grecopublishing.com April 2024 AASP-MN Announces 2024 - ’25 Board of Directors Short Legislative Session Priorities Take Shape TIME IS MONEY: ESTIMATING IN A POST-BLEND STUDY WORLD

AASP-MN News 2 | April 2024

Shannon Christian

MECHANICAL DIVISION DIRECTOR

Dan Gleason

ASSOCIATE DIVISION DIRECTOR

Paul Yager

COLLISION

Scott Miller

Brandon Wistrom

MECHANICAL

Ashlan Kaplan STAFF

EXECUTIVE

OFFICE

PUBLISHED

PHONE:

PUBLISHER

SALES DIRECTOR

Alicia Figurelli | alicia@grecopublishing.com

EDITORIAL & CREATIVE COORDINATOR

Alana Quartuccio | alana@grecopublishing.com

MANAGING EDITOR

Chasidy Rae Sisk | chasidy@grecopublishing.com

OFFICE MANAGER

Donna Greco | donna@grecopublishing.com

PRODUCTION COORDINATOR

Joe Greco | joe@grecopublishing.com

www.grecopublishing.com

UPCOMING EVENTS

Tuesday, June 11 29th

First Wednesday Each Month, 8am – 9:30am

Second Wednesday Each Month, 7:30am – 9:30am

Third Tuesday Each Month, 9:30am - 10:30am Mechanical Monthly Morning Zoom Meetup

Third Thursday Each Month, 9:30am - 10:30am Collision Monthly Morning Zoom Meetup

AASP of Minnesota is an association of independently-owned automotive service businesses and industry suppliers dedicated to improving the state’s automotive service industry and the success of its members. PRESIDENT’S MESSAGE ........................................................... 4 From the Big Picture To the Every Day! by Aaron Swanson, AASP-MN President LEGISLATIVE UPDATE .............................................................. 5 Short Legislative Session Priorities Take Shape by Sam Richie & Shannon K. Mitchell, AASP-MN Lobbyists LOCAL NEWS ........................................................................... 6 NATIONAL NEWS ..................................................................... 8 AASP-MN GOLF OUTING REGISTRATION ................................. 10 COVER STORY ......................................................................... 14 Time is Money: Estimating in a Post-Blend Study World by Chasidy Rae Sisk D.E.G. TIPS ............................................................................... 17 INSURANCE I.Q. ....................................................................... 18 Fiduciary Liability Insurance INDUSTRY UPDATE .................................................................. 19 EV Repair: Fire Safety Considerations COMPLETE HEALTH, ENVIRONMENTAL & SAFETY SERVICES (C.H.E.S.S.) .............................................................................. 20 What Does It Mean to Have a Safety Culture? CASH IN ON YOUR MEMBER BENEFITS! .................................. 22 AASP-MN and C.H.E.S.S. Team Up to Offer Members Safety Compliance Services ADVERTISERS’ INDEX AkzoNobel 11 Aramark/Vestis 18 Capital One.................................................... 19 CBIZ 7 Dentsmart 9 Inver Grove Honda 9 Inver Grove Toyota 9 Keystone 17 Maplewood Toyota 21 Mills Parts Center 2 Mopar 2 Morrie’s ......................................................... 21 Proven Force OBC Reliable Automotive Equipment 12-13 Straight & Square 5, 22 Toyota Group 2 WIN 19 CONTENTS AASP-MN News is the official publication of the Alliance of Automotive Service Providers, Minnesota, Inc. 1970 Oakcrest Ave., Suite 102 Roseville, MN 55113 Phone: 612-623-1110 Fax: 612-623-1122 email: aasp@aaspmn.org website: aaspmn.org. To keep its readers better informed, AASP-MN News allows its columnists to fully express their opinions. All views expressed are not necessarily those of the publication. AASP-MN News is published by Thomas Greco Publishing, Inc. ©2023 All rights reserved. Cover image www.istockphoto.com. AASP-MN BOARD MEMBERS 2023 - 2024 PRESIDENT Aaron Swanson IMMEDIATE PAST PRESIDENT Mike McLynn SECRETARY-TREASURER Randy Notto COLLISION DIVISION DIRECTOR

SEATS

SEATS

DIRECTOR

Linden Wicklund

MANAGER

Jodi Pillsbury

BY: Thomas Greco Publishing, Inc. 244 Chestnut St., Suite 202 Nutley, NJ

07110

FAX:

973-667-6922

973-235-1963

| thomas@grecopublishing.com

Thomas Greco

Annual

Golf

Majestic

Golf Club, Ham

AASP-MN

Outing

Oaks

Lake

Southern

Dakota

Metro Collision Shop Meeting

County Technical College, Rosemount

APH

Central MN Area Collision Repair Alliance Meeting

Headquarters, St. Cloud

AASP-MN News April 2024 | 3 Vol. 33 No. 4 @grecopublishing

By Aaron Swanson, AASP-MN President

By Aaron Swanson, AASP-MN President

From the Big Picture To the Every Day

As I step into the role of President for AASP-MN –which is an honor, thank you! – I figured it would be helpful to share a bit more about what I do day to day and my perspectives on how to win in this industry. And this seems particularly relevant given this month’s feature article on the SCRS blend study.

I am a Claims Process Manager at LaMettry’s Collision and have spent my professional life either in a shop, as an estimator, or working as an adjuster for an insurance company. I have a master’s in economics, so I have always focused on analyzing data to see if things are working. (I also played football and know how to knock people over, but that is a less relevant skill.) I spend my time bridging the gap between the everyday details of individual claims and the larger picture of the KPIs of the company. As an adjuster, I worked with many of the AASP-MN members and quickly learned you can’t go around starting wars when your goal is to settle claims.

A good day is when everyone is mad at me; meaning a reasonable compromise is reached and both sides have had to give a little. In my role, it is all one big claim. I spend time negotiating larger challenging claims and managing

relationships that make it so I can get a call-back from top line managers at insurance companies; I understand the hard work required to keep lines of communication open.

Claims are getting bigger and bigger, so more and more facts and data must be pulled together in challenging claims. I do lots of training for file managers and front office staff. Often this means showing them how to best build relationships that are critical when trying to find out what supporting material will move a claim forward. I tell them “don’t make anything personal.” This can mean saying, “I understand [insurance company] doesn’t normally pay for this…” while being careful to not insert the adjuster’s name.

By tracking initiatives, like implementing learnings from the blend study into our estimates, I’m able to see

continued on pg. 6

MARCH 2024

AASP-MN News 4 | April 2024

Revv ADAS Brooklyn, NY

Spectrum Auto Body Belle Plaine, MN

WELCOME NEW MEMBERS!

PRESIDENT’S MESSAGE

different from last year’s historic session. Lawmakers did not gavel in the year until mid-February, as opposed to starting right after the new year in 2023. With the same adjournment date for both years, this has meant a much more condensed schedule for 2024 with only six weeks from the start of session to the first and second committee deadlines. This artificially short session has significantly lessened the scope and ambition of lawmakers from what we saw in 2023.

The two-year state budget has already been set, and with a potential structural imbalance projected in the coming years, legislative leaders are urging restraint on additional spending. While we are still waiting to see what, if any, joint budget targets are agreed to between House and Senate leadership, conventional wisdom indicates new spending will be somewhere between extremely limited to nonexistent.

With limits on new spending, there have been a couple of session priorities that have already been addressed. First and foremost, a technical fix to last year’s omnibus tax bill quickly advanced through both

allowed to utilize in schools. There was ambiguity in the new requirements passed last year, which resulted in several school districts being left without officers in their schools, but a bipartisan group of lawmakers were able to hash out an approach that appears to have threaded the needle in satisfying law enforcement as well as school districts.

continued on pg. 9

AASP-MN News April 2024 | 5 LEGISLATIVE UPDATE

30659 Pearl Drive Unit #3 • St. Joseph, MN 56374 CALL US TODAY!! Toll Free: (855) 252-2102 Mike: (320) 267-2102 Randy: (320) 266-7239 www.straight-square.com Looking for FAST & EASY PULLING AND MEASURING in Your Shop? MAKE IT STRAIGHT & SQUARE! Frame Racks 30659 Pearl Drive Unit #3 • St. Joseph, MN 56374 i4s Smart Spot Welder CALL US TODAY FOR SERVICE, TRAINING AND SUPPORT! Mike: (320) 267-2102 Randy: (320) 266-7239 www.straight-square.com OEM APPROVED! TECHNICIAN APPROVED! Smart Spot Welding System

AASP-MN Announces 2024 - ’25 Board of Directors

April marks the beginning of service for the 2024-’25 AASP-MN Board of Directors. The Alliance is pleased to welcome new board members Ashlan Kaplan (Cannon Auto Repair; Cannon Falls), Scott Miller (Collision Specialists; Austin) and Brandon Wistrom (Deano’s Collision & Mechanical; Elk River). They join other members of the Board, which include:

• Aaron Swanson (LaMettry’s Collision; Eden Prairie) –President

• Mike McLynn (Automotive Electric; Grand Rapids) –Immediate Past President

• Randy Notto (Lenfer Automotive & Transmission; Lino Lakes) – Secretary/Treasurer

• Paul Yager (Enterprise Mobility; Eagan) –Associate Division Director

• Shannon Christian (Shannon’s Auto Body; Brainerd) –Collision Division Director

• Dan Gleason (Pro-Tech Auto Repair; Corcoran) – Mechanical Division Director

AASP-MN also extends a sincere thank you to this year’s outgoing board members:

• Travis Doyle (Arrowhead Auto Body; Duluth)

• Jesse Jacobson (Heppner’s Auto Body; Woodbury)

Volunteers are the heart and soul of the Alliance, and we appreciate the leadership and commitment of these dedicated members.

29th Annual AASP-MN Golf Outing Announced

The 29th Annual AASP-MN Golf Outing will be held Tuesday, June 11 at Majestic Oaks Golf Club in Ham Lake. All collision repair and auto service industry professionals and suppliers are invited to attend the event to enjoy a day of golfing and socializing with industry peers.

Play will begin at 12:30pm, followed by dinner and an awards presentation. The cost to participate is $100 per golfer or $400 per foursome. Golf holes are also available to sponsor for $350 each.

For additional information, see page 10 or visit the association’s website aaspmn.org. You may also email the Alliance office at aasp@aaspmn.org or call (612) 623-1110.

Minnesota Careers in Auto Repair & Service (MNCARS) is a non-profit organization established in 2016 by AASPMN. Its sole purpose is to promote careers in the automotive industry, recruit young people into the state’s college-level automotive service and collision repair programs and, ultimately, into industry workplaces.

To date, the following companies have made sponsorship commitments for 2024:

Premium Sponsor

LKQ Minnesota

Platinum Sponsor

Lube-Tech

Revv ADAS

Gold Sponsors

3M Automotive Aftermarket Division

AASP National

Auto Value Parts Stores/Benco Equipment

BASF

CBIZ

NCS/Single Source

Silver Sponsors

Axalta Coating Systems

Enterprise Mobility

O’Reilly Auto Parts

PPG Automotive Finishes

Sherwin-Williams

Suburban GM Parts

Vestis

Bronze Sponsors

aaa Auto Parts

C.H.E.S.S.

Dentsmart PDR

Precision Diagnostics

PRESIDENT’S MESSAGE

continued from pg. 4

the impact of the team’s efforts with individual claims on our overall KPIs. Knowing our metrics is so important in making change that is practical and has an impact on business. There is so much nuance, strategy and technique to getting through the gatekeepers, and at the same time we don’t want to hold claims up on the small things that aren’t worth it in the end. I can look at the KPIs and see we are trending in the right direction even if we aren’t “winning” on every claim.

Get out and get active in your local community promoting industry careers! Check out the MotorMouth toolbox at carcareers.org/motor-mouth

LaMettry’s knows reputation and relationships matter. The team has worked hard to be a top certified shop and build a brand through dealer relationships. We have team members who are at dealerships full-time and have been from the start. This sort of strategy is something that sets us apart, but the fundamental ideas are relevant for shops of every size. LaMettry’s operates with strong ethics, so as a team member it is easy to get behind initiatives and be reminded of the larger goals. That makes the daily battles that much easier to not take personally or take home with you at the end of the day.

You don’t know who you are going to work with in the future. Everyone knows everyone. Never make it personal. You don’t need to beat an individual to win the game. You don’t need to know everything; just know the right people to ask.

AASP-MN News 6 | April 2024

LOCAL NEWS

AASP-MN News April 2024 | 7 Two Great Companies. One Great Program. ® ® EMPLOYEE BENEFITS | PAYROLL | WORKERS’ COMPENSATION | PROPERTY & CASUALTY BRAD SCHMID Workers’ Compensation Property & Casualty (763) 549-2247 bschmid@cbiz.com CARRIE HOBROUGH Payroll and HR (612) 436-4620 chobrough@cbiz.com DIEGO CAMPOS Employee Benefits (763) 228-0259 diego.campos@cbiz.com WWW.CBIZ.COM © 2023 CBIZ, Inc. NYSE Listed: CBZ. All rights reserved. PROUD SUPPORTER OF AASP-MN!

www.langmarketing.com

More Sweet-Spot Light Trucks Boost Aftermarket

Light trucks in the U.S. average more aftermarket product use per year than passenger cars. Differences in product prices, accessory volume and vehicle use are among the leading factors that push light truck annual product volume higher per vehicle. This gap in annual product volume between light trucks and cars has widened in recent years.

Light trucks have steadily increased their share of the new vehicle market over the past 10 years. Consequently, light trucks have expanded their share of the repair-age sweet-spot (vehicles six to 10 years old), which represents the highest rates of annual use for many vehicle products. Light trucks’ sweet-spot share growth will help to boost light vehicle aftermarket sales in 2024 and for many years.

Light Trucks Average Greater Product Use

Since 2000, Lang Marketing has tracked differences between light trucks and cars in aftermarket product use. This annual product gap has widened over the years and will likely continue.

$175 Annual Product Gap

Light trucks averaged over $490 of annual product volume from 2018 through 2023 at user-price. In contrast, passenger cars averaged less than $315 in aftermarket product volume.

Last year, light trucks averaged over 60 percent more annual product volume per vehicle than cars. This is higher than the 50 percent difference 10 years earlier.

Causes of Product Use Differences

Three factors drive light trucks to have greater annual aftermarket product volume per vehicle than cars.

First, many products for light trucks cost more than comparable car parts. In addition, many light trucks have off-road and commercial

powertrain systems, which do not often appear on cars and require expensive replacement products.

Second, accessories record greater volume among light trucks than passenger cars. This is especially true of pickups and SUVs, which are the focus of many aftermarket accessories.

Third, light trucks have greater commercial use than passenger cars, which helps push their aftermarket product volume higher per vehicle.

Growing Sweet-Spot Position

The repair-age sweet-spot (vehicles six to 10 years old) is the vehicle age group that represents the highest annual use of many aftermarket products.

Light trucks have expanded their sweet-spot share significantly over the past 10 years.

They represented approximately 54 percent of vehicles six to 10 years old in 2013, up from less than 51 percent five years earlier.

Lang Marketing’s preliminary 2023 estimate is that light trucks accounted for 57 percent of vehicles six to 10 years old; the final analysis will be available in June.

Growing Light Truck Sales Share

Riding the tailwind of their strong new vehicle sales, light trucks are rapidly expanding their share of the new vehicle market. In 2013, they generated 51 percent of new vehicle sales.

By 2018, light trucks’ average share rocketed to more than 69 percent. Last year, light trucks topped 78 percent of the new vehicle market in the U.S.

Future Sweet-Spot Strength

Light trucks will climb to over 59 percent of vehicles six to 10 years old by 2025, up from less than 49 percent sweet-spot share 20 years earlier.

Increasing Number

Record-high light vehicle annual sales between 2015 and 2019 and the increasing light truck share of the new vehicle market have increased the sweet-spot’s population of light trucks.

There were nearly 40 million light trucks six to 10 years old during 2010. The number of light trucks in the repair-age sweet-spot topped 43 million by 2013.

Lang Marketing estimates there were over 46 million light trucks six to 10 years old in 2023.

Aftermarket Impact

The increasing aftermarket product gap per vehicle between cars and light trucks, the growing share of light trucks in the repairage sweet-spot, and the increasing number of light trucks in this age group will provide a strong boost to aftermarket product growth from 2023 to 2025.

Light trucks have generated all light vehicle aftermarket product growth over the last five years, and this trend will continue.

Smaller Sweet-Spot VIO

The sharp downturn in 2020 new vehicle sales, followed by the belowaverage size of the new vehicle market extending to 2023 (and likely beyond), will reduce the sweet-spot’s population beginning in 2026.

This will make the dominant share of light trucks in the six-to-10-year vehicle age group even more critical to the annual volume of aftermarket products.

Six Major Takeaways

• Light trucks average significantly more annual aftermarket product use per vehicle than passenger cars on U.S. roads. From 2018 to 2023, light trucks averaged approximately 55 percent more annual product volume than cars at user-price.

AASP-MN News 8 | April 2024 NATIONAL NEWS

• Last year, light trucks averaged approximately 60 percent more aftermarket product volume per vehicle than cars. Light trucks averaged over $175 more than cars per vehicle in 2023 product volume at user-price.

• There are three reasons for the greater per-vehicle product use of light trucks versus cars: differences in product prices, accessory volume and how vehicles are used.

• Light trucks’ share of the repair-age sweet-spot (six to 10 years) has grown significantly, between 2018 and 2023. Lang Marketing projects that light trucks’ sweetspot share will top 59 percent in 2025.

• The number of light trucks in the repair-age sweetspot has increased due to record-high new vehicle sales between 2015 and 2019 and the rising new vehicle market share of light trucks. Lang Marketing estimates there were over 46 million light trucks in the 2023 repair-age sweet-spot last year, up 15 percent from 10 years earlier.

• Light trucks have generated all light vehicle aftermarket product growth in the U.S. over the last five years, largely thanks to their growing dominance of the repair-age sweet-spot. This trend will continue for the next five years and beyond.

LEGISLATIVE UPDATE

continued from pg. 5

Those minor fixes, along with the traditional second year of the biennium task of assembling a bonding package to fund public infrastructure projects, were the stated goals of this session, so how much other legislation gets enacted remains to be seen. Unlike the first year of the biennium when lawmakers must pass a two-year budget, nothing else is required to be done this year and lawmakers appear to be happy with the amount of work done in 2023. While there have been hearings on policy issues in various committees, how robust those committee omnibus bills will be in the end is still very unknown.

As for AASP-MN’s legislative efforts to clarify and strengthen the Regulations of Claims Act: Minnesota Statute 72A.201, our lobby team and executive director have had productive meetings with rank and file lawmakers, as well as the relevant committee chairs, and remain hopeful in making meaningful progress this legislative session. We know change in this area of state statute is an iterative process and think we have made progress with our updated language dealing with Minnesota Statute 72A.201. We will continue to push until session adjourns in mid-May.

AASP-MN News April 2024 | 9

29th Annual AASP-MN Golf Outing

Tuesday, June 11, 2024 12:30pm Shotgun Start

Majestic Oaks Golf Club 701 Bunker Lake Blvd. Ham Lake, MN 55304

$100 per golfer/$400 per team

Fees Include: 18 Hole Green Fees, Golf Cart, Contests & Prizes, Social Hour & Dinner

AASP-MN 29th Annual Golf Outing Registration June 11 – Majestic Oaks Golf Club

Name: _______________________________ Company:

Address: _____________________________ City: ___________________ Zip:

Phone: _______________________________ Email:

1st Player: ____________________________ Company:

2nd Player: ___________________________ Company:

3rd Player: ____________________________ Company:

4th Player: ____________________________ Company:

Payment Options:

_____ Check enclosed. Payable to AASP-MN

_____ Credit card (Visa, MasterCard, Discover & American Express accepted)

Note: We add a 3% surcharge to all credit card payments. This surcharge is not greater than our total cost of accepting credit cards. Surcharge does not apply to debit cards.

Credit card #:

Exp. Date: ___/___ CVC #: ______

Billing Address:

Billing City/State/Zip:

Return by June 1 to: AASP of Minnesota, 1970 Oakcrest Ave., Suite 102, Roseville, MN 55113 Phone (612) 623-1110 - email: aasp@aaspmn.org

AASP-MN News 10 | April 2024

AkzoNobel quality and incredible value in a low VOC system.

Whether it’s a single spot repair or an entire respray, Wanda’s waterborne paint system is the easy and reliable answer to all your everyday color needs. Wandabase WB Plus is an enhanced, comprehensive waterborne basecoat system that enables a perfect match with a whole world of colors. Ready to spray and simple to apply, it gives consistent, professional-quality results while saving you time and money along the way.

AASP-MN News

Learn more

For over 30 years, Reliable Automotive Equipment has been the premier OEM Collision Repair equipment supplier. Continue reading for details on our range of OEM certified welders, tailored for diverse automotive needs. Discover the ideal choice for your workshop today!

WHICH INVERTAPULS WELDER IS BEST FOR YOUR SHOP?

IM240-i

SCAN TO LEARN MORE

Extremely simple to use entry-level welding machine for steel welding. Constructed with durable materials and produces great results on panels as thin as .023 inches. Perfect for standard shop use. Versatile dual torch welding machine capable of performing various welding processes with Automotive Cold Transfer including aluminum welding, MIG brazing on steel, traditional MIG welding, and pulse welding.

SINGLE

OEM APPROVALS

PHASE IP6-2 THREE PHASE

www.raeservice.com (800)328-7855

AASP-MN News 12 | April 2024

FIND YOUR SPARK.

VAS VERSION AVAILABLE

New generation of the IP6-2! Incredibly self-explanatory and dual torch welding machine capable of performing the same welding processes listed under IP6-2. 10-280 AMP’s of welding power professional shop use!

Cutting-edge triple torch machine capable of steel, brazing, aluminum, pulse and double pulse welding. Has memory of 90 welding parameters. The allrounder for body shop professionals.

*All of the above welders utilize inverter technology to provide better control over the welding arc, increase energy e ciency, and improve welding performance.

IP7-2 THREE PHASE

IP4-3 SINGLE PHASE

IP7-2 THREE PHASE

IP4-3 SINGLE PHASE

AASP-MN News April 2024 | 13

TIME IS MONEY:

ESTIMATING IN A

POST-BLEND STUDY WORLD

Blending takes longer than refinishing – it’s a fact that painters and other collision repair professionals have known for years, yet cries for an update to the 50 percent calculation cited by all three major information providers (IPs) fell on deaf ears until the Society of Collision Repair Specialists (SCRS) teamed up with AkzoNobel, Axalta, BASF, PPG and Sherwin-Williams to evaluate blending in comparison to full refinish values when considering solid, metallic and tri-stage refinish options across all the paint manufacturers. The results of the study, released during SEMA 2022, determined that blend times are 31.59 percent greater than full refinished value on average, a significant improvement over the accepted 50 percent less than

Repairers have hailed the blend study as a herald of much-needed change for the industry, but while some shops have enjoyed a lot of success in collecting more accurate compensation, others have struggled to negotiate an increase in the labor hours actually required when blending. Why is this happening, and how can shops overcome these difficulties? It’s important to first understand how the IPs responded to the SCRS blend study.

The IPs’ Response

So, how did the IPs – CCC/MOTOR, Audatex and Mitchell – respond to the study?

After conducting its own observational studies of the blend process, CCC/MOTOR released guidance in April 2023, changing its Estimated Worktime Development Methodology related to color blend of adjacent panels to account for variations in modern vehicle paint refinishing. Since their October system enhancement, users are able

to click a blend button in CCC ONE which automatically calculates a two-stage blend at 50 percent of the refinish time and a three-stage blend at 70 percent of the full refinish time. An on-the-spot evaluation allows users to either input a default value for two-stage and three-stage blends or opt to have the system prompt them for the blend time specific to that repair.

CCC also updated its Guide to Estimating to remove the prior formula and add verbiage clarifying that “estimated refinish times for color blending should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.”

MOTOR specifically identifies judgment time as “the outcome reached when an estimator or appraiser considers the specifics of the vehicle and repair or refinish operation being evaluated to determine the estimated work time,” according to their response to inquiry #36042 submitted by the Database Enhancement Gateway (DEG).

DEG’s inquiry questioning MOTOR’s removal of blend formulas elicited the following clarification: “MOTOR removed the previously published color blend formulas after determining they may not reflect the many variations encountered with modern vehicle finishes and designs. Citing these variations, MOTOR does not intend to publish a list of included or excluded items specific to color blend.”

Audatex followed suit with a July 2023 update, ultimately providing users with the ability to adjust refinish labor time to specify a value between 50 and 150 percent in October 2023, and by the end of 2023, the IP had updated its Database Reference Manual to remove its previous 50 percent blend formula guidance which was

AASP-MN News 14 | April 2024

COVER STORY

replaced with the following:

“Audatex refinish labor is based on the use of new and undamaged panels. Audatex Estimating does not provide a standard labor allowance for blended panels as this requires the estimate preparer’s judgment, expertise and consideration of the unique requirements for each repair. Determination and assessment of labor and materials necessary in the blending process is best provided by the estimate preparer during the estimate preparation process. To assist the user, profile settings allow for customization to enter a specified blend percentage, as necessary.”

While CCC/MOTOR and Audatex both made changes to their systems last year, Mitchell remained reticent… until earlier this year when Repair Sales Senior Vice President Jack Rozint casually announced an imminent enhancement to Mitchell Cloud Estimating during open mic at the Collision Industry Conference, held in Palm Springs in January.

“There have been a lot of questions, apparently, about what Mitchell is doing in the area of refinish calculations,” Rozint acknowledged, explaining that an upcoming release to Mitchell Cloud Estimating would offer “the opportunity for users to set up, at the profile level, seven different areas of refinish calculations,” allowing users to “set up their own default settings for clear coat, threestage and two-tone blend refinishing adjustments as well as different blends for each insurer, giving a ton of flexibility to our customers.”

In response to Rozint’s announcement, SCRS Executive Director Aaron Schulenburg asked, “Will the guidance in the Mitchell Guide also change relative to any of the formulas, or is it just the flexibility in the actual profile setup?” to which Rozint responded, “Our defaults will not change at this time.” So, Mitchell’s guide still indicates blends as 50 percent of the full refinish time, unlike the other two IPs that updated their solutions to provide profile flexibility and updated their guidance to recognize the variables associated with blending and changes in modern automotive refinish products. The updated guidance in CCC and Audatex addresses the difficulty of blending by recommending deference to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.

While Mitchell communicated these changes as an improvement, their insistence on adhering to the 50 percent formula that has been utilized in their Collision Estimating Guide for more than three decades will likely continue to make it challenging for shops to take advantage of the system’s newfound “flexibility.”

Although Rozint claimed that the enhancements are designed to provide users with greater flexibility and control over labor time calculations and will enable repair planners to adjust all seven common refinish calculations in the estimate profile (clear coat, refinish, blend, three stage, two tone, finish sand and buff and de-nib and finesse), Mitchell’s insistence on maintaining its previous guidance is curious in light of evidence that has been repeatedly presented.

Collision Industry’s Reactions Shops did not need to perform additional research;

by Chasidy Rae Sisk

they already knew the results of the SCRS blend study were accurate, and most were excited to see a formal acknowledgment of their experiences, though feelings about the IPs’ responses were very mixed.

“Based on how I have seen the blend study play out for our members here in Minnesota, shops’ initially positive convictions have been eclipsed by frustration in how third-party payers are responding,” reported AASPMN Executive Director Linden Wicklund. “Shops often look to the IPs as being impartial mediators, and this was a reminder to shops that the IPs step out of the way or hinder negotiations with ambiguity more than they are going to mediate. If people thought the study was about fighting bad facts with true facts backed by data, they are likely disappointed by the outcomes from the study. If they thought the study was about highlighting key flaws in the power dynamics of the industry and empowering shops to know and advocate for their work, then they are more likely to be fueled by the study. The theoretical debates that take place on the national stage are very different from the everyday debates on a local level.”

“Our painter is our best resource for information on his experiences in the booth, and he has always echoed exactly what the blend study found: that blending takes a lot more time and effort,” said Will Latuff (Latuff Brothers Auto Body; St. Paul). His shop’s primary database is CCC, and while he feels their decision to “acknowledge the blend formula was incorrect and remove it was a good first step, they completely failed the collision industry by neglecting to come up with a solution to the problem that was highlighted, which makes it much more difficult to process a claim.”

Aaron Swanson of LaMettry’s Collision agreed that the IPs’ response was disappointing. “The blend study proved what shops have argued for years – that it takes more time to blend a panel than to paint one – yet the IPs simply removed the calculated blend time in their systems, leaving it up to the shop and the adjuster to calculate, when they should have completed their own study and provided data to address a known problem with their product.”

“We have known for a long time that blending takes longer, but we just didn’t have any acceptable proof,” offered Nikki Anderson (D & B Auto Body, LLC; Sauk Rapids). “I was glad to see the IPs respond so quickly, but I was a little disappointed that Mitchell, my operating system, was not as quick to change.”

Giving “credit where it’s due,” Danny Gredinberg from the Database Enhancement Gateway (DEG) gave “kudos to CCC and Solera for acknowledging the industry’s concerns and making corrective actions after the study was completed in recognition of the fact that there are many variables in the refinish process; they no longer provide a formula and indicate the time must be determined based on ‘end user judgment.’ Although Mitchell took some additional time to respond, they finally did, and while it may not be what repairers had hoped for, at least they allow the end user to make a change in the database, regardless of whether the IP changed their formula. I know some people are frustrated because no one is saying what the time should be, and while the changes made obviously do not accommodate

continued on pg. 16

AASP-MN News April 2024 | 15

everyone’s concerns, we are still seeing movement in the right direction.”

Estimating Tips in a Post-Blend Study World

No matter how much data is available to justify the need for it, change is never easy. It always takes a while for it to be embraced by all involved parties, and that standard certainly seems to apply when there’s money involved. So, how can shops convince third-party payers to cover the actual labor hours it takes to blend?

“There’s going to be a lot of struggle ahead for the industry while this gets sorted out and a solution comes to fruition,” Latuff predicted.

The absence of definitive calculations has presented challenges for many repair facilities. According to Anderson, “So far, we have not been able to negotiate any more hours from our insurers. They claim that their company is leaving the standard of 50 percent for blend panels and not changing it. I use a paint inventory system and seem to have a 50/50 success rate on recovering the cost of materials.”

LaMettry’s has seen greater success in negotiations by using “the study results as the basis for our calculated blend time when entering in the blend value,” Swanson reported. “We also provide a link to the study in the body of the estimate for the adjuster to review.”

Reading the study results is vital – not only for insurers but, more importantly, for collision repair professionals who want to be able to charge accurately. “The first step is actually reading the blend study,” Latuff insisted. “It’s not a long document, and it’s very accessible. You have to share it with your entire team so everybody knows the basis for the decision for the change by the IPs. From there, engage your paint staff in a conversation about what it takes to blend. Then set up your estimating system to make the on-the-spot evaluation with a reminder to enter the judgment time, and train your blueprinters on that process.”

“A lot of shops get stuck on the fact that a study was done, but they have never even read the report,” Gredinberg agreed. “Shops need to understand the paint and repair process at hand. The study itself is not going to resolve the compensation portion; the shop has to understand their process because that process is going to differ between different paint companies. You need to understand your paint requirements and stop comparing yourself to another repairer or accepting the pushback that someone else can do it this much quicker because everyone is going to be a little different.

“CCC and Audatex acknowledged that there are variables in the paint process, so the first thing a shop needs to understand is what it takes to perform that blend, using the proper products to perform properly,” he continued. “And at the same time, they need to understand how the databases work and be willing to have a conversation about your processes up front. Just because the study offers certain conclusions, that doesn’t guarantee anything because each repair outcome requires an on-the-spot evaluation.”

Schulenburg also encouraged repairers to be conscientious that they spend time understanding the variables within their own process at their facility and use that to present data in a meaningful way.

“It’s easy to state that you’re doing something because of what the blend study says, but it fails to really express how the research relates to what is happening in your repair process and tasks that your technicians are already performing in your repair facility. Some carriers may push back because they don’t recognize SCRS as an entity that does time studies, and that’s fine; we’re not. But the IPs didn’t make those changes just because SCRS did the blend study. The study opened a conversation that led them to do their own research and come to their own conclusions, and noting that could lead to a very different conversation.”

Latuff has heard exactly that type of talk from insurance adjusters who “don’t have faith in the blend study, or they don’t believe the results, but the study was verified by DEKRA North America. Have they even bothered to read it?”

“They didn’t just update their system based on our research; they conducted their own research and based their system updates on their findings,” Schulenburg reiterated an important factor related to the IPs’ updates. “These changes are based on their decisions and are NOT the result of the SCRS blend study; that study was merely the catalyst that prompted them to re-evaluate their own information.

“This is an important fact for shops to understand and use as a talking point because an insurance company doesn’t need to believe what SCRS found during our blend study…those well-documented findings were persuasive enough that the IP re-evaluated its own studies and came to its own conclusion.”

Acknowledging that some shops have reported challenges in conversations with bill payers around blend times, Schulenburg suggested that repairers might find it valuable to present insurance carriers with documentation related to the IPs’ responses, including trade press articles on the topic, as a means of furthering the conversation. “When we have representatives from the estimating providers who share that they are aware and have been aware of this being an issue long before the SCRS blend study ever occurred, that’s probably useful in your dialogue.”

In fact, Solera Product Management Senior Director David Davoodi told industry news outlet Repairer Driven News in November 2023 that Solera was already aware of the concerns SCRS and other repairers had for months – if not years! – prior to the release of the results of the association’s blend study results.

While Latuff is willing to share the blend study with insurers via email, when it comes to interfacing with adjusters, he believes, “One of the most powerful words in the English language (and one that the collision industry needs to use more!) is ‘no.’ It has just as much power coming from a shop as from an insurer. Adjusters often like to tell us, ‘We’re just going to use the system time,’ and our response is ‘no.’ CCC and Audatex both removed their blend formulas, so those people still claiming there’s a certain percentage for blending are the equivalent of flat-Earthers.”

It’s time to arm yourself to estimate in a post-blend study world. Start by reading the results of the study, available for download at scrs.com/blendstudy

AASP-MN News 16 | April 2024

COVER STORY

ESTIMATING TIPS

HELPING TO IMPROVE COLLISION REPAIR ESTIMATE INFO THROUGH REPAIRER FEEDBACK

Solera Qapter (Audatex): Section 4-2 Labor Exclusion Update – Recent updates in Solera Qapter DBRM page 44, section 4-2 labor exclusions:

“Additional required operations that are taught in an OEM training environment but aren’t included in the current OEM reference material.”

Repair planners should always refer to OEM procedures as well as the OEM trained technician on required steps that must be performed but not detailed in OEM workshop instructions.

Mitchell: Radiator Supports – Mitchell estimating users will find two separate sections in Mitchell CEG relating to “Radiator Supports.”

Page 5 Cooling > Radiator Support R&R is referencing “bolt on” radiator supports.

Page 8 Front Inner Structure- Unibody > Radiator Support R&R is referencing welded on radiator supports attached to unibody structure.

CCC ONE Web: Line Count Past 400 – CCC One web users can complete a repair plan exceeding 400 lines using CCC ONE online web version. CCC ONE users can log into cccone.com using their current username and password

to add operations beyond the current 400-line limit in the desktop version. Once the work file is saved online, you can still access the work file from your desktop application. All edits/changes would need to be done through CCC One web.

Mitchell: Refinish Calculation Adjustments – Mitchell Cloud profile settings now allow users to modify blend percentage formulas for two stage and three stage. Users would modify the formula under “system profile” >> “calculations.”

[“User-defined percentages will appear on the estimate as a manual entry, denoted by an asterisk (*)”

No changes have been made to guidance in the Mitchell Collision Estimating Guide (CEG). The CEG continues to state:

Single Stage/Two Stage Colors - Blend adjacent panel(s): Allow .5 per refinish hour (50 percent) for each panel(s)/ refinish area(s) blended.

Three Stage Colors - Blend adjacent panel(s): Allow .7 per refinish hour (70 percent) for each panel(s)/refinish area(s) blended.

AASP-MN News April 2024 | 17

some recent

If you’re performing automotive repairs of ANY kind, you need to utilize the DEG! Check out

Database Inquiries - and their resolutions - below!

degweb.org to submit a Database

and contribute to database accuracy!

Visit

Inquiry

Call Us : 866-LKQ-CORP Visit Us Online : www.LKQCorp.com Drivetrain, Suspension, Body, Cooling/HVAC, Electrical, Emissions, Exhaust, Audio, Fuel Delivery, Interior, Power Steering, Restraint System Parts and More…LKQ has it! Paint | Aftermarket | Recycled | Transmissions & Engines Any P.A.R.T. Any Time. At LKQ, the “R” in P.A.R.T. stands for Recycled OEM parts LKQ first began 25 years ago through the acquisition of several auto salvage yards, and through the years, LKQ has grown to become the largest recycler of vehicles in the industry. LKQ now operates more than 125 auto recycling yards across North America. Through its stateof-the-art processes, LKQ recycles or re-sells more than 90% of the materials from end-of-life vehicles that would otherwise end up in landfills.

Note: The estimating databases are all intended to be used as a GUIDE ONLY. View these tips and others at DEGWEB.ORG

Fiduciary Liability Insurance

Offering employees a variety of benefits options, like pension plans, retirement accounts and health care coverage, is expected of today’s employers. Organizations that provide these resources to their workforce often task an individual or group of individuals called fiduciaries to oversee benefits plans.

A fiduciary’s job is to select advisors and investments, minimize expenses and follow plan documents exactly. Under the Employee Retirement Income Security Act (ERISA), fiduciaries must act in the interest of plan participants to avoid liability claims related to the denial of benefits, administrative error, improper advice, wrongful termination of a plan and similar allegations stemming from plan management.

For an organization to protect its fiduciaries, fiduciary liability

insurance is critical and can provide policyholders with the following:

• ERISA liability protection. Under ERISA, a fiduciary is any entity or person that is responsible for the management of benefits plans. Per ERISA requirements, these individuals can be held liable for any breach of duties, errors or omissions. Fiduciary liability insurance is designed to protect plan sponsors and their employees from fiduciary claims – claims that can easily reach six figures or more.

• Protection from common fiduciary claims. A number of parties, including employees, the Department of Labor and the Pension Benefit Guaranty Corporation can file fiduciary lawsuits. Claims can arise for several reasons, including

administrative error, wrongful termination of a plan, improper advice and conflicts of interest. Fiduciary liability insurance can go a long way in protecting employers and plan administrators from these common claims.

• Affordable coverage. While the cost of fiduciary liability insurance can vary depending on an organization’s assets and the number of plan participants, coverage is generally affordable. On average, fiduciary liability insurance plans range anywhere from $600 to $2,600 per year depending on a company’s specific requirements.

• Specialty protection not found in similar policies. Companies often wrongfully assume that employee benefits liability (EBL) or directors and officers (D&O) liability policies can provide protection for fiduciary claims. While EBL insurance can defend against claims of errors in plan administration, it provides no protection for more expensive and complex ERISA violations. D&O policies also typically exclude EBL – and ERISA-related claims, making fiduciary liability insurance a must.

• Coverage beyond fidelity bonds ERISA fidelity bonds are required by law and are meant to protect plans against losses related to acts of theft or fraud. While these bonds are critical if someone acting as a fiduciary deliberately defrauds or steals from a plan, they only protect employee benefits and not a fiduciary’s liability. Specifically, fidelity bonds do not provide any form of payment for legal defenses or damages related to fiduciary claims, making finding the right policy crucial.

For more information, contact Brad Schmid at bschmid@cbiz.com or (763) 549-2247.

AASP-MN News 18 | April 2024 INSURANCE I.Q.

EV Repair: Fire Safety Considerations

When it comes to repairing electric vehicles, safety should always be the number one priority. One of the primary risks in EV repair is the high voltage present in batteries and powertrain components. Even a small mistake could lead to a deadly situation.

Lithium-ion batteries, while efficient and powerful, can be prone to thermal runaway if damaged or improperly handled. This could result in a fire that is difficult to extinguish, posing significant danger to the entire repair area.

In addition to always wearing personal protective equipment when working on hybrid and e-vehicles, technicians must be trained using manufacturer procedures on how to safely handle lithium-ion batteries and how to respond in the event of a fire. Properly outfitting the repair area with preventative safety equipment and accessories is a necessary measure to not only ensure efficient and effective

repairs, but also minimize the risk of accidents or injuries.

If a fire does occur, products like the RAE containment blanket are essential to prevent building damage in the repair area. When used properly, the fire blanket will prevent flames from spreading to surrounding areas, isolating the fire and lowering the oxygen content at the scene of the fire. All this helps give professional emergency services time to respond to the incident.

The WS 1100 fire protection ceiling is non-flammable (A1) according to EN 13501-1, with innovative, mineral-coated hightemperature fabric on both sides with continuous thermal load up to 2012 °F. The blanket can withstand a short-term thermal load of up to 2462 °F, with a melting point above 2912 °F. It is extremely lightweight and easy to deploy in an emergency.

For more information on the WS fire containment blanket or critical safety measures that should

•

•

•

•

If a fire does occur, products like the RAE containment blanket are essential to prevent building damage in the repair area.

be considered when repairing EVs or conventional vehicles, Reliable Automotive Equipment is your source for products, training and support. Visit them at raeservice.com or call (800) 328-7855 to learn more.

AASP-MN News April 2024 | 19 Take your business to the next level with unlimited 2% cash back . Earn unlimited 2% cash back on every purchase, and enjoy spending power that adapts to your business with the Spark Cash Plus card. 1Earn up to a $2,400 cash bonus: $1,200 once you spend $30,000 in the first 3 months, and an additional $1,200 once you spend $500,000 in the first year. These spend bonuses may be earned independently, meaning you may earn one or both. 2No preset spending limit does not mean unlimited spending. The amount you can spend can change over time based on your spending behavior, payment history, credit profile and other factors. Contact your Relationship Manager today to get the Spark Cash Plus card. Unlimited rewards Earn unlimited 2% cash back for your business on every purchase, everywhere, no limits or category restrictions. Cash bonuses Invest more cash back into your business with a one-time cash bonus of up to $2,400: $1,200 once you spend $30,000 in the first 3 months, and an additional $1,200 once you spend $500,000 in the first year.1 Travel rewards Earn unlimited 5% cash back on hotels and rental cars booked through Capital One Travel. No preset spending limit 2 Enjoy purchasing power that adapts to your business needs based on your spending behavior, payment history, credit profile and other factors. Free employee cards Add employee cards for free, and earn unlimited 2% cash back from their purchases. $0 liability for unauthorized charges We’ve got you covered with $0 liability for unauthorized charges if your card is lost or stolen. Plus, get automatic fraud alerts via text, email or phone call. B nairuaerdneG pihsnoitalereganaMR Matosenni | 6 4144-202-21 | b moc.enolatipac@uaerdneg.nair S 8802-CB Take your business to the next level with unlimited 2% cash back . Earn unlimited 2% cash back on every purchase, and enjoy spending power that adapts your business with the Spark Cash Plus card. Contact your Relationship Manager today to get the Spark Cash Plus card. Unlimited rewards Cash bonuses Travel rewards No preset spending limit 2 Free employee cards $0 liability for unauthorized charges B nairuaerdneG pihsnoitalereganaMR Matosenni |6 4144-202-21 moc.enolatipac@uaerdneg.nair|b Take your business to the next level with unlimited 2% cash back . Earn unlimited 2% cash back on every purchase, and enjoy spending power that adapts to your business with the Spark Cash Plus card. 1Earn up to a $2,400 cash bonus: $1,200 once you spend $30,000 in the first 3 months, and an additional $1,200 once you spend $500,000 in the first year. These spend bonuses may be earned independently, meaning you may earn one or both. 2No preset spending limit does not mean unlimited spending. The amount you can spend can change over time based on your spending behavior, payment history, credit profile and other factors. Contact your Relationship Manager today to get the Spark Cash Plus card. Unlimited rewards Earn unlimited 2% cash back for your business on every purchase, everywhere, no limits or category restrictions. Cash bonuses Invest more cash back into your business with a one-time cash bonus of up to $2,400: $1,200 once you spend $30,000 in the first 3 months, and an additional $1,200 once you spend $500,000 in the first year.1 Travel rewards Earn unlimited 5% cash back on hotels and rental cars booked through Capital One Travel. No preset spending limit2 Enjoy purchasing power that adapts to your business needs based on your spending behavior, payment history, credit profile and other factors. Free employee cards Add employee cards for free, and earn unlimited 2% cash back from their purchases. $0 liability for unauthorized charges We’ve got you covered with $0 liability for unauthorized charges if your card is lost or stolen. Plus, get automatic fraud alerts via text, email or phone call. B nairuaerdneG pihsnoitalereganaMR Matosenni | 6 4144-202-21 | b moc.enolatipac@uaerdneg.nair S 8802-CB Earn unlimited 2% cash back on every purchase, and enjoy spending power that adapts to your business with the Spark Cash Plus card. 1Earn up to a $2,400 cash bonus: $1,200 once you spend $30,000 n the first 3 months, and an additional $1,200 once you spend $500,000 in the first year. These spend bonuses may be earned independently, meaning you may earn one or both. 2No preset spending limit does not mean unlimited spending. The amount you can spend can change over time based on your spending behavior, payment history, credit profile and other factors. SBC-2008 Why Join WIN? WIN offers education, mentoring and leadership development opportunities to build critical skills for success in the collision repair market.

Local/Regional Networking Events

•

Annual Education Conference

Educational Webinars

Mentoring Opportunities womensindustrynetwork.com

•

•

Program

Scholarship

Outreach

School

Program

Award

Most Influential Women (MIW)

INDUSTRY UPDATE

What Does It Mean to Have a Safety Culture?

You wouldn’t give back a justpainted car that had fish eyes to a customer. Nor would you return a vehicle that was not properly aligned. The quality of the work you do is important; it keeps customers returning and it protects you from a lawsuit if a vehicle is an accident, with claims of causation due to poor repair work. The safety of customers is important to your business.

So is the safety of your employees. An employee who is out of work due to an injury is costly, with workers’ comp being only part of the cost. Your production capability is lower. Other employees need to make up the work, making them more prone to injury if they are working too much overtime, if they are fatigued or if they are stressed.

The employee home with an injury is losing income. They are in pain, maybe having to go to therapy several times a week. They cannot do what they used to do, which puts stress on the family.

So, how do you help prevent injuries? We may not be able to prevent all of them, but we can reduce them and control what does happen. How do you enforce quality? You let employees know that it is important to your business. You show them what you expect. You coach them. Same with safety. Call out unsafe behaviors. And call out safe actions, too, so employees know you value that.

Set the example when you walk through your shop. Wear safety glasses. If it’s loud, put on earmuffs. If something’s out of place, blocking a fire extinguisher, an electrical panel or an exit, move it. If you see an unlabeled container, label it.

Make sure employees have the personal protective equipment they need, and that it fits. You’re legally obligated to provide them with the safety glasses, hearing protection and respirators needed for the job. This is not a place to skimp – if safety glasses get scratched up, employees won’t wear them. If the only type of hearing protection you provide are earplugs that employees find uncomfortable (or that don’t fit their

by Carol Keyes, CSP & Janet L. Keyes, CIH

ear canals), they won’t wear them. Encourage employees to let you know when they need a different tool, or a scaffold, or if a piece of equipment needs repair. And, act on that information. Responding to employee concerns and suggestions in a positive way is the best way to reinforce that their safety matters to you.

Provide safety training. Once a year for Right to Know/Hazard Communication is a great start, but add a quick safety reminder at shop meetings. Ask for feedback or concerns. Keeping safety in front of employees reinforces the importance of safety.

Work with employees to address the hazards of the job. An insurance company’s loss control rep, a safety consultant, the fire marshal, or OSHA might walk through your shop, but they’re seeing just a snapshot of what goes on. They’ll notice problems like a blocked exit, but unless the timing’s right, they won’t see the technician who starts a fire when he uses a torch because he left a rag in the way, or the detailer who sprays wheel acid without any eye or skin protection.

Have you ever heard of job hazard analyses? They’re also called job safety analyses. Fancy names for a simple process of walking through a job, step by step, to identify its hazards and come up with controls. Sort of like blueprinting a car. Ask your employees what tasks they think are the most hazardous. Then evaluate the top tasks. Work with them to list the steps – and the

control measures they should be taking to prevent harm. A simple example: using a floor jack. What could go wrong with placing it? With jacking up the vehicle? With lowering it?

We’re not suggesting you do the job hazard analysis for every job. Instead, consider it as one tool to get you and your employees thinking about a safe workplace. Your employees are your best resource for identifying and controlling the hazards in the workplace. They may not know the hazards of a particular chemical, but they know what they use and how they use it.

When we talk with shop owners, we often hear them lament about the difficulty in finding skilled technicians. That makes keeping good people critical to your success. What if those good employees can’t work because they’ve been injured? If you make the investment in their safety and health now, it will pay off.

What’s Wrong with this Picture?

AASP-MN News 20 | April 2024

COMPLETE HEALTH, ENVIRONMENTAL & SAFETY SERVICES

Eyewash is completely blocked by the tool chest, which is also blocking the exit.

AASP-MN News April 2024 | 21

Members Safety Compliance Services

Complete Health, Environmental & Safety Services, Inc. (C.H.E.S.S.) offers AASP-MN members a 20-percent discount on the following services:

Right to Know (RTK)/Hazard Communication

You must train employees before they start work and annually. You must have a written program. CHESS’ Right to Know written program and training guide is customized for your facility, whether you offer collision or mechanical repair. The written program and training guide is available exclusively to AASP-MN members for $515.

Safety Data Sheet Management

As part of the Right to Know/Hazard Communication OSHA law, you must provide your employees access to Safety Data Sheets (SDS) for the products in your shop. CHESS’ SDSLinks, an online SDS management tool, makes them easy to find. CHESS also provides support 24/seven if you cannot locate one. SDSLinks is available exclusively to AASP-MN members for $325 per year.

A Workplace Accident and Injury Reduction Program (AWAIR)

As of February 2020, you must have a program that outlines who has responsibility for safety, how safety is communicated, how hazards are identified, how accidents are investigated and how safety is enforced. AASP-MN member discounted price: $760.

Safety Reminder Posters

OSHA has some regulations, such as walking and working surfaces and ladder use that require training. Keeping safety in front of employees on a regular basis is one way to help reduce injuries. CHESS will email you a poster on a different topic each month relating to safety issues found in your shop. You can post it or review it with employees in a shop meeting. The Safety Reminder Posters program is available exclusively to AASP-MN members for $285 per year.

All of these services can be bundled for a fee of $1500, with annual renewal of the SDSLinks and posters for $575.

In addition, CHESS offers up to one hour of free phone consultation to any AASP-MN member with safety or environmental questions.

For more information, contact Carol Keyes at (651) 4819787 or carkey@chess-safety.com

AASP-MN News 22 | April 2024

IN ON YOUR MEMBERSHIP BENEFITS!

CASH

AASP-MN and C.H.E.S.S. Team Up to Offer

30659 Pearl Drive Unit #3 • St. Joseph, MN 56374 CALL US TODAY!! Toll Free: (855) 252-2102 Mike: (320) 267-2102 Randy: (320) 266-7239 www.straight-square.com Looking for FAST & EASY PULLING AND MEASURING in Your Shop? MAKE IT STRAIGHT & SQUARE! Frame Racks 30659 Pearl Drive Unit #3 • St. Joseph, MN 56374

AASP-MN MEMBER PREFERRED PROVIDER PROGRAMS

PROPERTY/LIABILITY AND WORKERS’ COMP INSURANCE

CBIZ

Contact: Brad Schmid

763-549-2247 / bschmid@cbiz.com

CBIZ AIA and United Fire Group (UFG) have created a program for members that includes a special premium discount, exclusive coverage and potential safety group dividend. CBIZ AIA can present quotes from multiple carriers and, as an added bonus, offer members an exclusive 10% discount on their property/liability insurance premiums.

EMPLOYEE BENEFITS

CBIZ

Diego Campos

763-228-0259 / diegocampos@cbiz.com

AASP and CBIZ are partnering to help make the process of purchasing employee benefits a lot less stressful for members. The CBIZ platform provides increased transparency and more options for savings, the ability to predict rate increases early, and guidance from CBIZ benefits experts. New Health Insurance Options Now Available!

EMPLOYEE VOLUNTARY BENEFITS

Colonial Life

Contact: Deb Ferrao

612-600-4135 / deb.ferrao@coloniallifesales.com or Tracy Bailey

612-801-0139 / tracy.coloniallife@gmail.com

Dedicated representatives can help members transform their benefit package with competitive rates, value added services at no cost and complimentary legal document preparation service. Colonial Life has the tools and flexibility to create a plan to fit everyone’s needs.

UNIFORM & LINEN SUPPLIES

Vestis (formerly Aramark)

Contact: Ryan Vick

612-269-2303 / vick-ryan2@aramark.com

Discounted pricing to members on rental of uniforms, entrance mats, shop rags, etc. Purchases are also discounted. Members receive annual rebate equal to 10% of their business with Vestis each year.

CREDIT CARD PROCESSING

Association BankCard Services

Contact: Carly Chivers

715-254-9600 / carleyc@midwesthardware.com

Competitive rates for AASP-MN members. Terminals and printers sold at cost. Monthly rental of equipment is also available.

LEGAL CONSULTATION

Fryberger, Buchanan, Smith & Frederick

800-496-6789

Members receive free, over-the-phone legal assessment and consultation (some restrictions apply) with an attorney who specializes in the area of law that is the subject of the call.

WEBSITE AND INTERNET MARKETING SOLUTIONS

Autoshop Solutions

Contact: Tony Mercury

919-267-1731 / tony@autoshopsolutions.com

Autoshop Solutions has developed the most cuttingedge marketing platform for AASP members. Really Powerful Marketing (RPM) is an all-in-one program that bundles your website, pay-per-click, search engine optimization, social media, and much more! With five levels of RPM to match your budget, goals, and competition, it’s built to drive your shop forward!

REPAIR SHOP PRODUCTS/SERVICES DISCOUNTS

CARS Cooperative

Contact: Stephenie Sheppard

405-547-4077 / membersupport@cars.coop Members receive discounts on a variety of products and services they use every day! From discounts on paint and rental cars to office supplies and phone services. Over 50 programs available!

INFORMATION PROVIDERS

Mitchell 1

Contact: Mitchell 1 Representative

888-724-6742 ext. 6986

Mitchell 1 offers AASP members a $10 per month discount on any eligible Mitchell 1 subscription.

Mitchell International

Contact: Mitchell International Representative

800-238-9111

AASP members receive $350 off Mitchell's MD500 all-in-one solution for scanning, calibration, estimating, and blueprinting.

TECHNICAL INFORMATION HOTLINE

IDENTIFIX

800-745-9649

Members enjoy a 20% annual savings on DirectHit and Direct-Help subscriptions, the industry's most reliable source for experience-based repair information.

CHECK GUARANTEE SERVICES

Certegy Check Services

877-520-2987

Discount rate of .75% to AASP-MN members. Use existing credit card terminal. Fast claim payments.

SAFETY COMPLIANCE

Complete, Health, Environmental & Safety Services (C.H.E.S.S.)

Contact: Carol Keyes

651-481-9787 / carkey@chess-safety.com

AASP-MN members receive a 20% discount on Safety Data Sheet Management (SDSLinks), Right to Know(RTK)/Hazard Communication program customized for your facility and monthly safety reminders, and other safety, OSHA or environmental assistance.

AUTO EMPLOYEE ASSESSMENT

Assessment Associates International

Contact: Nate Page

952-854-6551 / nate@aai-assessment.com

Designed to help facilitate and enhance hiring decisions. AASP-MN members receive 50% off retail price, starting as low as $15 per assessment.

BUSINESS FORMS/CALENDARS

AASP-MN

Contact: Jodi Pillsbury

612-623-1110 / jodi@aaspmn.org

Discounted rates on printed business forms and calendars.

PAYROLL PROCESSING

CBIZ Payroll

Contact: Carrie Hobrough

651-387-9168 / chobrough@cbiz.com

Members receive 20% discount off standard payroll, time and attendance, and HRIS products and services.

LIVE-ONLINE & ON-DEMAND

TECHNICAL TRAINING

Automotive Seminars

Contact: Tim Houghtaling

920-866-9813 / tim@automotiveseminars.com

Discounted pricing to AASP-MN members on all liveonline events, as well as on-demand training videos. Automotive Seminars specializes in diagnostic training that provides automotive technicians with knowledge, testing techniques and data interpretation skills needed to diagnose today’s vehicles. The live-online events and on-demand training videos focus on automotive electronics and engine management systems and are written and created by some of the industry’s leading diagnostic technicians.

BUSINESS COACHING

180BIZ

540-833-2014 / info@180biz.com

Members receive a 25% discount on Rick White's Pocket Business Genius subscription, offering independent auto shop owners fast access to actionable business advice from a leading industry expert.

SHOP SOFTWARE

Condition Now

888-868-5440 / conditionnow.com/body-shop

A platform that allows shops to supplement the accident or damage information reported on Carfax and Autocheck vehicle history reports. Every AASP member receives a discounted inspection rate, allowing them to generate additional revenue from their retail and dealer customers.

AASP-MN News April 2024 | 23

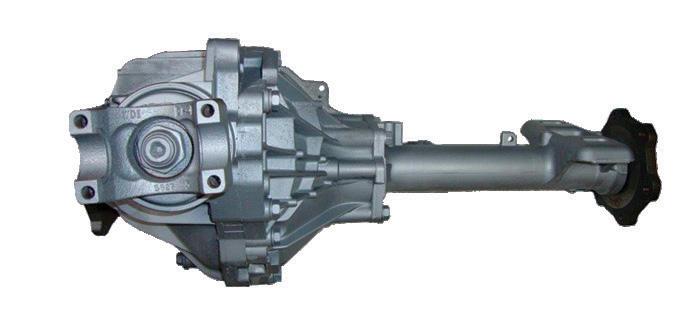

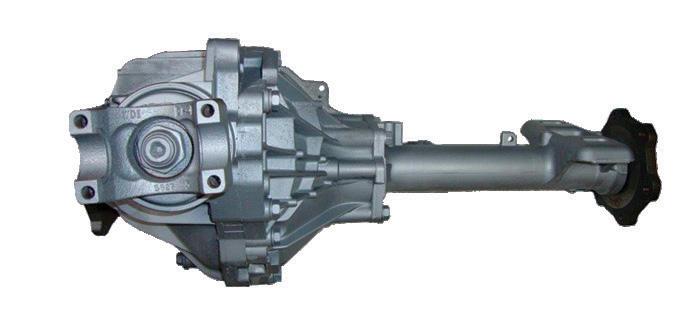

AASP-MN News 24 | April 2024 Choose a Replacement that Performs Better than OE. Inventory, Compatibility, Warranty and Service Automatic Transmissions Over 2,500 vehicle-specified units in stock Up to 3-Year/100,000 Mile Warranty Manual Transmissions 1-Year/Unlimited Mile Warranty Driveshafts Replacement, Custom Driveline We offer a complete line of all driveline parts. - Uncompromised Quality and Service4WD Transfer Cases 2-Year/Unlimited Mile Warranty PTUs (Power Transfer Unit) 2-Year/Unlimited Mile Warranty Differentials 2-Year/Unlimited Mile Warranty Maple Grove • (763) 425-7474 “From The Flywheel To The Drive Wheel” We Have What You Need - Delivered To You

By Aaron Swanson, AASP-MN President

By Aaron Swanson, AASP-MN President