Group Metropolitan takes a data centre's power supply to another level

Group Metropolitan has upgraded essential equipment on one level of a data centre, for a global telecoms company that offers co-location data centre facilities.

The project -on level seven of the nine-storey building in London's Docklands -involved replacing the uninterruptible power supply (UPS) and installing a new input-output switchboard. "UPSs are a fundamental part of a data centre's infrastructure," says Ben Rawson, Technical Compliance Manager at the Greenwich-based turnkey services contractor. "They're found where equipment can't be turned off, acting as a buffer and eliminating downtime. If the power goes down, batteries will take the load until the generators kick in, restoring mains power to equipment."

Replacing a UPS system is a challenge, particularly in single-fed installations such as this one. Temporary supply cables from alternative distribution equipment are installed before the replacement works are carried out. This allows the

project work to be delivered without prolonged downtime. Once the new installation is complete, the temporary supply is repurposed as a secondary alternative supply, providing full system resilience and the flexibility to transfer loads without isolation for future works.

Group Metropolitan has replaced UPS systems in this facility for more than 14 years. Initially appointed to undertake condition inspections of essential services in the building, the company was first involved in the Preventative Energised Maintenance Division (TEGG®) to check the equipment using thermography, ultrasound surveys, and power quality analysis. This revealed that a main rising bus bar that fed half the building's UPS systems was displaying elevated temperatures and was at risk of widespread power loss.

Group Metropolitan's design division developed a detailed strategy to enable replacement works to be implemented without a loss of service. They also

produced a life cycle report that prioritised and budgeted works over 10 years.

The company has replaced UPS systems on six levels and has just been commissioned to upgrade the ground floor. This will involve replacing the input/output switchboard panels and reconfiguring them to work with diverse systems to improve their resilience.

Rawson says the floor upgrades can only be carried out in phases because the work is costly and time-consuming requiring designing, planning and careful implementation.

Group Metropolitan has learnt many things, particularly the importance of arc flash awareness. An arc flash occurs when an electrical discharge travels through the air and releases an intense burst of energy. It can be fatal if operatives aren't wearing the correct personal protective equipment (PPE).

As a result, Group Metropolitan has upgraded its safety rules and invested in additional PPE.

With 2025 set to bring many changes and opportunities, NICEIC Technical Director Paul Collins looks at what NICEIC is doing to help you and your business

NICEIC's new campaign raises consumer awareness

Aico's free, award-winning Expert Installer training scheme is FIA CPD accredited and is designed to make sure installers have all the

they need to correctly install domestic home life safety systems, including Fire and Carbon Monoxide alarms and Environmental Sensors.

©2025

ISSN 2042-5732 niceic.com

Enquiries

01582 539000

Communications manager: Debbie Shields

debbie.shields@certsure.com

PR executive: Amar Tanna

Customer services: 0333 015 6625

Sales: 0333 015 6626

Training: 0333 015 6627

Technical helpline: 0333 015 6628

Insurance: 0333 015 6629

@offi.cialNICEIC

Published on behalf of Certsure by: Think, 65 Riding House Street, London, W1W7EH

Editor: Clare Dowdy

clare.dowdy@thinkpublishing.co.uk

Art director: Ian Hart

Associate director: Anna Vassallo

Client engagement director: Melissa Michael

Content development director: Matthew Rock

Advertising: Tom Davison

tom.davison@thinkpublishing.co.uk

Ben Sellers

ben.sellers@thinkpublishing.co.uk

Connections welcomes ideas for contributions. Please email connections@thinkpublishing.co.uk

All rights reserved. This publication (and any part thereof) may not be reproduced, transmitted or stored in any format without the prior written permission of the publisher. Think Publishing Ltd accepts no liability for the accuracy of the contents or any opinions expressed herein.

Printed by Acorn Web Offset, West Yorkshire. Connections and its paper wrapper are printed on paper from European mills, meeting the

?EFC highest quality and environmental standards. Both the magazine and the paper wrapper are fully recyclable.

Welcome to the winter issue of Connections magazine and the first of 2025, a year set to be full of change and opportunities for our industry.

To help NICEIC-certified businesses both navigate those changes and benefit from the opportunities that will no doubt arise from them, on page 12 we outline what NICEIC is doing to reach even more consumers on your behalf. Launched in 2023, our Don't do DIY Electrics campaign helped connect more than 400,000 householders with NICEIC-certified businesses through the 'find a trusted tradesperson' tool. To build on that success, we've launched the next phase of the campaign to reach more people, and again highlight the dangers of attempting to undertake electrical DIY or using a noncertified business.

There are also changes coming by way of government regulation, some of which is covered here (page 37), as well as households and businesses making new choices. Many readers will be seeing that first-hand on the jobs they're doing, such as an increasing number oflow-carbon heating installations or more electric vehicle charging points.

An important theme throughout this issue is skills, both in terms of new people entering the industry, and experienced professionals expanding their skillsets. We examine the

FindouthowNICEIC isreachingmore householdersonyour behalfPage12

Readourrefresheron CPDreQuirements for assessmentPagelB

Durguidetosuccession planningPage14

areas where the industry needs to improve, looking at how we can give people the right technical grounding, and how we can best recognise the depth of talent that we have in the electrotechnical sector.

There's an article on apprenticeships from NICEIC CEO Richard Orton (page 29); a roundup of excellent work by student electricians at SkillELECTRIC (page 26); and a look at life as a T Level student in our new Follow the Learner series (page 25).

For those seeking advice for their business, we have a thoughtprovoking piece on succession planning (page 14) and a refresher on CPD requirements for NICEIC assessments (page 18). It contains an important update, which comes into effect on 1 March.

I hope you find this issue useful and interesting. Remember to log what you read as CPD.

Paul Collins Technical Director, NICEIC

Avant Teena's new 32,000m 2 headquarters in Suffolk's Bury St Edmunds is not only the largest project ElecBuild Electrical and Building Services has worked on, but also the most energy efficient.

A BREEAM accreditation was part of the planning permission for the new building, which contains a warehouse, workshop, showroom and offices for the Finnish manufacturer of agricultural plant and machinery.

Given that the design team wanted to achieve a BREEAM 'Excellent' rating for the building, ElecBuild had to ensure they followed strict criteria and liaised with the BREEAM consultant to verify their evidence and installation.

"An example of the evidence needed was ensuring all equipment was metered and connected to the building management system," says Chris Double, Director ofElecBuild.

After winning the tender in September 2023, ElecBuild worked with main contractor SEH French to adapt the tendered drawings to produce a construction issued design, not easy in the tight timeframe.

"Most of our designs are working drawings and plans, usually at stage four level, but this project involved developing drawings to stage five, which is very detailed," says Double. "It's been a huge learning experience for us, from the project design to coordination, material procurement and the installation. We

have used this experience to excel in areas that we previously might not have been confident about."

ElecBuild installed all the electrical elements, which included CCTV, access control, a 100 kW PV array, three electrical vehicle charging posts, fire alarm, lighting and general power. Many different manufacturers were used because of the size of the building. These included Gripple for the containment hangers and fixing, and Legrand for the containment, such as basket and galvanised trunking. Fagerhult and Zumtobel (Thorn) provided the lighting, and Zumtobel Litecom was used for the lighting controls. Hager was specified for all the wiring accessories and lighting connection modules, Schneider for the

"It'ssafetosaywe've takenmuchmoreaway fromthisprojectthanjust thefinishedinstallation"

mains distribution and Apollo for the fire alarm detection system.

A DALI Smart System was installed because of its energy efficiency. The lighting system can be programmed and features absence detectors so that lights switch off when people leave a room, therefore saving energy.

The completed Avant headquarters was certified BREEAM Excellent, and the building will continue to be monitored to ensure that it retains its high sustainability standards.

"It's safe to say we've taken much more away from this project than just the finished installation," says Double. "It has made us hungry for bigger, more demanding projects and has pushed us in the right direction."

The campaign, which has also been tested for effectiveness with a consumer audience, reaches people across social media channels including YouTube and Meta, and the wider Google network, with all adverts pointing again to the 'find a trusted tradesperson' tool on the NICEIC website.

To benefit from this new phase of the campaign even further, NICEIC-certified businesses can access the marketing toolkit on the NICEIC customer portal to discover downloadable assets that can be used across various platforms including your website and social media.

During the development of the new phase of the campaign, NICEIC commissioned a YouGov survey to find out more about the views and attitudes of householders towards undertaking electrical work in a domestic setting.

TherearemanybenefitstobeinganNICEICcertifiedbusiness.Fromthecredibilityofbeing withtheelectricalindustry'smostrecognised certificationbodytothetechnicalsupportand continuingprofessionaldevelopment[CPD] opportunitiesavailable,NICEICiscommitted toraisingawarenessofcertificationinthe industryandconnectingconsumerswith NICEIC-certifiedbusinesses.

Vou may remember that during 2023 NICE IC launched its Don't Do DIY Electrics campaign. Since then, the campaign has gone on to achieve over 21 million impressions through Google, YouTube and Meta, and in turn has connected over 400,000 householders with NICEIC-certified businesses through the 'find a trusted tradesperson' tool. That works out at over 1,000 householders a day!

To build on this success, NICEIC has launched the next phase of the campaign targeting householders and decisionmakers to highlight the dangers of either using a non-certified business or attempting to complete electrical works in a domestic setting themselves.

With the clear objectives ofraising awareness of the NICEIC brand and driving customers to connect with NICEIC-certified businesses, a series of new digital adverts (see above and niceic.com/dontdiy) have been created to highlight the invisible dangers of unsafe electrical work and to remind householders that they should always instruct a certified business to carry out works rather than making attempts themselves.

The results are interesting. Findings show that 87% of UK adults tend to agree or strongly agree that electrical work should be carried out by a qualified electrician, additionally 89% tend to agree or strongly agree that undertaking domestic electrical work could be dangerous or life threatening (YouGov,2024).

Despite a clear understanding that electrical work can be unsafe when not completed by a qualified electrician, almost one in three (30%) of those surveyed still admitted to having completed electrical DIY at home (YouGov,2024).

Whilst the stats demonstrate that consumers recognise that poor electrical work has the potential for devastating effects, including injury or even death, some are still attempting to complete electrical work in the home themselves. These findings have helped shape the next phase of the campaign to further educate consumers of the importance of using a qualified electrician, ultimately driving more awareness ofNICEICcertified businesses.

"Thisnewphaseofthecampaign

PAULCOLLINS,NICEICTECHNICALDIAECTDA

The challenge remains that anyone can call themselves an electrician, therefore certification by NICEIC enables your business to stand out from the crowd. It demonstrates your business' commitment to upholding standards which in turn can enhance both your professional reputation and market competitiveness. It assures your customers that your business is serious about its work and is dedicated to maintaining high standards.

Paul Collins, Technical Director at NICEIC, commented: "We're committed to highlighting to consumers the need to use an NICEIC-certified business to ensure safe electrical installations. The results from the first phase of the Don't Do DIY Electrics campaign were fantastic and the sheer number of householders using the 'NICEIC find a trusted tradesperson' tool demonstrates the effectiveness of the campaign.

"It was encouraging to see in the results of the YouGov survey that a large number of consumers are aware of the importance of using a qualified electrician to carry out electrical works in the home but worrying to see that despite this, almost one in three have still carried out DIY works themselves.

"This new phase of the campaign aims to bridge that gap and demonstrate just how easy it is for householders to find NICEIC-certified businesses in their area to complete any domestic electrical works. I'd highly recommend that NICEIC-certified businesses visit the customer portal to download the free assets that can be utilised across their own marketing platforms."

Formoreinformationaboutthecampaign, visitnicelc.com/dontdiy

Thisquestionisguaranteedtomakeany businessownerponder.WillIretire? WhatbiglifeeventwillmeanInolonger runmybusiness?Inthisintroduction to ournewseriesonsuccessionplanning, RebeccaBurn-Callandersetsouttheoptions

As difficult as it might feel to confront these possibilities, it's vital: understanding who will run the business in future, what role you will have (if any) and how you intend to benefit (or not) from the business you've created gives you a clear path to follow.

It also offers certainty to your family, customers and team, and allows you to prepare, mentally and emotionally, for the next stage.

This process is known as succession planning, and fewer than one in 10 r---- .... --, business owners ever attempt it, according to research by accountancy and advisory firm Azets. This series will examine various exit routes in detail and help you make an informed choice.

Julie Wong is a finance specialist, fractional finance director and business mentor, who works with leaders from trade businesses to help them plan for succession. "I talk about this a lot with my clients," she says. "If you've worked hard building an electrical contracting

business? Would you like to extract value at exit? Or do you just want to shut up shop? Once you understand your ultimate objective, you can plan."

Having these conversations with yourself and those around you can help you prepare for a potential exit. "It's an emotional journey," explains Wong. "Your business is a big part of your identity. It may feel disconcerting to think about letting go, but starting these discussions early can save you harder conversations later."

Succession planning has many benefits. If you know you would like to sell the business to your management team, this gives them a reason to stay with the business, knowing that they will have the chance to take the reins eventually. If you plan to pass the baton to a family member, you can ensure they work across various departments, getting to know the whole business inside and out, in order to become a better leader.

In smaller businesses, where the owner typically wins most of the business and maintains the client relationships, the company could flounder without a succession plan that explains what would happen without that individual at the helm.

As Wong says: "Alot of business owners from the Baby Boomer generation are thinking about selling up or retiring right now. It's hard to do that if you have made yourself irreplaceable."

Ensuring that you have an up-to-date client book, recording the value of each client and the job history, is one way to preserve business value, she says. "Whether you are passing the business on to a family member or selling up, you will need to understand the value of the business and allow the next owner to step into warm shoes."

When is the right time to start

business, for example, and have a great thinking about succession? "Yesterday,"

reputation, loyal clients and a strong team, Wong says. you've created value. Succession planning allows you to protect that value when you eventually hang up your boots."

Succession planning doesn't have to be a painful process. At first, it just requires a little thinking time. According to Wong, the first question to ask yourselfis: What do I want out oflife?

"How do you want to exit your business?" she asks. "Are you looking to retire? Do you want to stay involved in the

WeaskedourNICEICcertifiedbusinesseswhat theirsuccessionplansare. Of873respondents: 30%planto allowthe businessto winddown 22%planto pass thebusinessto familymember/s 17%havenosuccession plansandintendto continueinthe businessforever 15%will gradually removethemselves fromtheirbusiness

9%intendto sell thebusiness

7%hadotherplans

Whichexitstrategymakessense for youandyourbusiness?

• Familysuccession:Passing the businessonto a son, daughterorclosefamily memberisa popularchoice. However, it canbechallenging, especially if there'smorethan onepotentialbeneficiary.

• Managementbuyout[MBDJ: Thisoptionallowsyour managementteamto buy intothebusiness.

• Externalsale:Sellingto an externalbuyeris a common route,oftenallowingthe founderto extractthe most valuefromthebusiness.

• EmployeeOwnershipTrust [EDT]:EDTsallowownership to betransferredto employeeswithoutthe needfor a directbuyout. It's a modelthat ensures employeesareincentivised to continuedrivingbusiness success,andithastax advantagestoo.

• Winddownandclosure: Forsome,this mayfeellike theonlyoption.However, to protectcustomerrelationships andtreatemployeesfairly, it's still importantto havea planin place.

• I'mnevergoingtoretire: Planningto worktill youdrop? Makesureyouhaveallthe factssothatthereareno surprisesdowntheline.

RuthDevineMBE,EmployerChairofThe ElectrotechnicalSkillsPartnership[TESP], takesalookatskillsdevelopments throughout2024andexplainswhat'sin thepipelinefor2025

For new apprenticeships in England, 2024 was a strong year. Provisional government data shows 7,230 starts on the Installation and Maintenance Electrician apprenticeship over the past academic year. This is the third year in a row that intake figures have been this high, a significant improvement on the pre-Covid average of around 5,500 annually. In total, more than 26,000 apprentices are currently progressing their training. There's also a positive picture with around 2,000 apprenticeship starts across Scotland, Wales and Northern Ireland over the past year.

There's no time to put our feet up, though, as we still need a continued and significant increased supply of electricians to meet our future skills needs. TESP's efforts to support employers to increase apprenticeship starts and achievements is continuing in 2025. Our aim is to encourage employers to recruit at least 10,000 new apprentices a year and to drive continuous improvement of achievement rates.

Looking at the newest sector apprenticeship standard, there were 60 Domestic Electrician apprentices in training to September 2024, a promising start. The number ofregistered training providers has more than doubled to 30,

so we are keen to see enrolment data in January for the 2024-2025 academic year to find out how this is progressing.

Outside of apprenticeships, there has been lots of activity around raising and embedding competence standards, with a strengthened regulatory regime and obligations following the implementation of the Building Safety Act.

The latest Electrotechnical Assessment Specification (EAS) and accompanying EAS Qualifications Guide were published in October, including new work categories for electric vehicle charging equipment (EVCE), Solar PV, electrical energy storage systems (EESS) and micro wind.

NICEIC will provide further guidance on EAS updates in the following months.

Domestic electrical work will also see strengthened qualification requirements.

In the 'green' and low carbon arena,

"Westillneeda continuedandsinificant increasedsupplyof electricianstomeetour futureskillsneeds"

TESPisanot-for-profit'communityinterestcompany'that worksonskillsprojectsto benefittheelectrotechnicalindustry. ItscoremembersaretheElectricalContractors'Association, theJointIndustryBoard,NationalElectrotechnicalTraining,

TheDepartmentfar Educationissetting up'SkillsEngland'asa newgovernmentbody ta replacethe Institute far Apprenticeshipsand TechnicalEducation. SkillsEnglandwill bring togethera widerange of partnersta shapethe futureskills system.

In2024,wewerepleased taraiseawareness of training'packages'and theirpotentialpitfalls, androlledoutavideota informpotentiallearners. In2025,we'llbeworking closelywithAwarding Organisationstatarget undesirablepracticesand improvethequalityof trainingdelivery.

recognition of the 'Electrician Plus' concept is growing rapidly. We now have leading awarding organisations and training providers using the logo to demonstrate that their qualifications meet the TESP criteria for entry requirements, content and assessment methodology. TESP will publish Electrician Plus training routes for EVCE, Solar PV and EESS shortly.

So, 2024 was a busy year overall with significant progress, but there's still much to do and employers' contributions are crucial. We look forward to working with our partners and supporters in 2025 to improve the skills landscape even further, protecting public safety and assuring performance.

UnitetheUnionandSELECT.CertsureworkscloselywithTESPon projectssuchastheExperiencedWorkerAssessmentandthe ElectromchnicalRssessmentSpecificationaualificationsGuide.

TESPprovidesresourcesandguidance,includingtheElectrical Careerswebsite,theIndustryintoEducationcampaignand Industry-approvedtraining. (JJ the-es,n.Dl1/.Uk

Smithgives a refresheronCPD requirements duringyour assessment,andexplains what'schanging

Since2020ithasbeen a requirement of your certification by NICEIC to provide documented evidence of continuing professional development (CPD) of all 'employed persons'; this means anyone engaged in electrotechnical work, including subcontractors. This followed an update to the Electrotechnical Assessment Specification (EAS), which applies to all electrotechnical certification bodies.

As this update has been in place for some time, and all NICEIC-certified businesses have had an opportunity to adapt, your assessor will need to see evidence of the requirement being met during your assessment visits.

Whatdoesthismeanfaryou?

From 1 March 2025, if you can't provide sufficient evidence of CPD during your assessment (previously known as the office audit), you'll be required to submit it within 30 days.

What'sthevalueofCPD?

Having a robust CPD framework isn't just about ticking compliance boxes. It shows you're investing in your people, which nurtures and enhances skills, and helps to retain employees. We know

there's a skills shortage in the industry, and that keeping good staff can be a challenge. CPD helps you to do that.

CPD also helps ensure your business is keeping up with innovation, and that can open up new markets. You might want to broaden your portfolio by moving into green technologies such as electric vehicle charging points, solar PV and battery storage. But to do this work staff should possess the right skills, knowledge, experience and behaviours (SKEB).

During the management systems review stage of the assessment (previously known as the office audit), to comply with the scheme requirements, you must make CPD records available for all employed persons, for the assessor to review and sample. The Assessor assesses against the EAS, which forms the assessment framework for certification and registration bodies.

Maintaining competence through CPD is akeypartoftheEAS, and CPD includes formal and informal activities. It's good practice to have a framework for assessing the effectiveness ofthe CPD your employees and contractors do.

Businesses are also required to hold records ofrelevant qualifications, training (including CPD) and experience. This can be shown through documents such as personnel records, training matrices and contractor records. We find that most

"HavingarobustCPD framework ... shows you'reinvesting in yourpeople"

people are doing CPD, but not recording it. It's important to log it for all employed people, including temporary, agency or sub-contracted staff.

NICEIC has produced a CPD record template, or you can use self-made CPD recording systems. If you're a member of a professional body, you're probably logging your CPD on their portals. For ECA members, the ECA eCOMS platform is a useful tool which also helps businesses capture and log CPD.

There's no minimum number of hours of CPD specified within the EAS. But you must be doing something, and it must be something that takes you forward in your role, so you're not just resting on a qualification you obtained five years ago. It's a key part of development, and CPD should be ongoing throughout your career.

In the past, people have seen CPD as formal class-based learning, but it can be done in different ways. CPD includes

"Mostpeoplearedoing CPD,butnotrecording it"

watching an NICEIC webinar, reading an article in Connections magazine, looking at our Pocket Guide app, listening to live Technical Q&As, doing peer-to-peer reviews or shadowing, training and refresher courses, toolbox talks, mentoring or supervision. When you record CPD, it doesn't have to be categorised as formal or informal.

Staypreparedfarassessments

Failure to provide evidence of CPD activities will lead to a non-conformance being recorded during assessments. However, NICEIC has a wealth of resources to make staying up to date easy. Take advantage of these to prepare for the assessment process.

WHATCPDINFORMATION SHOULD\IOURECORD?

Foreachactivity,briefly describewhatyoudid [likejoininga webinar, ortakinganonline course).Notethe date andhowmanyhours it took.Thenhighlight the keyknowledgeand skillsyougained.Most importantly,explainhow this activity contributes to yourprofessional development.

WHOISRESPONSIBLE FDRRECORDINGCPD?

Theassessedbusiness is responsiblefor providingrecordsof all relevantqualifications, training[includingCPD) andexperiencefor everyoneengagedin electrotechnicalwork in the business.The OualifiedSupervisor is responsiblefor monitoringthe suitability of everyonewithin the businesswho undertakeselectrical work,whichincludestheir qualifications,training andCPDrequirements.

ISCPDARECOGNISED DUALIFICATIDN?

No,CPDis nota qualificationitself. It's a processof ongoing learningto stay upto date in yourfield.However, youcanrecordrelevant qualificationsasCPD.

WHATARETHE BENEFITSOFCPD BE\IDNDMEETING REQUIREMENTS?

CPDequipsyouandyour employeeswiththeskills, knowledge,experience andbehaviours[orSKEBJ to complywiththe Building Safetynet.It alsobuilds customertrust andkeeps youat theforefrontof the industry,whichhelpsyou staycompetitive.

WATCHTHEWIRE /TH£WJR£1webinaronthe electrotechnical assessment,whichcoversthe importanceof supervisionandtrainingreQuirementsfor your business.niceic.com/thewire

•1READ

NICEIC'sprincipal • II EIII dutyholderandqualified supervisorguideto roles andresponsibilities.bit.ly/0S-guide

NICEICPOCKETGUIDESAPP givesusersaccessto more than35technicalreference guidesandhandycalculators. bit.ly/Pocket-Guides-app

DOWNLOADNICEIC'S 1-.,,,,____ 1 TEMPLATESforCPDand supervisionrecords. bit.ly/CPD-template and bit.ly/supervision-records

The government in England has pledged to implement new standards, guidelines and regulations that will require all newly constructed homes from 2025 onward to generate 75%-80% fewer carbon emissions compared with homes built according to the current regulations.

What advice can contractors give to customers to improve indoor air quality?

• Increase ventilation: Proper

ventilation is crucial for improving indoor air quality.

Manyofourcertifiedbusinessesaregettingintouch withourteamstogetclarityontherequirements for ventilationsystems.Here,wespellouttheissues,and ourTechnicalarticleonp58goesintothedetails

Why is ventilation such a hot topic?

NICEIC's Head of Standards, Dani Putney, explains: "The changes in England and Wales to Approved Doc F, and ventilation strategy requirements in PAS 2035 and Part Lare all prompting queries, as are concerns highlighted in the press about the effects of air quality on human health."

What is indoor air quality?

Indoor air quality refers to the quality of air within and around building structures, specifically concerning the health and comfort of the people living there. It's influenced by factors such as pollutants inside or outside the home, including biological contaminants, ventilation rates, temperature and humidity levels. Poor air quality is detrimental to the health of occupants in the short term and long term. Solutions include air filtration, proper ventilation and measures to reduce or eliminate pollutant sources.

What are the relevant standards?

In England and Wales, ventilation systems are covered in Part F of the Building Regulations. In Scotland, they are dealt with in Section 3.14 of the Building Standards Technical Handbook. In Northern Ireland, they are in Technical Booklet K.

These 2021 amended regulations mandate higher ventilation rates and mechanical ventilation for airtight new homes to improve indoor air quality. They specify increased whole-building airflow, room-specific background ventilation, and purge ventilation requirements based on window openings to allow sufficient air changes per hour.

Each provides a set of minimum standards for new ventilation systems, covering areas such as determining appropriate types of controlled ventilation, minimum performance standards and commissioning procedures to ensure ventilation systems operate correctly.

• Control the source of pollutants: Find and reduce sources ofindoor pollutants such as combustion

appliances, building materials, cleaning products and so on.

• Purify the air: This helps remove particulate pollutants, gases and odours.

• Clean and maintain: Regularly clean or replace filters, vents and ductwork.

• Check ifrecirculation is efficient: Ensure any air ventilation systems are not recirculating stale indoor air.

For more on Approved Document F, which covers England and Wales, go to page 58.

How do you comply?

The Building Act stipulates that installation and commissioning should only be completed by competent installers. One way to demonstrate competence is to be certified on a Competent Persons Scheme.

Alternatively, you can advise the local Building Control Body after the installation is complete to organise a regularisation assessment.

Changes introduced by the Building Safety Regulator specifically identify Registered Building Inspectors (RBIs) and Registered Building Control Approvers (RBCAs) who can undertake this assessment.

Minimalisation

Requirement to monitorindoorairqualityin all new-buildcommercialandhigh-riskbuildings Performance-basedventilationstrategy Assessment

BUILT TO LAST, LIGHTING THE WAY

THE NEW, ROBUST OUTDOOR FLOODLIGHTS FOR ANY WEATHER

The new standard for demanding outdoor applications: The FLOODLIGHT GEN 4 range is extremely efficient and very durable. Thanks to MULTI LUMEN, the brightness can be adapted to requirements. Sensor and Photocell versions add a further layer of versatility. Reliable even in the harshest conditions thanks to the waterproof cable gland, breather membrane, C4 corrosion resistance and up to IP66 and IK08. FLOODLIGHT GEN 4 are easy to install and come with a comprehensive 5-year guarantee.

Infutureissues,wewanttofeature yourgreatrepairworkalongside thebotchedjobs.Pleasesend beforeandafterphotosto

Charlie Backwell at Naked Solar in N ewquay found this at a client's house when there to fit solar PV and a battery. "Interesting way to heat the swimming pool." The customer had put an immersion heater element in a plastic box with a load of silicone sealant and left it floating in his pool to heat the water, Backwell explains. "He wanted it wired to an immersion diverter to make use of the excess power generated by the PV system we were asked to install." Naked Solar advised him that this was incredibly dangerous and told him to remove it. "Obviously, we didn't wire in the immersion diverter either," Backwell adds.

Chris Welling of Chris Welling Electrical in Norwich was asked to do an EICR at this rental property, only to open up the unit to find this: CPC in the neutral block, no sleeving, neutral in the neutral bar (after the main switch); 2.5 mm 2 feeding the MET above the consumer unit and nothing mechanically protected or double insulated; 16 mm 2 T+E feeding the board and no RCD protection. The cooker switch was the same. The tenants had been there for12years.NoEICRhad ever been issued and there was no RCD protection to any of the circuits, he adds. "I raised and replaced the board, so the cables sat inside (rather than outside) the consumer unit; I updated the mains tails to 25 mm 2 instead of the 16 mm 2 twin and earth. This was also placed in trunking, as no mechanical protection to the cable; I used a 16 mm 2 earth instead of2.5 mm 2 ; I made the correct terminations to the main switch and neutral bar; I bonded the gas with 10 mm 2 from the consumer unit, as this was a TN system and they had TT'd it." He finished off with a full RCBO and surge protection. Then test and certification. "One of the worst I've seen in 22 years of trading."

Paul Grace atK&J Engineering in Essex spotted this horror. "We disconnected the supplyto the shower and left it safe, while others are doing a refit." His team will return to the site once the refit has been done "and install the appropriate light fitting for the shower".

Asrenewabletechnologiessurgeinpopularity,weofferarangeof trainingqualifications,acrosstheUK,tosupportthisgrowth,including solarPV,EVchargingandbatterystorage.

Our qualification in the Design, Installation and Commissioning of Electrical Energy Storage Systems (EESS)is just one of our MCS approved qualifications that can allow you to future proof your business.

Your expert tutor will cover a range of areas on the course such as:

• Thenewlandscape - distributedgenerationandthe'prosumer'.

• Anoverviewofkeysafetyconsiderations,legislationandguidance.

• ThefundamentaldifferencesbetweenACandDC.

• EESScomponents - anoverviewofEESSarrangements.

• Fundamentalsystemdesignprinciples.

• Inspection,testingandcommissioning.

• Notificationandhandover - G98,G99.

This course concludes with a multiple-choice on-screen exam, followed by a half-day practical assessment at a later date.

Inthefirstofouroccasionalseries,wecheckinwithnewstudentWadeGamble tofindoutwhattheTLevelexperienceislikefromtheinsideByPaulThompson

Wade Gamble is one of the latest 50-plus-strong T Level student cohort at Leicester College. "My dad is an electrician and I was looking for an apprenticeship," says the 16-year-old from Leicestershire. "I sent off lots of applications but didn't hear anything back, and so I thought about the T Level course."

Attracted by the split the course offers between classroom-based theory, workshop-based practical skills and onsite work experience, Gamble started his T Level in autumn 2024.

Rweekin thelifeofaTLeveller

For Gamble and his course mates, a standard week is four days in college and one day on site gaining practical experience through a work placement. Such is the popularity of the T Level course, the year group has been split into three with each group spending two days in the workshop doing practical tasks and two days in the classroom. There, they go through the theory of electrical installations and learn about the wider

Whentheylaunchedin TechnicalLevelqualifications [TLevels)wereheraldedas thekeyto encouragingmore youngstersintoengineering andtechnicalprofessions, andawayof managingthe disconnectbetweenthose whodowellat coreSTEM subjectsandthosewhogoon to chooseconstructionand engineeringcareers.

Theelectrical-specific qualificationwasdrawn ~-' upwithinputfromacross

construction sector. The three groups all have a day set aside for their work placement, when students will be either on site gaining experience, or spending time trying to find companies that are willing to offer such opportunities.

Gamble says: "The college day runs from 8:30am until 4:45pm so it's longer than a typical school day. But to be honest, when you're studying so much new material, time seems to pass more quickly."

The theory side of the course is proving just as interesting to him as the practical. "We aren't learning only about the electrical side of things but also about project management and the whole of the construction industry. I wasn't really expecting that when I first started, but it is useful to know."

Practical sessions feature tuition on a wide range of installations and focus on gaining experience in scenarios students are likely to come across on their work placements.

Both the theory and the practical elements are backed up by a rigorous testing and examination regime put in place by his college lecturers. These tough tests aim to keep students fully engaged with their studies and help to benchmark their progress. "We had our first round of tests in November. They were difficult but I managed to complete everything," Gamble says.

He has a work placement lined up with local firm, NICEIC-certified East Goscote Electrics. This will contribute to the 350 work placement hours he needs to amass to gain the qualification. "I'd like to get as many work placement hours as I can -even if I'm well over the 350 I need. I want to get as much experience as possible," he says.

Sahawdoeshefeelthreemonthsin?

''I'd still have preferred to have found an apprenticeship, but the T-Level is a great alternative. It allows me to gain work experience while learning about the trade."

• We'llcatchupwithWadeGambleagain,to getmoreinsightsfromhimonthecourse

the industry, apprenticeyoutakeonis immediatelycomfortableand usefulansite."

includingfromNICEIC's TechnicalDirector,PaulCallins.

"TheideabehindTLevels is to givestudentsa base levelof understanding ofthe constructionindustryaswell asafocusona particulararea," hesays."Theygivestudentsan understanding ofwhatbeingan electricianis allaboutandtheir roleinthewiderconstruction sector.They'renota replacement foranapprenticeship-but theywillensurethatanyTLevel

LeicesterCollegelecturer Wattershasbeeninvolved inhelpingstudentsnavigate TLevelssincetheirlaunch,and echoesCollins'enthusiasm. "Theyprovidelearnerswith opportunities.Theycancarryon intotheworkforceandbecame a qualifiedelectrician,butwith universitiesnowacceptingthe TLevelasavalidpathwayinto highereducation, it alsogives

thosewhowantto godown thatroutethechanceta doso."

BothCollinsandWatters stresstheimportance of workplacements. "It canbe a challenge to findthem,and that'swherecontractorscan help,"saysCollins.

Wattersagrees:"I'd encourageall businesses to asklocalcollegesabout placements.It's about developingtheworkforceand helpingbringmoreelectricians intothesector."

In November, eight of the UK's finest student electricians lined up to test themselves against their peers in a bid to take home the coveted SkillELECTRIC gold medal.

Hosted by Oldham College, the event is part of the WorldSkills UK competition framework, organised by industry charity National Electrotechnical Training and supported by its delivery partners NICEIC and Scolmore Group.

This year's finalists faced a gruelling three-day practical installation with an electric vehicle charging and a fault-finding task thrown in.

"The industry is constantly evolving and so the tasks we set have to reflect that," says Alex Robinson, Head of Product Development at NICEIC.

He -and NICEIC -have been closely involved in supporting the event through supp lying judges, helping organise training sessions, working out judging criteria and formulating tasks.

"This competition helps participants understand the range and scope of work that is available to them beyond

the 'traditional' electrician role," says Robinson. "It helps contestants build on their existing skills through training and competition, and for employers the success of their staffbecomes a quality-mark for their business."

Developing careers; supporting young electricians; enhancing their technical ability -it's all going on at SkillELECTRIC.

KalumLow MSElectricaland Renewables/SECTT

RichardWestwood DudleyCollege

John-Ross

Campbell

ACampbellElectrical Services/SECTT

MillySmith

CSMcKerlieElectrical Services/SECTT

FabieQ MacieJewski LeicesterCollege

EwanThomas

JGMServices

ElectriciansLtd/ SECTT Skills

Jonathan Gough

MDElectrics/ SouthernRegional College

CharlieMoore

BramhamElectrical/ Collegeof WestAnglia

Charlie Moore ofNICEIC-certified Bramham Electrical and the College ofWestAnglia won SkillELECTRIC's gold medal. Tim Bramham, Director at Bramham Electrical, says: "We are all really chuffed for Charlie. We're quite a small business and still have to pay his wages when he's at college or away on training courses or in competition -so there isn't anything in it for us financially. But Charlie doing well has given the whole team a lift. Even our clients have started to recognise his ability and ask for him specifically:' Silver went to Dudley College's Richard Westwood, with Jonathan Gough ofNICEIC-certified MD Electrics and Southern Regional College taking bronze. The work ofKalum Low of MS Electrical and Renewables and Milly Smith of CS McKerlie Electrical Services was 'highly commended'.

Wecatchupwithsomeoflastyear's SkillELECTIUCfinaliststoseehowtheir careersareprogressing

The gold medal winner is working nights for his employer, Grants (Dufftown), on a large installation at a distillery -arguably the dream job for a proud Scotsman.

He's continuing to gain experience on a broad range of projects and has been given some supervisory experience on smaller schemes.

The silver medallist is still with his employer, NICEIC-certified Lloyd Morris Electrical, and has used the experience of the final to mentor two of his colleagues in competitions in Wales.

Now a fully qualified electrician, he says that his showing in the 2023 SkillELECTRIC final has had a positive impact on his career.

"It has definitely helped. My bosses really trust my work and have faith in my ability."

Whitehead says her run in last year's competition increased her confidence both on and off site. Her job with William Davis Homes sees her working predominantly on domestic properties. She predicts that renewable installations -solar, heat pumps and electric vehicle charging -will be a major focus for the industry over the next few years.

digital and communication skills, and develop commercial, customer service and problemsolving capabilities.

Thevalueofapprenticeships

Aselectricalbusinessesdigesttherecent budgetchanges,CertsureCEORichardOrton stressestheimportanceofcontinuing to investinskillsdevelopmentandyoungtalent

The UK government's autumn 2024 budget introduced a raft of measures affecting businesses, but two have grabbed the headlines: changes to employer National Insurance Contributions (NICs) and increases in the living and minimum wages.

As electrical businesses of all shapes and sizes consider the potential impact of these changes on their finances and resource planning, we urge employers to take a long-term view and continue to invest in skills development, including apprenticeships. Closing the skills gap and helping young talent access the sector are crucial if the industry is to continue to thrive.

The rise in employer NI Cs has been one of the budget's biggest talking points. From April 2025, the government will increase the rate of employer NI Cs from 13.8% to 15%and reduce the peremployee threshold at which employers become liable to pay NI (the secondary threshold) from £9,100 to £5,000.

Although these changes are significant, employers don't

have to pay NICs for apprentices if they under 25 years old, on an approved UK government apprenticeship standard and earn less than £967 a week (£50,270 a year). This hasn't changed in the latest budget. If you have existing or new apprentices who meet these criteria, you'll continue to pay no NICsforthem.

To help offset the effect of the rises on smaller businesses, the government is also increasing the Employment Allowance. This currently gives a discount of £5,000 to employers with NIC bills of £100,000 or less. From April 2025, this discount will rise to £10,500. The £100,000 eligibility cap will also be removed, making the allowance available to all businesses.

In her budget speech, Chancellor Rachel Reeves said the increase in the Employment Allowance means that 865,000 employers won't pay any NI Cs next year, and more than one million will pay the same or less than they did previously. She added that this "will allow a small business to employ the equivalent of

"Investinginpeopleremainsattheforefront ofcreatingaprosperousindustry"

four full-time workers on the National Living Wage without paying any National Insurance on their wages".

Reeves also announced rises in the national minimum and living wages. From April 2025, the national living wage for employees aged 21 and over will go up from £11.44 to £12.21 per hour. The national minimum wage for those aged 18-20 will increase from £8.60 to £10.00 per hour, and for those aged 16-17 and apprentices from £6.40 to £7.55.

These rises may have a cost impact on many businesses, but we believe it's imperative this doesn't deter the investment in people and skills necessary to meet the wider challenges facing the industry.

And it's not just aboutthe bigger picture for the sector; apprentices make an invaluable contribution to the firms they work for. When you take on an apprentice, you're not just getting their talent, enthusiasm and commitment. You'll also reap the benefit of new skills and capabilities. As an example, the latest apprenticeship standards include work with key low-carbon technologies such as solar PV, electric vehicle charging points and battery storage. Apprentices now also learn up-to-date

Qualifying as an electrician requires hands-on, practical experience, so apprenticeship schemes provide a vital route into the industry, and a stepping stone for career development. The electrical sector has long been at the forefront of delivering highquality apprenticeships, and electrotechnical apprenticeships are still some of the most popular in construction and the built environment.

As the sector faces a growing skills gap, our need to nurture new talent has never been greater. ECA statistics show there's a national shortage of qualified electricians. Part of the challenge is that although people are enrolling in classroom-only courses, they aren't then able to move on to apprenticeships.

The ECA has found that 12 months after finishing their classroom-only courses, only 10% of potential electricians secure an apprenticeship. The remaining 90% can struggle to enter the workforce and establish themselves in the electrical industry, which may lead some to leaving the sector altogether. This imbalance highlights the urgent need for more apprenticeship places.

Businesses need to take a long-term view of skills development and continue to support entry to the industry through apprenticeships. We recognise the pressures all businesses are under, and the concerns raised by the budget announcements. But investing in people, the sector's greatest asset, remains at the heart of future-proofing the industry.

Learnmoreaboutapprenticeships atthe-esp.org.uk/apprenticeships

Givingyouaccesstotheindustry's besttechnicalmindsandresources.

Technicalhelpline for expert support with installations, compliance and products.

NICEICPocketGuidesapp with 37+ technical guides.

CPDresources including THE WIRE

I webinars, NICEICevents, quarterly Connections magazine and live Q&As.

In-personandonlinetraining for core topics and new technologies.

Regularassessments to help you stay compliant, with guidance and technical advice.

NICEICOnlineCertificationSystem

-saving you time and money by selfg certifying your work and completing and sending certificates and reports.

Savings on specialist, tailored trade insurance.

Discounts on branded NICEICworkwear and tools in our online shop and 10% t@ off selected purchases at Tradepoint.

Nationalmarketingcampaigns to raise public awareness of the high standards of NICEIC-certified businesses.

'FindatrustedNICEICtradesperson' tool to drive demand for your services.

Opening-upopportunities with specifiers such as facilities businesses, landlords and housing associations.

Representingyouintheindustry.

Communicatingyourvoice and influencing government and sector bodies through our role on industry committees.

Shapingfuturepolicyandregulations informed byyourfeedback.

ByDavidAdams

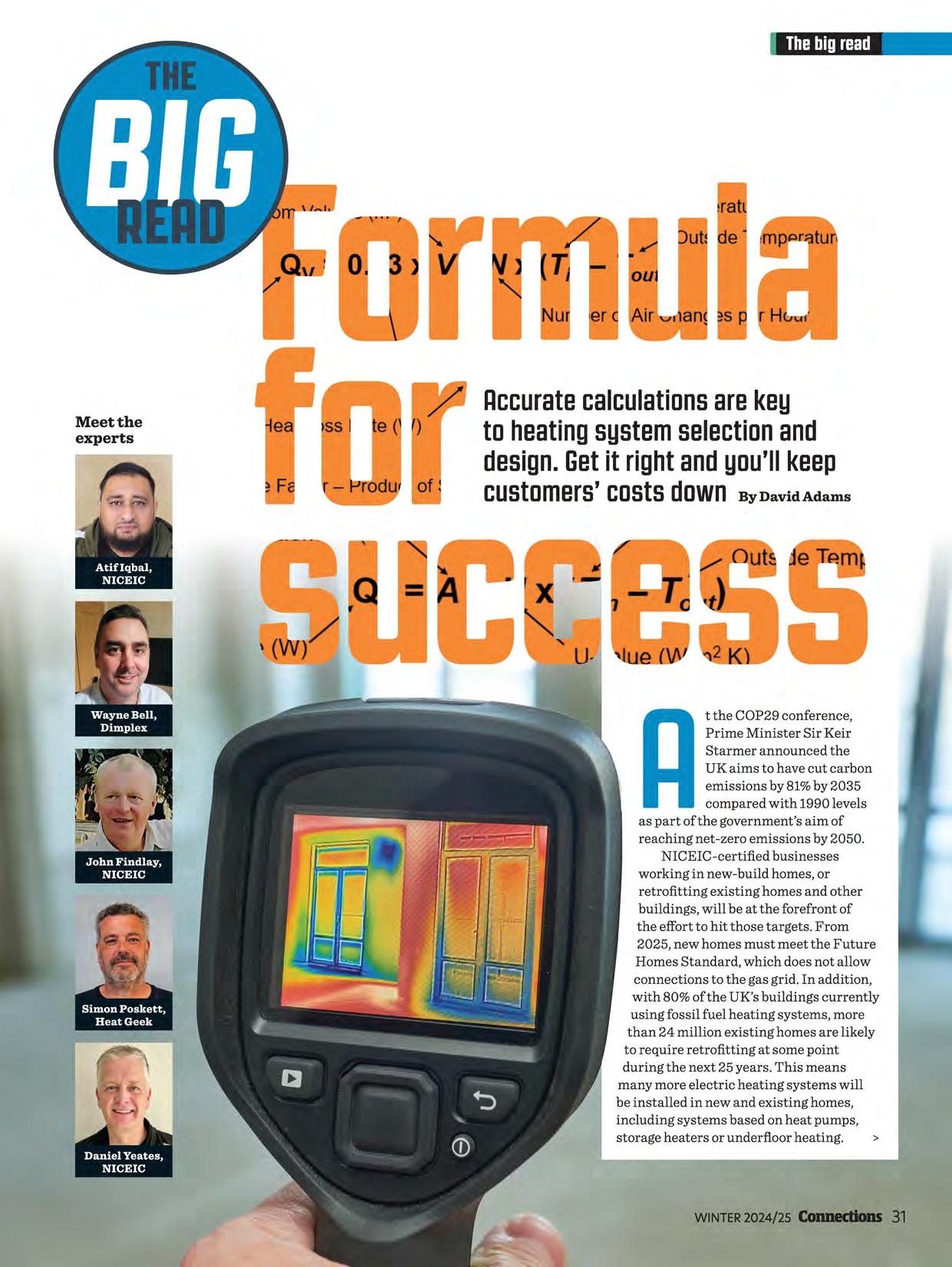

t the COP29 conference, Prime Minister Sir Keir Starmer announced the UK aims to have cut carbon emissions by 81% by 2035 compared with 1990 levels as part of the government's aim of reaching net-zero emissions by 2050.

NICEIC-certified businesses working in new-build homes, or retrofitting existing homes and other buildings, will be at the forefront of the effort to hit those targets. From 2025, new homes must meet the Future Homes Standard, which does not allow connections to the gas grid. In addition, with 80% of the UK's buildings currently using fossil fuel heating systems, more than 24 million existing homes are likely to require retrofitting at some point during the next 25 years. This means many more electric heating systems will be installed in new and existing homes, including systems based on heat pumps, storage heaters or underfloor heating. >

The number of Connections readers who install electric heating systems is growing, as demand for them rises. But any business doing this work must do so properly: selecting the right type of system and appropriate equipment for each building, with radiators or other heat emitters perfectly sized and placed to meet the heating requirements of each room. System selection and design must both be based on accurate heat loss calculations.

Get heat loss calculations wrong and a system will be inefficient and expensive to run. Customers will be unhappy, the installer may suffer reputational damage, the installation could be in breach of Building Regulations (see page 34) or, if the system is based on a heat pump, of MCS standards. Ultimately, poor heat loss calculations could increase public scepticism about renewables and lowcarbon technologies, which will delay progress towards net zero.

NICE IC Customer Relations Manager Atifiqbal reports a 20% increase in complaints about heat pump-based heating in the year to October 2024 compared with the previous 12 months. In most cases, he says, these complaints refer to installation problems that can be fixed: an installer may have failed to adjust a heat pump's default factory settings to suit a specific location, for example.

But NICEIC Energy Efficiency Scheme Manager Daniel Yeates echoes this, adding that most of these complaints can be traced back to inaccurate heat loss calculations. He thinks that about two or three out of every 10 heat pump installers calculate heat loss manually, but most use software or apps instead. However, even the best technology is only as good as the data fed into it. For this reason, says Yeates, NICEIC assessors seek to ensure that installers "have an understanding of what heat loss calculations mean and how they are interpreted".

Heat loss calculations for heat pump systems also need to be understood in the context of the differences between heat pump and gas boiler-based systems, says

Simon Poskett, Lead Technical Engineer at the heating engineer community and service provider Heat Geek. Gas systems use big boilers and very hot water, with a flow temperature of perhaps 70 °C. But with a heat pump, usually running with a flow temperature of30 °C to 55 °C, "you need to trickle in enough heat to replace heat that has been lost," Poskett explains. This is why radiators in a heat pumpbased system need to be larger than for a gas system; and why better insulation throughout the house and well-designed, more airtight windows also increase system performance.

Unfortunately, data Heat Geek has gathered in recent years suggests many heat pump installations are over-sized, which may not be a disaster, but can mean the heat pumps frequently switch themselves off, reducing efficiency and increasing costs.

Poskett says problems are sometimes caused by installers basing heat loss calculations purely on information about building fabric elements drawn from the Chartered Institution of Building Services Engineers (CIBSE) Guide Bl: Heating. This is the source recommended in the Building Regulations to help with heat loss calculations, but its figures are not infallible and may not take into account specific features within a property. This is another reason why installers must understand best practices for completing heat loss calculations (see 'The sum of the parts', opposite).

Ensuring the accuracy of heat loss calculations is not just necessary to

"NICEICassessorsseektoensure installers'haveanunderstanding of whatheatlosscalculationsmean"'

comply with Building Regulations, but also to meet MCS Heat Pump standards for Design and for Installation. The Design standard includes a table of temperatures MCS recommends are used in heat loss calculations for specific rooms, alongside other factors to consider when calculating heat loss.

John Findlay, Operations and Schemes Manager at NICEIC Certification, says installers must understand the core principles of heat loss calculations before choosing to use one of the various apps available. "Learn how to calculate heat loss using current industry published methods before you start using apps," he advises.

Findlay suggests that installers competent in system design should complete ventilation and fabric heat loss calculations for existing properties based on the current state of the property, then, if appropriate, do a second calculation based on a scenario with improved insulation. The customer will then have a clear picture of the full operational and cost-efficiency benefits they could gain if they make those changes as well as installing the new heating system.

Installers of other types of electric heating system also need to optimise heat loss calculations. Dimplex uses The Electric Heating and Ventilation Association (TEHVA) DOM 8 guide, which contains guidance on heating requirements for specific types ofrooms within dwellings at different times of year, and for different types of storage heating or underfloor heating systems.

Dimplex is developing an app for use by installers in its network. It will apply the DOM 8 method to establish optimum product sizes for specific installations. For underfloor heating, product selection is not usually so complex, but there are still >

How to calculate heat loss -and avoid pitfalls

Heat loss is worked out by calculating ventilation heat loss (due to warm air leaving a building and colder air entering through open doors, windows, vents or defects in the building's fabric); and fabric heat loss (heat conducted through the fabric of the building, including walls, windows, doors, the ground floor and the roof).

Ventilation heat loss calculations concern the rate at which air enters or leaves a building, the difference in temperatures inside and outside the building, and the heat capacity of the air (usually constant). This formula can be used to calculate ventilation heat loss:

RoomVolume(m3)

IndoorTemperature(°C) "'. / / OutsideTemperature(°C)

Qv=0.33 X Vx N X (T,n- Tout)

V,atllatioo H~t Loos Rat, {W)/ \ "- N,mbo, of Ai Chaogos P" Hom

AirChange Factor- Productof SpecificHeat capacityand Densityof Airunder standard conditions

Fabric heat loss depends on temperature variation across materials within a building, the size of each element, and the thermal conductivity and thickness of structural materials. The rate at which the structure conducts heat is called the U-value, which expresses how many watts of heat will flow through 1 m 2 of the fabric at a temperature difference ofl Kelvin (K). This equation can be used to calculate fabric heat loss:

Areaof BuildingElement(m2)

IndoorTemperature(°C) "'. / / OutsideTemperature(°C)

QF=AX U X (T;n- Tout)

FabricHeatLoss Rate (W)/ "' u-value(W/m2K)

• Note: T;nand Tautused across an internal structure such as wall or suspended floor.

Calculations must include any heated area and any surface or element through which heat might flow. Accurate internal measurements of every surface of the fabric in each room -walls, doors, ceilings and windows, including frames of doors, windows and rooflightsare needed to calculate U-values for each room. CIBSE Guide Bl and other standard industry publications give U-values for different materials, such as rendered brick walls with brick and plaster of specific thicknesses, timber frame constructions, or internal plasterboard stud partitions. But some features within an individual building, such as unusual floor or window shapes, may not be listed within industry standard guides.

U-values can also be affected by a thermal bridge or cold bridge in a structure, such as a break in cavity insulation, poor insulation, or a component such as a lintel or wall tie. In such cases it may be necessary to use the thickness and thermal conductivity of individual layers within an element to calculate a U-value for that element.

The colder the average temperature outside the building, the greater the heat loss. Average minimum

winter temperatures vary considerably between northern Scotland (-5 °C), northern England or Northern Ireland (-4 °C); and London (-2 °C) or southern England (-1 °C). It may also be necessary to account for a building's exposure to prevailing winds and adverse weather conditions.

If a property is attached to another, best practice is to assume the adjoining property is unheated and at a mean UK average temperature oflO °C. (The same figure is used for unheated rooms within a building.)

Air change rates may also be affected by the age of the building, with older buildings likely to see a faster air change rate than buildings constructed in compliance with more recent versions of the Building Regulations.

The subject of heat loss from a building and designing heating systems is complex and this is only an overview ofrequirements. NICEIC Training is among the training providers that can help: knowledge and understanding criteria for fabric and ventilation heat losses in dwellings are covered in the NICEIC Certification air source heat pump training and assessment package -see shop.niceic. com/heat-pumps-installation-course

Summary of Part L of the Building Regulations (England)

Part L of the Building Regulations that apply in England outlines requirements for conserving fuel and power in buildings. Volume 1, Section 1 states that heat gains and losses should be limited through the building fabric and "from pipes, ducts and vessels used for space heating, space cooling and hot water services" -including electric heating systems. Extensions to existing dwellings, initial provision of fixed building services or an increase to the installed capacity of fixed building services may also require "consequential improvements" to the system (see Section 12 of Part L, Volumel).

Section 5.8 of Part L, Volume 1 states that specification of space heating systems in dwellings should be based on an appropriate heat loss calculation, and a sizing methodology that "takes account of the properties of the dwelling". Systems "should not be significantly oversized".

Section 5.12 states that heat pumps "should be selected to meet the full space heating requirement at the design condition chosen for heat loss calculations" and not assume any heat will be supplied by additional electric heaters. The document also includes guidance for electric underfloor heating.

"Themostimportantprincipletofollow istoacguireasmuchinformation relevanttotheinstallationaspossible"

> key principles installers should follow, summarised in Part L of the Building Regulations and in the DOM 8 guide.

Whichever type of electric heating system is installed, the most important principle to follow is to acquire as much information relevant to the installation as possible, says Wayne Bell, Manager of the pre-sales department at Dimplex. The other crucial step is to complete all relevant training courses, and to keep this expertise up to date.

NICEIC Training is among the training providers able to help, but other sources of training are also available and useful. Paskett says he expects the new Low Carbon Heating Technician apprenticeship, which was launched in September, to be a useful addition to the range of training available for the next generation of electric heating installers.

Armed with the knowledge needed to calculate heat loss and to play a part in the design and/or installation of electric heating systems in new builds or when retrofitting existing housing, NICEICcertified businesses will also be able to explain the operational or cost benefits of such systems to customers. Paskett thinks this is particularly important for consumers who are "unpicking fear, uncertainty and doubt in the national press about heat pumps".

He says: "[Customers] may want to switch to a heat pump for carbon reduction reasons and to future-proof their homes, but they're petrified that they might spend £15,000 then find that

it doesn't work the way it's supposed to. Trust in the installer is vital."

Accurate heat loss calculations dramatically reduce the chances of such problems, helping to build trust in any installer of these technologies. So, says NICEIC's Iqbal, the most important thing any business installing electric heating systems can do really is to "Do heat loss calculations properly!" And to consider the problems they could create for themselves and their customers if they fail to do so.

For further information:

• Building Regulations England Part L bit.ly/PartLregs

• Building Regulations Scotland bit.ly/BuildingRegsScotland

• Building Regulations Wales bit.ly/BuildingRegsWales

• Building Regulations Northern Ireland bit.ly/BuildingRegsNI

• Chartered Institution of Building Services Engineers (CIBSE) Guide

Bl: Heating bit.ly/GuideBlHeating

• The Electric Heating and Ventilation Association (TEHVA) DOM 8 guide bit.ly/TEHVA-DomS

• MCS Heat Pump Design and Installation standards bit.ly/HeatPumpDesign and bit.ly/HeatPumplnstallation

e NICEIC Air Source Heat Pump installation training shop.niceic.com/heat-pumpsinstallation-course

• Heat Geek heatgeek.com

Ourmonthlye-newsletterdeliversalltheinformationyou needtokeepup-to-datewiththeelectrotechnicalindustry.

Carefully curated each month to bring you and your team the most relevant and up-to-date information on the topics that matter most. You can expect to receive information such as:

• industrynews

• regulationchanges

• technicalinsights

• upcomingevents

• essentialcertificationupdates.

Thisemailissenttoqualifiedsupervisorsandprincipal dutyholders.

As an exclusive new benefit of certification with NICEIC,this e-newsletter does the hard work for you, so you can keep your finger on the pulse.

Want to learn more about recent amendments and industry developments? Have a read of one of our latest issues.

In November 2024, the Department for Energy Security and Net Zero announced changes to its Warm Homes Plan, which aims to provide upgrades to 300,000 homes through clean heating technology and improved insulation. The new measures and extra funding announced signal that the government is making this a priority, with potentially significant implications for heating, renewables and electrical installers.

Domestic heating is a significant contributor to our greenhouse gas output, accounting for 14% of total national emissions 1 To meet the UK's targets for cutting carbon emissions by 45% by 2030, and net-zero emissions by 2050, the transition from fossil fuel-based heating systems must be speeded up.

More funding

Primarily, this will be achieved by upgrading traditional gas boiler heating systems to energy-efficient alternatives, such as air-source heat pumps. The government announced an extra £30m in funding for the Boiler Upgrade Scheme this financial year, and an increase in allocated spending for the next financial year, taking the budget to £180m. Administered by Ofgem, the scheme provides upfront capital grants to support the installation of heat pumps and biomass boilers in homes in England and Wales. Installers, on behalf of householders, can apply for a grant of £7,500 off the cost and installation of an air-source heat pump.

In an effort to meet its target of 600,000 heat pump installations per

year by 2028, the government also announced major changes to the planning rules. Previously, a heat pump within 1 m of a neighbouring property required planning permission. From 2025, permitted development rights will remove the 1 m boundary rule, enabling heat pumps to be installed within 1 m of the property boundary and increasing the size limit of the heat pump for homes from 0.6 m 3 to 1.5 m 3 •

It is estimated that 34% of those who order a heat pump are discouraged or drop out for planning reasons. So this intervention may be crucial in unlocking demand and increasing heat pump installations in the medium term. It's a real opportunity for certified businesses in 2025 to be right at the heart of the UK's clean homes transformation.

This is further supported by changes to the regulatory framework that underpins the transition to lowcarbon heating, the Clean Heat Market Mechanism (CHMM). The CHMM, which comes into effect on 1 April 2025, includes a market standard for heat pumps as a proportion of fossil fuel boiler sales, currently set at 6%. This

is designed to provide manufacturers with certainty and the confidence to invest and to make heat pumps attractive to households.

The social housing sector is also impacted, with £1.29bn committed to the Warm Homes: Social Housing Fund over the next three years. The investment aims to enable the upgrading of a significant amount of the social housing stock below Energy Performance Certificate band C, while also reducing carbon emissions, and helping to grow the retrofit sector.

The policies announced amount to a range of targeted interventions, which have been designed in collaboration with manufacturers and installers, with the potential to drive demand and accelerate adoption oflow-carbon technologies. In 2024, a record year for heat pump installations, average monthly installs were up 39% compared with 2023, indicating that consumers will choose new solutions if the incentives are right. With the new investments and policy changes, there is a real opportunity to build on that momentum.

Free to NICEIC-certified businesses and their employees, the NICEIC's webinar series, THE WIRE, delivered more than 17 hours ofhighquality CPD content, reaching over 13,900 live viewers and 44,000 ondemand viewers in 2024.

One of the webinars that got the most live views was Top tips for completing certificates and reports. And Amendment 3 (2024) BS 7671:2018 Wiring regulations was one of the most popular webinars watched on-demand.

"THE WIRE has once again proved to be a valuable resource for NICEIC-certified businesses and the wider electrical industry," says Sam Donaghy, NICEIC Head of Technical Advice and Practice.

To revisit the year's most watched webinars, go to niceic.com/thewire

Could one of your jobs win the next NICEIC Installation Award?

Our new competition highlights the best work ofNICEIC-certified businesses. To be in with a chance

of winning an NICEIC training course of your choice (subject to entry requirements), send us a direct

message via the NICEIC Linkedln, Instagram or Face book page with photos or a video of your entry and tell us why it deserves to win the next NICEIC Installation Award title.

Our next entry deadline is 31 March 2025. One entry per NICEICcertified business.

You should always be mindful of email security. To protect your business from financial scams, we encourage you to remain vigilant when receiving emails claiming to be from NICEIC.

With online sales at their peak, fraudsters are sending more phishing emails than ever. Stay vigilant when receiving emails requesting payments, to protect your business from financial scams.

If you ever have doubts about the legitimacy of an email that claims to be from NICEIC, please forward the suspicious email to customer.services@niceic.com for verification.

A reminder that the British Standard for fire detection and alarm systems in non-domestic premises, BS 5839-1, is undergoing significant updates. The draft for public comment closed earlier this year, and the final version is expected to be published on 29 April 2025. This update will refine guidelines on system design, installation and maintenance to enhance fire safety.

Key changes include stricter recommendations for forms of automatic fire detection for premises where people sleep, and clearer requirements for manual call point placement in multi-storey buildings. We'll provide more details as soon as the final document is released.

MCShasconfirmedthat it will announce plansfortheredevelopment of MCSin Januaryi!Oi!5.Astherearenoimmediate changes,pleasemakesureyour businesscontinuesto maintainthe requirementsof thecurrentNICEICMCS ContractorScheme.

NICEICandotherMCScertification bodieswillattaintheupdated accreditationduringi!Oil5-i!Oi!6.After this,we'lltransitionyourbusinessto the redevelopedscheme.Atpresent,MCS is unableto confirmthetimelineforthis processasit's setbyUKAS.We'llbringyou moreinformationasitbecomesavailable.

Aproductrecallhasbeenissuedfor certainMartindale/Drummond test lamps, primarilyintendedto testfor absenceof voltagewhencarryingouta safeisolation procedurepriorto workingonlowvoltage circuitsorequipment.TheOfficefor ProductSafetyandStandards[OPSSJ saystheaffectedmodelspresenta riskof electricshockbecauseof anintermittent indicationfault.Seebit.ly/lamp-recall

Also,MKElectrichasissueda product safetyreportfor MKessentialsthree-pin socketswithswitches.Thisis NOT a productrecallandtheonlyrecommended correctiveactionis to removethe productsfromsale,althoughanysuch itemsinstockshouldnotbeinstalled. Seebit.ly/MK-socketsfor details.

Greater Manchester's Electrotechnical Training and Careers Alliance, which launched in November 2024, is the first of its kind in the UK.

The alliance includes the Electrical Contractors' Association (ECA) -which has led on the initiative for local employers -Greater Manchester Chamber of Commerce, electrical businesses and education providers.

ECA's research and work with the local skills improvement plan is helping the initiative identify the key areas that need addressing, especially where

there is no provision currently in place.

Andrew Eldred, ECA's Chief Operating Officer, says: "Together we can deliver for the region, for local people and for business."

Chris Fletcher, Policy Director and GMLSIP Director at Greater Manchester Chamber of Commerce, hopes the alliance "will become a model of how organisations can work together to tackle skills gaps in this sector".

ECA's aim is for the initiative to take off elsewhere, connecting ECA members, skills providers and local authorities.

The NICEIC team are gearing up to visit six ELEXSHOW venues in England. First up is Bolton Arena in Bolton on 7 March, then London's Alexandra Palace on 28 March, Westpoint in Exeter on 25 April, Yorkshire Event Centre, Harrogate, in May, Coventry Building Society Arena, Coventry, in September and Sandown, Esher on 6-7 November.

As usual, our experts will be on hand at NICEIC's stand. And on the stage, yet more of our experts will give technical presentations.

Then in June, we'll be at the InstallerSHOW at the NEC, Birmingham.

BS 9991:2024 Fire safety in the design, management and use of residential buildings code of practice has been published and came into effect on 30 November 2024. The British Standards Institution has produced a freely available Executive Briefing guide, which has a summary of the principal changes. For more information and a link to the Executive Briefing, go to bit.ly/BSI-Executive-Briefing

From 1 April 2025, landlords offering properties for rent in Northern Ireland must have all fixed electrical installations inspected and tested by a qualified electrician at least every five years. This will bring Northern Ireland in line with the rest of the UK.

Landlords in NI will have to provide prospective tenants with a certificate of compliance. Any electrical fault notified to the landlord between inspections must be repaired within 28 days. Existing tenancies will have until 1 December 2025 to comply.

Powered by cutting edge technology, Selectric introduces our new wireless GRID360Kinetic range.

The GRID360Kinetic range is a revolutionary wireless switch system that eliminates the need for batteries or power cables. Unlike traditional wired switches, these switches can be installed on any surface and don't require complicated cable runs within walls. The system provides a clean, convenient, and safe solution that is not only easy to install but also reliable.

GRID360Kinetic uses the Tuya Smart & Smart Life Apps.

THEWIRElive andon-demand

WatchTHEWIRECPD-accredited webinarsliveoron-demandatwork, onyourlunchbreak,orfromyoursofa.

Our industry experts deliver informative, engaging and trusted insights on the latest need-to-know topics.

Missedanepisode?

If you miss the live webinar, join at a time and place that suits you. THE WIRE on-demand library features over 30 hours of CPD-accredited webinars.

Cominguplive:

Electricalfundamentals

Ventilation

Qualificationsand apprenticeships

EICRcodingforcommercial andindustrialinstallations

Check out our monthly live-stream Technical Q&A across social media channels: Facebook, Linkedln and YouTube. Talk directly to experienced experts and engage with your peers.

Wanttomeetinperson?

Get exclusive access to our technical team and connect with colleagues at our new in-person CPD events in 2025.

Hear the latest regulatory updates, take home some business tips, or learn how to boost your wellbeing.

Durtechnicalengineersansweryourquestionsonsocketoutlets,consumerunits,andperiodicinspectionsandreporting

I am working on an extension to a house in England. The customer would like the socketoutlets to be installed at the same height as those in the original property that is being extended. However, ApprovedDocumentM (ADM) advises that socket-outlets should be installed such that their centre line is between 450-1200 mm above floor level. Can I install the new socket-outlets at the same height above floor level as those in the restoftheproperty?

Yes you can. Schedule 1 of the Building Regulations states, in respect of access and use of dwellings, that:

'Reasonable provision shall be made for people to(a) gain access to, and (b) use the building and its facilities'

However, it continues to state that:

'The requirements of this part (of the Building Regulations)

do not apply to(a) an extension of or material alteration of a dwelling'.

Considering the requirements of BS 7671 in respect of such work, provided that the height of the outlet permits a plug to be inserted without stress on the flexible cable the socket-outlets can be installed to match the existing outlets (553.1.6).

'When changing a consumer unit, do we have to test insulation resistance at 500 Vfor existing circuits or is it acceptable to test at 250 Vin case any vulnerable equipment is still connected? Where equipment has been connected to a circuit, an insulation resistance test at 250 V DC shall be applied between the live conductors and the protective conductor connected to the earthing arrangement (643.3.3).