go through this process, so attendees will have the chance to ask questions of someone who does what they do, day in and day out.”

Additional courses include “Do You Have Leaky Profit? Find Out Where Profit Leaks from Your Collision Center and How to Fill the Holes!” with OEConnection’s Taylor Moss as well as “Increased Profitability Through Proper Documentation: How Communication, Documentation and Collision Shop Positioning Must Change in 2024 and Beyond,” presented by Keith Manich of Automotive Training Institute.

Plan ahead by checking out the full class schedule on the preceding page, and register now for SCC 2024 and its can’t-miss classes at southeastcollisionconference.com H&D

Executive Director’s Thoughts

301-847-2239

To help shop owners do this, Schronce will be sharing a clear proven process of “what it looks like to do this from the simplest perspectives, and we’ll also offer an opportunity to partner with us to help that become a reality. Consultants often tell customers what to do but don’t really help them through that process, but because we’re a business consulting firm and a leadership development organization,

5:00pm

3:00pm

Still reviewing so will advise when all good.

We are excited to have such a variety of classes addressing today’s most pressing issues and topics. Every repairer, in every position of the facility, will have takeaways. It rings true on both days, where the entire industry community can engage with thought leaders, fellow participants, and association communities. With having a concentrated approach, it is well worth the endeavor to take the one day from the shop and spend the Thursday night through Saturday afternoon getting as much info internalized as possible. While making new connections!

-

Jordan Hendler

For over eight decades, the Volvo name has been synonymous with unmatched quality and performance. that legendary Volvo quality starts with Volvo Genuine Parts.

For Volvo Genuine parts at the right price, right now, please contact:

Hours: M-F 7:30am-5pm S 8am-3pm

herbgordonvolvowholesaleparts@mileone.com

28 April 2024

Only Genuine Nissan Parts deliver the fit, reliability, and performance to meet your shop’s collision repair needs. So keep it original: Keep it real with Genuine Nissan Parts. GENUINE NISSAN PARTS MAKE ALL THE DIFFERENCE. Contact us for all your parts needs: Passport Nissan 5000 Auth Way Suitland, MD 20746 Phone: 301-423-6930 Fax: 301-423-2965 Vans. Born to run. Get your customers back on the road faster with Genuine Sprinter Parts. Call our Sprinter Certified Parts Advisors today to get started. Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904 301-890-3060 Fax: 301-890-5473 mbsilverspring@mileone.com Hours: M-F 7:30am-5pm, S 8am-3pm Give your and quality Mercedes-Benz 3301 Briggs Silver Spring, 301-890-3060 mbsilverspring@mileone.com Hours: M-F Contact our Parts Advisors Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904 301-890-3060 Fax: 301-890-5473 mbsilverspring@mileone.com Hours: M-F 7:30am-5pm, S 8am-3pm Mercedes-Benz Quality Repairs Start With Volvo Genuine Parts. www.volvogroup.com Volvo Cars Silver Spring 3121 Automobile Blvd. Silver Spring, MD 20904 301-890-5456 Fax: 301-847-2239