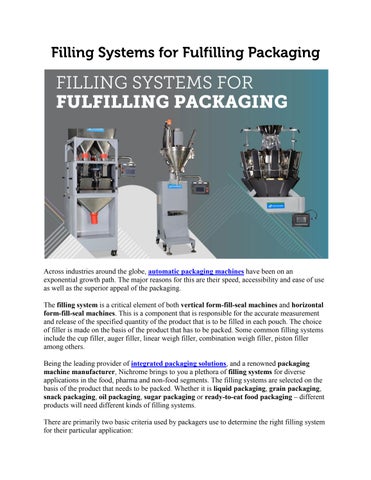

Across industries around the globe, automatic packaging machines have been on an exponential growth path. The major reasons for this are their speed, accessibility and ease of use as well as the superior appeal of the packaging. The filling system is a critical element of both vertical form-fill-seal machines and horizontal form-fill-seal machines. This is a component that is responsible for the accurate measurement and release of the specified quantity of the product that is to be filled in each pouch. The choice of filler is made on the basis of the product that has to be packed. Some common filling systems include the cup filler, auger filler, linear weigh filler, combination weigh filler, piston filler among others. Being the leading provider of integrated packaging solutions, and a renowned packaging machine manufacturer, Nichrome brings to you a plethora of filling systems for diverse applications in the food, pharma and non-food segments. The filling systems are selected on the basis of the product that needs to be packed. Whether it is liquid packaging, grain packaging, snack packaging, oil packaging, sugar packaging or ready-to-eat food packaging – different products will need different kinds of filling systems. There are primarily two basic criteria used by packagers use to determine the right filling system for their particular application:

Issuu converts static files into: and more. Sign up and create your flipbook.